Plastic particle vibrating sieve

A technology of plastic granules and vibrating screen, which is applied in the field of plastic processing, can solve the problems of poor screening effect of plastic granules, and achieve the effects of improving screening effect, cleaning effect and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

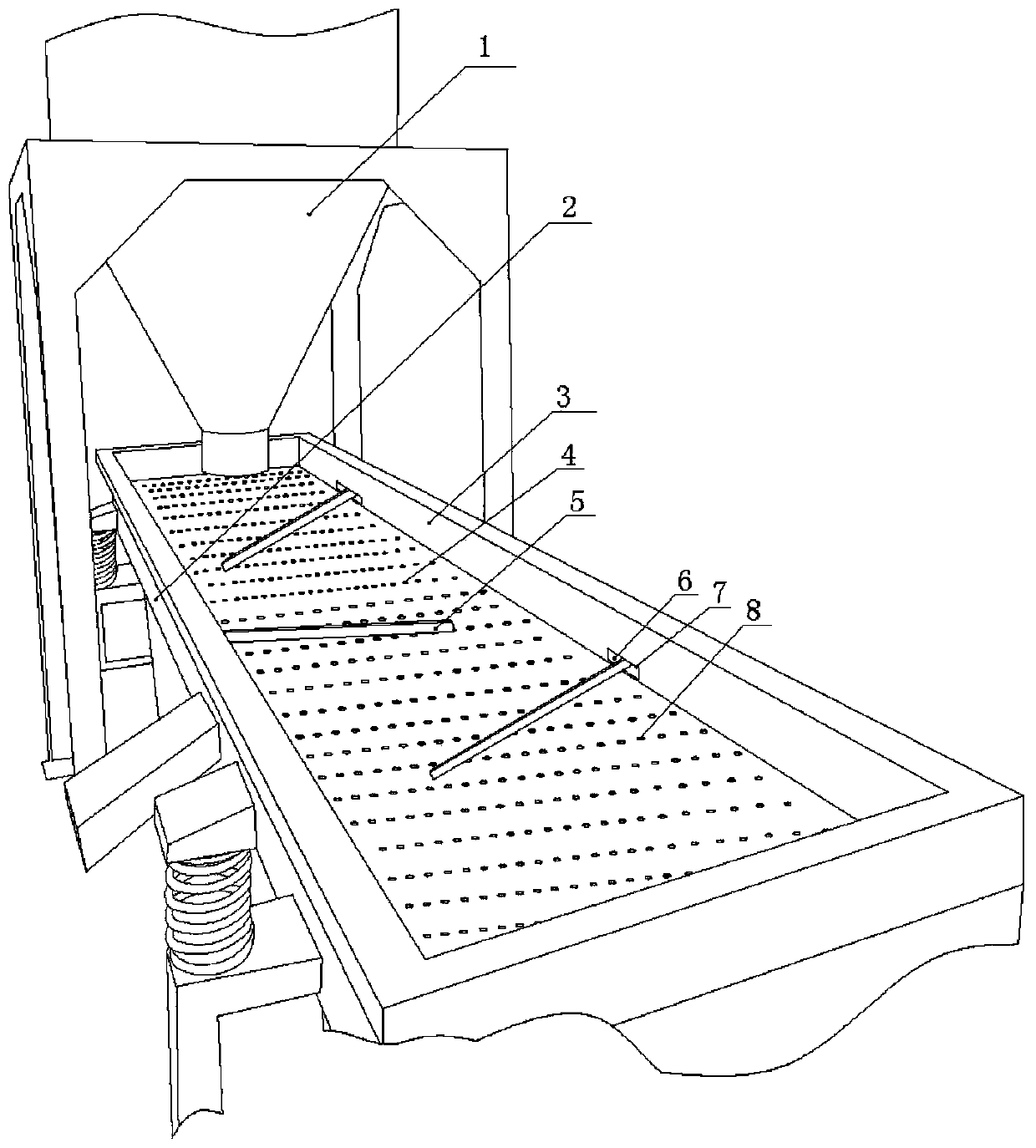

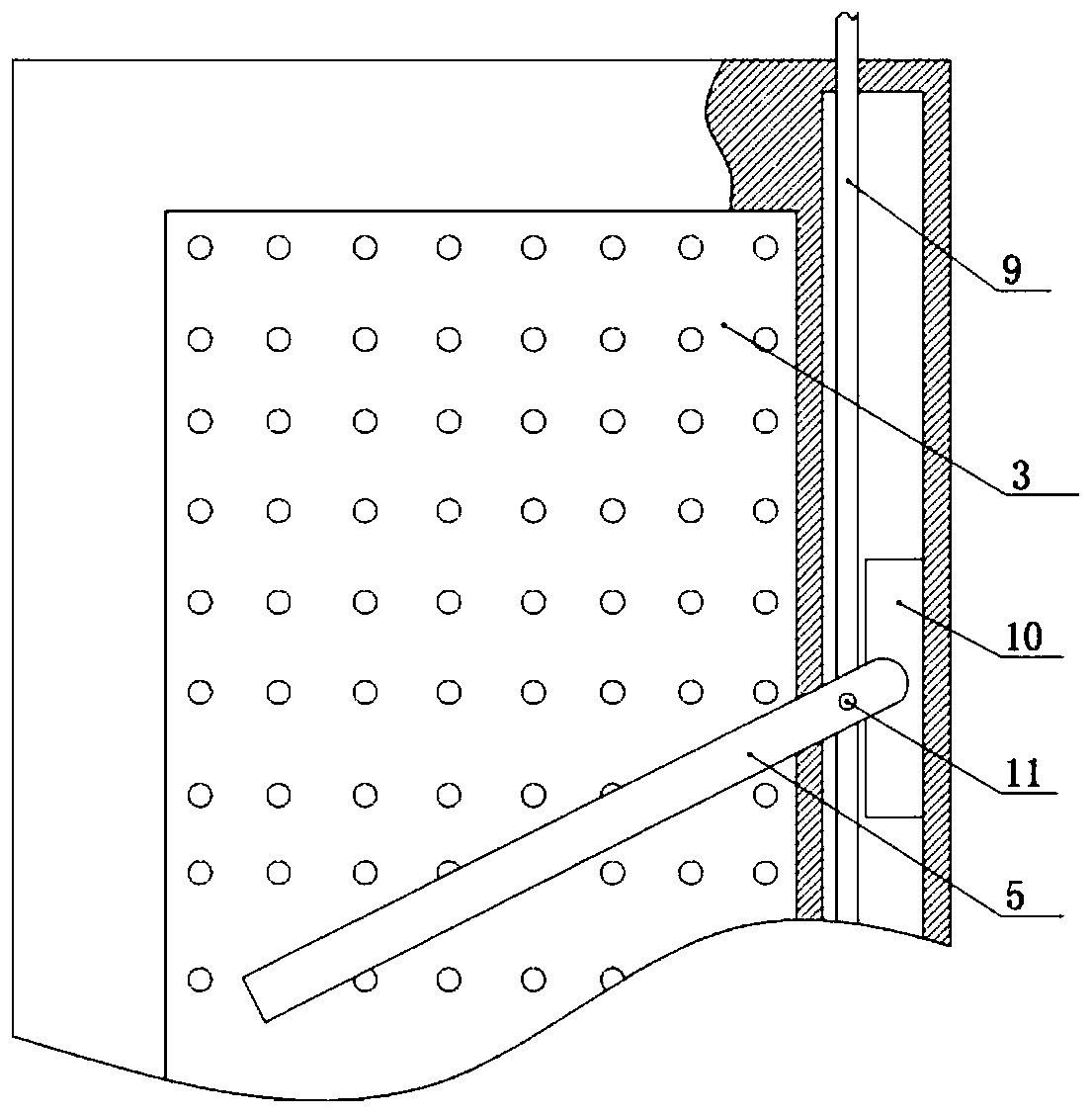

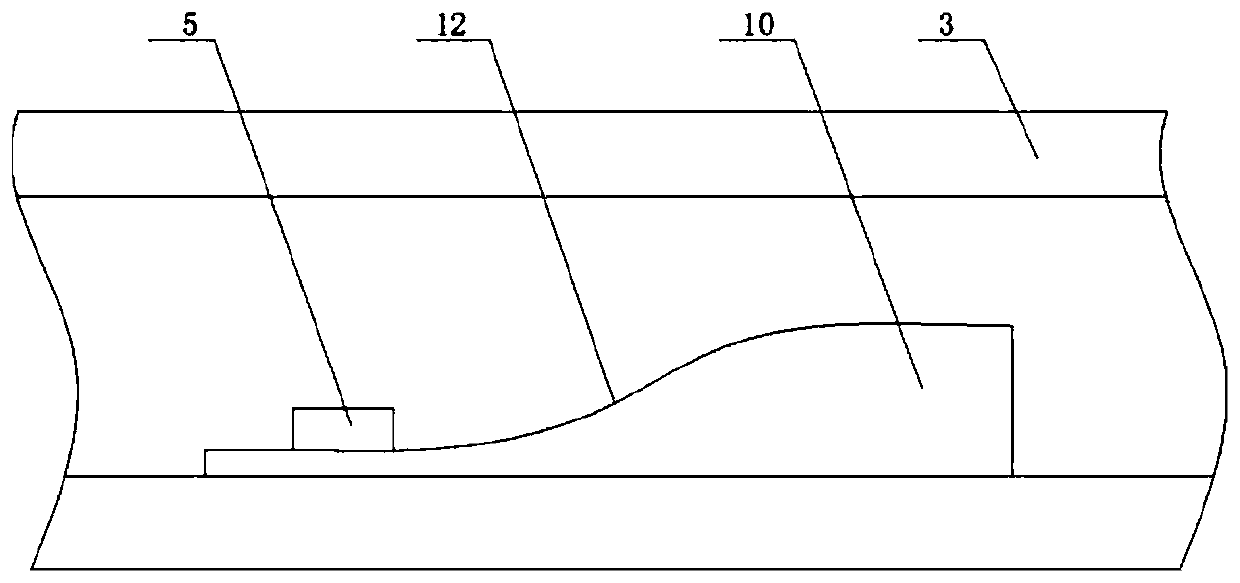

[0026] The vibrating screen for plastic particles includes a base and a vibrating screen body. The vibrating screen body includes a screen box 2 with an open top, and the screen box 2 is installed on the base. A vibrating motor is installed on the base, and the vibrating motor is used to drive the screen box 2 to vibrate. A hopper 3 is installed on the top of the sieve box 2, and both the hopper 3 and the sieve box 2 are installed obliquely. The feed cylinder 1 is installed vertically above the high end of the hopper 3, and the low end of the sieve box 2 is provided with a discharge port. Out of the barrel. The bottom of the hopper 3 is provided with several sieve holes. The sieve holes include a first sieve hole 4 and a second sieve hole 8 . The first sieve hole 4 has a smaller aperture than the second sieve hole 8 . The first sieve 4 is used to sieve powder and impurities in the plastic granules, and the second sieve 8 is used to sieve the finished plastic granules. The si...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that there are several brush strips glued to the bottom of the baffle plate 5. When the baffle plate 5 swings toward the high end of the hopper 3, the brush strips can clean the bottom of the hopper 3, thereby reducing the risk of screen hole clogging. Condition.

Embodiment 3

[0040] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a balance bar 13 is installed on the hopper 3, the balance bar 13 is arranged across the hopper 3, the left end of the balance bar 13 is sleeved with a wire, and the wire is welded to the screen box 2 superior. The right end of the balance bar 13 is fixed on the hopper 3 through a lock. During use, the balance bar 13 is fastened by the lock to press it against the hopper 3, which can reduce the vibration amplitude of the hopper 3 and prevent the plastic particles in the hopper 3 from splashing due to excessive vibration amplitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com