Conveying system of uncoiling blanking die

A conveying system, uncoiling and blanking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

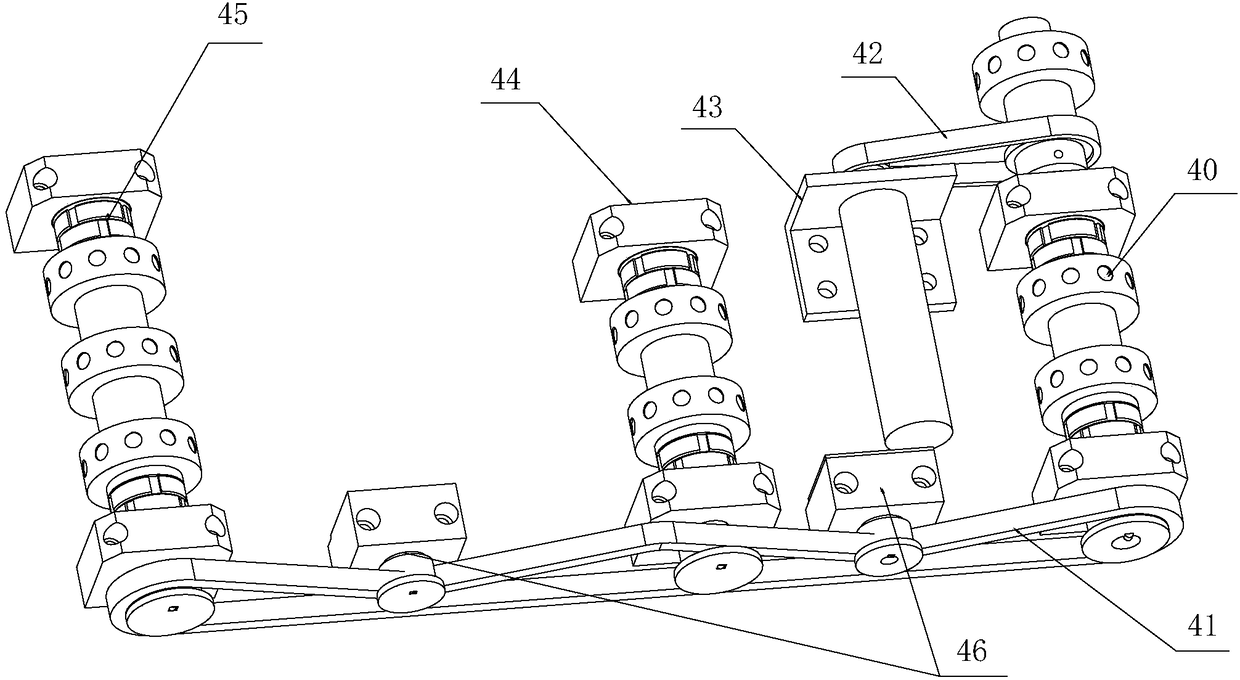

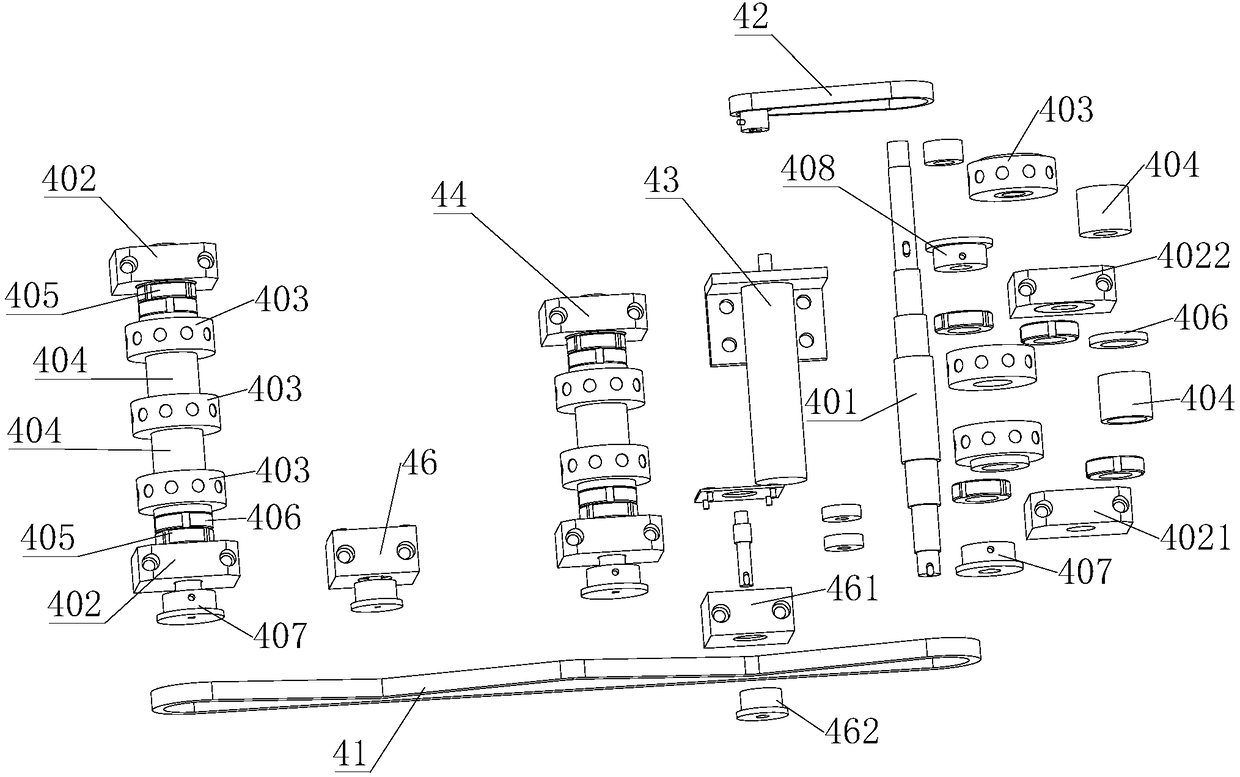

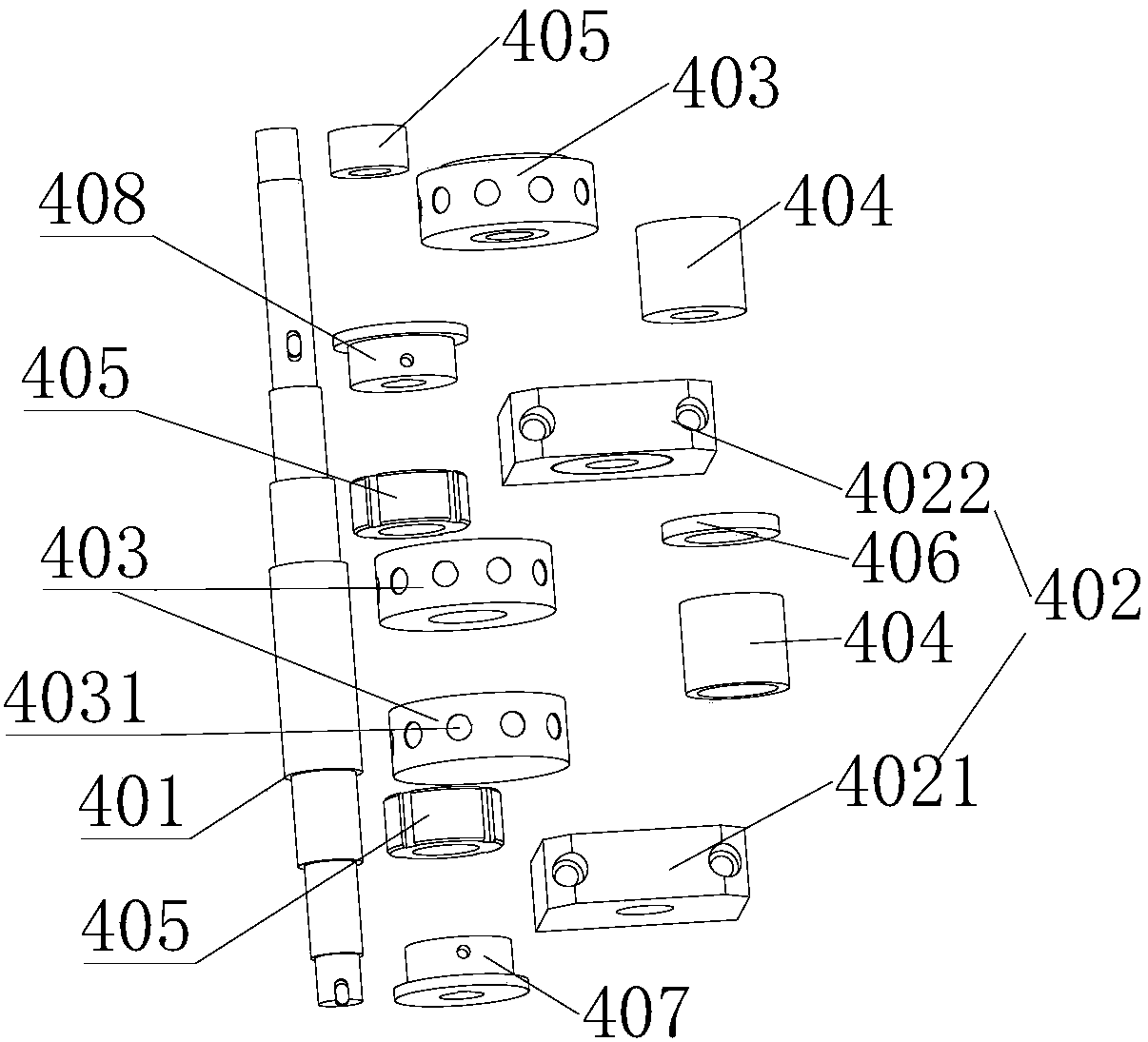

[0027] Embodiments of the present invention: as figure 1 with figure 2 As shown, a conveying system of an uncoiling blanking mold is disclosed, comprising a main roller device 40, a motor 43 driving the main roller device 40 and at least one passive roller device; the passive roller device and the main roller device 40 are arranged side by side and generate linkage through the transmission member 41; the main roller device 40 and the passive roller device both include a rotating shaft 401, a support seat 402 supporting the rotation of the rotating shaft 401, and a hub 403 for transmitting blanks, and the hub 403 The number is provided in multiples, and the side wall of the hub 403 is evenly distributed with magnets 4031 to make the blank move smoothly, and the output shaft of the motor 43 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com