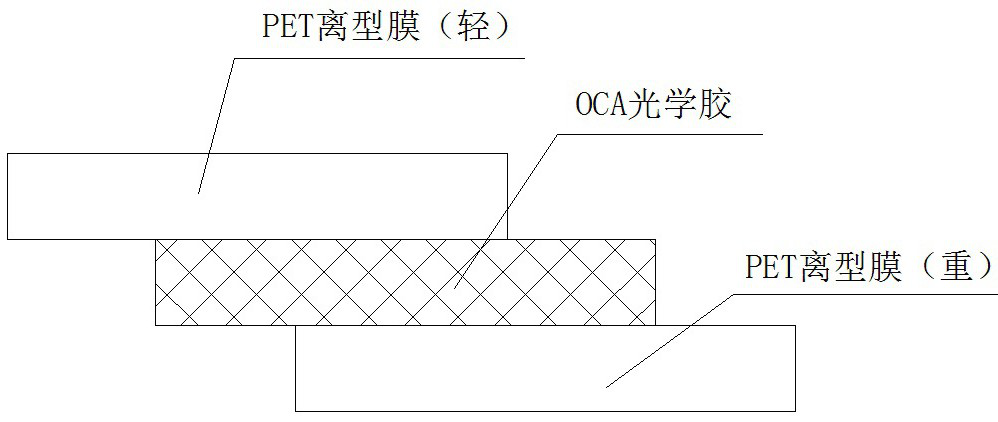

Preparation process of high-end release protection polyester base film for OCA

A polyester base film, preparation process technology, applied in the direction of film/sheet adhesive, application, adhesive, etc., can solve the problems of dispersion, weak research and development strength, etc., to improve performance, improve antistatic performance, reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

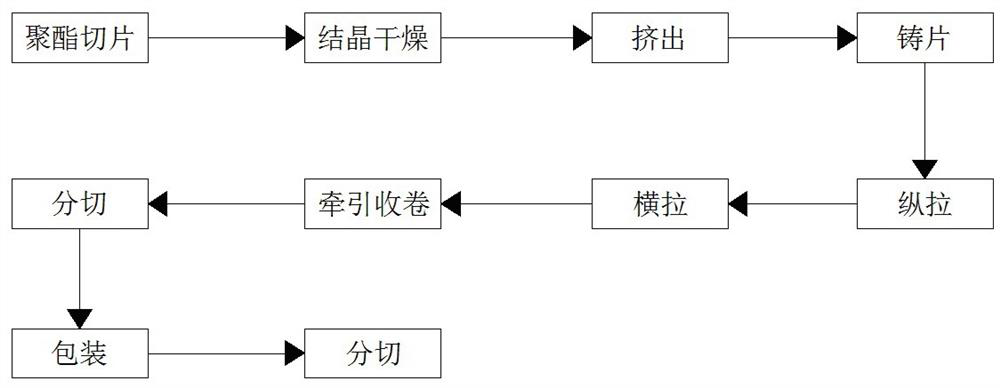

Method used

Image

Examples

Embodiment 1

[0029] visual inspection

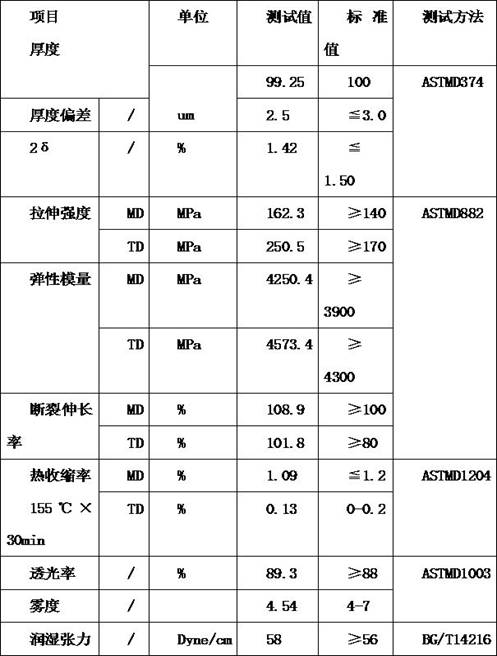

[0030] Test equipment and methods

[0031] Microscopic heat table HS82 (thermal analysis table + polarizing display mirror), digital measurement projector CPT-3025A, black board.

[0032] Visual inspection, colorless and transparent, without any defects.

[0033] Use lighting and a black board for visual inspection, tilt the sample 20-45 degrees, and observe whether there are foreign objects, bumps, bends, scratches, etc. If visual inspection cannot be judged, a magnifying glass can be used.

Embodiment 2

[0035] Lightness, chroma, haze test

[0036] Test equipment and methods

[0037] Test equipment: quartz glass plate, micro-heating table, haze transmittance tester AT-4725, darkness meter 6801; gloss meter 4454-45; electronic thickness gauge C1216; cutter JDC-15M-10

[0038] Calibrate with the glass washed with the solution, a spectrometer and a haze meter, and then use a 30mm light release film to peel off the heavy release film on the laminated glass plate to test the lightness, chroma and haze.

Embodiment 3

[0040] Adhesion test

[0041] Test equipment and methods

[0042]Test equipment: quartz glass plate, tensile testing machine, silicone roller, Shore hardness tester, cutter JDC-15M-10

[0043] Cut off the sample at 15mm, peel off the light release film, stick it on the cleaned glass plate, peel off the heavy release film, attach the support film, press the pressure roller three times by hand, and test the adhesion with a tensile machine after 30 minutes in the room Test, test conditions, peeling angle 180 degrees, pulling speed 100mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com