Patents

Literature

60results about How to "Maintain detection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

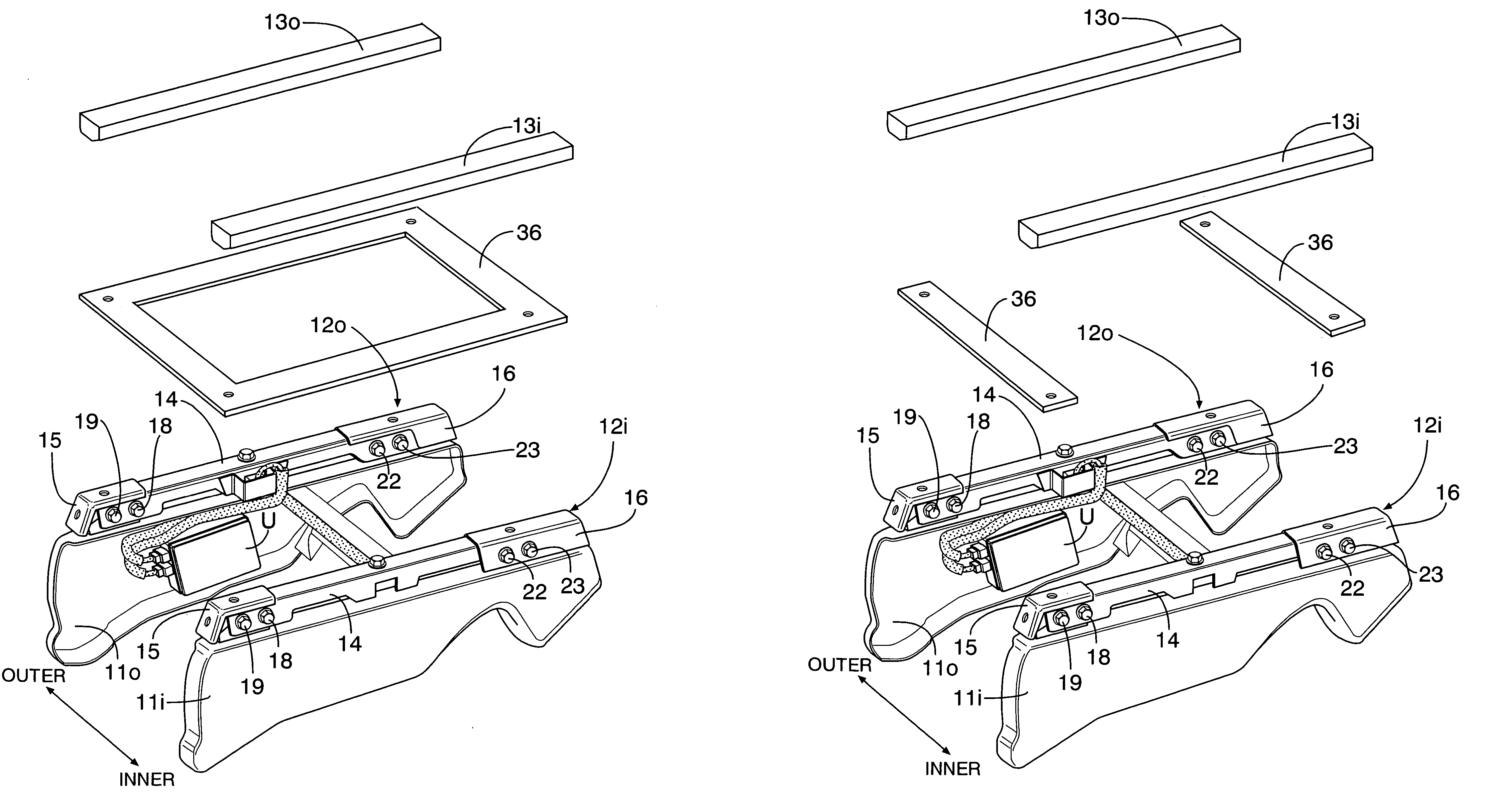

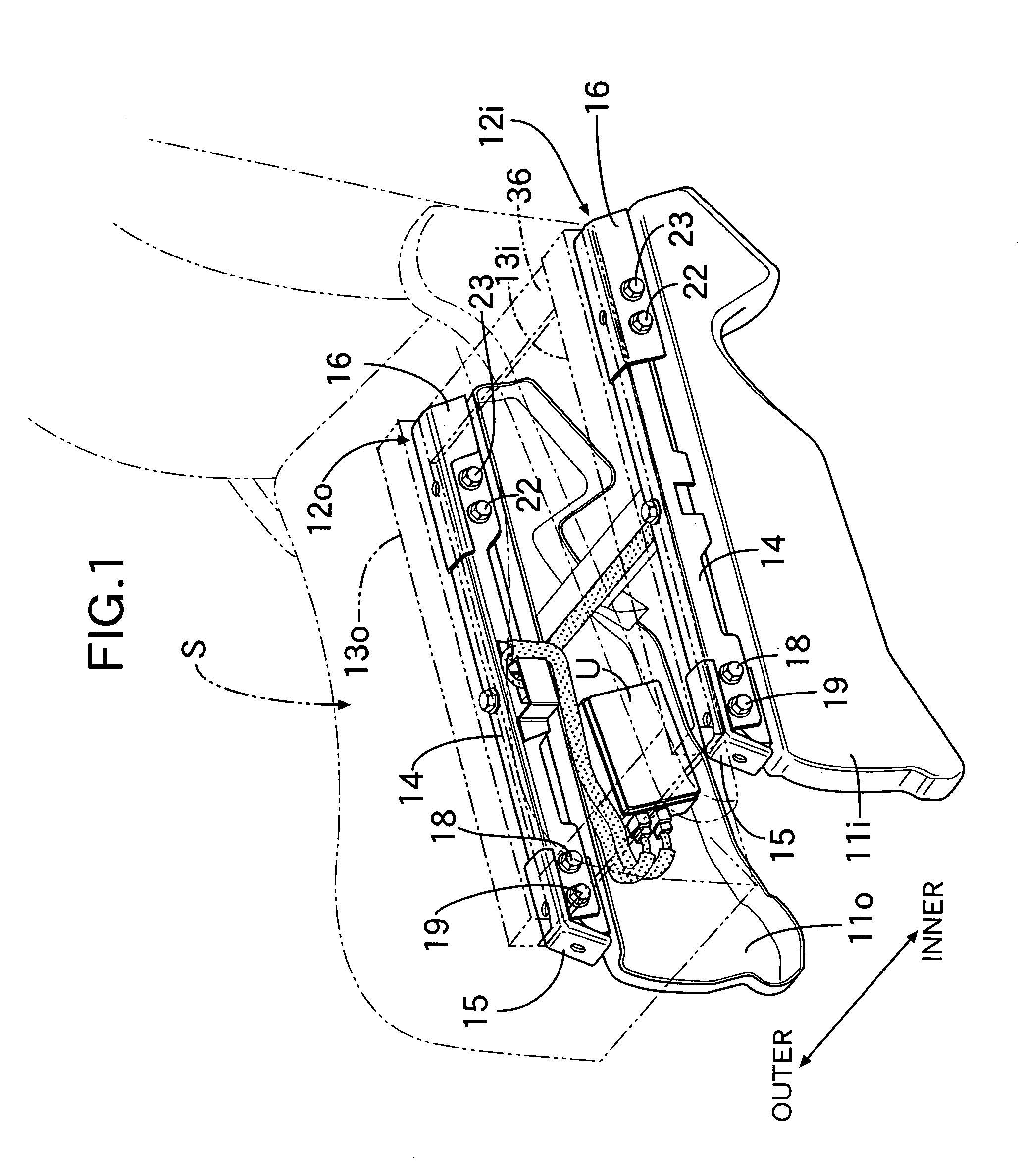

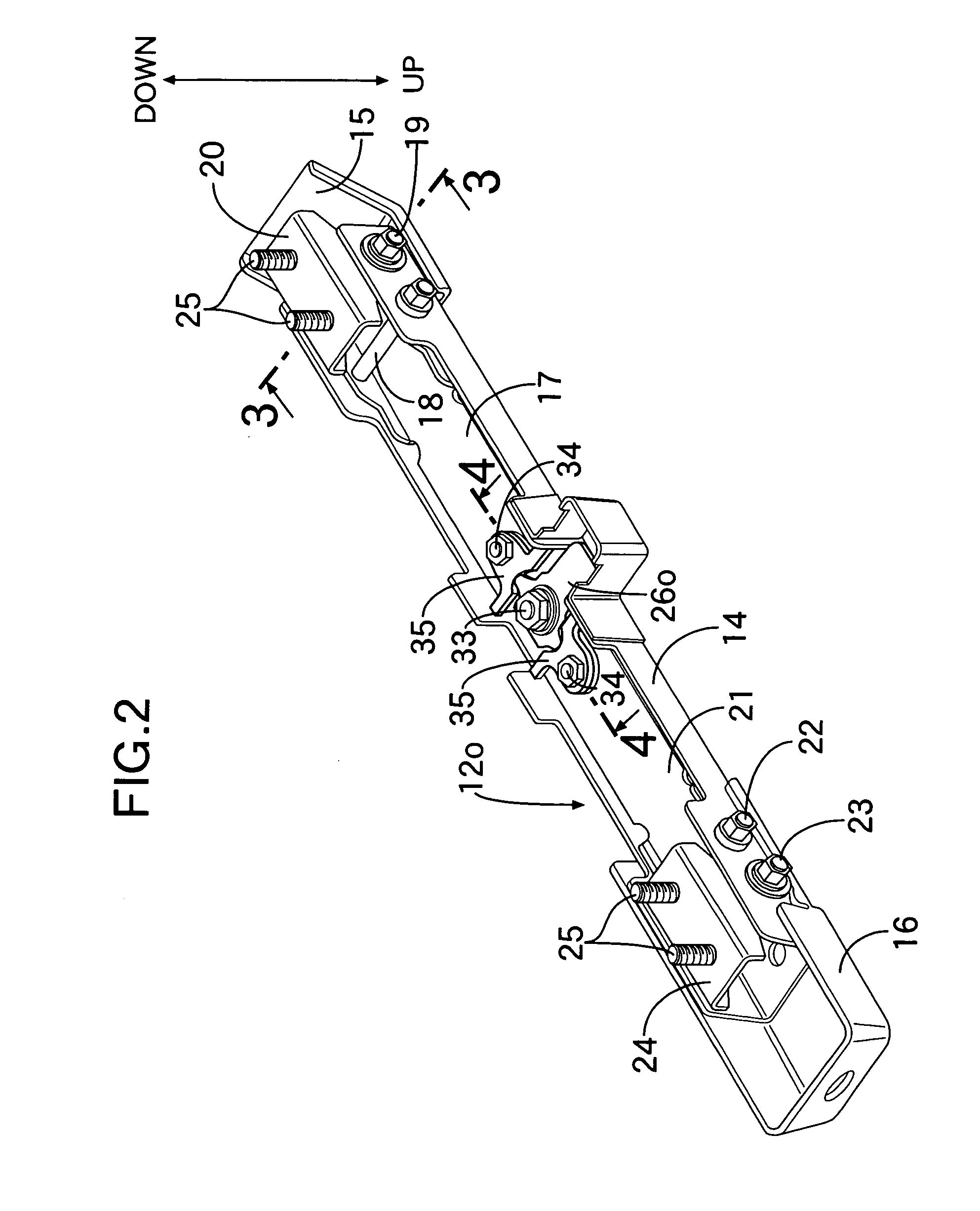

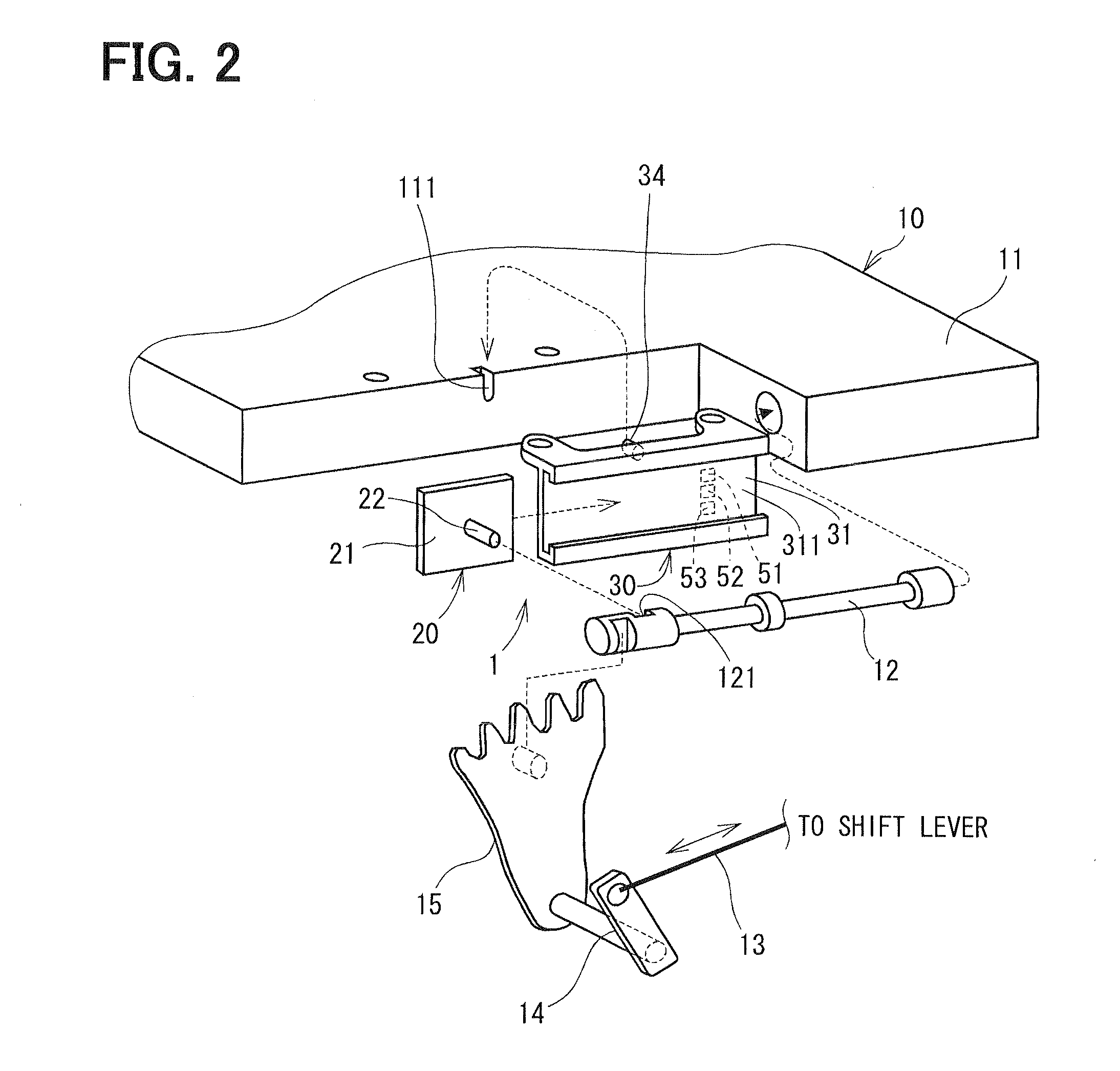

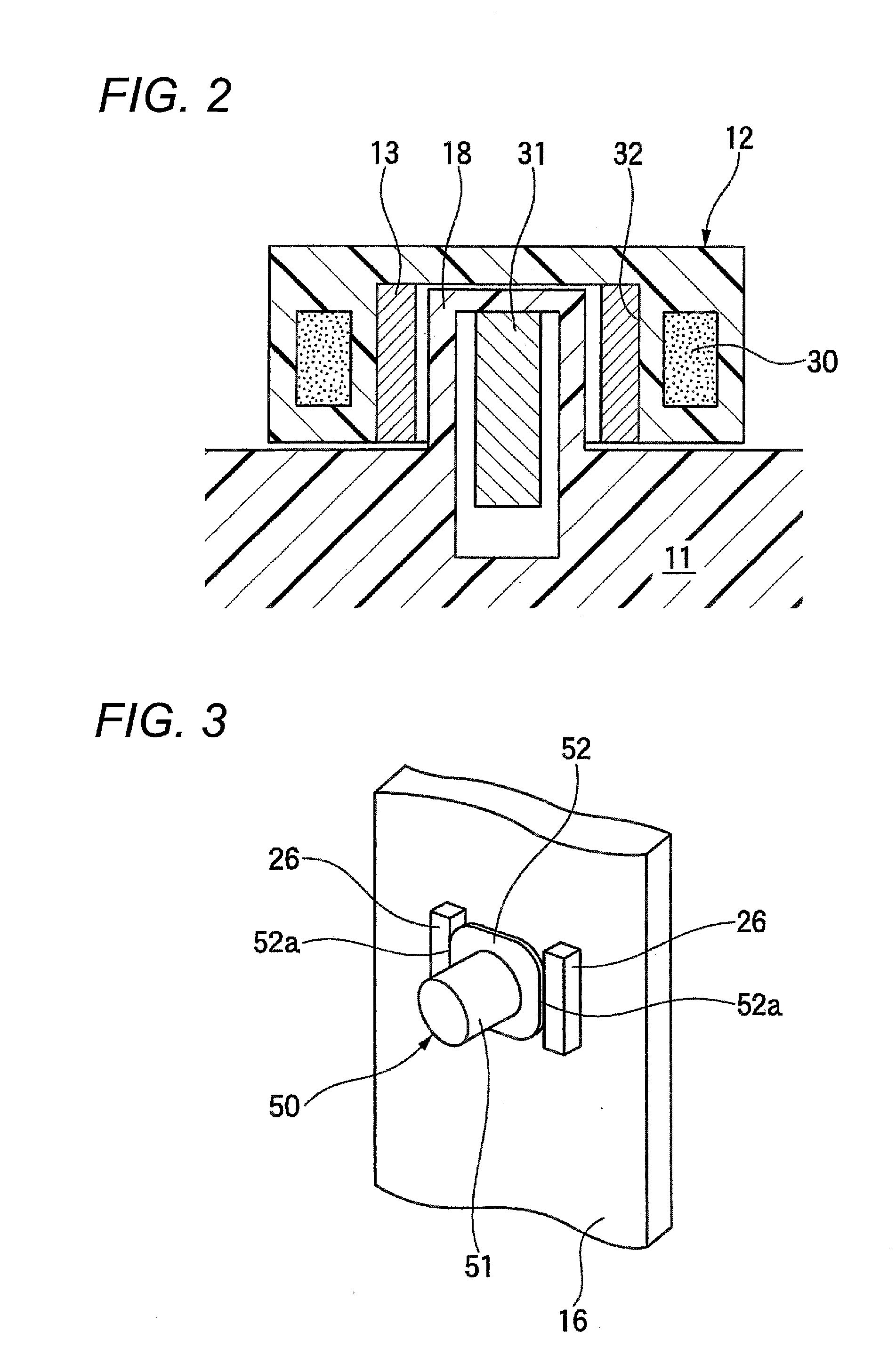

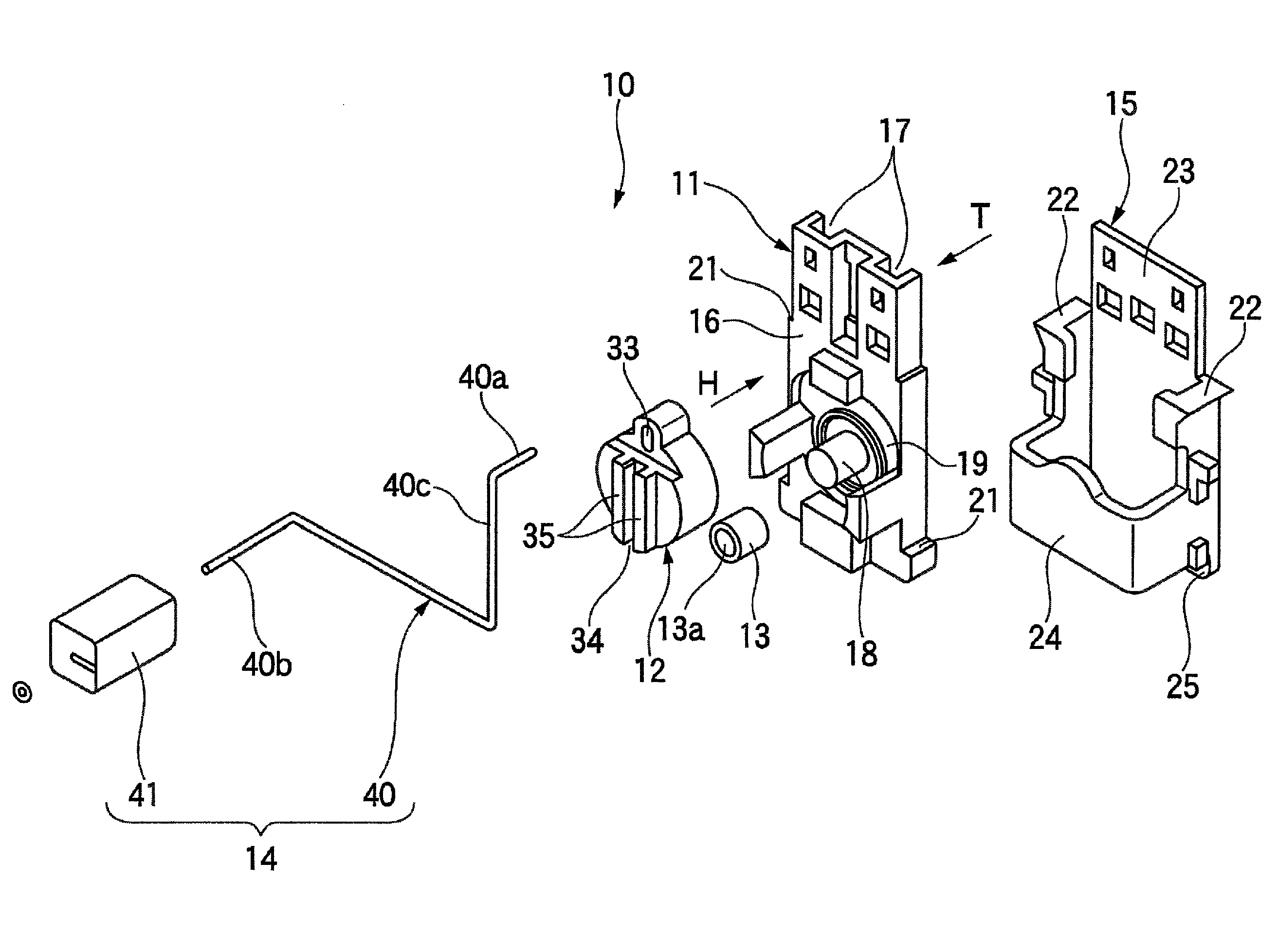

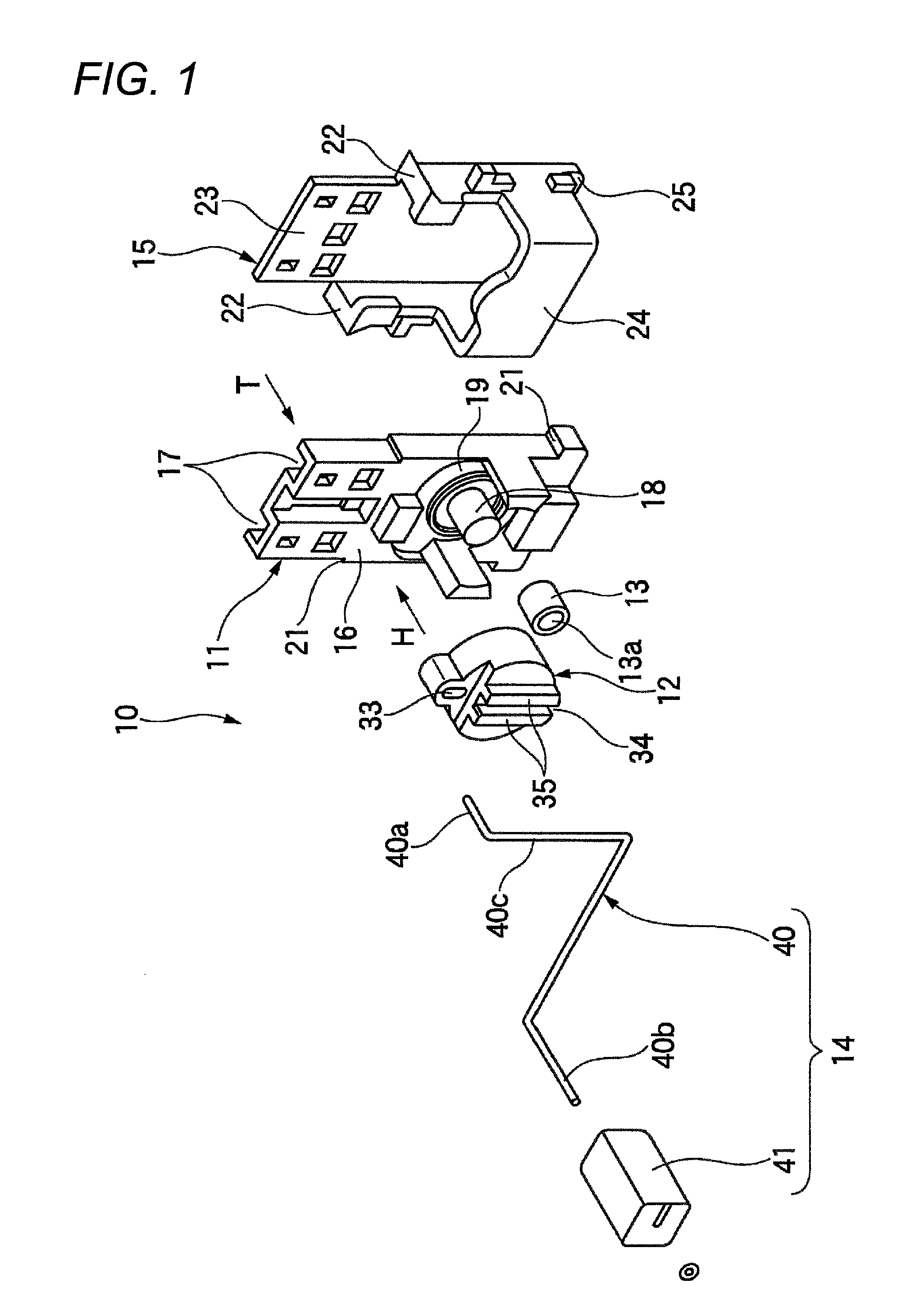

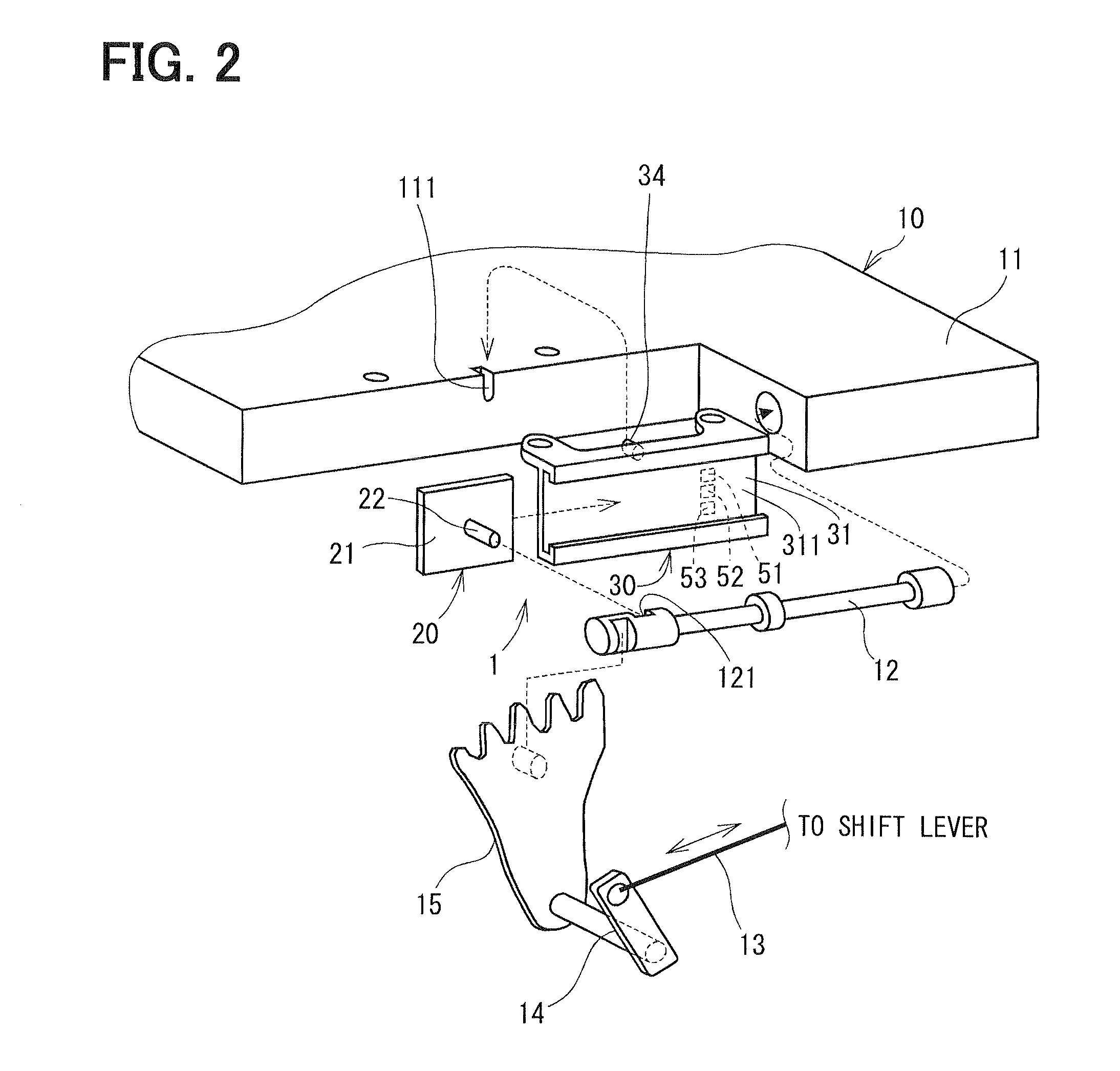

Occupant weight detection system having linked weight detection means with maintained positional relationships

InactiveUS7091426B2Improve detection accuracyMaintain detection accuracyVehicle seatsElectric devicesEngineeringLink weight

In an occupant weight detection system, a pair of weight detection units are mounted along upper faces of base members fixed to a floor of an automobile. A square-frame-shaped linking member made of an iron sheet is interposed between the pair of weight detection units and a pair of seat rails. The pair of weight detection units are integrally linked by the linking member to maintain a positional relationship to each other at a predetermined relationship. Therefore, it is possible to prevent these weight detection means from being mounted in a state in which they are twisted or displaced relative to each other, thereby maintaining the detection accuracy.

Owner:HONDA MOTOR CO LTD

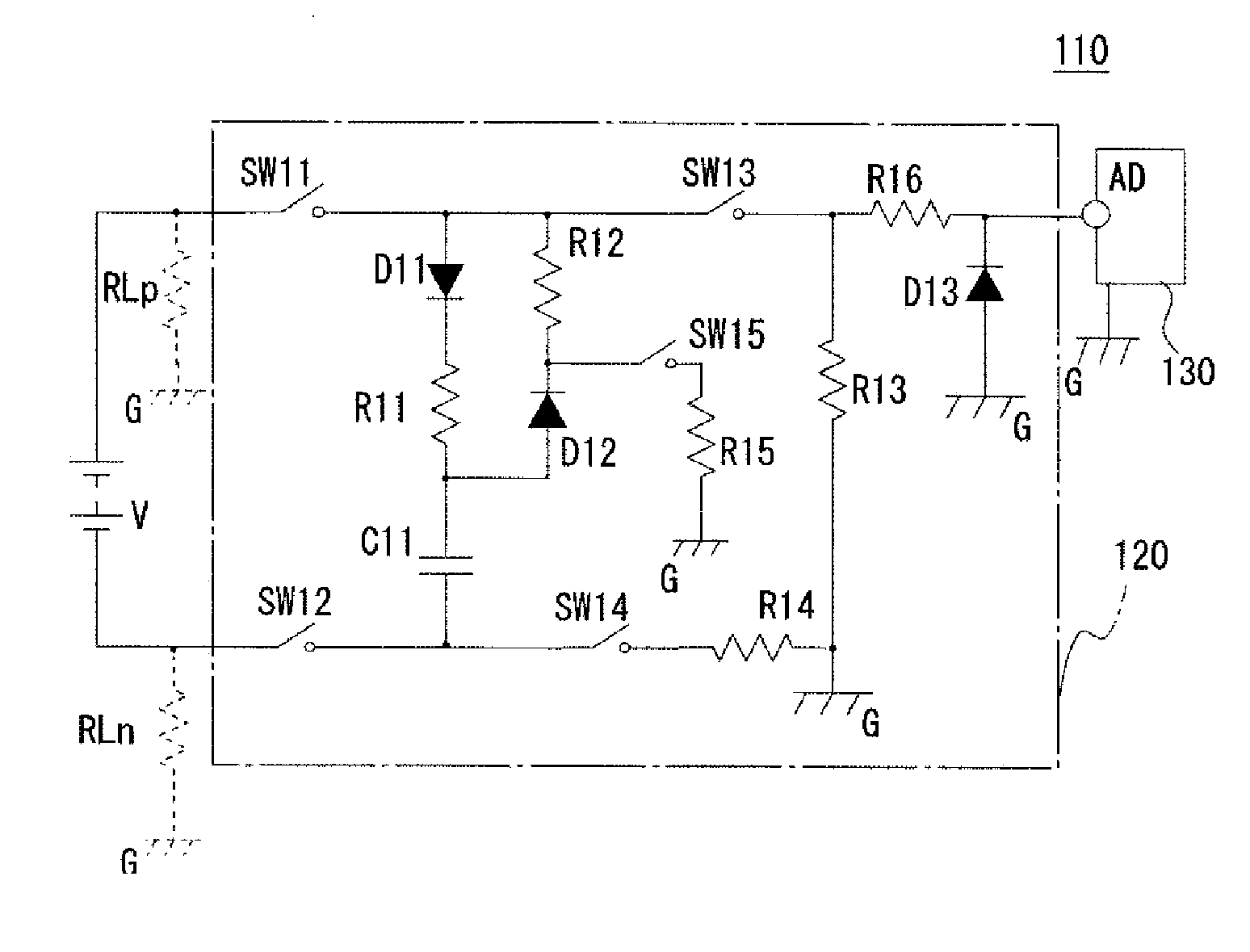

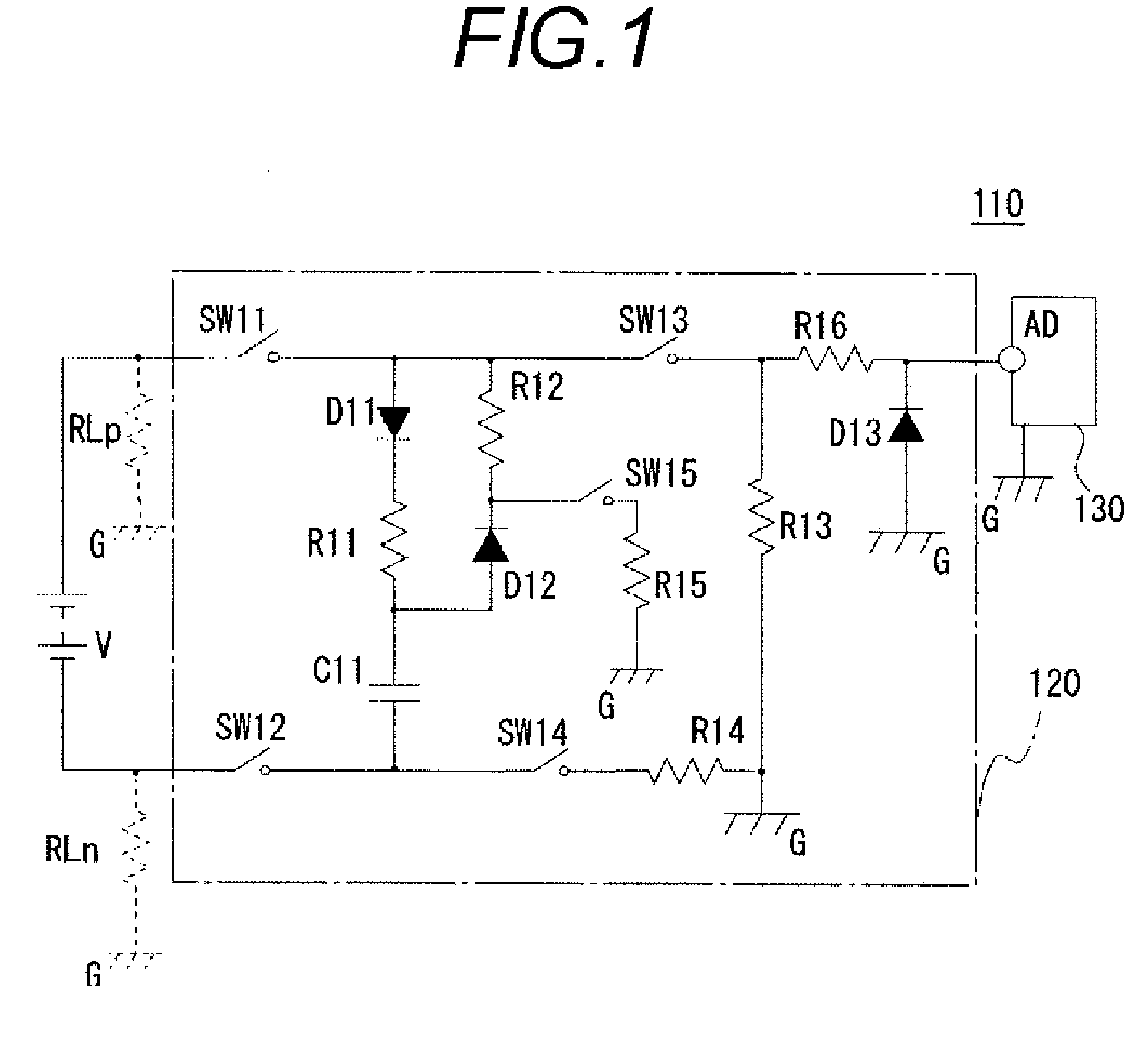

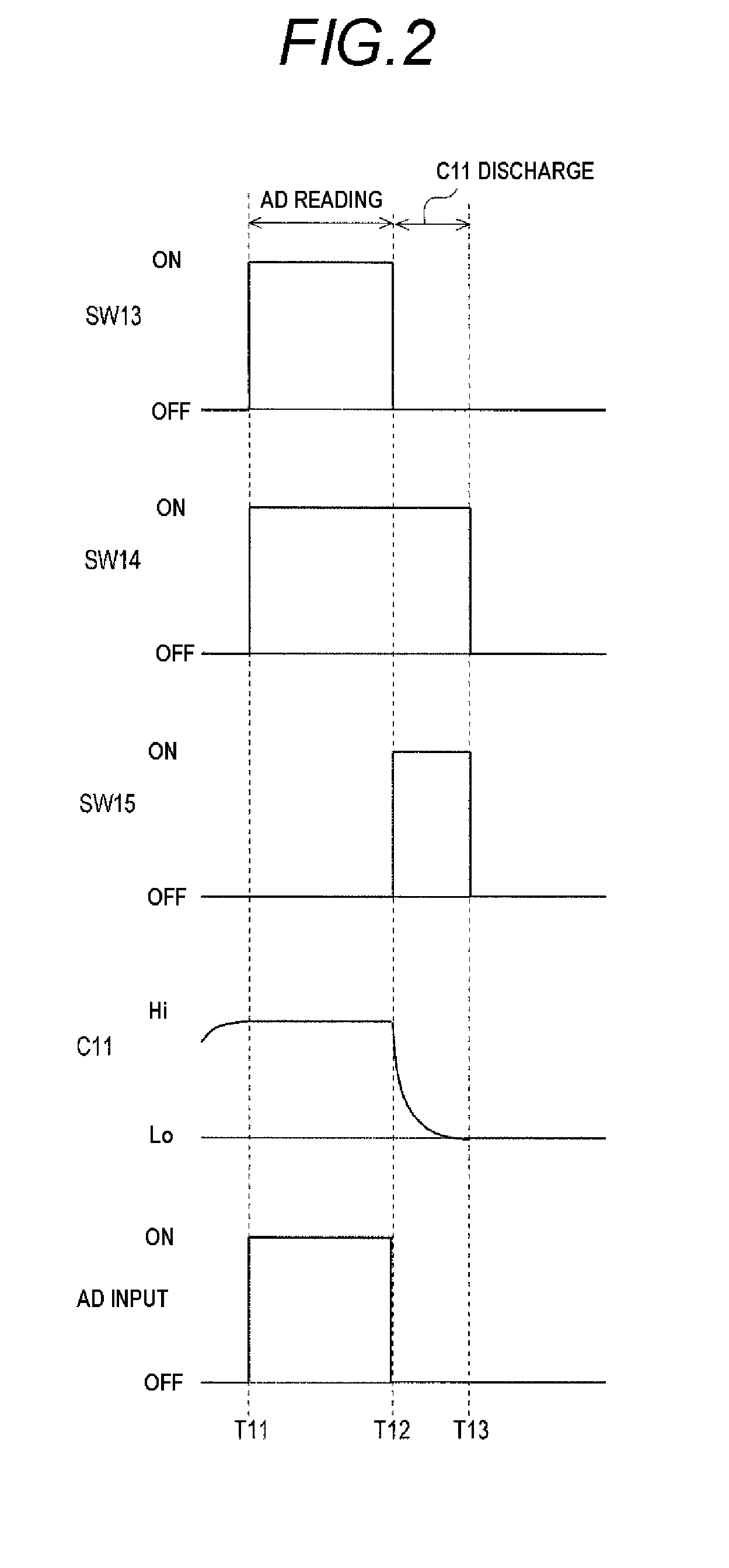

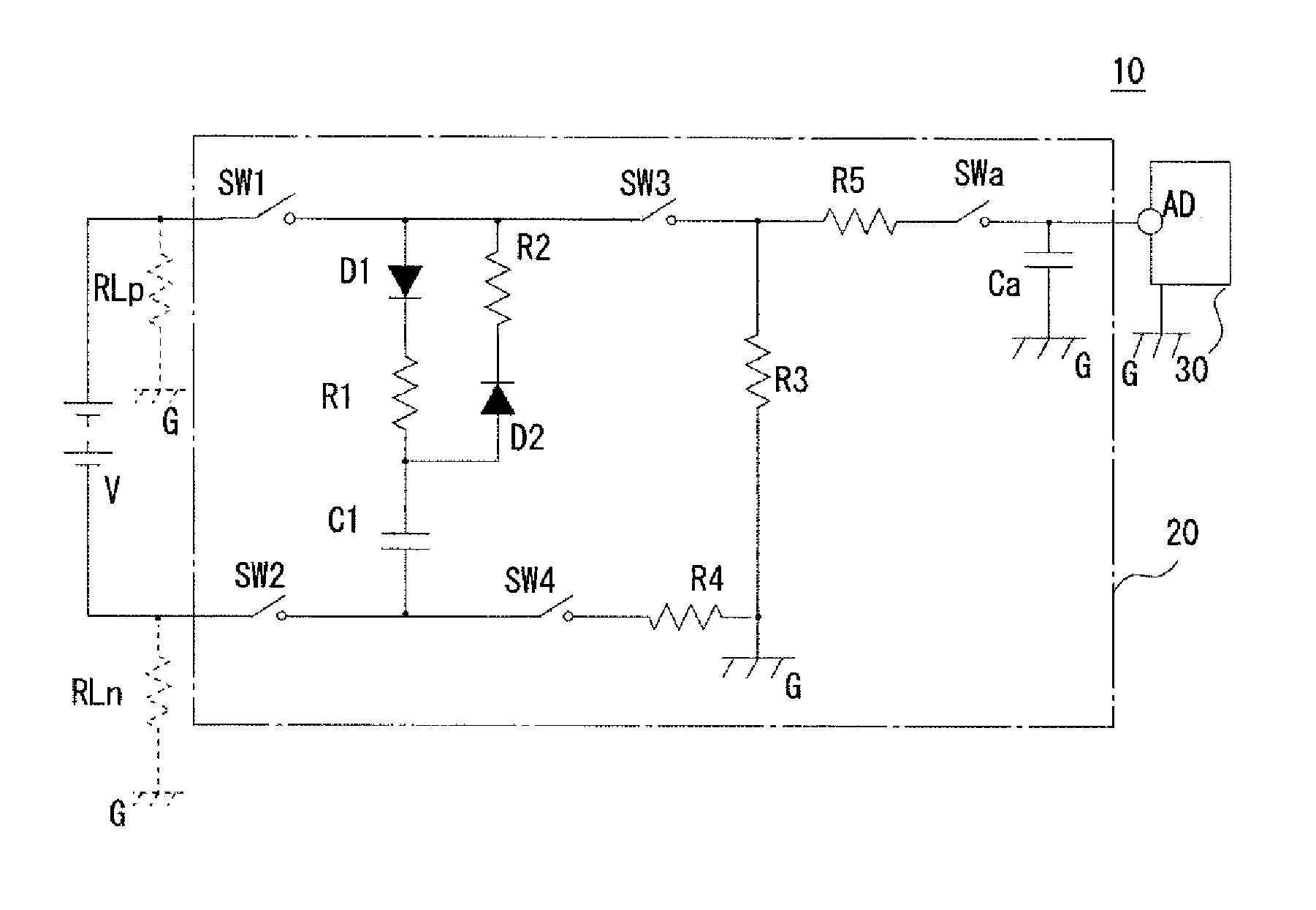

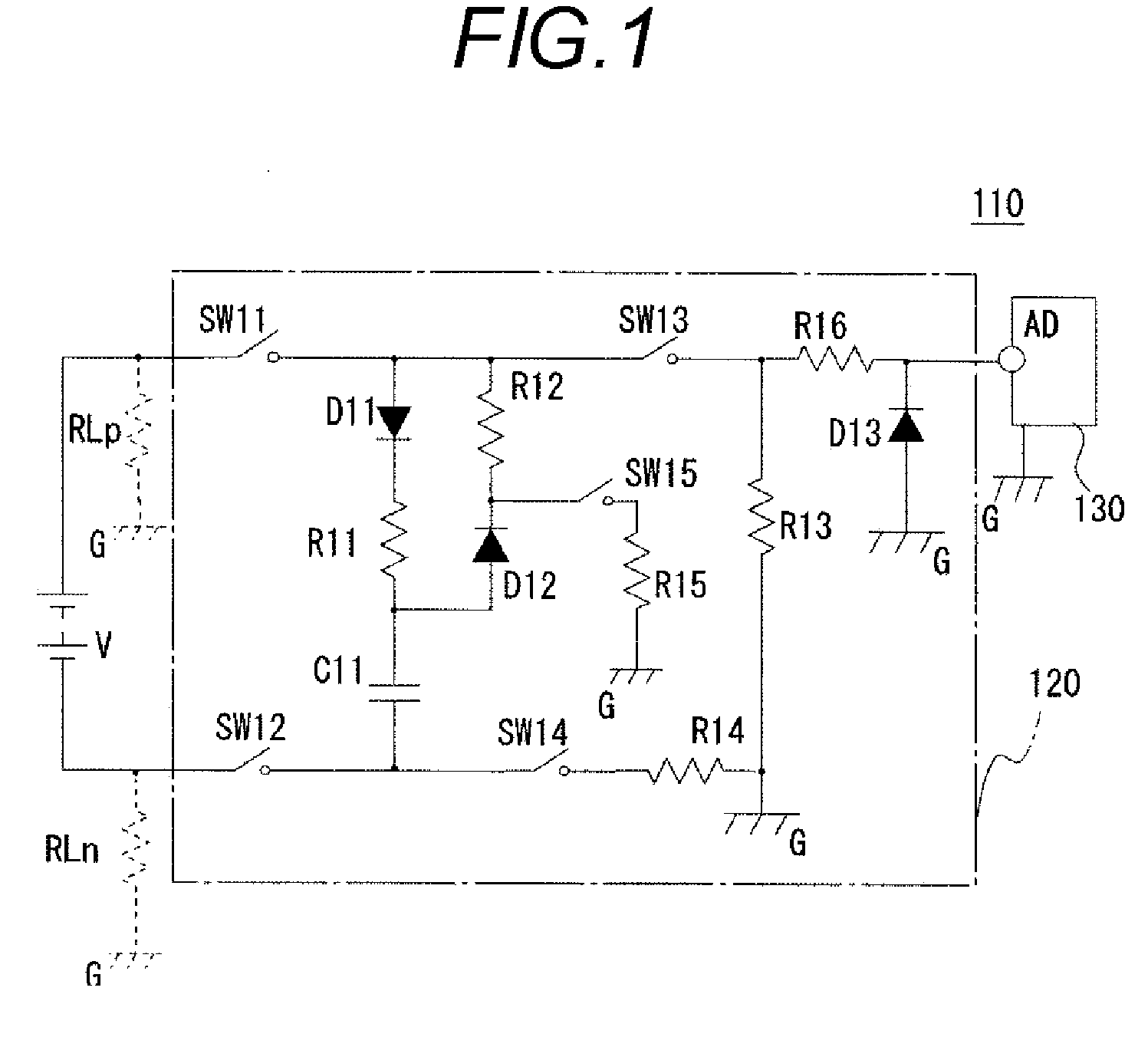

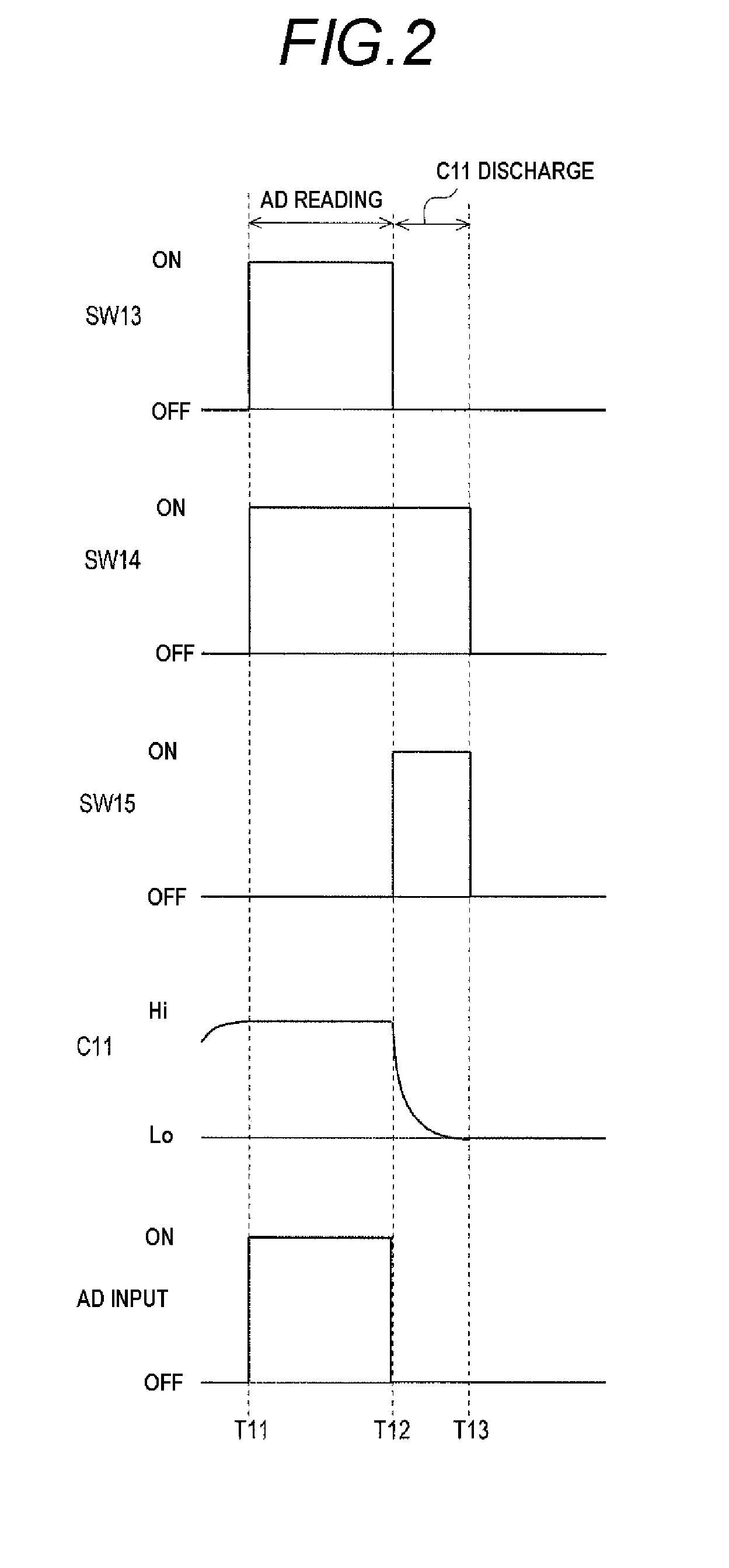

Insulation measuring apparatus

ActiveUS20110084705A1Low costReduced measurement timeVery high resistance measurementsMaterial analysis by electric/magnetic meansMeasurement deviceEngineering

An insulation measuring apparatus, comprises: a measuring circuit including a first capacitor; a control unit that reads a voltage set on the first capacitor to decide an insulation state of a power supply, and control a path configuration of the measuring circuit; a switching section provided in a path located between the measuring circuit and the control unit; and a second capacitor provided between a ground and a path located between the switching section and the control unit. The control unit controls the path configuration of the measuring circuit, by turning ON the switching section to set a voltage corresponding to the voltage that is set on the first capacitor on the second capacitor, and then by turning OFF the switching section to read the voltage set on the second capacitor and to discharge an electric charge corresponding to the voltage being set on the first capacitor.

Owner:YAZAKI CORP

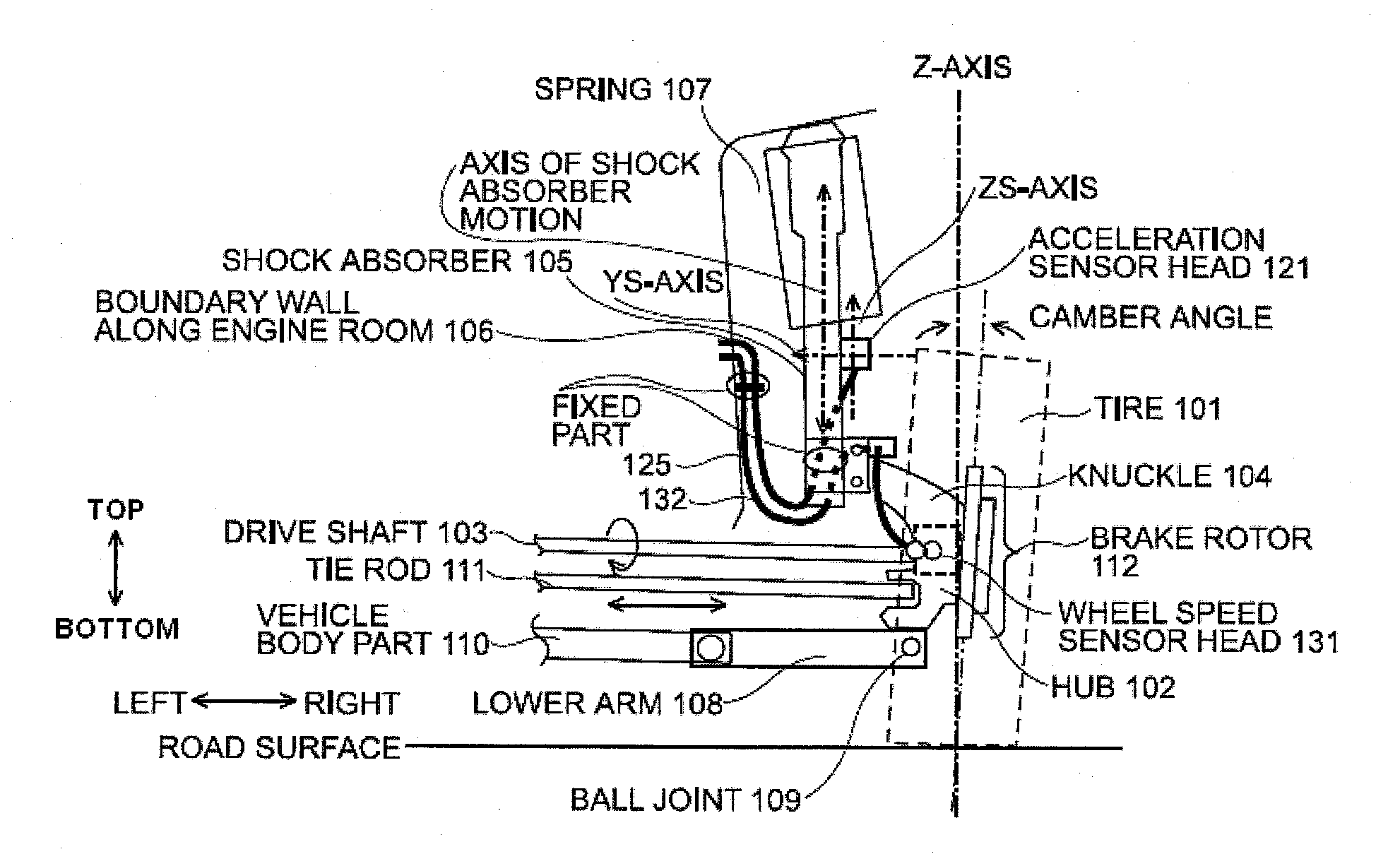

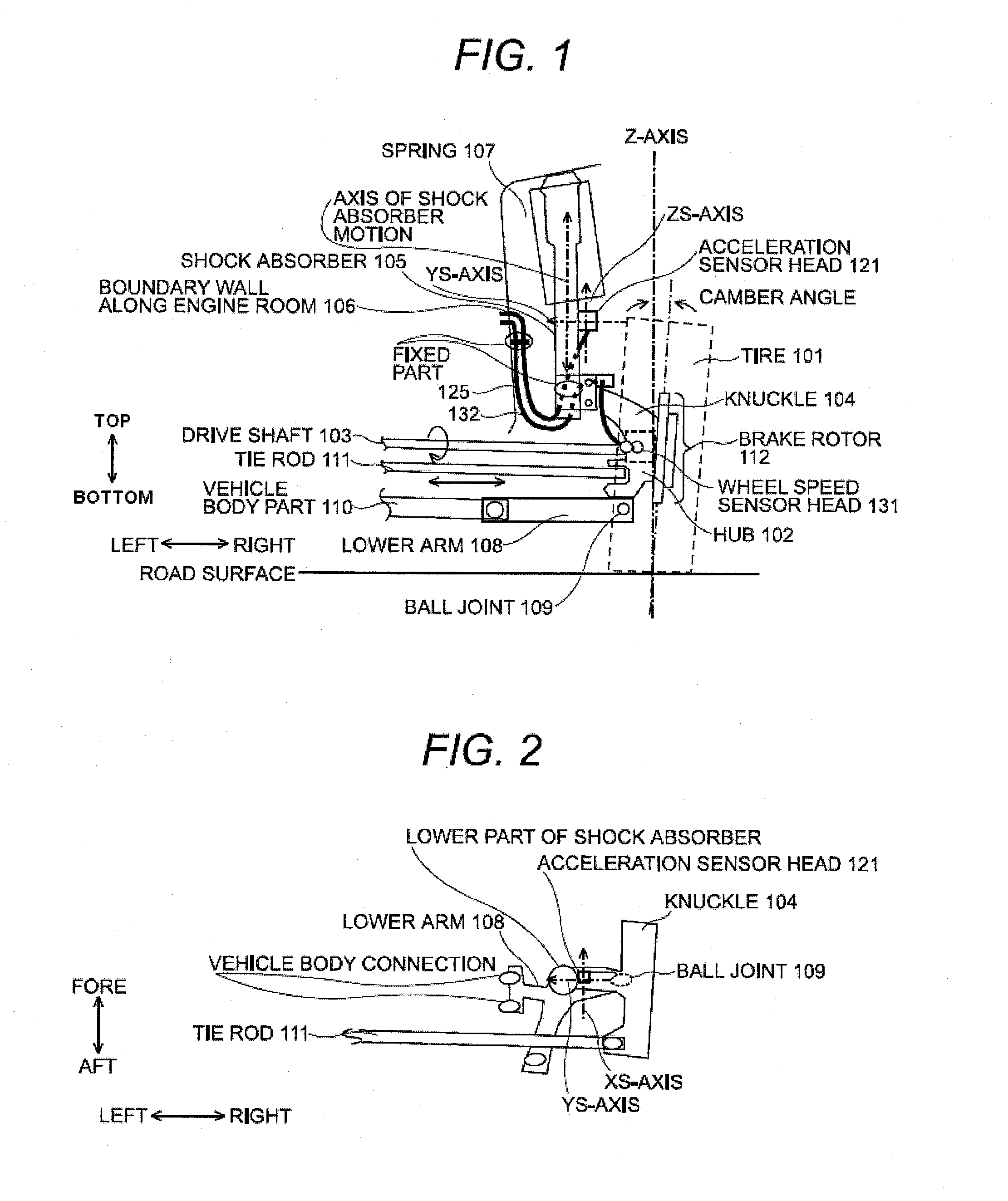

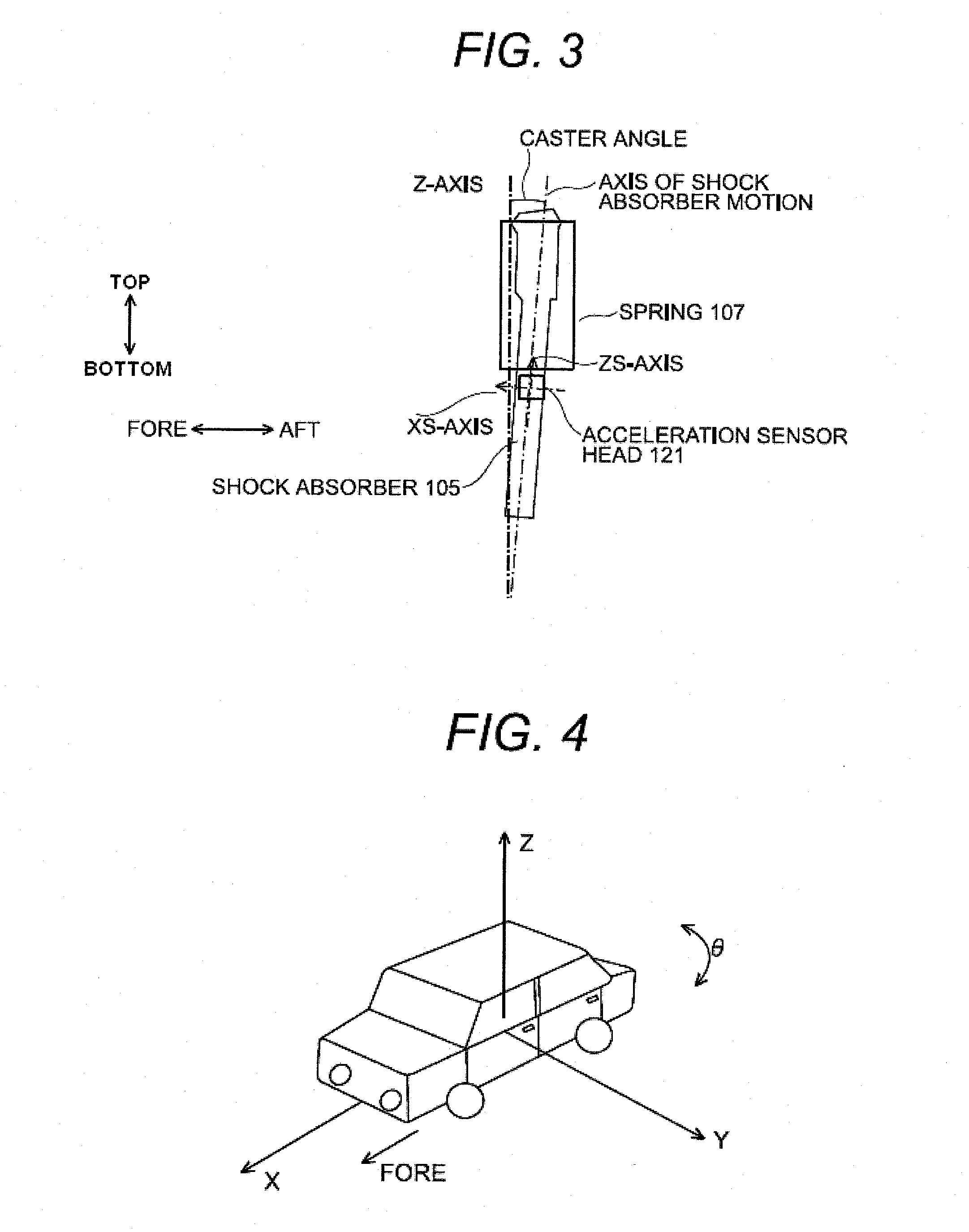

Sensor system for motion control of a moving unit and a method of installing a sensor system for motion control of a moving unit

InactiveUS20110035091A1Avoid delaySuppressing positional fluctuationSuspensionsVehicle testingEngineeringMovement control

A sensor system for motion control of a moving unit such as a vehicle, which is comprised of a uniaxial physical value sensor having a single detection axis and the uniaxial physical value sensor being installed in a unsprung mass of a suspension device provided in the moving unit, wherein the detection axis of the uniaxial physical value sensor and the working axis of a vibration-buffering member provided on the suspension device are approximately parallel.

Owner:HITACHI CABLE

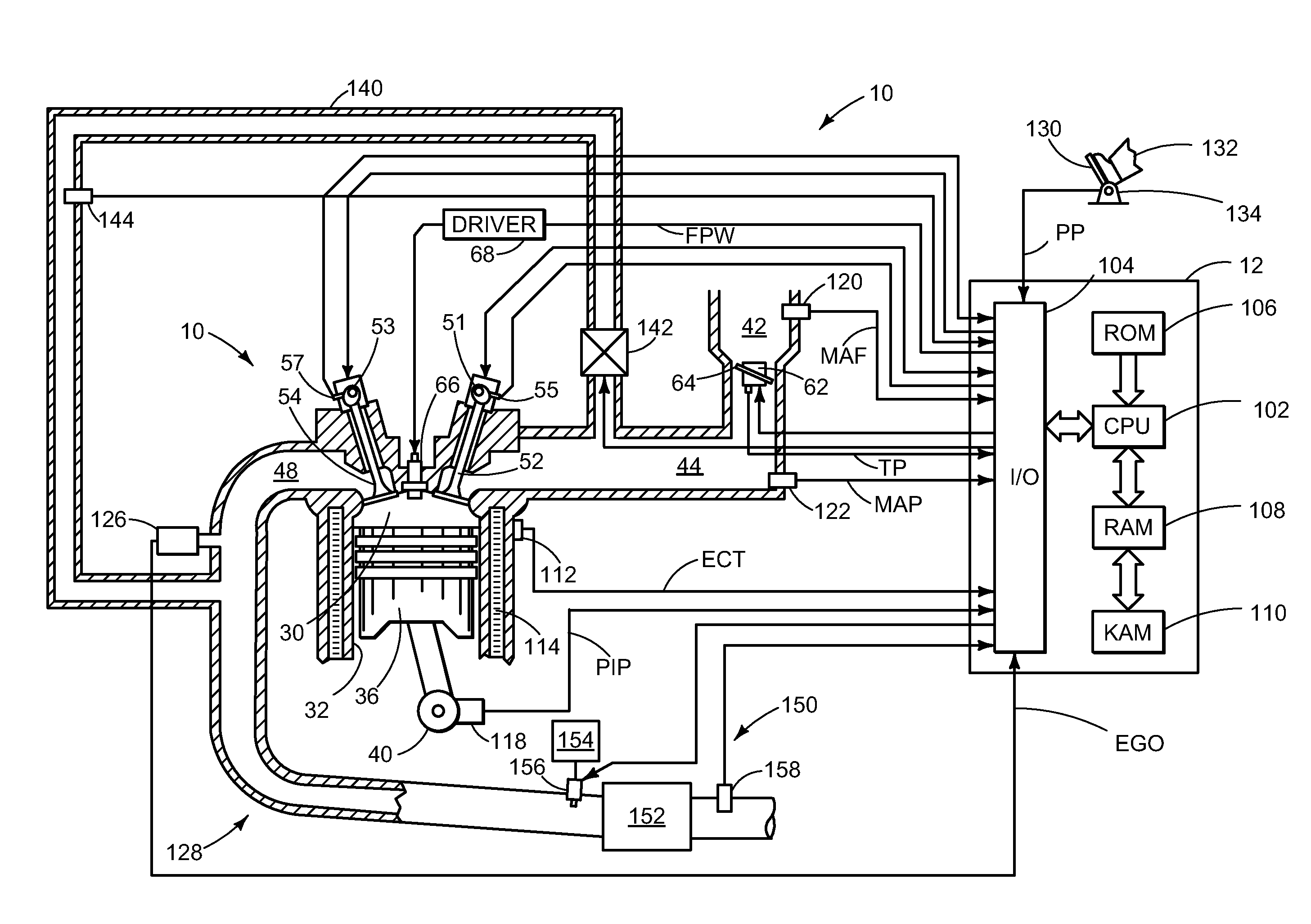

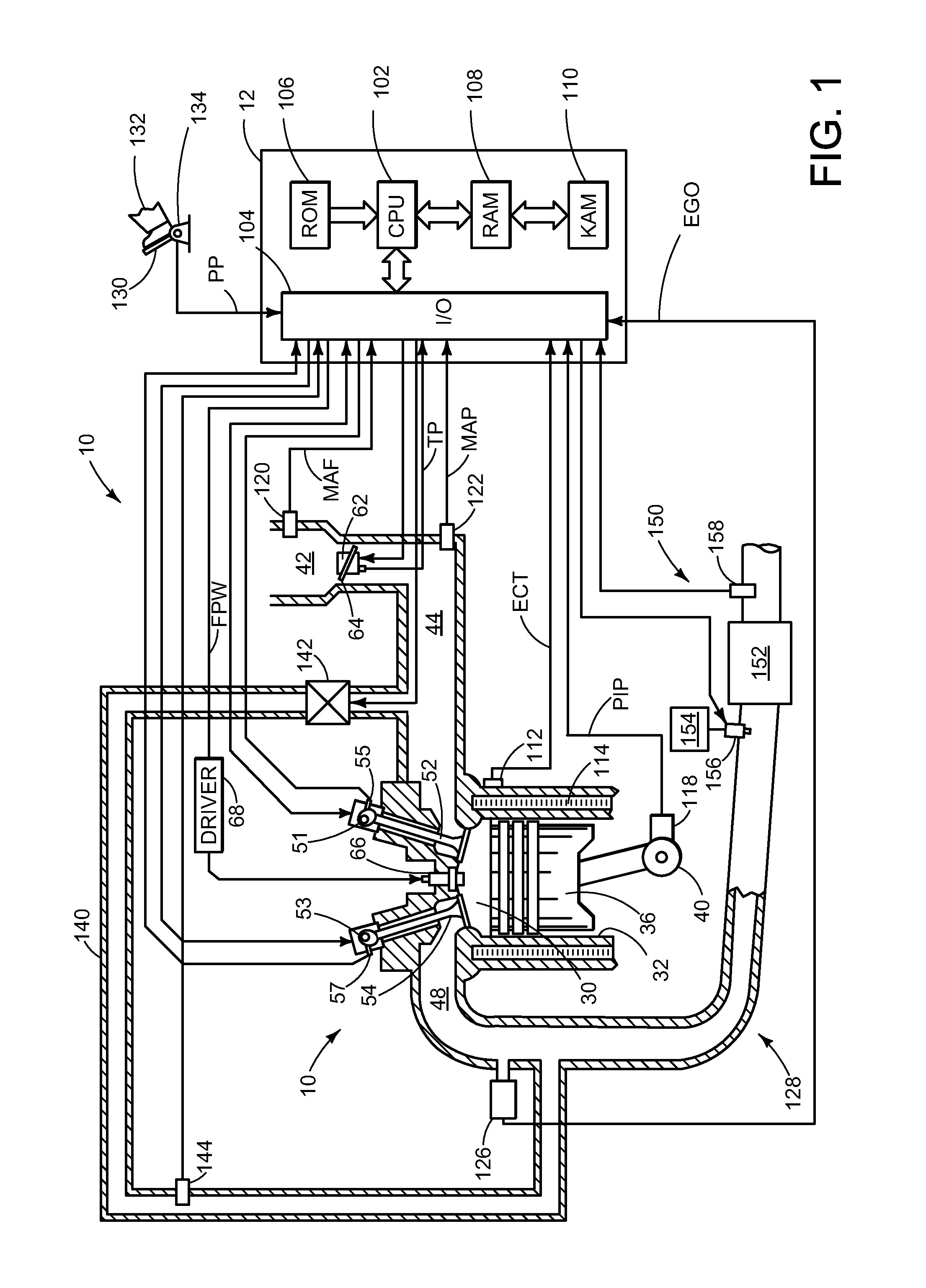

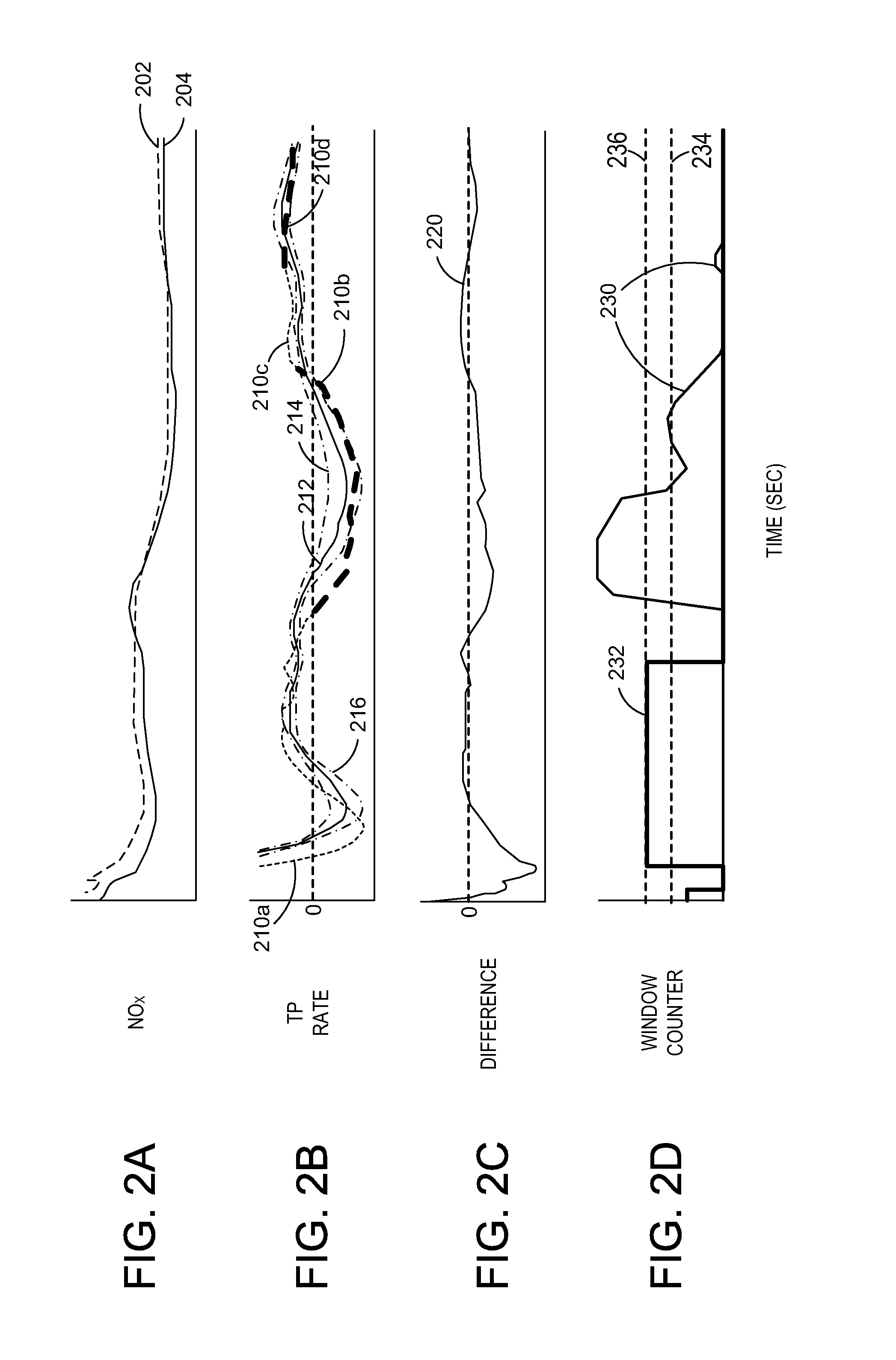

Enhanced real-time ammonia slip detection

ActiveUS20140301925A1Configuration highImprove the level ofInternal combustion piston enginesExhaust apparatusEngineeringAmmonia

Systems and methods for detecting ammonia slip in an exhaust system based upon transient NOx sensor responses are described. In one example method, an exhaust system allocates tailpipe NOx sensor output to NOx and NH3 levels responsive to the transient sensors using a segment length method that processes the transient signals based on the total segment lengths calculated within a window. A ratio of segment lengths relative to a threshold is determined for a measured and expected NOx rate of change downstream of an SCR that is further used to determine a probability of NOx and NH3 based on the measured sensor activities, and a controller is included to adjust one or more parameters based on the allocation and changes of sensor output.

Owner:FORD GLOBAL TECH LLC

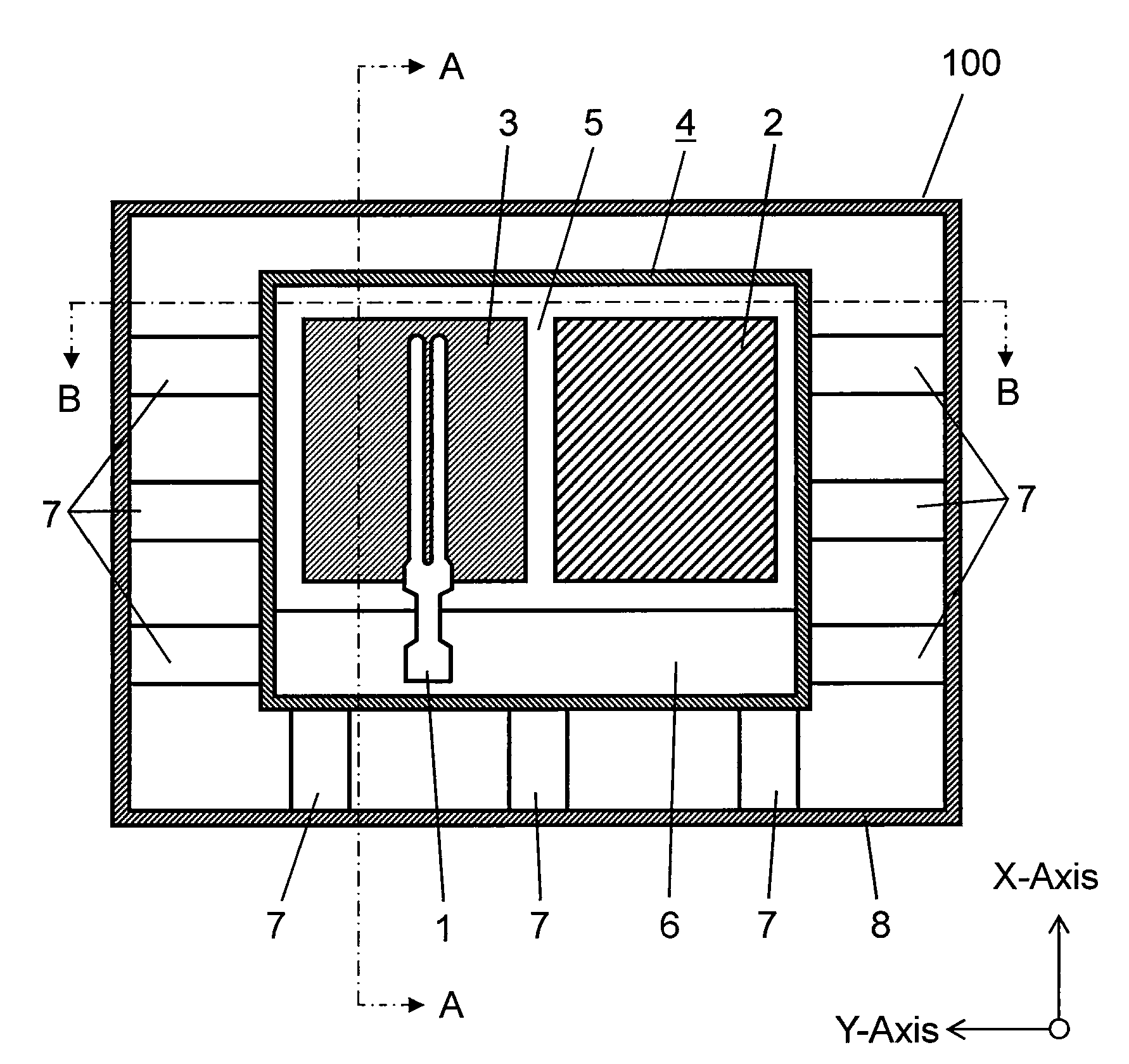

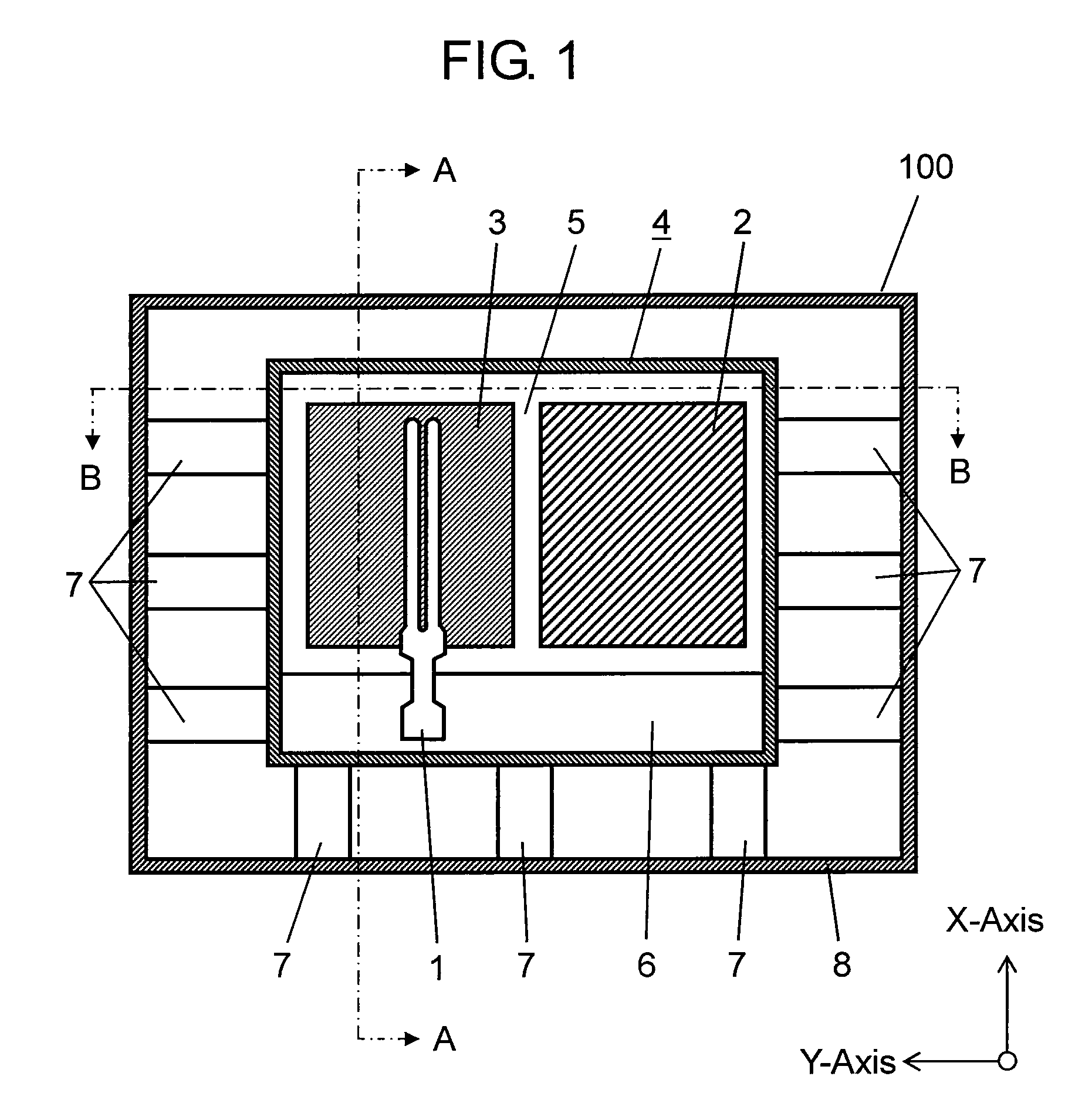

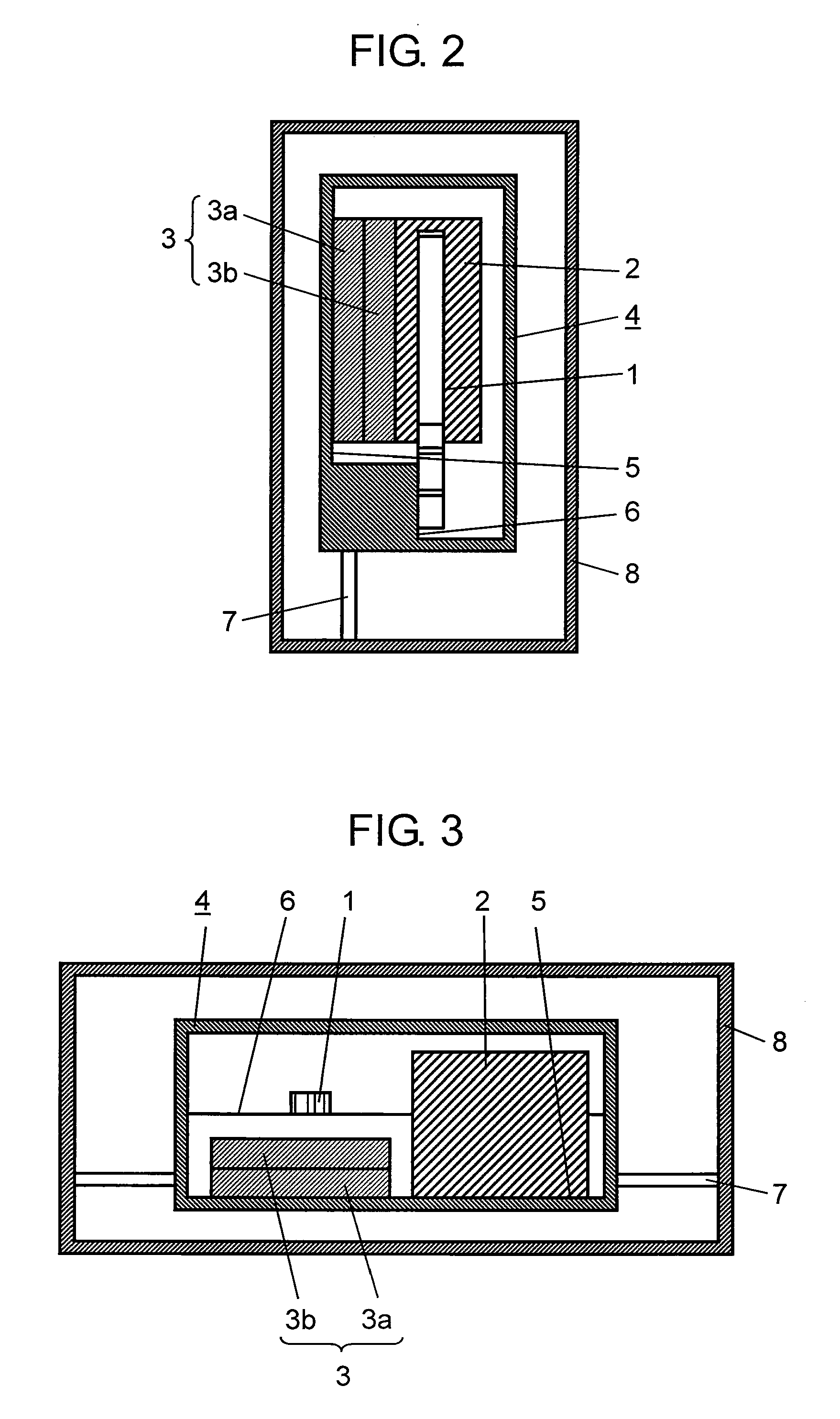

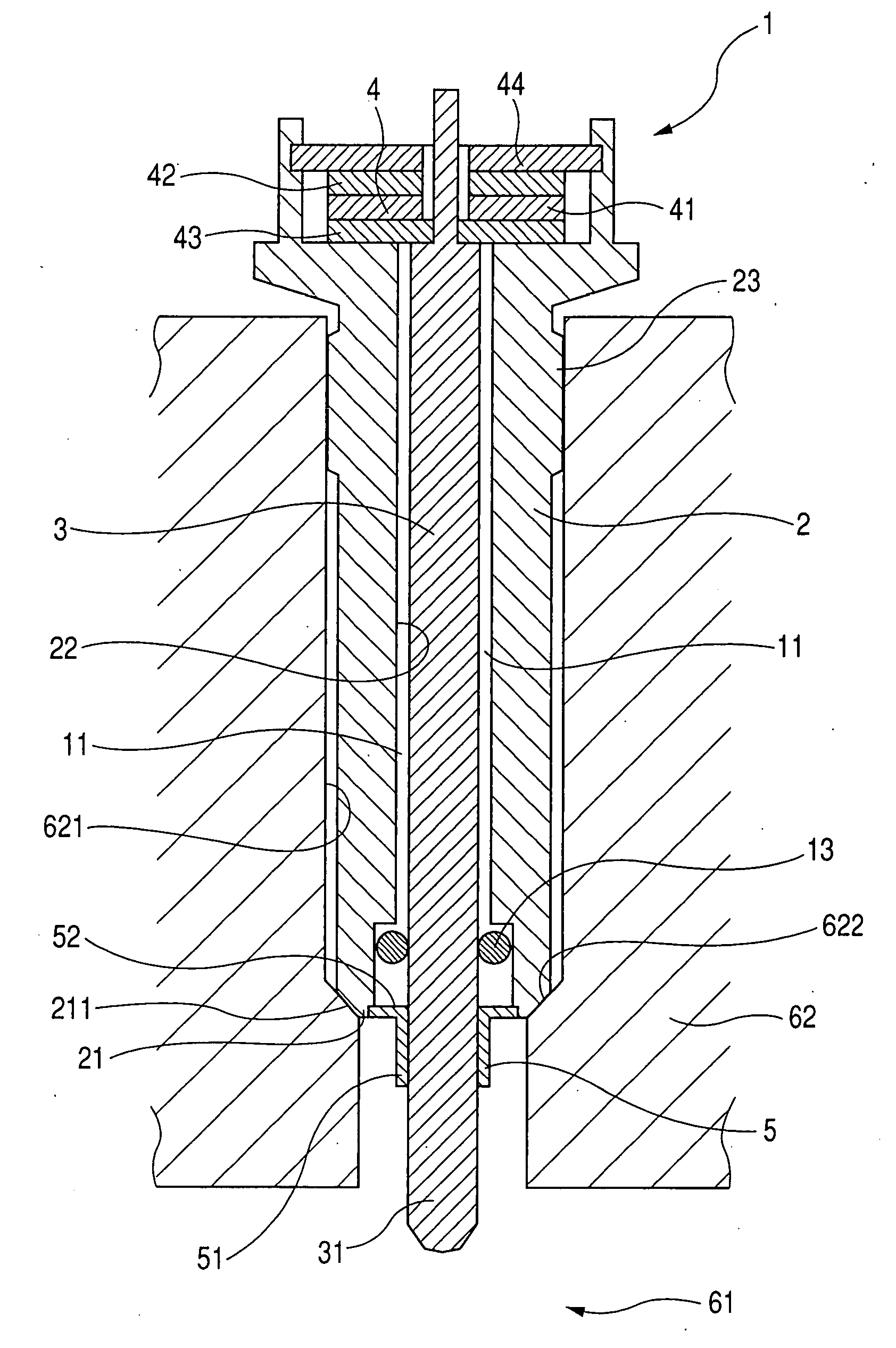

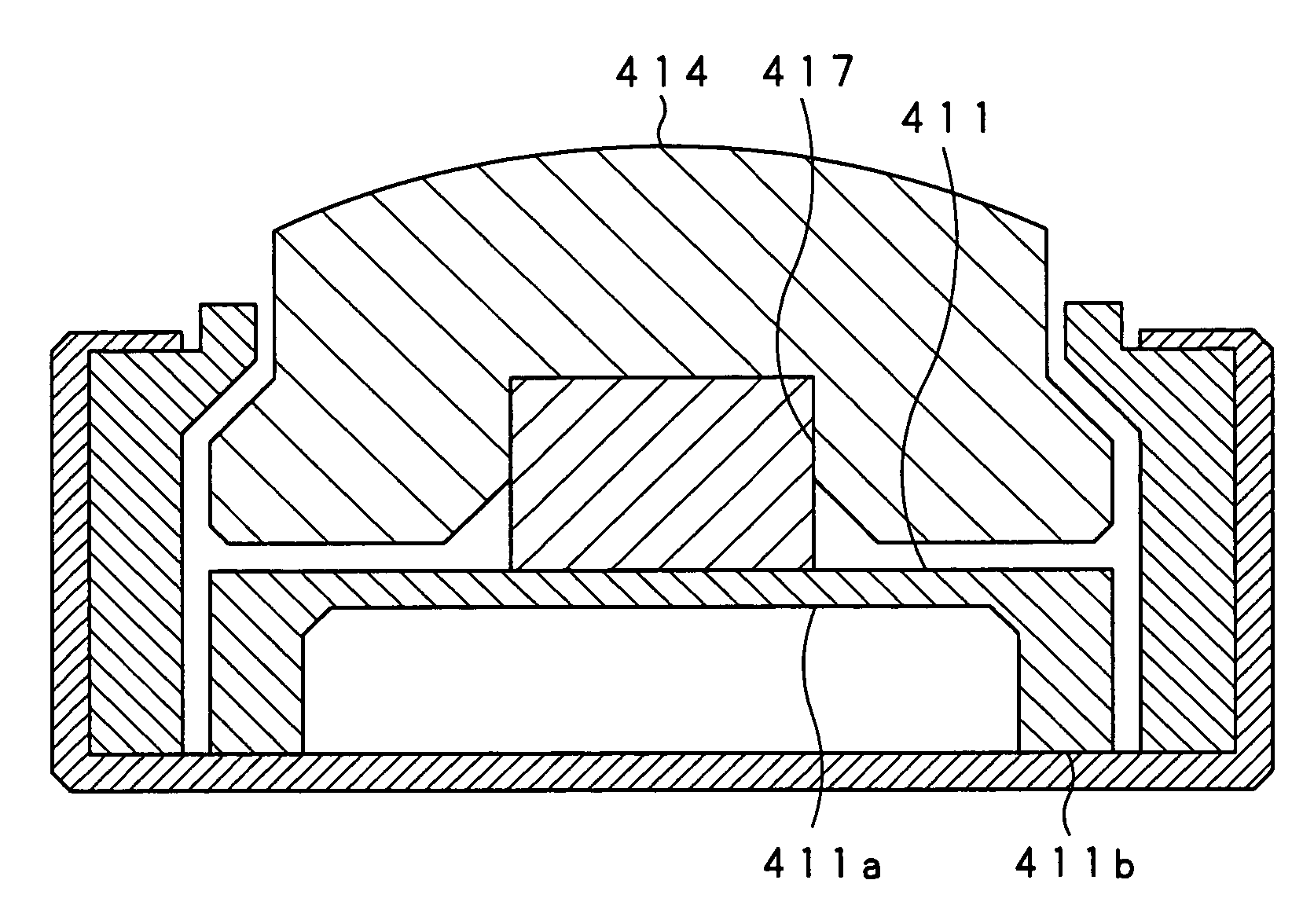

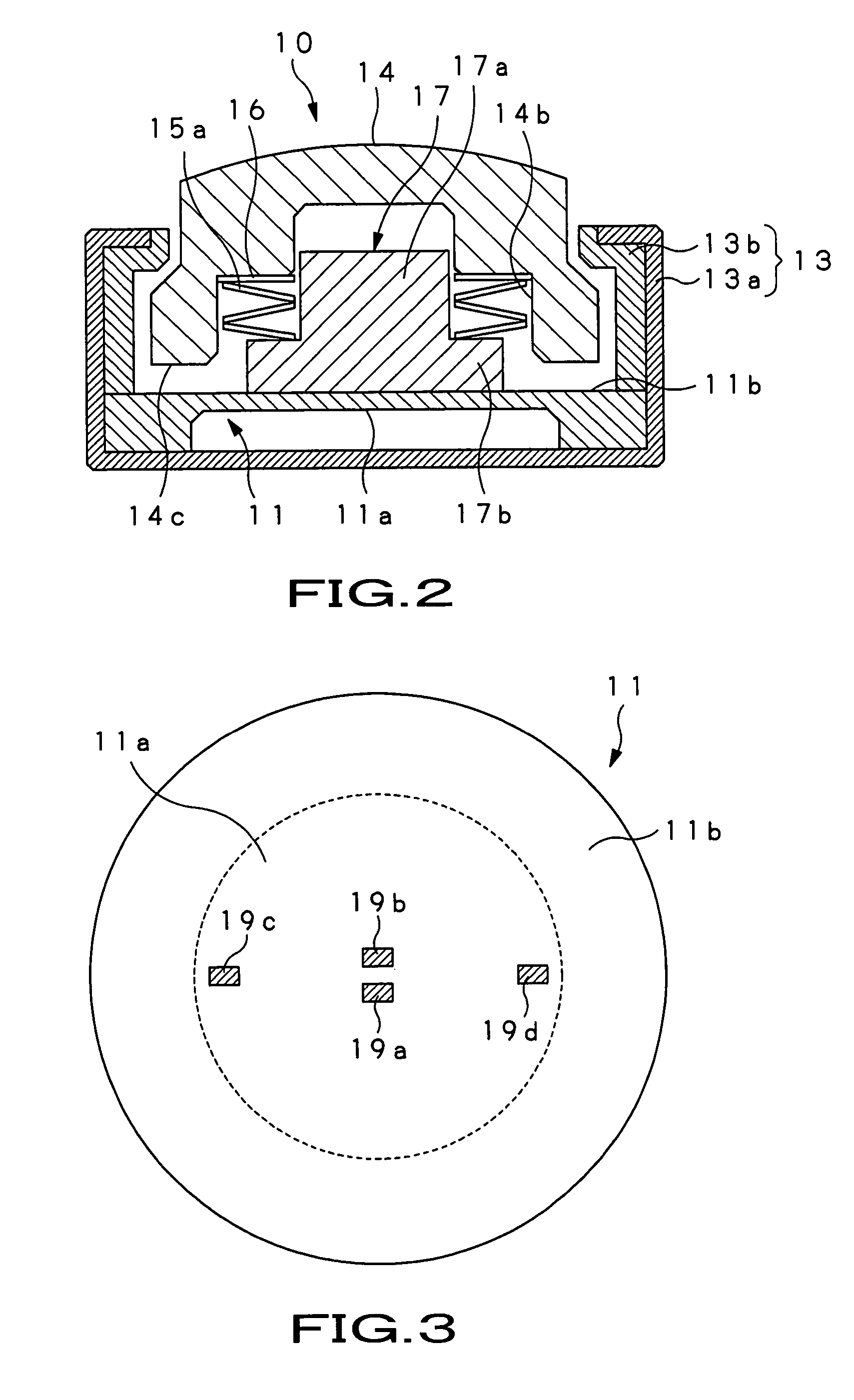

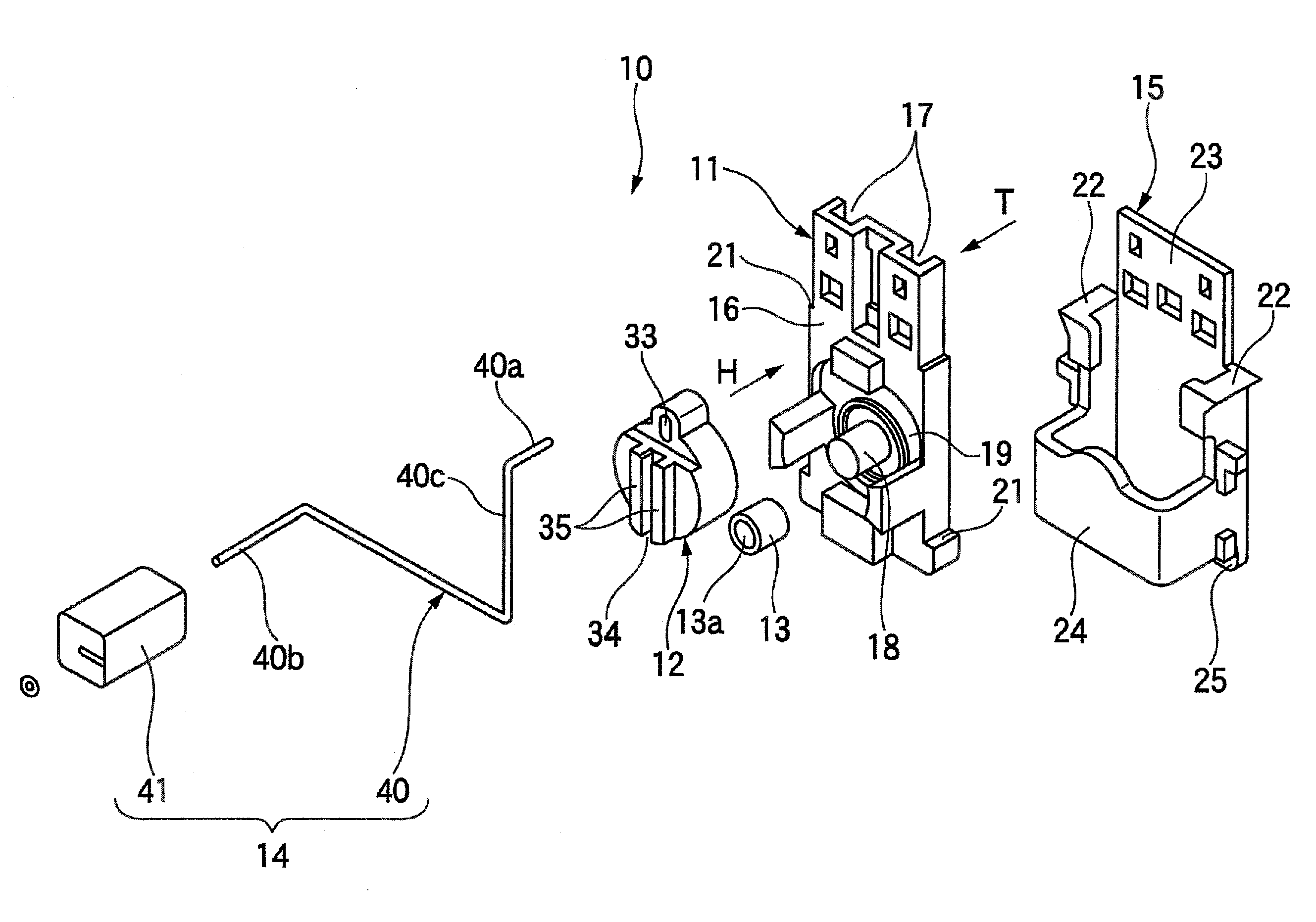

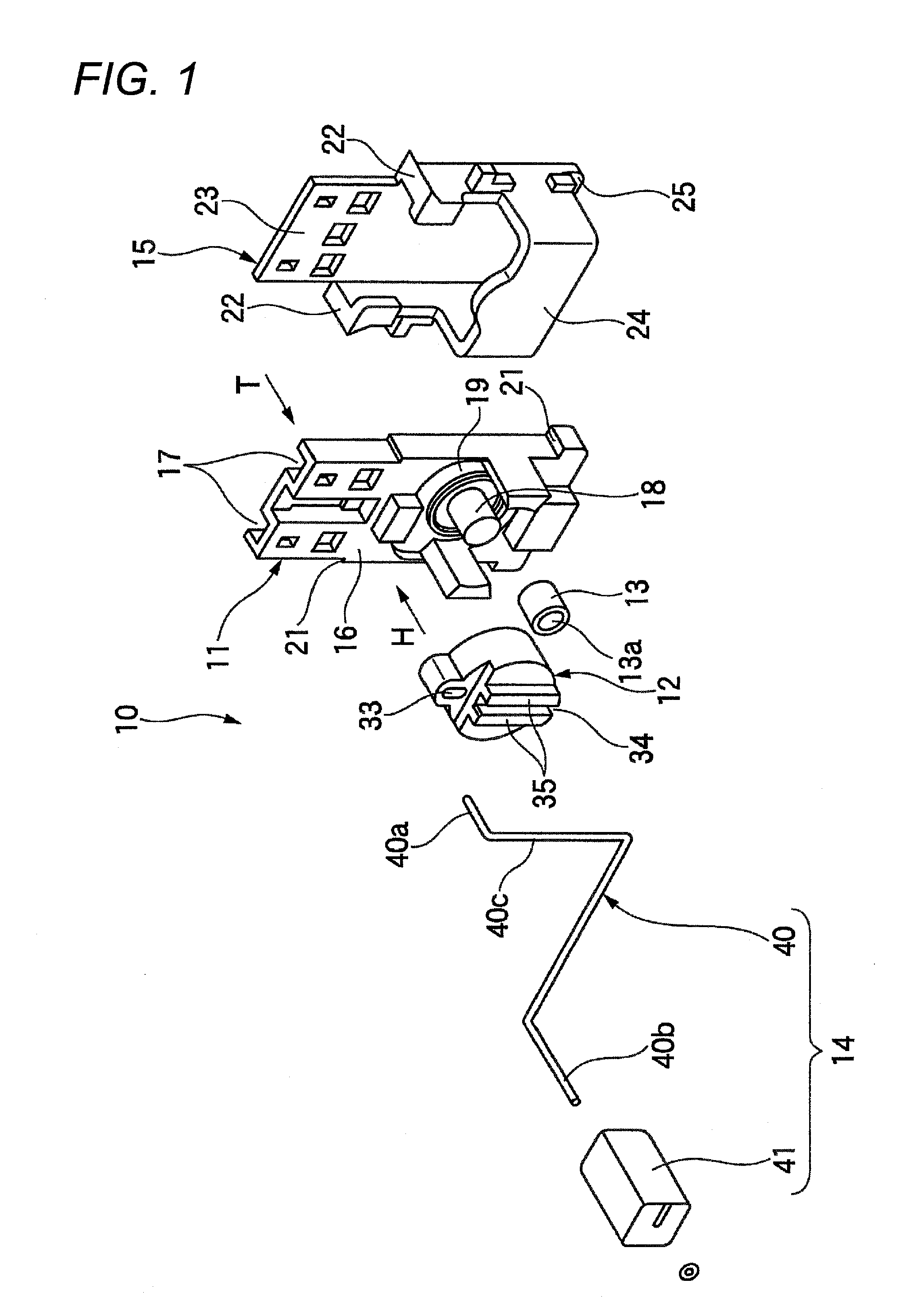

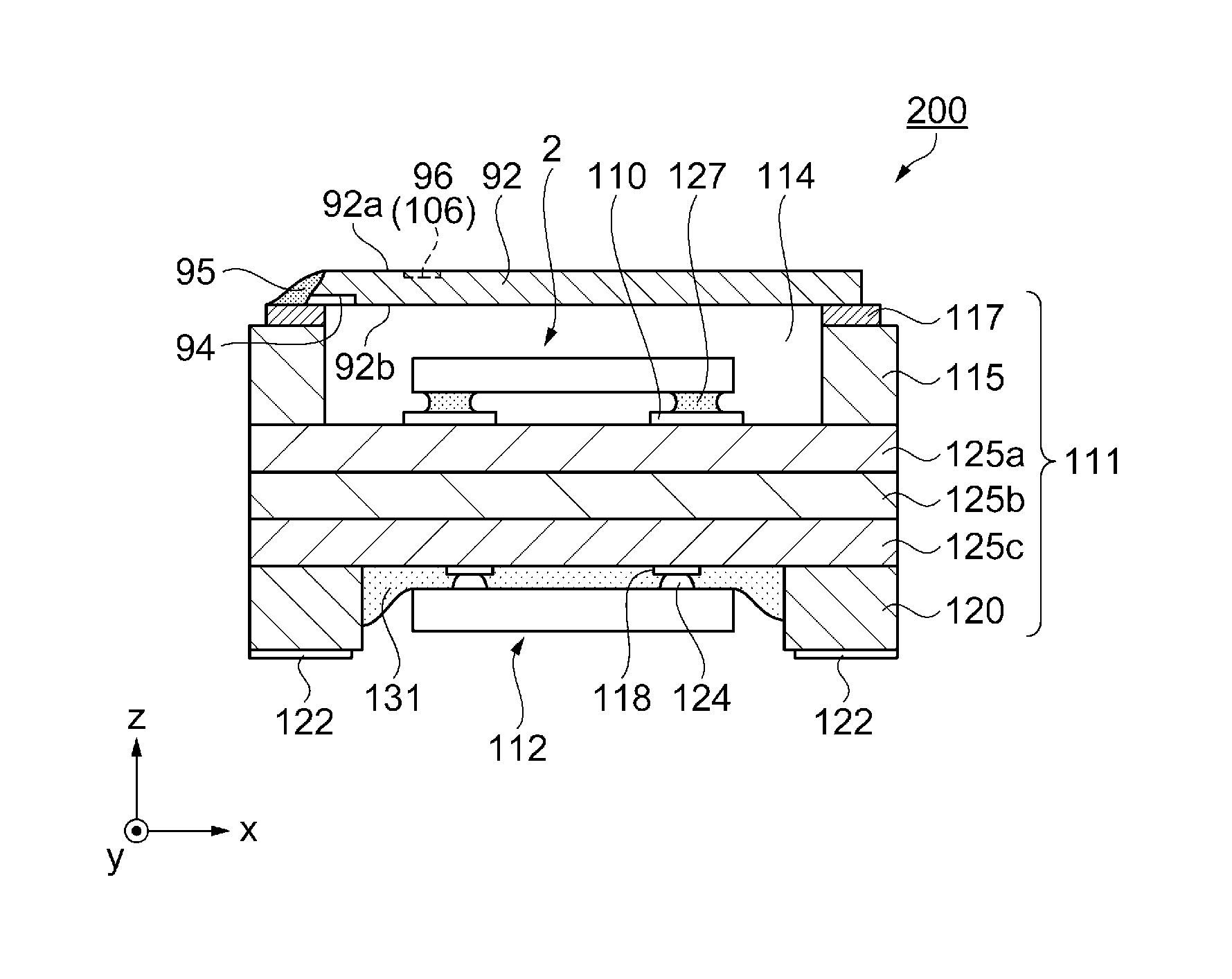

Composite sensor

ActiveUS20090013784A1Increases moment of inertia momentReduce detection accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocitySignal processing

A composite sensor includes an angular velocity sensor element, an acceleration sensor element, a signal processing IC for processing signals from the angular velocity sensor element and the acceleration sensor element, an inner package for accommodating the angular velocity sensor element, the acceleration sensor element, and the signal processing IC; a coupler connected to this inner package, and a fixing member connected to this coupler for holding the inner package via this coupler. The coupler is elastically deformable. One of the acceleration sensor element and the signal processing IC is located at the right with respect to the center of the inner package, and the other of the acceleration sensor element and the signal processing IC is located at the left with respect to the center of the inner package. The composite sensor angular maintains its characteristics of the angular velocity sensor element while the angular velocity sensor element and the acceleration sensor element are accommodated in one package.

Owner:PANASONIC CORP

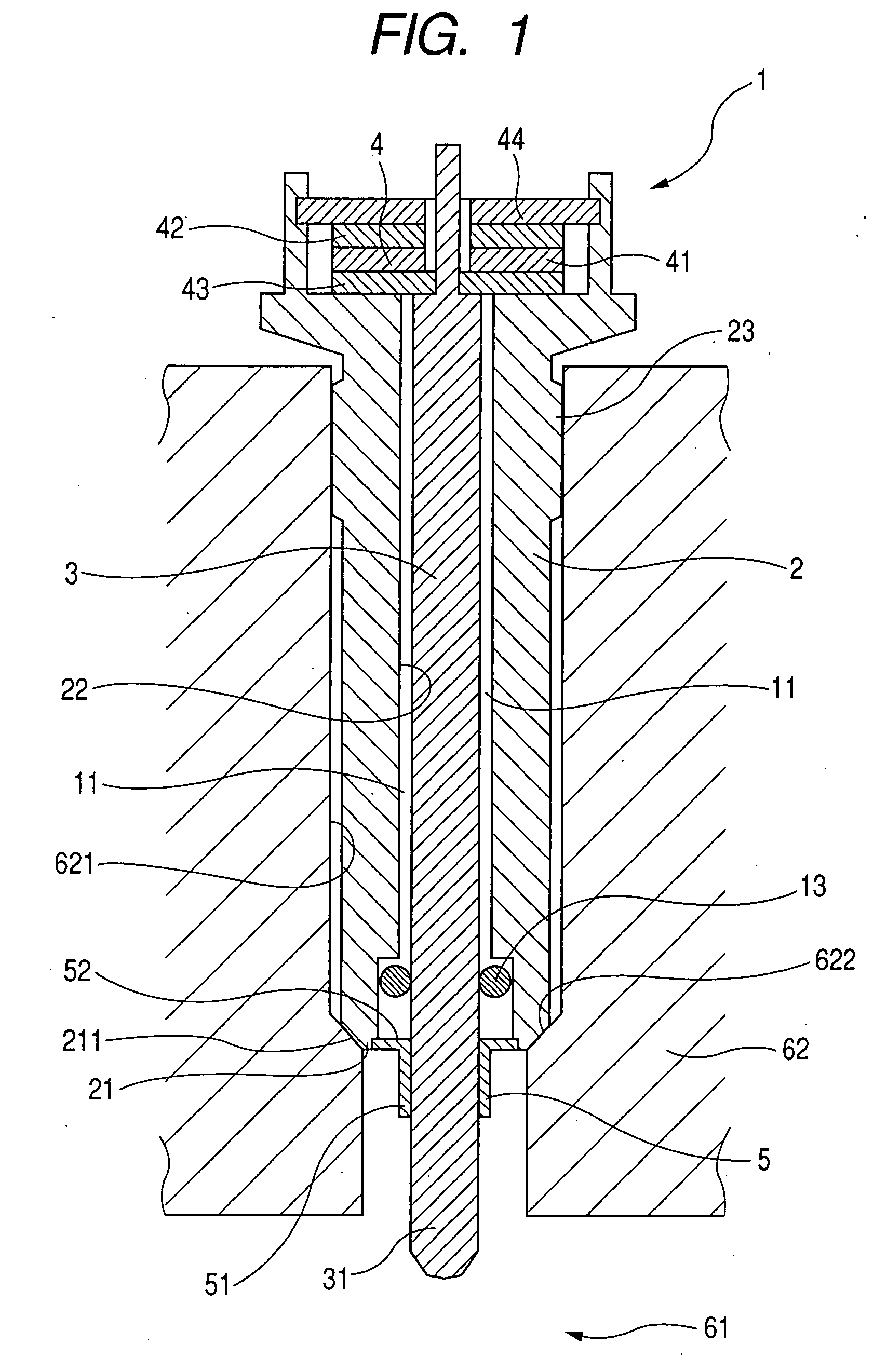

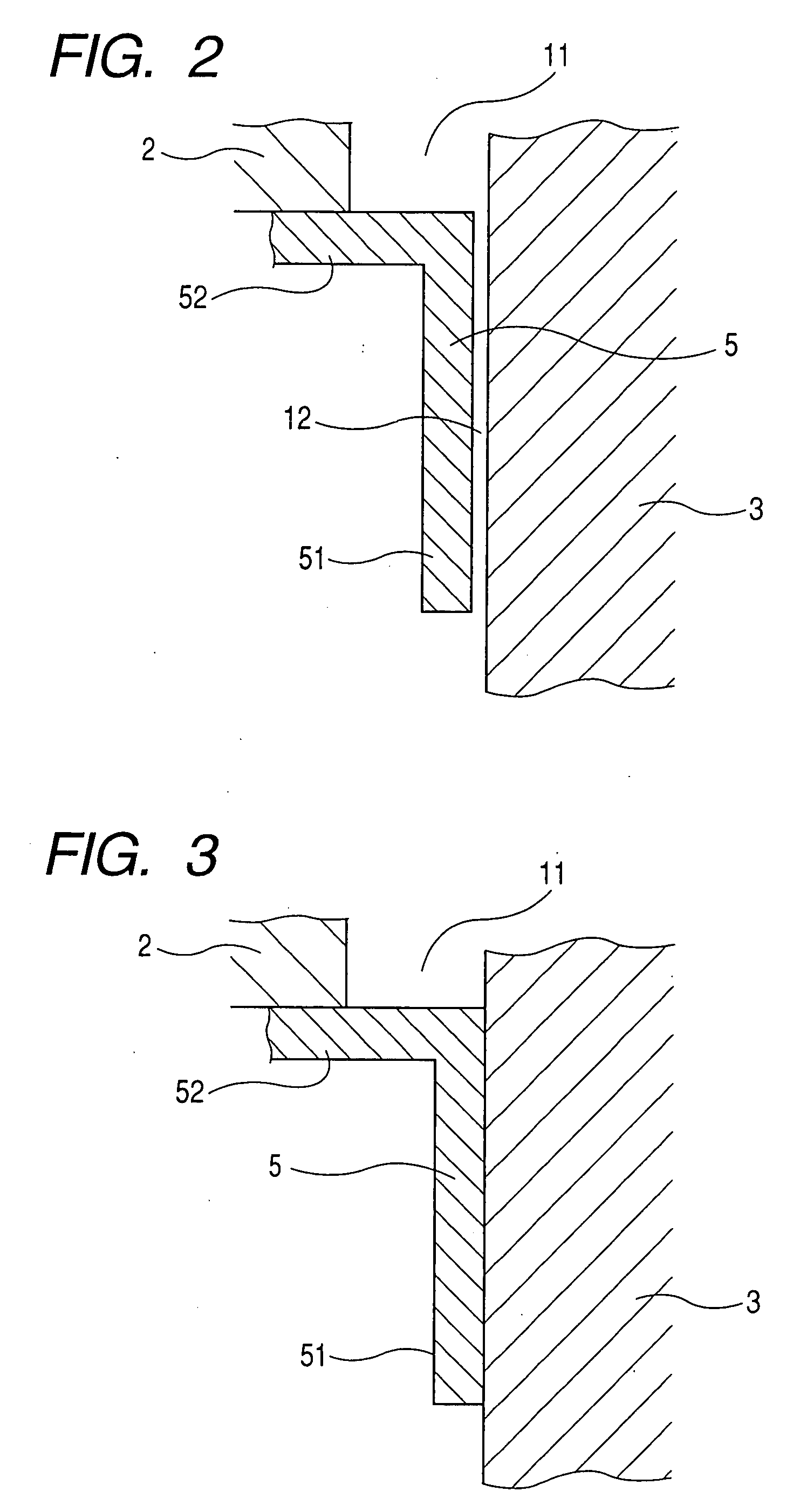

Combustion pressure sensor

InactiveUS20080223139A1Improve sealingEasy to adjustIncandescent ignitionFluid pressure measurement using elastically-deformable gaugesPressure transmissionCombustion chamber

A combustion pressure sensor for detecting a pressure in the combustion chamber of an internal combustion engine includes a seal member sealing a clearance between a housing and a pressure transmitting member slidably inserted through an axial hole of the housing. The seal member is fixed to the housing at a position forward of a load detecting section disposed between the housing and the pressure transmitting member. The seal member is not fixed to the pressure transmitting member.

Owner:DENSO CORP

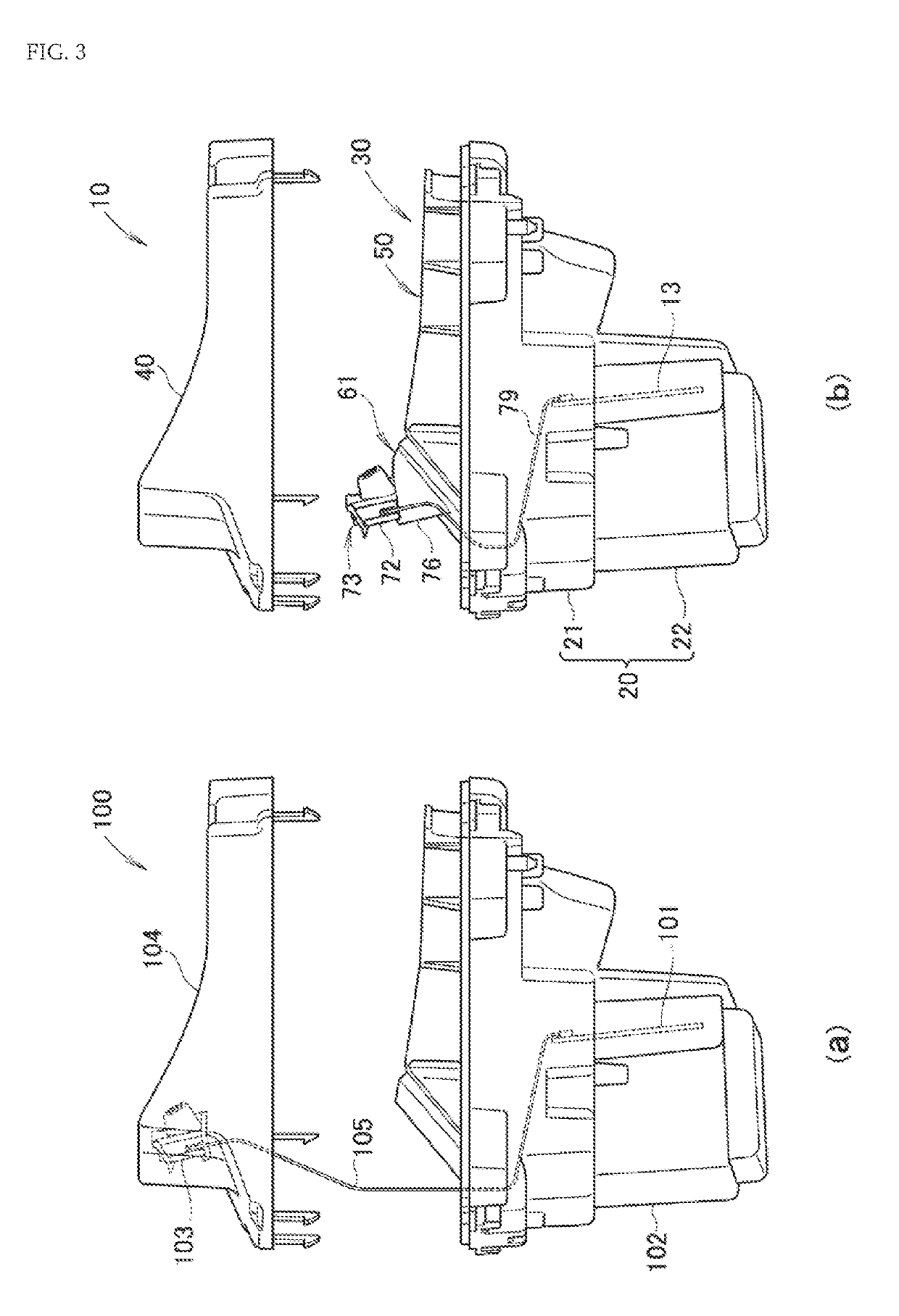

Range detection device

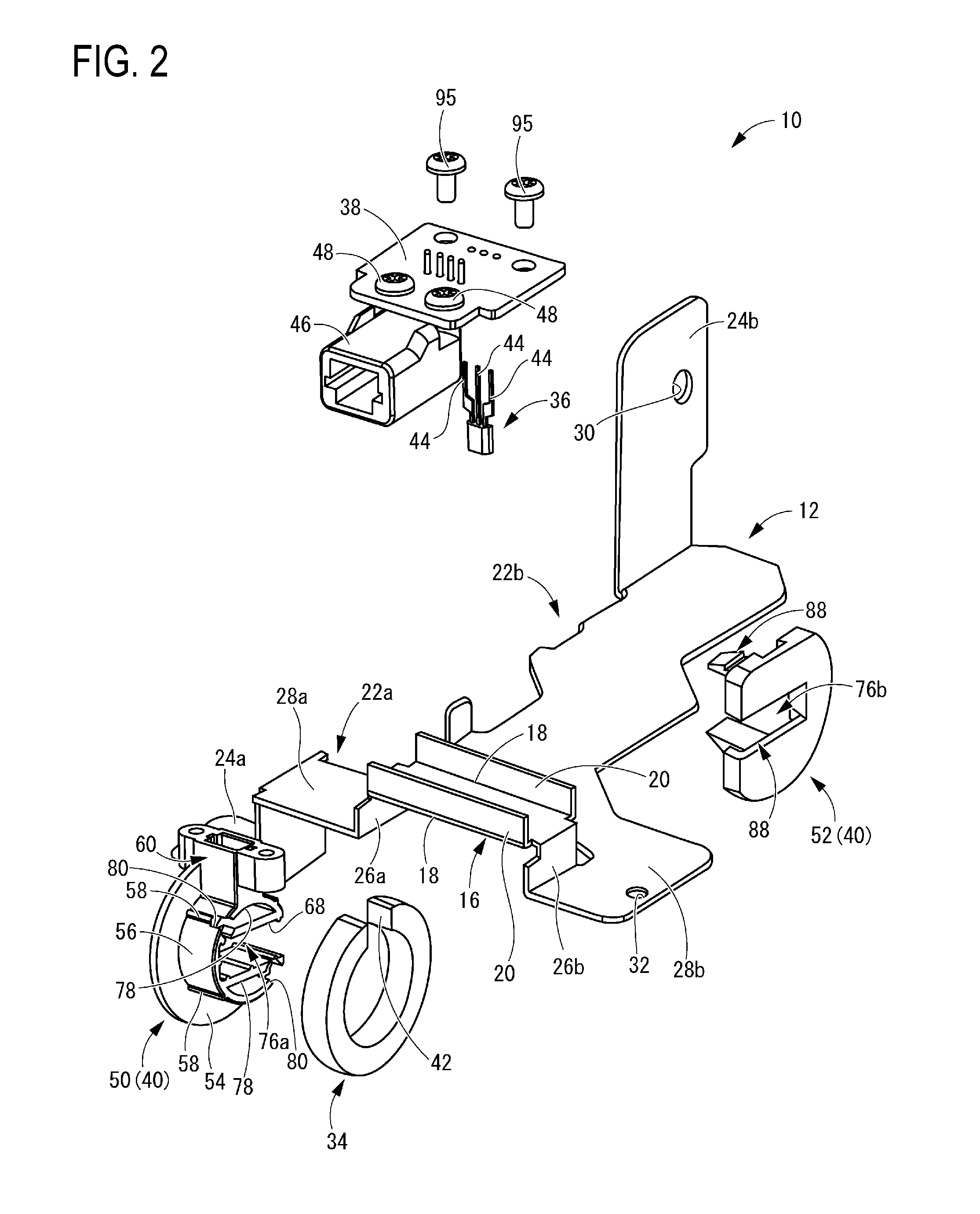

ActiveUS20110025308A1Easy to manufactureMaintain detection accuracyMagnetic measurementsGearing controlMechanical engineeringMagnetism

In a range detection device, a movable member has a magnetized portion and can move with a manual valve of a control device. A supporting member includes a plate portion having a surface opposed to the magnetized portion and a recess formed in an opposite surface of the plate portion, and supports the movable member such that the movable member is capable of moving parallel with the plate portion. A substrate is placed in the recess and has a first hole that penetrates the substrate. A magnetic detection element is installed to a surface of the substrate at a side of the plate portion to correspond to a position of the first hole, and detects magnetism of the magnetized portion. A sealing member is filled in the recess and covers the substrate and the magnetic detection element.

Owner:DENSO CORP

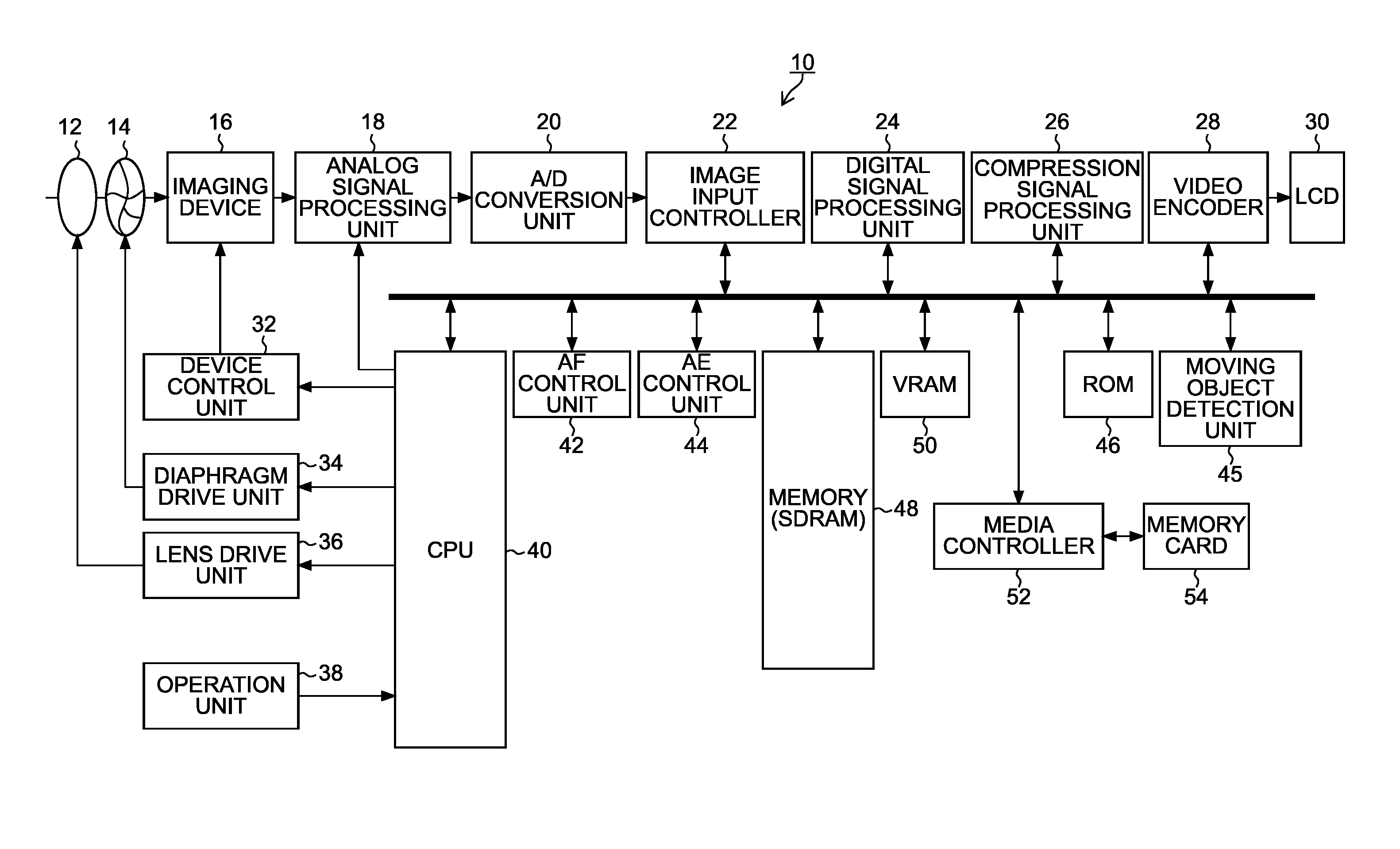

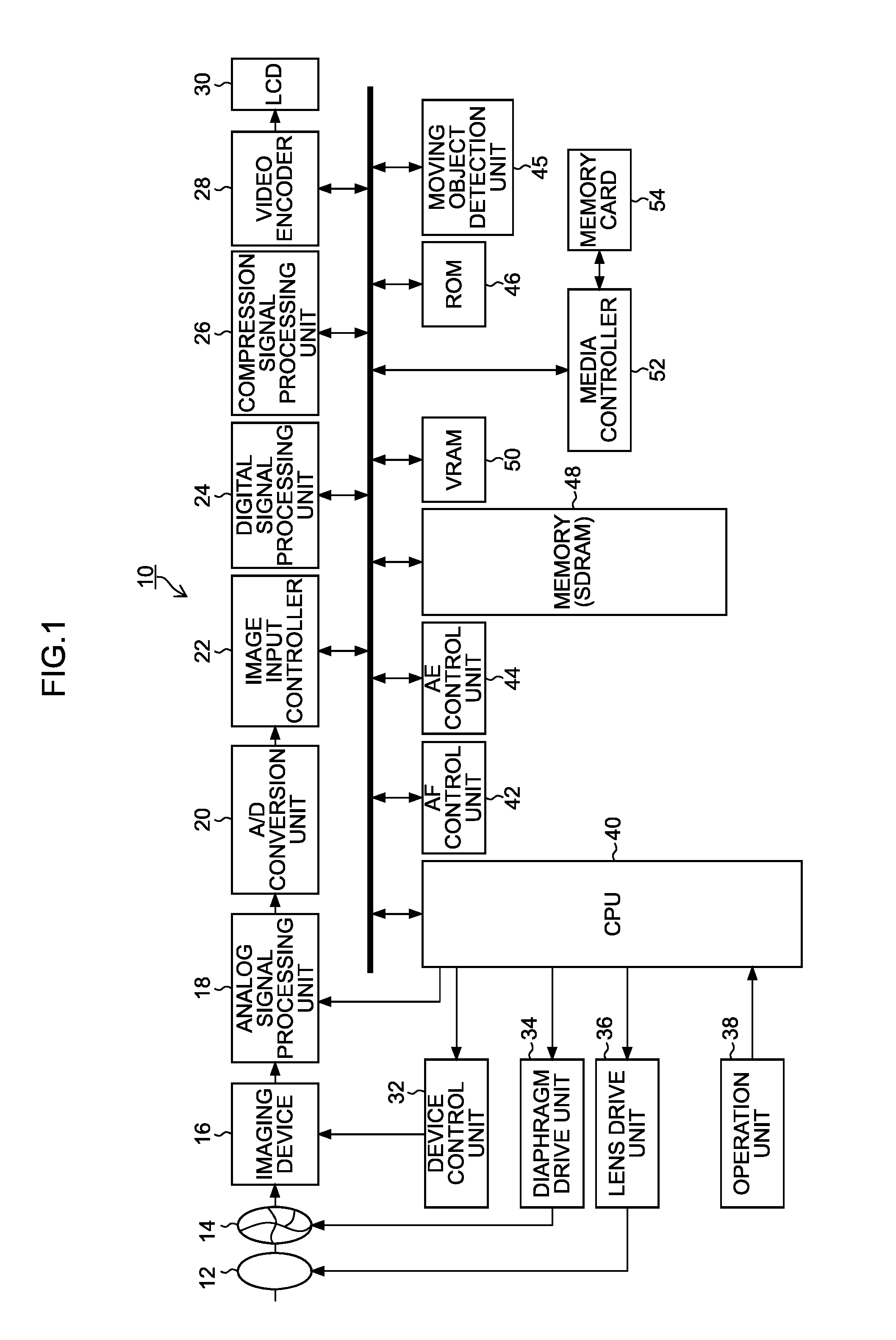

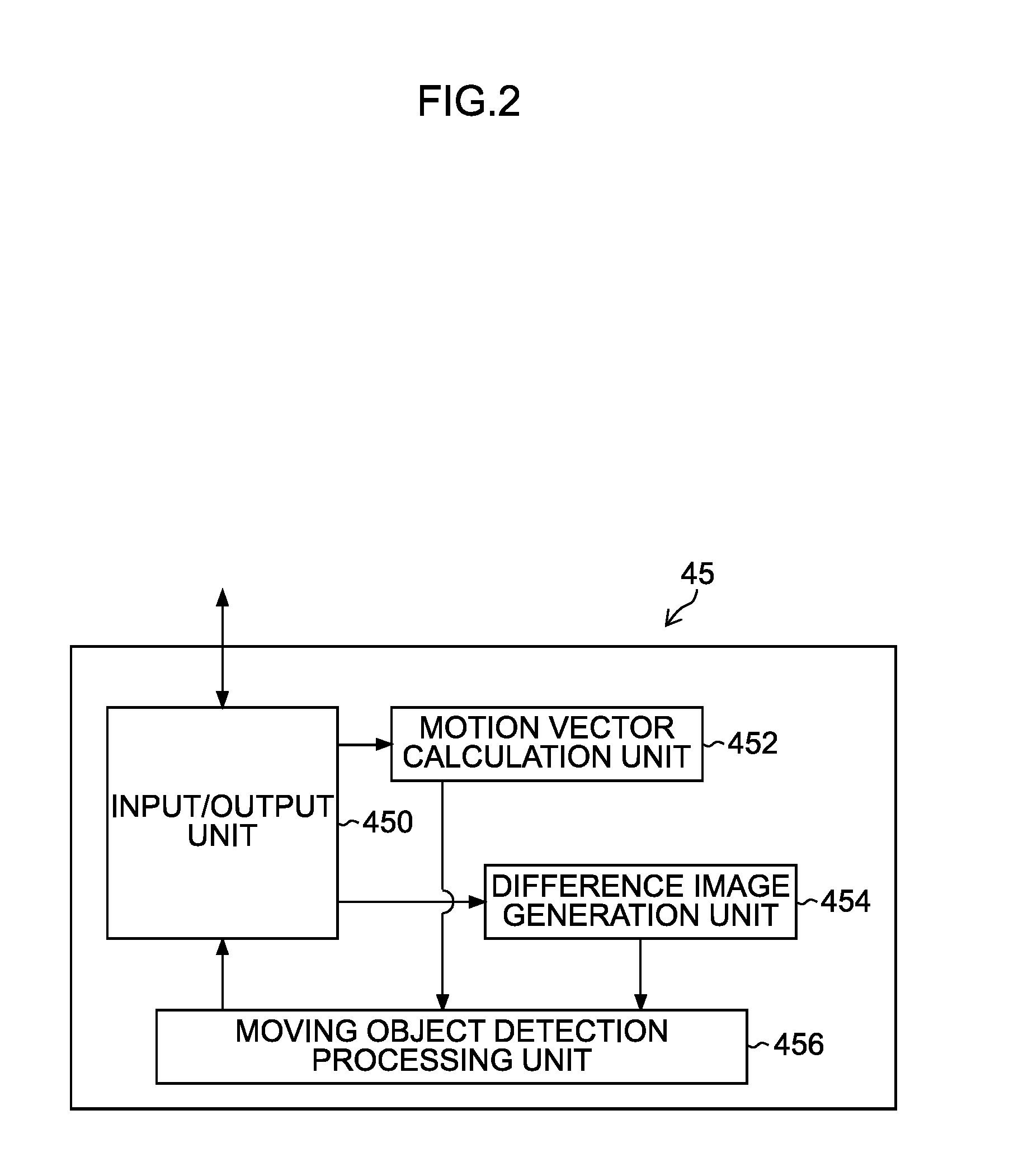

Device and method for detecting moving objects

ActiveUS20140146182A1Maintain detection accuracyImprove responsivenessTelevision system detailsImage enhancementObject basedObject detection

A moving object detection apparatus comprising: an image acquisition device; a first moving object detection device; a difference image generation device; a second moving object detection device for detecting existence / nonexistence of the moving object based on the difference image generated by the difference image generation device; and an integration device for integrating a detection result by the first moving object detection device and a detection result by the second moving object detection device and determining that the moving object is detected in a case where the moving object is not detected by at least the first moving object detection device and the moving object is detected by the second moving object detection device.

Owner:FUJIFILM CORP

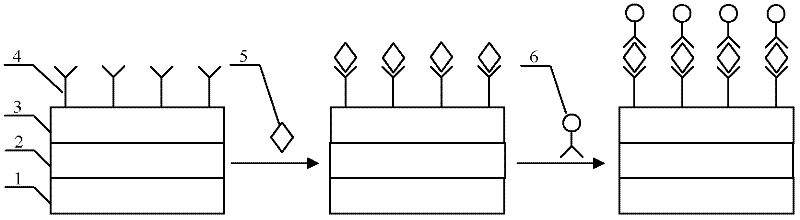

Magnetically-labeled biological sensor as well as production method and detection method thereof

ActiveCN102393453AMaintain detection accuracySimple structureMaterial analysisElectricityChemical coupling

The invention discloses a magnetically-labeled biological sensor. A bioprobe fixing layer of the magnetically-labeled biological sensor comprises a conducting layer, an insulating layer and a power supply device, wherein a plurality of conducting units are embedded into the surface of the insulating layer; each conducting unit is electrically connected with the conducting layer; the conducting units form a conducting unit array; when the power supply device is used for supplying power, the magnetically-labeled bioprobe is fixedly adsorbed on the surface of the conducting unit array; after detection, the magnetically-labeled bioprobe is immediately separated from the conducting unit array by stopping power supply; and the magnetically-labeled bioprobe can be thoroughly removed by cleaning.Therefore, the phenomenon that the recycle of a chip is influenced because of the magnetically-labeled bioprobe which cannot be effectively removed after detection caused by fixation of the bioprobe by adopting a chemical coupling method in the prior art is avoided; meanwhile, traditional detection precision can be maintained; and the magnetically-labeled biological sensor is a novel magnetically-labeled biological sensor which has the advantages of simple structure, convenience in use, capability of being repeatedly used and potential application value.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

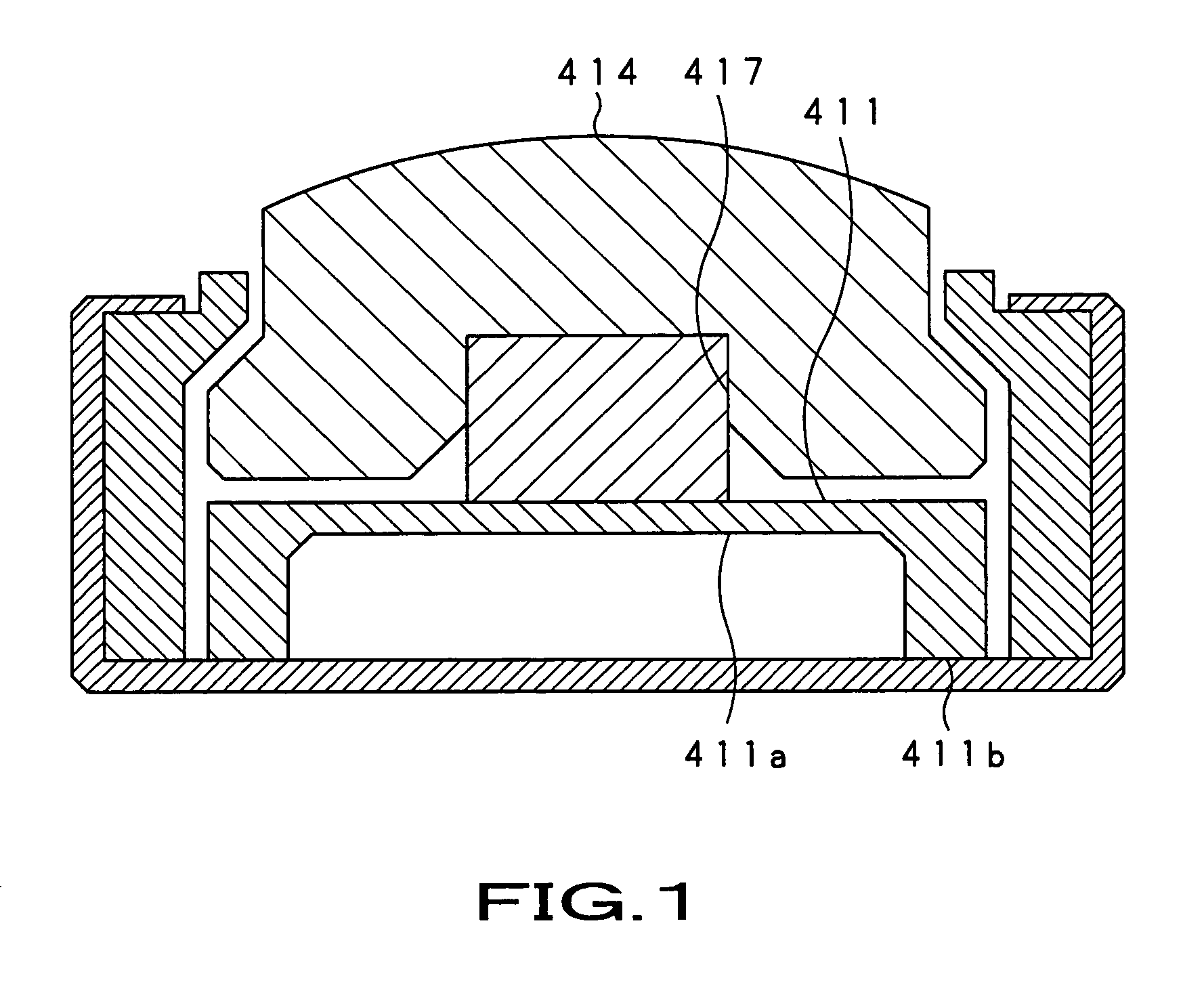

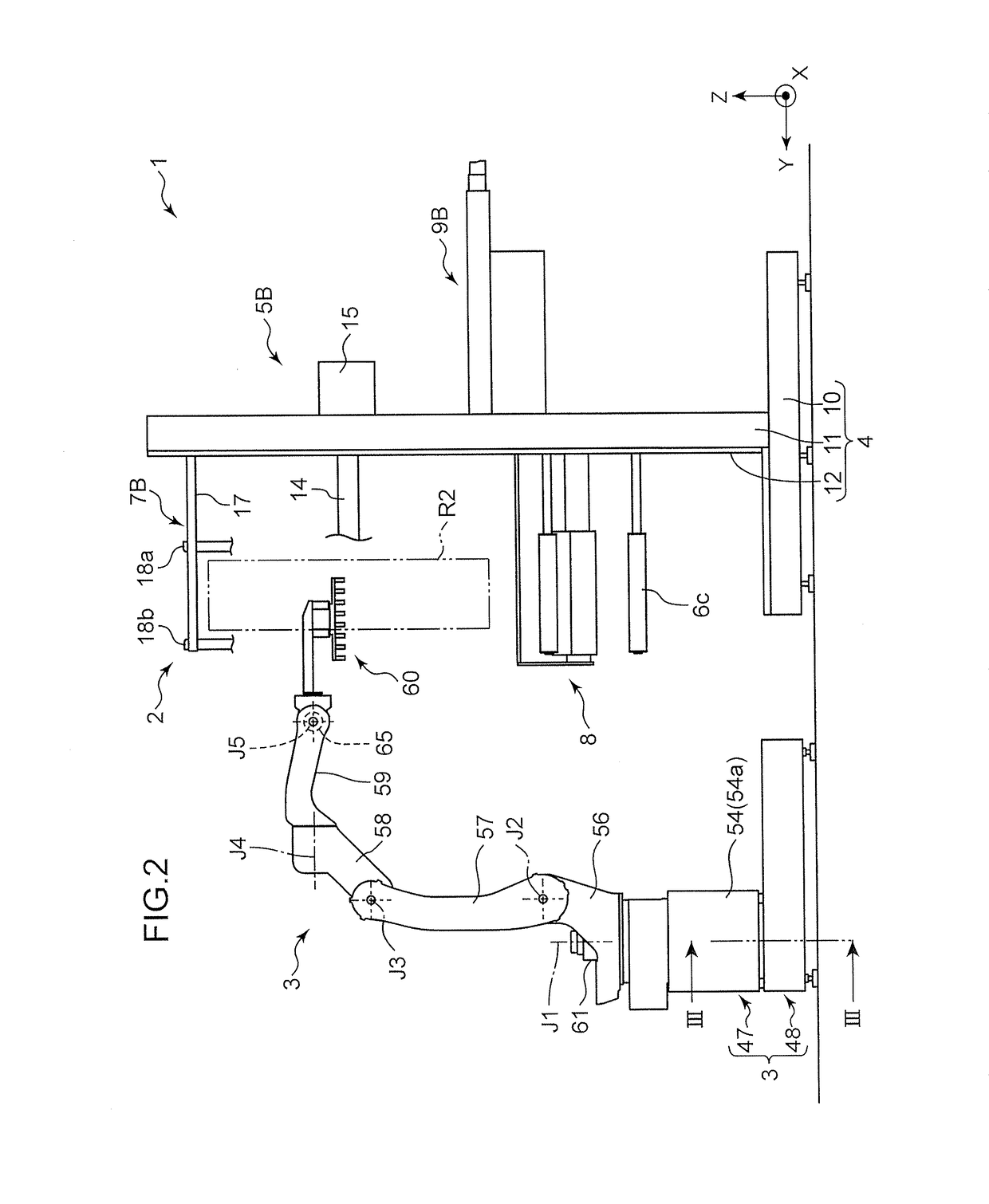

Robot apparatus and load sensor

ActiveUS7343223B2Simple structureSimple designProgramme controlComputer controlLegged robotEngineering

A load sensor that is inoperable even when applied with a large load, has a simple structure easily designed to be lightweight and compact and can detect a load with a high accuracy, and a legged robot apparatus including the load sensor in each of legs thereof. The robot apparatus includes the load sensors counting more than one and each of which detects, as an external force, a reaction applied when the leg abuts a ground surface. The load sensor includes a diaphragm, an activating member that is applied with an external force, a driving member forming along with the activating member a double structure and which presses the pressure-sensitive portion, and an elastic member.

Owner:SONY CORP +1

Contactless liquid level sensor

ActiveUS20110036165A1Prevent rotationInhibit wearMachines/enginesLubrication indication devicesEngineeringMagnetic flux

The present invention is to prevent a drop in the detection accuracy caused by wear of the central shaft of a frame where a magnet holder and the magnet are fitted to each other in the course of prolonged use. A contactless liquid level sensor includes: a magnet holder which includes a resin holder body having an inner circumferential surface for defining a fitting hole and a magnet accommodated inside the holder body along the inner circumferential surface; a resin frame including a frame body, a central shaft protruding from the frame body, and a magnetic-electric converter accommodated inside the central shaft; a float arm including one end fixed to the magnet holder and the other end attached to a float vertically moving in accordance with a liquid level; and a metallic rotary support including a hollow cylindrical part arranged between the inner circumferential surface of the holder body and an outer circumferential surface of the central shaft. When the magnet holder rotates about the central shaft in accordance with the liquid level, a magnetic flux density passing through the magnetic-electric converter is varied thereby detecting a variation in the liquid level.

Owner:YAZAKI CORP

Contactless liquid level sensor

ActiveUS8671750B2Avoid detectionInhibit wearMachines/enginesLubrication indication devicesEngineeringMagnetic flux

Owner:YAZAKI CORP

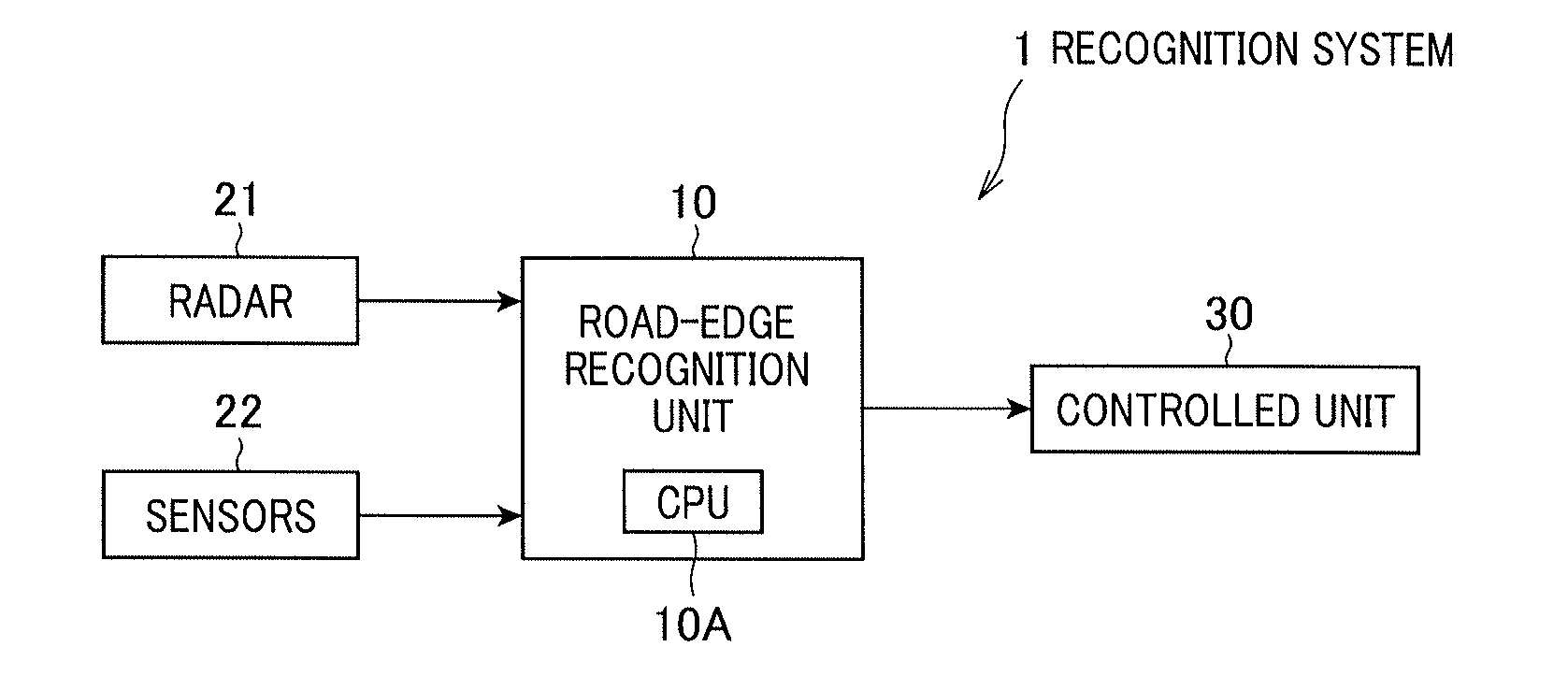

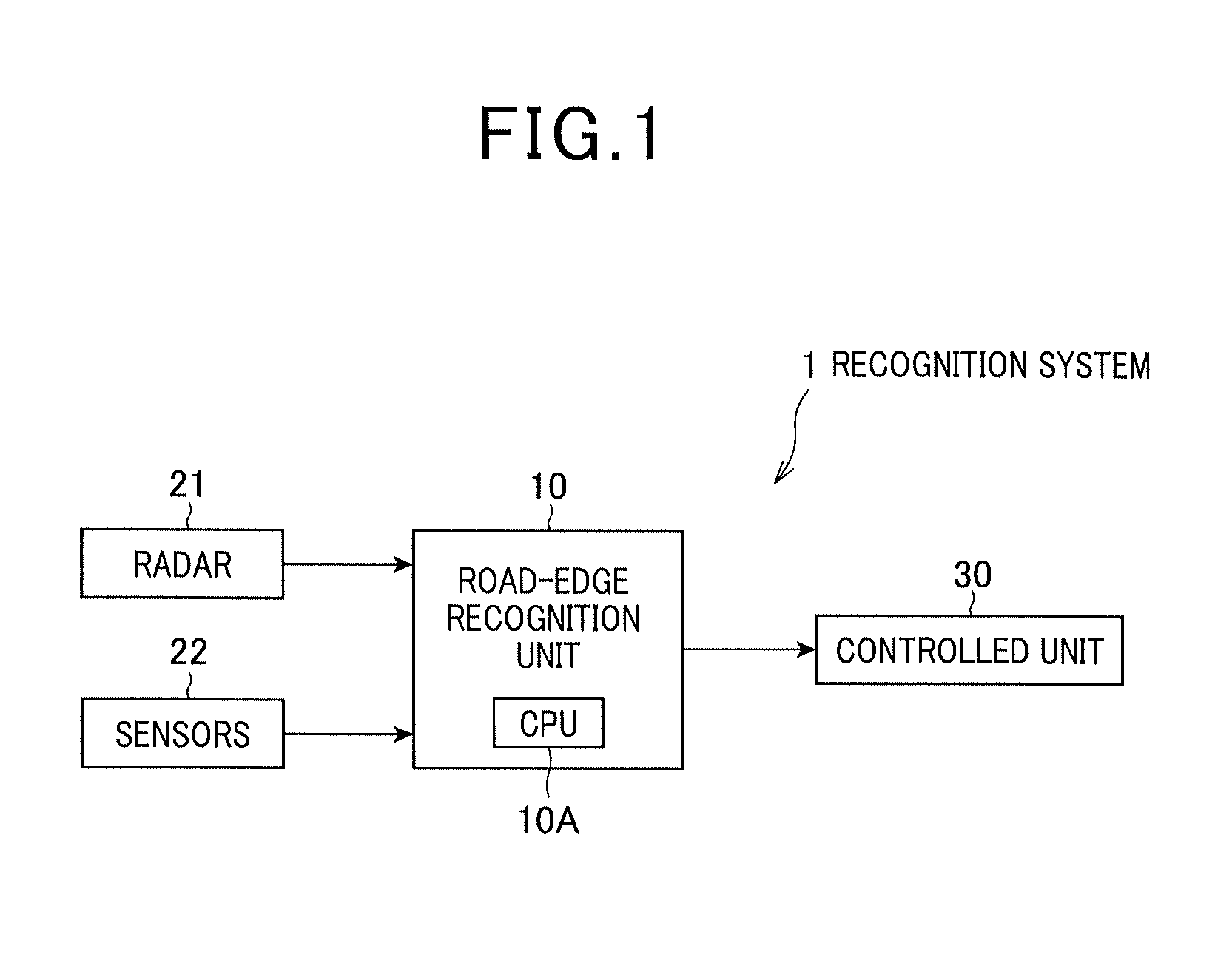

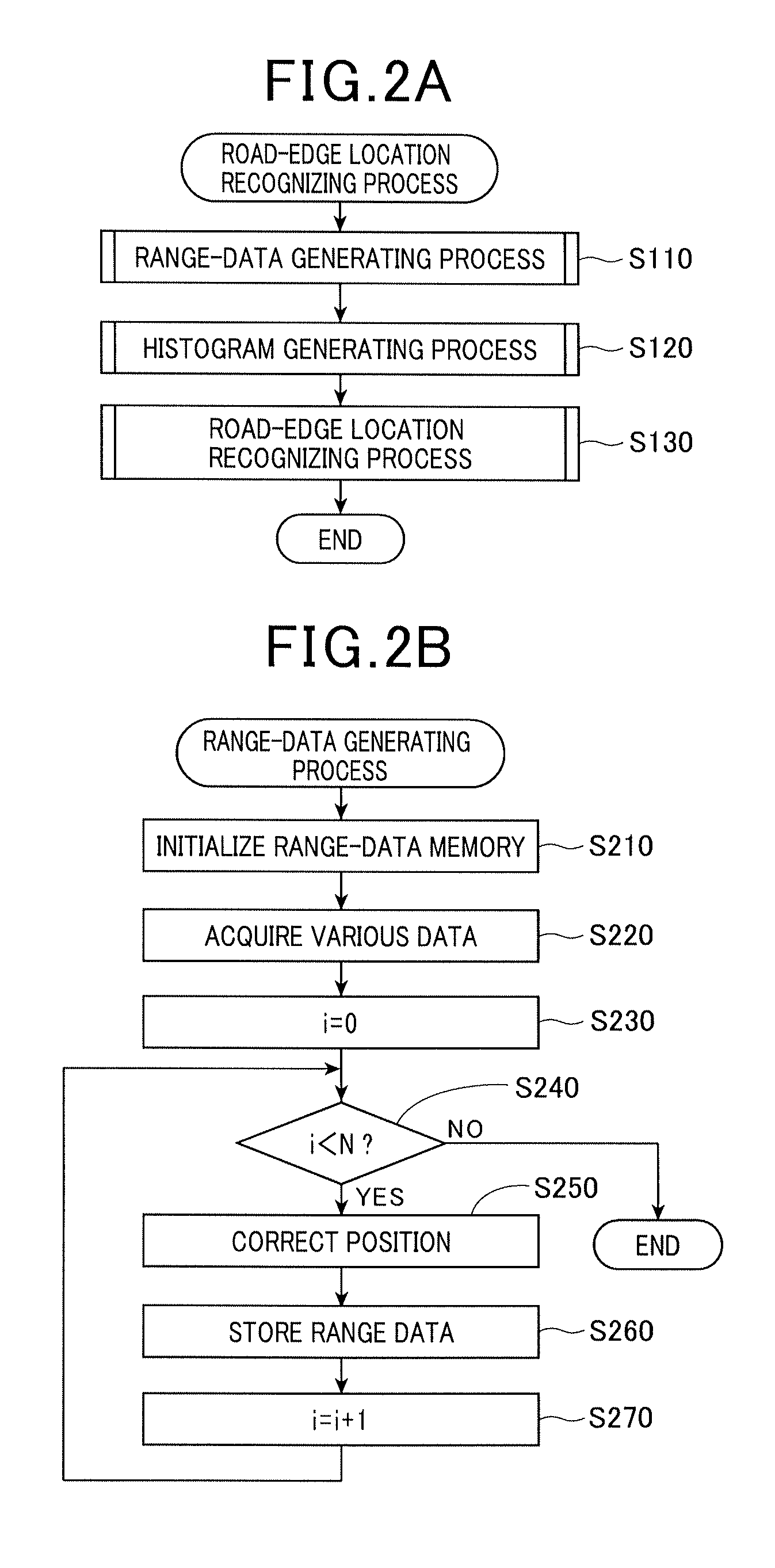

Method and apparatus for detecting road-edges

InactiveUS20110227781A1Maintain detection accuracyAccurate delay timeImage enhancementImage analysisEngineeringRoad edge

An on-vehicle apparatus detects at least one of right and left edges of a road on and along which a vehicle travels. In the apparatus, acquired is information indicative of a plurality of detection points which are given as a plurality of candidates for the edges of the road viewed forward from the vehicle. Further acquired is information indicative of behaviors of the vehicle. A calculating member calculates, based on the acquired information, every detection point, a plurality of passing positions each indicating a position of each of the detection points to a position of the vehicle provided that the vehicle travels to a position on the road which is located right beside each of the detection points. A road edge obtaining member obtains the edges of the road based on the plurality of passing positions calculated.

Owner:DENSO CORP

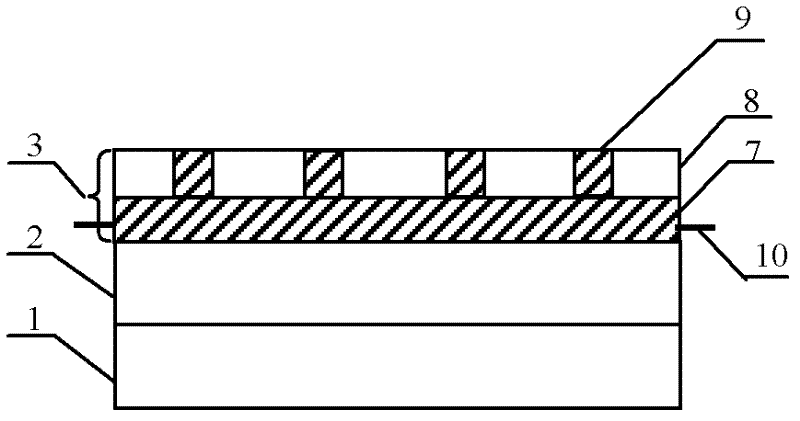

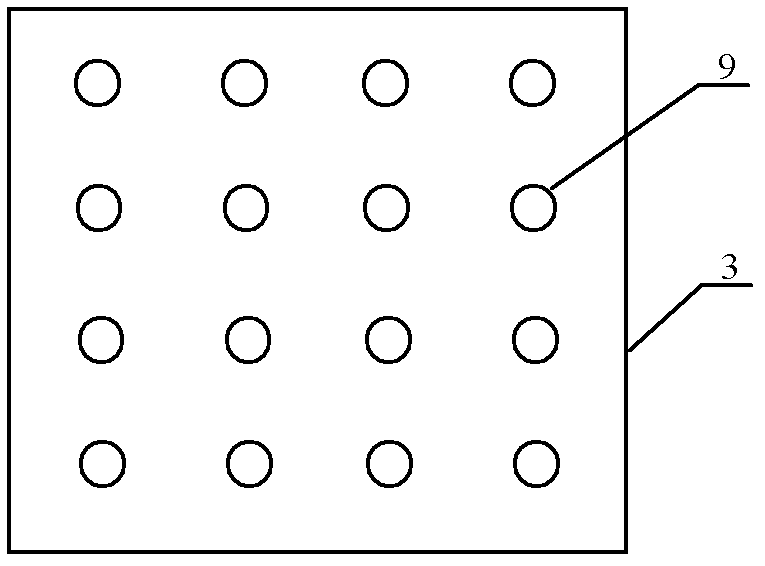

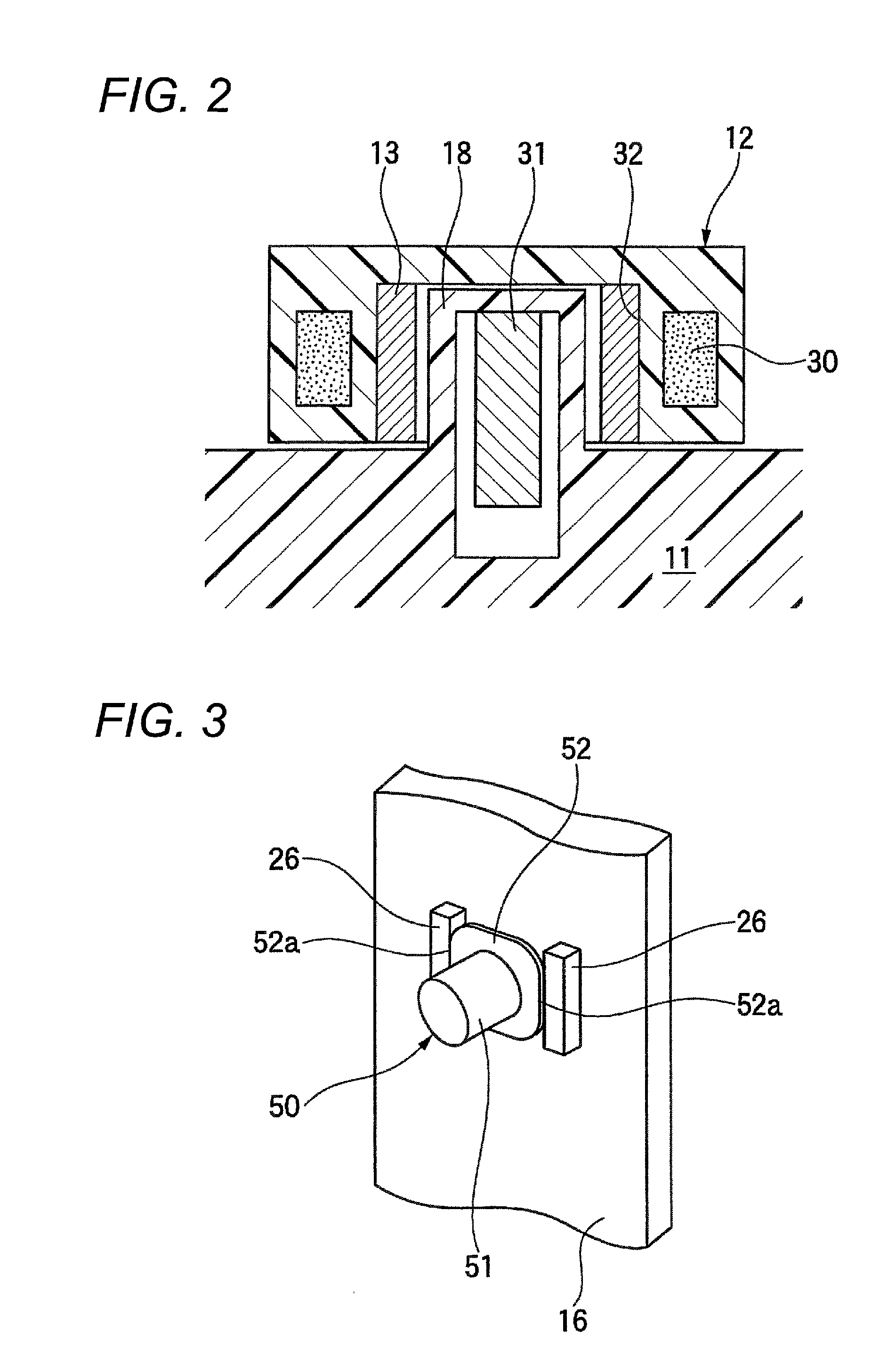

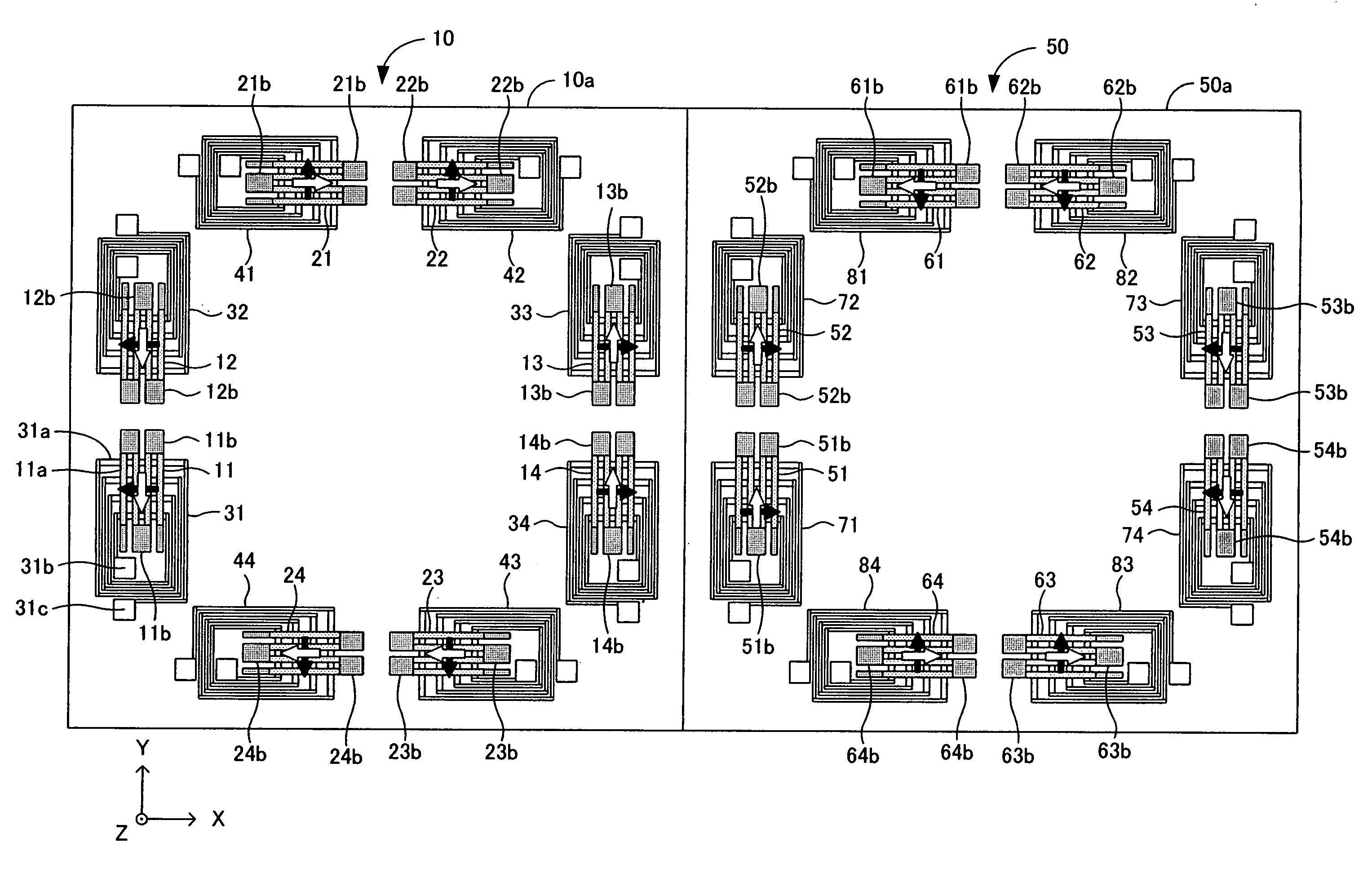

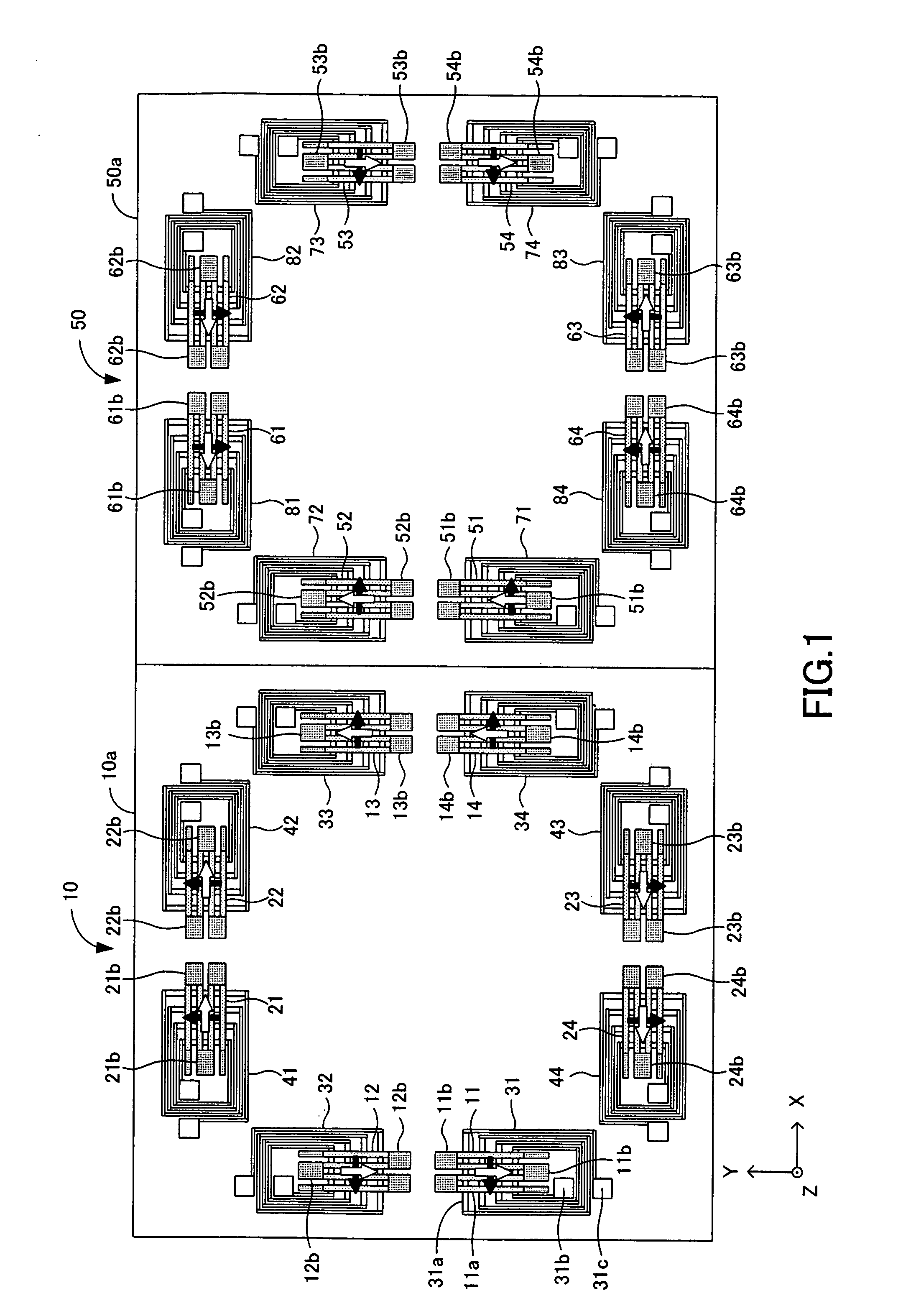

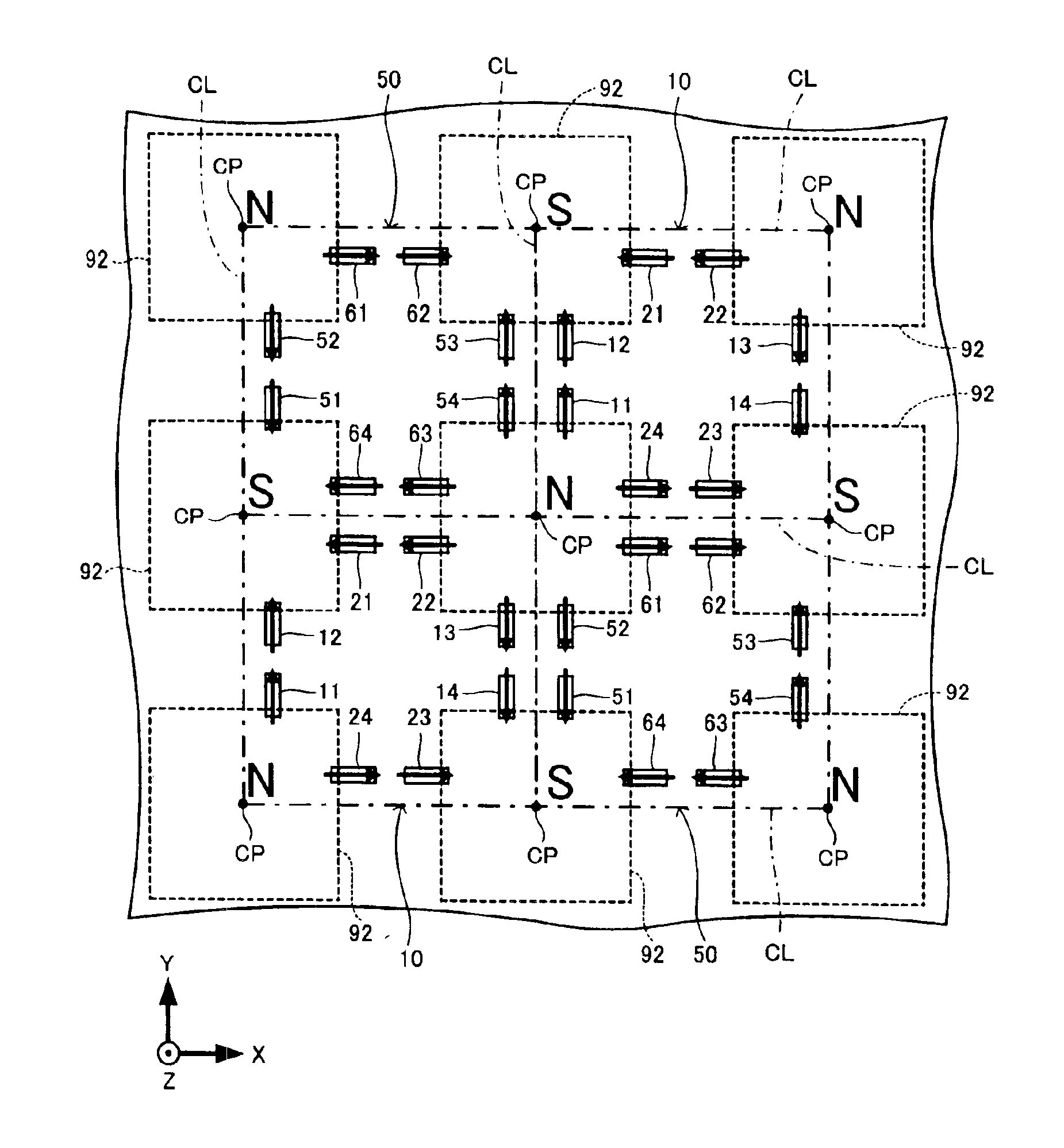

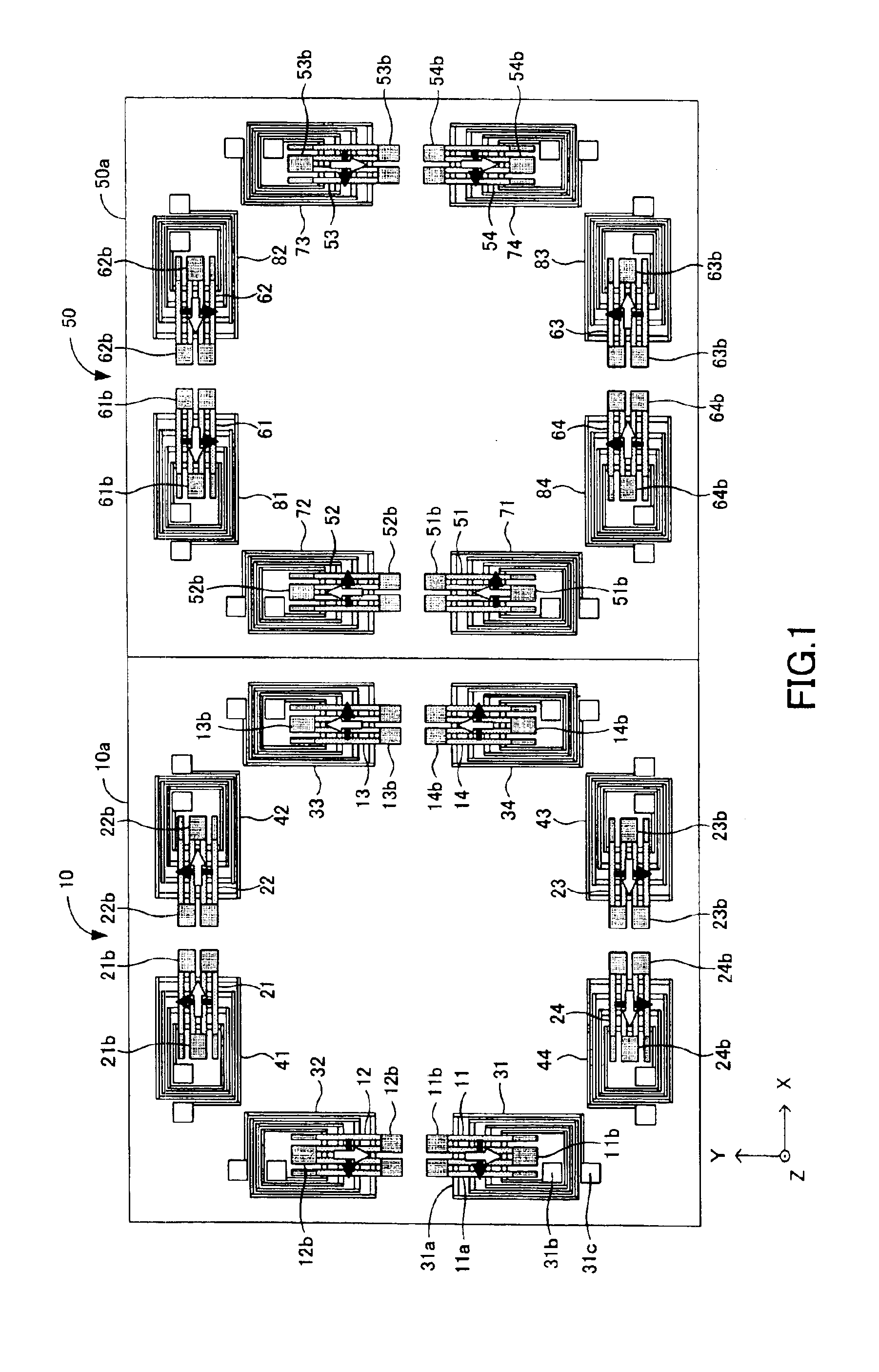

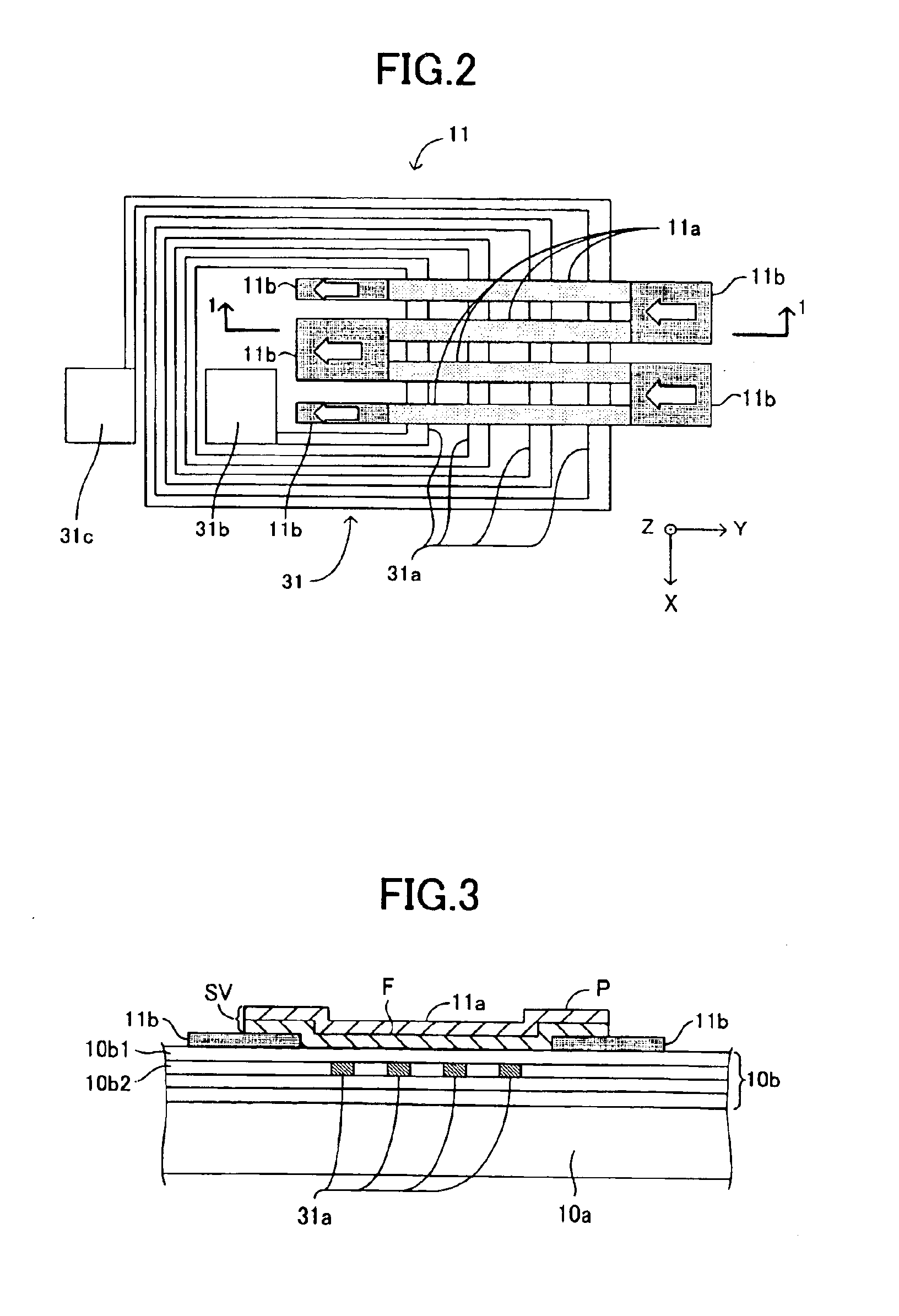

Magnetic sensor, production process of the magnetic sensor and magnetic array suitable for the production process

InactiveUS20050212632A1Efficient magnetizationMaintain detection accuracyNanostructure applicationNanomagnetismElectrical polarityMagnetic orientation

The present invention aims to provide a magnetic sensor provided with a magnetoresistive effect element capable of stably maintaining a direction of magnetization in a magnetic domain of a free layer. The magnetic sensor includes a magnetoresistive effect element provided with narrow zonal portions 11a . . . 11a including a pinned layer and a free layer. Disposed below both ends of the free layer are bias magnet films 11b . . . 11b composed of a permanent magnet that applies to the free layer a bias magnetic field in a predetermined direction and an initializing coil 31 that is disposed in the vicinity of the free layer and applies to the free layer a magnetic field having the direction same as that of the bias magnetic field by being energized under a predetermined condition. Further, magnetizing the bias magnet films and fixing the direction of magnetization of the pinned layer are performed by a magnetic field formed by a magnet array configured such that plural permanent magnets are arranged on a lattice point of a tetragonal lattice and a polarity of a magnet pole of each permanent magnet is different from a polarity of the other adjacent magnet pole spaced by the shortest route.

Owner:YAMAHA CORP

Current sensor

InactiveUS20150276814A1Avoid feverMaintain detection accuracyVoltage/current isolationMagnitude/direction of magnetic fieldsCurrent transducerElectric current flow

Provided is a current sensor capable of being assembled even if a bus bar inserted through a magnetic core has a complex shape that is difficult to insert through an opening portion of a case. A case includes a first case segment and a second case segment provided with opening portions having a cut-out shape that is open toward a direction orthogonal to a direction in which a detection target portion of a bus bar extends, and the case is assembled to the detection target portion by inserting the detection target portion into the opening portions from the direction orthogonal to the direction in which the detection target portion extends.

Owner:SUMITOMO WIRING SYST LTD

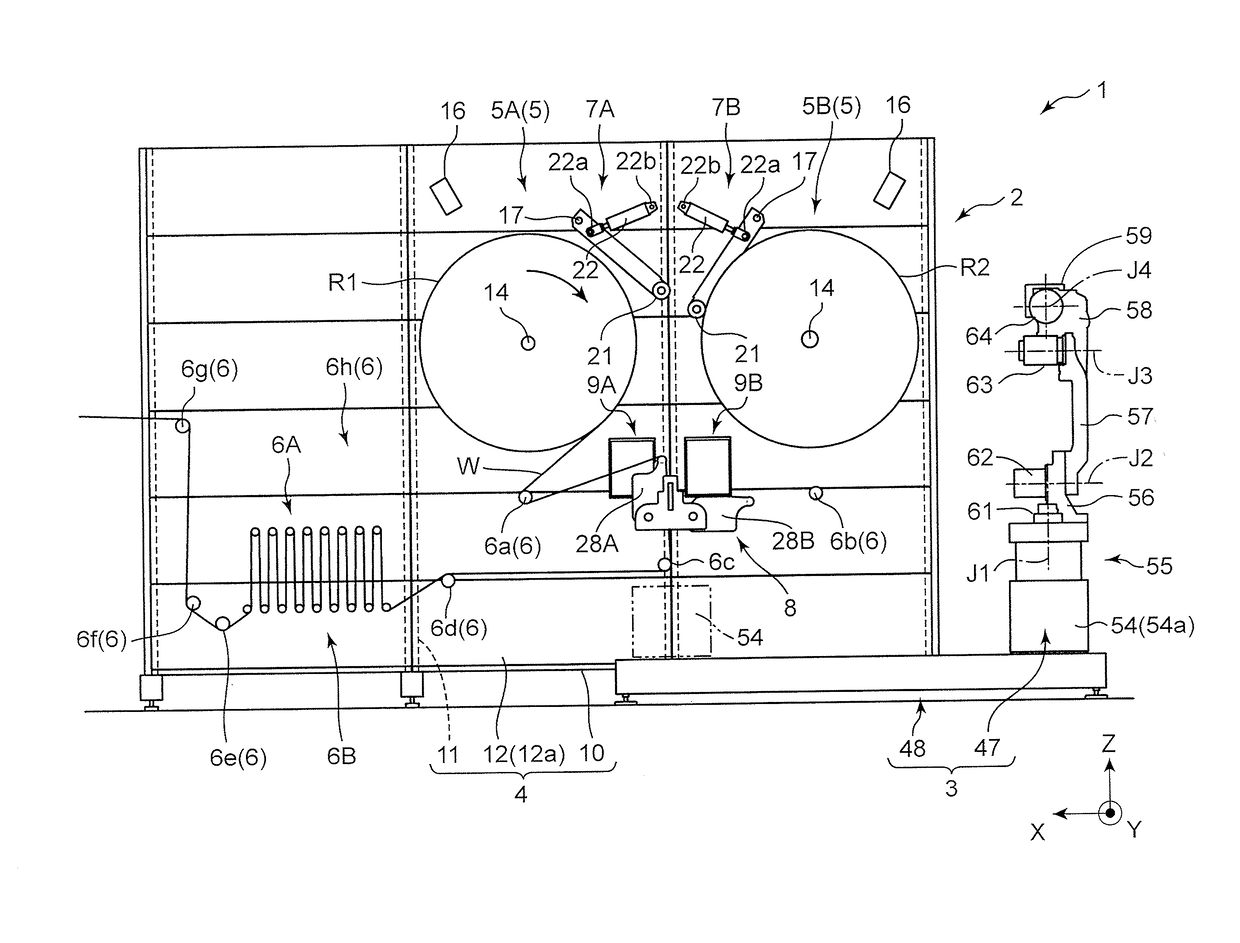

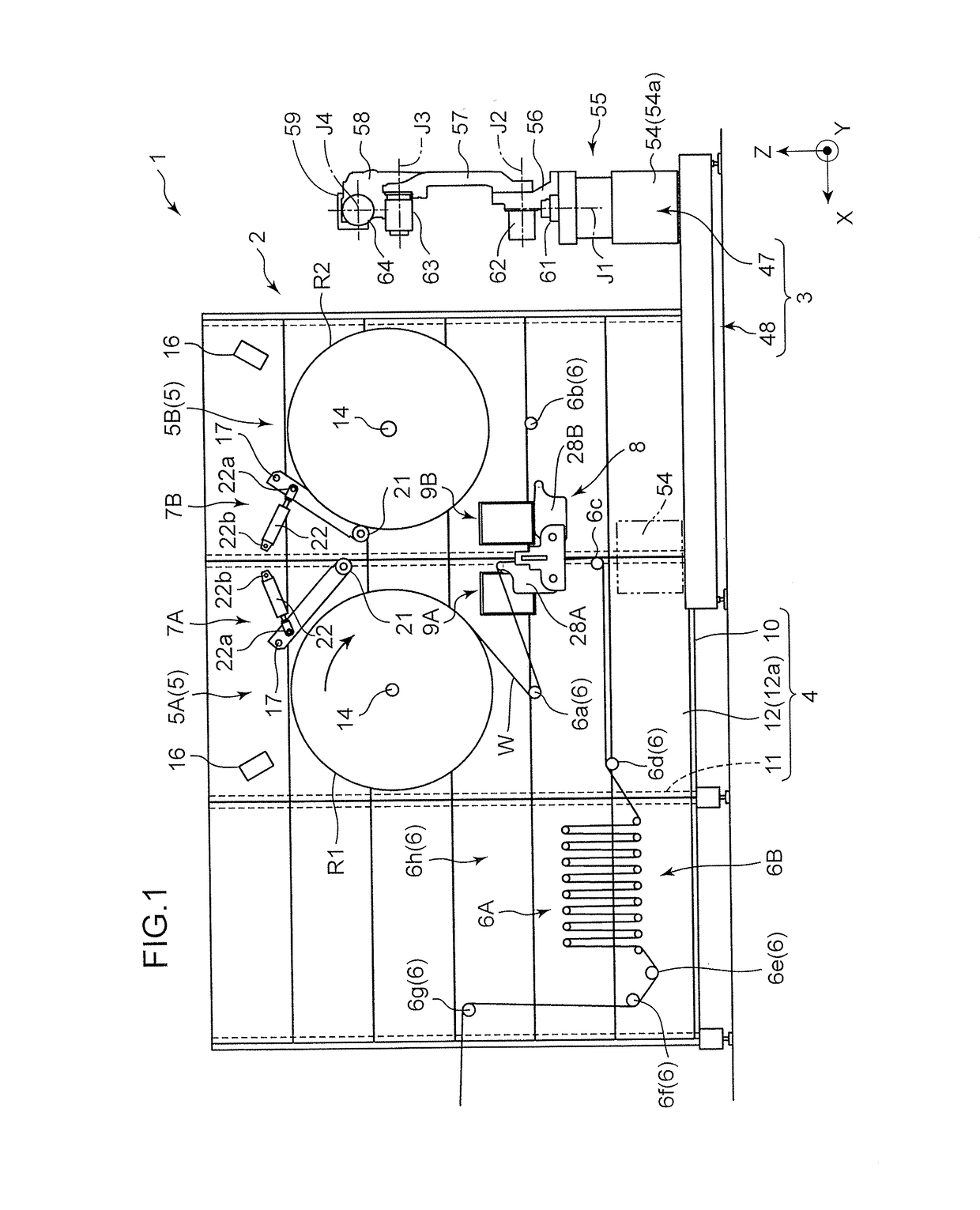

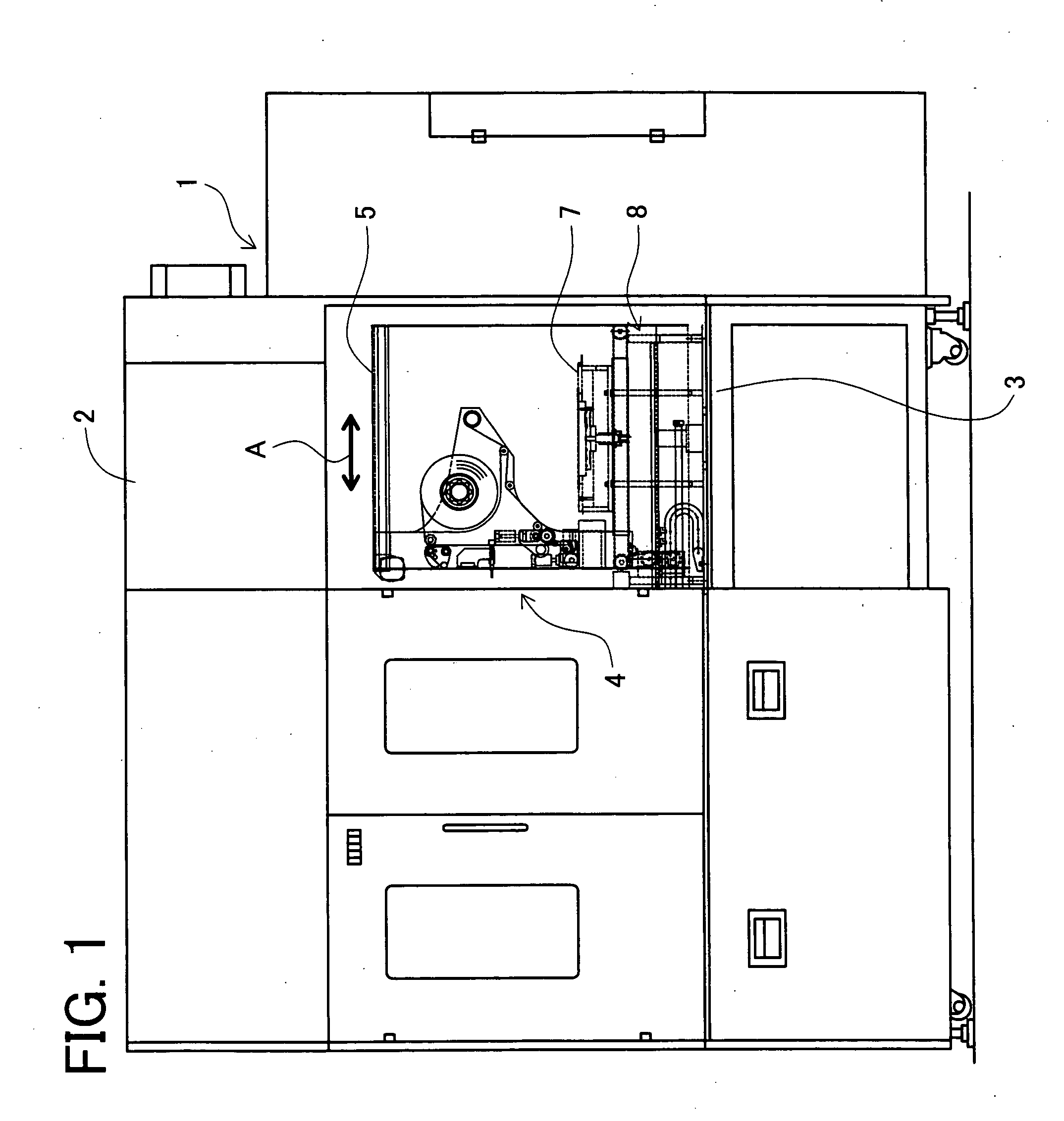

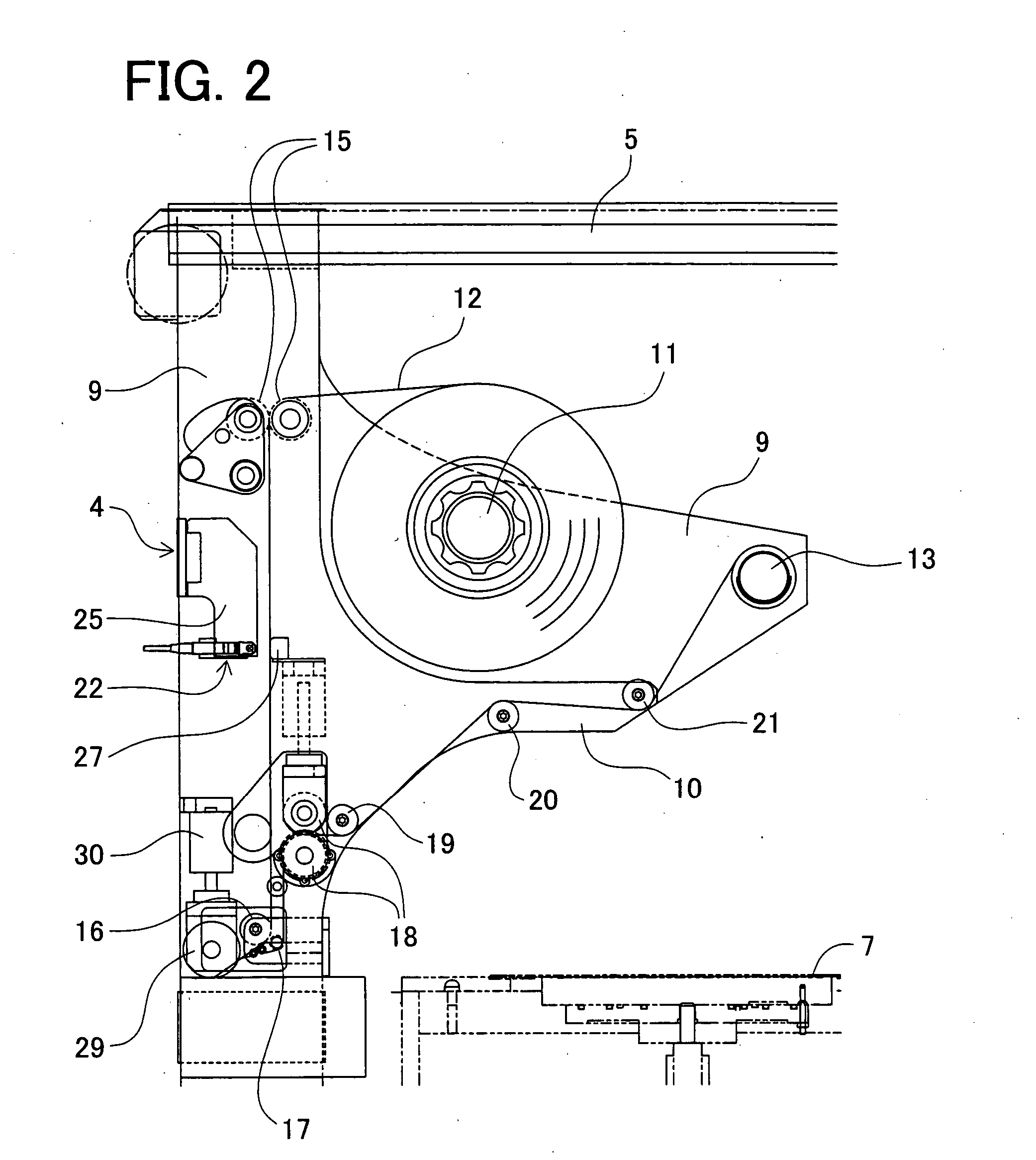

Sheet delivery system and sheet delivery method using same

ActiveUS20170137247A1Avoid normal workMaintain detection accuracyWebs handlingEngineeringDrive motor

A sheet delivery system includes: an end section detector which detects a position of an end section of a sheet; an operation robot which holds the end section of the sheet and which conveys the end section of the sheet to a joining unit; a roll driving motor which rotationally drives the standby-side original material roll around a central axis thereof; and a suction roller which is capable of coming into rolling contact with an outer peripheral surface of the standby-side original material roll, and which includes an outer peripheral surface capable of suctioning the end section of the sheet in order to separate the end section of the sheet from the standby-side original material roll. The end section detector is attached at a position which enables detection of the end section of the sheet separated from the standby-side original material roll by the suction roller.

Owner:ZUIKO CORP

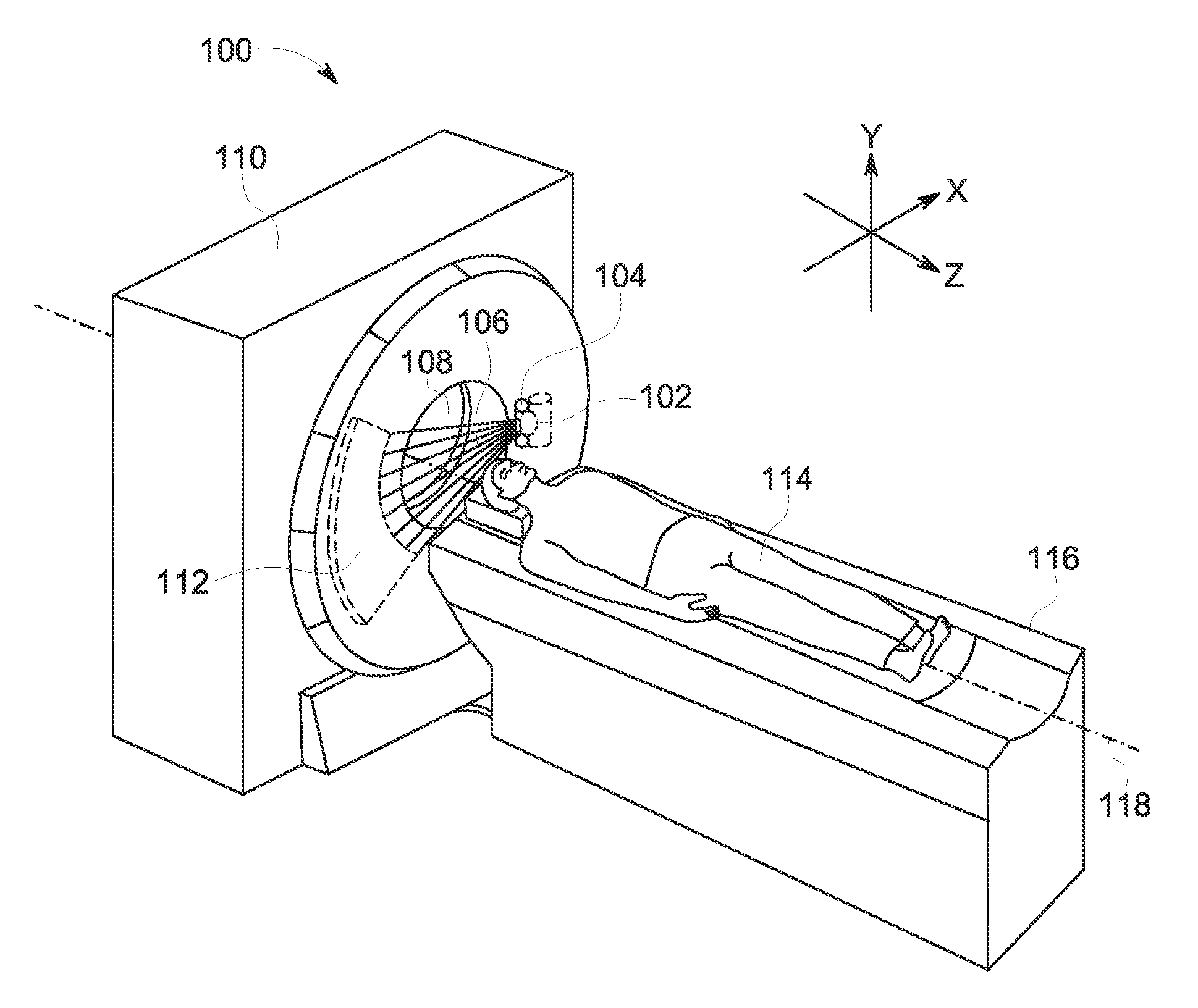

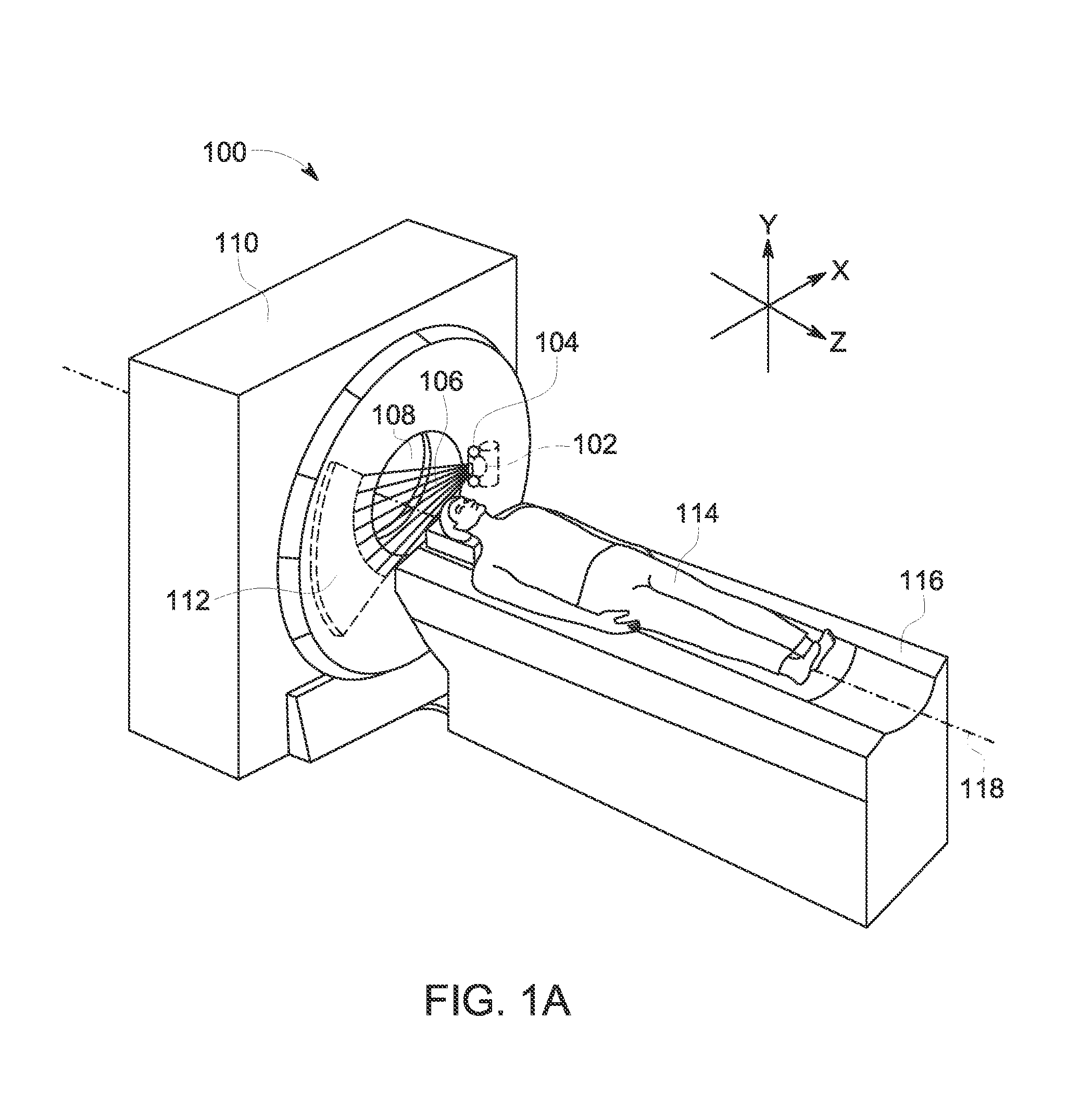

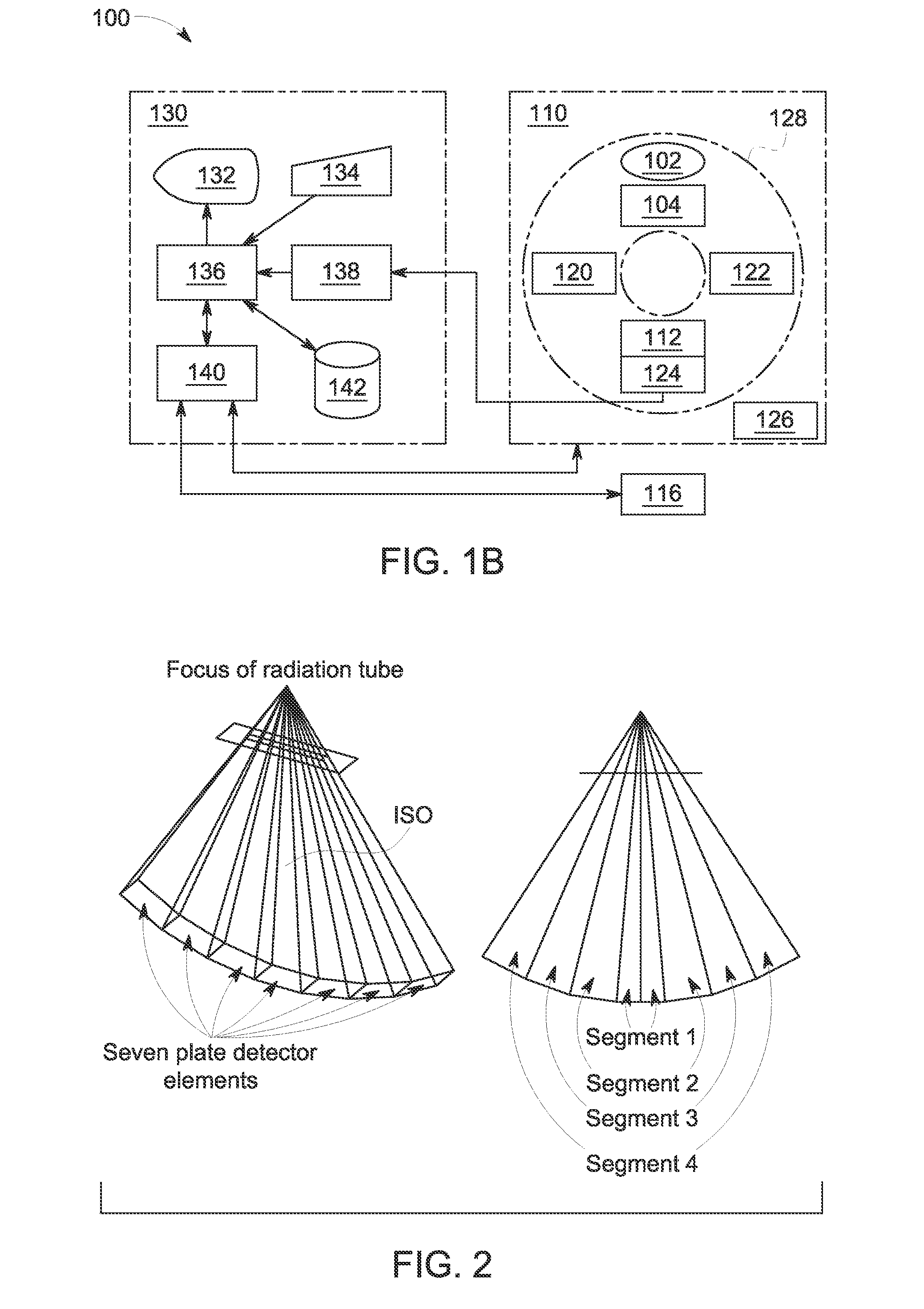

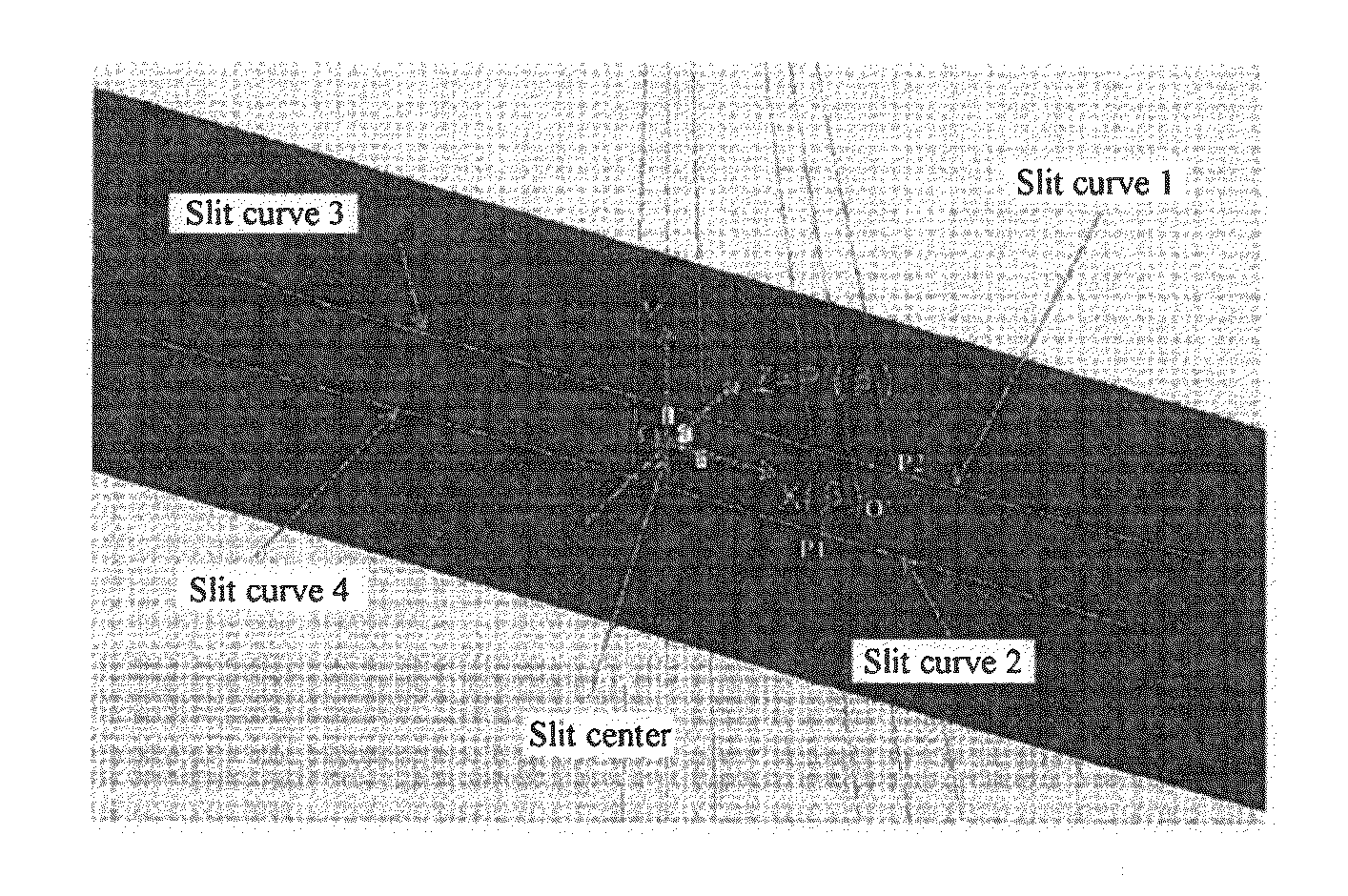

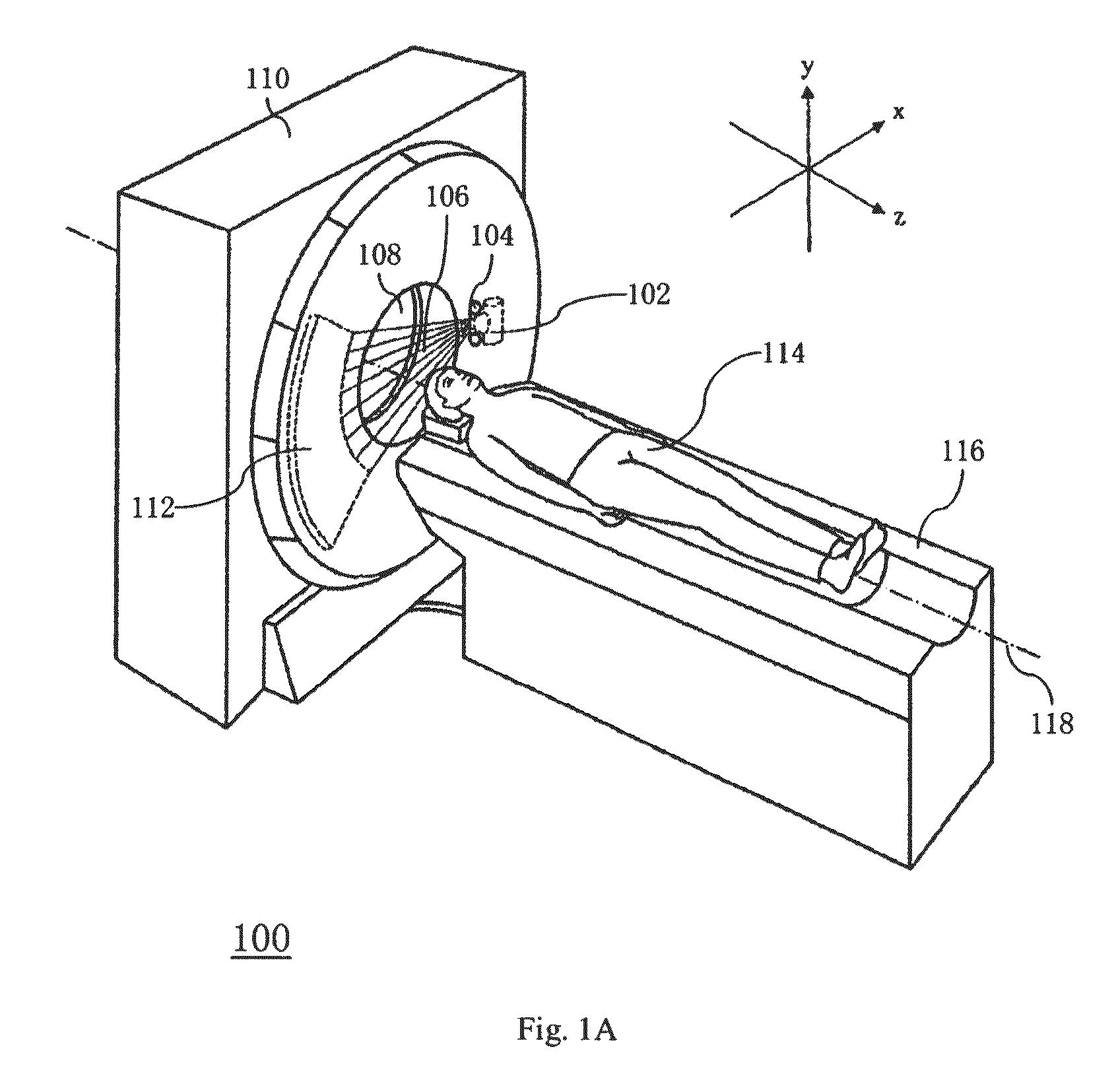

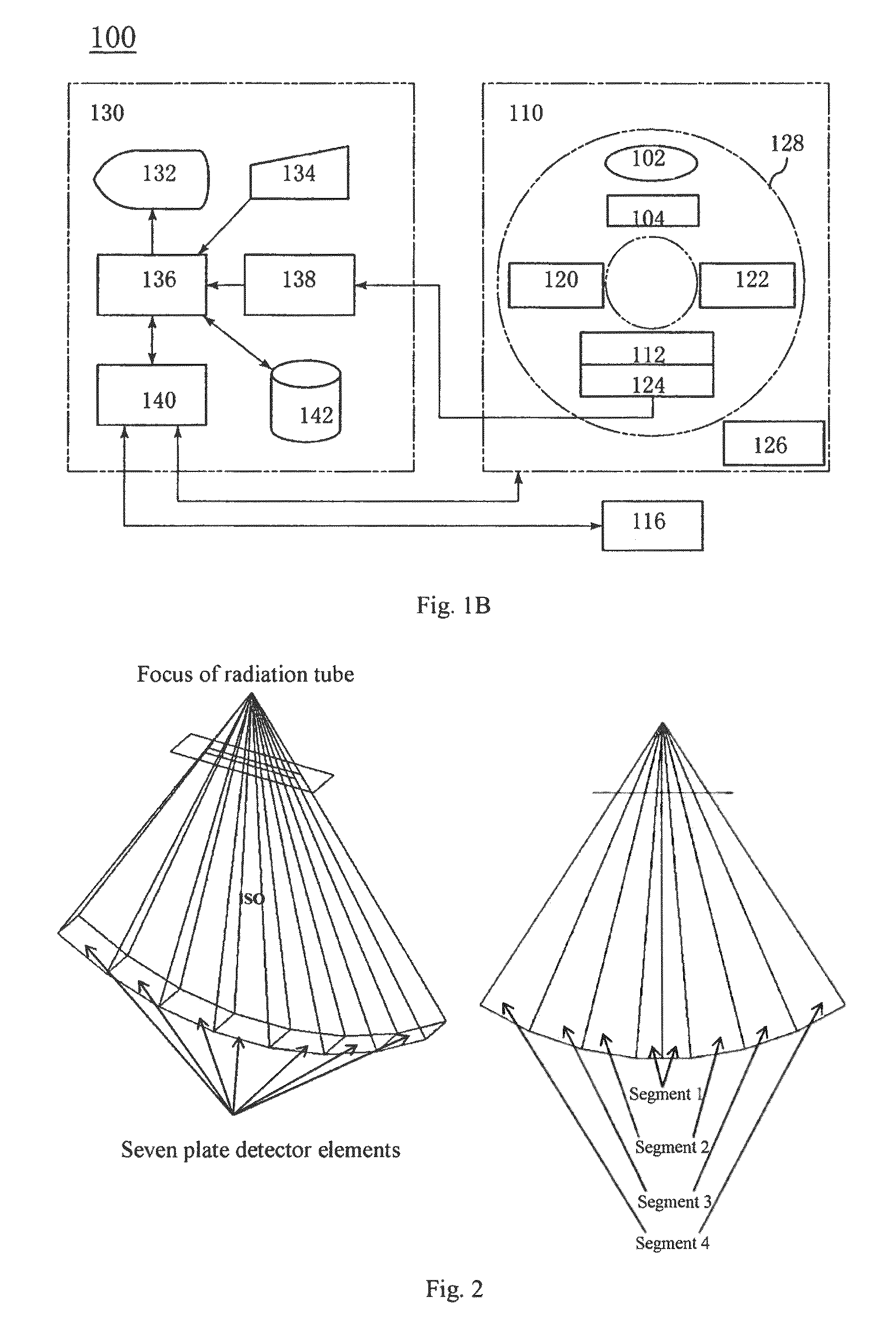

Advanced collimator aperture curve

ActiveUS20140211913A1Maintain detection accuracyAvoiding or reducing the additional radiation doseHandling using diaphragms/collimetersTomographyPhysicsRadiation rays

A CT imaging system and a method for determining a CT collimator slit profile. The method includes determining a profile of two opposite edges of the collimator slit in a longitudinal direction thereof based on the following: a vertical distance between a focus of a radiation source to the collimator slit, a vertical distance between the focus and the radiation detector, an inclination angle between adjacent detector elements, a length of each detector element, a desired width of projection on the radiation detector by the radiation rays passing through the slit whose longitudinal edge profile is to be determined, and an offset angle of a connecting line from a point on a longitudinal center line of the slit to the focus relative to a plane passing said focus and perpendicular to the slit.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

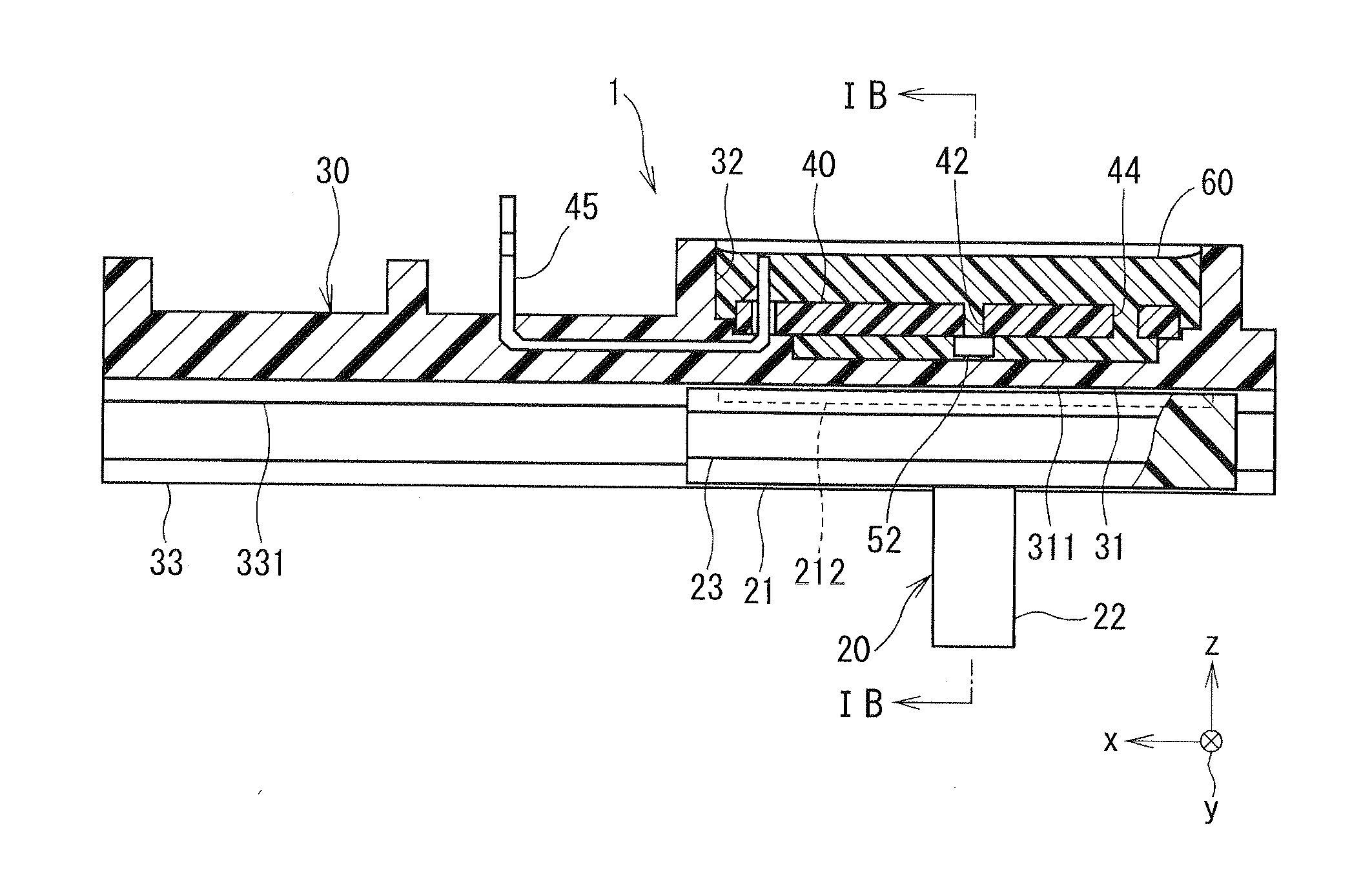

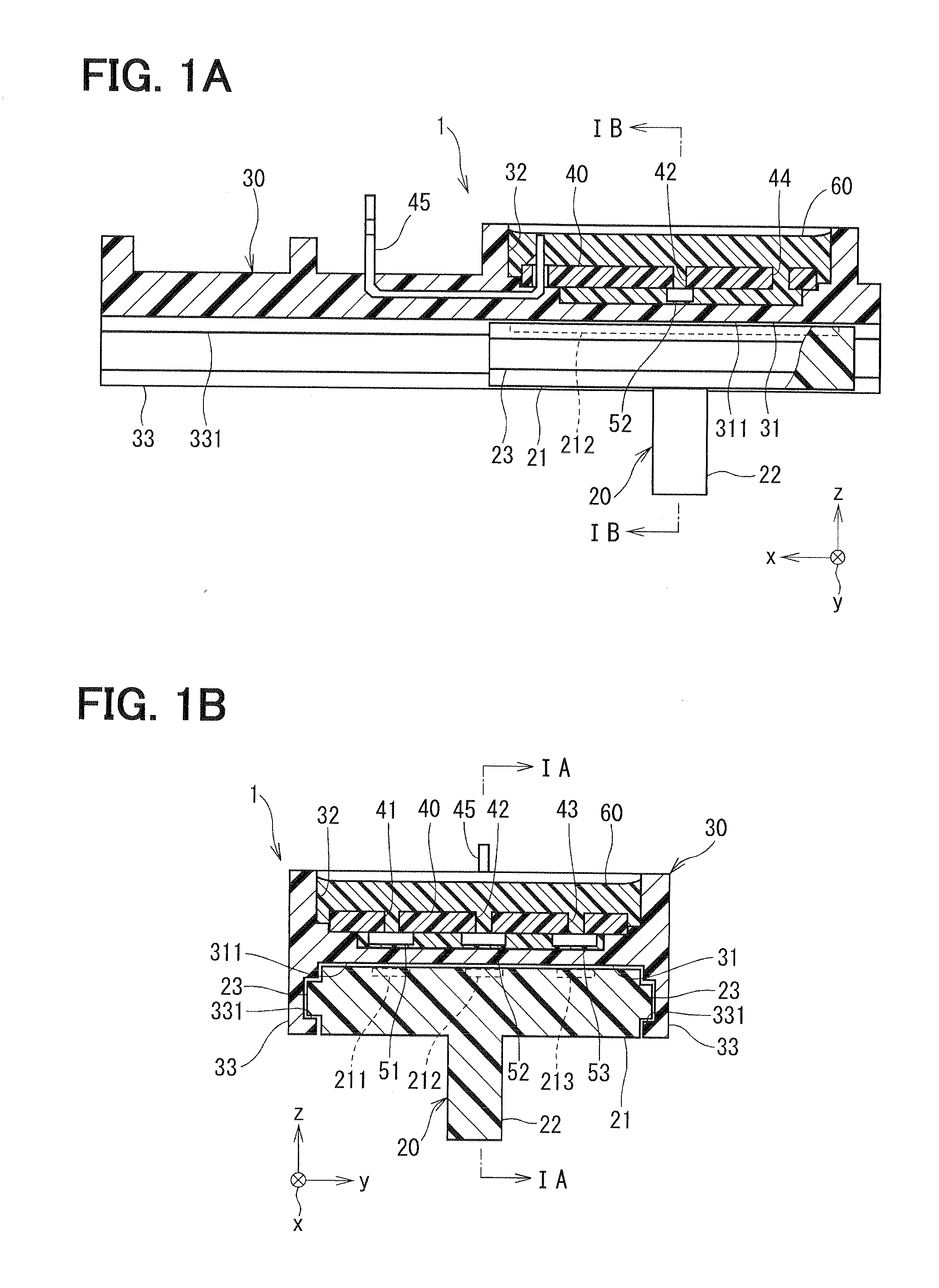

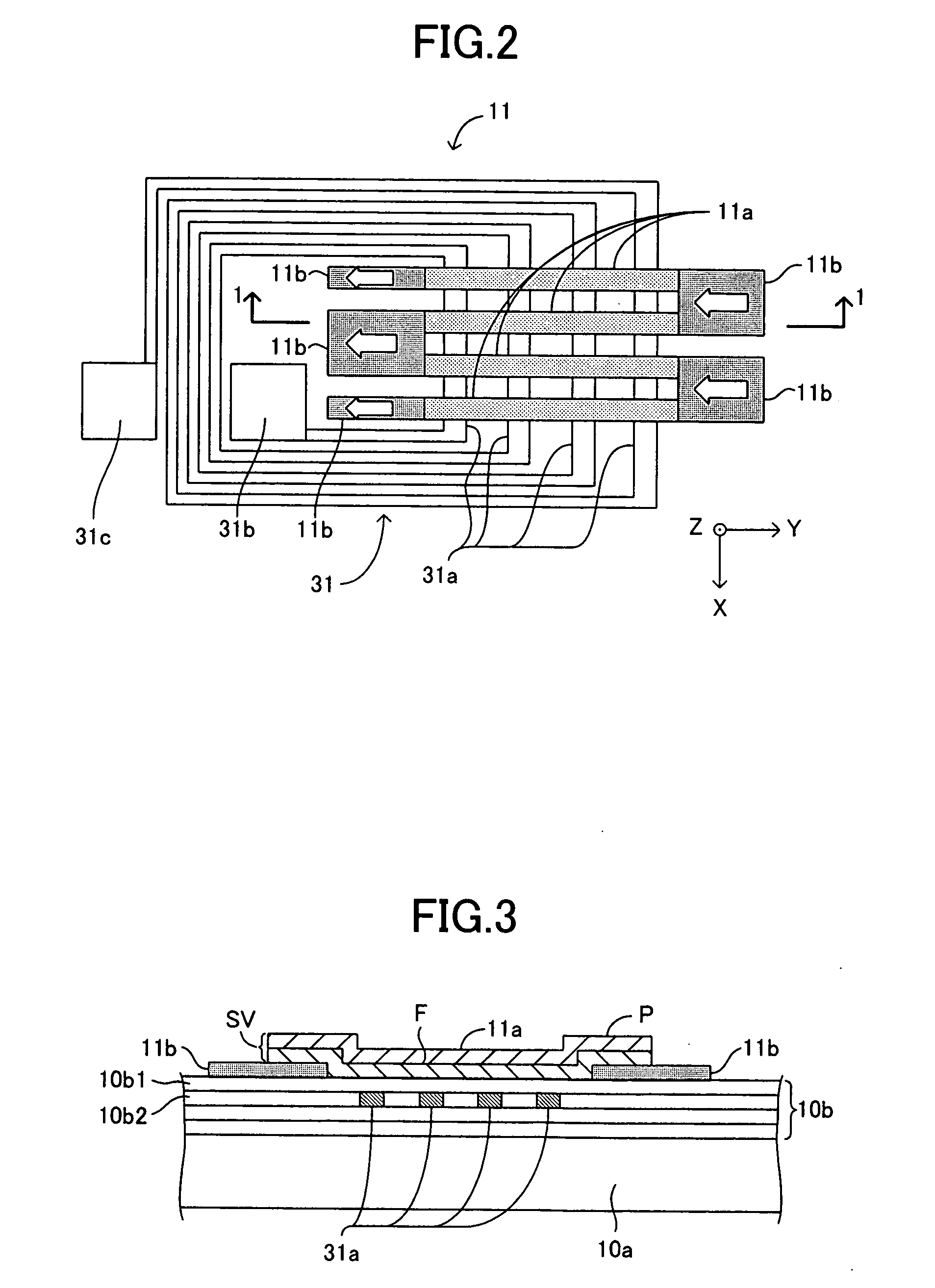

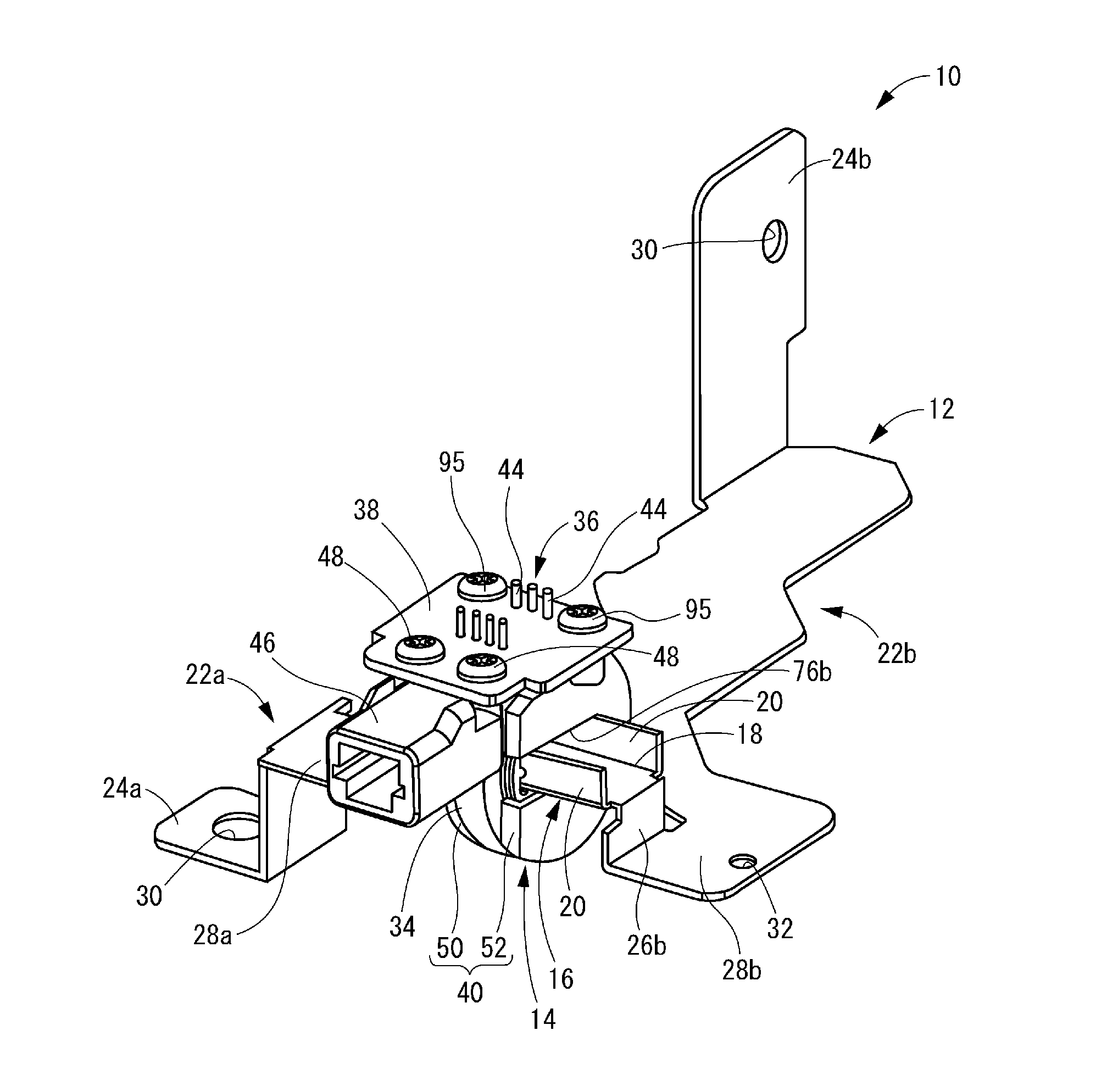

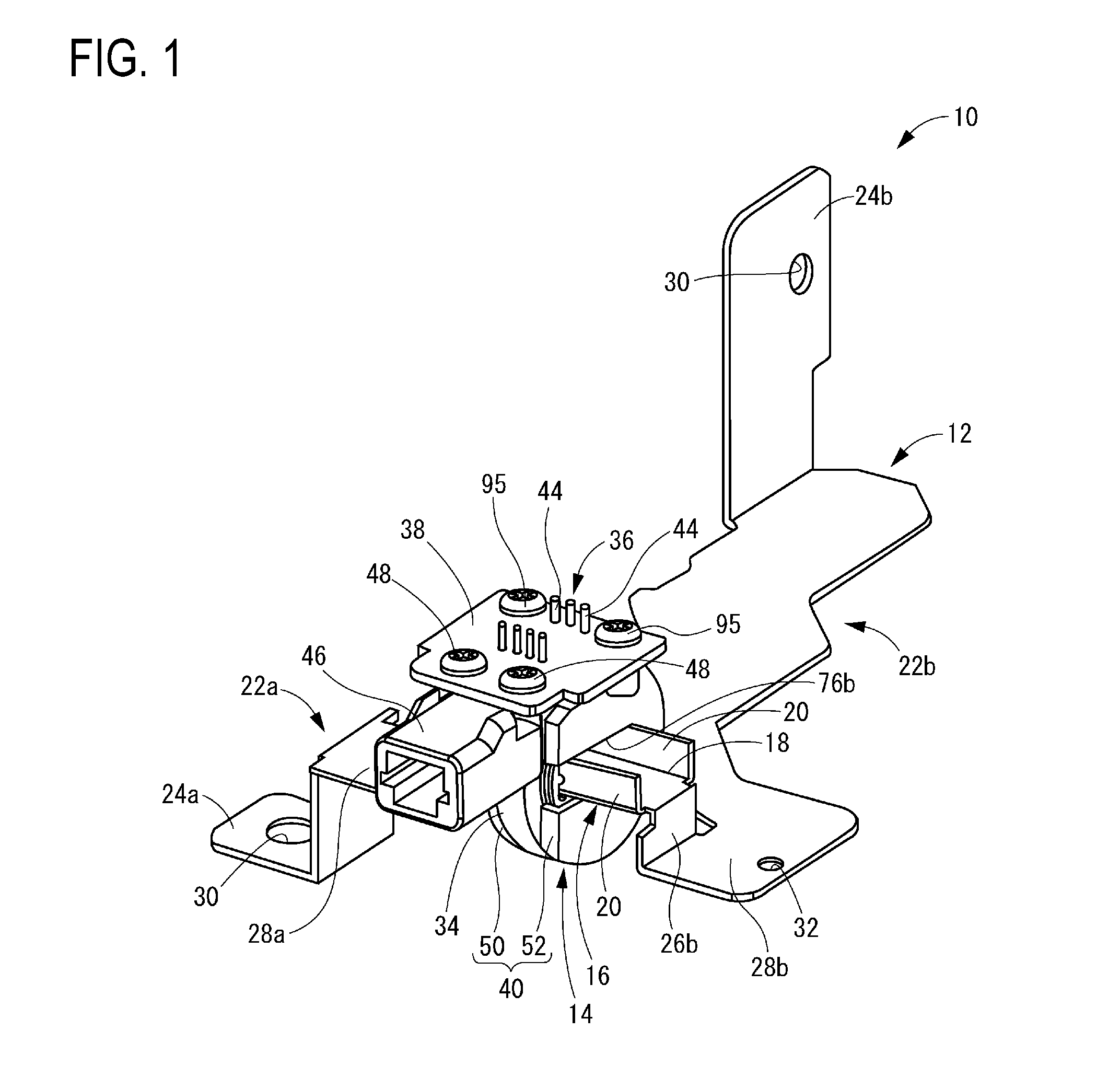

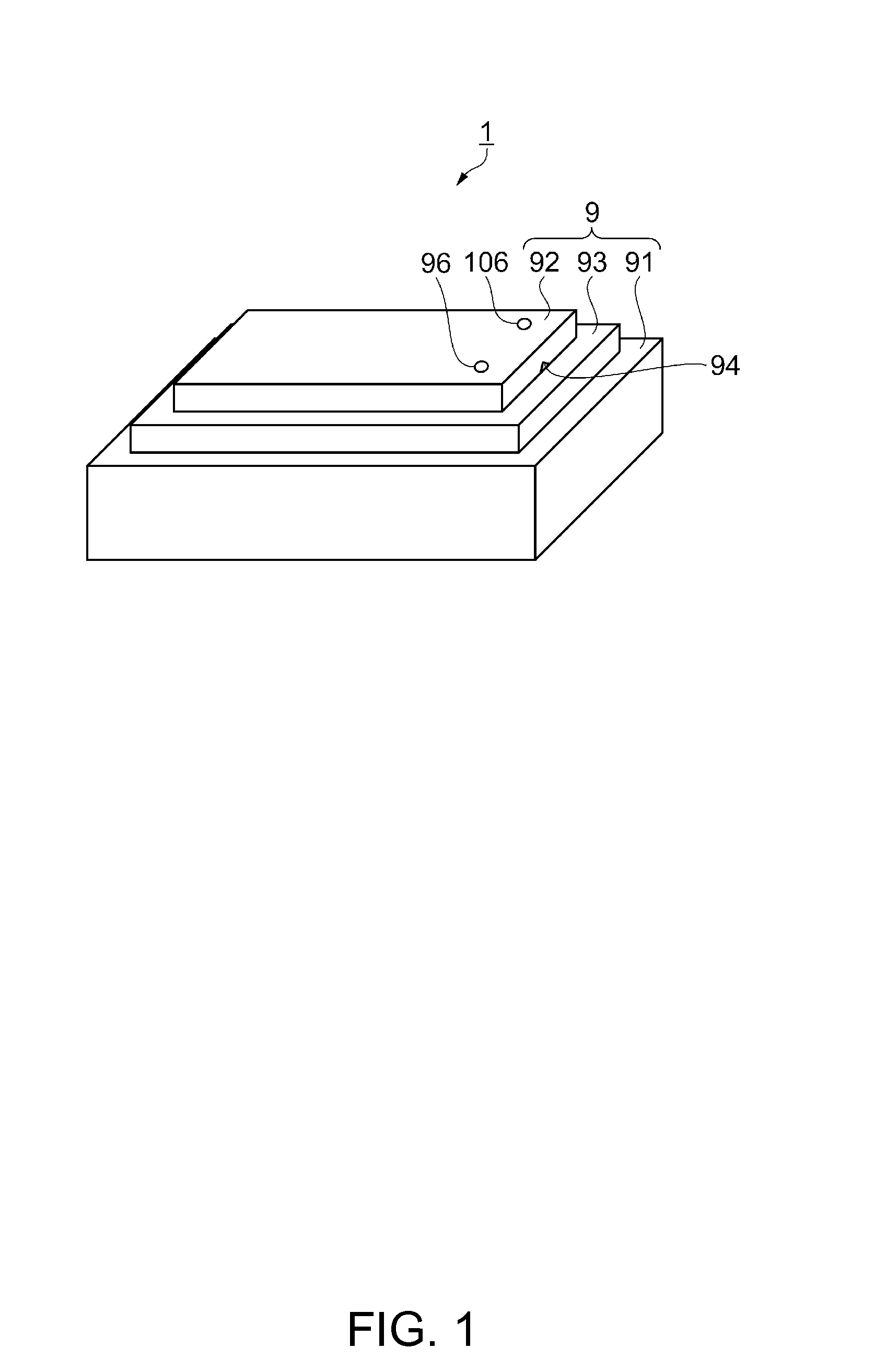

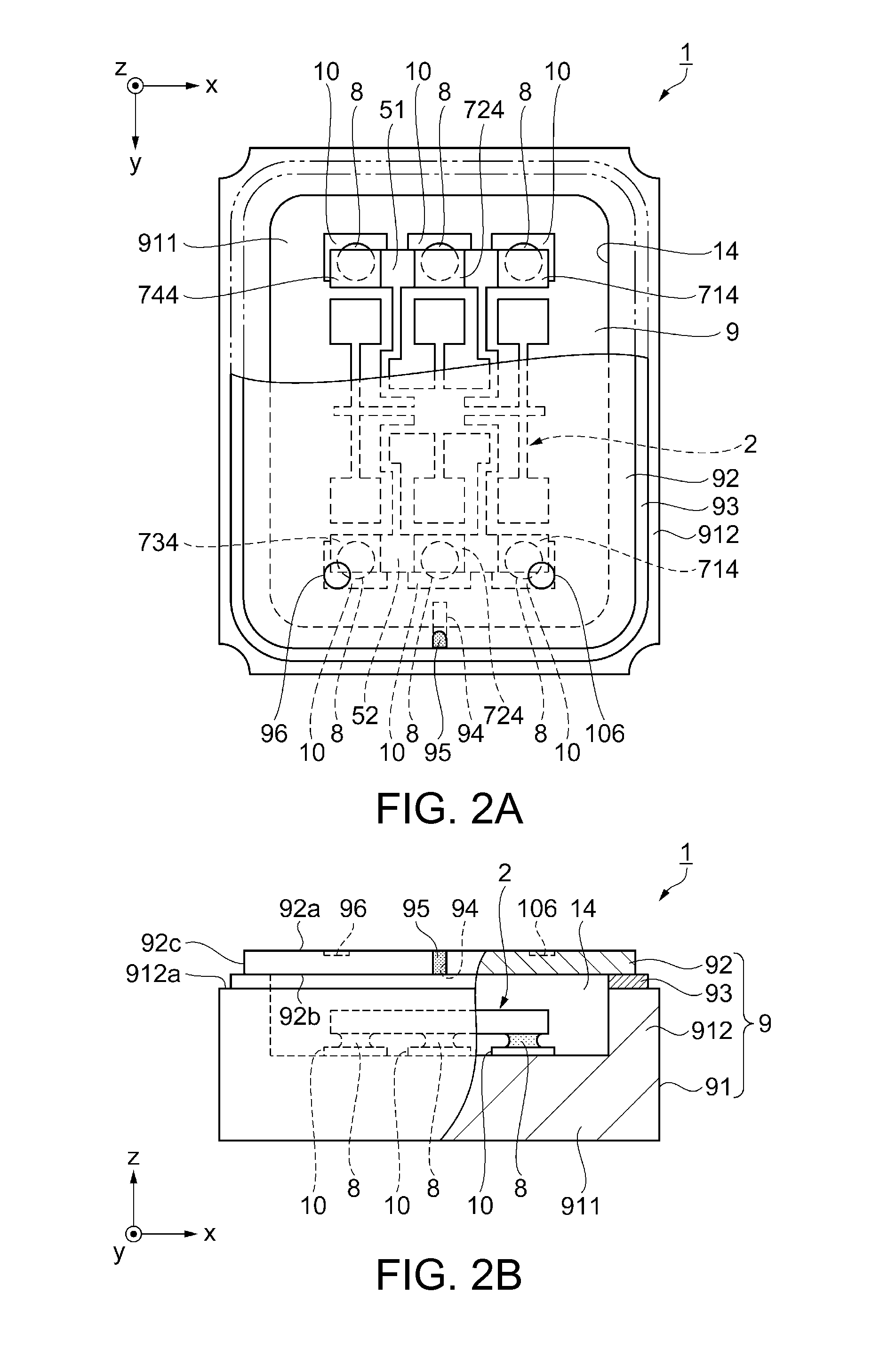

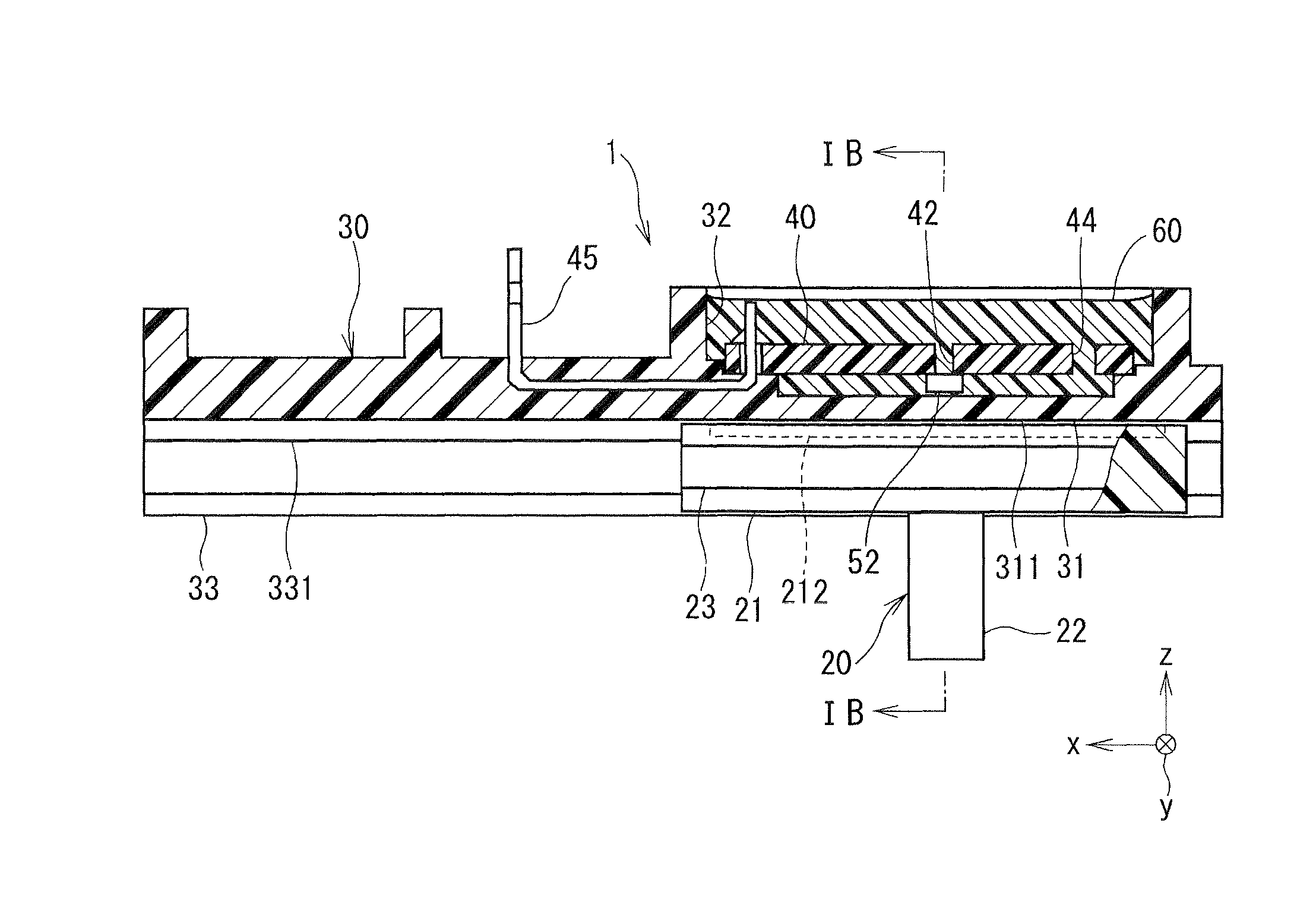

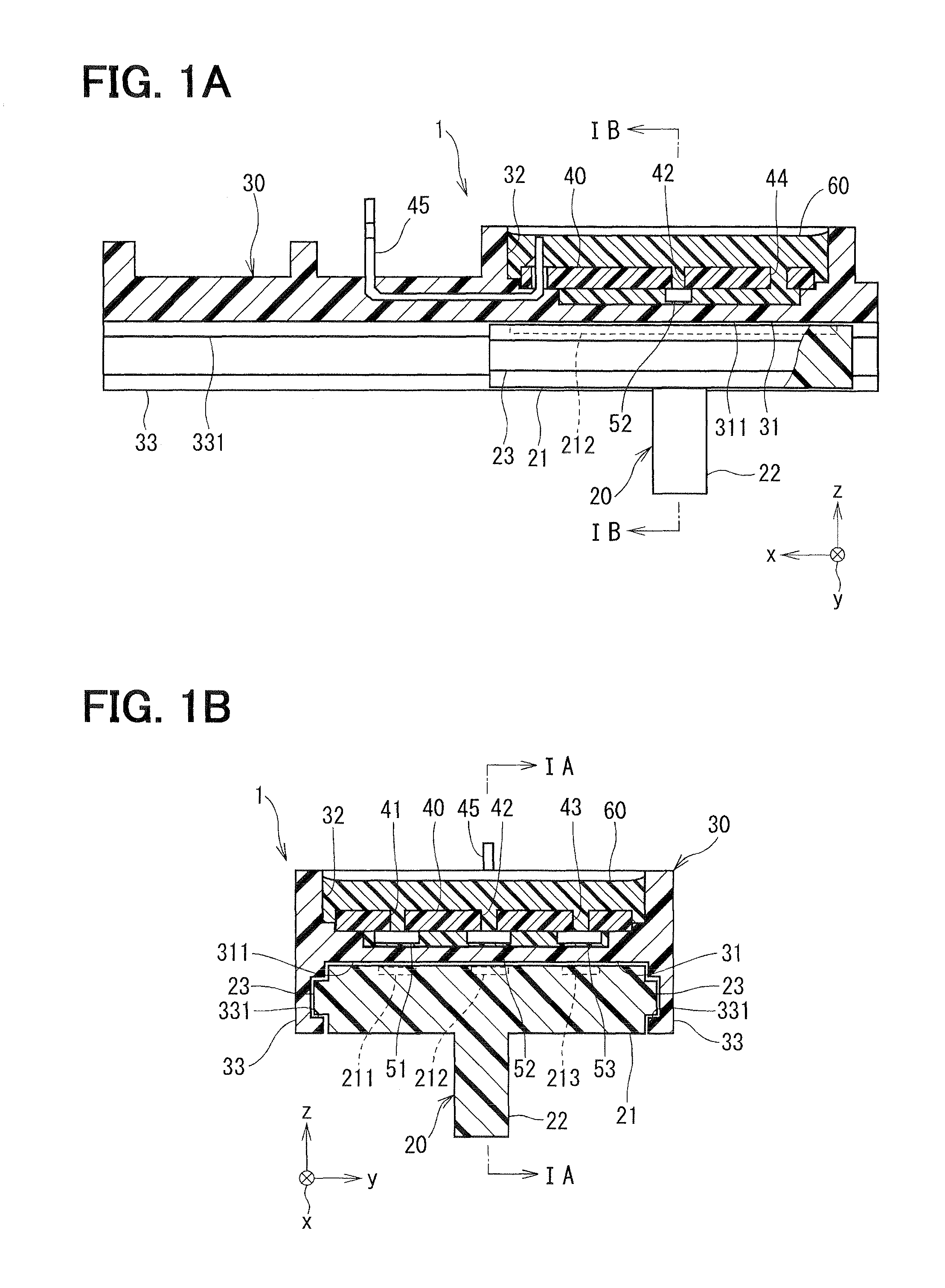

Lid body, package, electronic apparatus, moving object, and method for manufacturing package

ActiveUS20150130548A1Avoid misalignmentReduce generationCapsSemiconductor/solid-state device detailsEngineering

A lid body includes: a first surface; a second surface having a top-bottom relation with the first surface; an outer peripheral surface connecting the first surface and the second surface; a groove provided in the first surface from the outer peripheral surface toward an interior of the first surface; and first and second marks arranged at positions that do not overlap with an outer peripheral edge of the second surface in a plan view.

Owner:SEIKO EPSON CORP

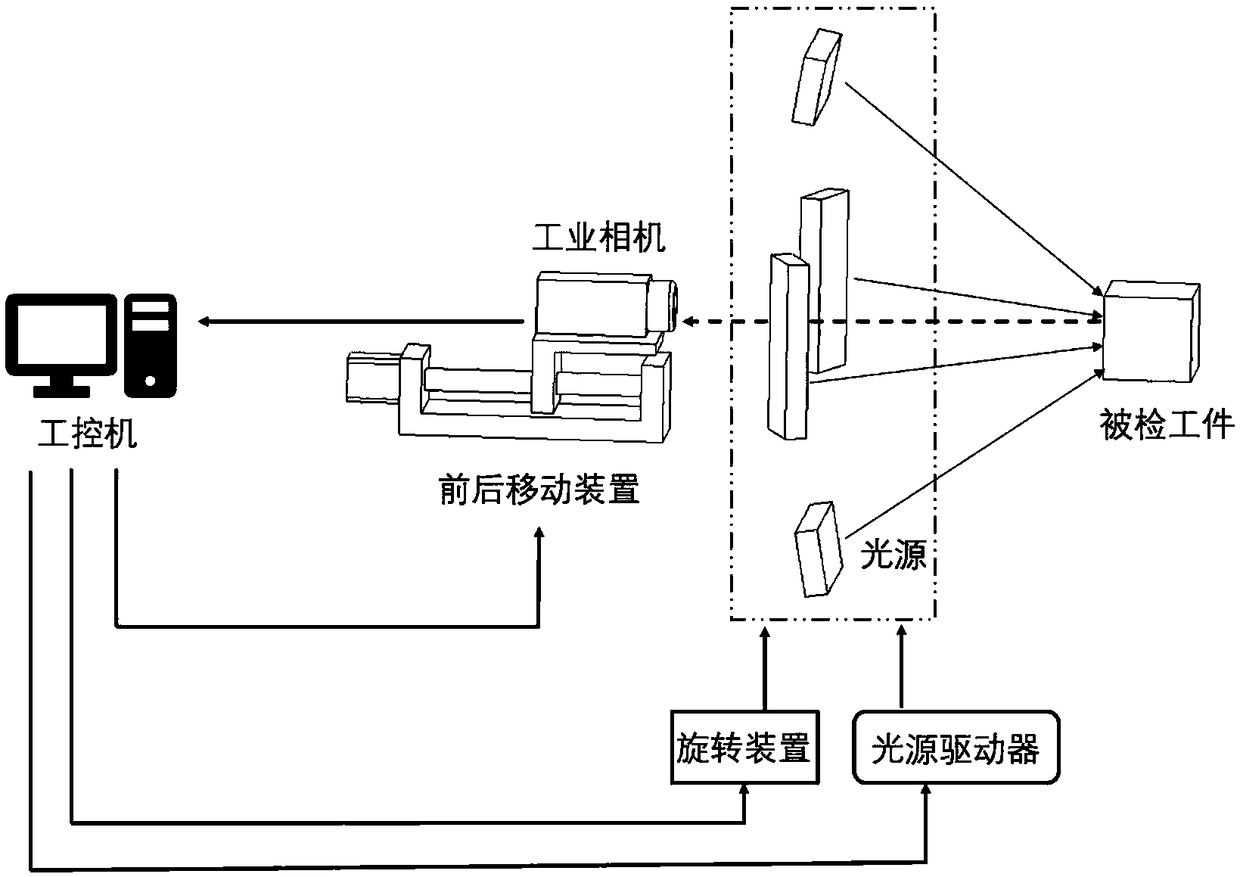

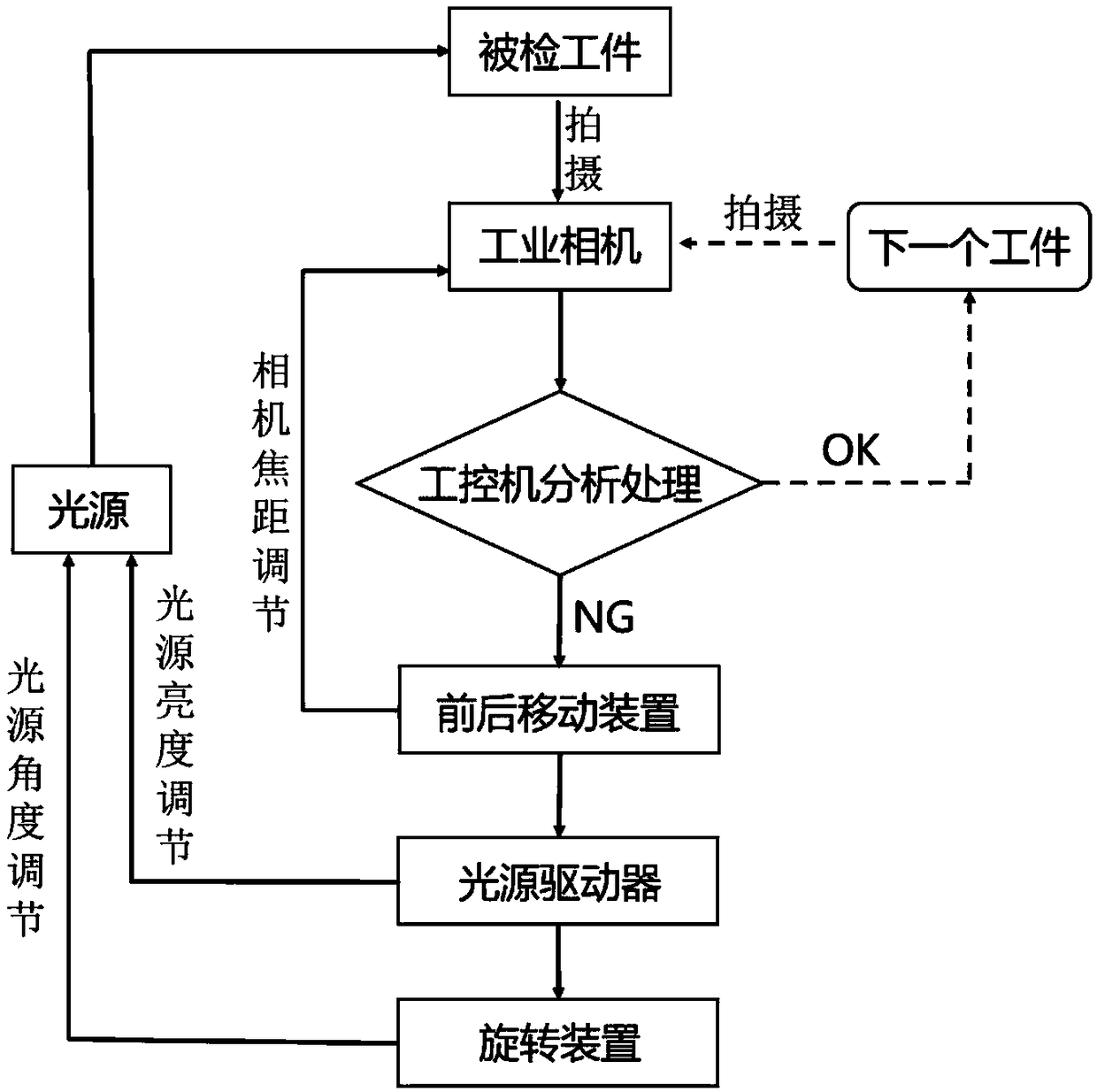

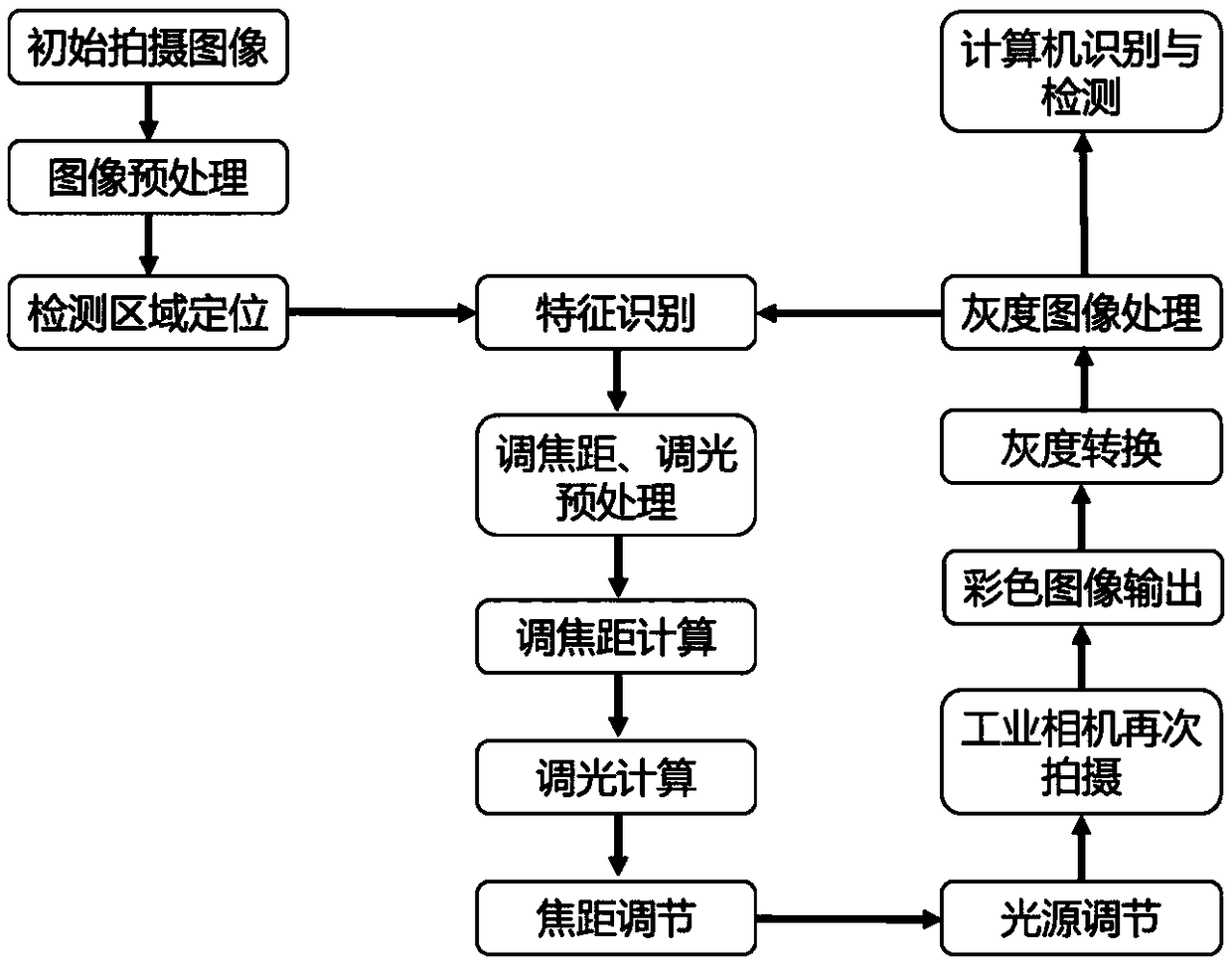

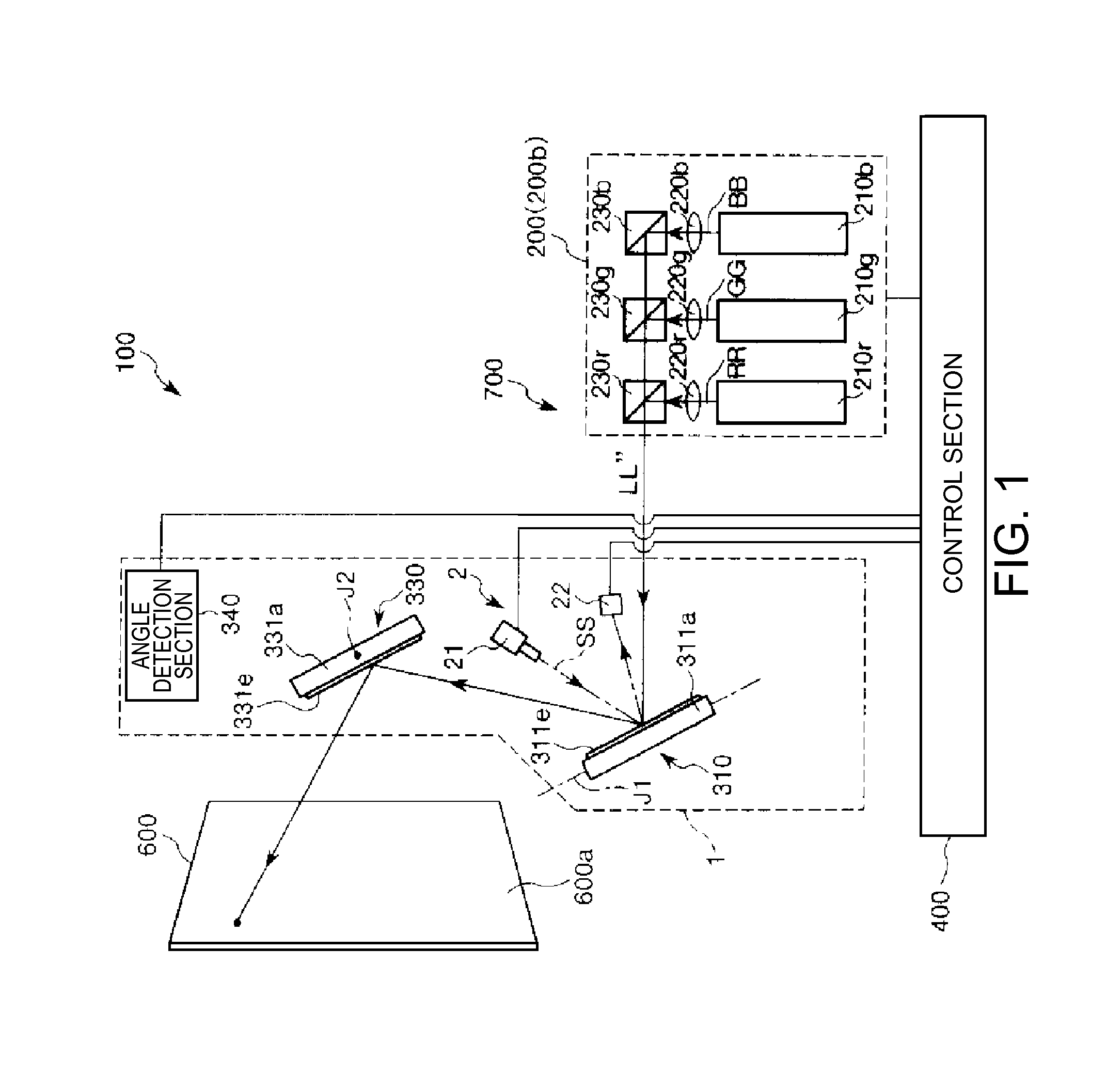

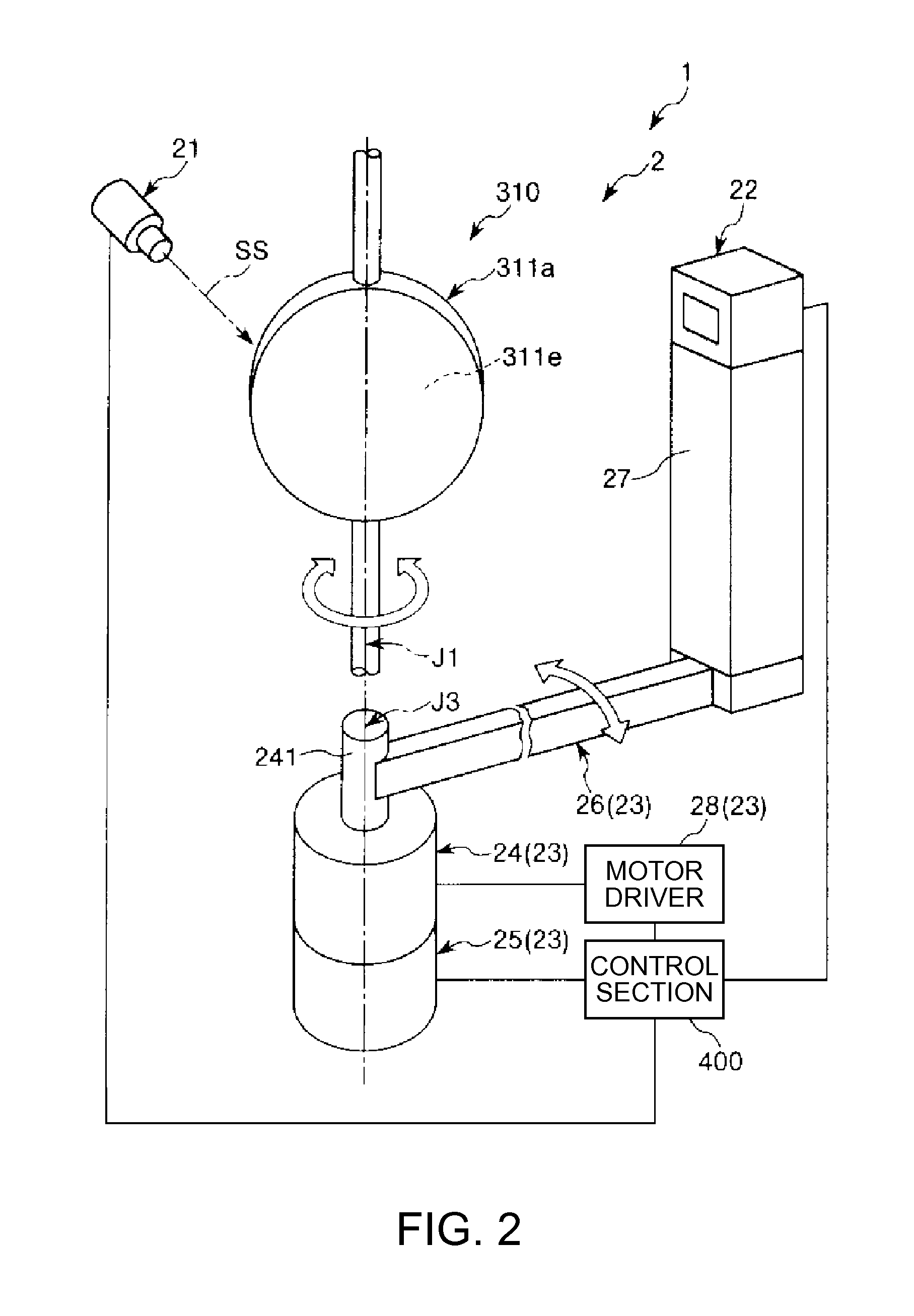

An industrial camera self-adaptive intelligent adjusting device

InactiveCN109068051AMaintain detection accuracyImprove detection accuracyTelevision system detailsColor television detailsExposureSelf adaptive

The invention discloses an industrial camera self-adaptive intelligent adjusting device, which comprises an industrial camera, a light source, a workpiece to be inspected, an industrial control computer, a back-and-forth moving device, a rotating device and a light source driver. The industrial camera collects images of the workpiece to be inspected and transmits data back to the industrial control computer. The back-and-forth moving device can control that backward and backward movement of the industrial camera to adjust the focal length of the camera, the rotating device adjusts the angle atwhich the light source irradiates the workpiece to be inspected, the light source driver adjusts the brightness of the light source, controls the exposure of the workpiece to be inspected when the image is collected, the industrial control computer analyzes and processes the image data to give a processing signal, and controls the back-and-forth moving device, the rotating device, and the light source driver. As that intelligent adjust device is adopted, real-time adjustment can be realize during production, high detection accuracy can be maintained, machine stoppage caused by unqualified detection due to product replacement or machine vibration and environmental change can be avoided, manual operation can be reduced, the degree of intelligence is high, and the use is convenient.

Owner:方汝松

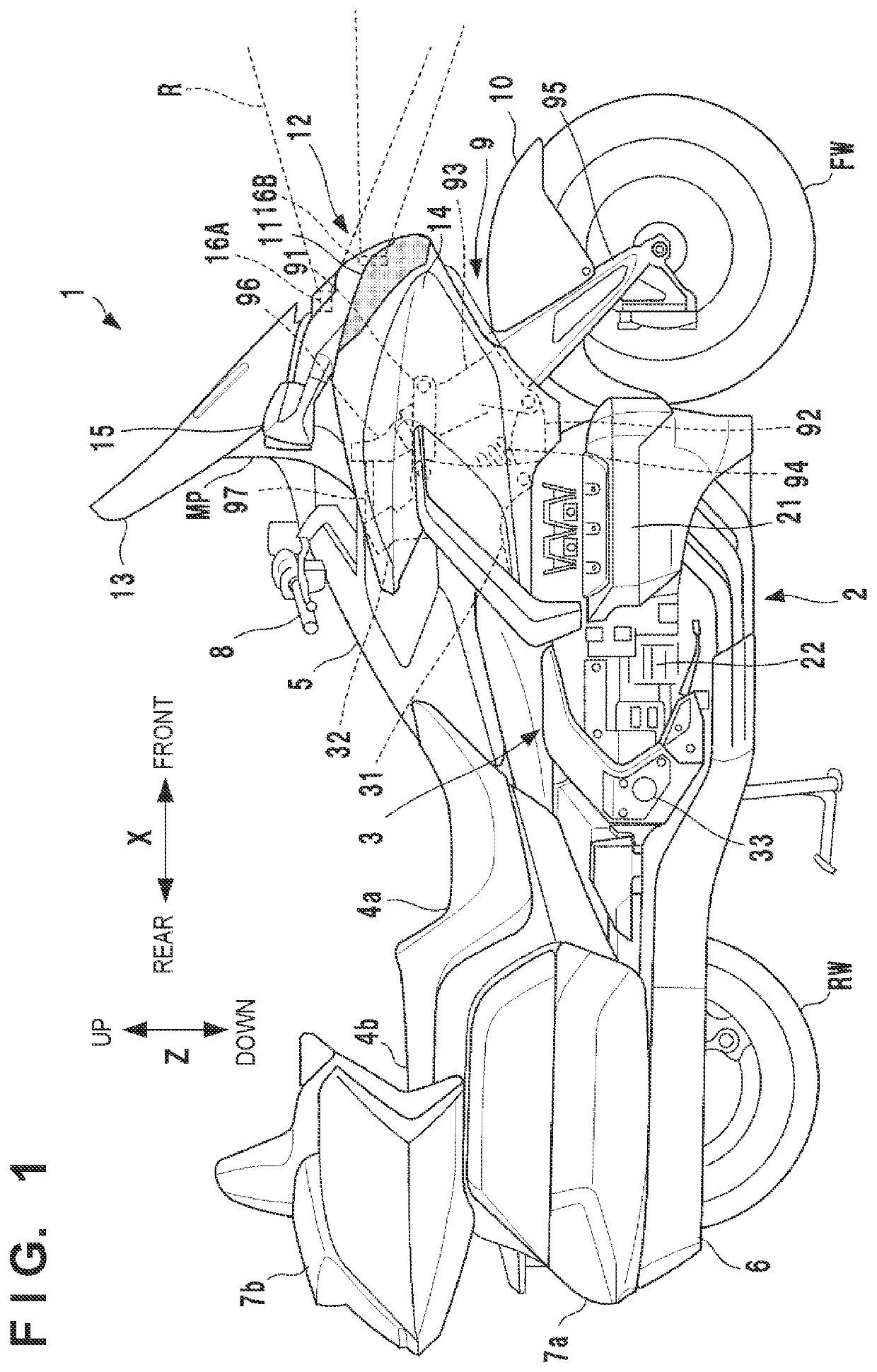

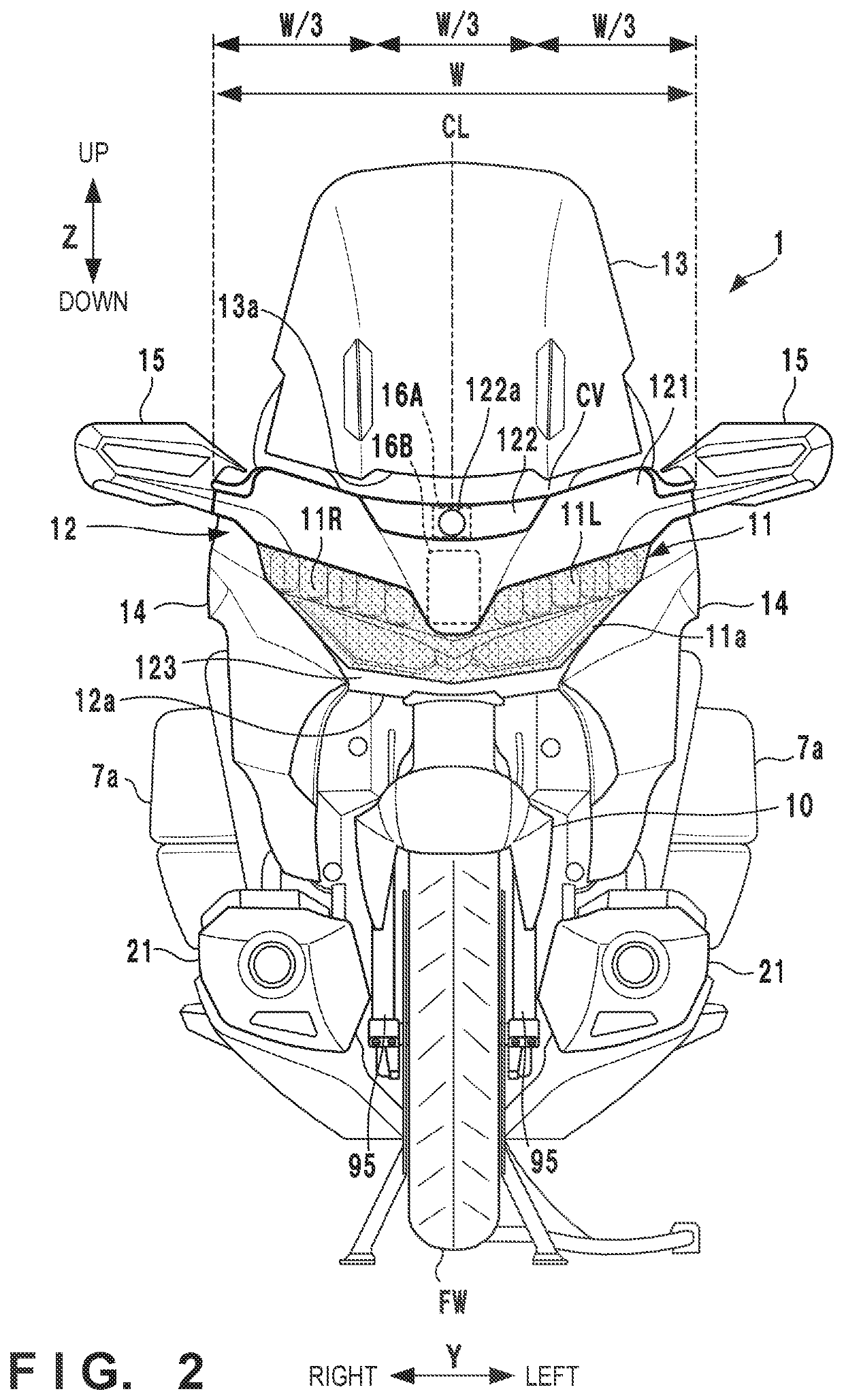

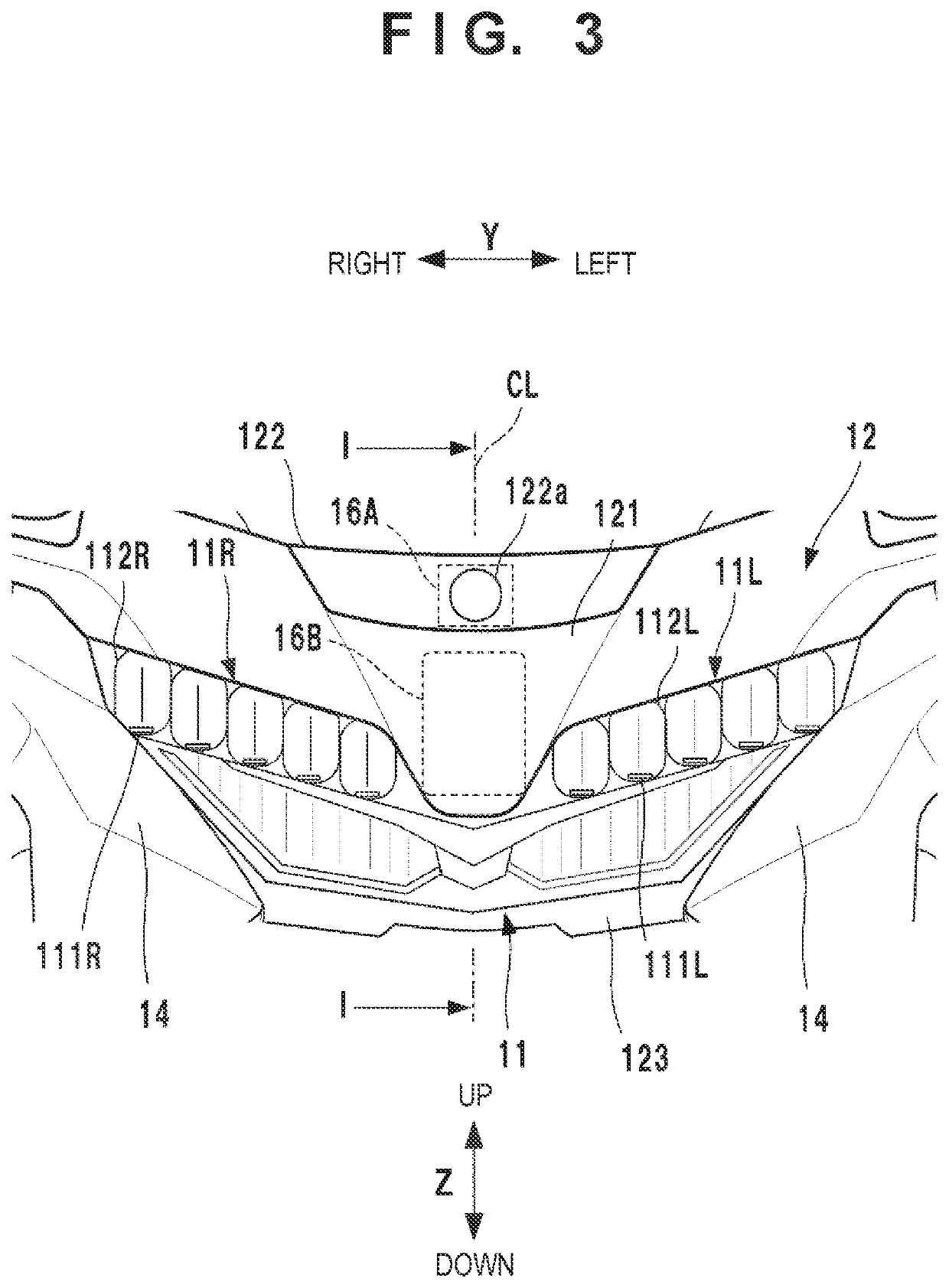

Straddle type vehicle

PendingUS20200398924A1Maintain detection accuracyOptical signalCycle safety equipmentsMechanical engineeringElectrical and Electronics engineering

A straddle type vehicle includes a front cowl configured to cover a front part of the vehicle, a shield arranged above the front cowl, and a detecting unit configured to detect a situation in front of the vehicle. The detecting unit includes at least an image capturing unit that is positioned above a lower end of the front cowl and in a central portion of the straddle type vehicle in a vehicle width direction, and is arranged in a position where the shield does not interfere with an image capturing range. The image capturing unit is arranged behind an upper portion of the front cowl.

Owner:HONDA MOTOR CO LTD

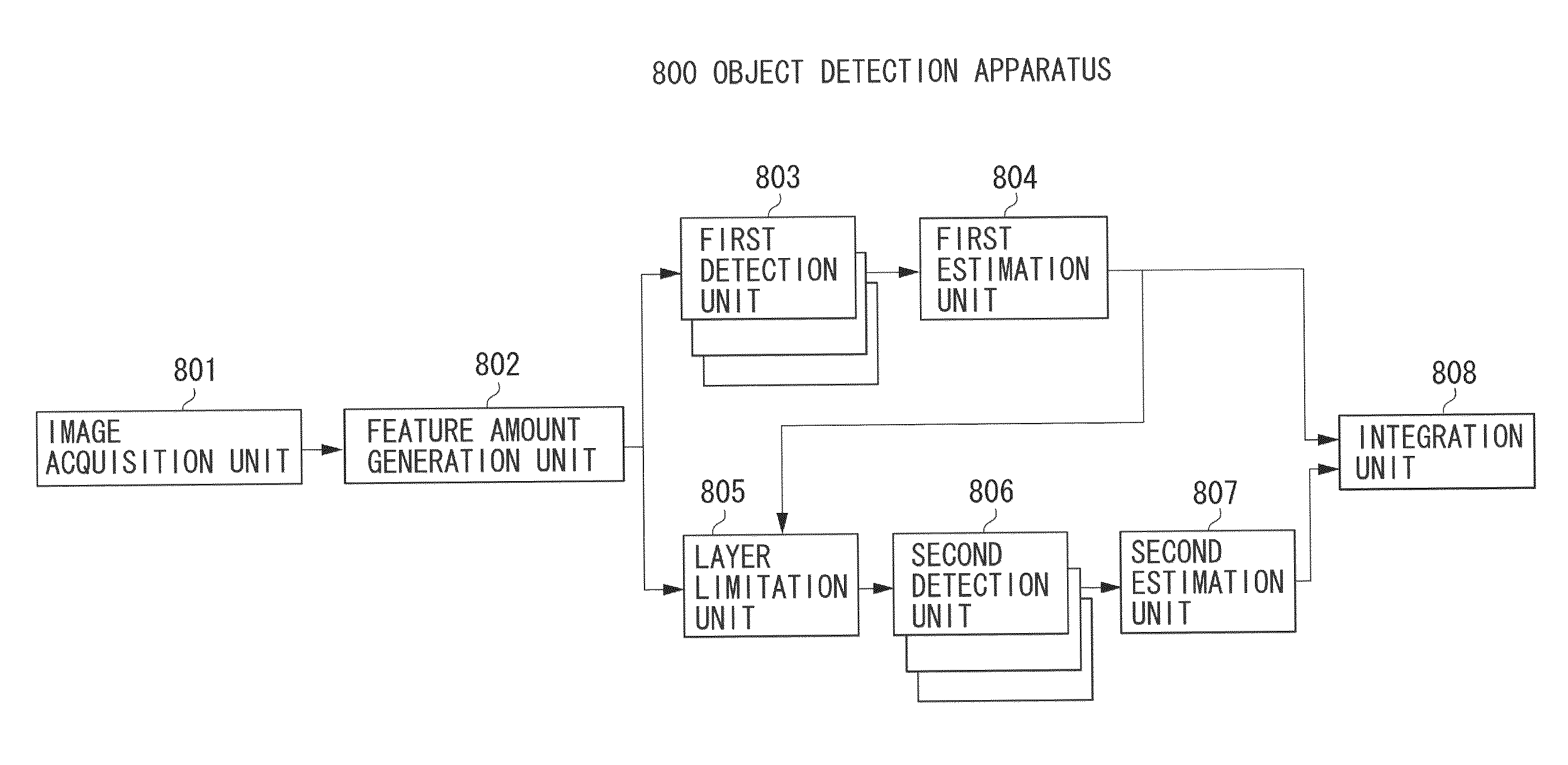

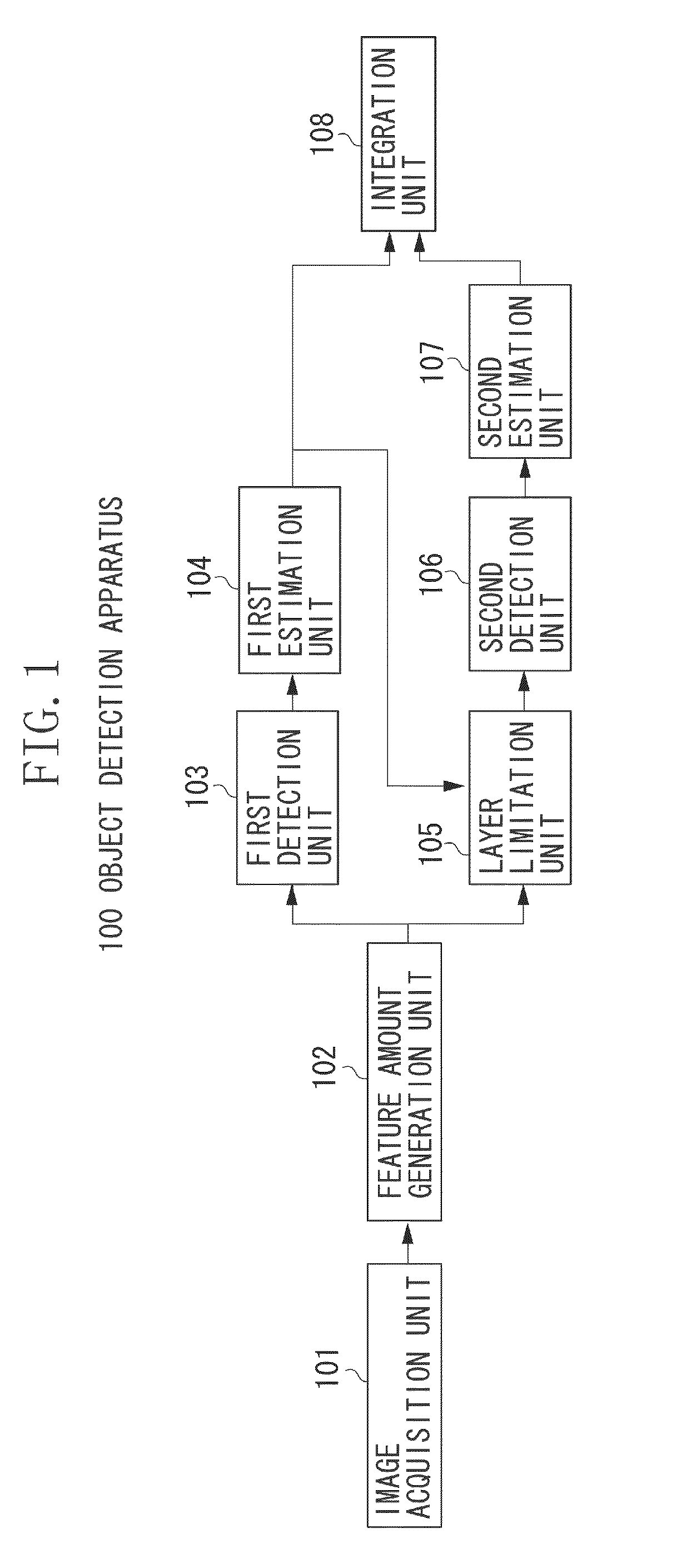

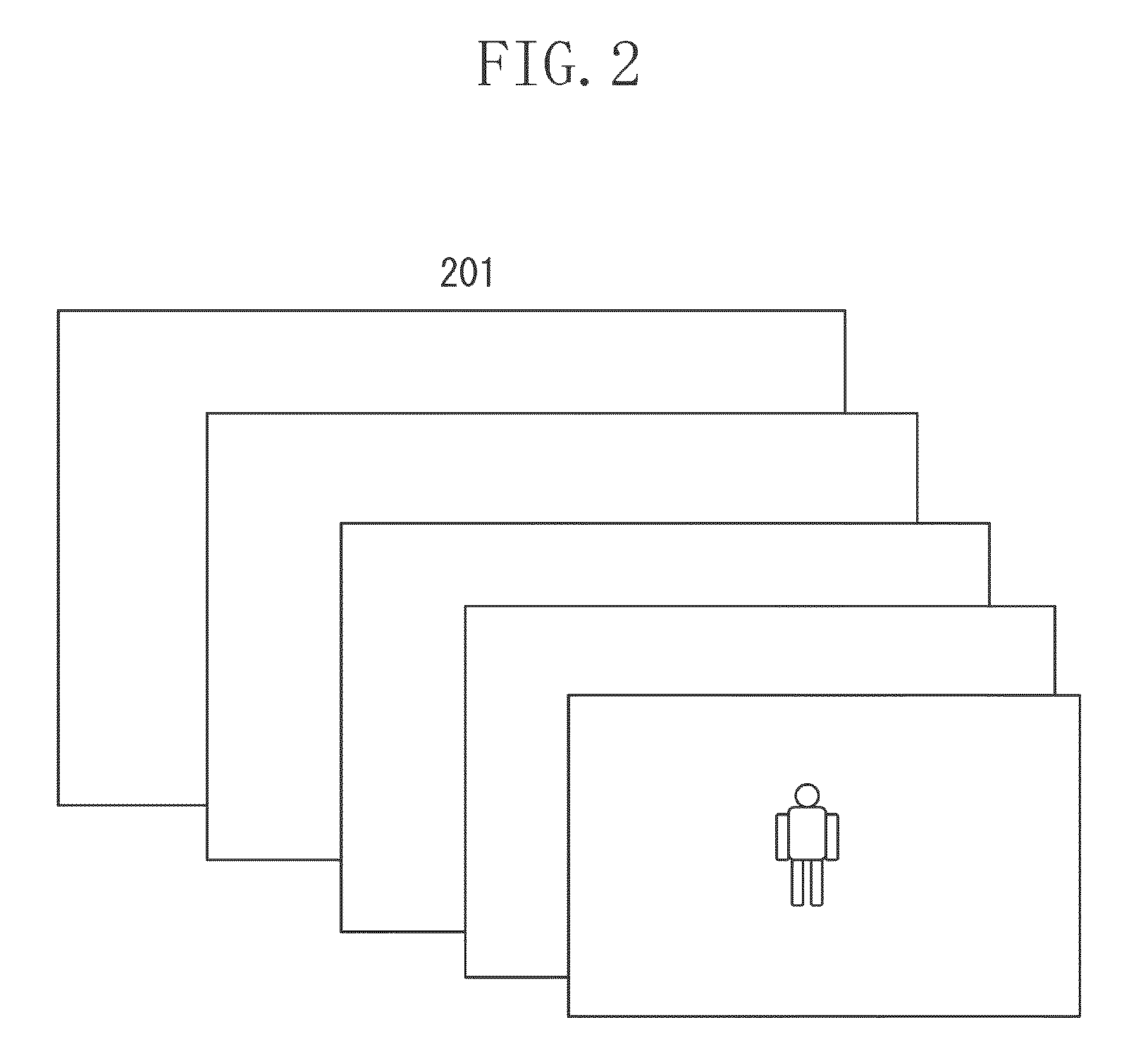

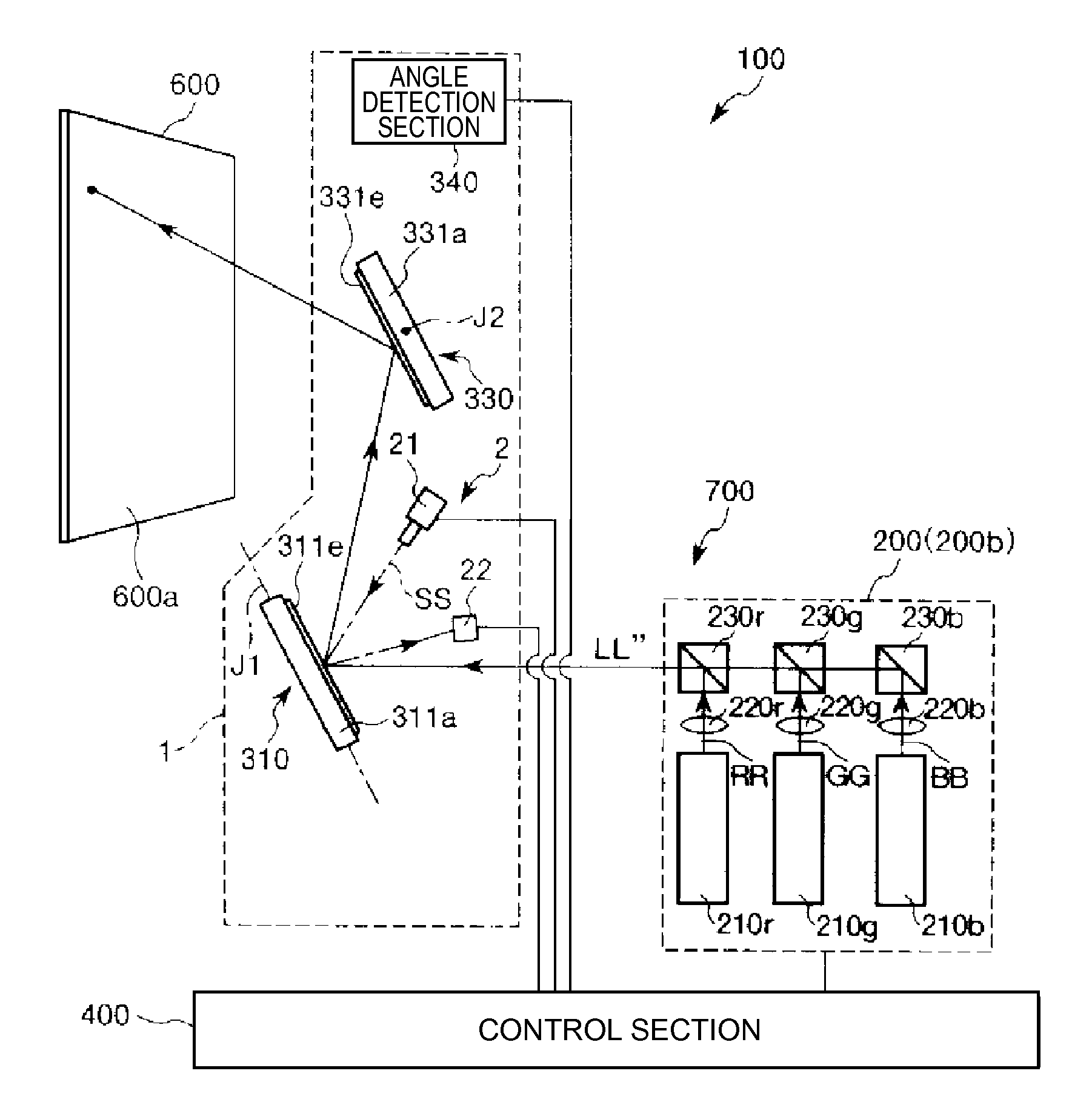

Object detection method, object detection apparatus, and program

ActiveUS9213909B2Processing speedMaintain detection accuracyGeometric image transformationBiometric pattern recognitionPattern recognitionLearning data

An object detection method includes an image acquisition step of acquiring an image including a target object, a layer image generation step of generating a plurality of layer images by one or both of enlarging and reducing the image at a plurality of different scales, a first detection step of detecting a region of at least a part of the target object as a first detected region from each of the layer images, a selection step of selecting at least one of the layer images based on the detected first detected region and learning data learned in advance, a second detection step of detecting a region of at least a part of the target object in the selected layer image as a second detected region, and an integration step of integrating a detection result detected in the first detection step and a detection result detected in the second detection step.

Owner:CANON KK

Light scanning device and image formation apparatus

ActiveUS20120257262A1Maintain detection accuracyDetection accuracy of the maximum deflection angle can be maintainedPhotometry using reference valueMaterial analysis by optical meansDeflection angleLight reflection

A light scanning device includes: a movable section which has a light reflection section reflecting light and oscillates around an oscillating axis and in which a maximum deflection angle thereof is variable; and a detection section which detects the maximum deflection angle of the movable section, wherein the detection section includes a light source which irradiates light toward the light reflection section, a light-receiving section which receives reflected light of the light from the light source, reflected by the light reflection section, and a displacement drive section which changes a position of the light-receiving section in accordance with the maximum deflection angle of the movable section.

Owner:SEIKO EPSON CORP

Magnetic sensor, production process of the magnetic sensor and magnetic array suitable for the production process

InactiveUS6940701B2Efficient magnetizationMaintain detection accuracyNanostructure applicationElectromagnets without armaturesElectrical polarityEarth's magnetic field

The present invention aims to provide a magnetic sensor provided with a magnetoresistive effect element capable of stably maintaining a direction of magnetization in a magnetic domain of a free layer.The magnetic sensor includes a magnetoresistive effect element provided with narrow zonal portions 11a . . . 11a including a pinned layer and a free layer. Disposed below both ends of the free layer are bias magnet films 11b . . . 11b composed of a permanent magnet that applies to the free layer a bias magnetic field in a predetermined direction and an initializing coil 31 that is disposed in the vicinity of the free layer and applies to the free layer a magnetic field having the direction same as that of the bias magnetic field by being energized under a predetermined condition. Further, magnetizing the bias magnet films and fixing the direction of magnetization of the pinned layer are performed by a magnetic field formed by a magnet array configured such that plural permanent magnets are arranged on a lattice point of a tetragonal lattice and a polarity of a magnet pole of each permanent magnet is different from a polarity of the other adjacent magnet pole spaced by the shortest route.

Owner:YAMAHA CORP

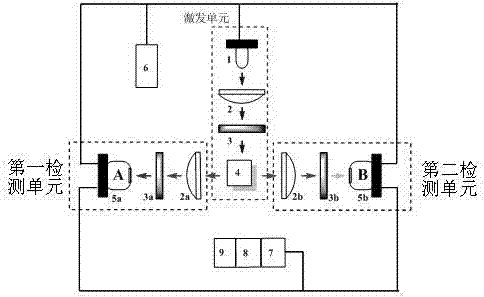

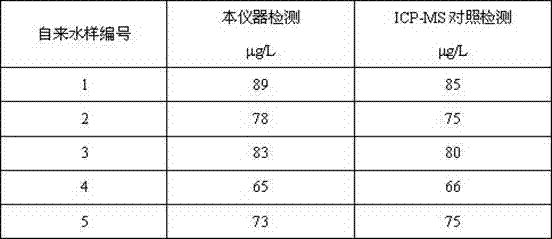

Trace substance detector with two fluorescence emission surfaces, and detection method

The invention discloses a trace substance detector with two fluorescence emission surfaces, and a detection method, and relates to an instrument used for detecting toxic and hazardous trace substances contained in environments, food, health care products, traditional Chinese medicines, cosmetics and the like in the technical field of spectrographic detection. The detector comprises an excitation unit, a first detection unit and a second detection unit, wherein the first detection unit is parallel to the second detection unit; the excitation unit is perpendicular to the first detection unit. Compared with a dual-waveband fluorescence intensity ratio detection system with a single fluorescence emission surface, the detector is not provided with a dichroic mirror or a fluorescence condensing lens on the basis of keeping the detection stability and an accuracy rate, so that a fluorescence loss is low; an optical path is short; the sensitivity is higher; a detection limit is lower. Under the equivalent condition of copper ion detection, by comparison of an optical system with two fluorescence emission surfaces and an optical system with a single fluorescence emission surface, the fluorescence detection strength is improved by 1.2 times and the detection limit is reduced from 0.03 mg / kg to 0.015 mg / kg. The detector is smaller in size and simple to operate, and can be used for on-site real-time quantitative rapid analysis and detection.

Owner:苏州尚稷电子科技有限公司

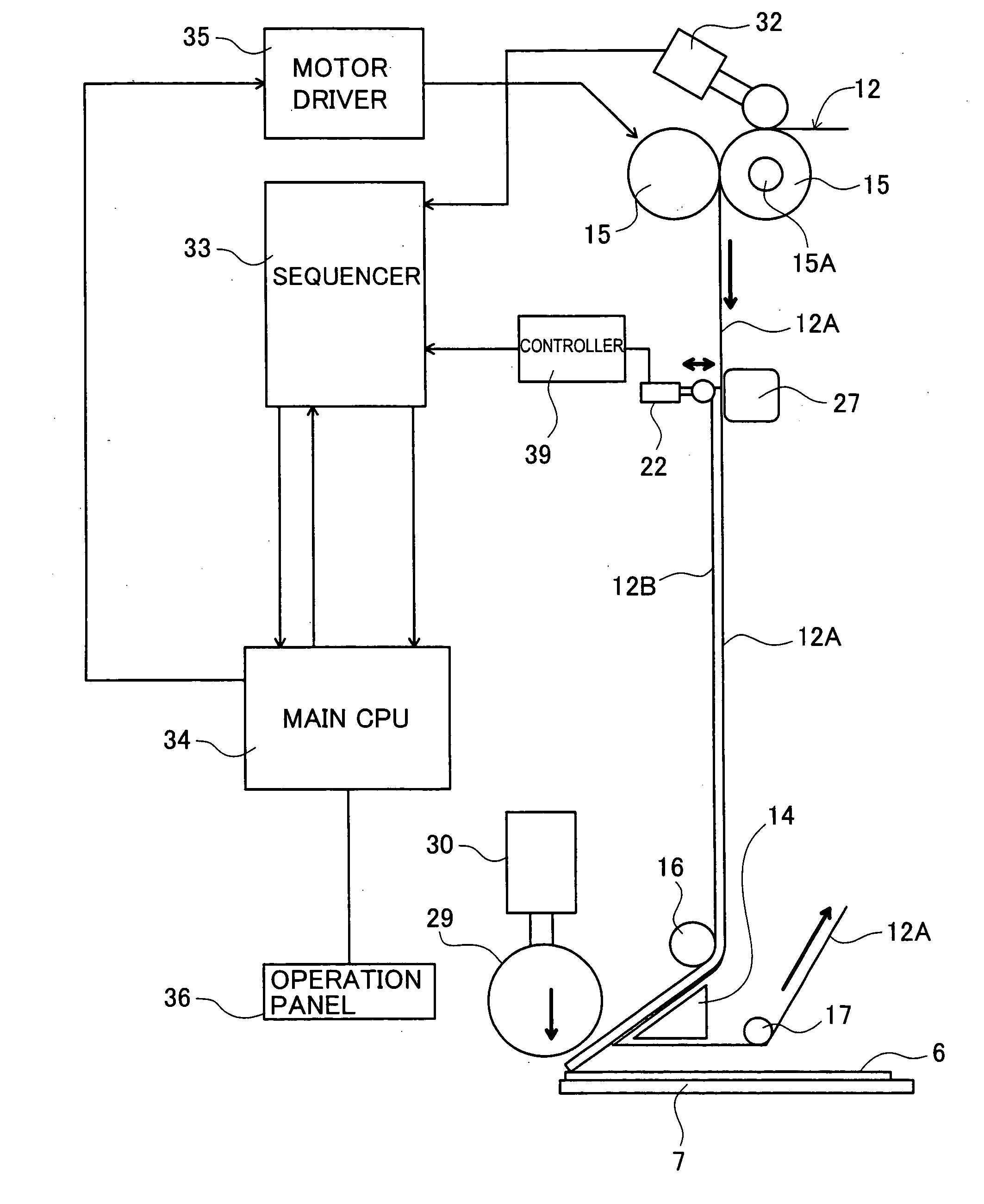

Adhesive film sticking apparatus

InactiveUS20060027331A1Reliable detectionFlexible operationAdhesivesLabelling machinesContactorEngineering

For detection of an adhesive film adhesively provided on a base tape of a film supply tape, a front end of the adhesive film is detected based on the detection of a predetermined displacement amount of a roller contactor of a detection sensor, the roller contactor being displaceable in a direction of thickness of the adhesive film. Based on a detection signal from the detection sensor, feeding rollers and others are controlled to feed the film supply tape by a predetermined feeding amount until the front end of the adhesive film comes to near a fold-back point of the base tape by a guide member.

Owner:NITTO DENKO CORP

Range detection device

ActiveUS8253409B2Easy to manufactureMaintain detection accuracyMagnetic measurementsGearing controlEngineeringMechanical engineering

In a range detection device, a movable member has a magnetized portion and can move with a manual valve of a control device. A supporting member includes a plate portion having a surface opposed to the magnetized portion and a recess formed in an opposite surface of the plate portion, and supports the movable member such that the movable member is capable of moving parallel with the plate portion. A substrate is placed in the recess and has a first hole that penetrates the substrate. A magnetic detection element is installed to a surface of the substrate at a side of the plate portion to correspond to a position of the first hole, and detects magnetism of the magnetized portion. A sealing member is filled in the recess and covers the substrate and the magnetic detection element.

Owner:DENSO CORP

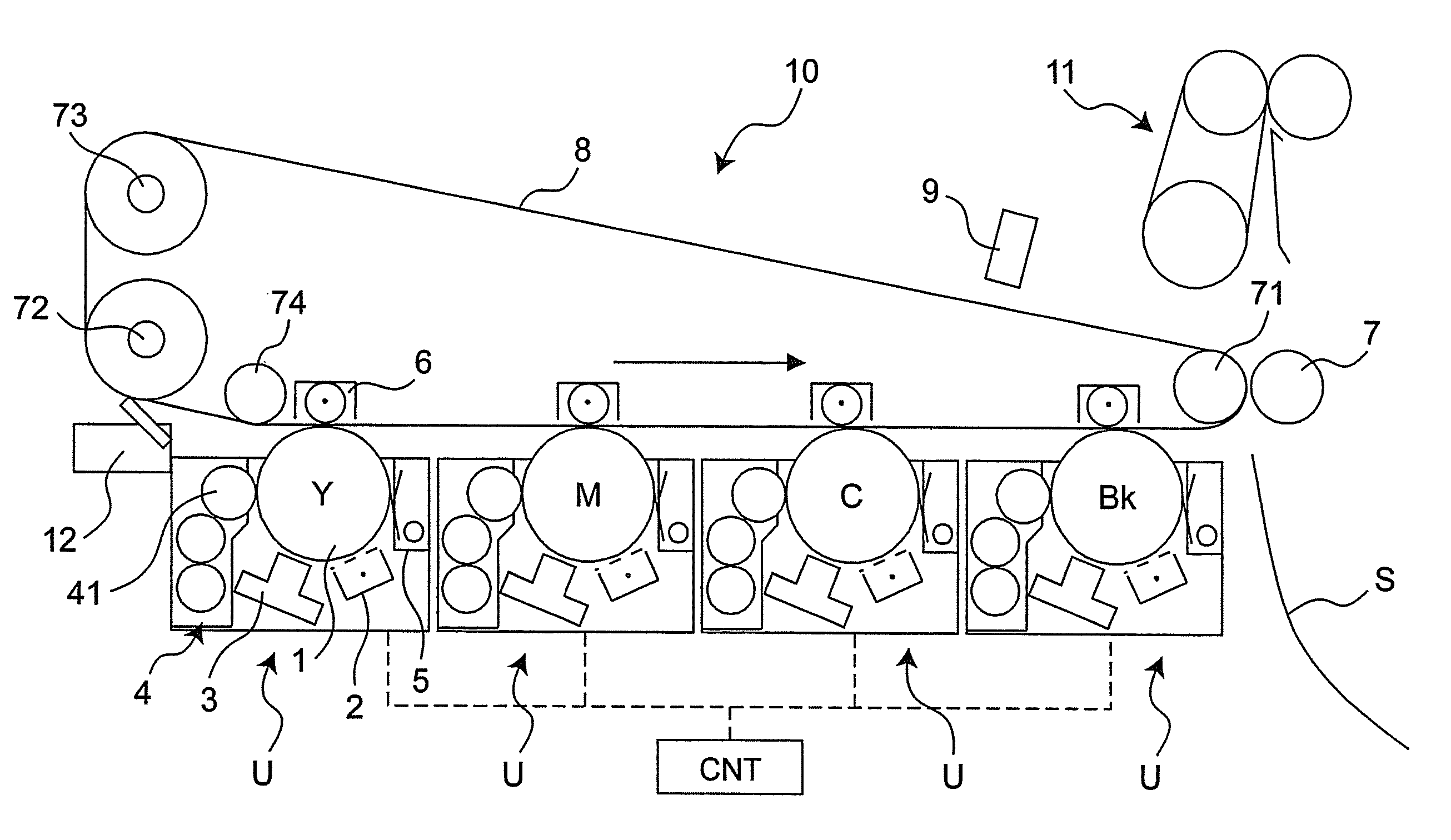

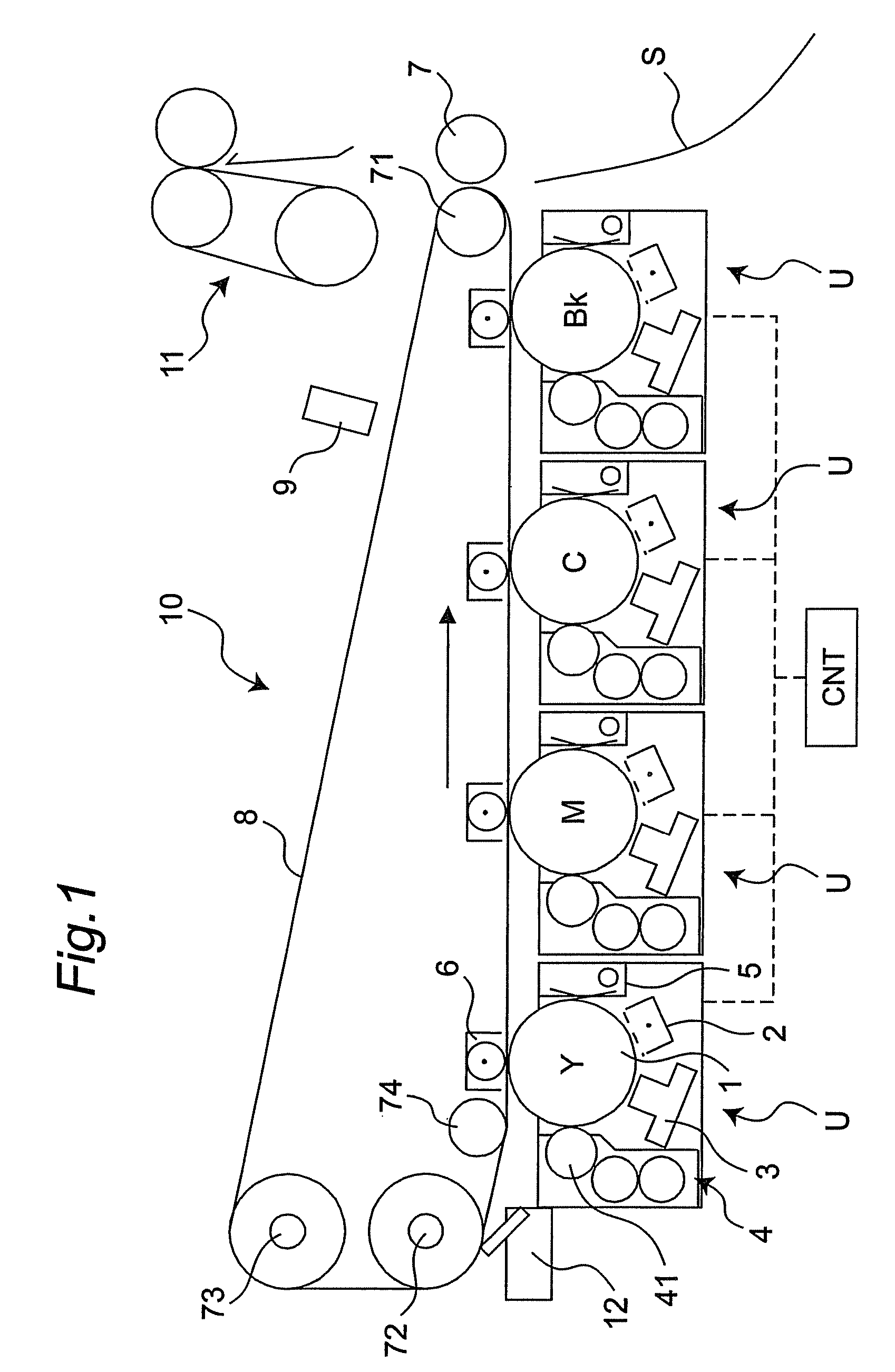

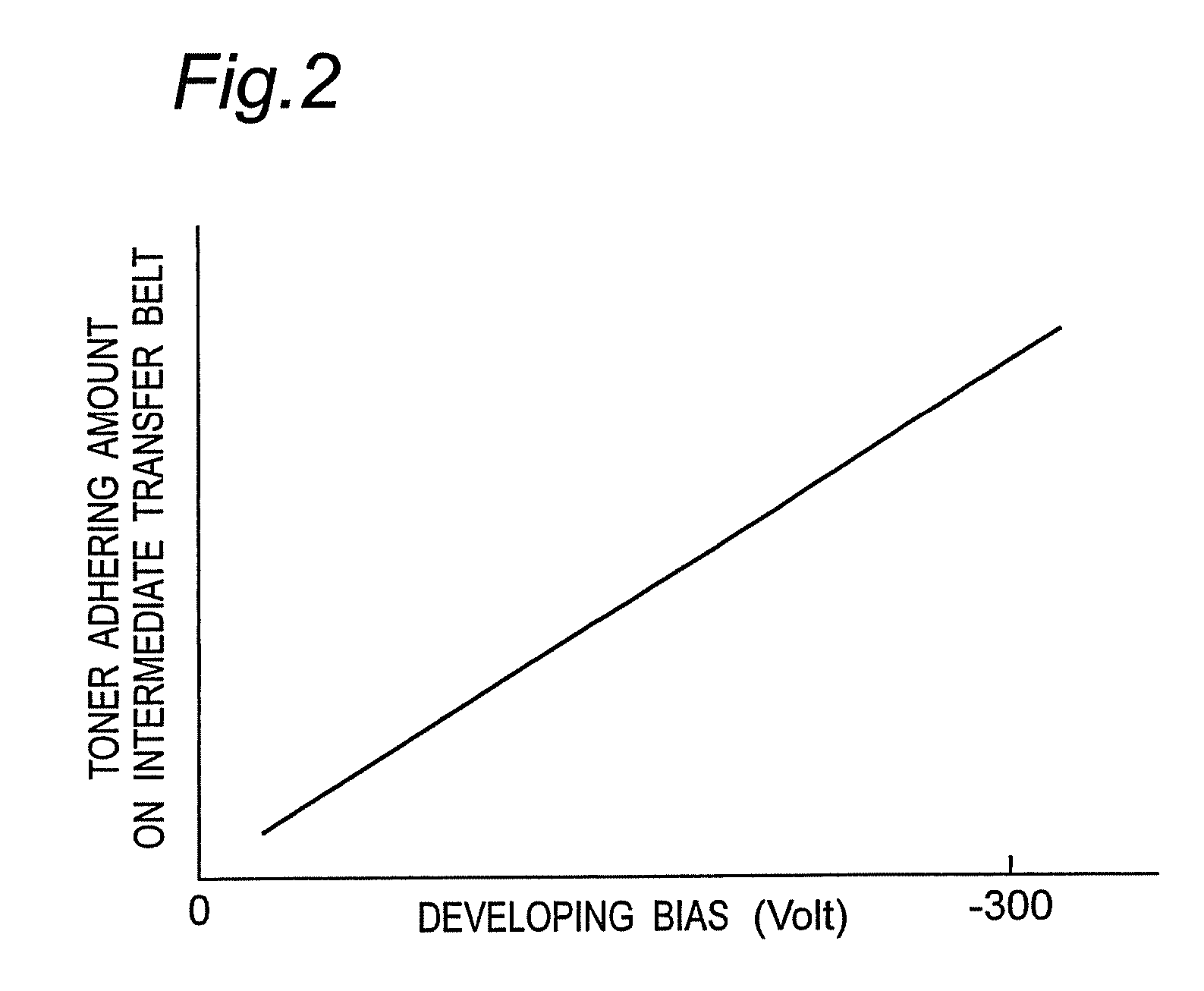

Image forming apparatus and image forming method

InactiveUS8005379B2Decreases waste toner amount and toner consumptionShorten the timeElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

Advanced collimator aperture curve

ActiveUS9395313B2Avoiding or reducing the additional radiation doseMaintain detection accuracyHandling using diaphragms/collimetersComputerised tomographsRadiation raysCt imaging

A CT imaging system and a method for determining a CT collimator slit profile. The method includes determining a profile of two opposite edges of the collimator slit in a longitudinal direction thereof based on the following: a vertical distance between a focus of a radiation source to the collimator slit, a vertical distance between the focus and the radiation detector, an inclination angle between adjacent detector elements, a length of each detector element, a desired width of projection on the radiation detector by the radiation rays passing through the slit whose longitudinal edge profile is to be determined, and an offset angle of a connecting line from a point on a longitudinal center line of the slit to the focus relative to a plane passing said focus and perpendicular to the slit.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Insulation measuring apparatus

ActiveUS8368406B2Low costReduced measurement timeVery high resistance measurementsMaterial analysis by electric/magnetic meansCapacitorVoltage

An insulation measuring apparatus having a measuring circuit including a first capacitor; a control unit that reads a voltage set on the first capacitor to decide an insulation state of a power supply, and control a path configuration of the measuring circuit; a switching section provided in a path located between the measuring circuit and the control unit; and a second capacitor provided between a ground and a path located between the switching section and the control unit. The control unit controls the path configuration of the measuring circuit, by turning ON the switching section to set a voltage corresponding to the voltage that is set on the first capacitor on the second capacitor, and then by turning OFF the switching section to read the voltage set on the second capacitor and to discharge an electric charge corresponding to the voltage being set on the first capacitor.

Owner:YAZAKI CORP

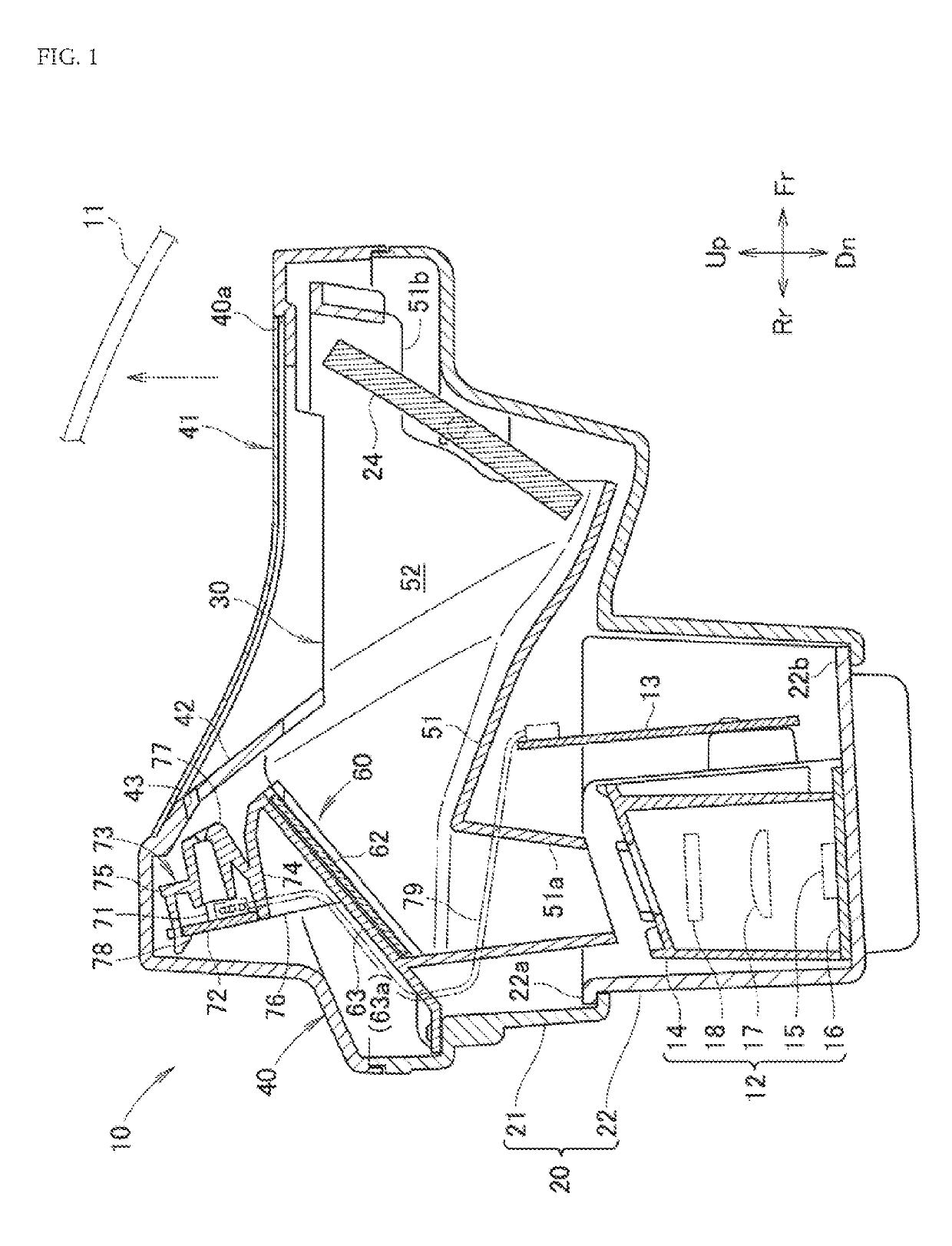

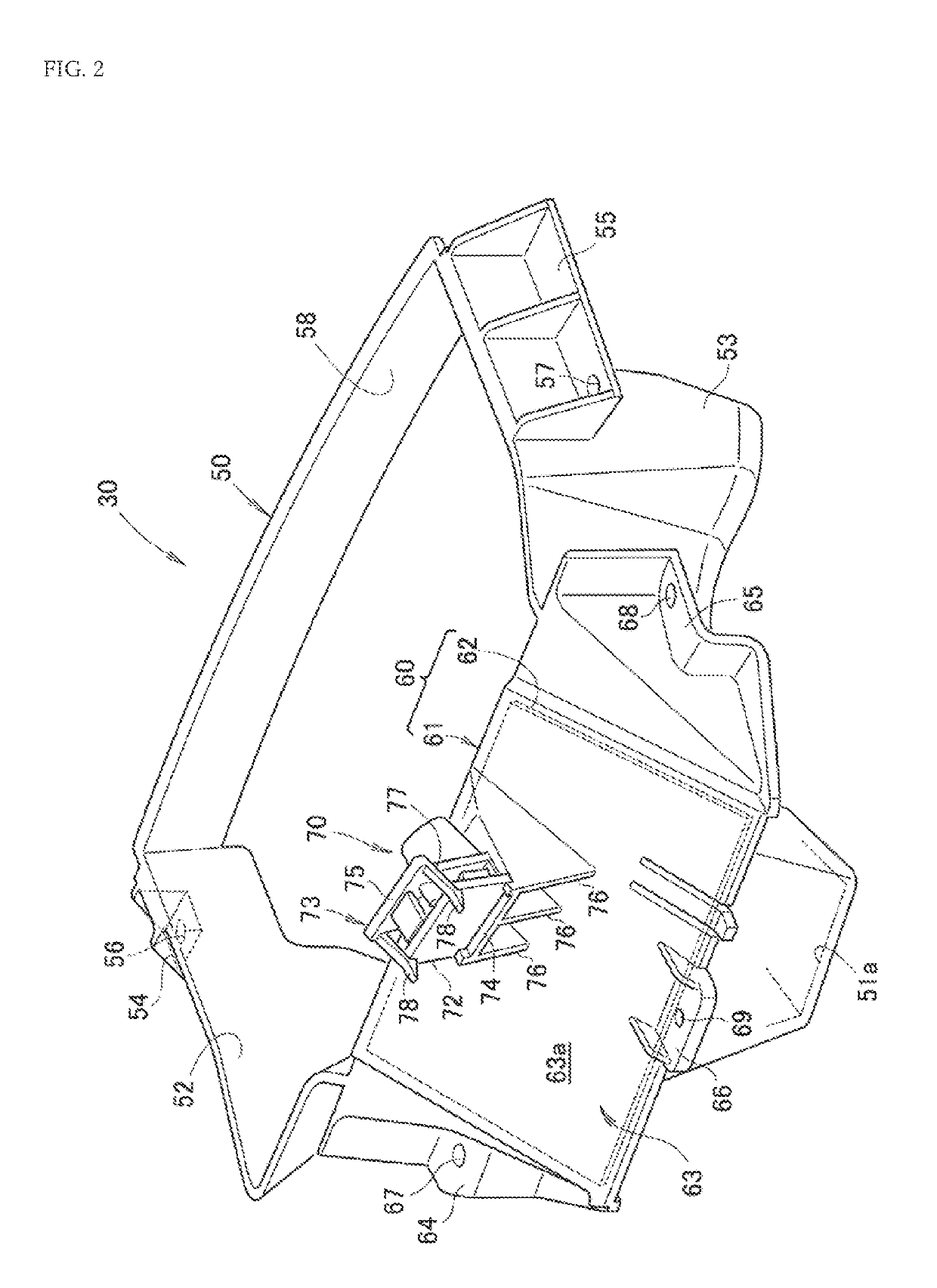

Head-up display device

ActiveUS20190293932A1Fitting of the lid body is facilitatedReduce detectionProjectorsVehicle componentsHead-up displayDisplay device

Provided is a head-up display device wherein in a state where a light-receiving unit is connected to a control substrate, a lid can be easily mounted to a case. Housed in a case of a head-up display device are a substrate for controlling a projector and a reflection unit for reflecting light projected thereon by the projector. The reflection unit is configured to have a reflecting mirror that is held by a holder, while the substrate is connected, via a connection member, with a light-receiving unit for detecting light from outside. The light-receiving unit is configured to have a light-receiving sensor that is held by a sensor holding part. The sensor holding part for holding the light-receiving sensor is held by the holder.

Owner:NIPPON SEIKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com