Cooling and blowing device for radar level gauge and material level detection system

A technology of material level gauge and radar, which is applied in the field of material level detection, can solve the problems of inability to guarantee the detection accuracy of radar level gauge, sudden drop of cooling and sweeping effect, waste of energy, etc., achieve simple structure, reduce energy consumption, and manufacture convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

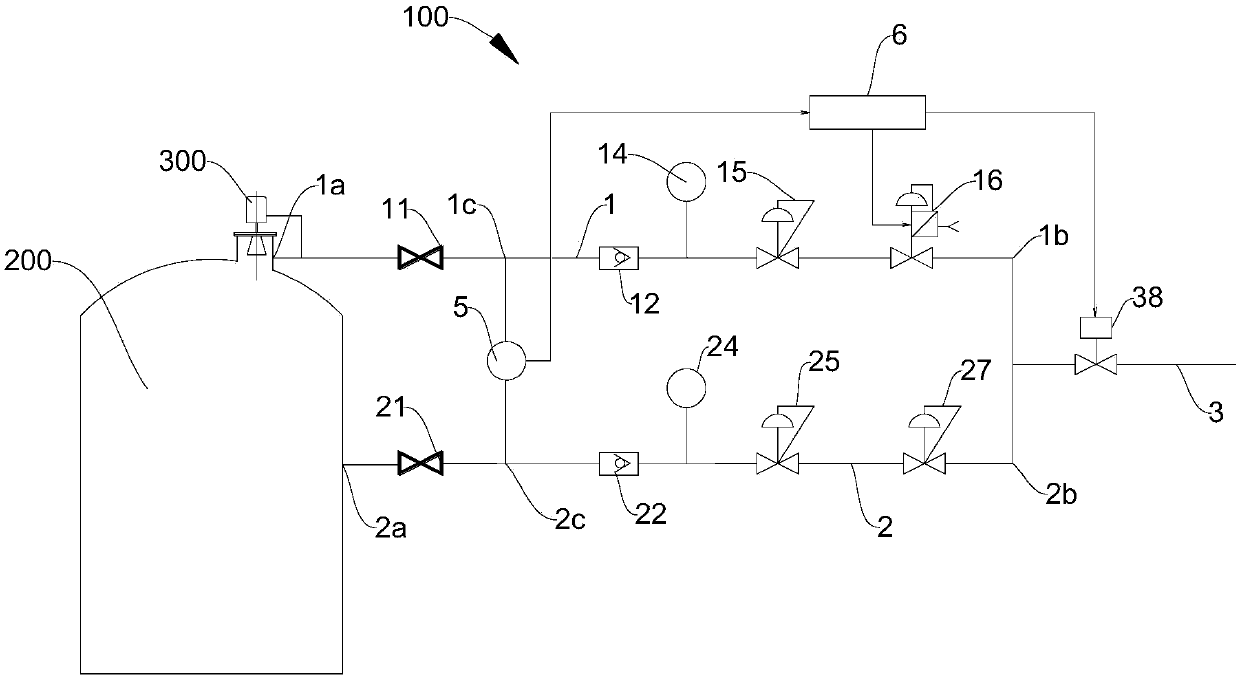

[0030] figure 1 A material detection system according to the present invention and an existing sealed container are shown. Such as figure 1 As shown, the material detection system includes a radar level gauge 300 and a cooling and purging device 100, wherein the radar level gauge 300 is installed on the top of the sealed container 200, and the cooling and purging device 100 is used to cool and purge the radar level gauge 300 The transceiver end (that is, the receiving and transmitting end) to reduce the influence of high temperature, dirty, humid and pressurized gas on the radar level gauge 300. The cooling and purging device 100 mainly includes a first branch 1 with a flow regulating valve 16 , a second branch 2 with a pressure reducing valve 27 , a dry circuit 3 , a differential pressure transmitter 5 and a controller 6 .

[0031] The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com