Method for demolishing ultra high cast-in-place pile head

A technology of cast-in-situ piles and pile heads, which can be applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of low labor intensity, and achieve the effect of low labor intensity, practical operation, and smooth pile top surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

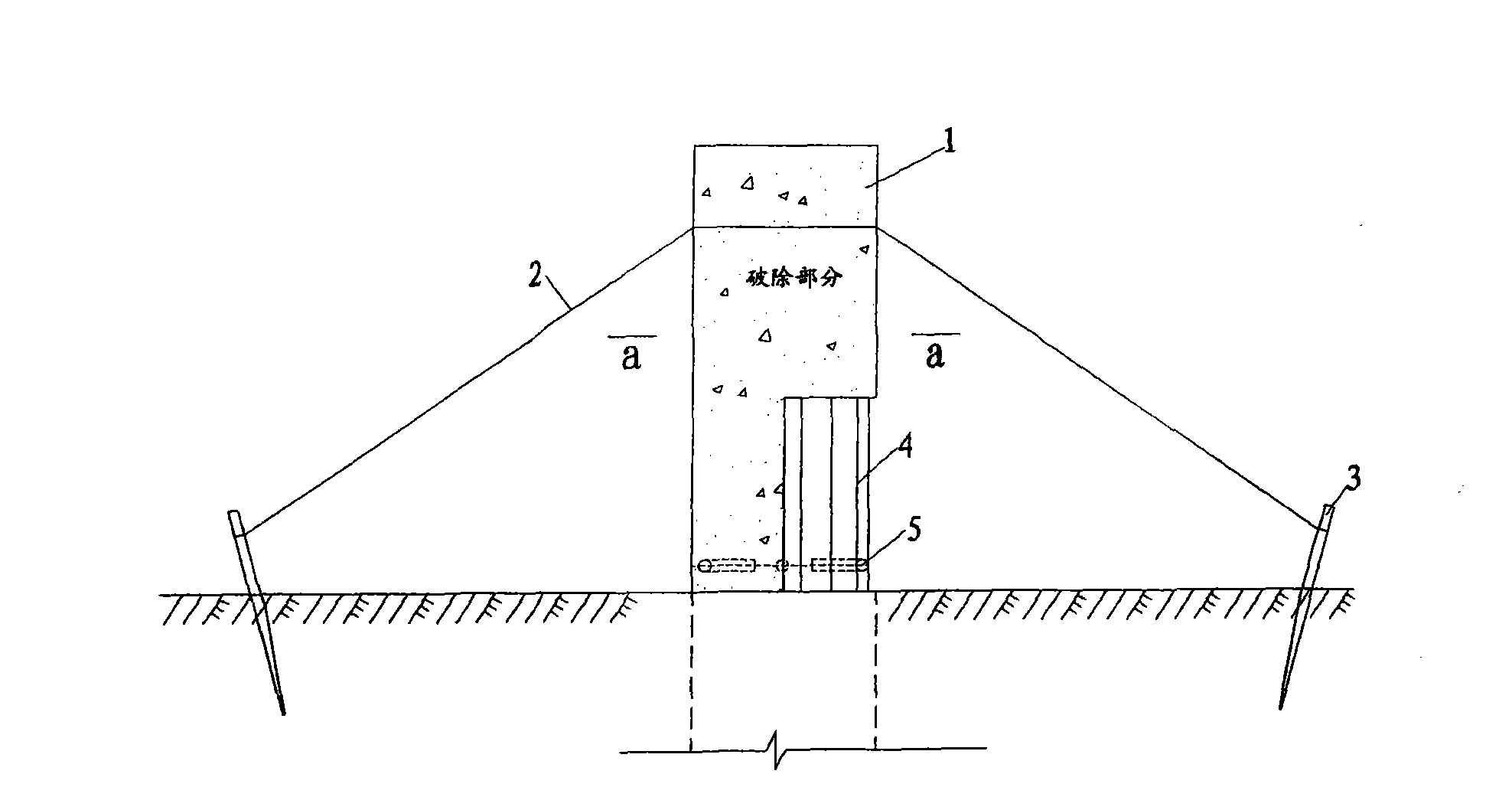

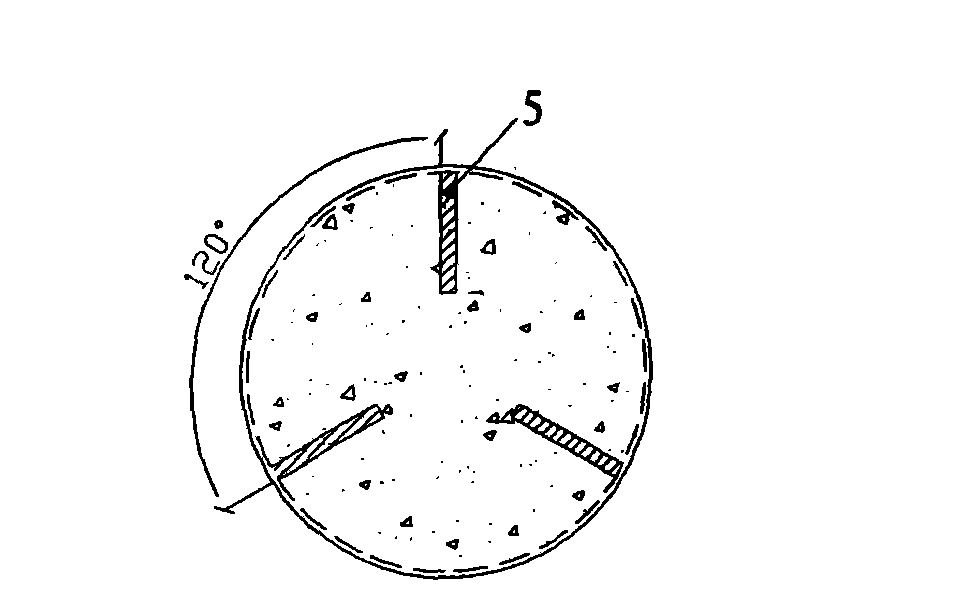

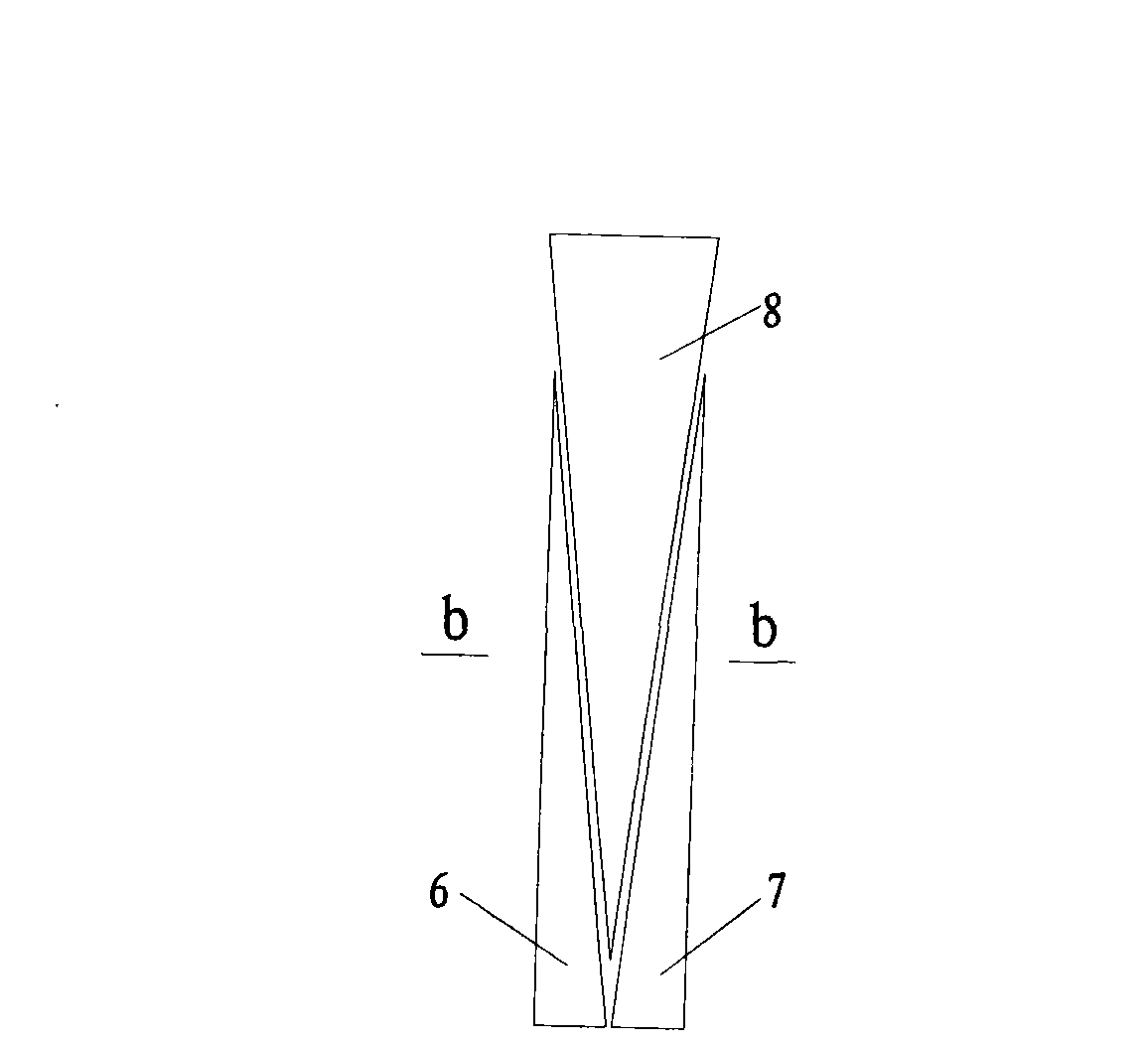

[0019] The invention considers the problems of simple and practical operation and high safety factor in demolition. The ultra-high pile head adopts the procedures of chiseling away the protective layer of pile reinforcement from above the design pile top elevation, cutting off the pile reinforcement, drilling and demolishing, and pulling to the pile head.

[0020] Below with reference to accompanying drawing, describe concrete operation step of the present invention in detail:

[0021] 1) Excavate the pile head of the super-high cast-in-place pile, and measure the height of the broken pile head:

[0022] ① After the construction of the concrete bored pile is completed, the earthwork of the foundation pit is excavated to the bottom elevation of the cushion layer, and the super-high pile head 1 is exposed. The design pile top and the elevation of the broken pile head are measured and marked with red paint.

[0023] ②Select three points on the ground along the circumference of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com