Energy-saving environment-friendly construction waste reusing device and recycling method

A construction waste, energy saving and environmental protection technology, applied in the direction of construction waste recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of pollution, flying lime and sand environment, large land requisition costs, construction costs for garbage removal costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

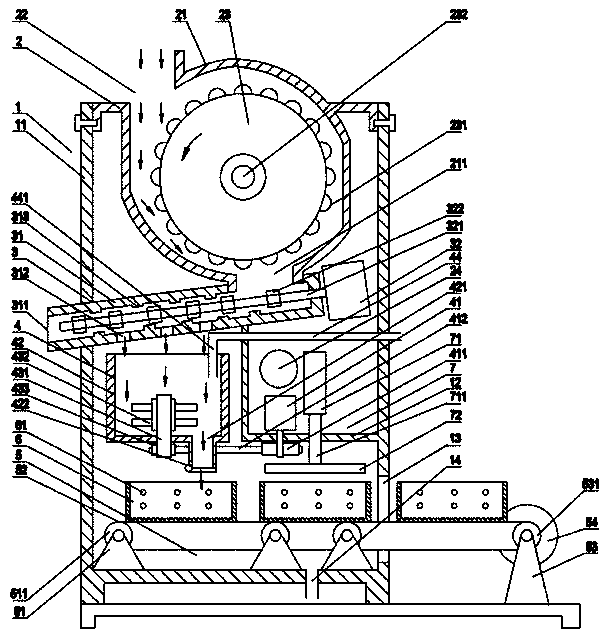

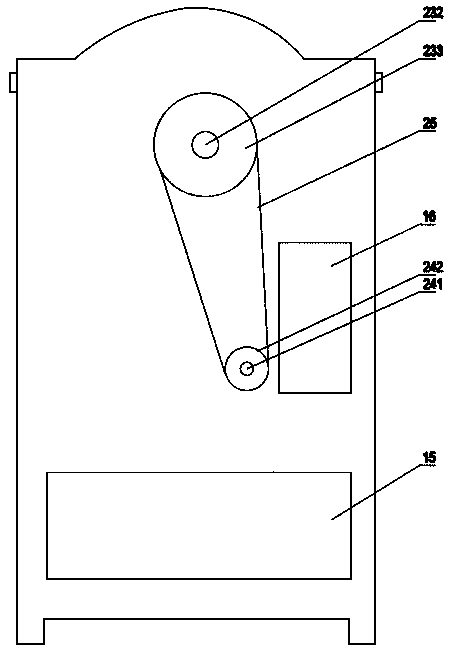

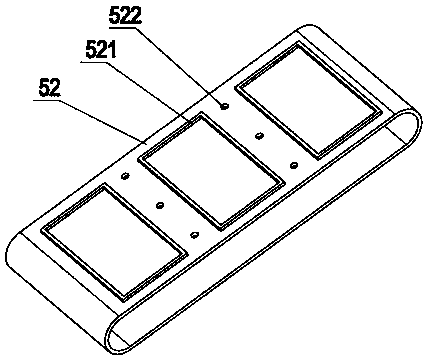

[0032] Such as Figure 1 to Figure 3 As shown, according to the present embodiment 1, an energy-saving and environment-friendly construction waste recycling device includes a machine cover 1, a transmission device 5, a compacting device 7, and a crushing device arranged in the machine cover 1 sequentially from top to bottom. Mechanism 2, milling mechanism 3 and seasoning device 4, the hood 1 includes a housing 11, a partition 12 is provided inside the housing 11, a discharge port 13 is provided on the lower part of the right side wall, and a drain is provided on the bottom wall 14, the lower part of the rear side wall is provided with a mold insertion port 15, and the middle part of the rear side wall is provided with a maintenance port 16. The crushing mechanism 2 includes a crushing outer plate 21 and a wheel 23 installed in the crushing outer plate 21. The crushing outer plate 21 is fixedly connected with the housing 11, and the upper left side is provided with a material i...

Embodiment 2

[0045] According to the recovery method of an energy-saving and environment-friendly construction waste recycling in Embodiment 2, the energy-saving and environment-friendly construction waste recycling device is applied, and the recovery method includes the following steps:

[0046] S1. Put the material from the material inlet 22, start the crushing motor 24 to drive the crushing drive wheel 242 to rotate, drive the crushing power take-off wheel 233 through the crushing power transmission belt 25, and then drive the driving wheel 23 to rotate, so that the material is crushed in the crushing outer plate 21 Extrude and crush;

[0047] S2. The crushed material flows into the milling pipe 31 from the crushing outlet 211, and the milling motor shaft 321 is driven to rotate in the milling pipe 31 by the milling motor 32. The grinding of the material is realized under the extrusion of the second 322 to achieve further crushing. The large particle material flows out of the milling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com