Caking index tester and application method thereof

A technology of cohesion index and measuring instrument, which is applied in the direction of removing certain components and weighing, can solve the problems of cumbersome operation and inability to realize test automation, etc., and achieve the effect of realizing automation, reducing labor intensity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

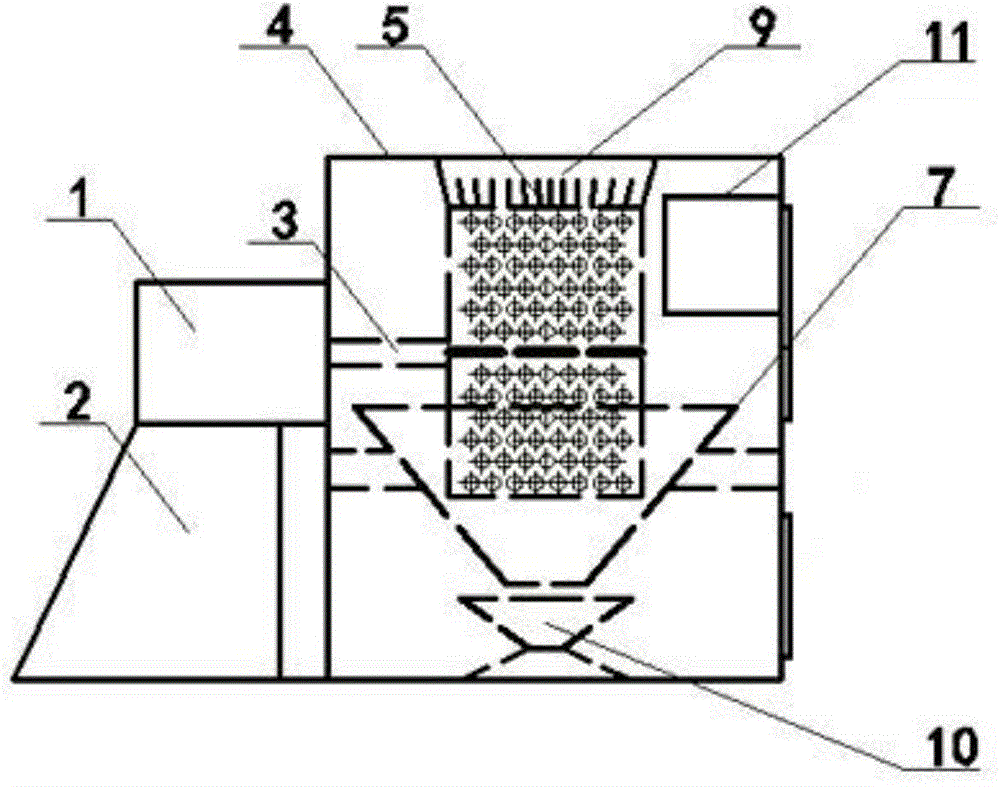

[0024] as attached figure 1 As shown, a cohesion index tester includes a motor 1, a drum 5 and a collecting hopper 7, the motor 1 is fixedly installed on the support 2, and the rotating drum 5 and the collecting hopper 7 are all arranged on the equipment casing 4 Inside, a collecting hopper 7 is arranged below the rotating drum 5 , the rotating drum 5 is connected with the motor 1 through the bearing 3 , and the motor 1 can drive the rotating drum 5 to rotate. The surface of the drum 5 is evenly distributed with sieving holes, the diameter of the sieving holes is 1mm, and a hairbrush 9 is installed on the top of the equipment casing 4 above the drum 5, and the bristles of the hairbrush 9 The end is in contact with the outer surface of the drum 5 to prevent the coke powder from clogging the screening holes of the drum due to long-term work. Described hairbrush 9 and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com