Drying and sieving all-in-one machine

An all-in-one machine and drying screen technology, applied in the direction of drying gas layout, dryer, filter screen, etc., can solve the problems of increased number of operators, low production efficiency, large equipment investment, etc., to reduce heater power and hot air flow. The effect of reducing and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

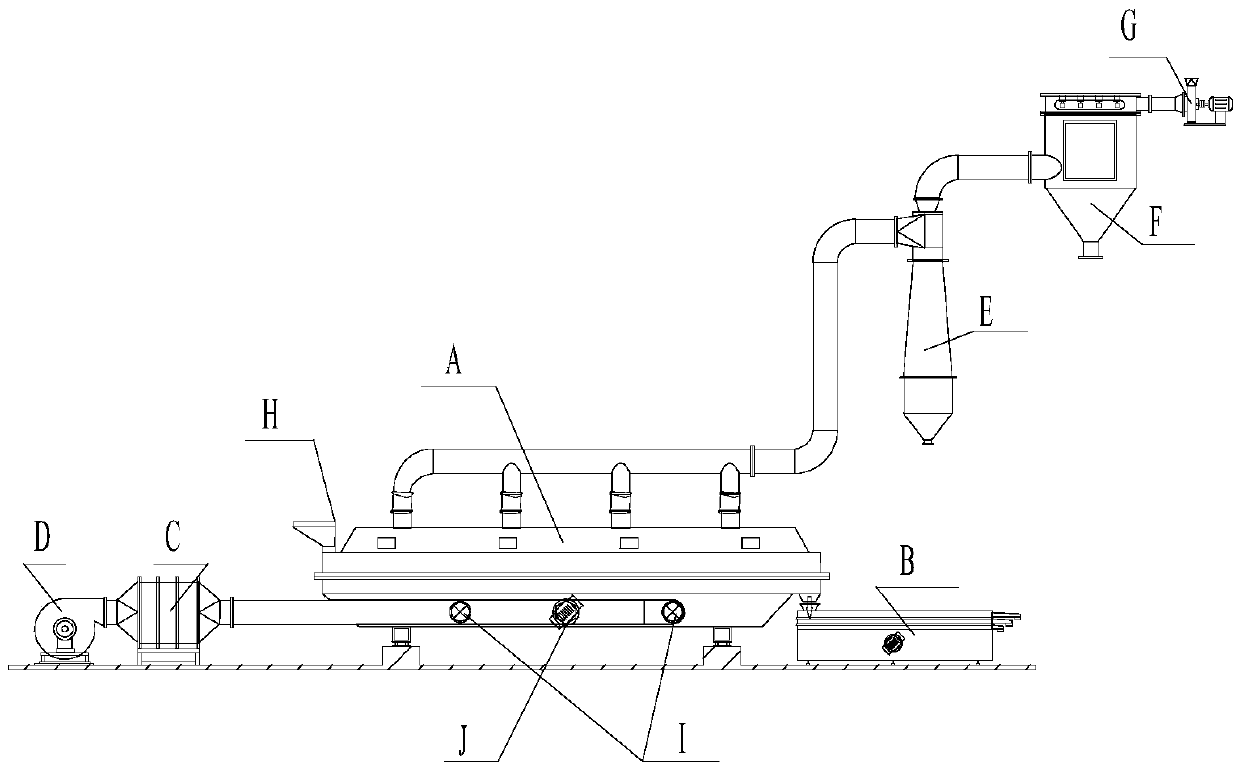

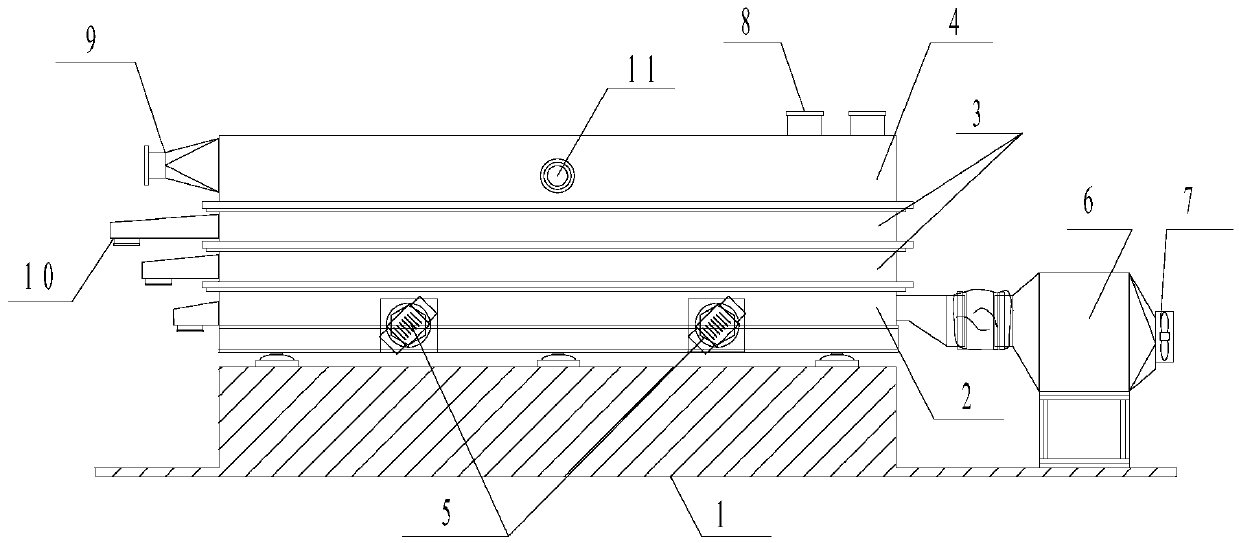

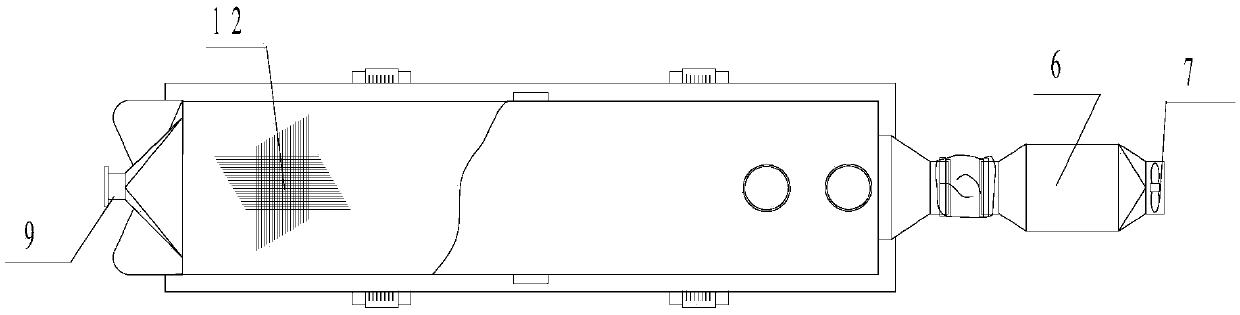

[0021] see figure 1 , which is a kind of drying and screening equipment in the prior art, which includes a vibrating fluidized bed A, a vibrating device J is connected to the bottom of the vibrating fluidized bed A, and the vibrating fluidized bed A is provided with an air inlet I, and the air inlet I is connected to To the hot air delivery device, the hot air delivery device includes a heater C and a blower D, the blower air outlet is connected to the heater C, the heater C is connected to the air inlet I, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com