Self-service unattended warehousing system based on acousto-optic picking and control method thereof

A warehousing system and self-service technology, applied in the field of Internet of Things technology applications, can solve problems such as inconsistent shelf specifications, inconsistent receiving procedures, and unreasonable regional divisions, so as to improve inventory turnover and rotation rates, and improve material management. The effect of leveling and reducing the workload of warehouse managers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

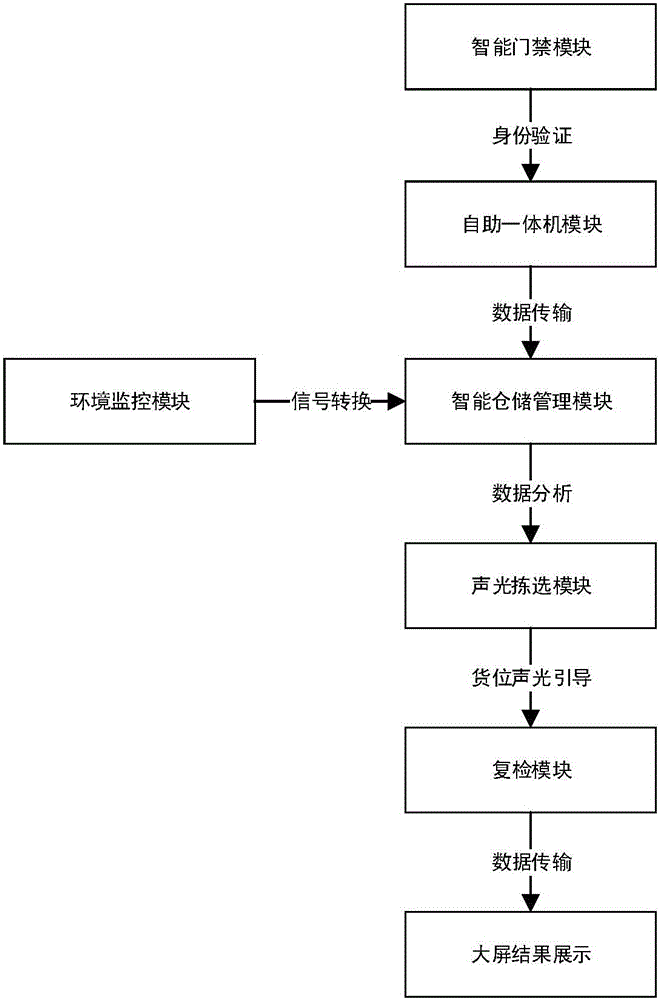

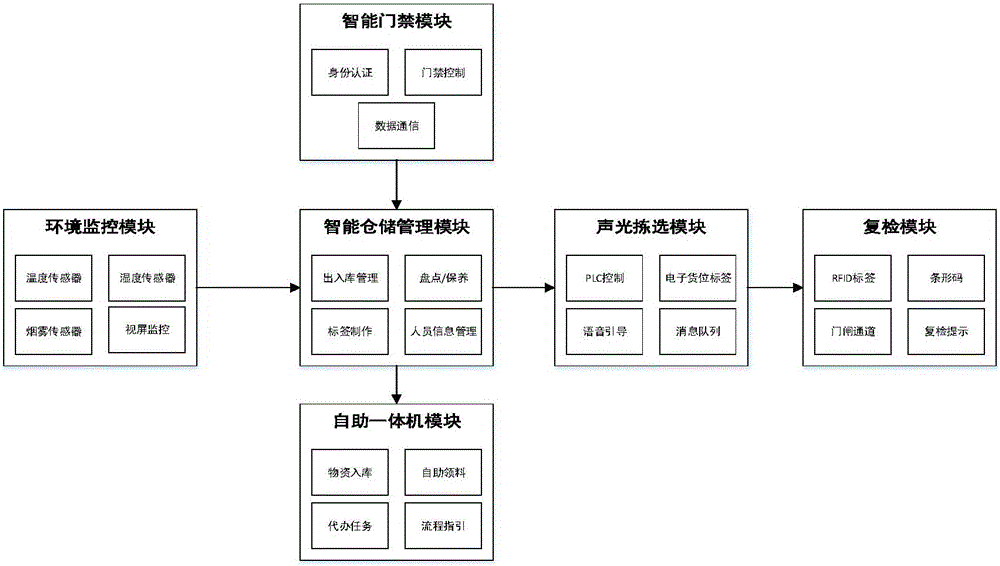

[0021] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0022] A self-service unattended storage system based on acousto-optic picking, the present invention is characterized in that: the unattended storage system is sequentially connected by an intelligent access control module, a self-service all-in-one machine module, an intelligent storage management module, an acousto-optic picking module, and a re-inspection module Composition; the intelligent warehouse management module is also connected with the environmental monitoring module; where:

[0023] A smart access control module, used when personnel enter the unattended warehouse, they need to go through identity authentication first, and then they can enter the warehouse after the authentication passes the access control control;

[0024] B self-service all-in-one machine module, mainly used for warehouse personnel to provide self-service operation at the front desk;

[0025] C e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com