Die mechanism with sliding blocks provided with sliding block pulling cores

A slider core-pulling and mold mechanism technology, which is applied in the field of metal die-casting molds and plastic injection molding molds, can solve the problems of unstable product size, unsafe worker safety, and high product scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

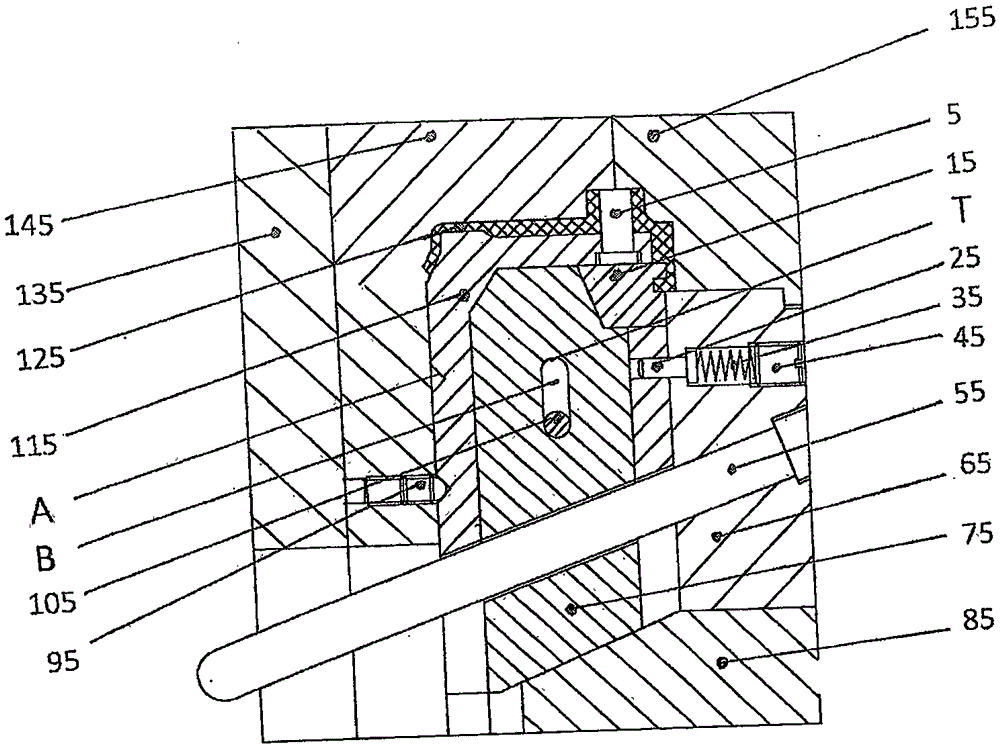

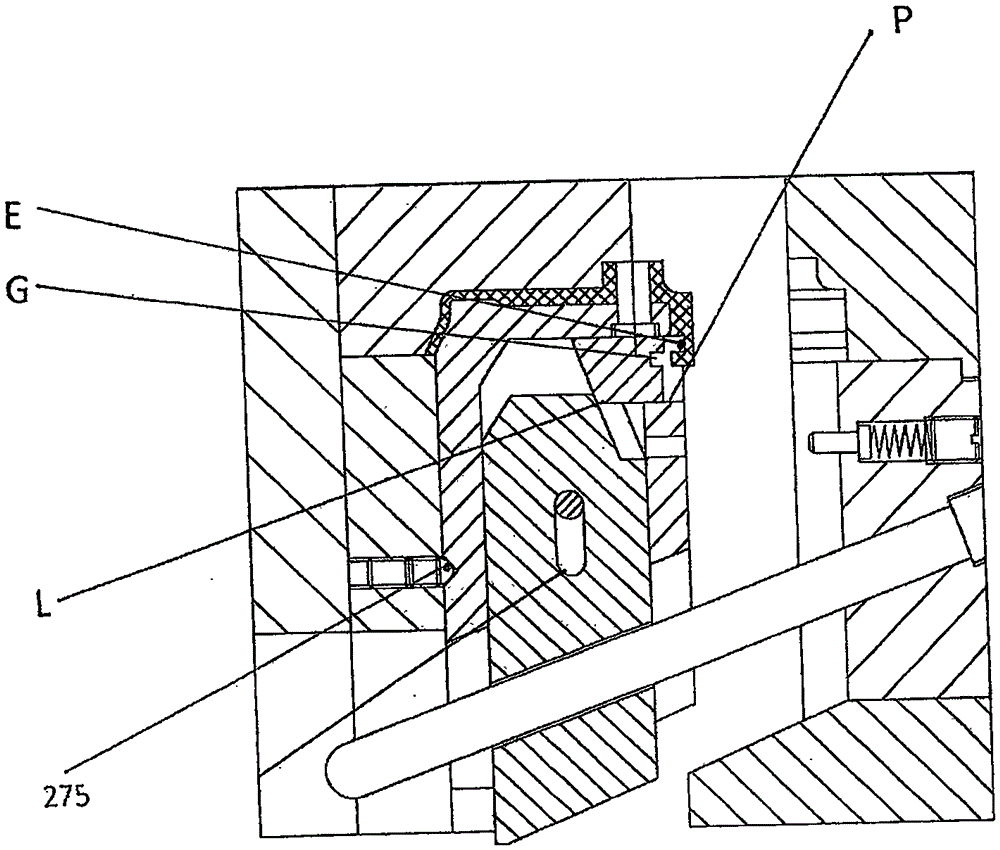

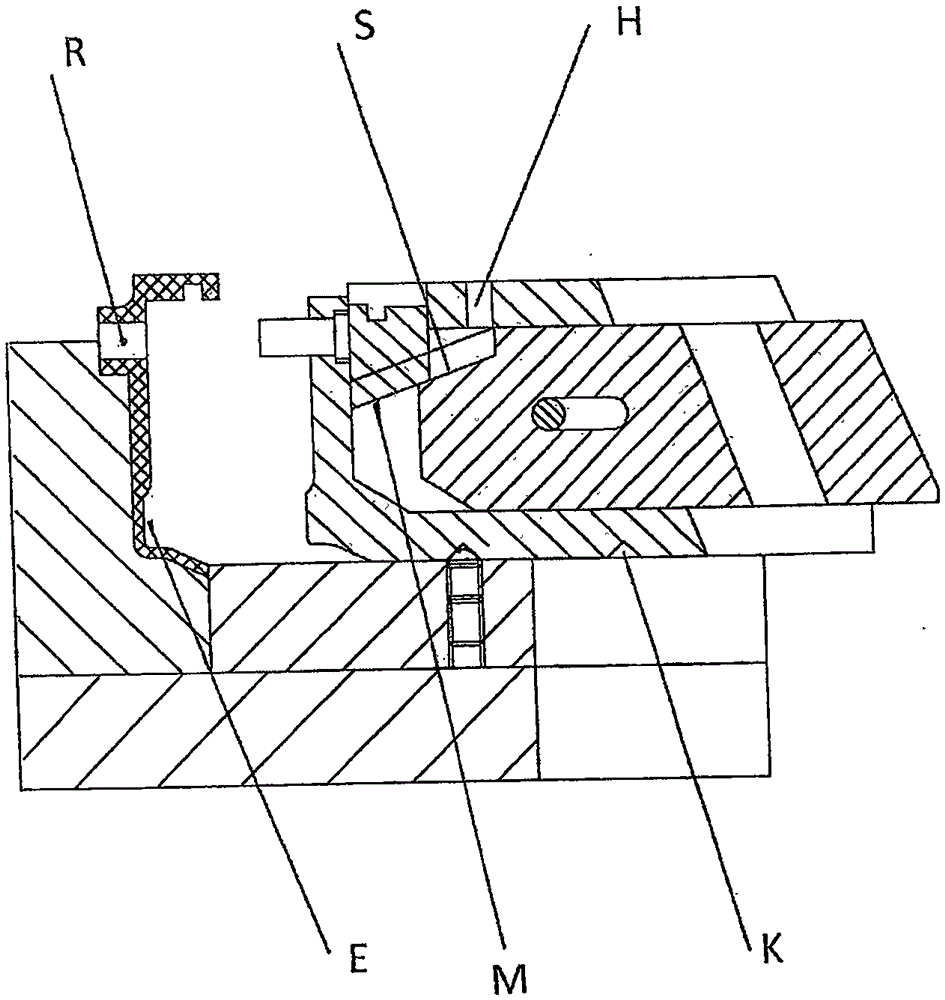

[0030] As shown in the figure, it is a mold mechanism that sets the core of the slider in the slider. It can be seen from the figure that due to the special nature of the product, there are grooves and holes in different directions on the product (125). Groove forming and core-pulling cannot be achieved by using the core-pulling mechanism of the existing mold. Therefore, in combination with the special circumstances of the product, a mold mechanism with a slider core-pulling set in the slider is used to complete the molding and core-pulling, so that the mold In one mold opening process, the slider is used to drive the slider to complete the grooves in different directions on the product to realize fully automatic core pulling. After this implementation, the mold has a high degree of intelligence, beautiful product quality, firm and reliable action, and convenient mold installation, debugging and maintenance. The action principle of this mechanism is described in detail below: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com