An industrial camera self-adaptive intelligent adjusting device

An industrial camera and intelligent adjustment technology, which is applied to TVs, color TV parts, electrical components, etc., can solve problems such as high professionalism requirements for adjustment personnel, complex and time-consuming manual adjustments, and impact on detection accuracy, etc., to reduce production waits time, avoiding deterioration of detection accuracy, and the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

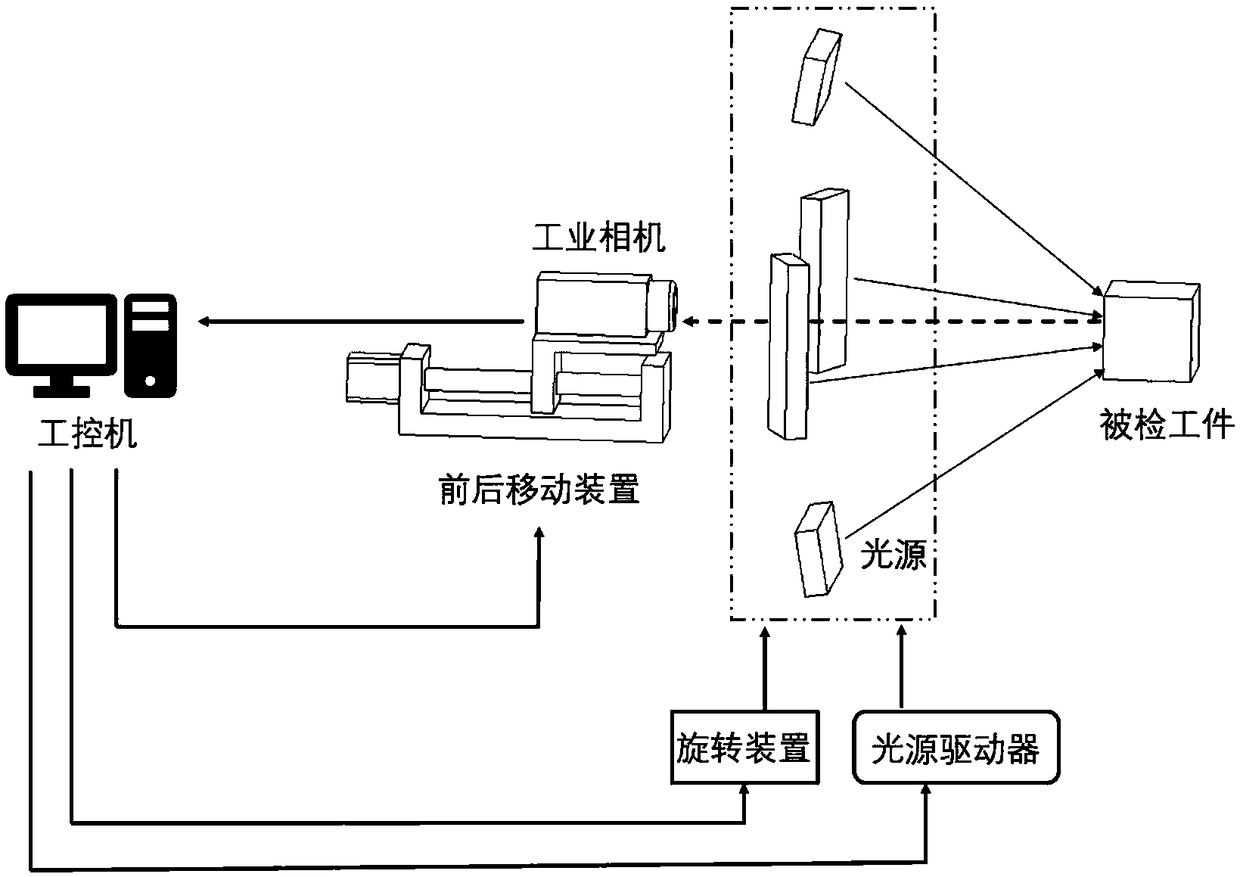

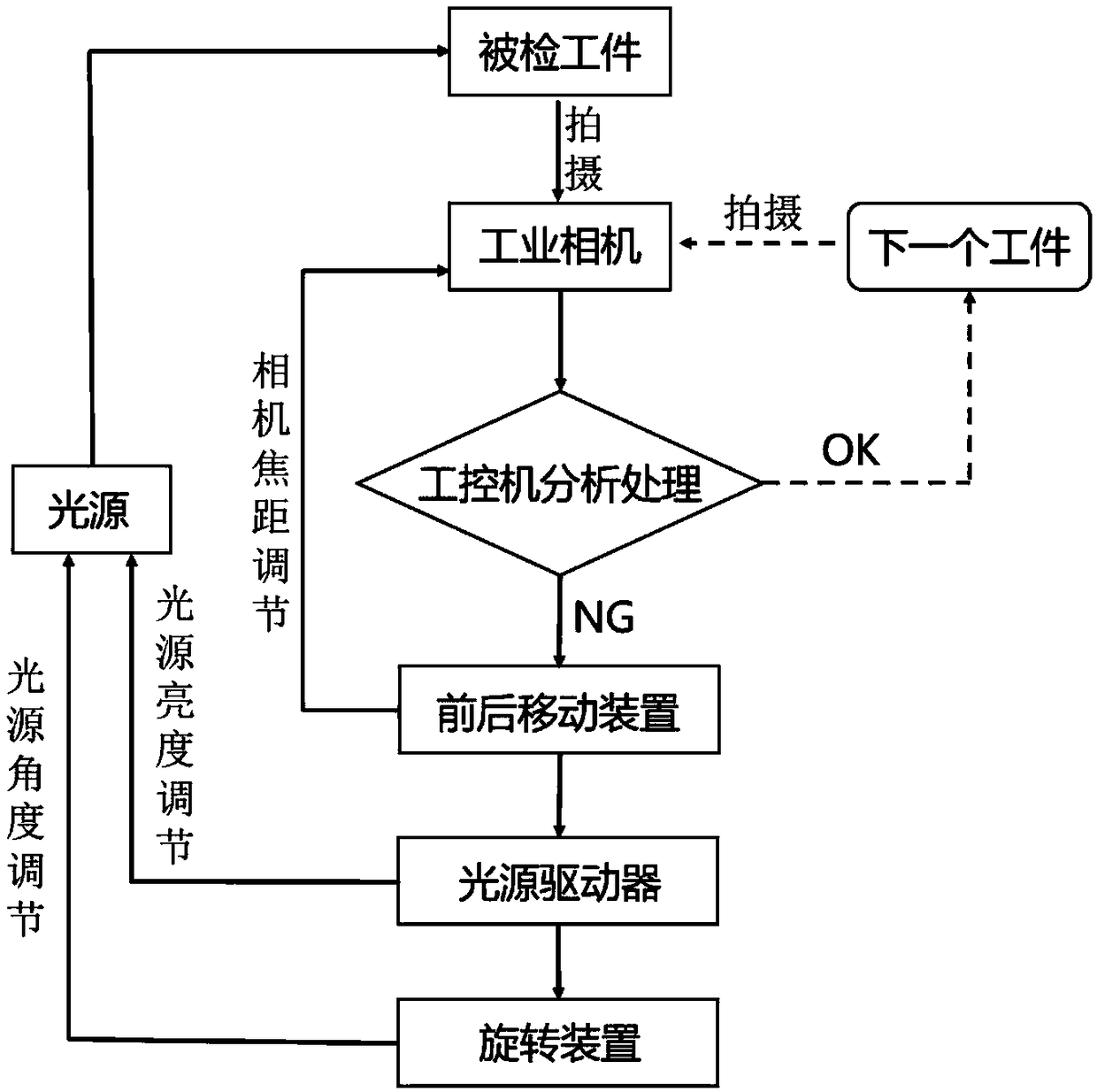

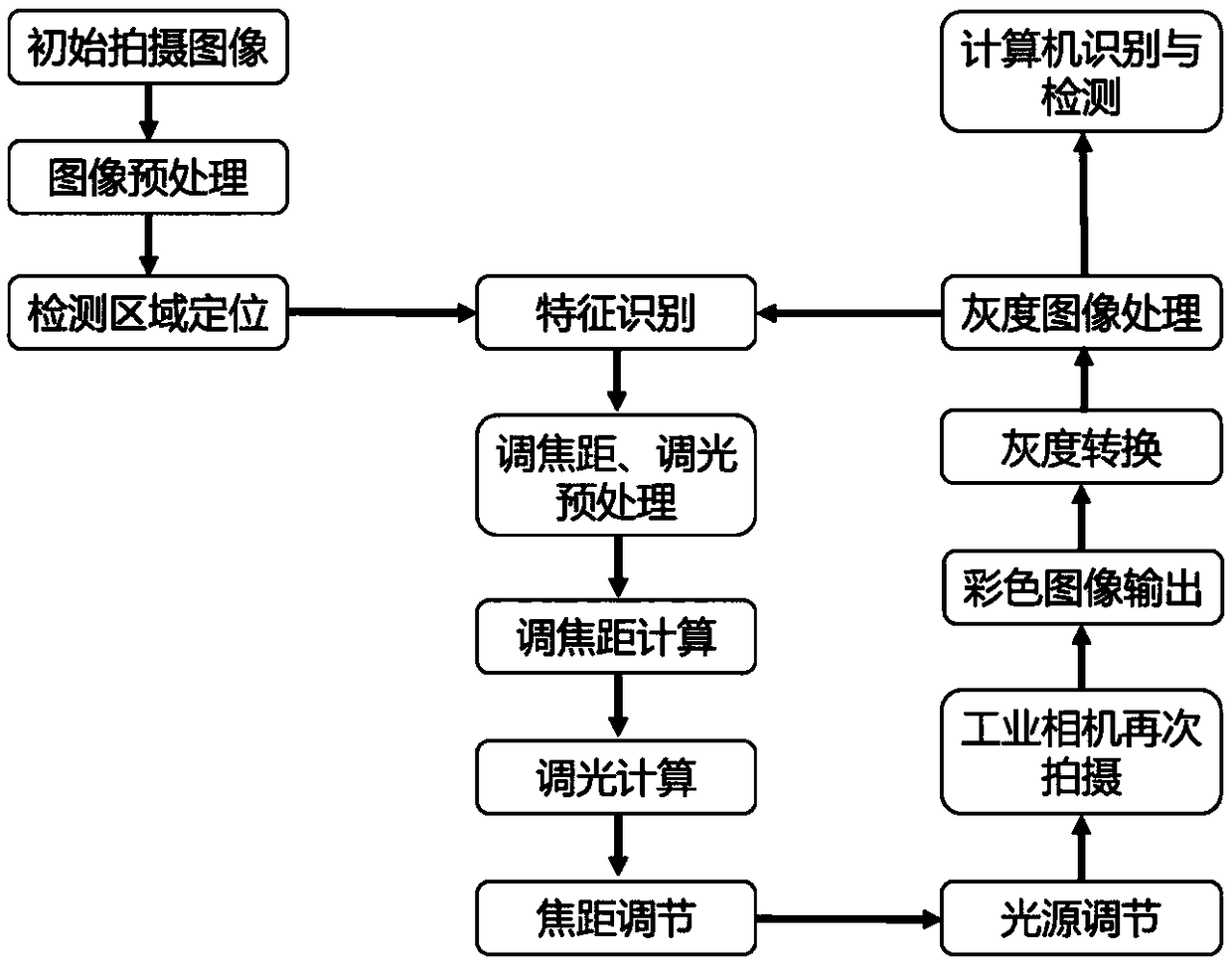

[0029] The industrial camera adaptive intelligent adjustment device is composed of hardware and algorithm programs. The composition of the industrial camera adaptive intelligent adjustment device is as follows: figure 1 As shown, it includes industrial camera, light source, inspected workpiece, industrial computer, forward and backward moving device, rotating device, and light source driver. The industrial camera combines the light source to collect the image of the inspected workpiece and transmit the data back to the industrial computer. The industrial computer analyzes and processes the collected image data according to the algorithm program, and gives processing signals to control the front and rear moving devices, rotating devices and light source drivers. The forward and backward moving device can control the industrial camera to move forward and back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com