Patents

Literature

53results about How to "Avoid detection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

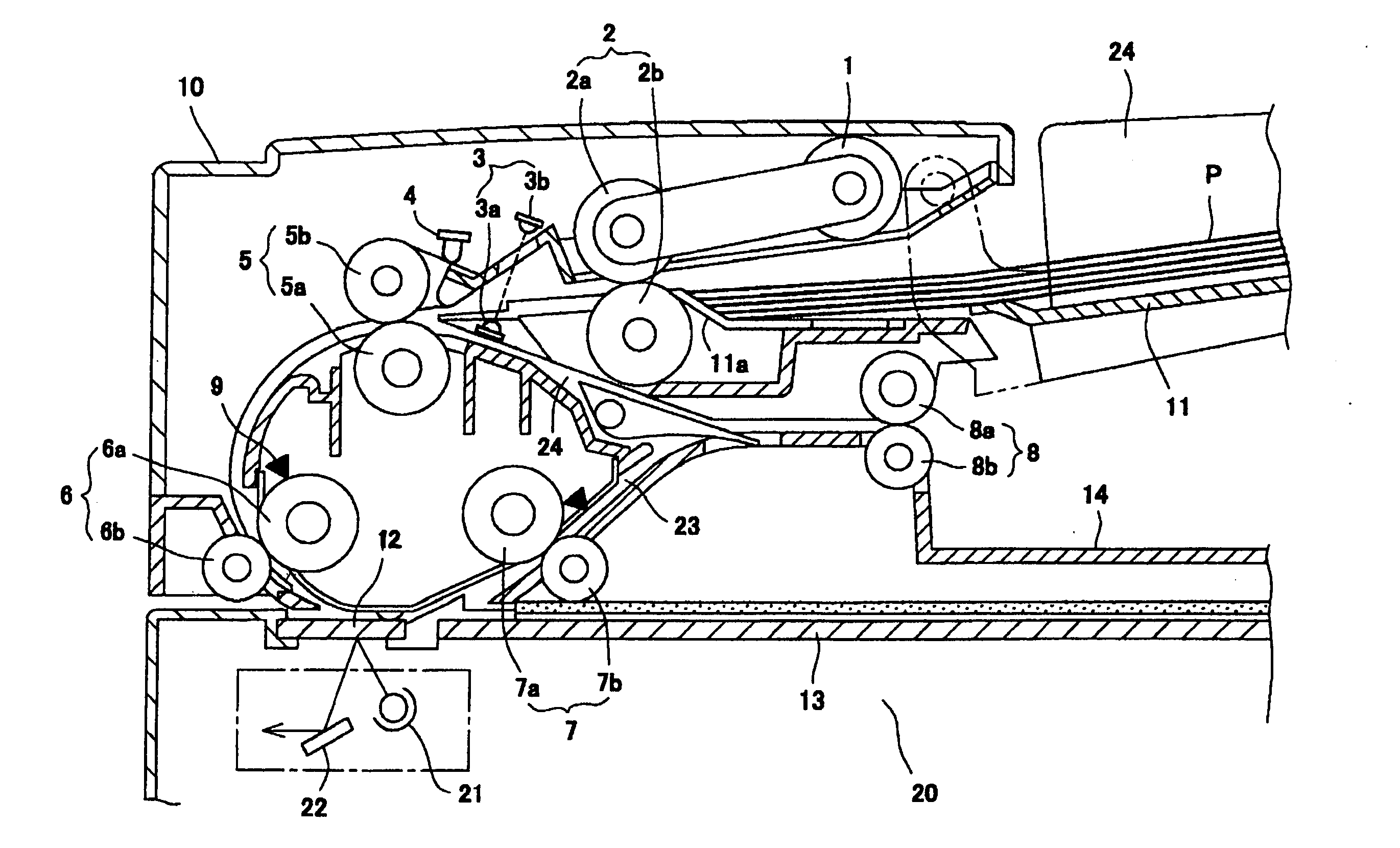

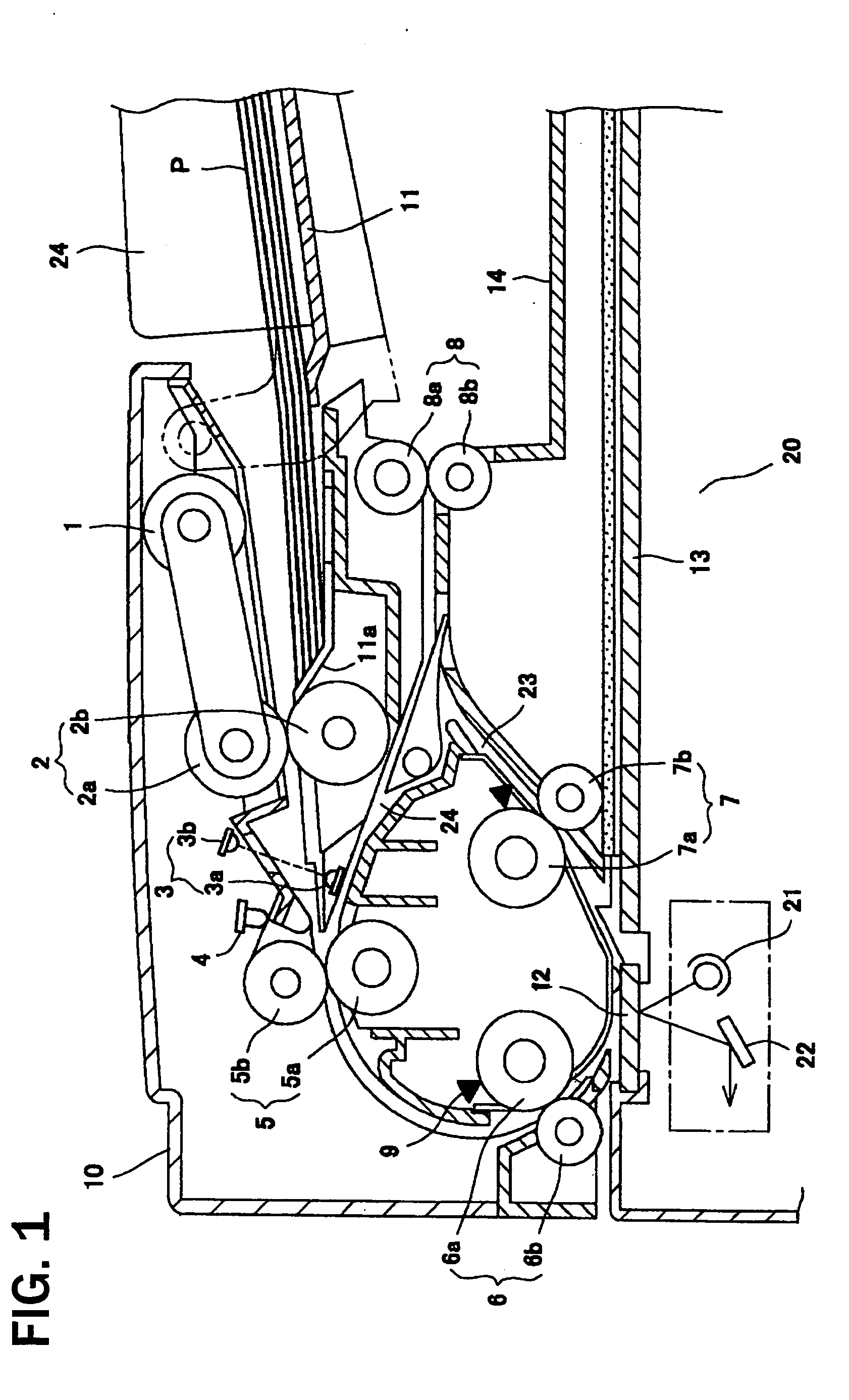

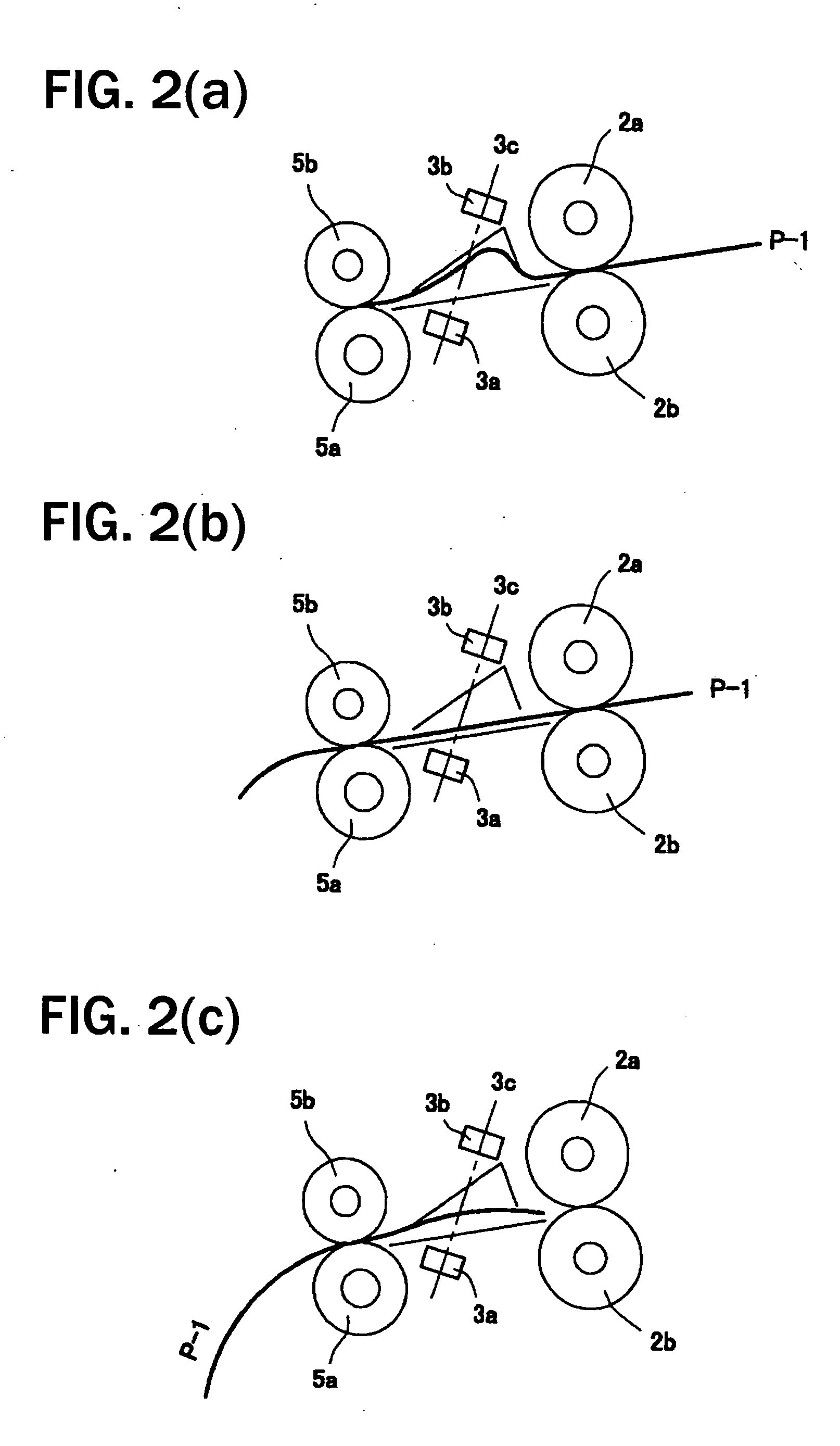

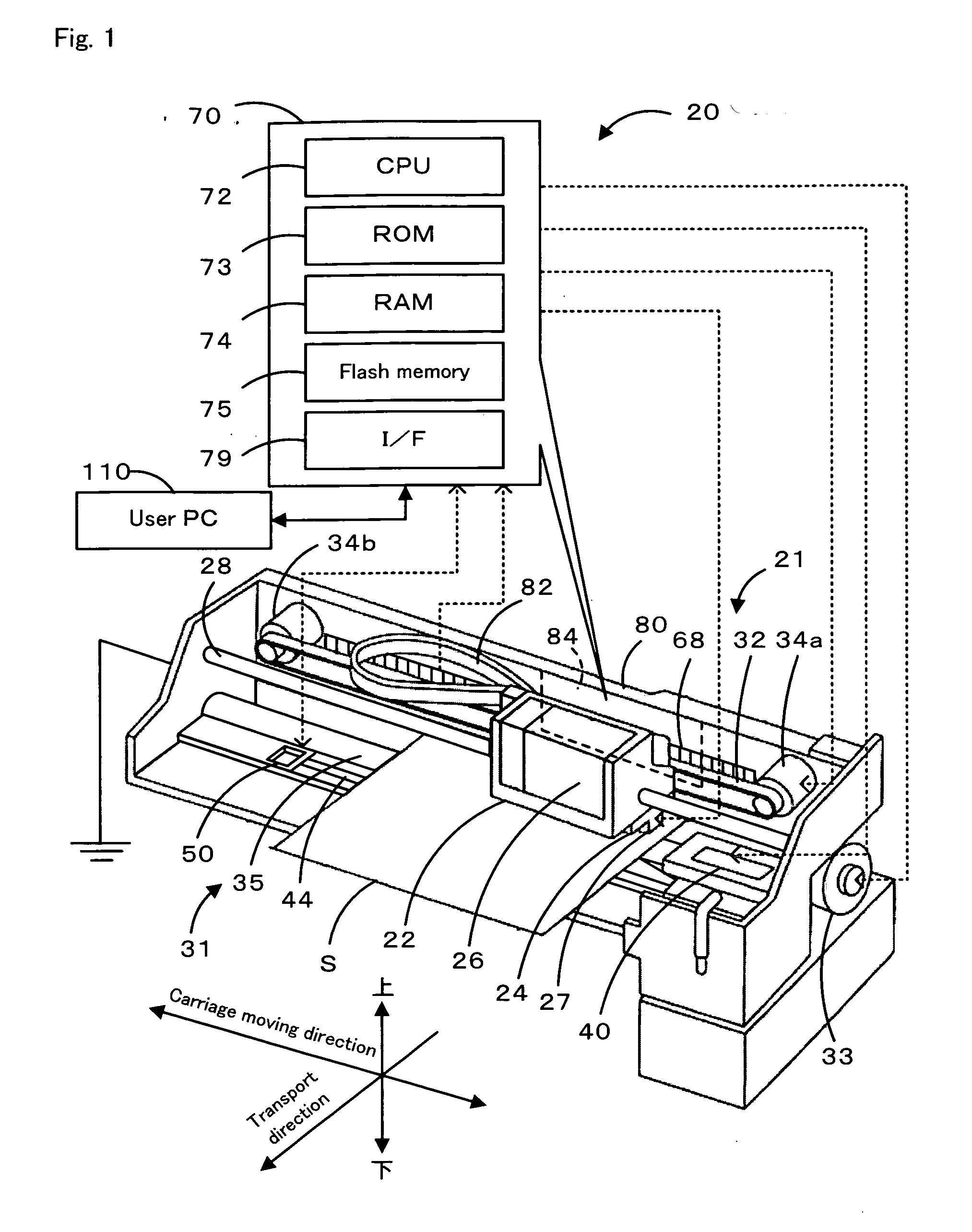

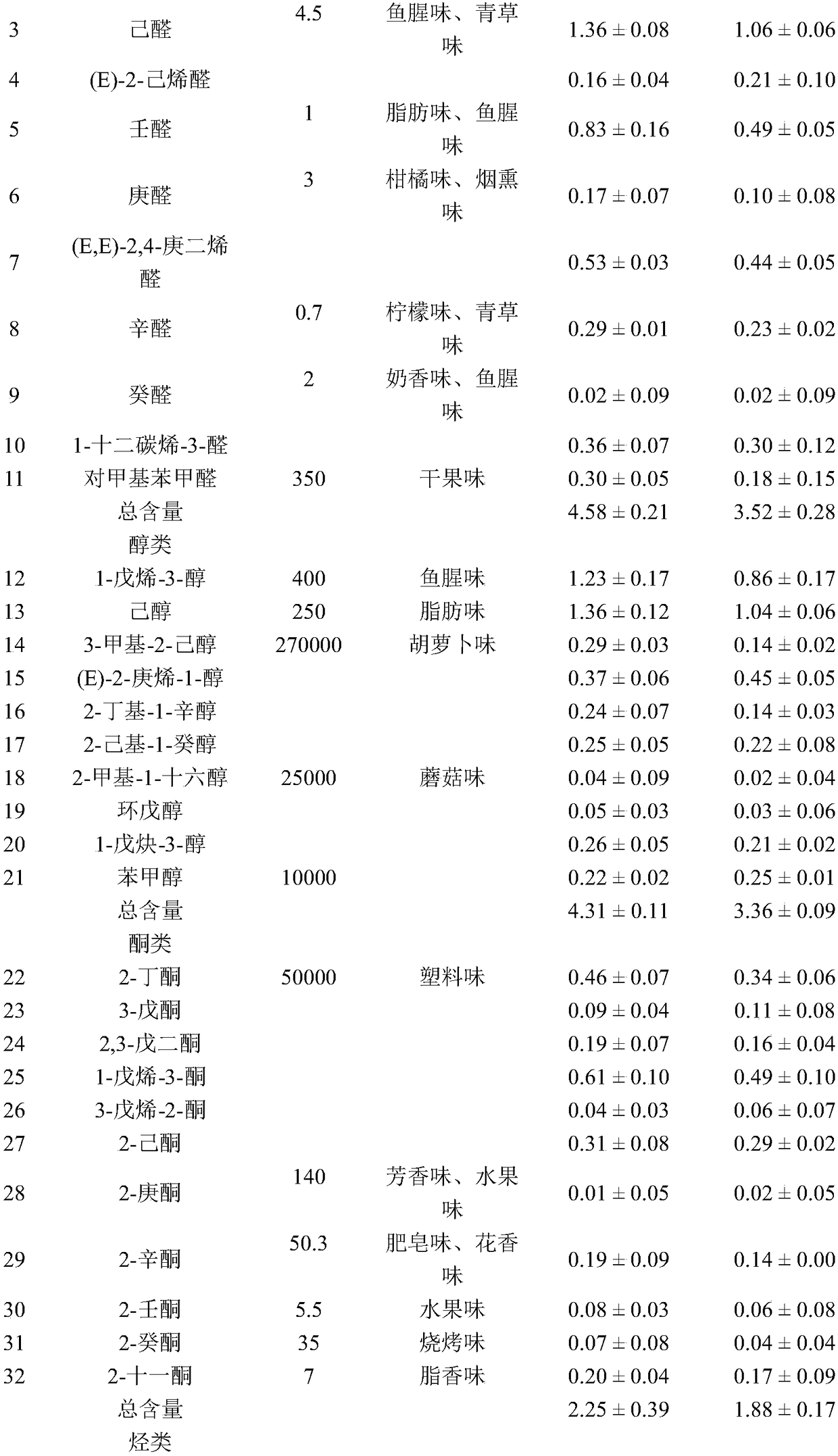

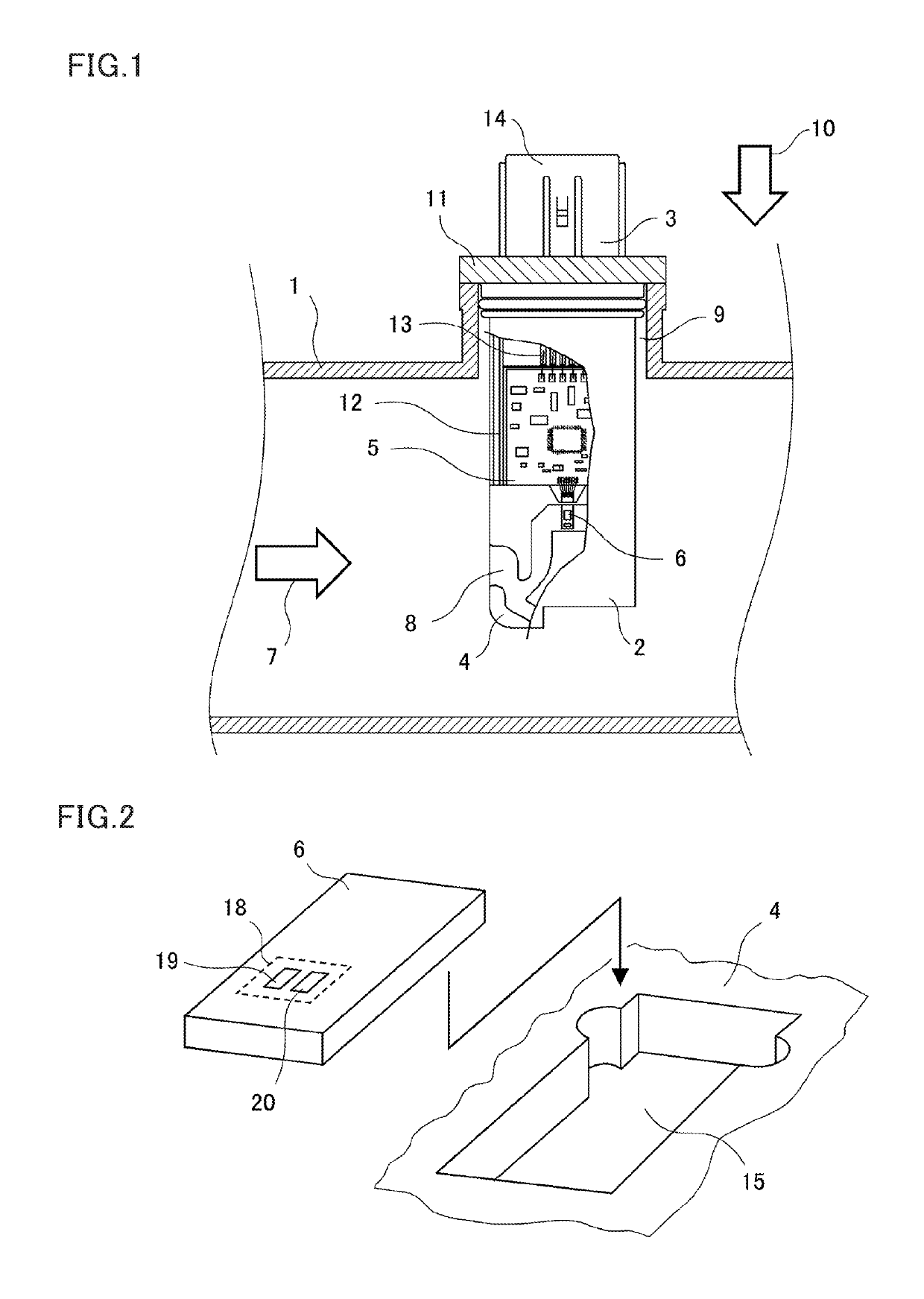

Sheet handling apparatus and image reading apparatus

InactiveUS20050012259A1Accurate detectionSimple structureTesting/calibration apparatusRegistering devicesElectricityEngineering

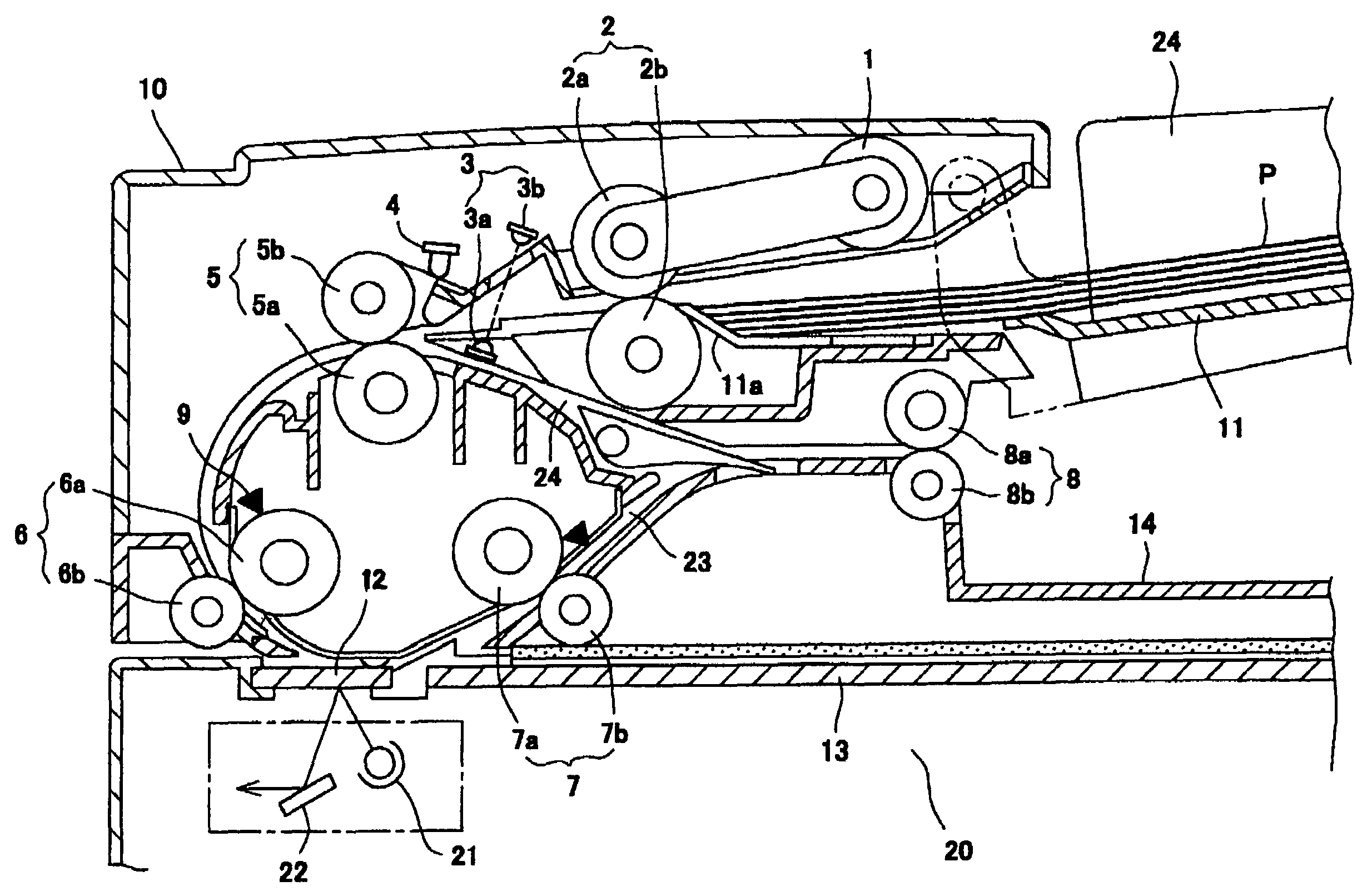

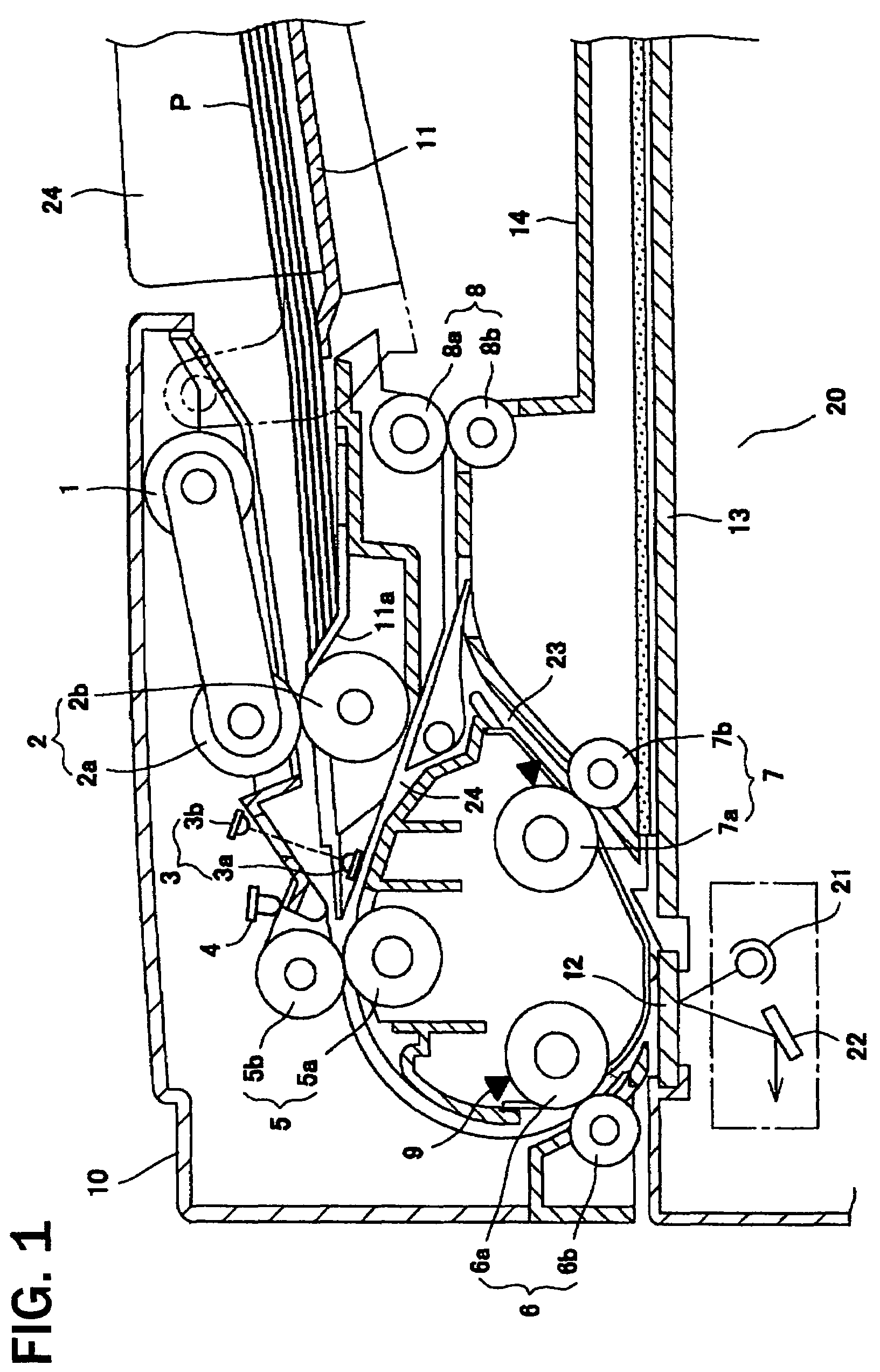

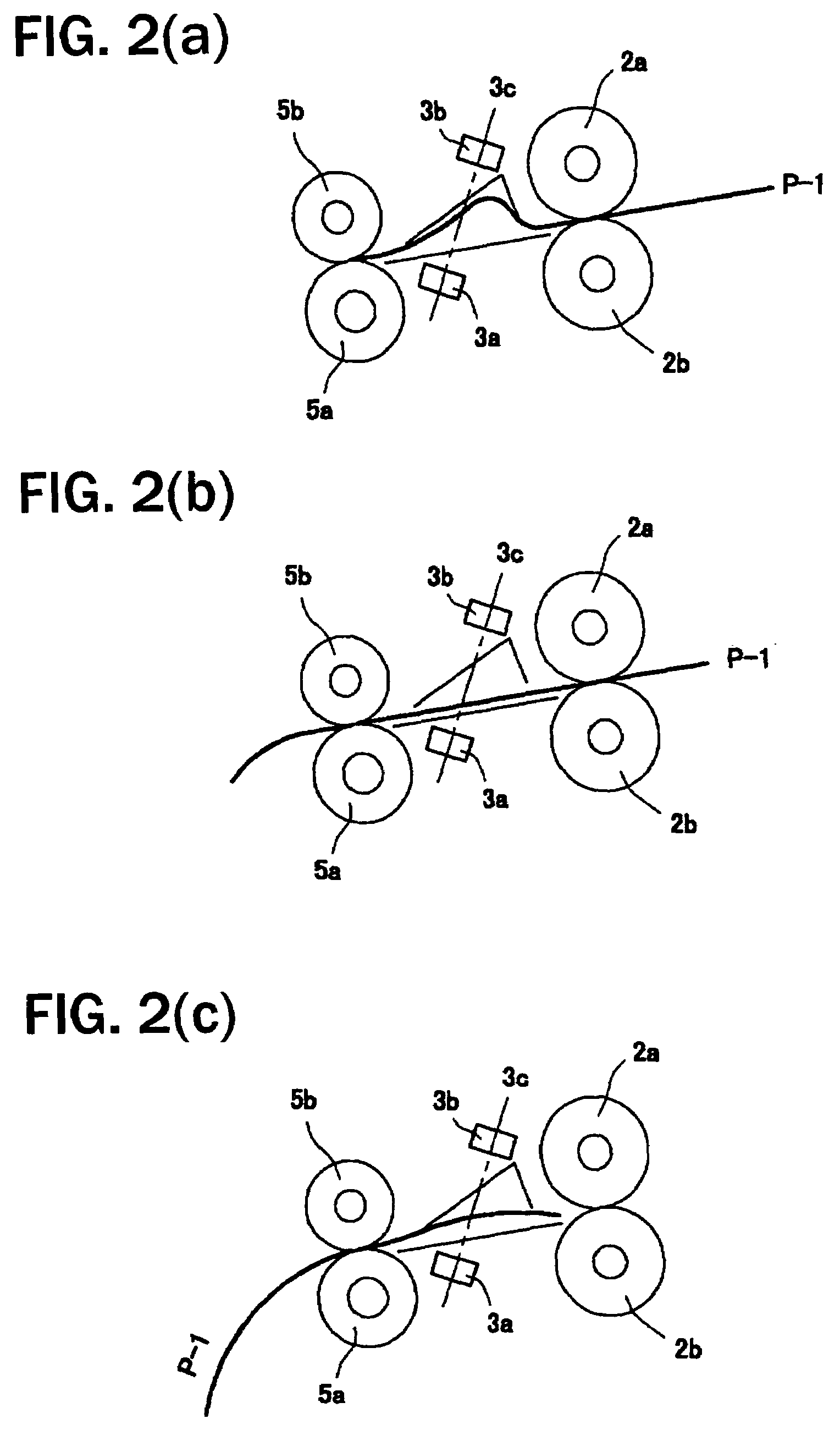

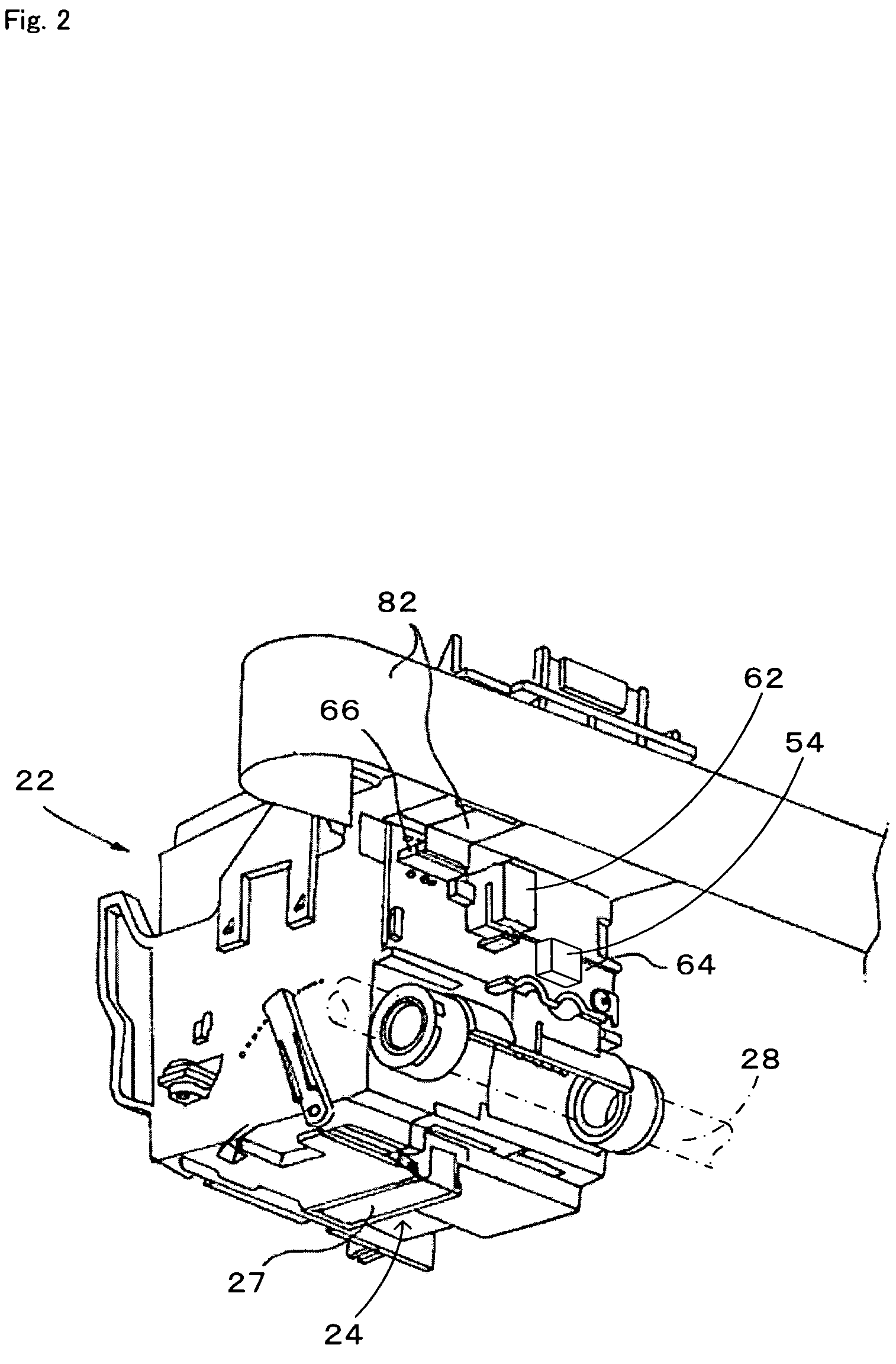

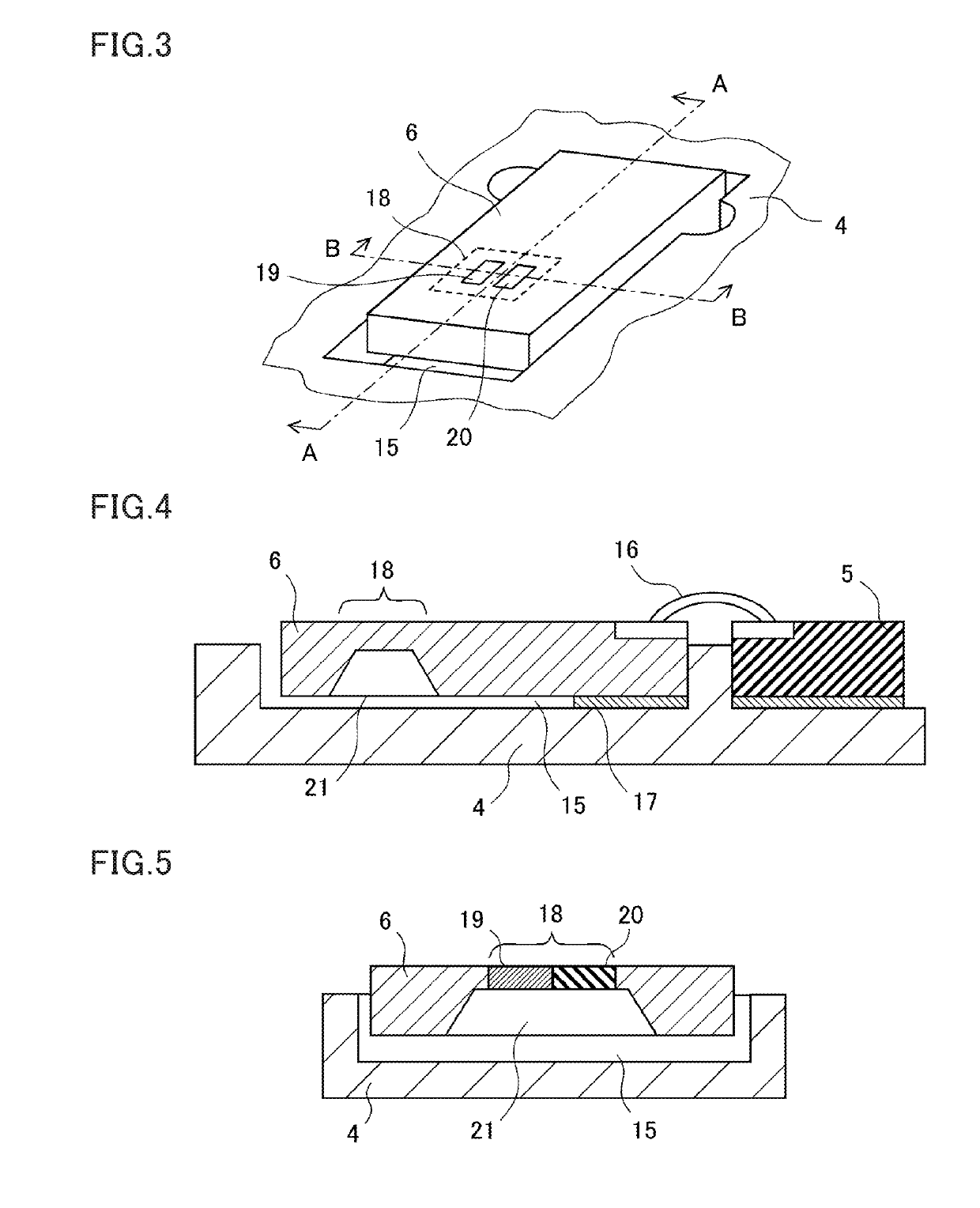

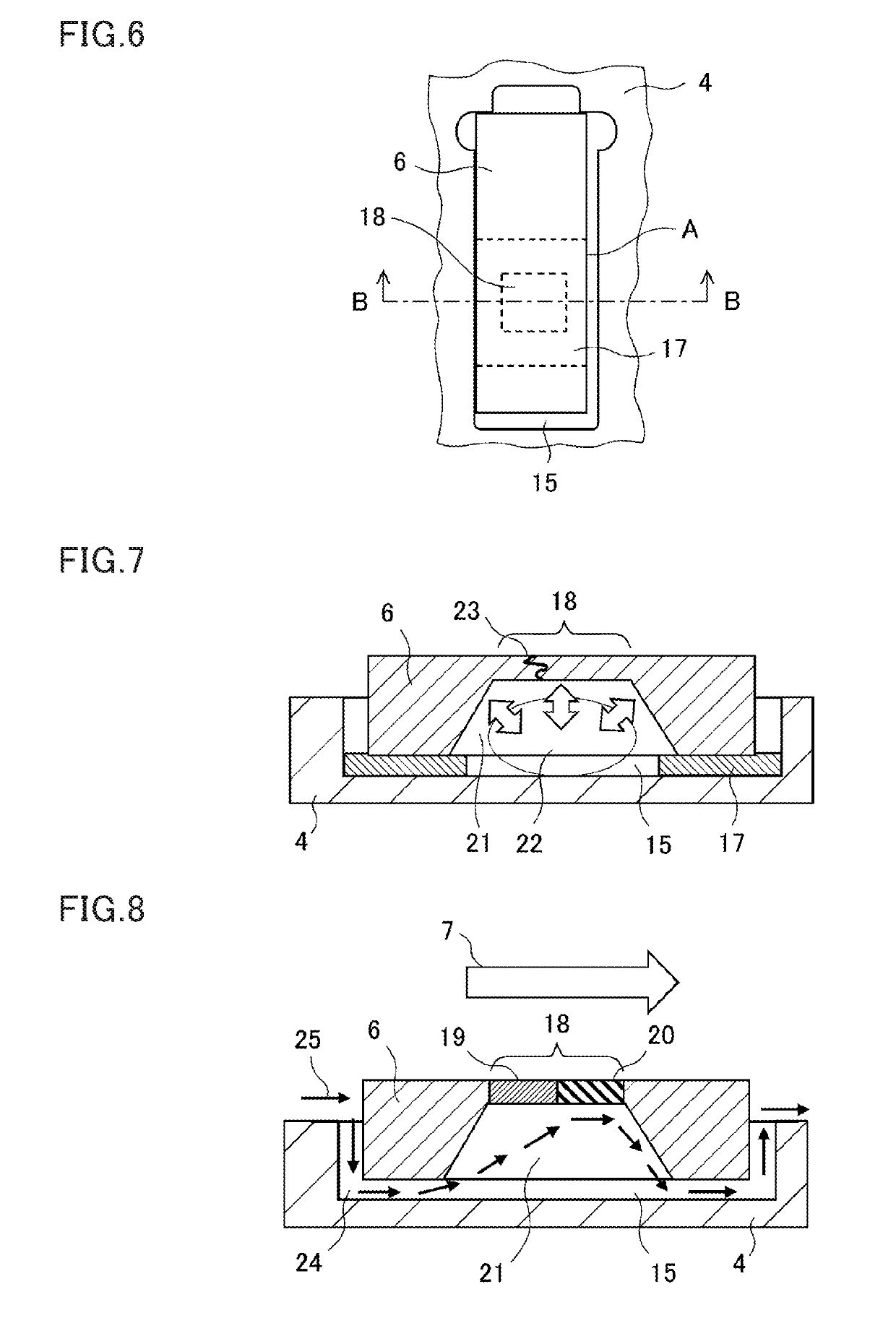

A sheet handling apparatus includes a sheet stacker for stacking sheets; a separating device for separating and feeding the sheets stacked on the sheet stacker; and a register roller disposed adjacent to the separating device for correcting a skew of the sheet. An ultrasonic wave sensor composed of a wave sending sensor and a wave receiving sensor is arranged between the separating device and the register roller obliquely relative to a surface of the sheet. A judging device is electrically connected to the ultrasonic wave sensor for detecting a double feed of the sheets based upon an output signal from the wave receiving sensor at a predetermined time after the register roller starts rotating. A control device electrically connected to the judging device and the register roller controls the register roller to stop and rotate.

Owner:NISCA KK

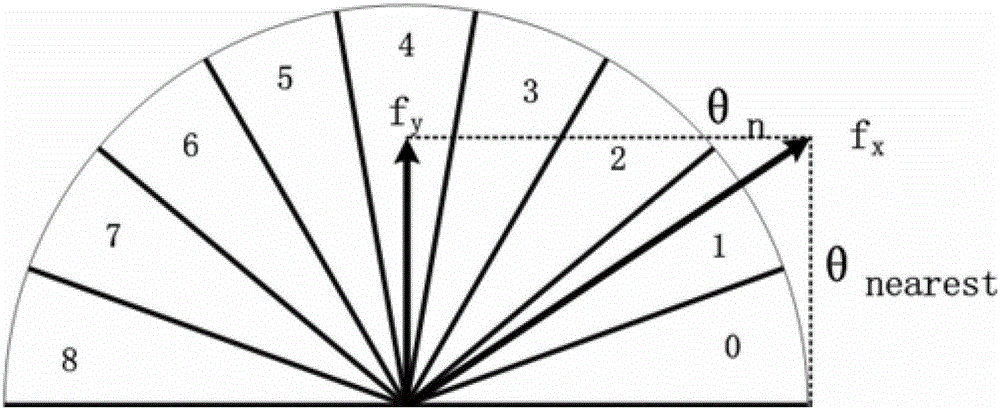

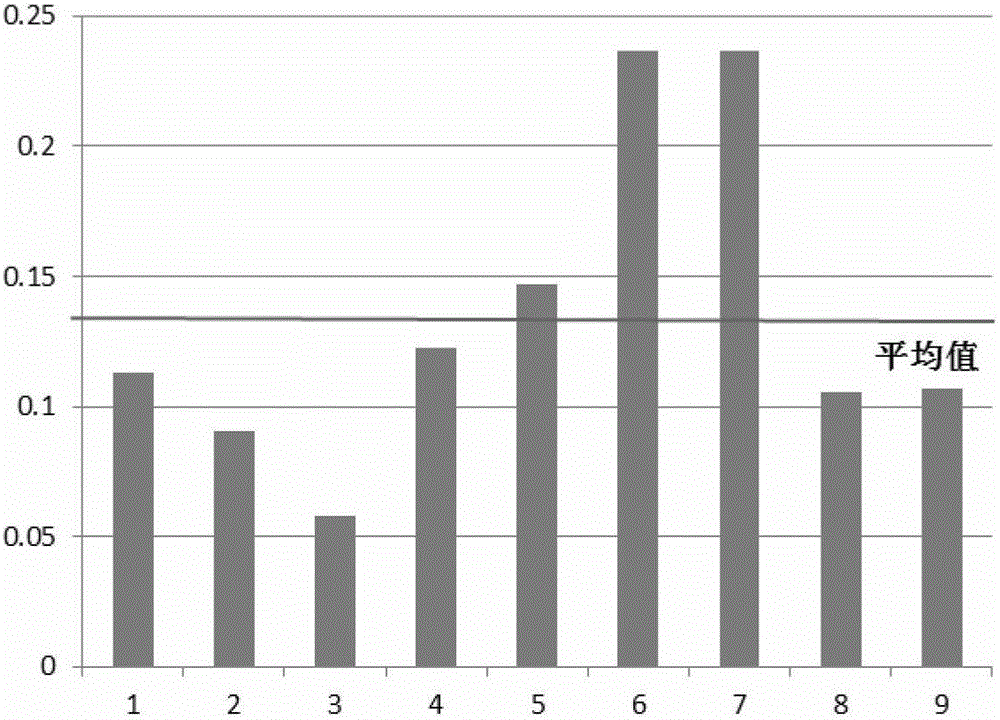

FPGA (field programmable gate array) architecture of HOG (histogram of oriented gradient) and SVM (support vector machine) based pedestrian detection system and implementing method of FPGA architecture

InactiveCN103177262ATroubleshoot Migration Optimization IssuesAvoid detection accuracyCharacter and pattern recognitionFpga architectureComputer architecture

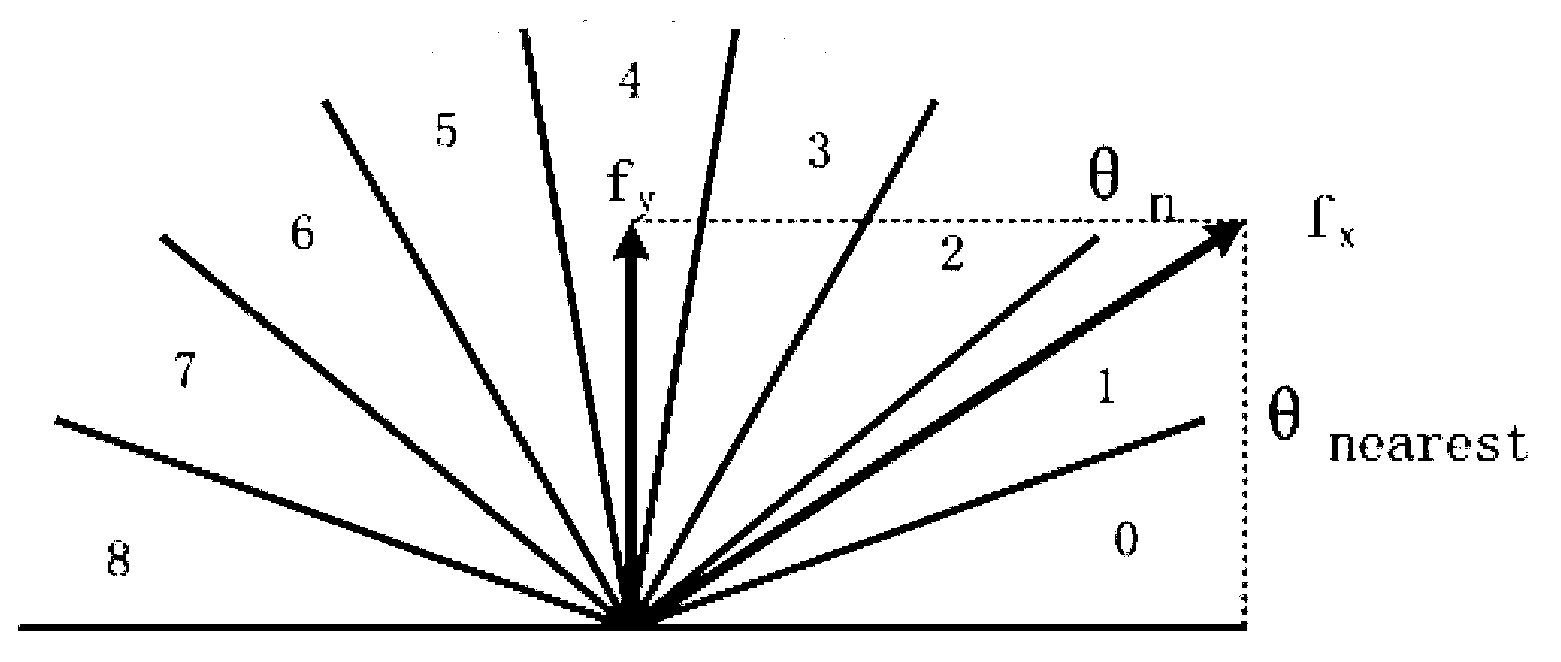

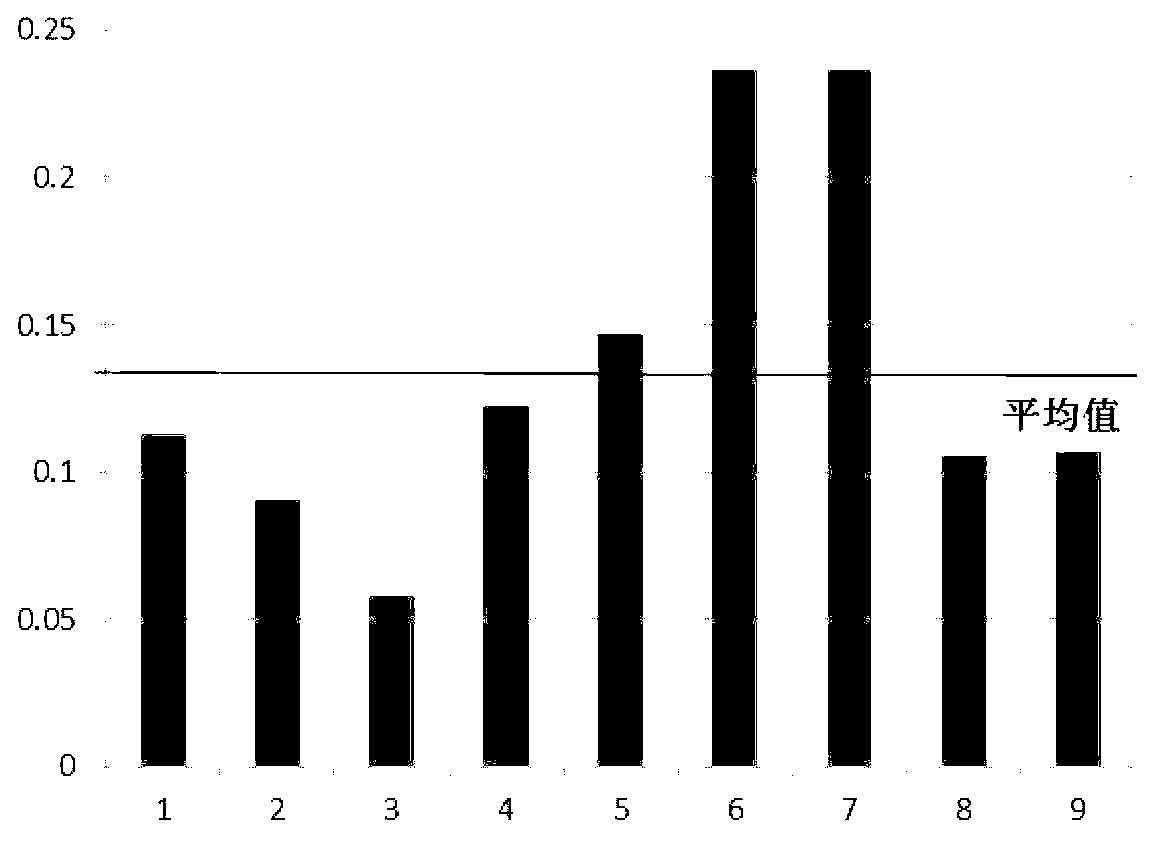

The invention discloses an implementing method of FPGA (field programmable gate array) architecture of an HOG (histogram of oriented gradient) and SVM (support vector machine) based pedestrian detection system. The implementing method includes steps of inputting, gradient and direction computation, histogram generation, binaryzation, SVM classification and outputting. The invention further provides the FPGA (field programmable gate array) architecture of the HOG and SVM based pedestrian detection system. By the FPGA architecture and the implementing method thereof, the problem that an HOG and SVM based pedestrian detection algorithm is slow in computation on a PC(personal computer) is solved, transplant optimization of hardware is realized, the FPGA architecture of an embedded pedestrian detection system is implemented in the scheme with low power consumption, high detection efficiency and low resource consumption in real time, and thus, pedestrian detection is popularized and developed in the embedded field according to the scheme.

Owner:SHANDONG UNIV

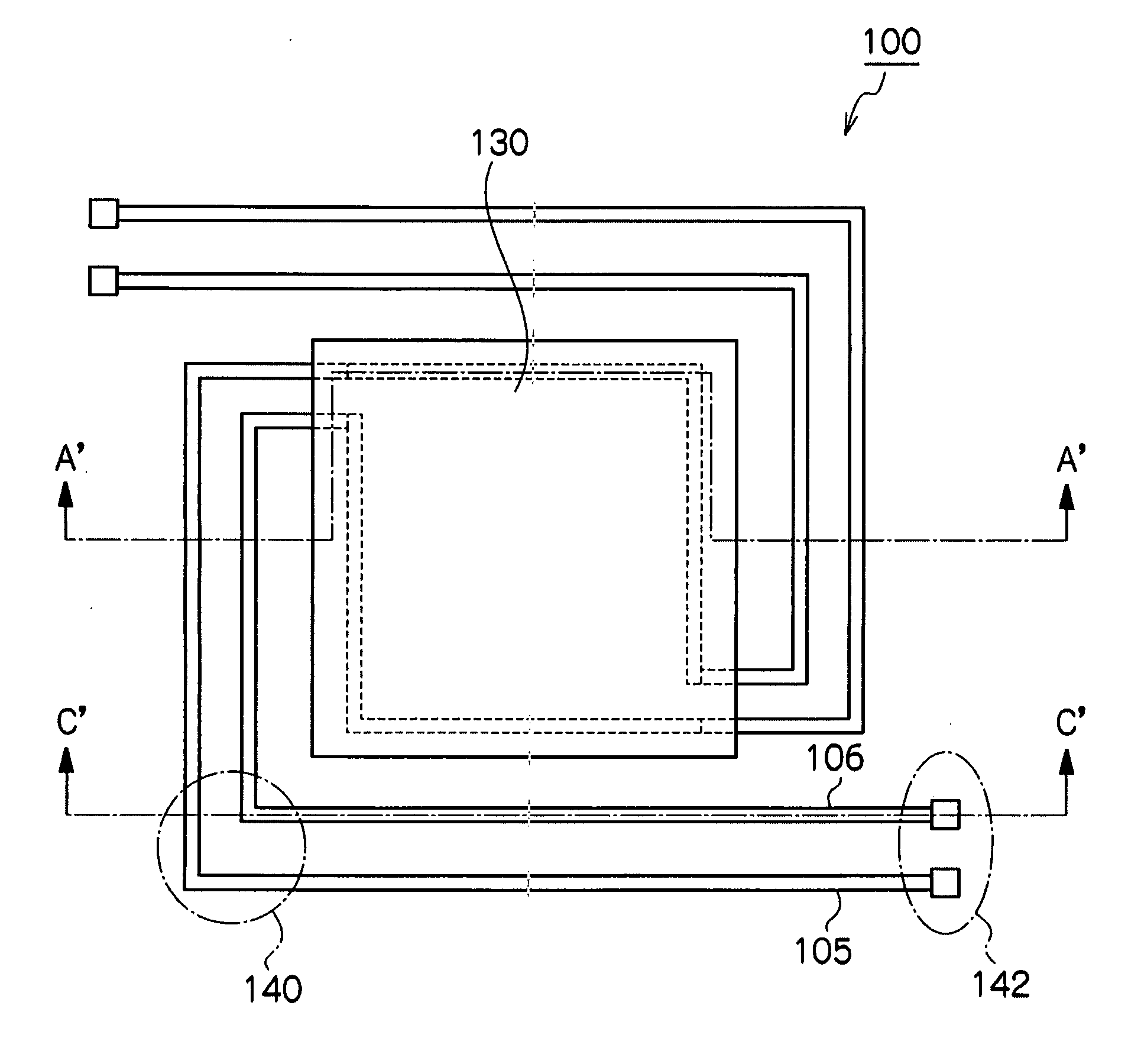

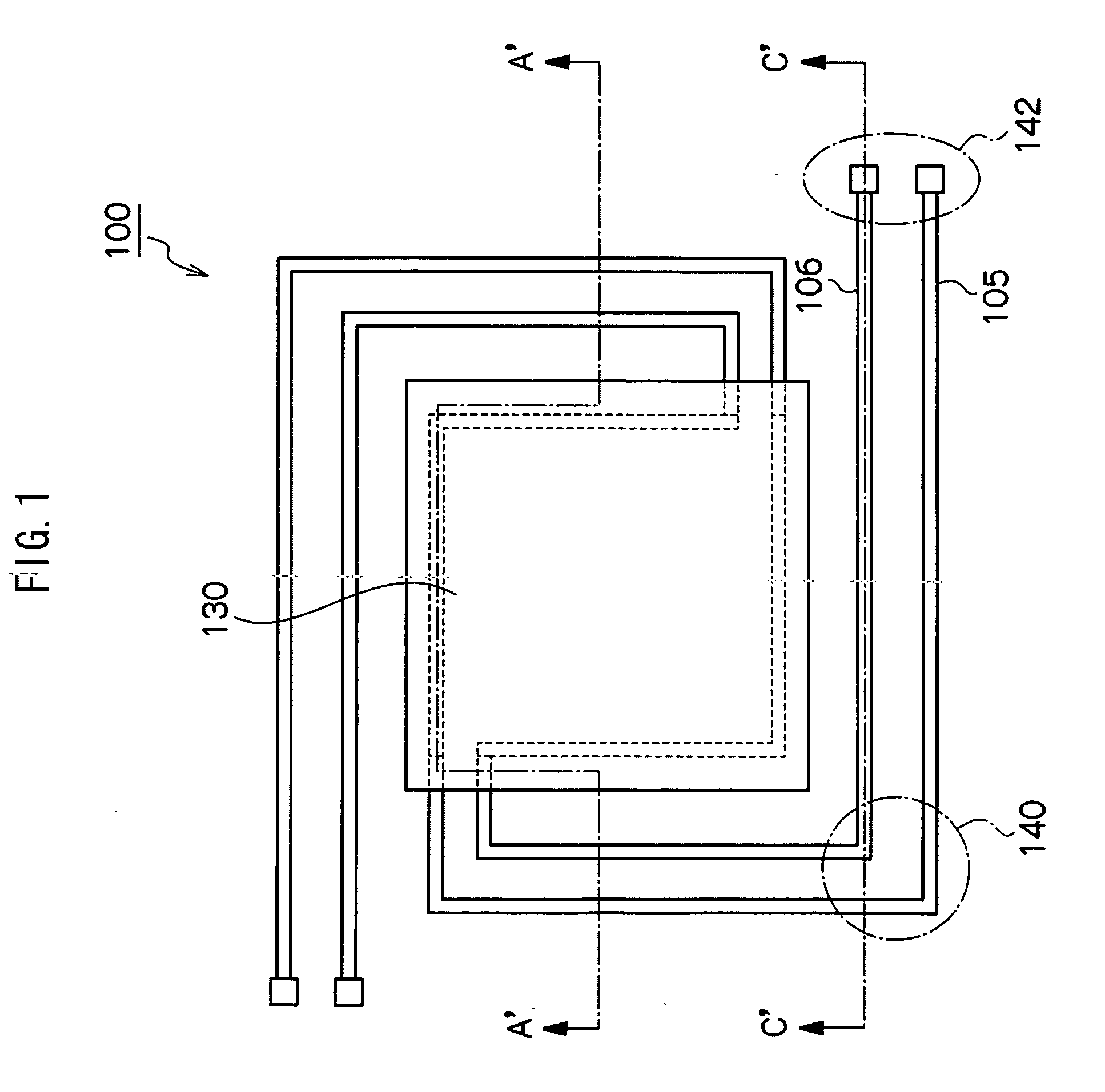

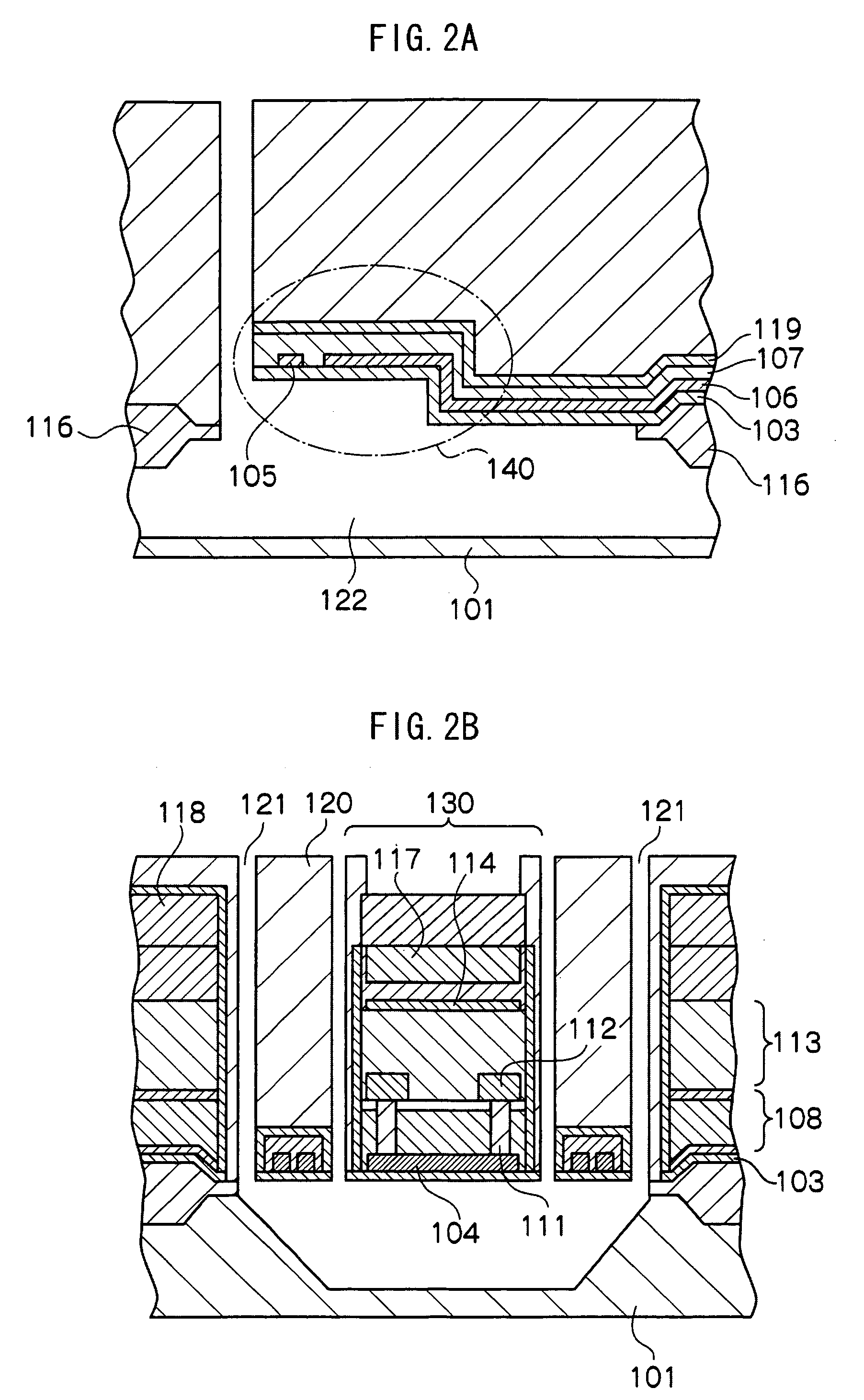

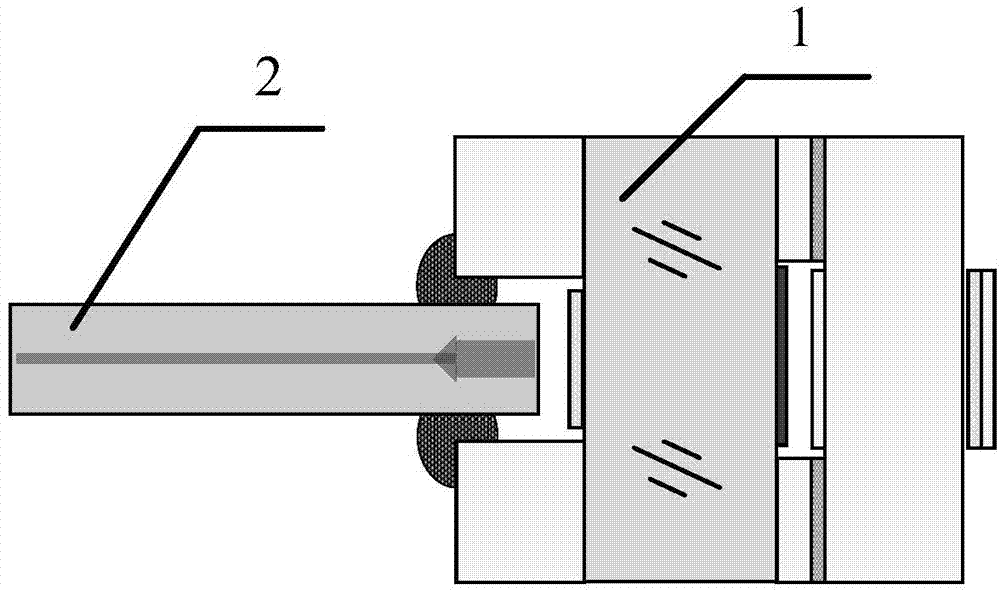

Sheet handling apparatus and image reading apparatus

InactiveUS7425001B2Accurate detectionAvoid detection accuracyTesting/calibration apparatusRegistering devicesElectricityEngineering

A sheet handling apparatus includes a sheet stacker for stacking sheets; a separating device for separating and feeding the sheets stacked on the sheet stacker; and a register roller disposed adjacent to the separating device for correcting a skew of the sheet. An ultrasonic wave sensor composed of a wave sending sensor and a wave receiving sensor is arranged between the separating device and the register roller obliquely relative to a surface of the sheet. A judging device is electrically connected to the ultrasonic wave sensor for detecting a double feed of the sheets based upon an output signal from the wave receiving sensor at a predetermined time after the register roller starts rotating. A control device electrically connected to the judging device and the register roller controls the register roller to stop and rotate.

Owner:NISCA KK

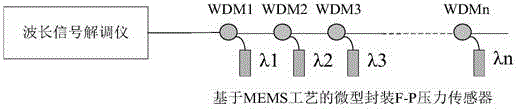

MEMS process based miniature packaged F-P pressure sensor and forming method

ActiveCN104596685ATaking into account the measurement accuracyTaking into account over-range capabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansMechanical reliabilityStrain gauge

The invention discloses an MEMS process based miniature packaged F-P pressure sensor and belongs to the field of high-accuracy optical fiber sensing measurement. The F-P pressure sensor mainly comprises an F-P strain sensitive MEMS chip and a collimation and beam expanding optical fiber, wherein the F-P strain sensitive MEMS chip consists of an SOI silicon wafer, a glass sheet and a double-parabolic silicon wafer. The SOI silicon wafer comprises top layer silicon, a middle oxidization layer and bottom layer silicon. The SOI silicon wafer is fixed the glass sheet through silicon-glass anodic bonding. The glass sheet is fixed to the double-parabolic silicon wafer through silicon-glass anodic bonding. The collimation and beam expanding optical fiber is fixed in a through hole formed in the double-parabolic silicon wafer through a welding flux. The F-P strain sensitive MEMS chip is prepared based on an MEMS micromachining technology, the F-P strain sensitive MEMS chip and the collimation and beam expanding optical fiber are aligned and packaged to form the F-P pressure sensor, and miniaturized and batch manufacture of the strain gauge can be achieved. The MEMS process based miniature packaged F-P pressure sensor is high in flexibility and measurement accuracy, excellent in over-range capacity, high in mechanical reliability and good in dynamic measurement response characteristic.

Owner:SHANGHAI BAIANTEK SENSING TECH CO LTD

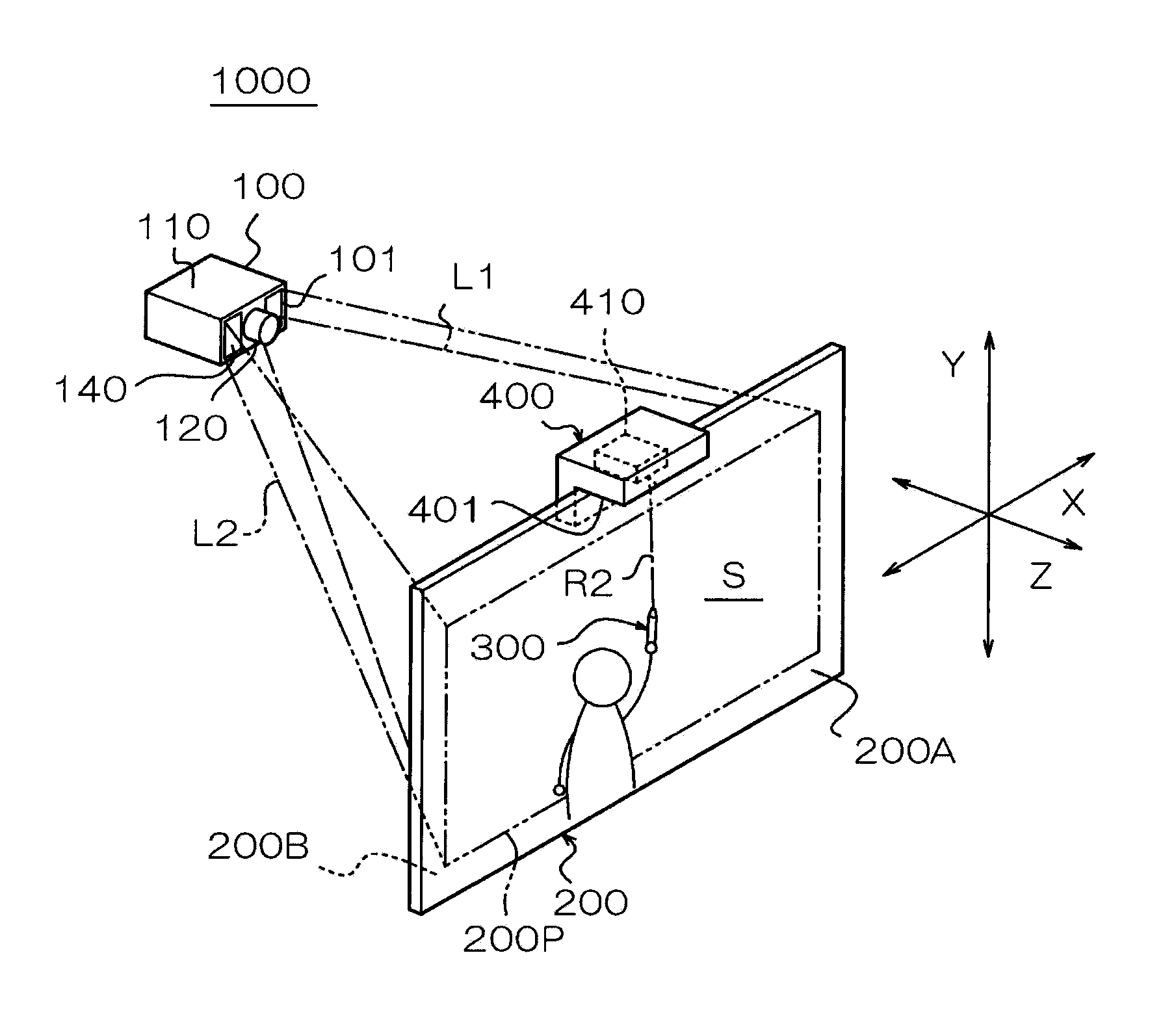

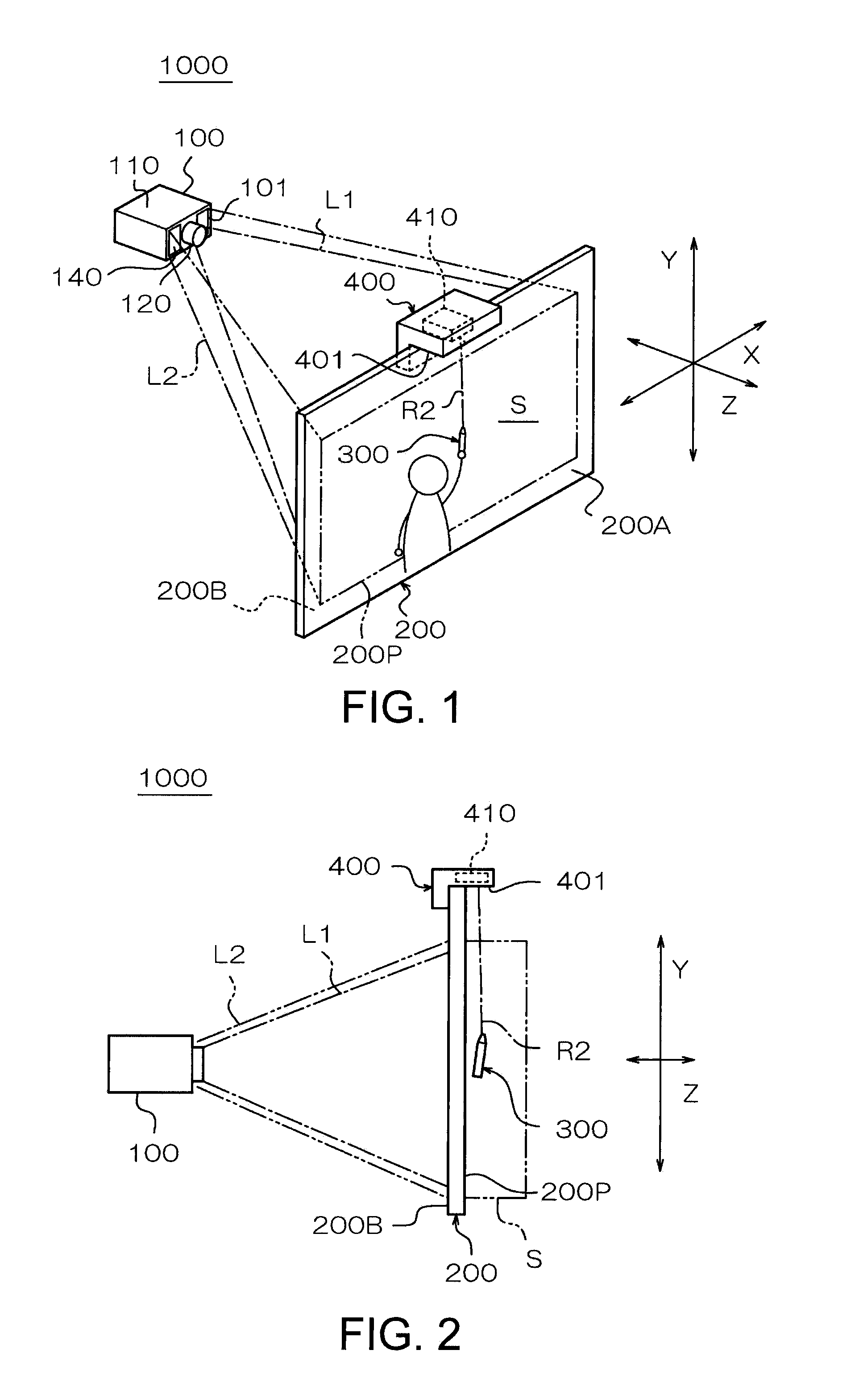

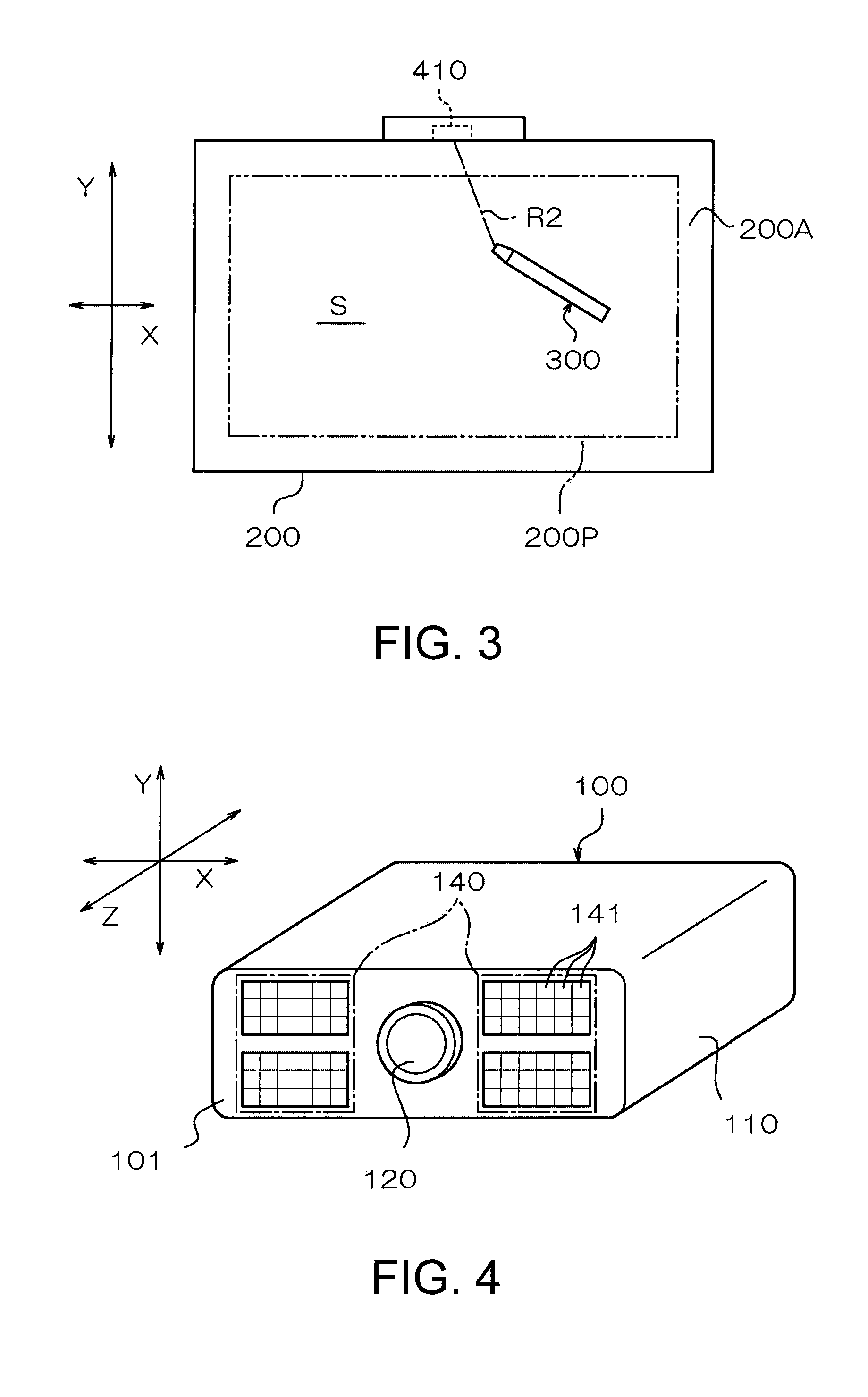

Optical position detection device and projection display device

InactiveUS20110134080A1Easy to implementEfficient use ofUsing optical meansInput/output processes for data processingLocation detectionObject based

An optical position detection device includes: a light source section adapted to emit a position detection light beam to form a light intensity distribution in which the intensity varies along a reference surface; a light detection section adapted to detect the position detection light reflected by a detection target object located in a detection space in which the light intensity distribution is formed; and a position detection section adapted to detect a position of the detection target object based on a detection value of the light detection section, wherein the light detection section has a light receiving section provided with a light detection surface, and a light blocking section adapted to block a part of the position detection light, and the light blocking section has an opening section disposed between the detection space and the light detection surface with a distance from the light detection surface.

Owner:SEIKO EPSON CORP

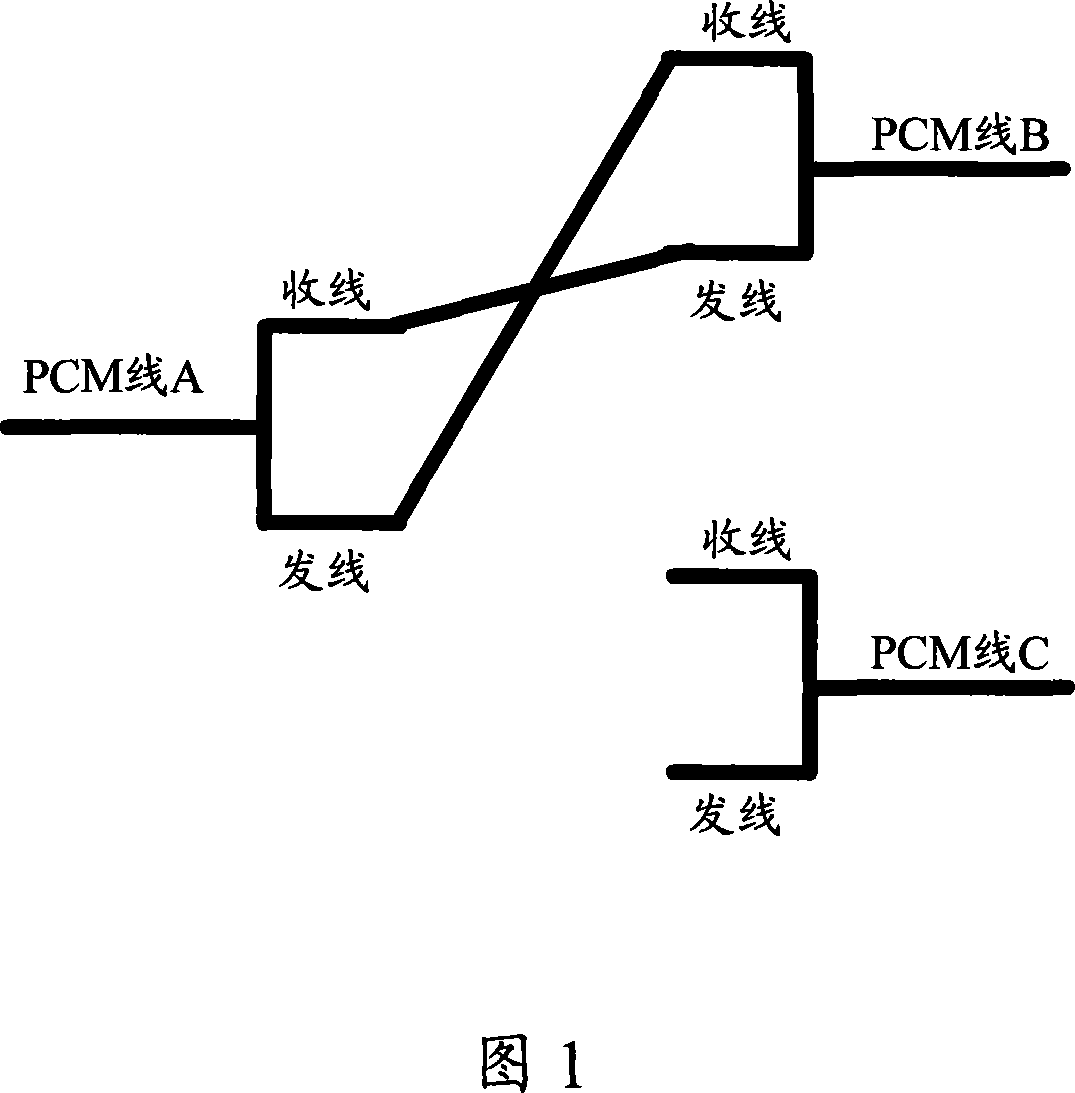

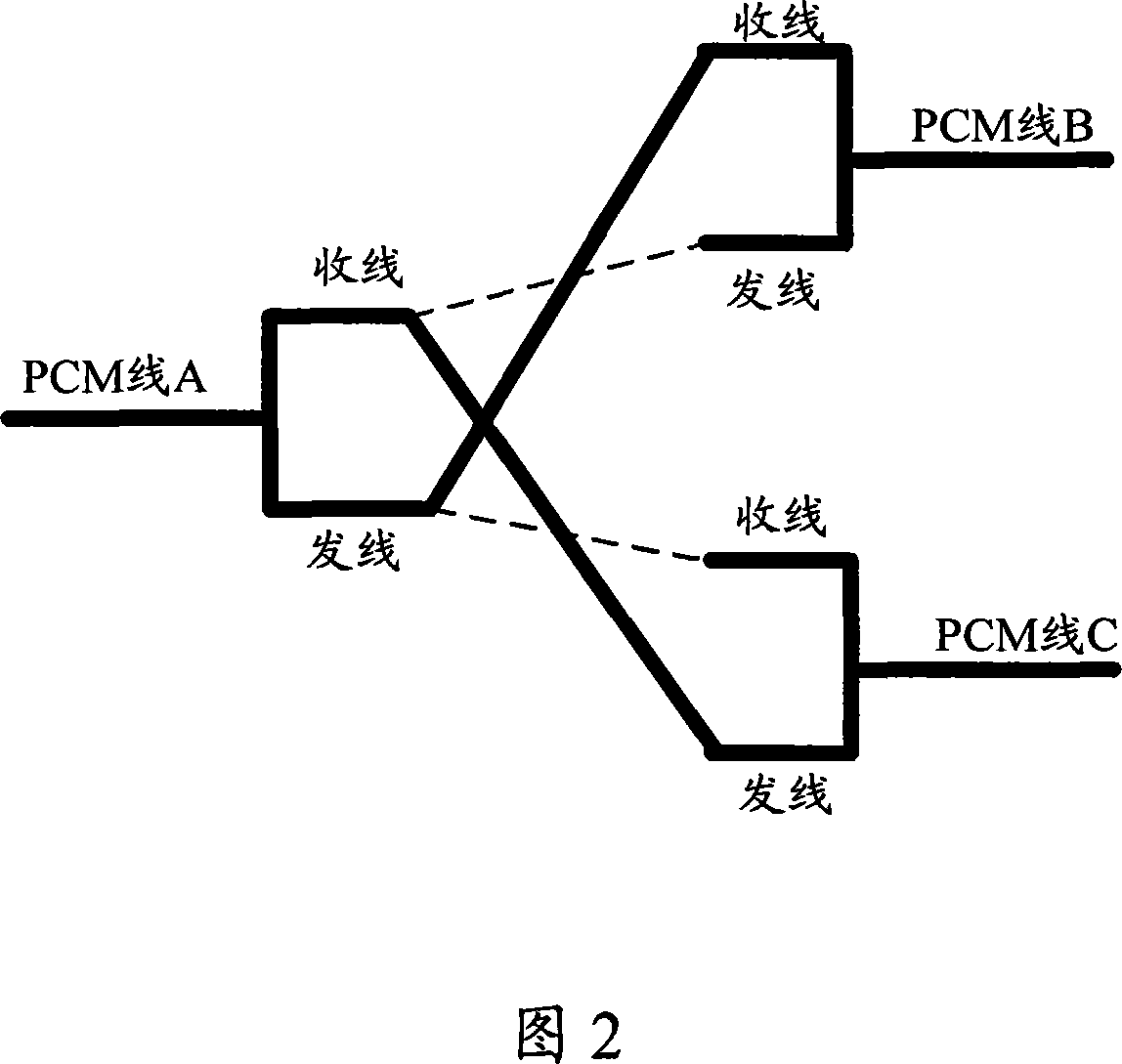

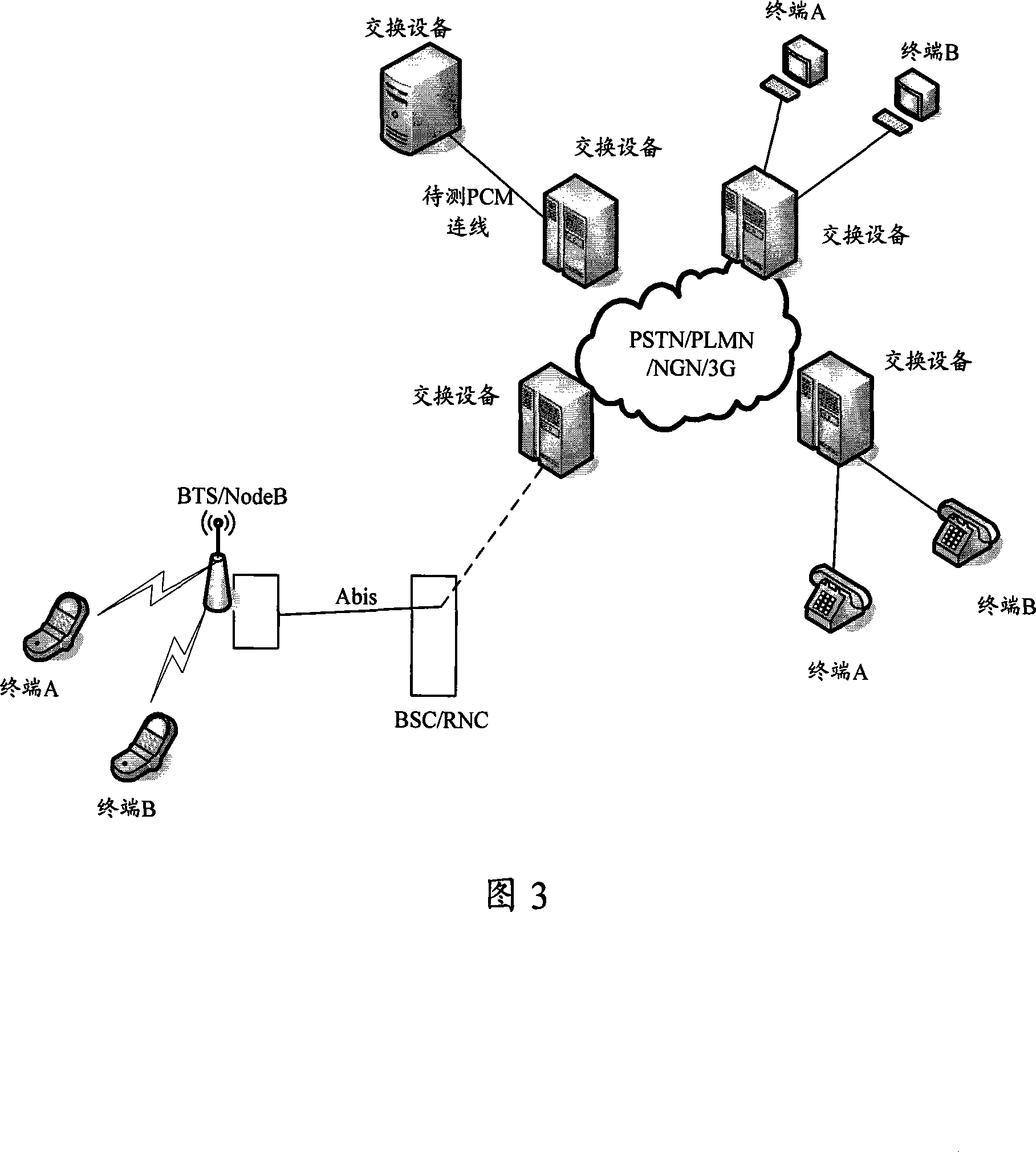

Trunk state detecting method, device and testing information terminal equipment thereof

InactiveCN101068119AImplement automatic detectionEasy to detectTransmission monitoringLine-transmission monitoring/testingTerminal equipmentEngineering

A method for detecting state of relay line includes emitting test information by relay line to be detected, receiving detour test information from terminal end of said test information, comparing said test information with detour test information to see whether contents of two said test information are consistent to each other or not and confirming that fault is occurred on relay line to be detected when comparison result is not consistent to each other. Another method for detecting state of relay line is also disclosed.

Owner:HUAWEI TECH CO LTD

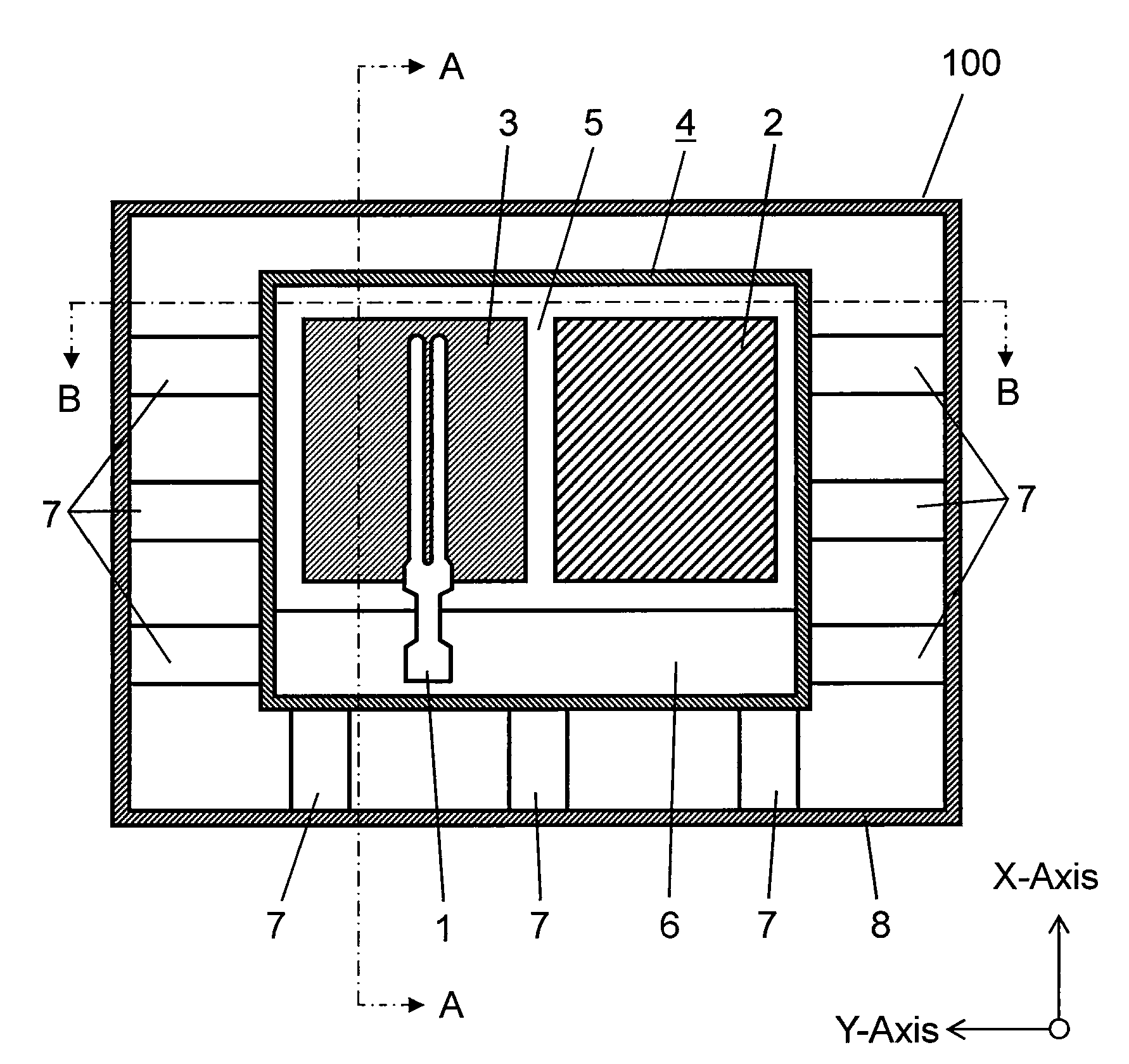

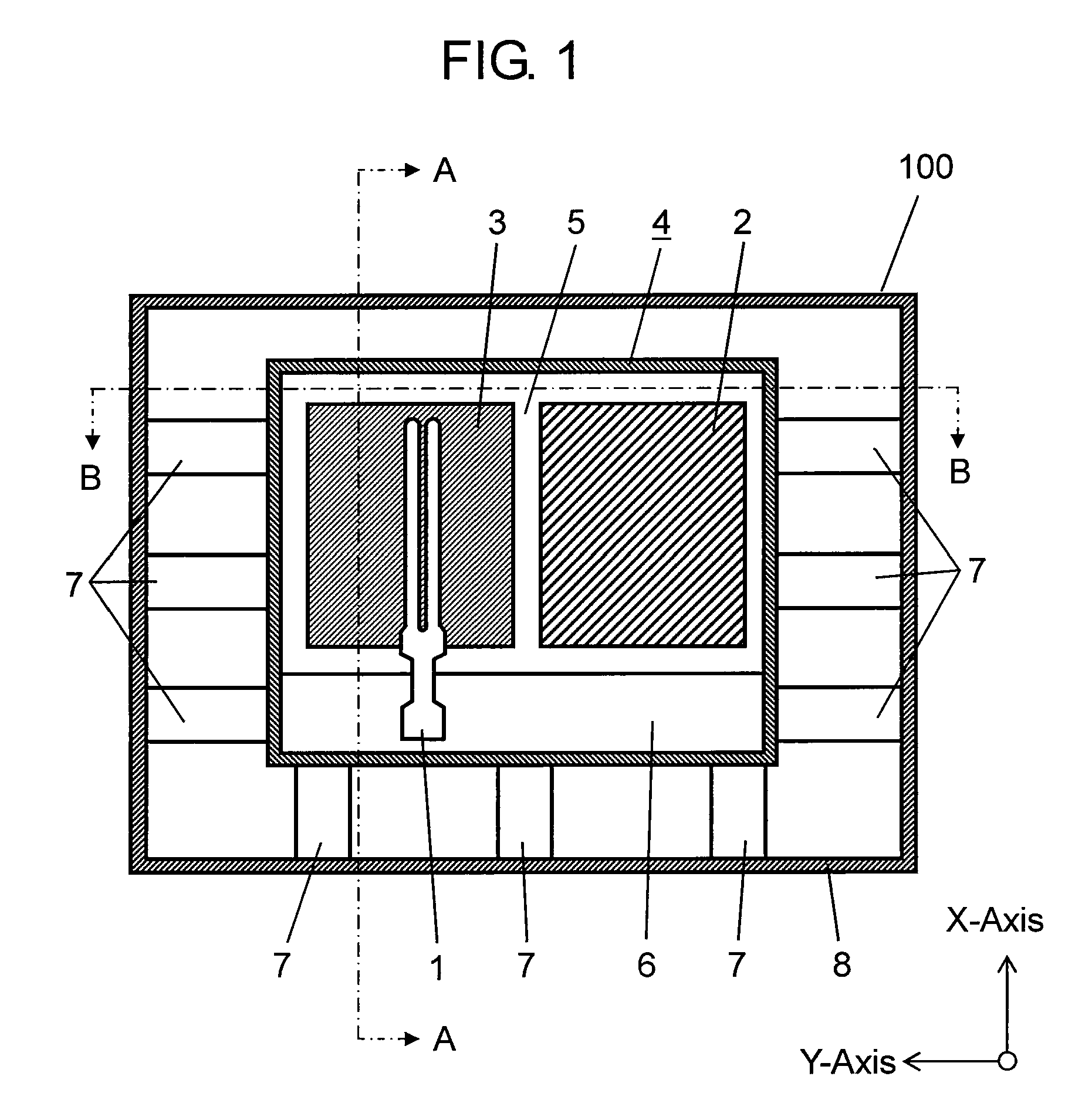

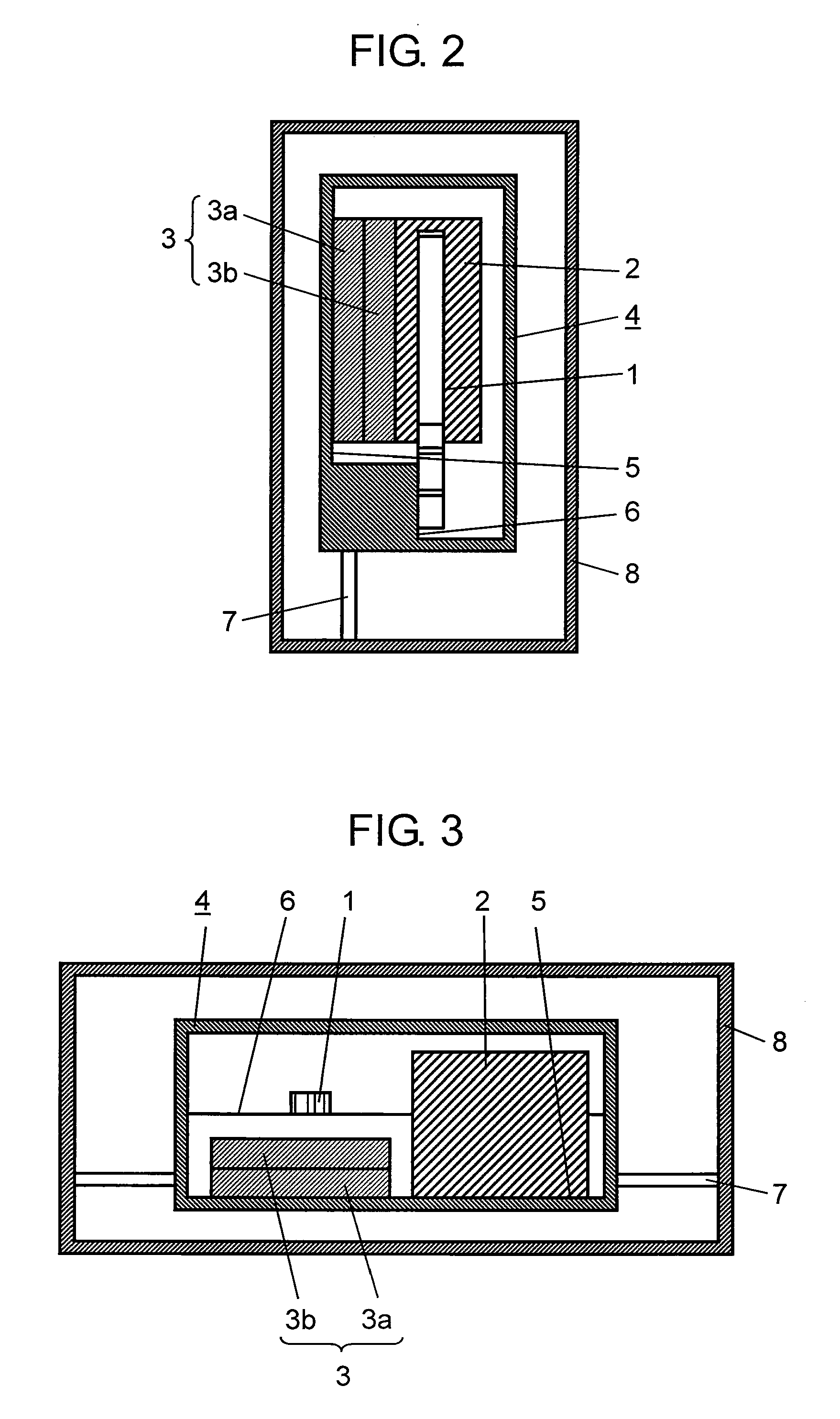

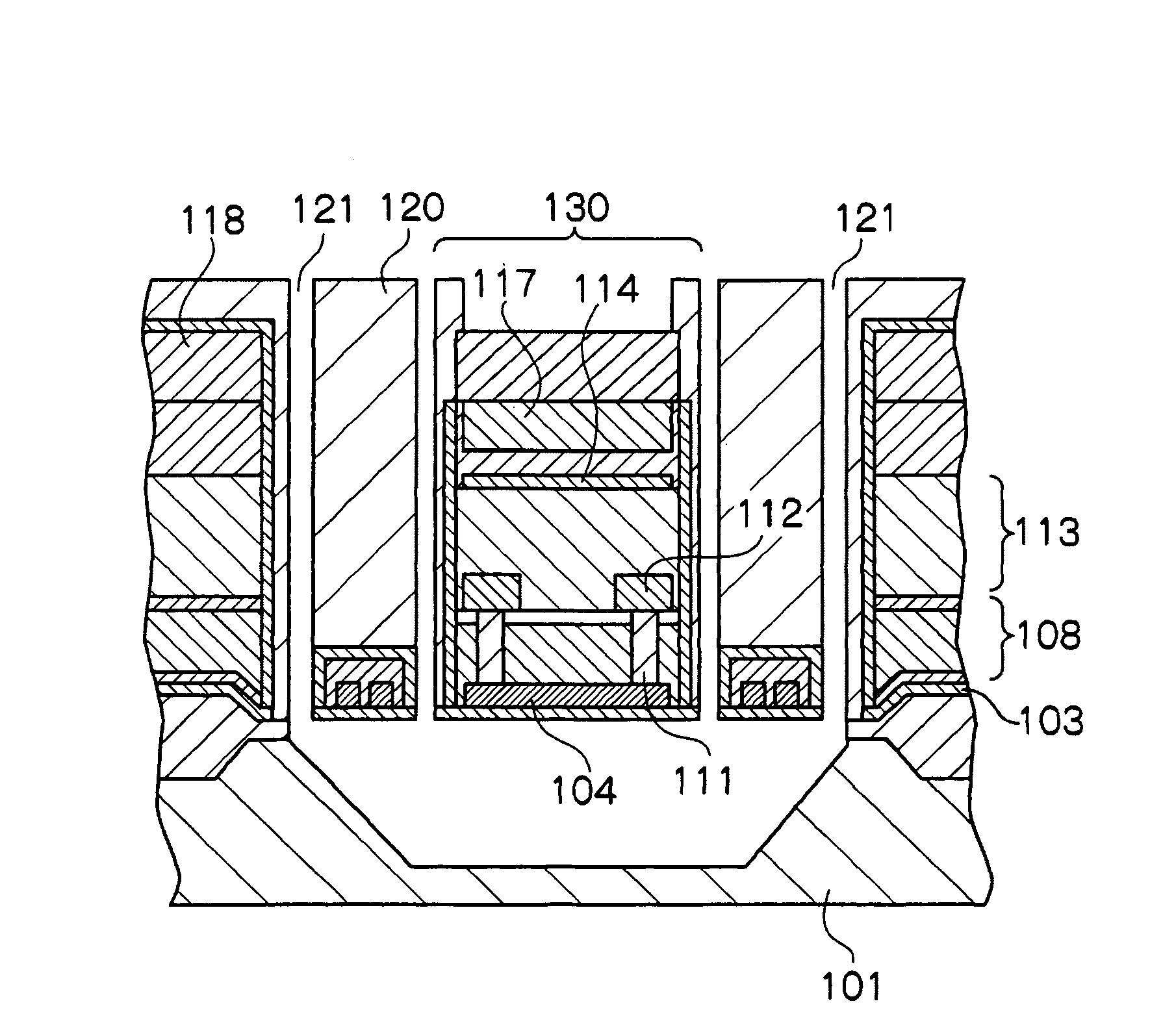

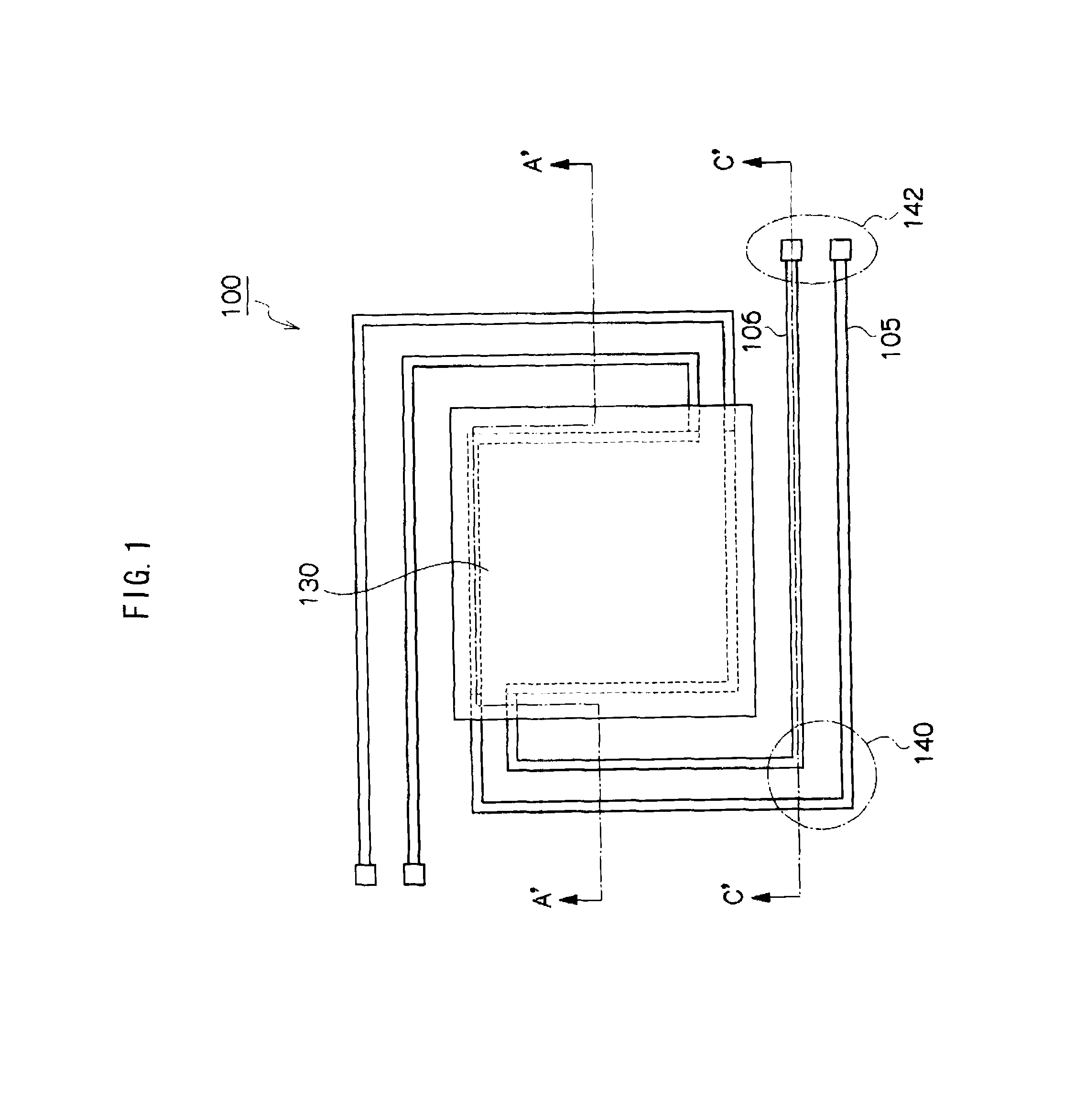

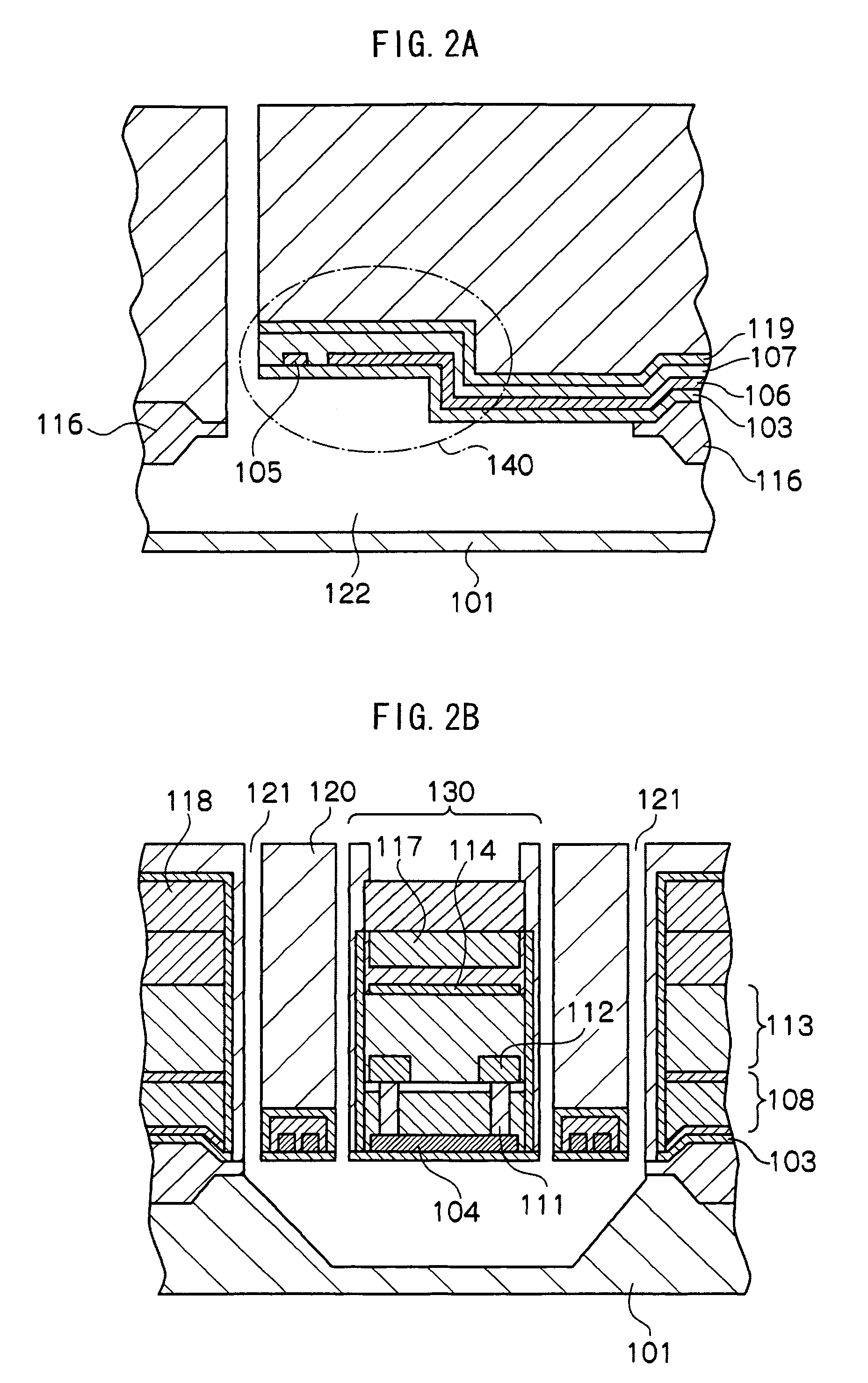

Composite sensor

ActiveUS20090013784A1Increases moment of inertia momentReduce detection accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocitySignal processing

A composite sensor includes an angular velocity sensor element, an acceleration sensor element, a signal processing IC for processing signals from the angular velocity sensor element and the acceleration sensor element, an inner package for accommodating the angular velocity sensor element, the acceleration sensor element, and the signal processing IC; a coupler connected to this inner package, and a fixing member connected to this coupler for holding the inner package via this coupler. The coupler is elastically deformable. One of the acceleration sensor element and the signal processing IC is located at the right with respect to the center of the inner package, and the other of the acceleration sensor element and the signal processing IC is located at the left with respect to the center of the inner package. The composite sensor angular maintains its characteristics of the angular velocity sensor element while the angular velocity sensor element and the acceleration sensor element are accommodated in one package.

Owner:PANASONIC CORP

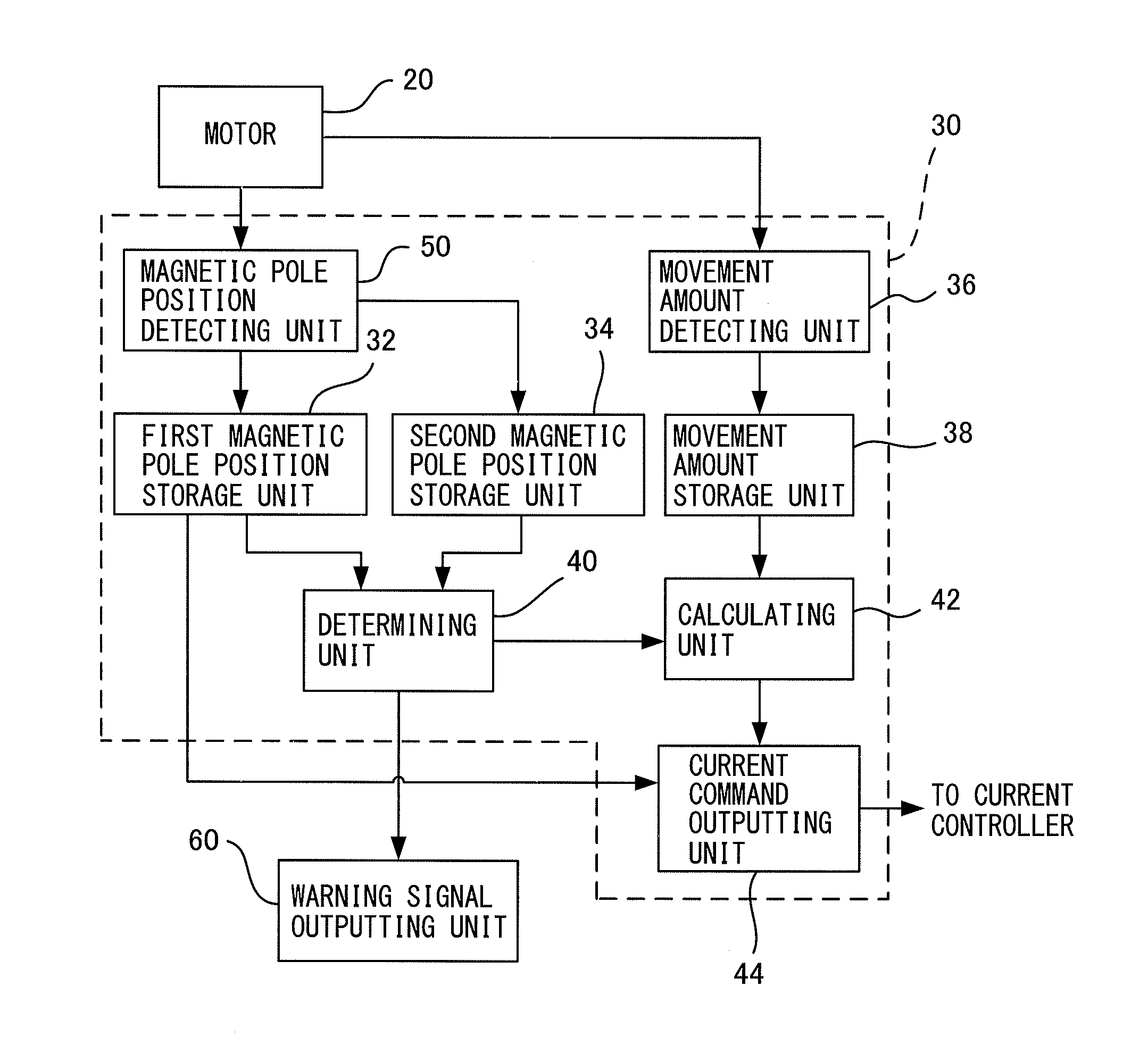

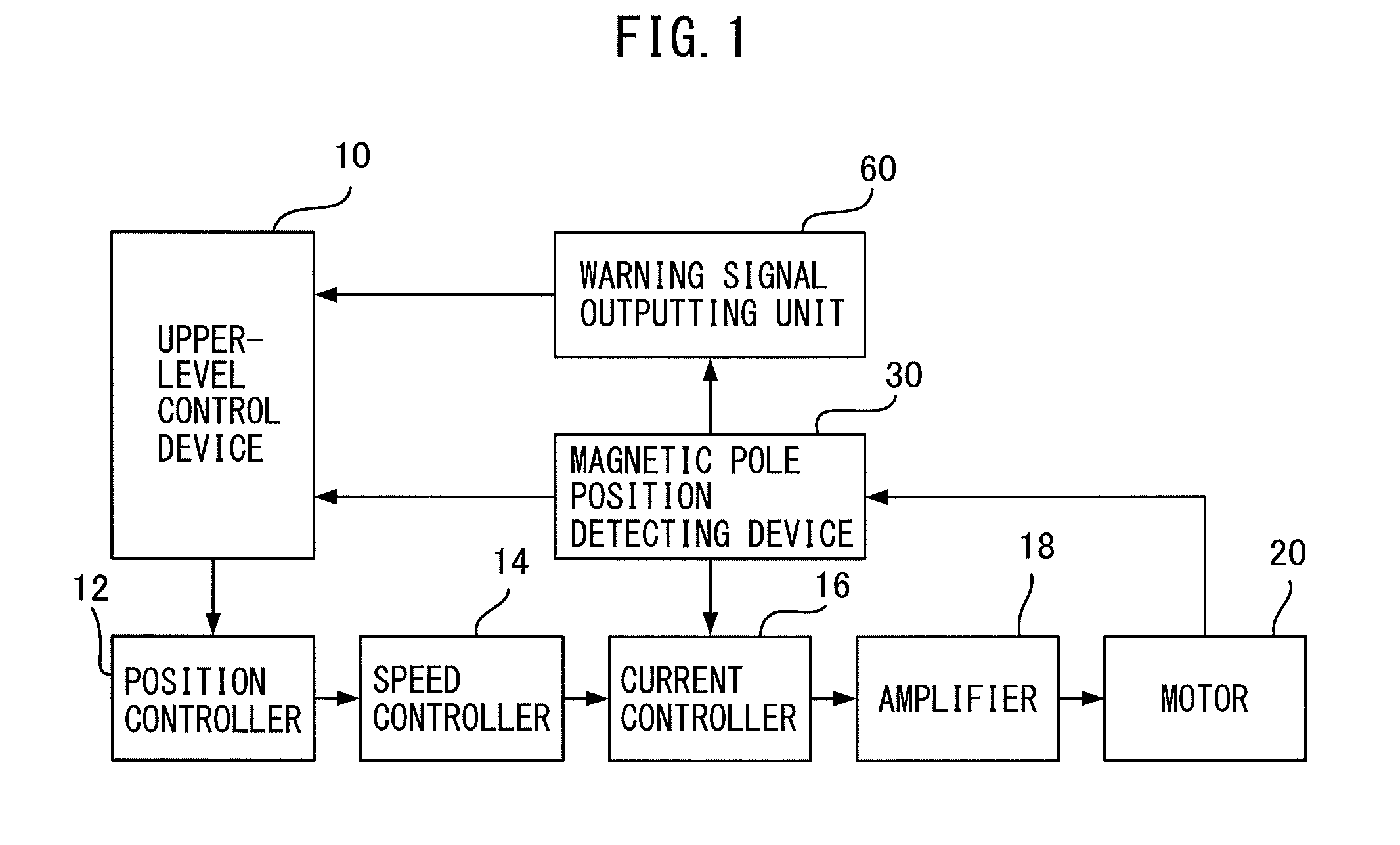

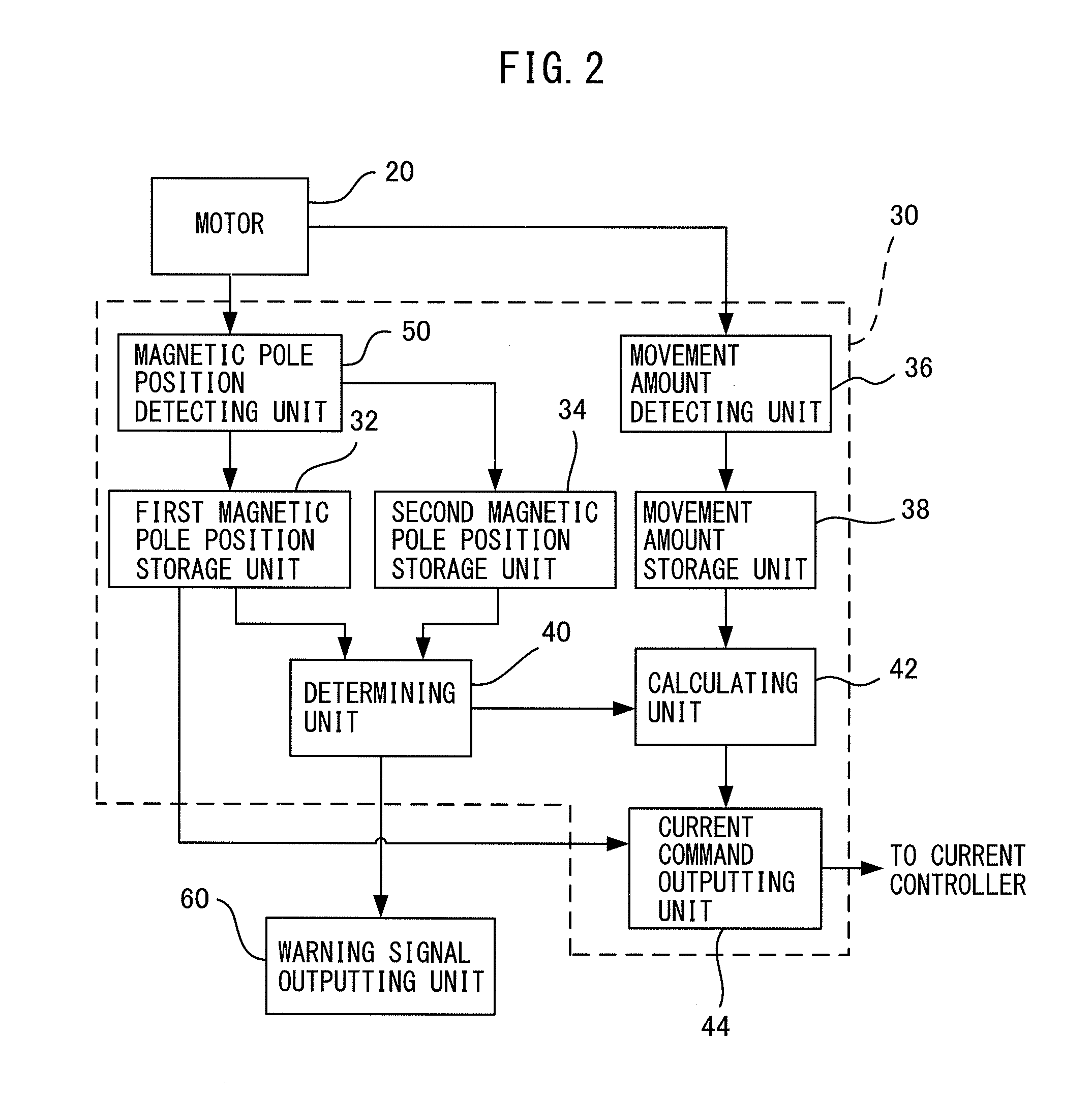

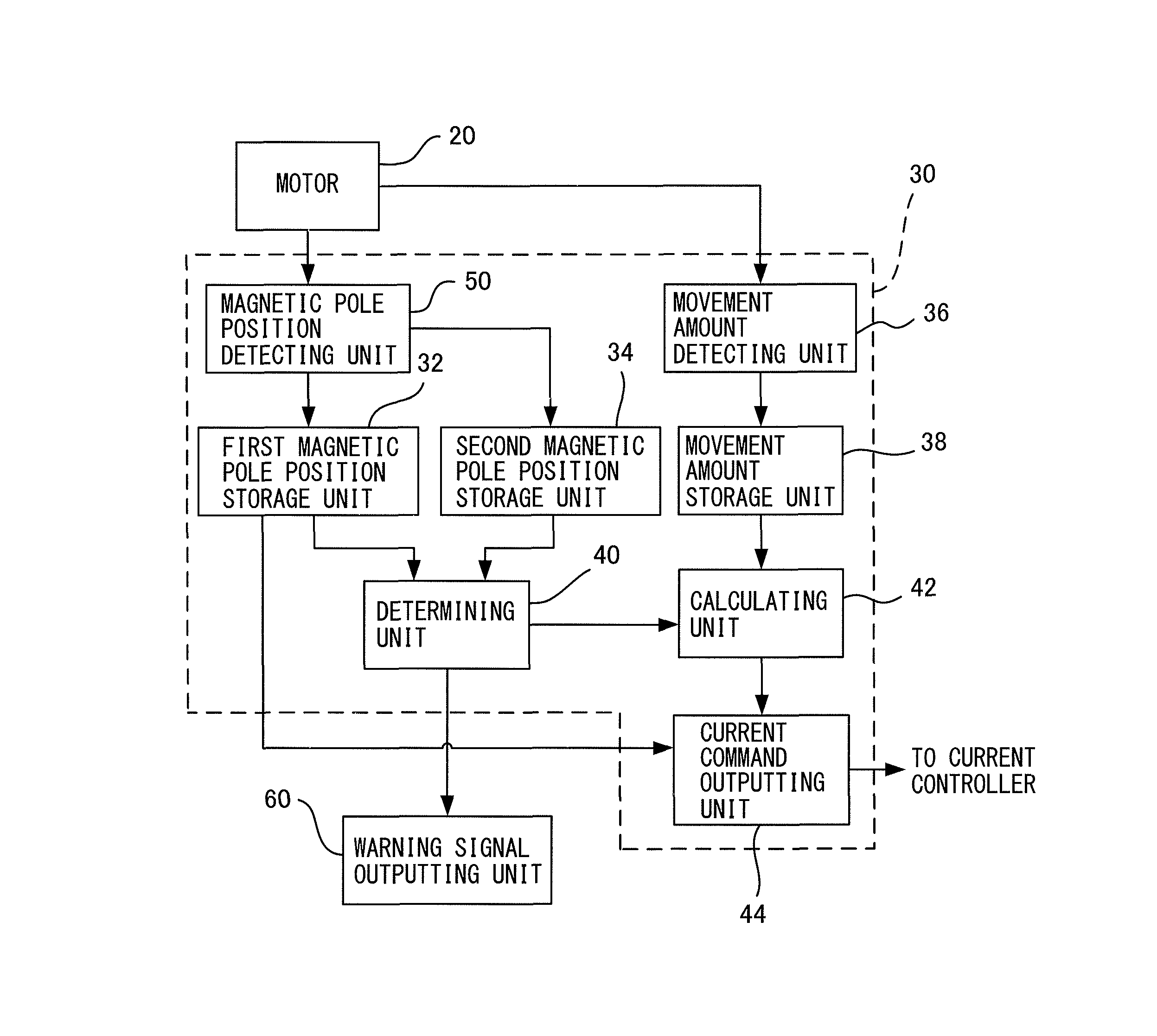

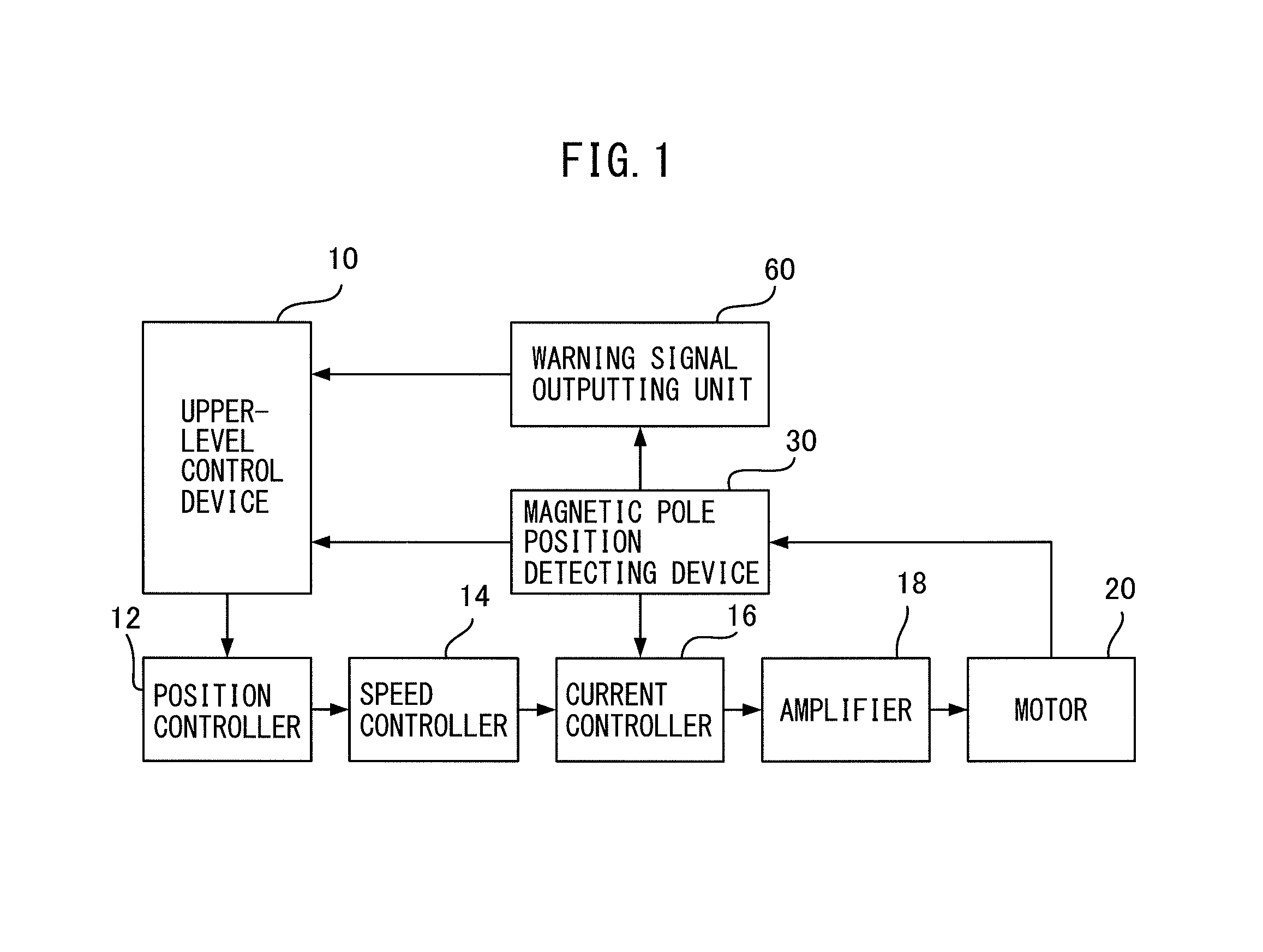

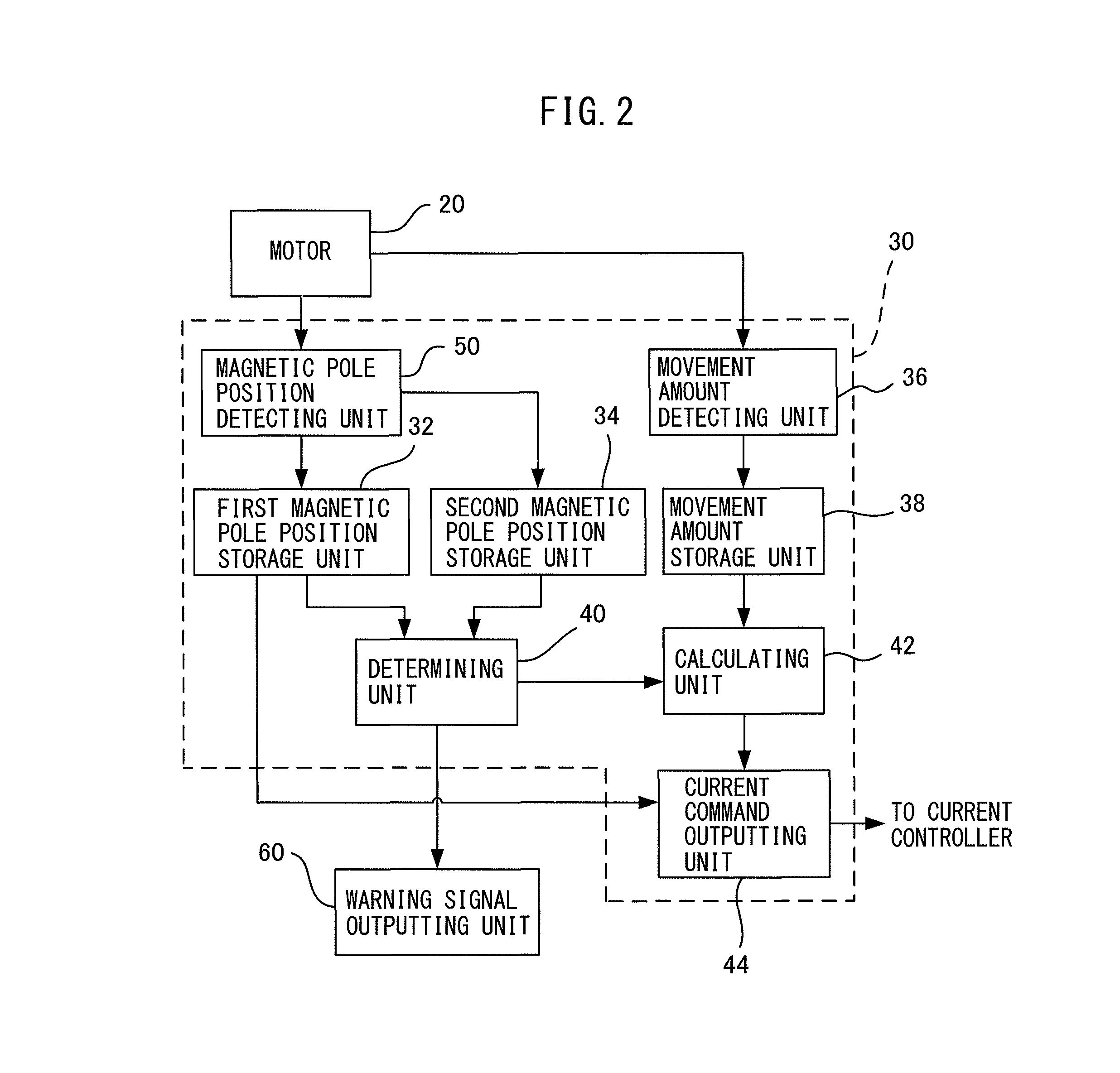

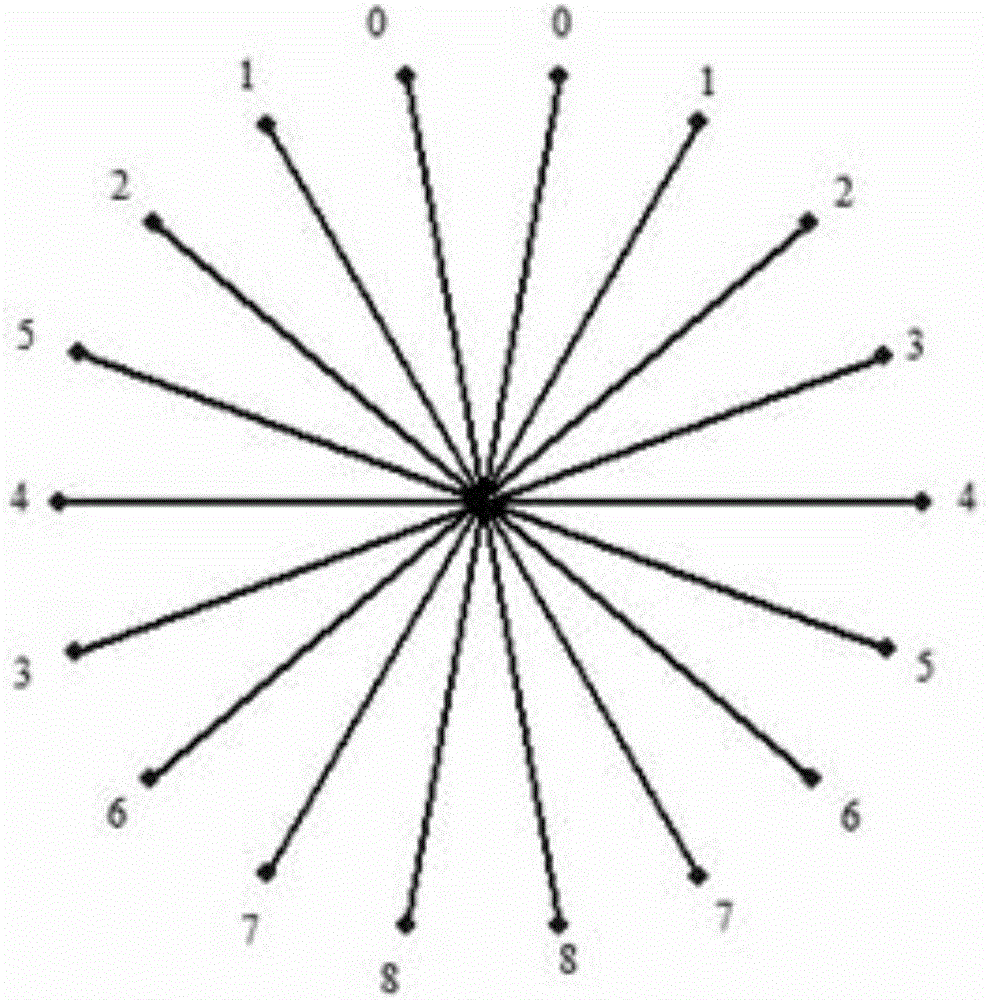

Magnetic pole position detecting device for detecting magnetic pole position of rotor in permanent-magnet synchronous motor

ActiveUS20130307452A1Avoid detection accuracyImprove reliabilityMotor/generator/converter stoppersSynchronous motors startersSynchronous motorPermanent magnet synchronous motor

A magnetic pole position detecting device includes a calculating unit for correcting a magnetic pole position detected by a magnetic pole position detecting unit. In this magnetic pole position detecting device, an additional phase is added to the magnetic pole position detected by the magnetic pole position detecting unit, in order to move a rotor. In relation to a movement amount before and after this movement, a movement amount detected by the magnetic pole position detecting unit is compared with a movement amount detected by an encoder. When a difference between them is larger than a predetermined threshold, a process of detecting the magnetic pole position is determined as false detection.

Owner:FANUC LTD

Infrared detector and fabricating method of infrared detector

InactiveUS20090184246A1Overcome problemsControlled amount of strainSolid-state devicesPhotovoltaicsLight beamPolycrystalline silicon

There is provided an infrared detector including: a silicon substrate provided with a concave portion; an infrared receiver having a polysilicon layer; and a beam that supports the infrared receiver above the concave portion, and extends along a side of the infrared receiver from the infrared receiver to connect with the silicon substrate, the beam having at least two bent portions, wherein at least one of the bent portions of the beam is disposed at a position on a side opposite to the concave portion with the polysilicon layer as a reference point.

Owner:LAPIS SEMICON CO LTD

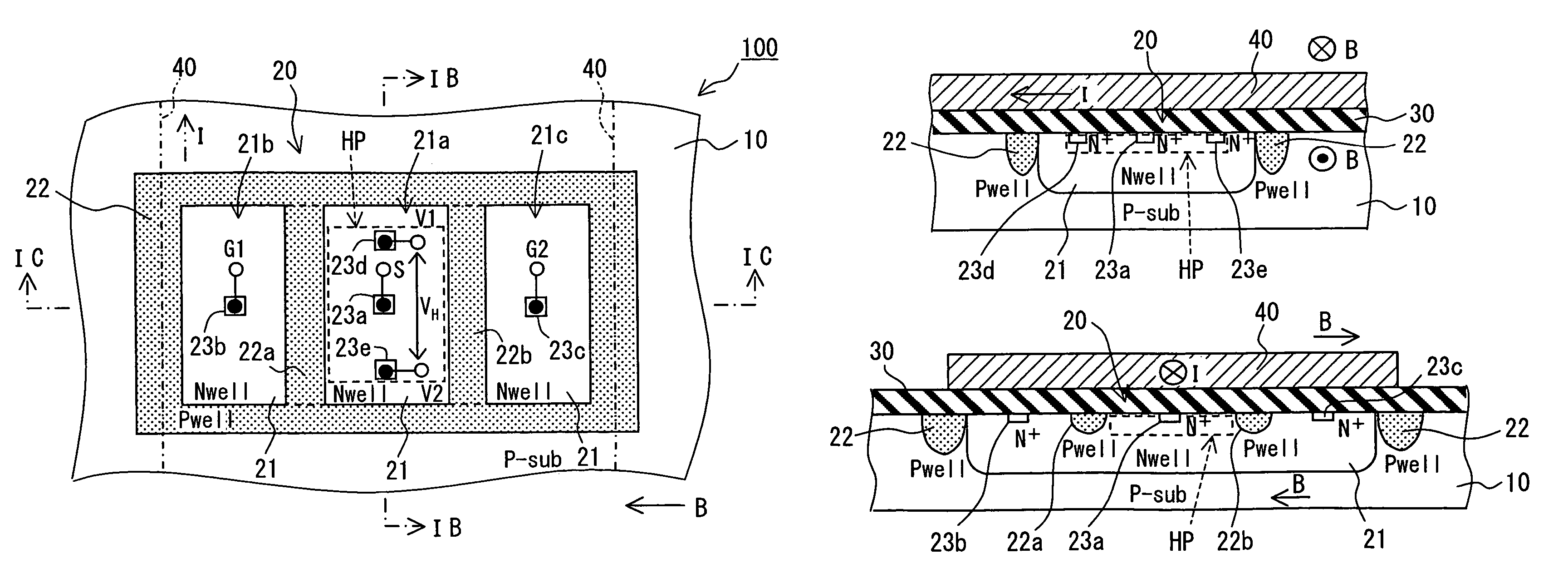

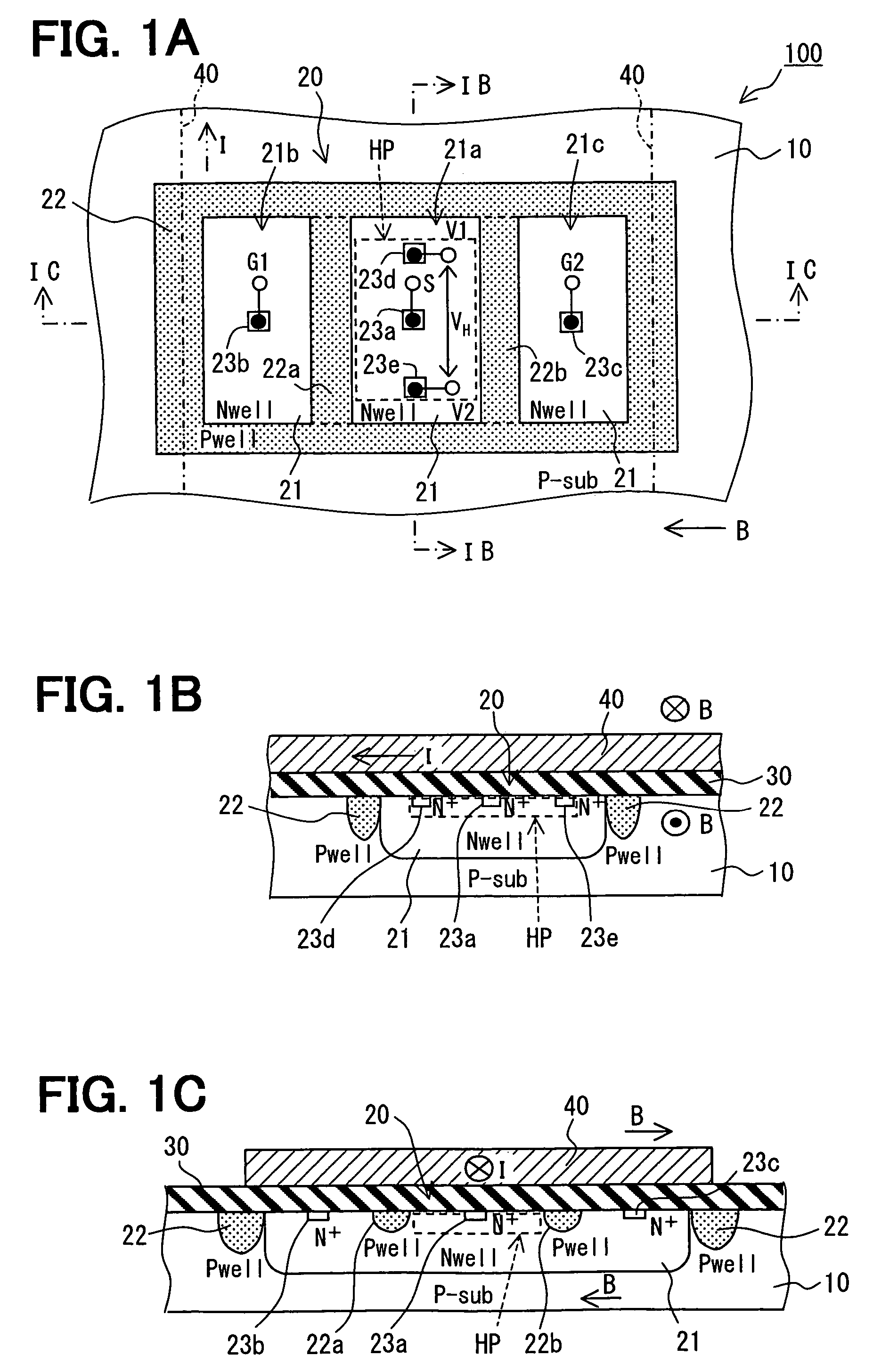

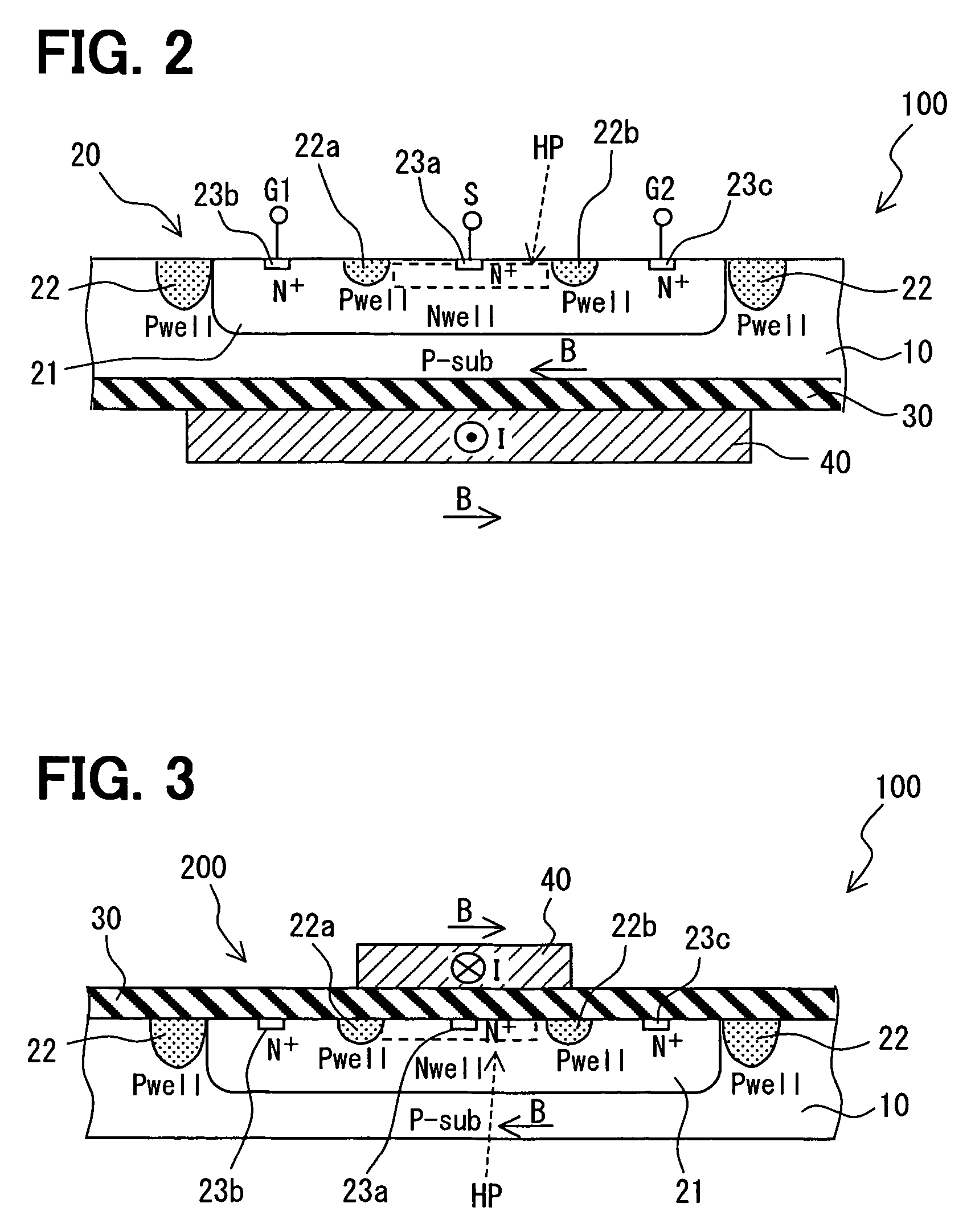

Current sensor having hall element

InactiveUS7253601B2Improve detection accuracySmall dimensionMeasurement using dc-ac conversionMagnetic measurementsDriving currentElectricity

A current sensor includes: a current path; a semiconductor substrate; and a Hall element on the substrate. The Hall element detects a magnetic flux in a magnetic field caused by a detection object current. The Hall element generates a Hall voltage corresponding to the magnetic flux when a driving current flowing in a direction perpendicular to the semiconductor substrate is supplied to the Hall element, and when the magnetic flux having a component parallel to the semiconductor substrate affects the Hall element. The current path is disposed on the semiconductor substrate. The current path is electrically isolated from the Hall element.

Owner:DENSO CORP

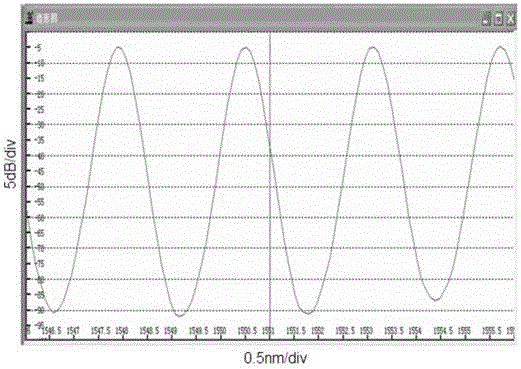

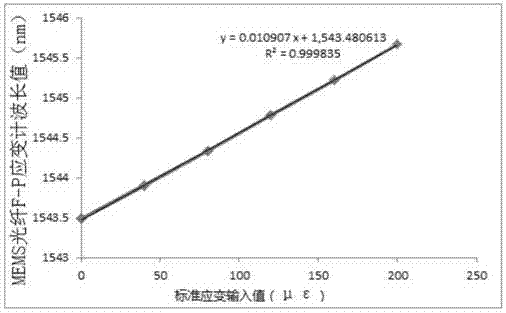

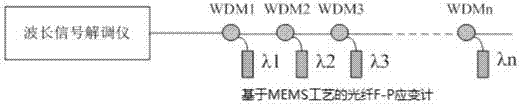

Optical fiber F-P strain gauge based on MEMS technology and formation method thereof

ActiveCN104501729AWide operating temperature rangeResistant to chemical corrosionPrecision positioning equipmentDecorative surface effectsEngineeringTime-division multiplexing

The invention discloses an optical fiber F-P strain gauge based on an MEMS technology and a formation method thereof, and belongs to the field of high-precision optical fiber sensing measurement. The optical fiber F-P strain gauge mainly comprises an F-P strain sensitive MEMS chip and a collimated and beam expanded optical fiber. The F-P strain sensitive MEMS chip is composed of an SOI strain beam, a glass fixed pole and a silicon bushing. The SOI strain beam comprises top layer silicon, an intermediate oxide layer and bottom layer silicon. The SOI strain beam is fixed on the glass fixed pole via silicon-glass anodic bonding. The glass fixed pole is fixed on the silicon bushing via silicon-glass anodic bonding. The collimated and beam expanded optical fiber is fixed on the silicon bushing via soldering material. The F-P pressure sensitive MEMS chip is prepared on the basis of an MEMS micromachining technology so that miniaturized and mass manufacturing of the device can be realized. The strain gauge has high-fineness F-P interference spectrum, high sensitivity and high measurement precision can be acquired by adopting wavelength signal demodulation, and series connection of multiple strain gauges on the single-core optical fiber can be realized via wavelength division multiplexing and time division multiplexing.

Owner:SHANGHAI BAIANTEK SENSING TECH CO LTD

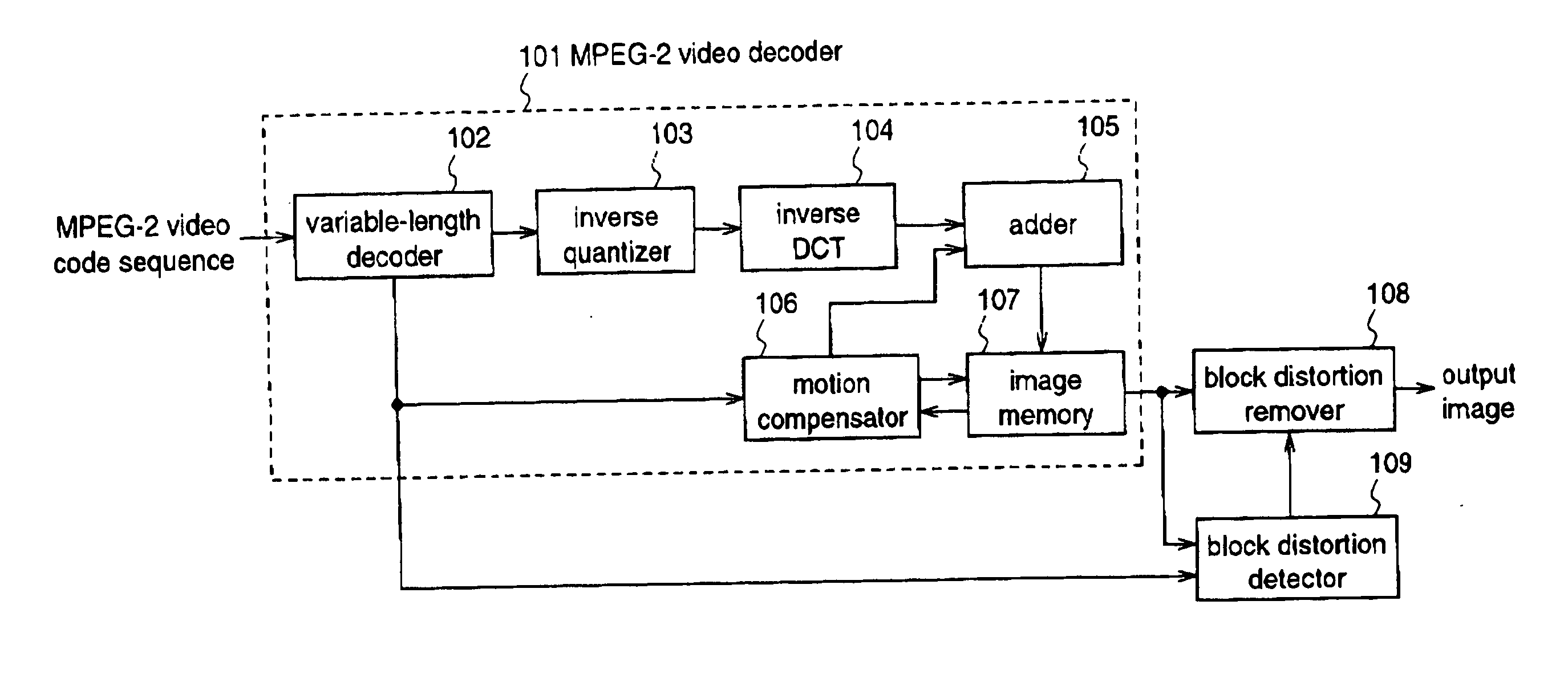

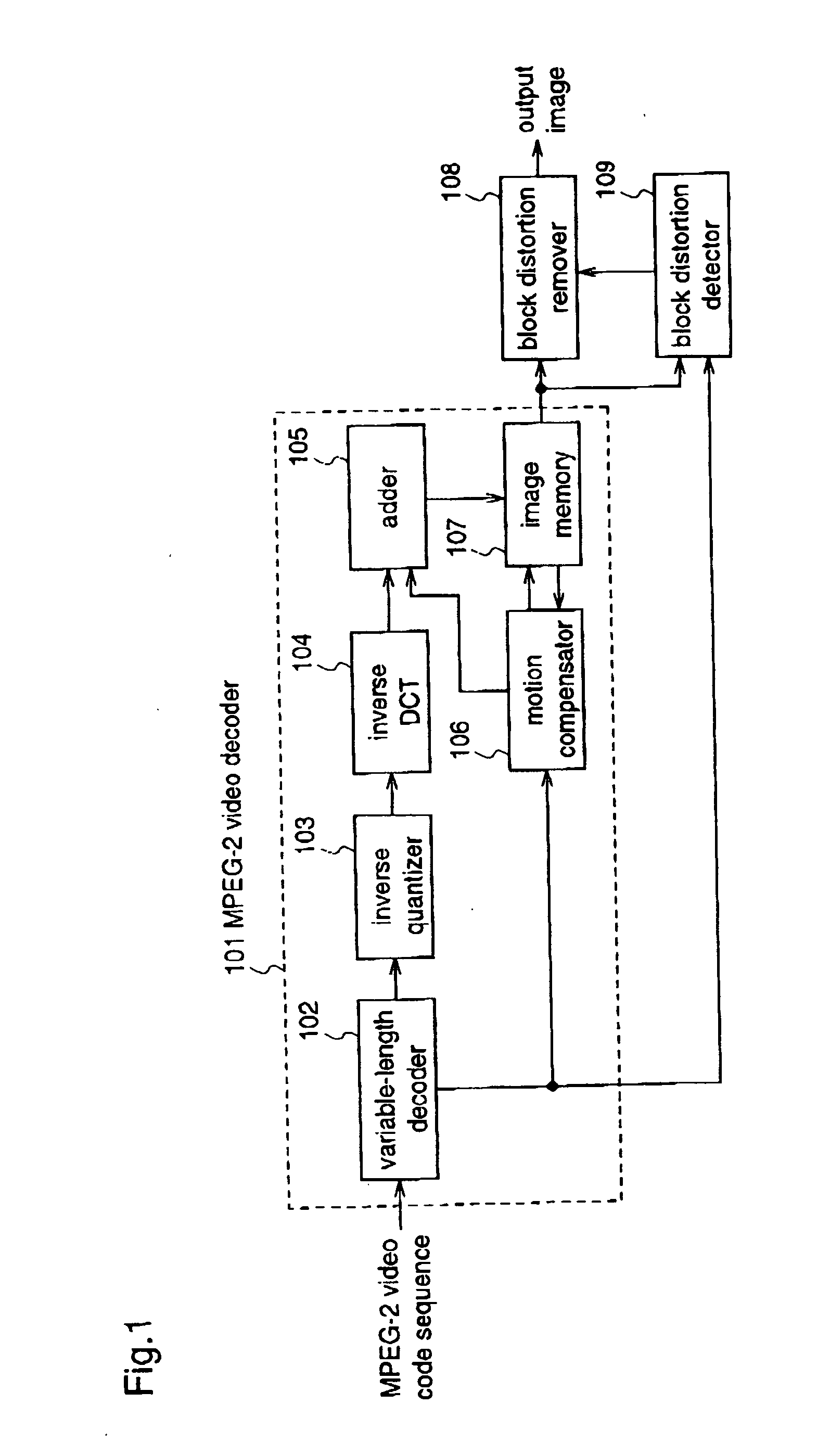

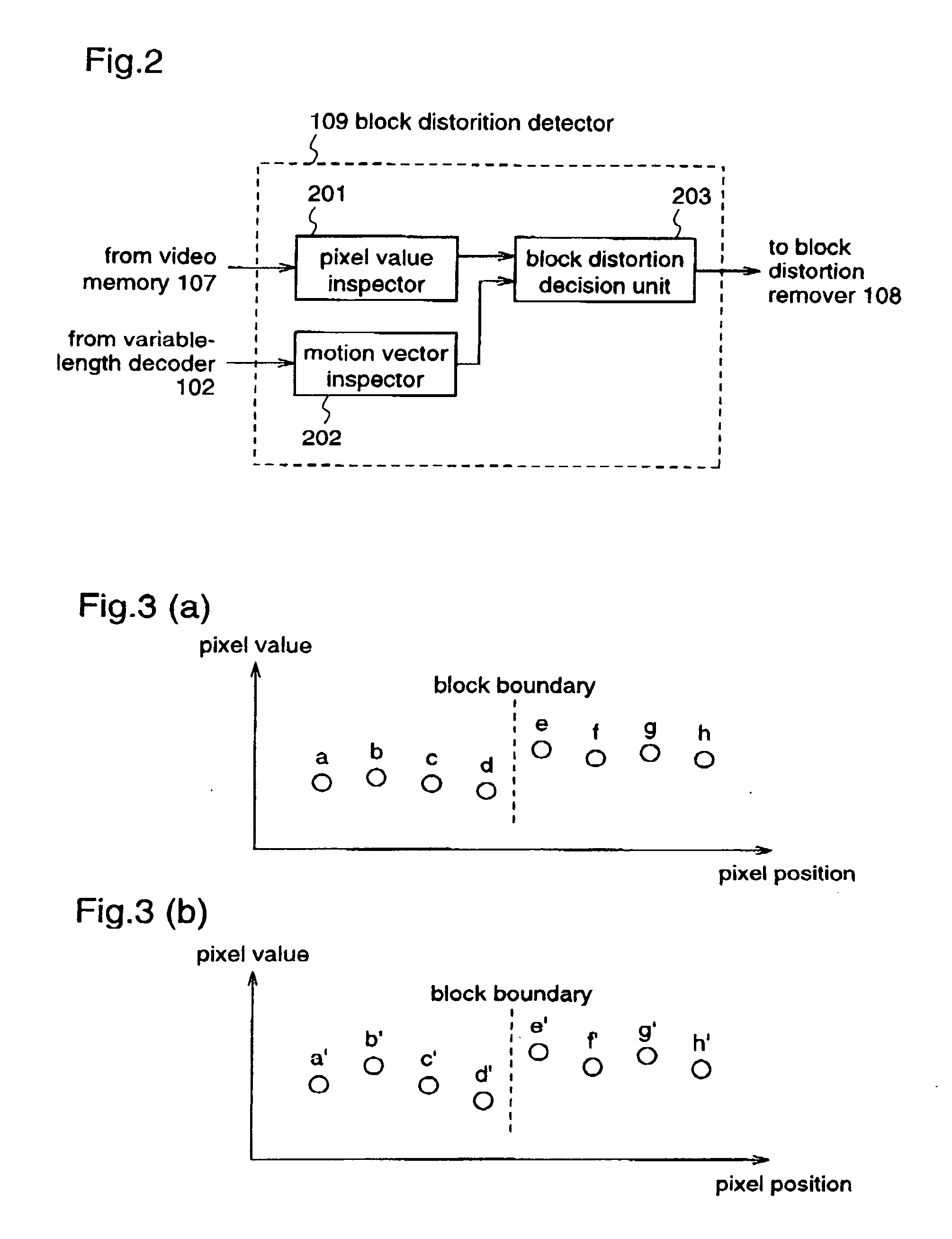

Block distortion detection method, block distortion detection apparatus, block distortion removal method, and block distortion removal apparatus

ActiveUS20050141619A1Avoid detection accuracyImprove accuracyColor television with pulse code modulationColor television with bandwidth reductionMotion vectorVideo decoder

A video decoder is connected with a block distortion detector for specifying the boundary of blocks where block boundary occurs, using decoded image data and information of motion vectors, which are supplied from the video decoder; and a block distortion remover for subjecting pixels in the vicinity of the block boundary of the decoded image to filtering on the basis of the result of detection from the block distortion detector, thereby removing the block distortion. Therefore, block distortion is accurately detected when a compressed and coded image is decoded, and the detected block distortion is removed while minimizing the blurriness of the image.

Owner:GK BRIDGE 1

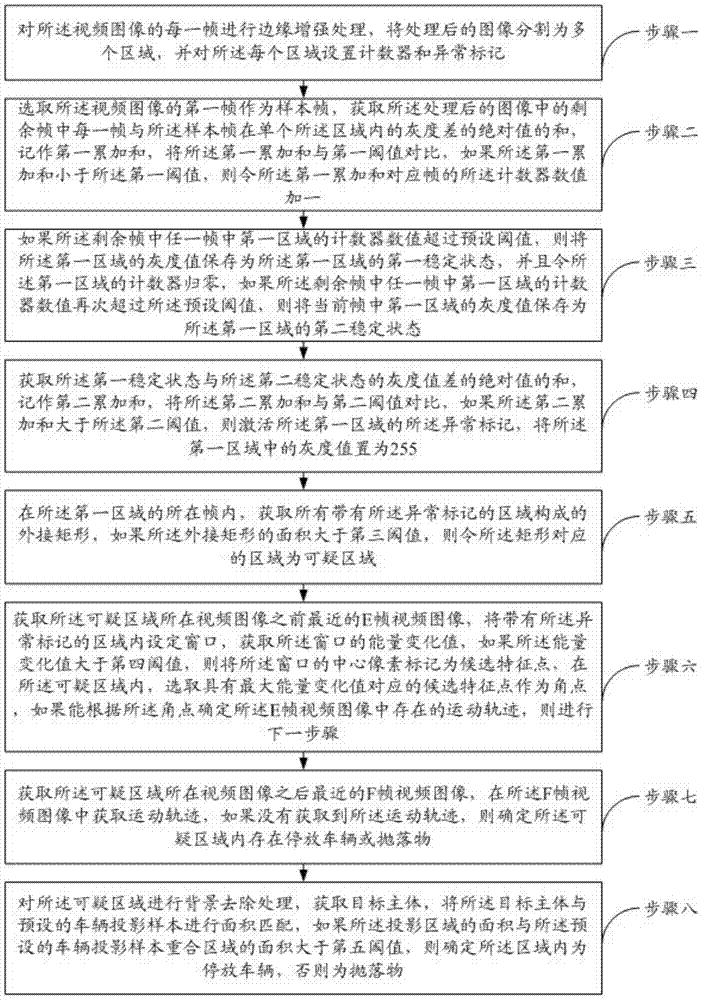

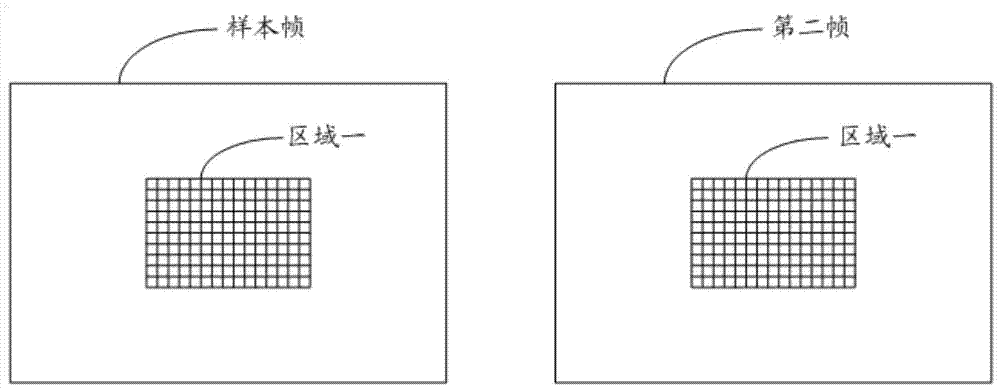

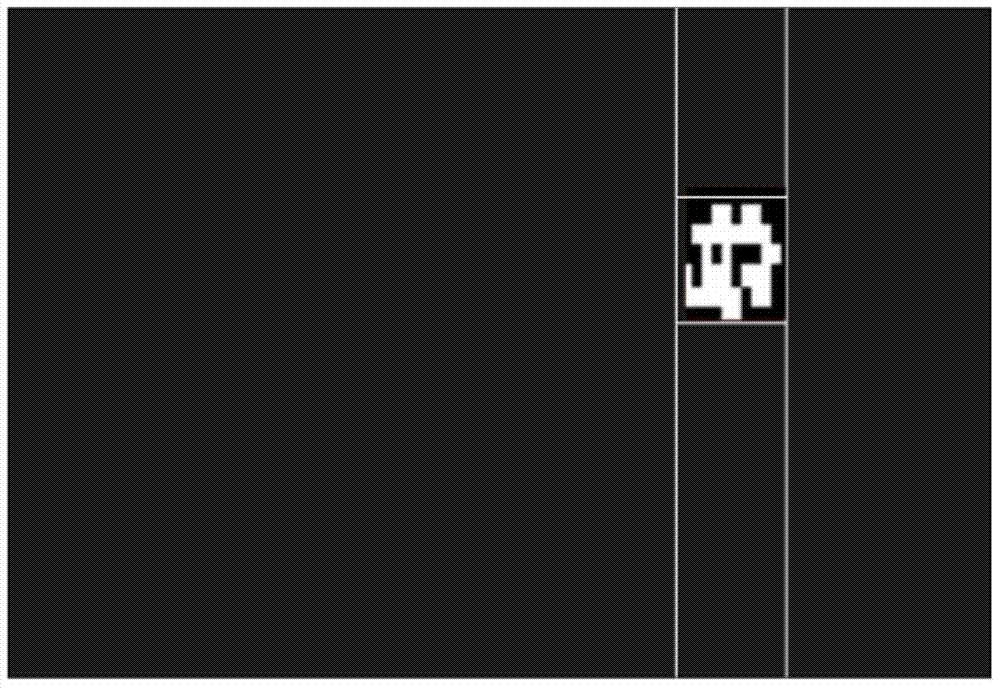

Method for distinguishing parked vehicle from falling object

InactiveCN104504730AAvoid detection accuracyImprove detection accuracyImage enhancementImage analysisDimensionality reductionVideo image

The invention discloses a method for distinguishing a parked vehicle from a falling object and belongs to the field of traffic. The method comprises the following steps: determining a suspicious region where a parked vehicle or a falling object may occur in a video image, and specifically judging the condition in the suspicious region. According to the method disclosed by the invention, an acquired video image is processed, and a projection area of an object main body corresponding to a track is compared with the projection area of a preset vehicle after the condition that the track of the parked vehicle or the falling object exists in the video image is judged, so the object main body in the video image is a parked vehicle or a falling object is judged, the problem of poor detection accuracy caused by loss of height information of the object during dimensionality reduction of an existing detection technology can be avoided, and the detection accuracy can be improved.

Owner:CHANGAN UNIV

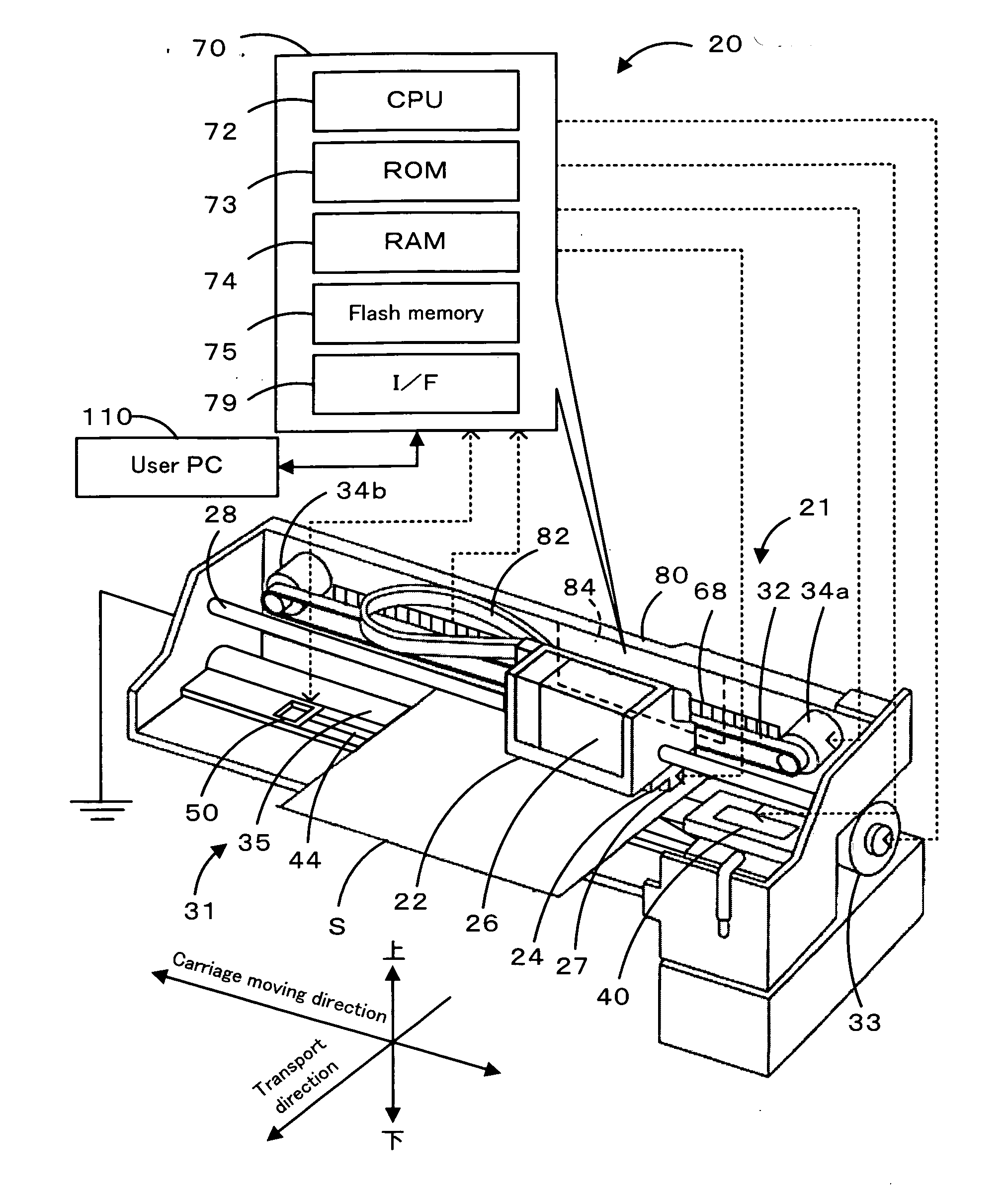

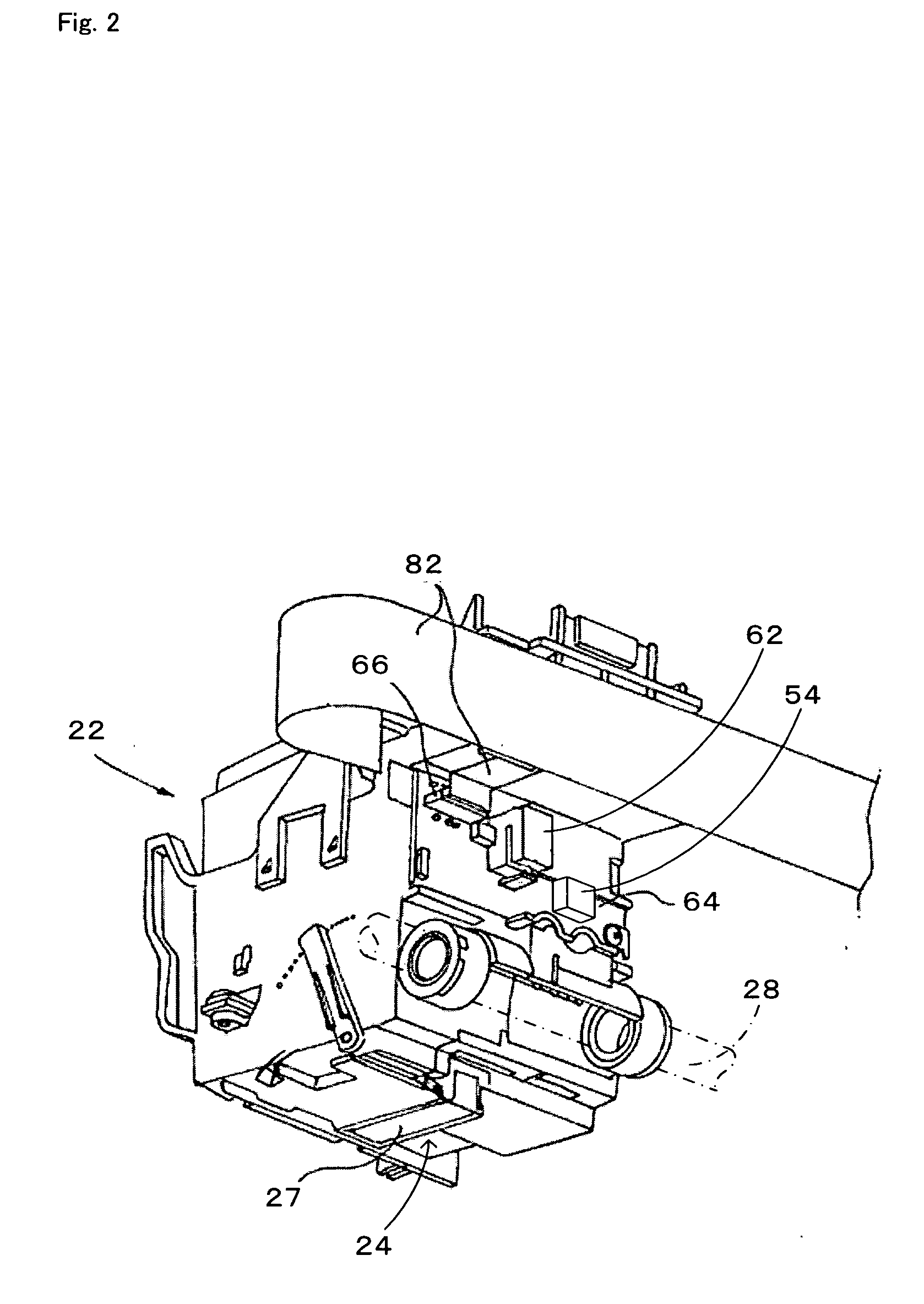

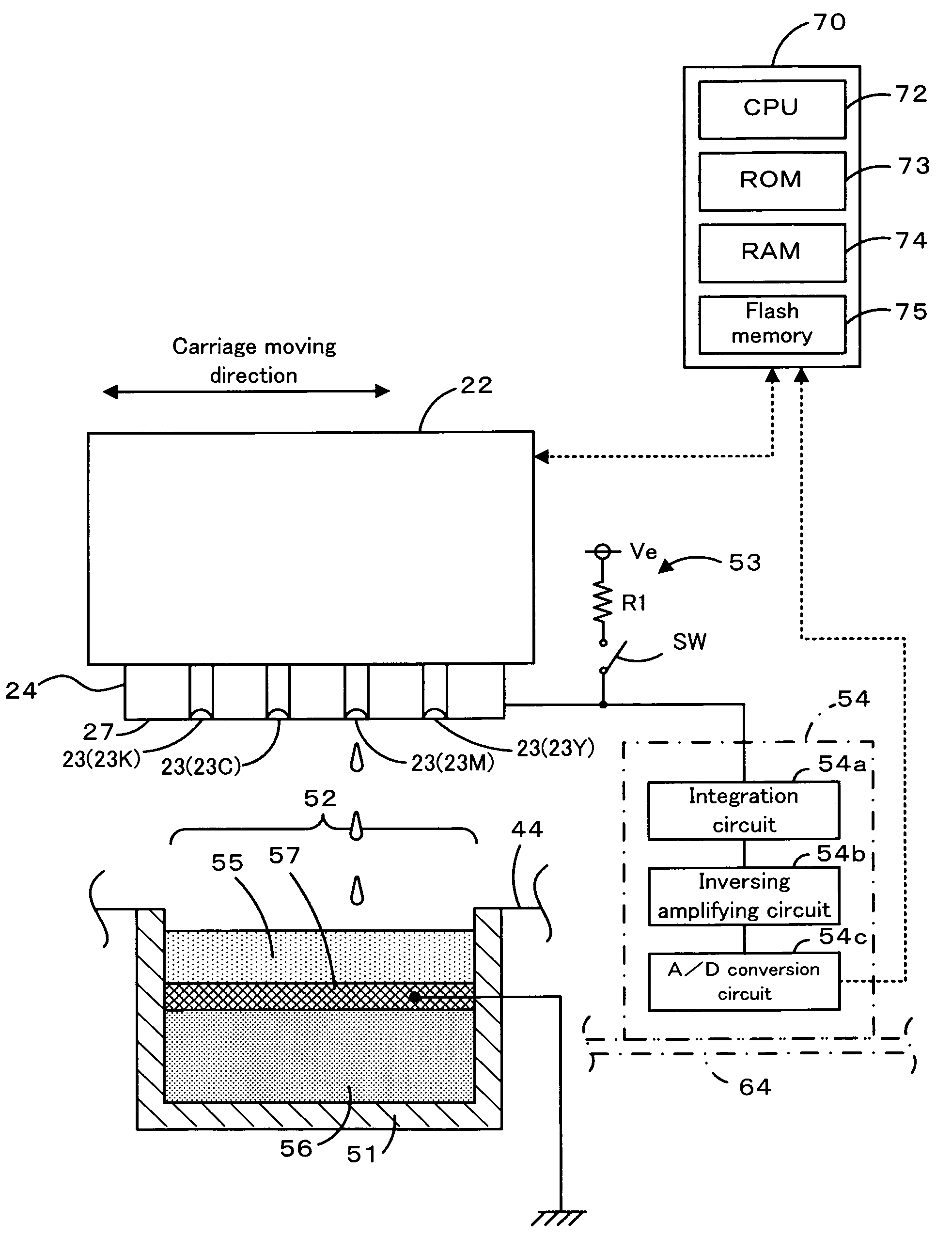

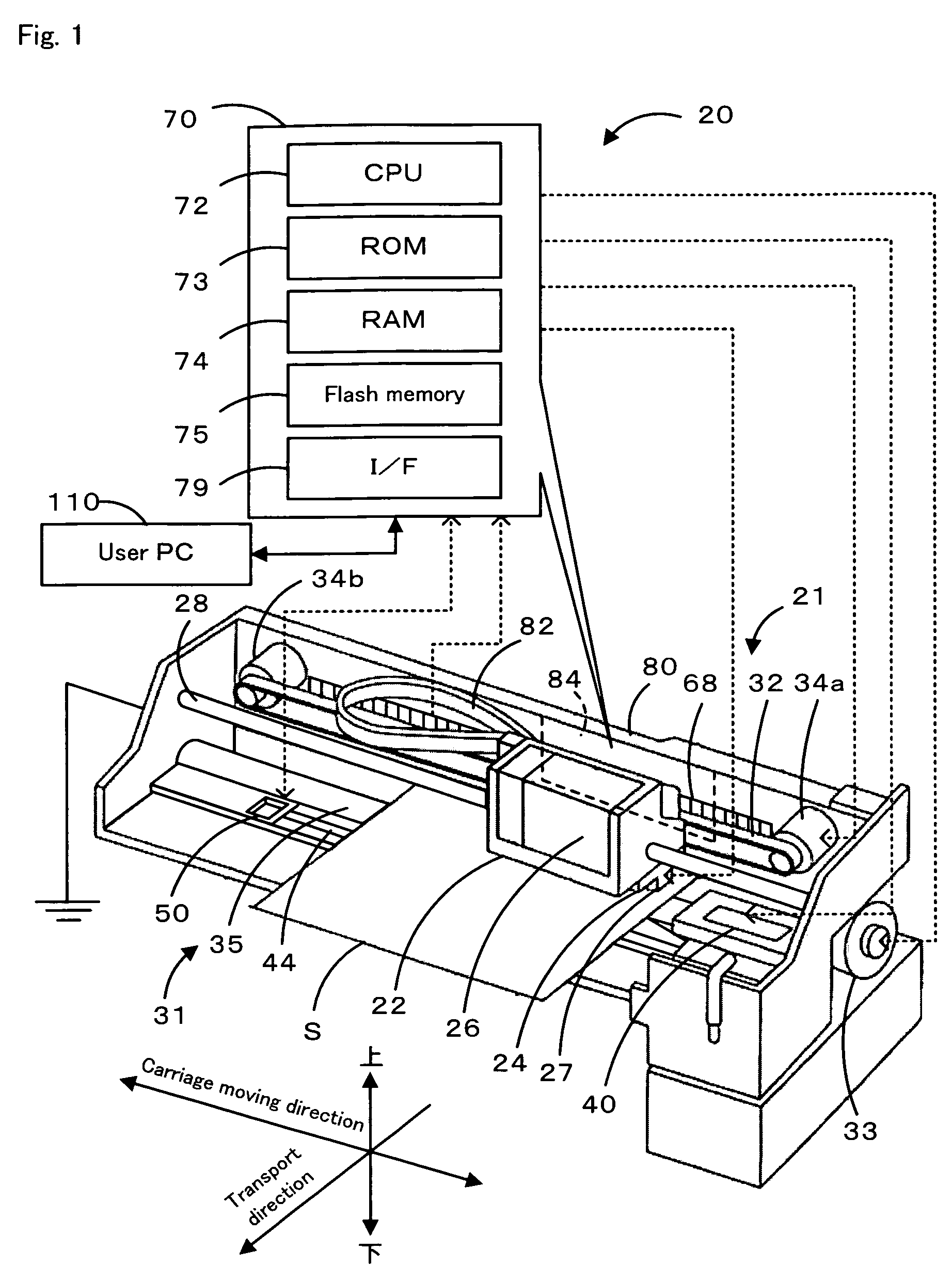

Ink jet recording apparatus, nozzle inspection method and program thereof

InactiveUS20070076029A1Reduce distanceLess susceptible to noiseOther printing apparatusPotential differenceInk printer

In this ink jet printer, on the basis of voltage of a nozzle plate 27 at the time that a print head 24 is driven and in a state in which a predetermined potential difference has been generated between the nozzle plate 27 and the inspection area 52, a nozzle inspection is performed so as to confirm whether or not ink is in practice being ejected from each nozzle 23, so that ink can be sequentially ejected to an inspection area 52 from each nozzle. According to the nozzle inspection voltage change is detected in the nozzle plate 27 by a voltage detection circuit 54 provided on an encoder board 64 on a carriage 22. Since both the nozzle plate 27 and the voltage detection circuit 54 are installed on the carriage 22, and the distance between the two of them is shorter, they are less likely be affected by noise. In addition, there is no need to prepare a new board on which the voltage detection circuit 54 needs to be mounted.

Owner:SEIKO EPSON CORP

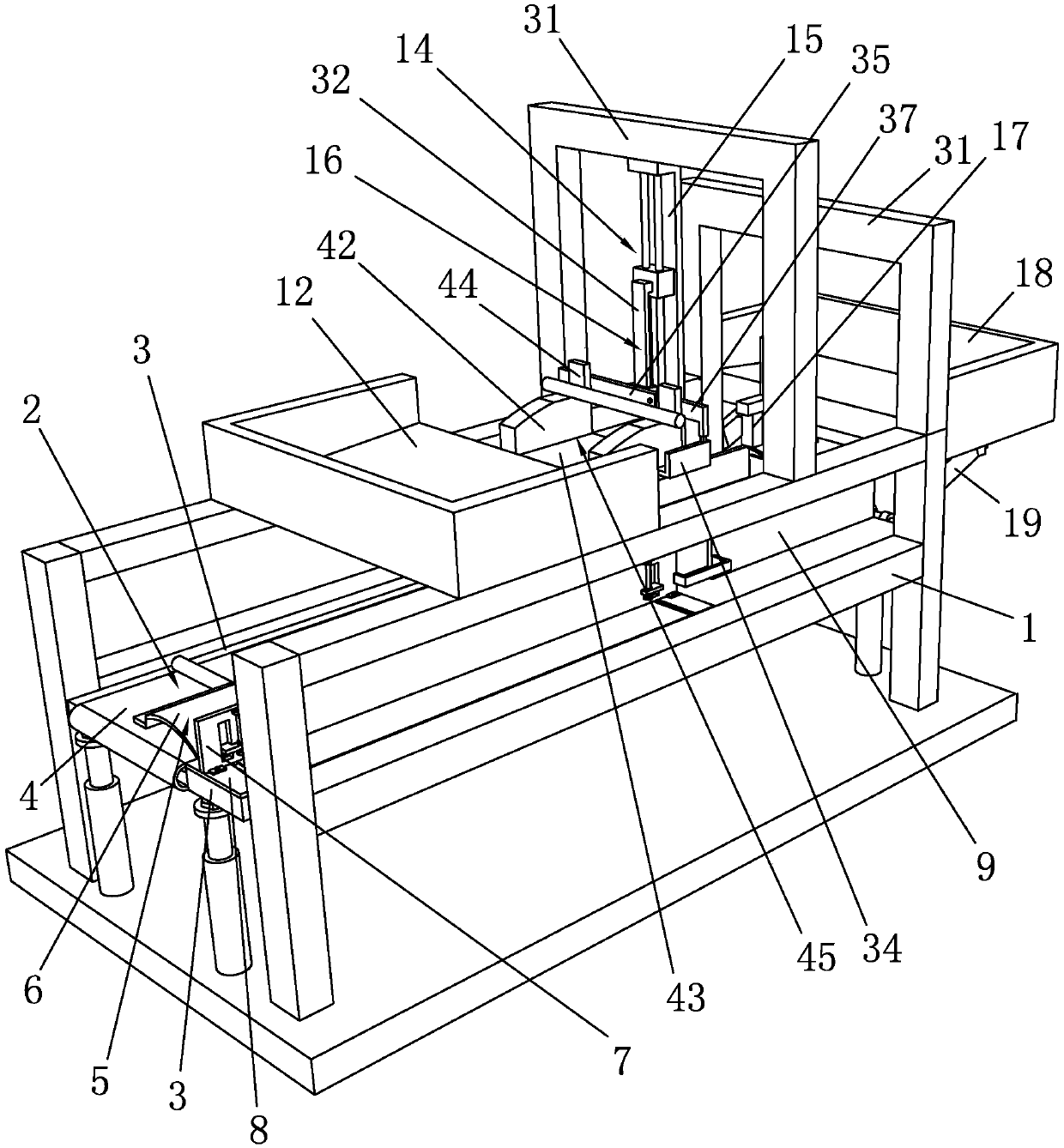

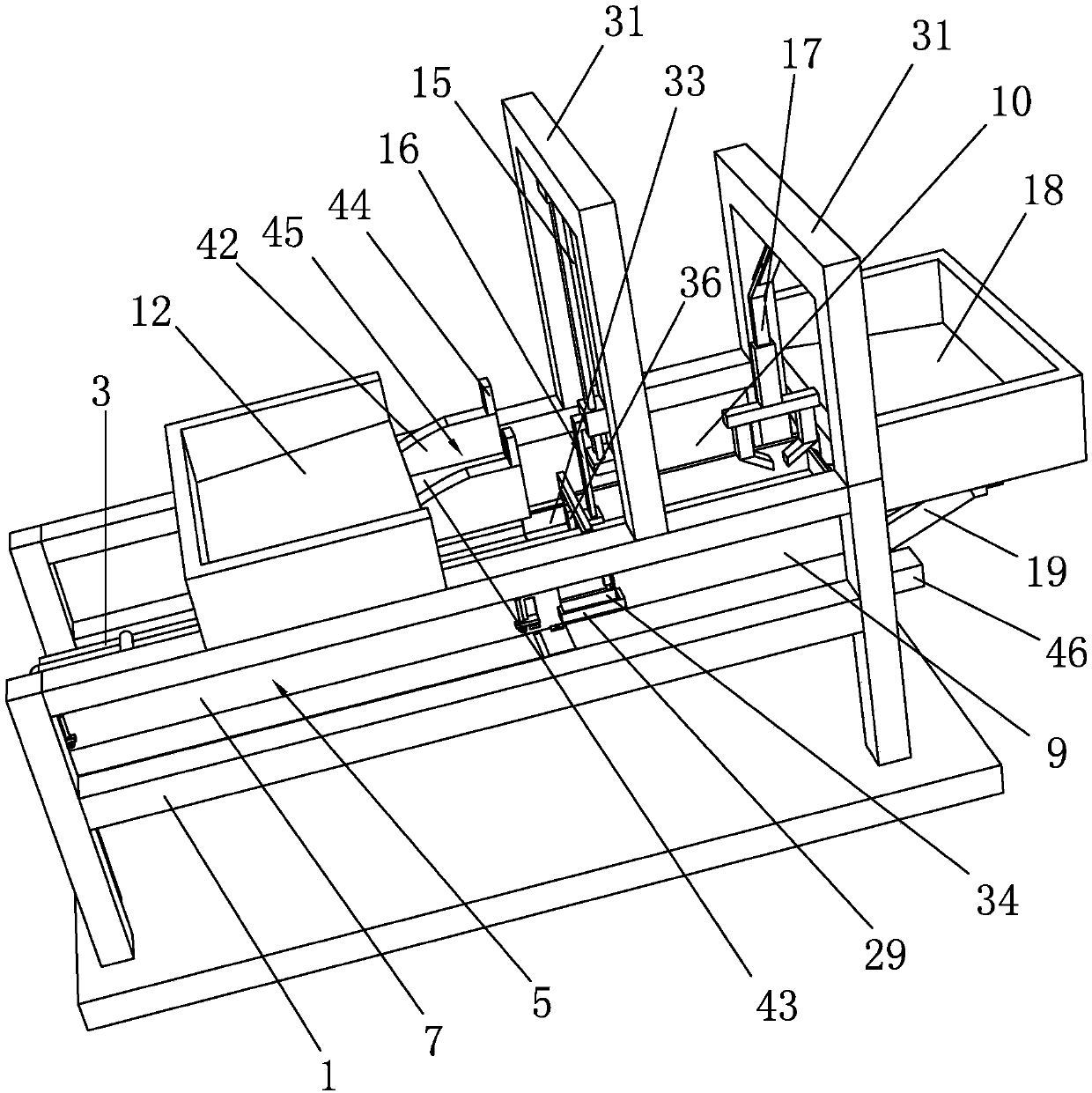

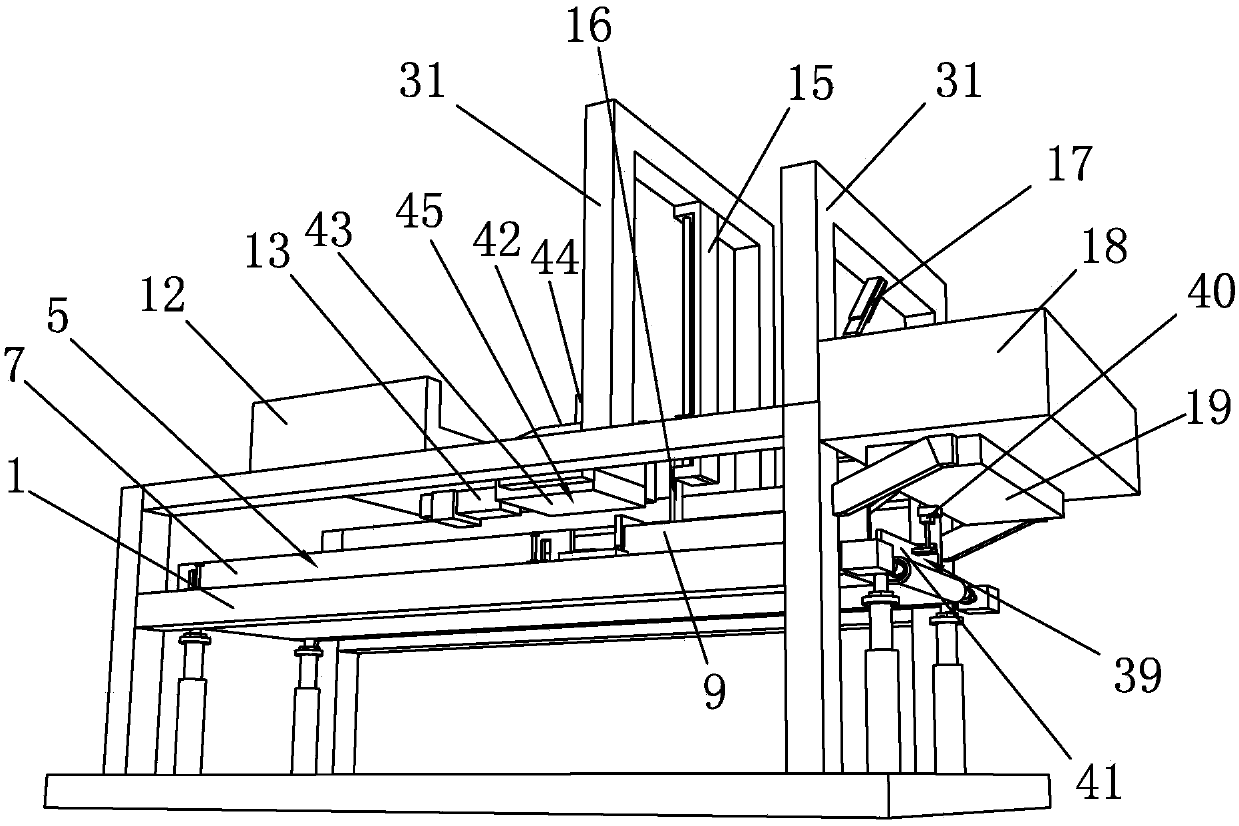

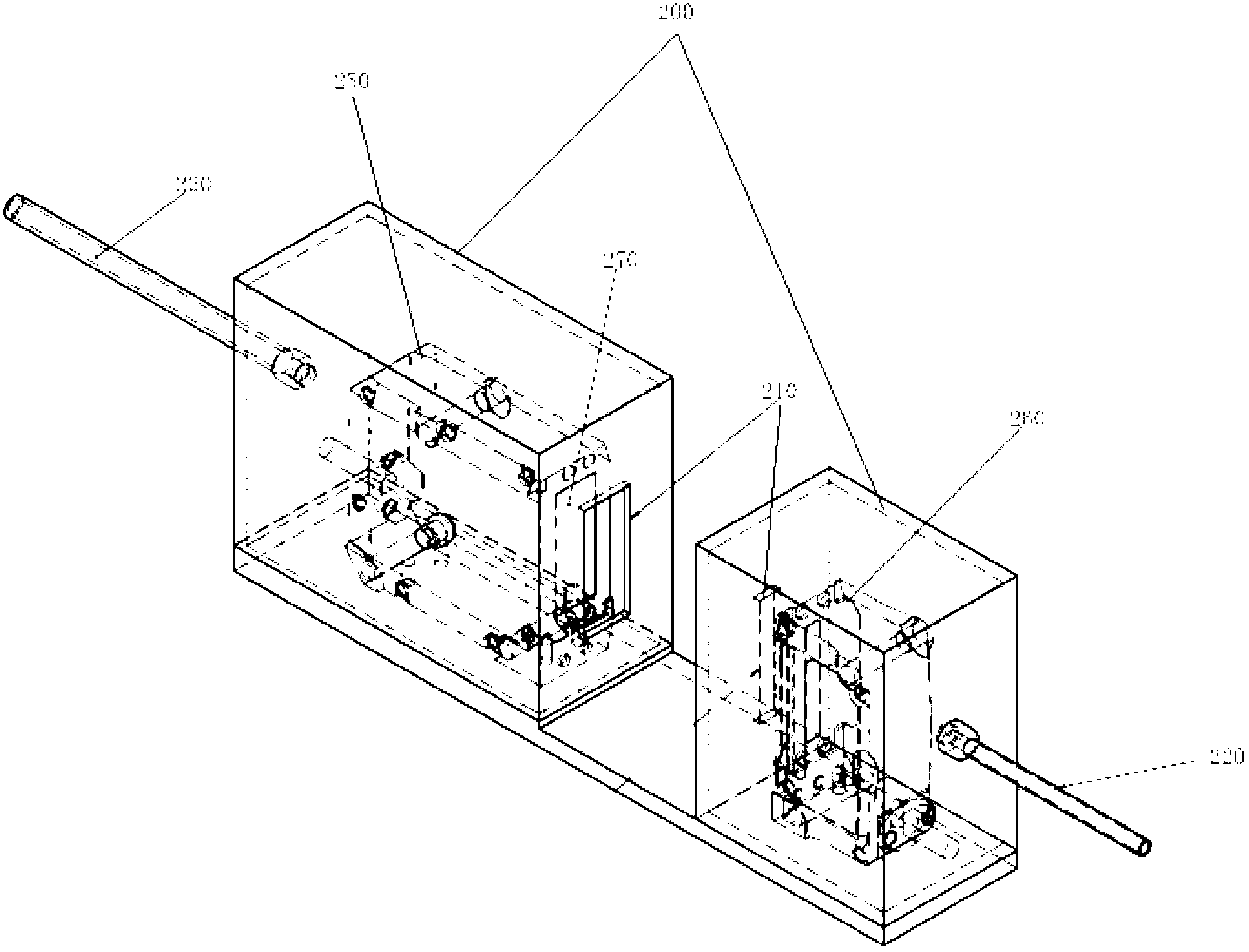

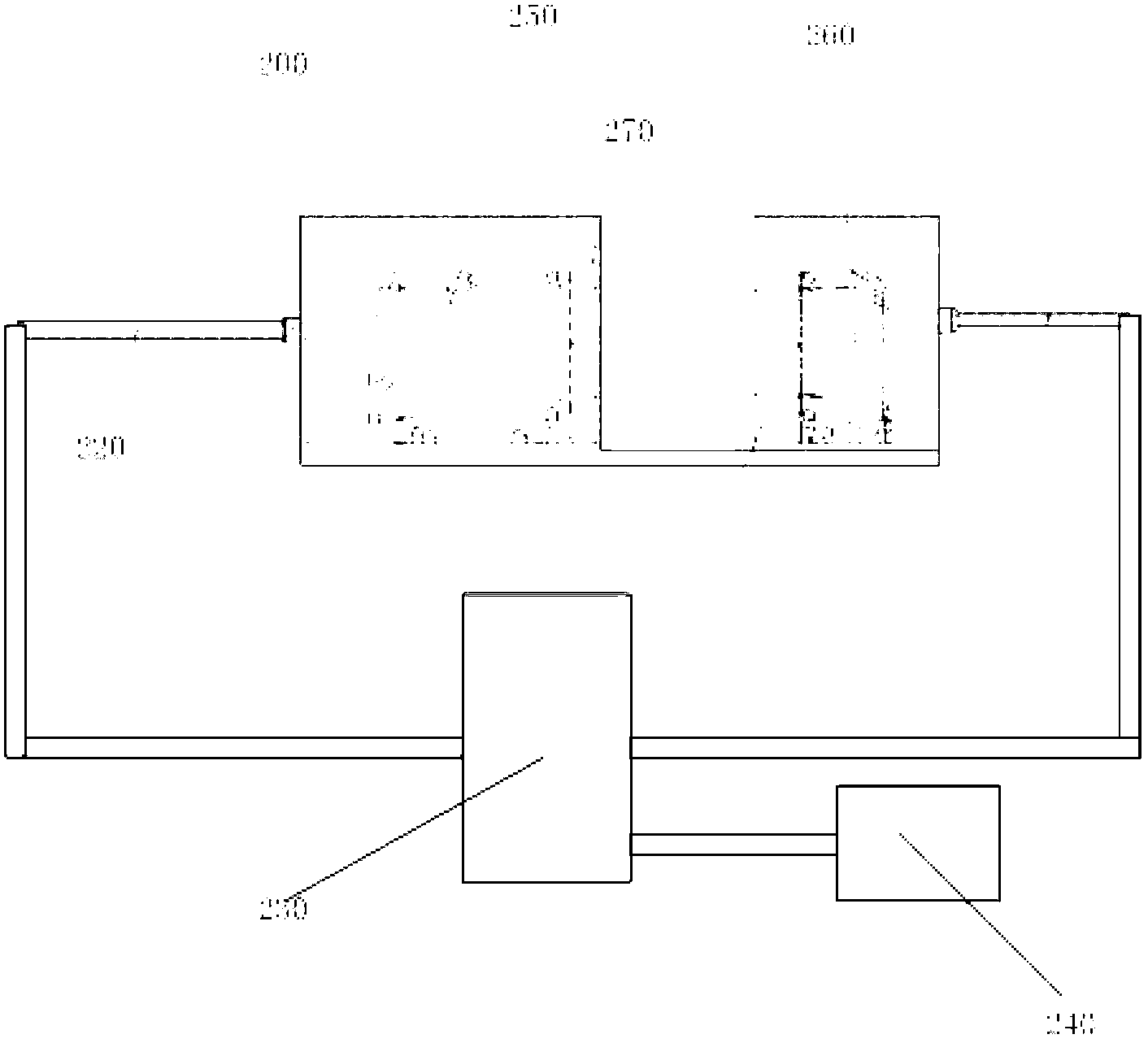

Length detection device of hardware round tube finished product

ActiveCN109530249AInhibit sheddingConvenient card connectionSortingGradingPulp and paper industryEngineering

The invention discloses a length detection device of hardware round tube finished products. The length detection device comprises a limiting frame and a conveying table, wherein the conveying table comprises a machine frame and a conveying belt set, a positioning and flattening device is arranged on the conveying table, the positioning and flattening device comprises a flattening plate, a verticaladjusting plate, a transverse adjusting plate and an auxiliary side plate, a positioning side plate is arranged opposite to the auxiliary side plate, a first waste box is arranged above the flattening plate, a pushing air cylinder is arranged at the bottom of the first waste box, the pushing air cylinder is connected with an intercepting frame, and a material blocking device is arranged on the rear side of the intercepting frame. The length detection device is simple in structure, high in practicability, good in safety, and convenient to operate; and automatic detection and classification canbe carried out on the length of the finished round tube finished products, and the round tubes with the length larger than the set range or smaller than the set range are taken away, so that the length of the round tubes collected by finished products meets the actual requirements, the operation automation is realized, the labor intensity of workers is effectively reduced, and the accuracy of thedetection and classification of the length of the round tubes is improved.

Owner:裘士兴

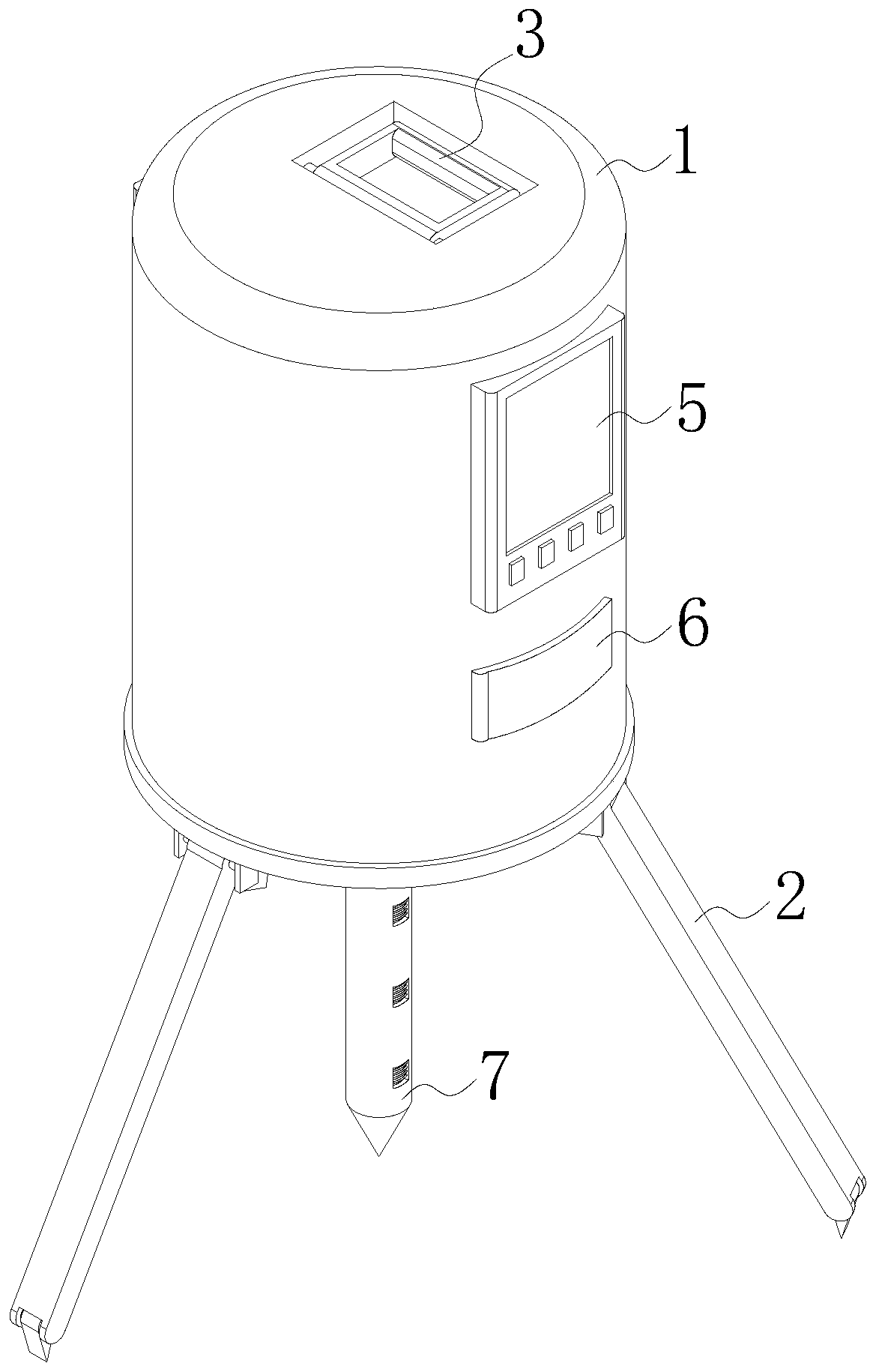

Agricultural soil pollution degree detection device

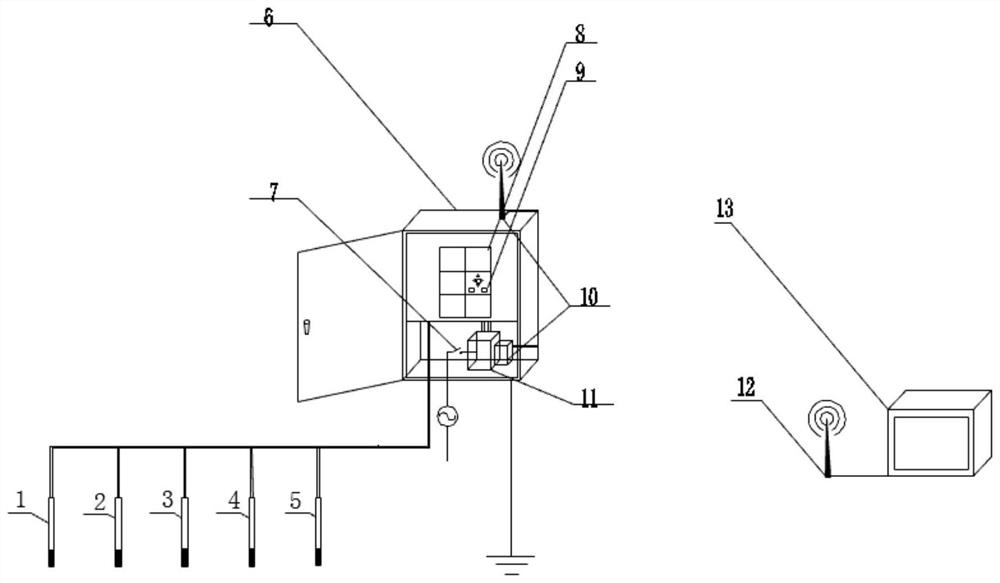

ActiveCN110568162AAvoid the problem of mutual doping affecting the detection accuracyAvoid detection accuracyWithdrawing sample devicesEarth material testingPhase detectorGas phase

The invention discloses an agricultural soil pollution degree detection device, and belongs to the technical field of soil detection. The agricultural soil pollution degree detection device comprisesa cylinder body; three supporting legs are hinged to the bottom of the cylinder body at equal intervals in a surrounding mode; a storage type handle is movably installed at the top of the cylinder body; a soil liquid phase detector and a soil gas phase detector are fixedly installed on the left side and the right side of the cylinder body respectively; opening and closing plates are arranged belowthe soil liquid phase detector and the soil gas phase detector respectively, and the two opening and closing plates are hinged to the left side and the right side of the cylinder body respectively and are designed to penetrate through the inner wall of the cylinder body. According to the agricultural soil pollution degree detection device, a sampling mechanism is adopted, so that sampling work ofsoil at different depths can be completed in the process of inserting and pulling out of a soil layer at a time, the problem that detection accuracy is affected due to mutual doping of soil at different depths can be effectively avoided, and the sampling mechanism can effectively smash and store solidified soil blocks in the sampling action process.

Owner:ZHEJIANG ZHIHUIYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

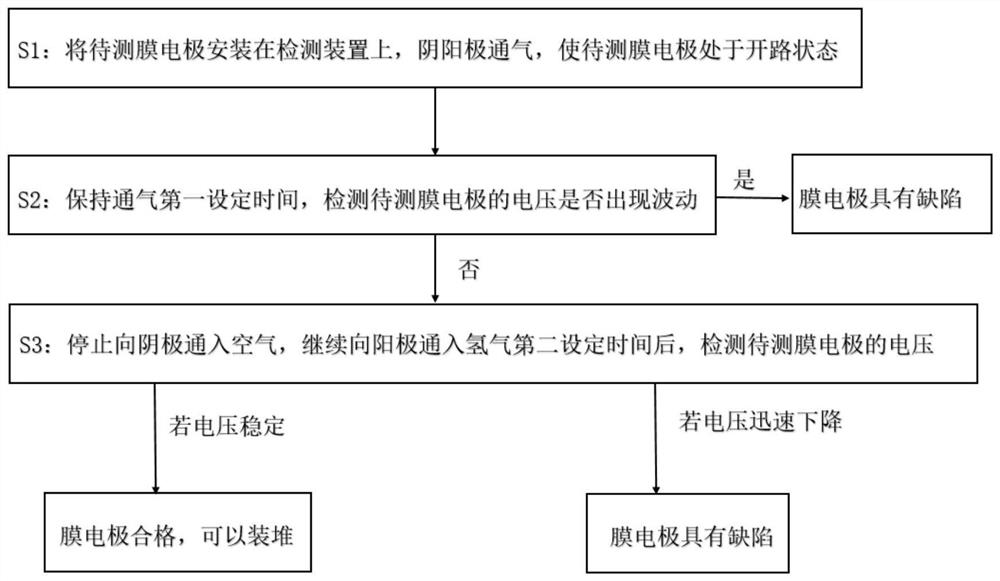

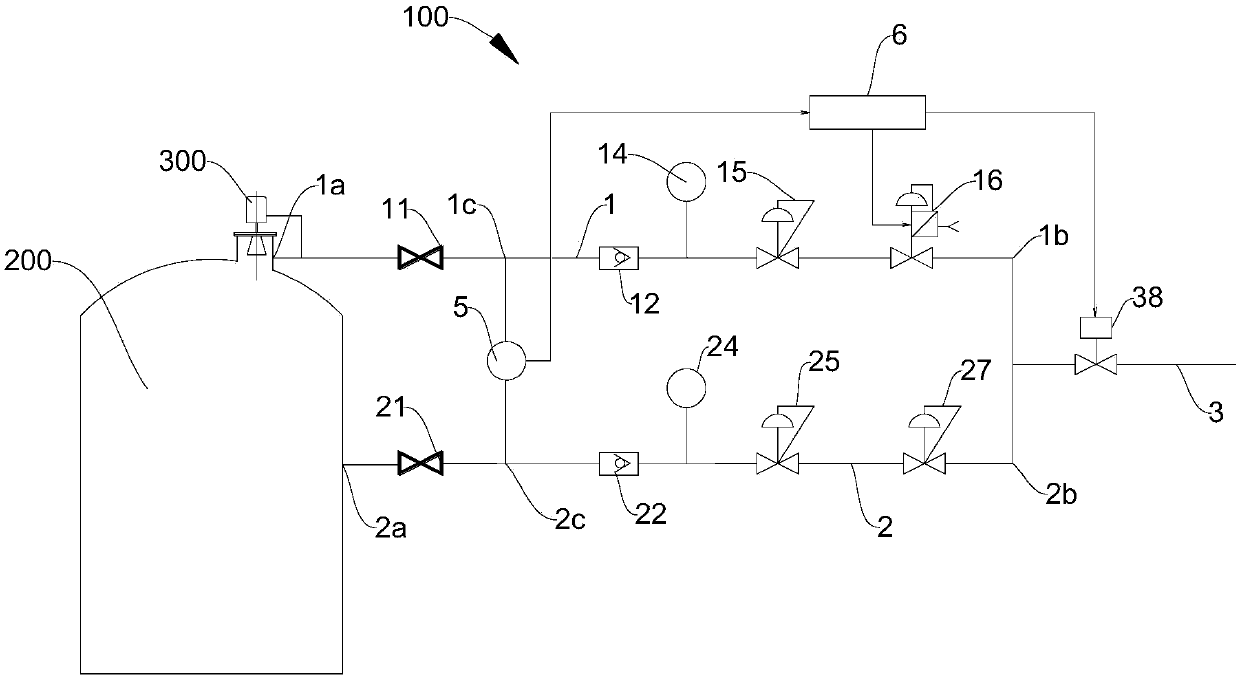

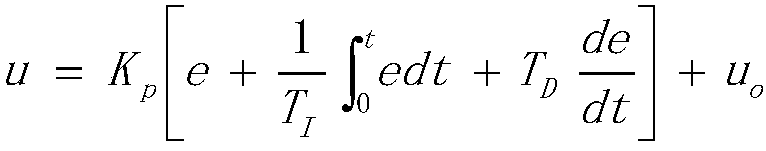

Defect detection method for membrane electrode of fuel cell

ActiveCN112213369AImprove detection efficiencySolve misalignmentMaterial analysis by electric/magnetic meansFuel cellsChemical physicsFuel cells

The invention relates to a defect detection method for a membrane electrode of a fuel cell, which mainly comprises the following steps of S1, mounting a membrane electrode to be detected on a detection device, introducing hydrogen into an anode of the membrane electrode to be detected, and introducing air or oxygen into a cathode of the membrane electrode to be detected, so that the membrane electrode to be detected is in a power generation state, wherein the voltage of the membrane electrode to be measured is an open-circuit voltage; S2, keeping the ventilation state for a first set time, andif the voltage of the membrane electrode to be detected fluctuates, judging that the membrane electrode to be detected has defects; if the voltage of the membrane electrode to be detected does not fluctuate, carrying out the step S3; and S3, stopping introducing air or oxygen into the cathode of the to-be-detected membrane electrode, continuously introducing hydrogen into the anode of the to-be-detected membrane electrode for a second set time, and judging whether the to-be-detected membrane electrode is qualified or not according to the voltage of the to-be-detected membrane electrode. According to the detection method, whether the membrane electrode has defects or not can be detected before the fuel cell stack is assembled, so that the fuel cell stack is prevented from being repeatedlydisassembled and assembled.

Owner:浙江锋源氢能科技有限公司 +1

Cooling and blowing device for radar level gauge and material level detection system

ActiveCN107830909AReduce the impactReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusDifferential pressureRadar

The invention relates to a cooling and blowing device for a radar level gauge and a material level detection system. The cooling and blowing device comprises a first branch circuit which is provided with a flow regulating valve and a first opening and installed on a sealed container, a second branch circuit which is provided with a reducing valve and a second opening and installed on the side wallof the sealed container, a main circuit connected with air inlets of the first branch circuit and the second branch circuit so as to receive gas, a differential pressure transmitter and a controller,wherein two pressure measuring openings of the differential pressure transmitter are connected with the first opening and the second opening respectively, and the controller is connected with the differential pressure transmitter and the flow regulating valve. The controller can regulate the opening of the flow regulating valve according to a detection value of the differential pressure transmitter, the air outlet of the first branch circuit cools and blows the transceiving end of the radar level gauge so as to lower the influence of gas with high temperature, dirt, moisture and pressure inside the sealed container on the radar level gauge, pressure changes of the air outlet of the first branch circuit are in positive correlation with pressure changes inside the sealed container, and therefore the purpose of lowering energy consumption is achieved.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

Magnetic pole position detecting device for detecting magnetic pole position of rotor in permanent-magnet synchronous motor

ActiveUS8766586B2Avoid detection accuracyImprove reliabilitySingle-phase induction motor startersMotor/generator/converter stoppersSynchronous motorPermanent magnet synchronous motor

A magnetic pole position detecting device includes a calculating unit for correcting a magnetic pole position detected by a magnetic pole position detecting unit. In this magnetic pole position detecting device, an additional phase is added to the magnetic pole position detected by the magnetic pole position detecting unit, in order to move a rotor. In relation to a movement amount before and after this movement, a movement amount detected by the magnetic pole position detecting unit is compared with a movement amount detected by an encoder. When a difference between them is larger than a predetermined threshold, a process of detecting the magnetic pole position is determined as false detection.

Owner:FANUC LTD

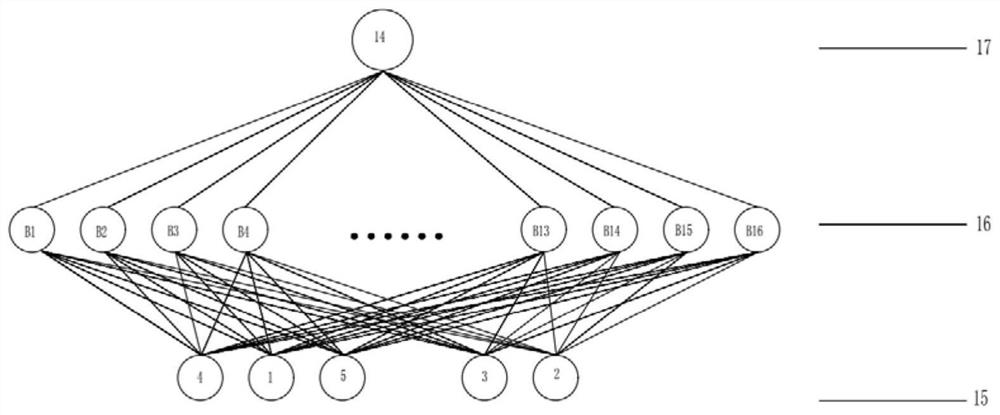

The fpga architecture and implementation method of pedestrian detection system based on hog and svm

InactiveCN103177262BTroubleshoot Migration Optimization IssuesAvoid detection accuracyCharacter and pattern recognitionFpga architectureComputer architecture

The invention discloses an implementing method of FPGA (field programmable gate array) architecture of an HOG (histogram of oriented gradient) and SVM (support vector machine) based pedestrian detection system. The implementing method includes steps of inputting, gradient and direction computation, histogram generation, binaryzation, SVM classification and outputting. The invention further provides the FPGA (field programmable gate array) architecture of the HOG and SVM based pedestrian detection system. By the FPGA architecture and the implementing method thereof, the problem that an HOG and SVM based pedestrian detection algorithm is slow in computation on a PC(personal computer) is solved, transplant optimization of hardware is realized, the FPGA architecture of an embedded pedestrian detection system is implemented in the scheme with low power consumption, high detection efficiency and low resource consumption in real time, and thus, pedestrian detection is popularized and developed in the embedded field according to the scheme.

Owner:SHANDONG UNIV

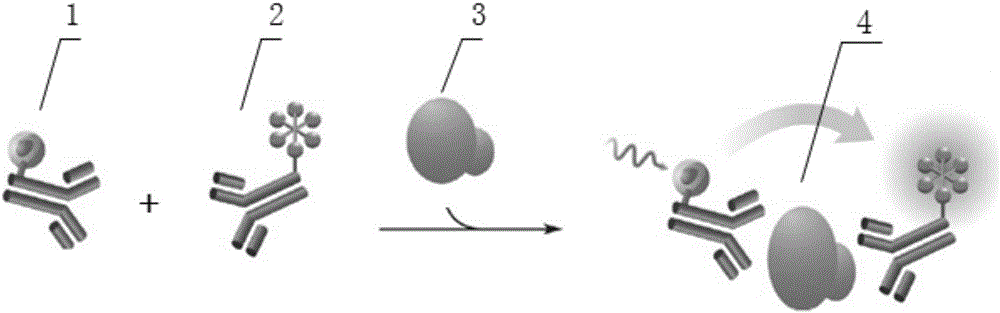

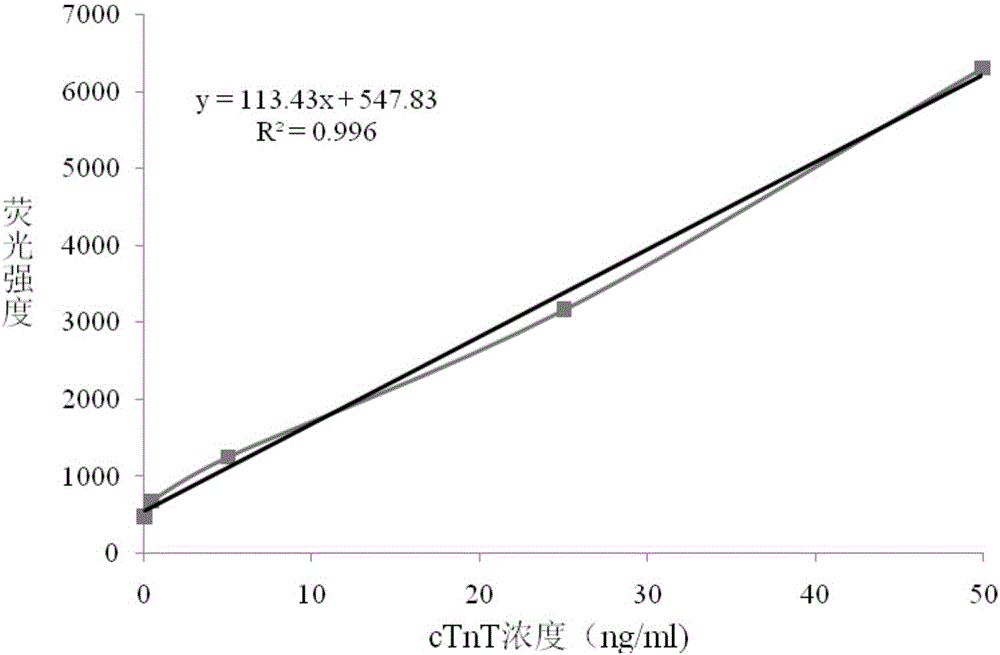

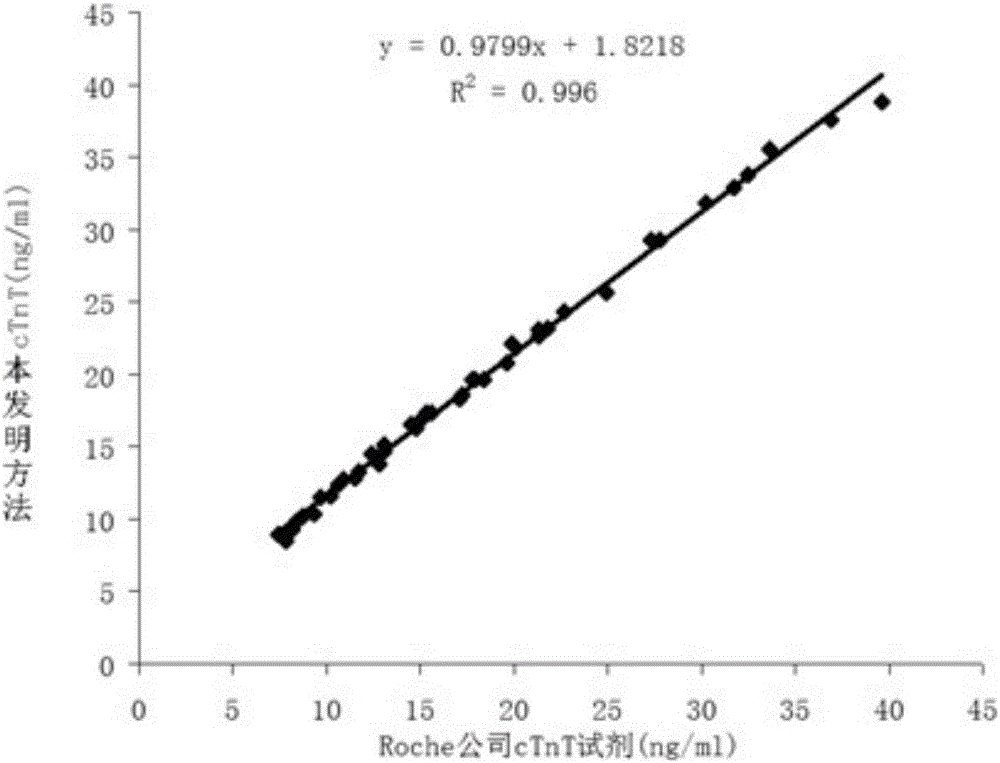

Homogeneous fluorescence immunoassay reagent for rapid and quantitative detection of troponin T and preparation and detection methods thereof

InactiveCN106645744ASensitive and goodImprove featuresDisease diagnosisBiological testingRare-earth elementFluorescence

The invention discloses a homogeneous fluorescence immunoassay reagent for rapid and quantitative detection of troponin T and preparation and detection methods thereof. The homogeneous fluorescence immunoassay reagent for rapid and quantitative detection of troponin T comprises anti-cTnT (cardiac troponin) labeled with rare earth element chelate, another anti-cTnT labeled with a near infrared fluorescent compound and cTnT calibrators with a series concentrations. With the adoption of a rapid homogeneous fluorescence detection technology as well as the high sensitivity characteristic of fluorescence, adverse effects on detection accuracy and repeatability due to the non-uniform characteristics of pores of a nitrocellulose membrane in colloidal gold or fluorescent cTnT dry immune test paper are also prevented, and the detection sensitivity and the linear range can be greatly improved. The reagent has the characteristics of being easy to operate, rapid, sensitive, good in specificity and the like when applied to detection of cTnT in human blood, serum or plasma, and has good clinical application prospect.

Owner:SHANDONG UNIV QILU HOSPITAL

Infrared detector and fabricating method of infrared detector

InactiveUS7888762B2Controlled amount of strainAvoid detection accuracySolid-state devicesPhotovoltaicsLight beamPolycrystalline silicon

There is provided an infrared detector including: a silicon substrate provided with a concave portion; an infrared receiver having a polysilicon layer; and a beam that supports the infrared receiver above the concave portion, and extends along a side of the infrared receiver from the infrared receiver to connect with the silicon substrate, the beam having at least two bent portions, wherein at least one of the bent portions of the beam is disposed at a position on a side opposite to the concave portion with the polysilicon layer as a reference point.

Owner:LAPIS SEMICON CO LTD

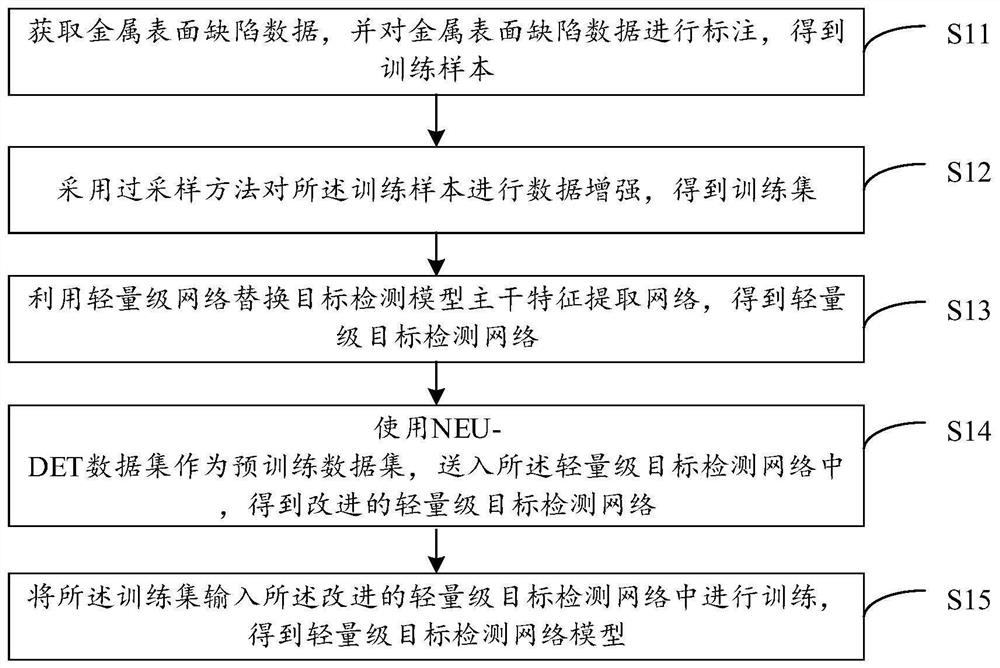

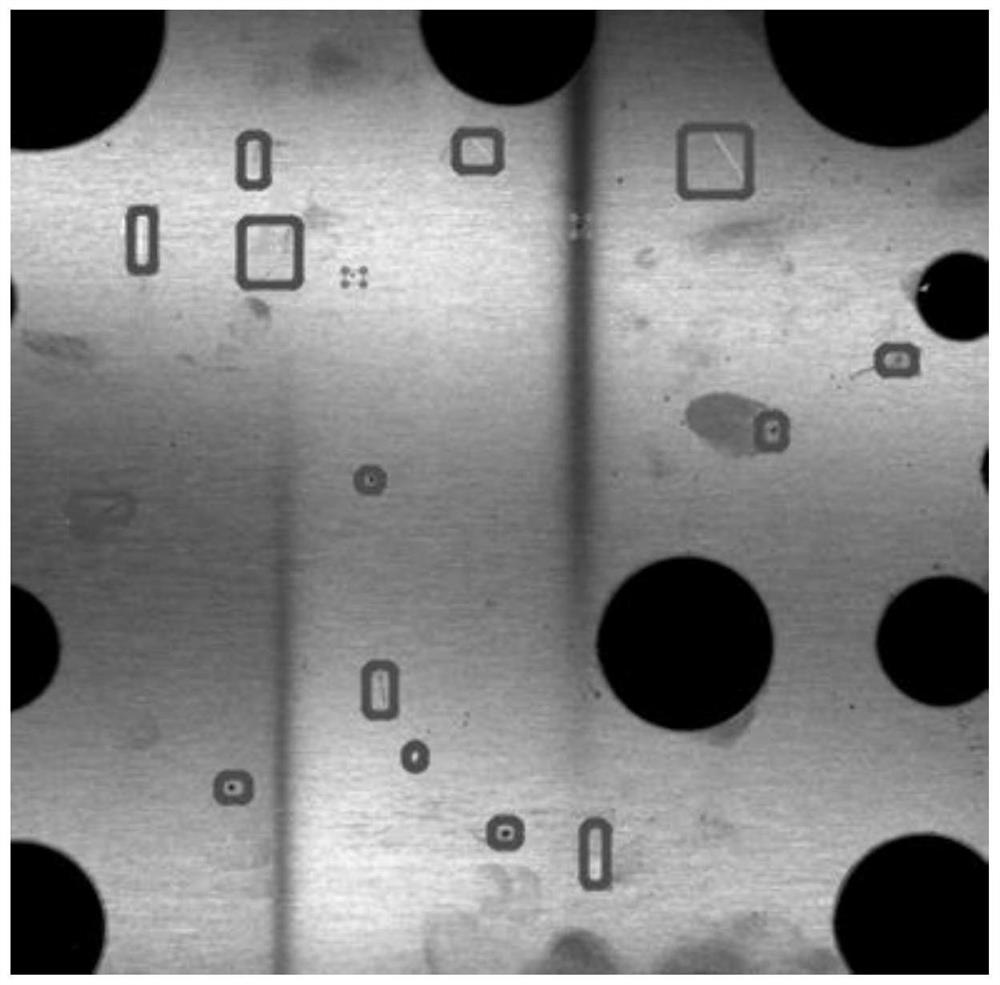

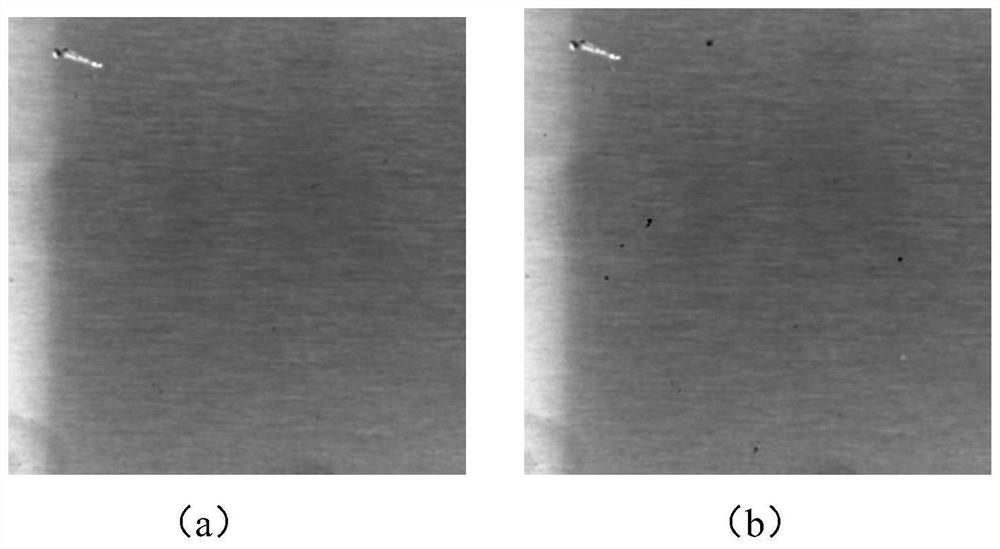

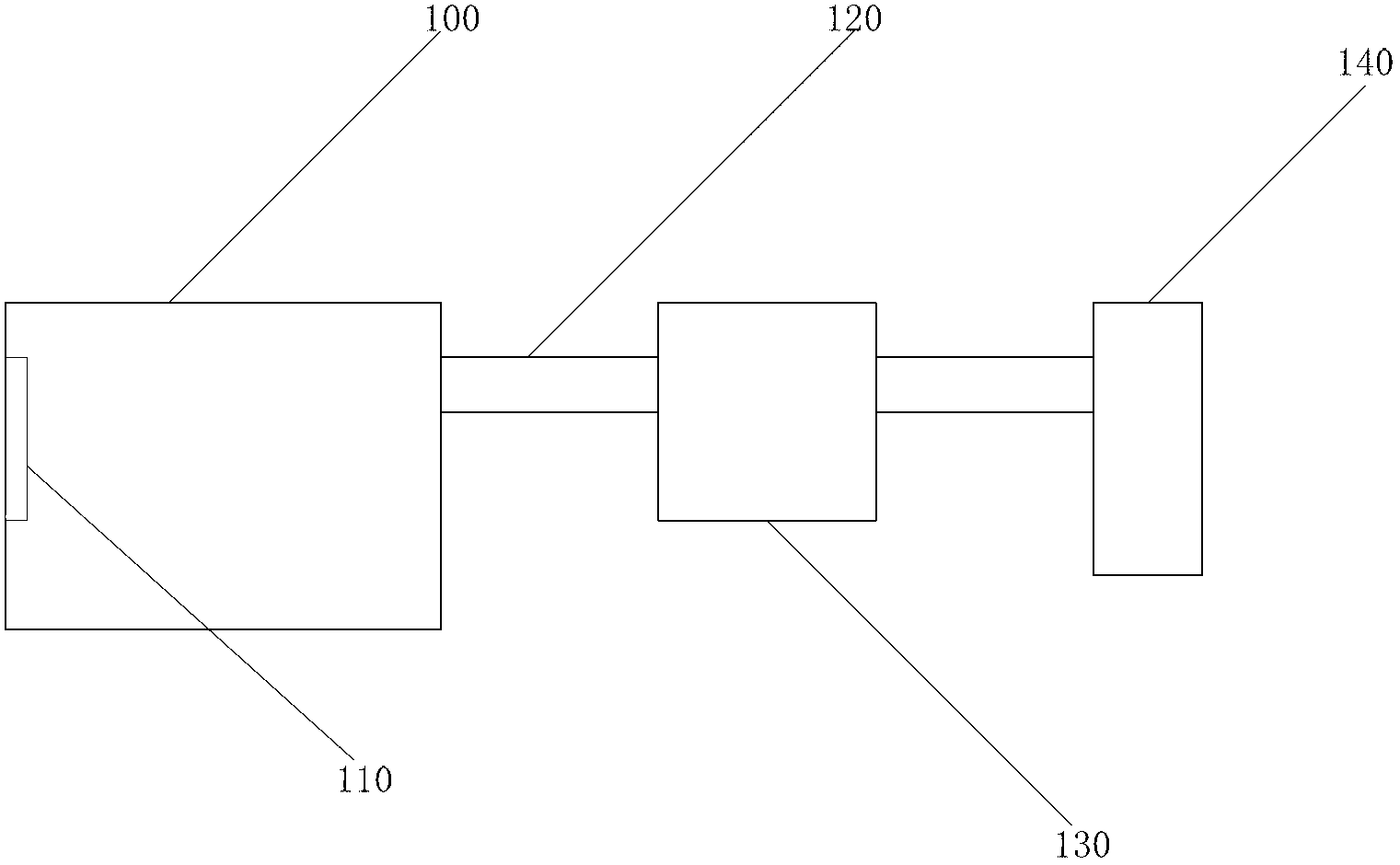

Network model training method, metal surface defect detection method and electronic equipment

PendingCN113888477ABig amount of dataAvoid detection accuracyImage enhancementImage analysisData setFeature extraction

The invention discloses a network model training method, a metal surface defect detection method and electronic equipment, and belongs to the related technical field of defect detection. The training method comprises the following steps: obtaining and marking metal surface defect data to obtain training samples; performing data enhancement on the training samples by adopting an oversampling method to obtain a training set; replacing a trunk feature extraction network of a target detection model with a lightweight network to obtain a lightweight target detection network; using an NEU-DET data set as a pre-training data set, and sending the pre-training data set into the lightweight target detection network to obtain an improved lightweight target detection network; and inputting the training set into the improved lightweight target detection network for training to obtain a lightweight target detection network model. The invention can effectively realize automatic detection of large-scale metal surface small defects, has high accuracy, has the characteristics of lightweight, high-precision real-time picture monitoring and the like, and can be applied to industrial scenes.

Owner:ZHEJIANG UNIV

Protecting device and calibrating device with same

InactiveCN103175480AQuality improvementGuaranteed cleanlinessUsing optical meansEngineeringCompressed air

The invention discloses a protecting device and a calibrating device with the same. The protecting device is applicable to pipe calibrating devices and comprises a protecting cover with an opening, a ventilating pipeline connected with the protecting cover, an oil-mist separator connected with the protecting cover through the ventilating pipeline and a compressed air source connected with the oil-mist separator. By the protecting device and the calibrating device with the same, cleanness of a detecting window is guaranteed, the problems of detection error and detection precision lowering can be avoided, and detection precision is guaranteed.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Ink jet recording apparatus, nozzle inspection method and program thereof

InactiveUS7645007B2Reduce distanceLess susceptible to noiseOther printing apparatusPotential differenceEngineering

In this ink jet printer, on the basis of voltage of a nozzle plate 27 at the time that a print head 24 is driven and in a state in which a predetermined potential difference has been generated between the nozzle plate 27 and the inspection area 52, a nozzle inspection is performed so as to confirm whether or not ink is in practice being ejected from each nozzle 23, so that ink can be sequentially ejected to an inspection area 52 from each nozzle. According to the nozzle inspection voltage change is detected in the nozzle plate 27 by a voltage detection circuit 54 provided on an encoder board 64 on a carriage 22. Since both the nozzle plate 27 and the voltage detection circuit 54 are installed on the carriage 22, and the distance between the two of them is shorter, they are less likely be affected by noise. In addition, there is no need to prepare a new board on which the voltage detection circuit 54 needs to be mounted.

Owner:SEIKO EPSON CORP

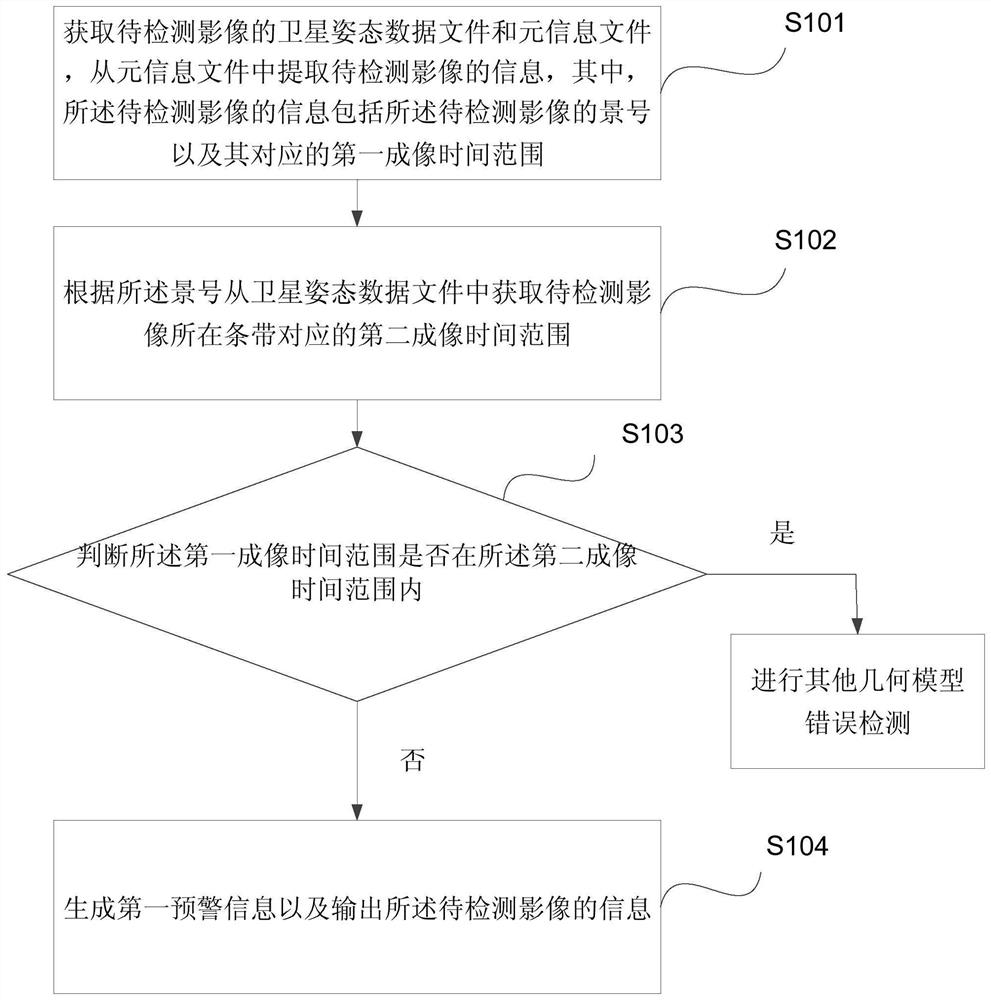

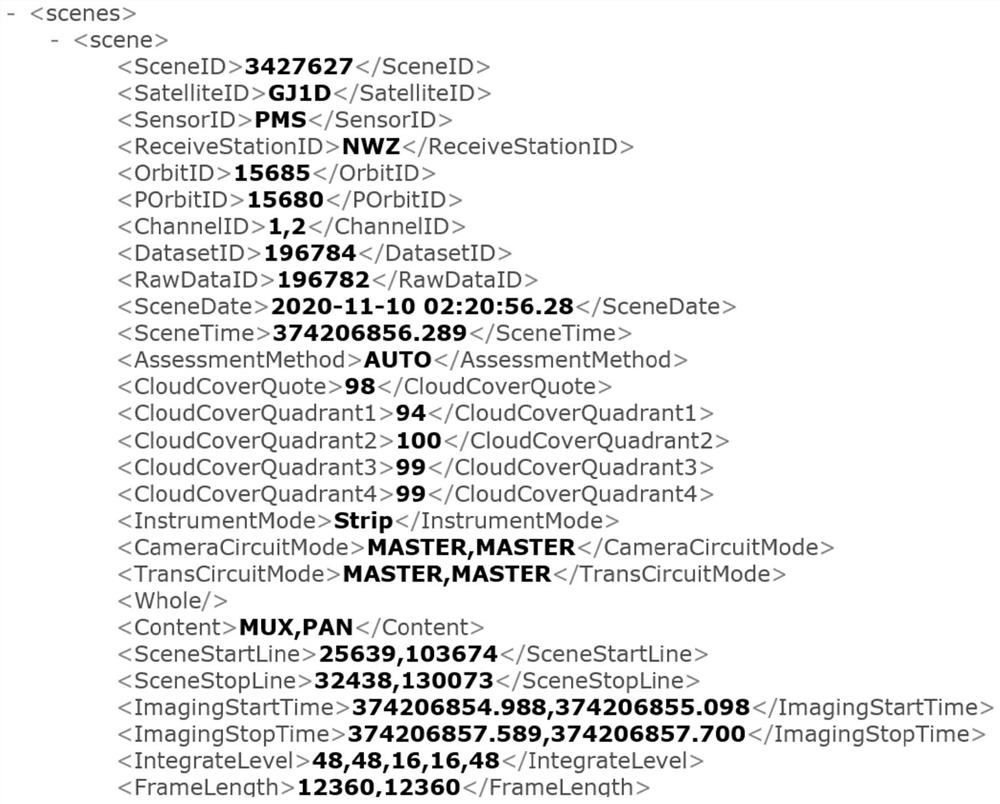

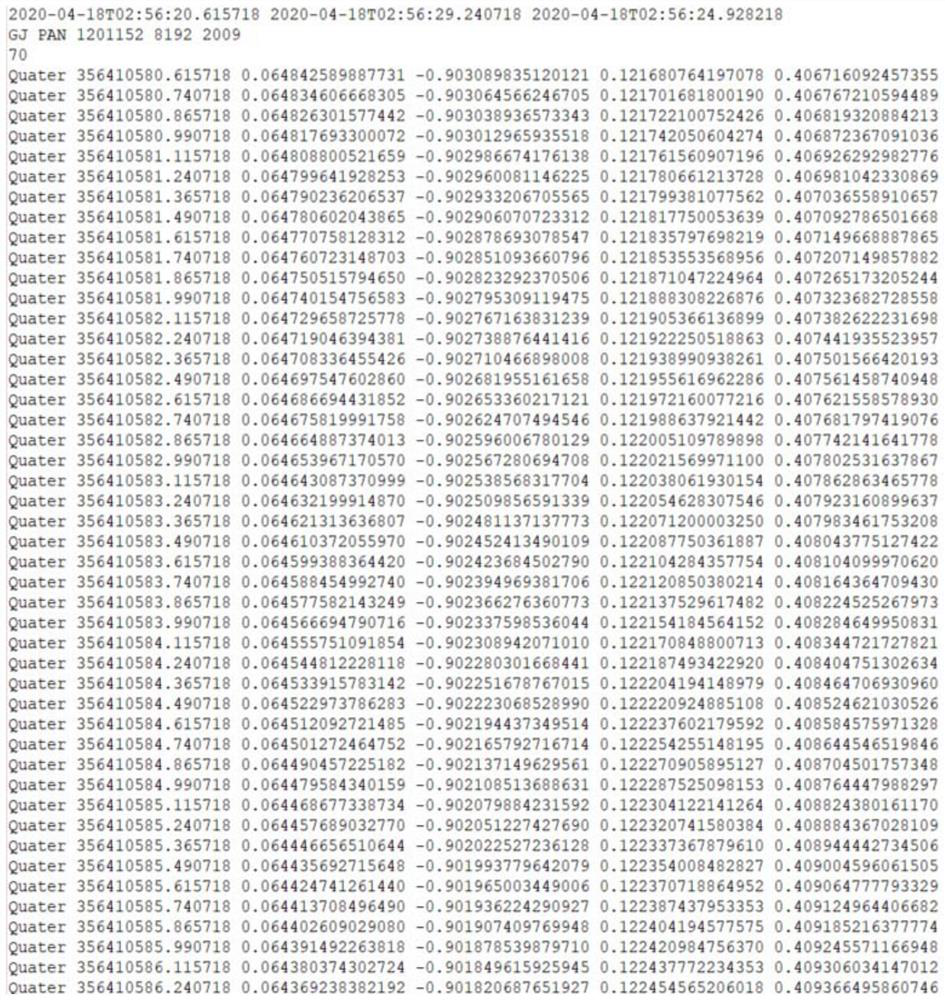

Rapid detection method for geometric model error of remote sensing image

PendingCN113570560AAvoid detection accuracyIssues Affecting False DetectionsImage enhancementImage analysisData fileComputer vision

The invention discloses a rapid detection method for geometric model errors of a remote sensing image, and the method comprises the steps of obtaining a satellite attitude data file and a meta-information file of a to-be-detected image, and extracting the information of the to-be-detected image from the meta-information file, wherein the information of the to-be-detected image comprises a scene number of the to-be-detected image and a first imaging time range corresponding to the scene number; acquiring a second imaging time range corresponding to a strip where the to-be-detected image is located from the satellite attitude data file according to the scene number; judging whether the first imaging time range is within a second imaging time range or not; if not, forming first early warning information and outputting information of the to-be-detected image, wherein the first early warning information is used for indicating that the to-be-detected image may have whole-scene wave band dislocation. The technical problem of low detection efficiency and precision in the prior art is solved.

Owner:CHINA CENT FOR RESOURCES SATELLITE DATA & APPL

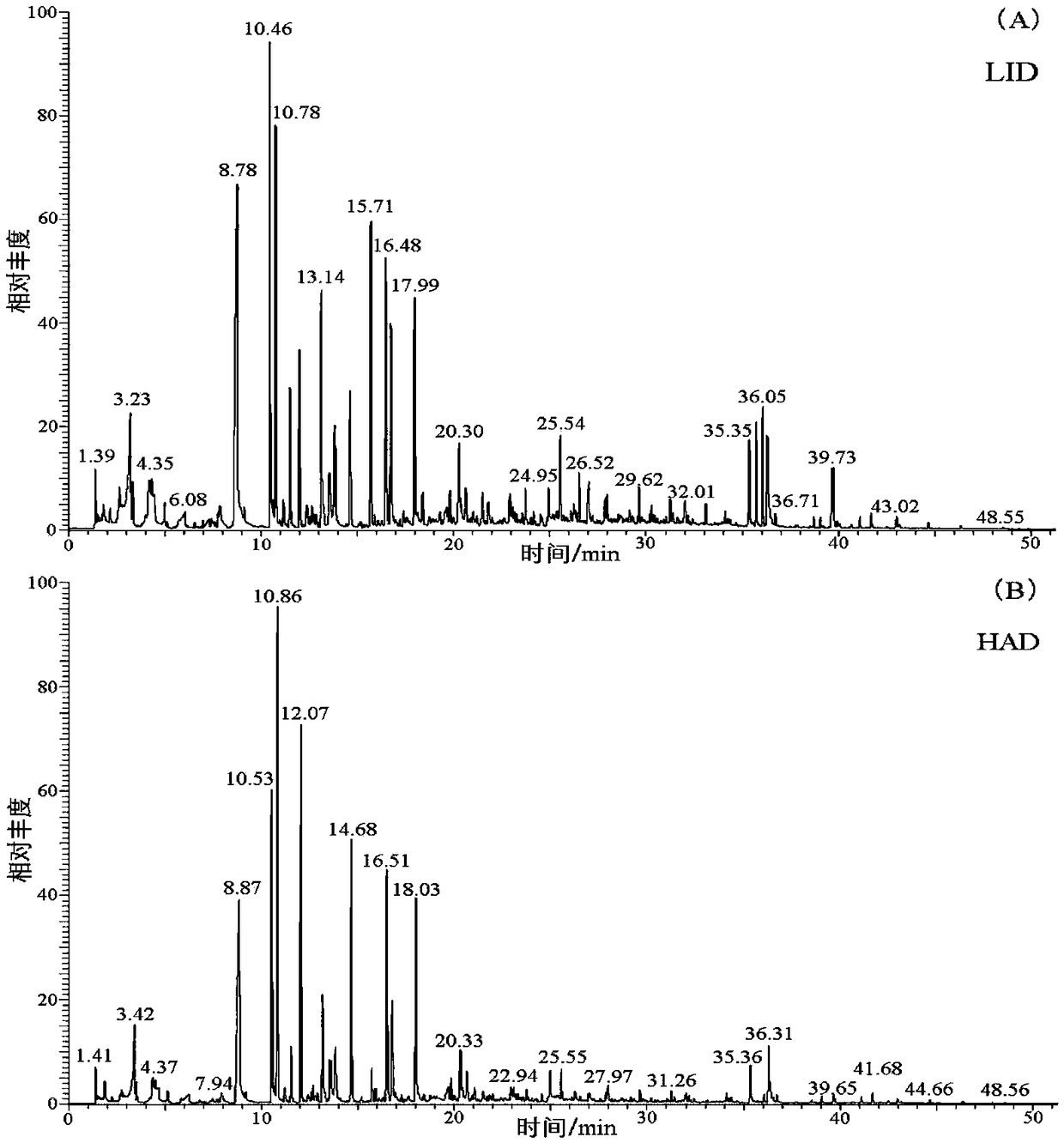

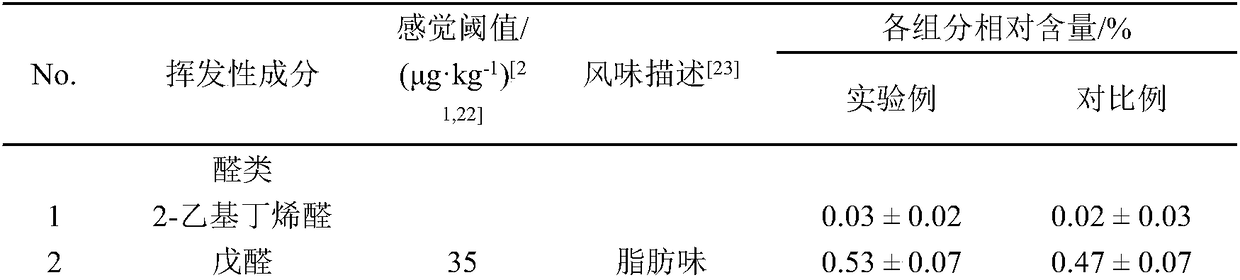

Method for detecting volatile components of turtle oil

PendingCN109374770AShorten extraction timeAvoid detection accuracyComponent separationEnvironmental geologyRadiation

The invention discloses a method for detecting volatile components of turtle oil. According to the method, turtle oil samples are adsorbed and extracted in a laser radiation assisting mode, and detection is performed in a GC-MS detection method. The method for detecting the volatile components of the turtle oil is efficient, simple, convenient, low in cost, precise and comprehensive.

Owner:杭州邦沃森生物科技有限公司

Flow measuring device

ActiveUS20190107421A1Reduce detection accuracyAvoid influenceVolume/mass flow measurementVolume meteringProject areaEngineering

Provide a flow measuring device which inhibits a reduction of flow detection accuracy, which is caused by an influence of a bottom flow which is flowed and inputted from a fit gap between a flow detecting element and an installing portion of the flow detecting element. A concave portion, which inhibits an influence of a bottom flow which is flowed and inputted from a fit gap between an installing portion and a flow detecting element, is provided at a bottom surface of the installing portion of a plate which is positioned on a projected area of a cavity of the flow detecting element.

Owner:MITSUBISHI ELECTRIC CORP

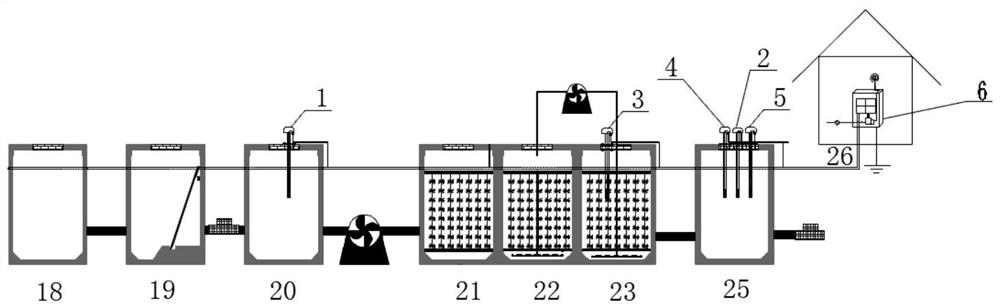

Soft measurement method and device for total phosphorus in effluent of agricultural sewage facilities based on artificial neural network

ActiveCN112782232BQuick responseAccurate prediction of total phosphorus concentrationMaterial analysis by electric/magnetic meansNeural architecturesData platformSewage

Owner:ZHEJIANG UNIV

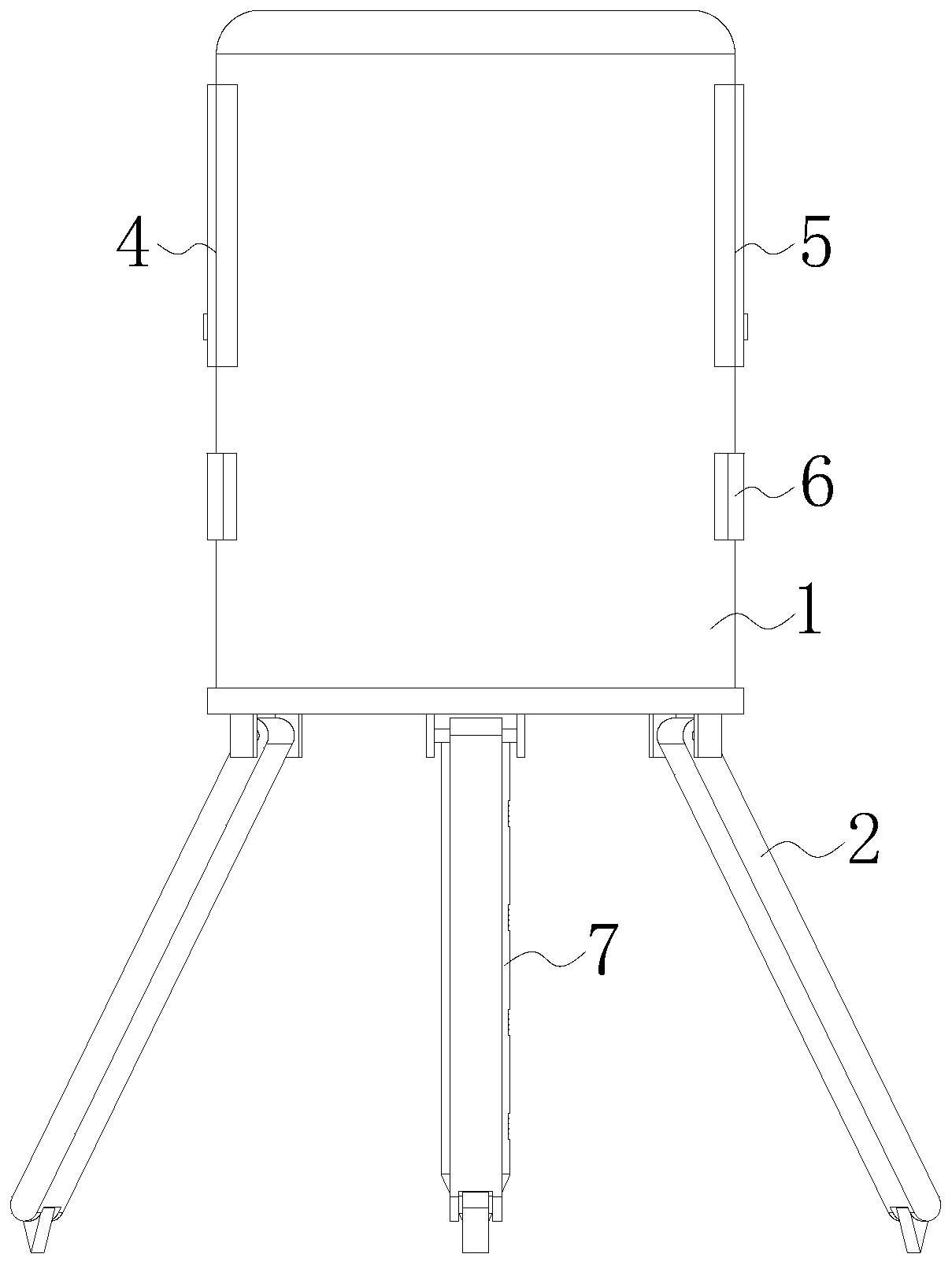

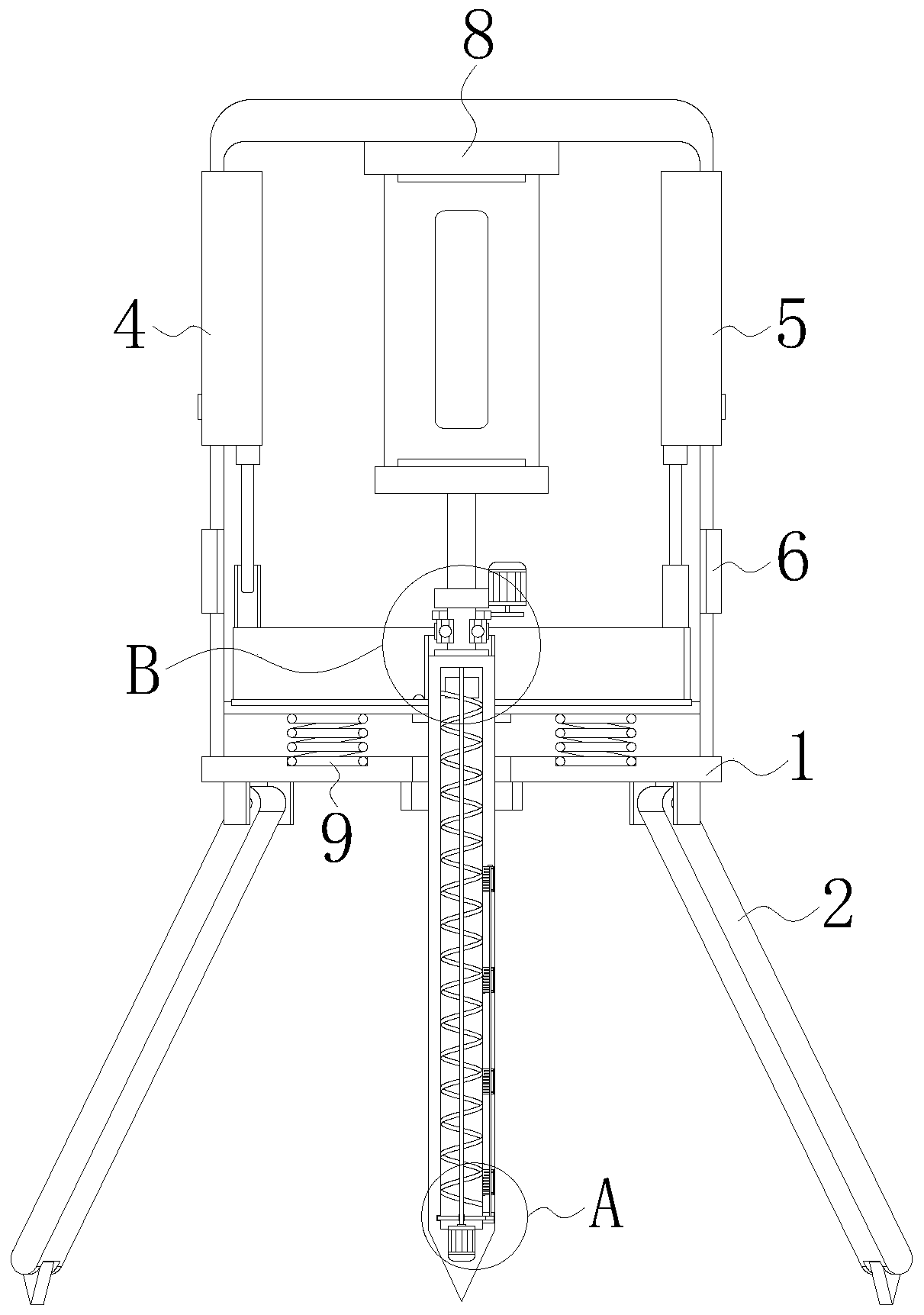

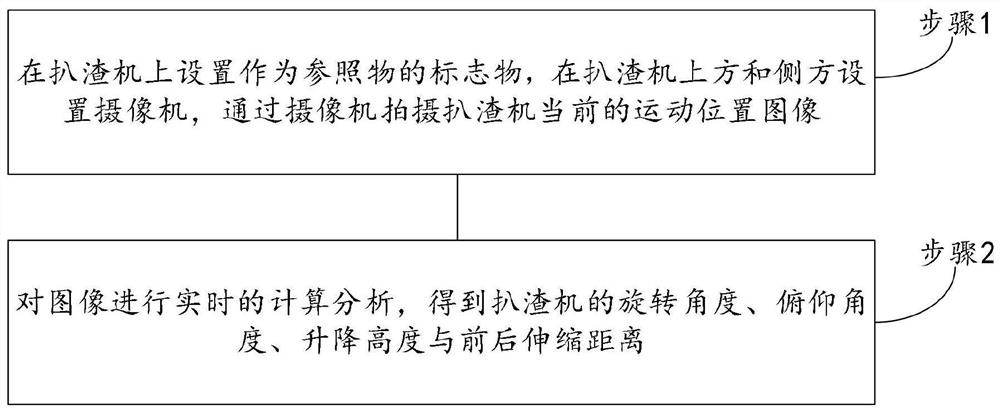

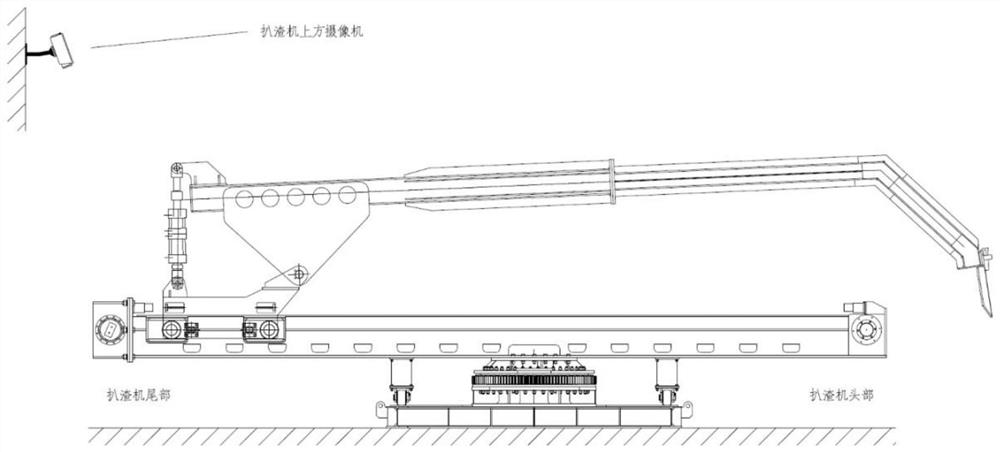

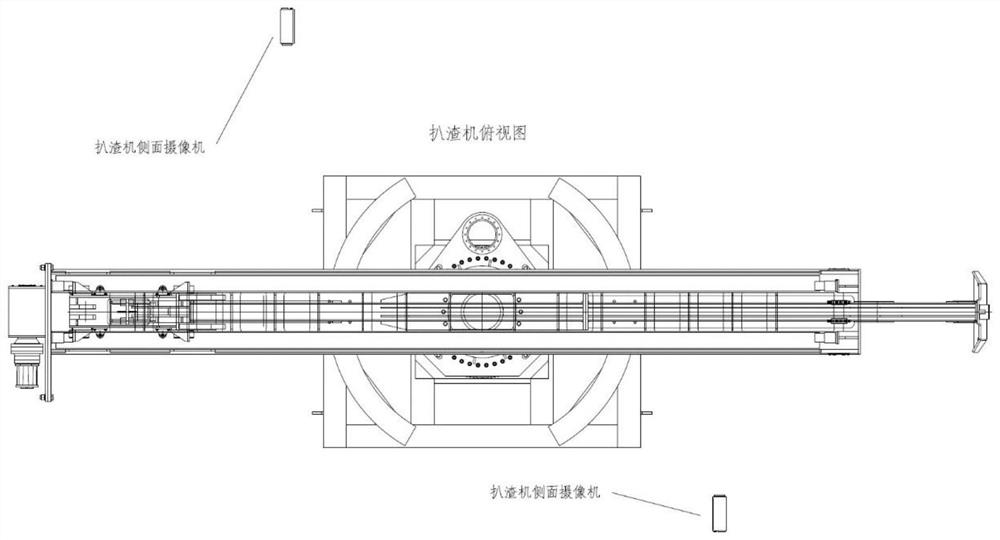

Detection and calculation method for four-dimensional motion position parameters of crawler loader

ActiveCN113532272ASolve the detection accuracySolve detection stabilityUsing optical meansSimulationLoader

A detection and calculation method for four-dimensional motion position parameters of a crawler loader. The method comprises the following steps: 1, setting a marker serving as a reference object on the crawler loader, setting cameras above and on the side of the crawler loader, and shooting a current motion position image of the crawler loader through the cameras; and 2, carrying out real-time calculation and analysis on the image to obtain a rotation angle, a pitching angle, a lifting height and a front-back telescopic distance of the crawler loader. According to the invention, a sensor does not need to be mounted on the crawler loader so that the problems that the sensor is difficult to overhaul and the detection precision, stability and reliability of the sensor are influenced due to frequent action and vibration of the crawler loader during working are well solved and avoided.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com