Defect detection method for membrane electrode of fuel cell

A fuel cell membrane and defect detection technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of fuel cell stack overall performance degradation, reduced work efficiency, membrane electrode misalignment, etc., to solve membrane electrode misalignment, cost The effect of short time and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

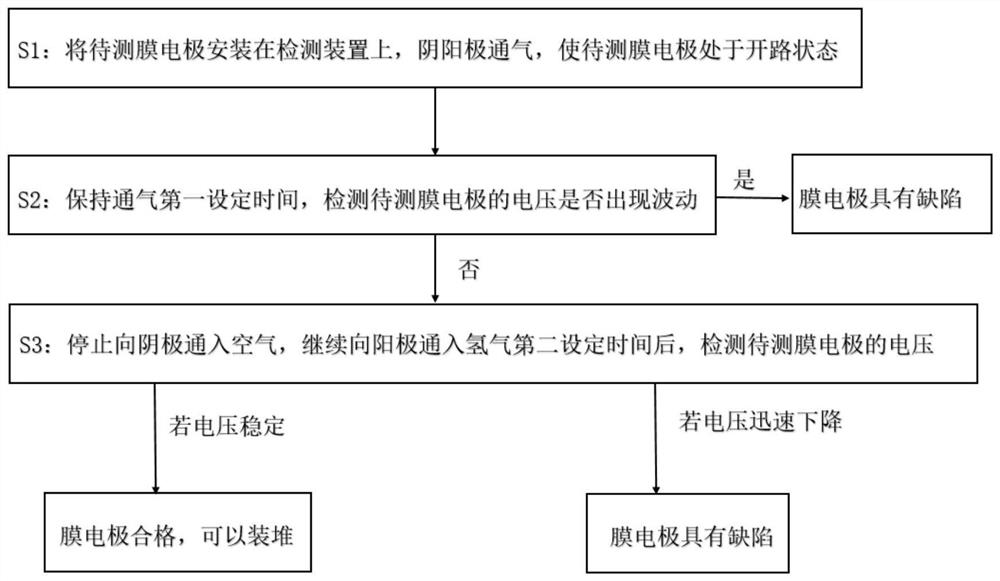

[0056] In this embodiment, a defect test is performed on one of the membrane electrodes (defined as the first membrane electrode), and the specific steps are as follows:

[0057] Step S1: Install the first membrane electrode in the jig, connect the anode air inlet on the jig to the anode gas source, the cathode air inlet to the cathode gas source, and connect the circulating water structure on the jig to the water source; set the voltage detection device to In the fixture, it is used to detect the voltage of the first membrane electrode. Open the anode inlet valve to feed hydrogen to the anode of the first membrane electrode, open the cathode inlet valve to feed air to the cathode of the first membrane electrode, and the inlet pressure is 30Kpa. At this time, the first membrane electrode is in a power generation state (ie, an open circuit state, with an open circuit voltage of 0.9-1.0V).

[0058] Step S2: Keep the ventilation state for 2 minutes, the voltage of the first memb...

Embodiment 2

[0061] In this embodiment, a defect test is performed on one of the membrane electrodes (defined as the second membrane electrode), and the specific steps are as follows:

[0062] Step S1: Install the second membrane electrode in the jig, connect the anode air inlet on the jig to the anode gas source, the cathode air inlet to the cathode gas source, and connect the circulating water structure on the jig to the water source; set the voltage detection device to In the fixture, it is used to detect the voltage of the second membrane electrode. Open the anode inlet valve to feed hydrogen to the anode of the second membrane electrode, open the cathode inlet valve to feed air to the cathode of the second membrane electrode, and the inlet pressure is 40Kpa. At this moment, the second membrane electrode is in a state of generating electricity (that is, an open circuit state with an open circuit voltage of 0.9-1.0V).

[0063] Step S2: Keep the ventilated state for 1.5 minutes, the vol...

Embodiment 3

[0066] In this embodiment, a defect test is performed on one of the membrane electrodes (defined as the third membrane electrode), and the specific steps are as follows:

[0067] Step S1: install the third membrane electrode in the jig, connect the anode air inlet on the jig to the anode gas source, the cathode air inlet to the cathode gas source, and connect the circulating water structure on the jig to the water source; set the voltage detection device to In the fixture, it is used to detect the voltage of the third membrane electrode. Open the anode inlet valve to feed hydrogen to the anode of the third membrane electrode, open the cathode inlet valve to feed air to the cathode of the third membrane electrode, and the inlet pressure is 30Kpa. At this time, the third membrane electrode is in a state of generating electricity (that is, an open circuit state with an open circuit voltage of 0.95V).

[0068] Step S2: Keep the ventilated state for 1.5 minutes, the voltage of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com