Intelligent warehousing system used for vehicle production line

A technology for production lines and vehicles, which is applied in the field of intelligent storage systems for vehicle production lines, and can solve the problems of wrong tracking results, errors, poor real-time performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in combination with specific embodiments, so that those skilled in the art can implement it with reference to the description.

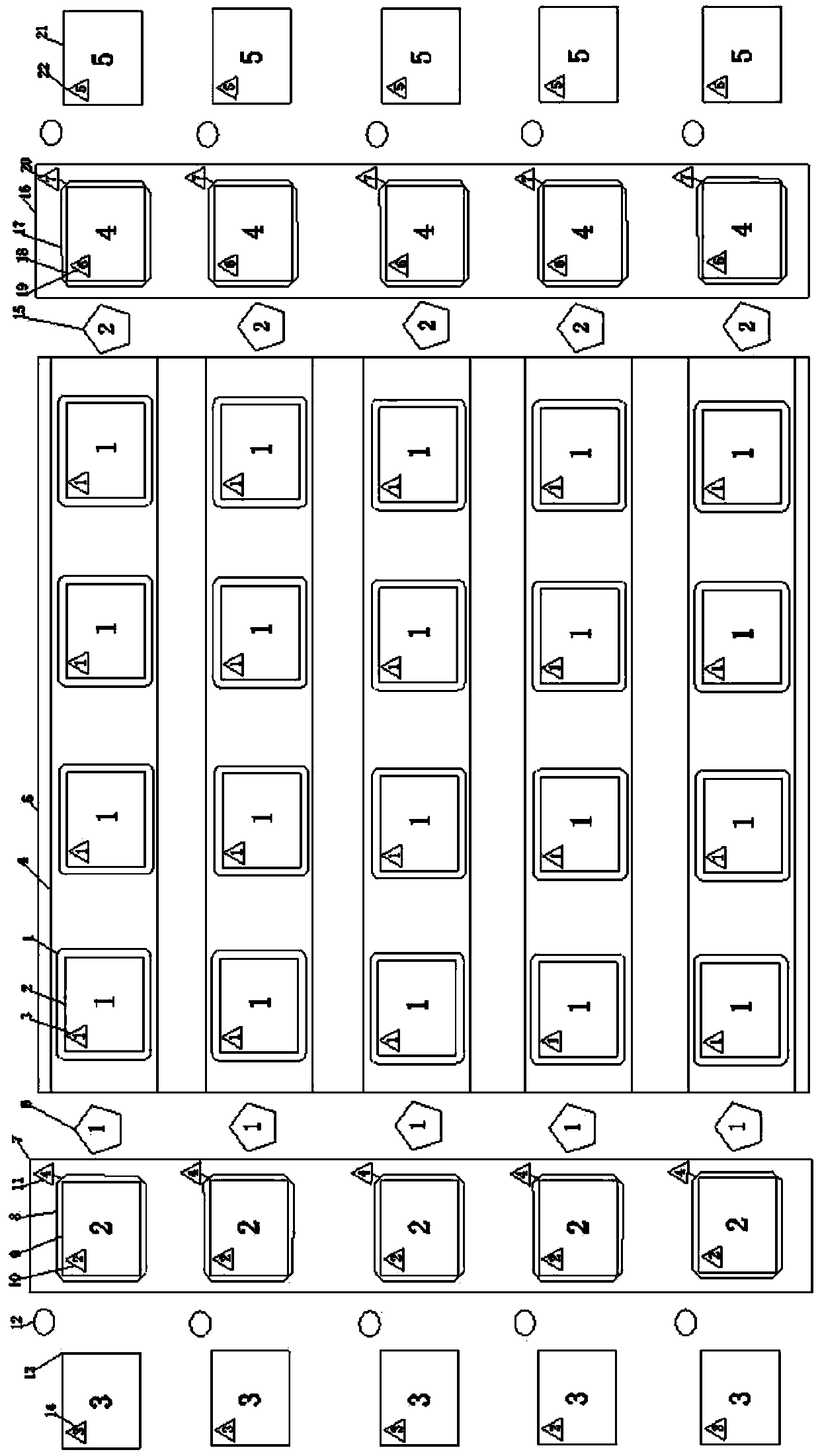

[0056] The invention provides an intelligent warehousing system for a vehicle production line, including:

[0057] A storage area 5, in which several storage lanes 4 are arranged, and each storage lane 4 is distributed with a number of storage positions 1, and the storage positions 1 are used for storing vehicles;

[0058] a first identification tag, which is used to identify the identity of the vehicle;

[0059] An identifier 12, which is arranged at the entrance of the warehouse, is used to read the vehicle identity information in the first identification tag and upload it to the database;

[0060] A plurality of first state detectors 3, each first state detector 3 is arranged on a storage location 1, for detecting whether the storage location 1 is occupied, when each storage l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com