Graphene oxide membrane with tent-like structures, and preparation method and application thereof

A technology of graphene membrane and graphene membrane, which is applied in the field of ultra-thin graphene oxide and its preparation, can solve the problem of weakening selectivity, difficult adjustment of sieving channels at the molecular level, precise control of the distance between graphene membrane layers, etc. problem, to achieve the effect of increasing water flux, realizing water flux, and maximizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

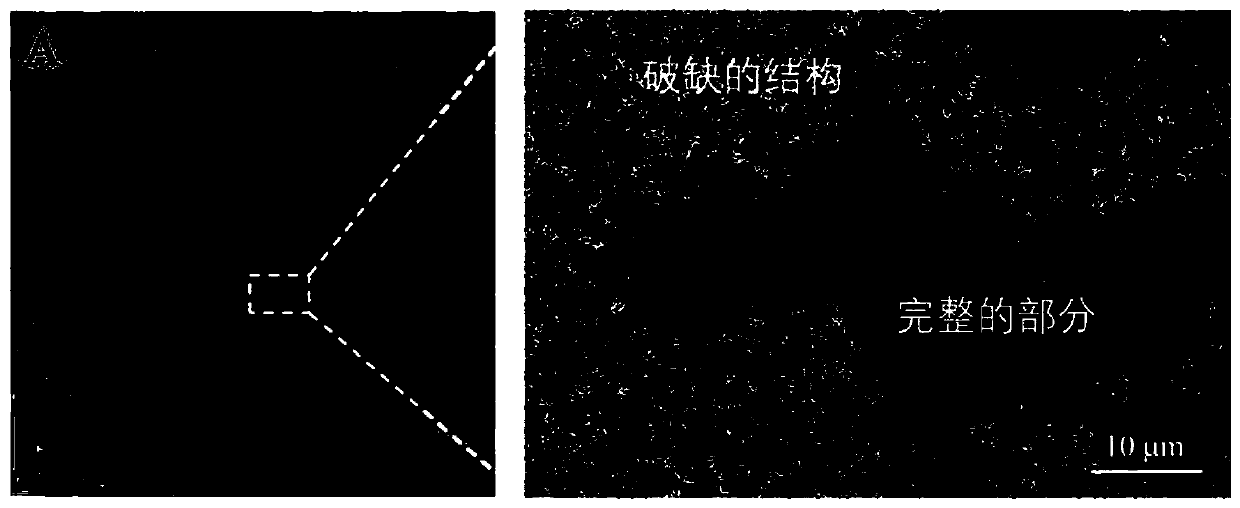

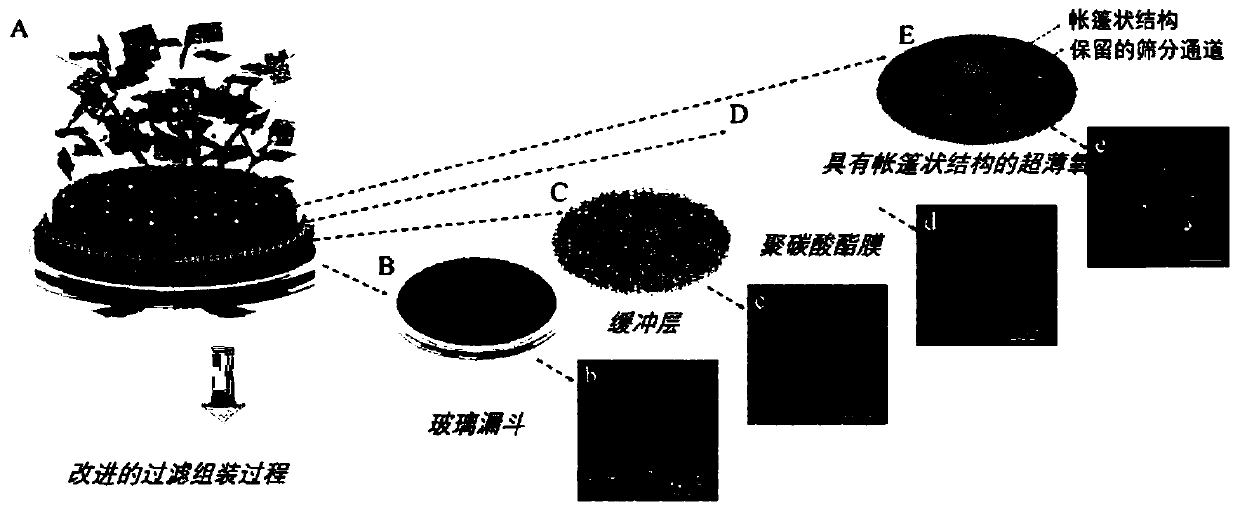

[0064] Utilize the improved filtration assembly method among the present invention to prepare the concrete process of ultra-thin graphene oxide film as follows:

[0065] (1) Place the buffer layer (mixed cellulose ester film) on the peeling funnel, wet it with water, and make the two fully bonded.

[0066] (2) Place the support film (polycarbonate film) on the buffer layer and wet it with water to make the two fully bonded.

[0067] (3) Prepare a graphene oxide dispersion with a concentration of 1.5 mg / L, and ultrasonically disperse it for 10 minutes.

[0068] (4) Take 10 ml of the prepared graphene oxide dispersion, filter and assemble under a vacuum pressure of 0.9 bar to obtain a membrane structure.

[0069] (5) The obtained membrane structure is dried at 60°C.

Embodiment 2-5

[0086] In order to allow researchers in the field to better understand the construction of tent-like nanostructures in ultra-thin graphene oxide films, we will further illustrate the present invention through specific examples and accompanying drawings below. The specific steps of the ultra-thin graphene oxide film with a tent-like structure are as follows:

[0087] (1) Place the buffer layer (mixed cellulose ester film) on the peeling funnel, wet it with water, and make the two fully bonded.

[0088] (2) Place the support film (polycarbonate film) on the buffer layer and wet it with water to make the two fully bonded.

[0089] (3) configure graphene oxide dispersion liquid, and silicon dioxide (30nm) dispersion liquid joins in graphene oxide dispersion liquid, wherein the concentration of graphene oxide is controlled at 1.5mg / L, the amount of silicon dioxide added is the same as The mass ratios of graphene oxide are 0.01:1, 0.1:1, 1:1 and 10:1 respectively, and are respectiv...

Embodiment 6

[0108] In order to confirm the possibility of other nanoparticles constructing tent-like structures, we later selected silver nanoparticles with an average diameter of 1 μm and an average size of 10 nm for experiments. The preparation process of the material is consistent with that of Example 3. Such as Figure 22 As shown, Example 6 has a tent-like structure similar to that of Example 3, but the size of the constructed tent-like structure is different due to the difference in the size of the nanoparticles. Since the screening performance and part of the surface properties of the membrane are determined by its microstructure, the adjustment of the membrane screening performance and surface properties can also be realized through the adjustment of the nano-silver intercalation ratio. Example 6 shows that according to the method of the present invention, nanoparticles of different sizes and materials can also realize the construction of nano-tent structures between ultra-thin g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com