Efficient powder sieving equipment

A screening equipment and powder technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of easy blocking of screen mesh, low manufacturing cost, inaccurate screening, etc., and achieve the realization of screening reliability, Low manufacturing cost and guaranteed screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

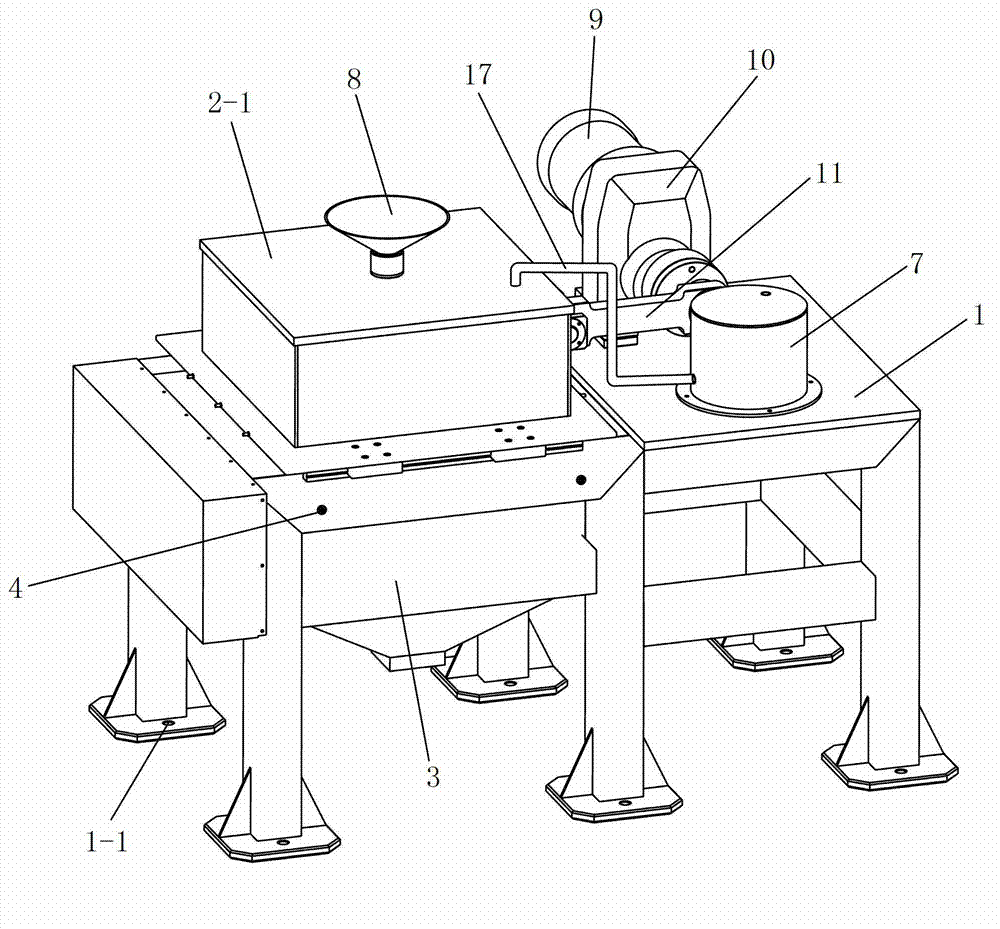

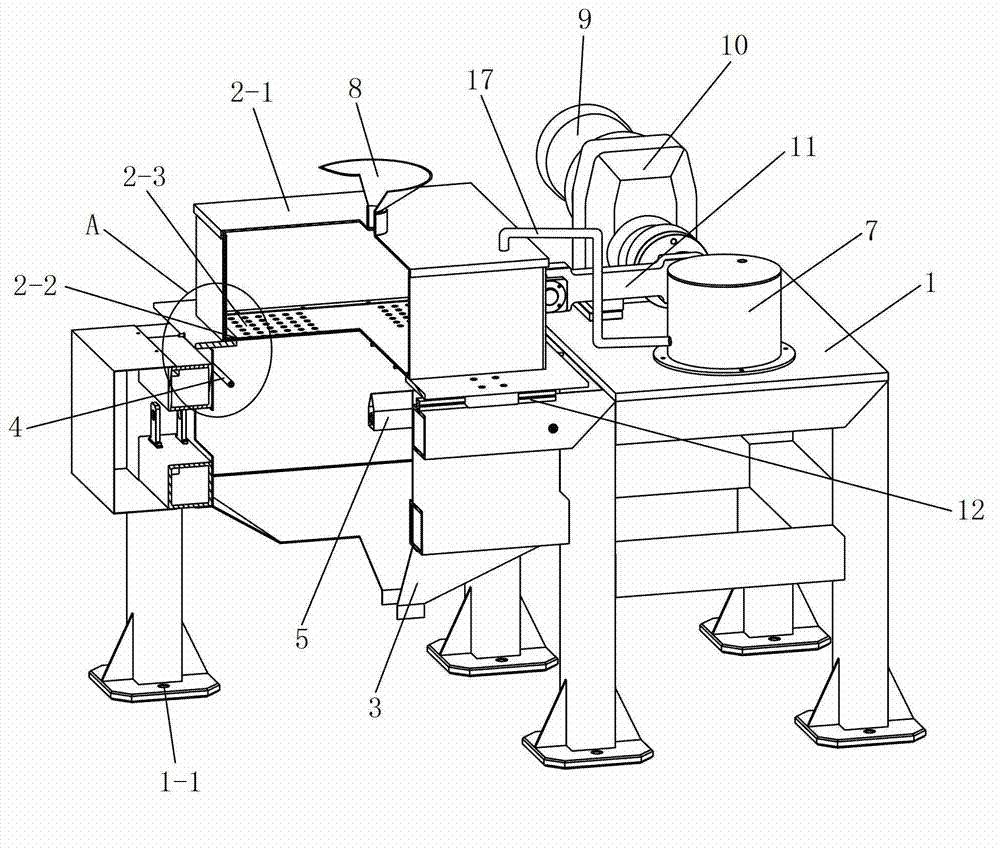

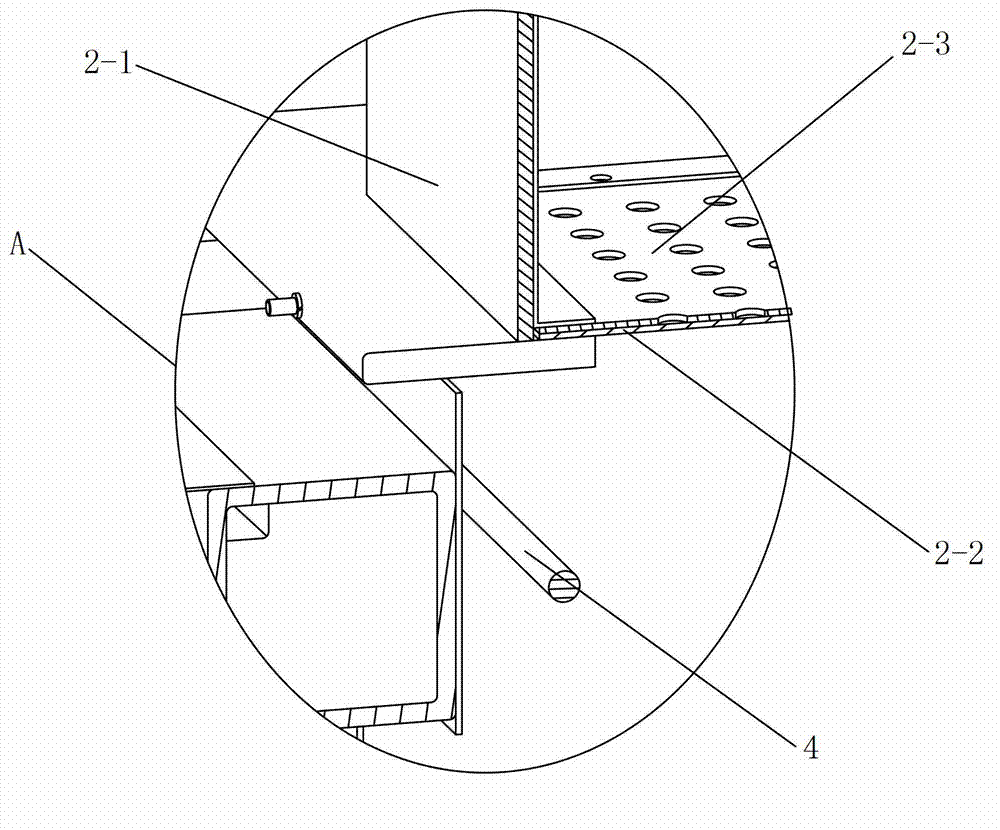

[0039] like Figure 1 to Figure 5 As shown, the present invention includes a bracket 1, a lower hopper 3, a screening box and a screening box swing system installed on the bracket 1, and the screening box includes a box body 2-1 and is installed inside the box body 2-1. The screen 2-2, the box 2-1 is arranged on the support 1 and can reciprocate along the track 12 installed on the support 1, the lower bin 3 is installed at the bottom of the box 2-1, so A compressed gas blowback system is provided below the box 2-1, and the compressed gas blowback system includes a polished rod 4, an air knife 5, a servo motor 6, a first synchronous pulley 13, a second synchronous pulley 14 and a synchronous belt 15, the number of the polished rods 4 is two and the two polished rods 4 are installed in parallel on the support 1, the servo motor 6 and the second synchronous pulley 14 are all installed on the support 1, and the first synchronous pulley 13 is fixedly installed on the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com