Patents

Literature

82results about How to "Easy defect detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

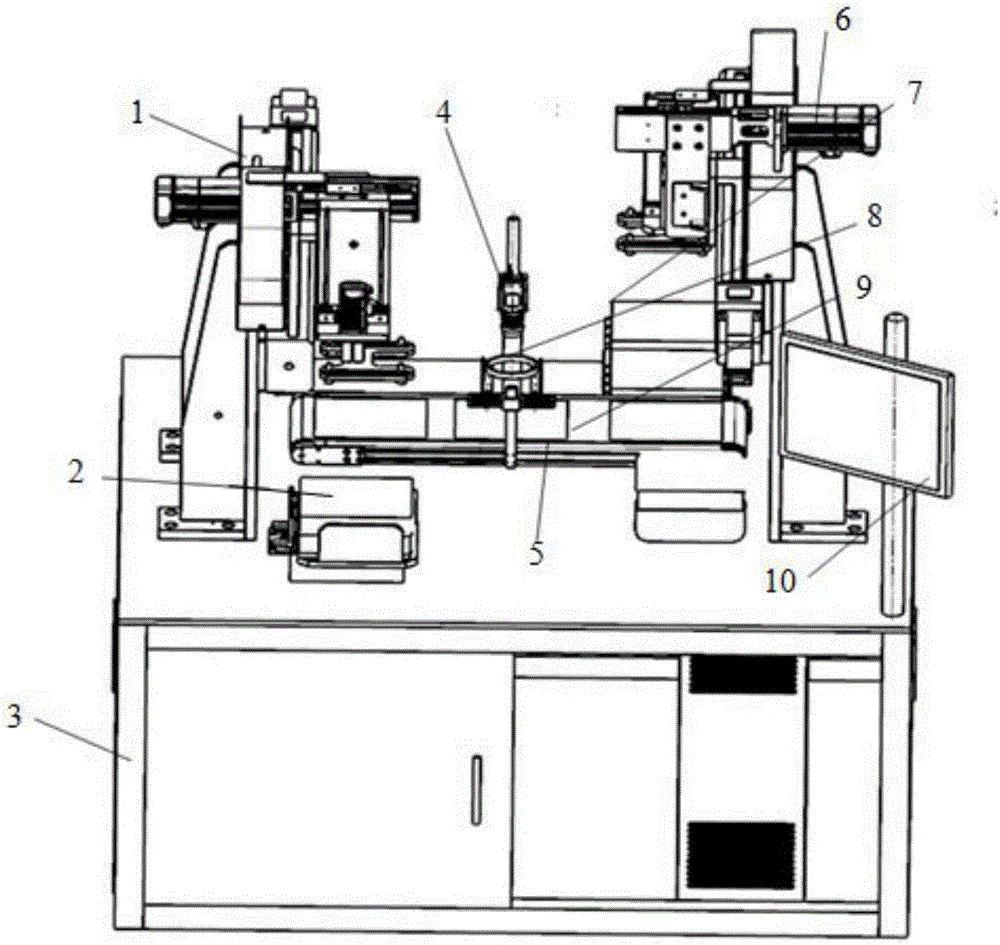

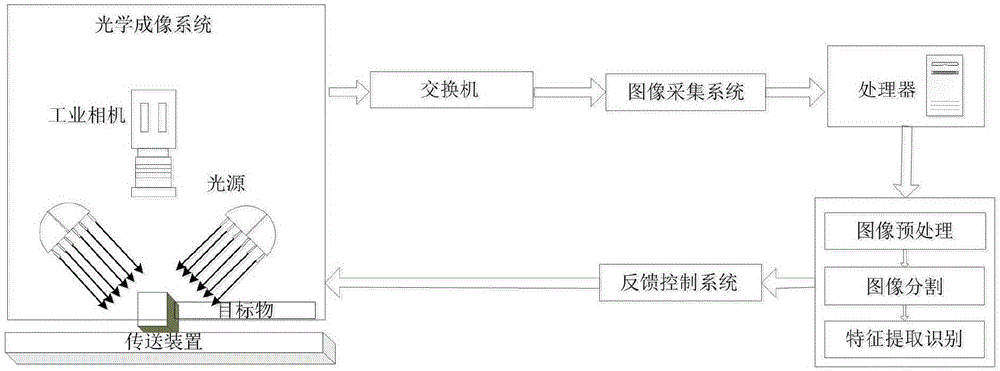

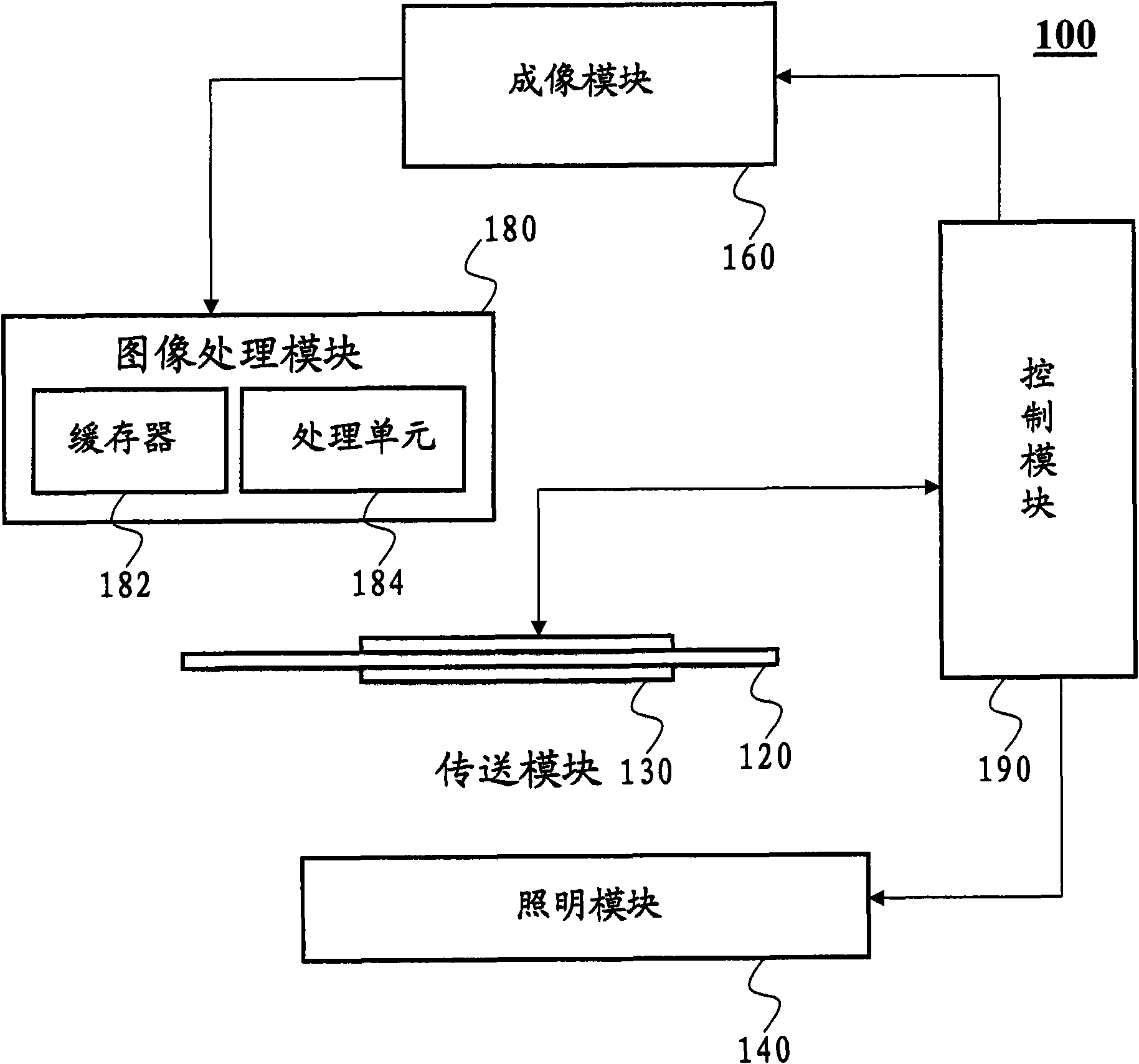

Solar silicon wafer defect detecting system and method

ActiveCN106409711AStrong subjectivityPoor repeatabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProduction lineImaging processing

The invention provides a solar silicon wafer defect detecting system. The solar silicon wafer defect detecting system comprises a visual image acquisition system, an image processing system and a sorting system; the visual image acquisition system is used for automatically acquiring images of silicon wafers on an automatic silicon wafer production line; the image processing system is used for analyzing the acquired silicon wafer images, automatically identifying the silicon wafer images and sending identification signals to the sorting system; and the sorting system is used for executing the signals of the image processing system, sorting out defective silicon wafers and sorting the silicon wafers with the same defects into same sorting boxes to realize accurate sorting of the silicon wafers. The invention also provides a detecting method based on the solar silicon wafer defect detecting system disclosed by the invention; the silicon wafers can be conveyed rapidly and rapid defect detection of the silicon wafer images can be carried out; and a high-speed and high-precision visual detection requirement of the production line can be met.

Owner:广东佛智芯微电子技术研究有限公司

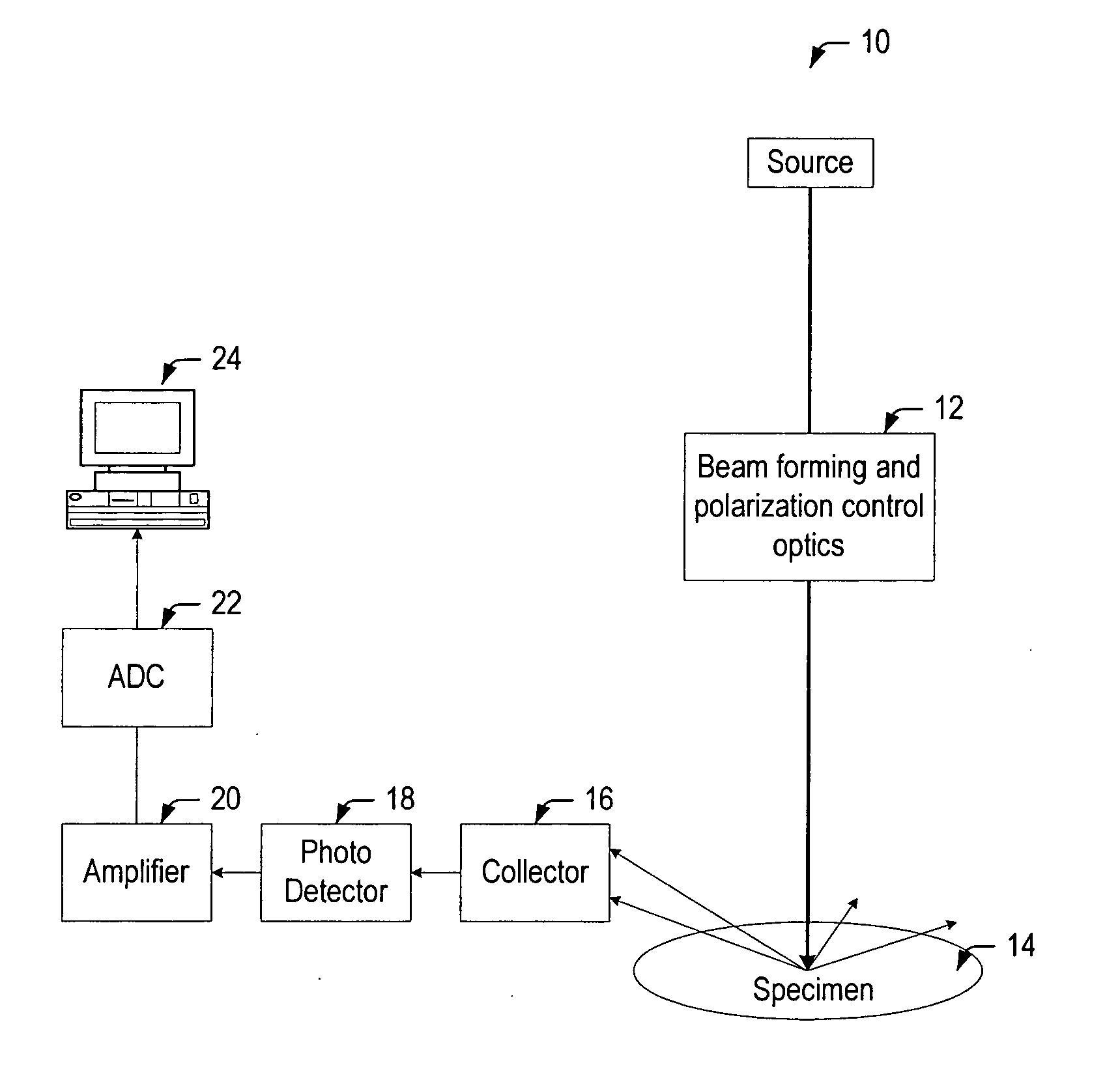

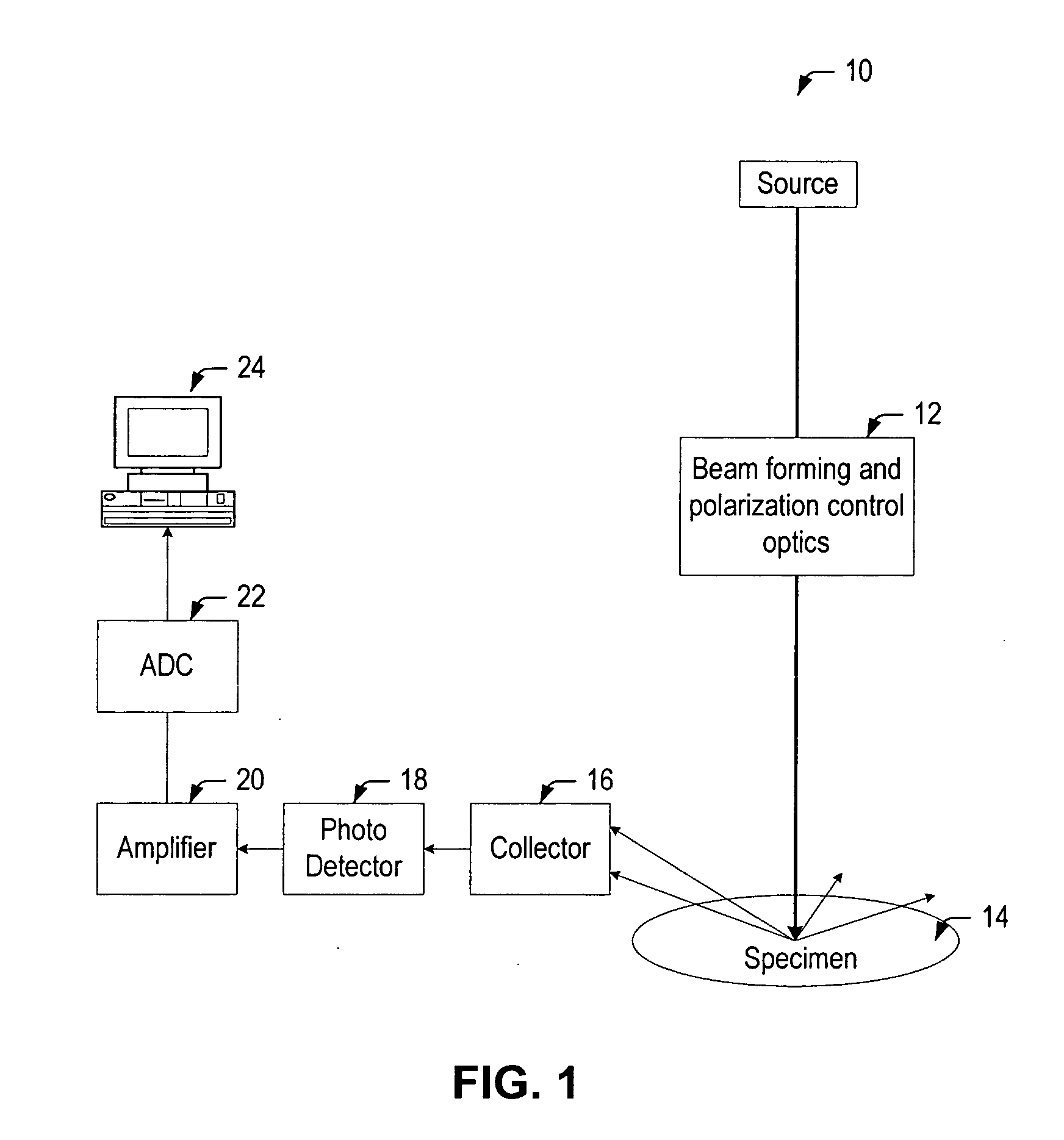

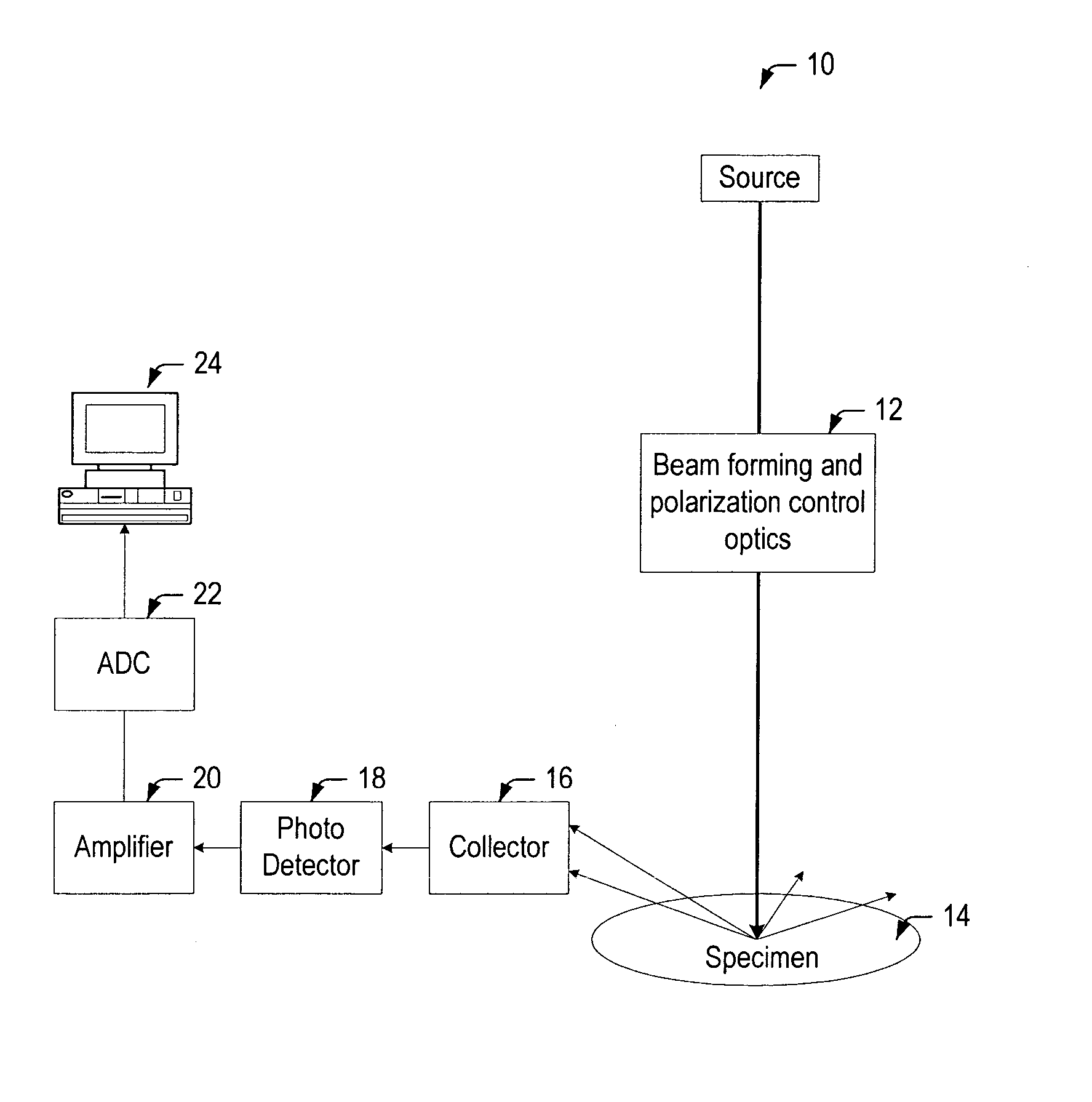

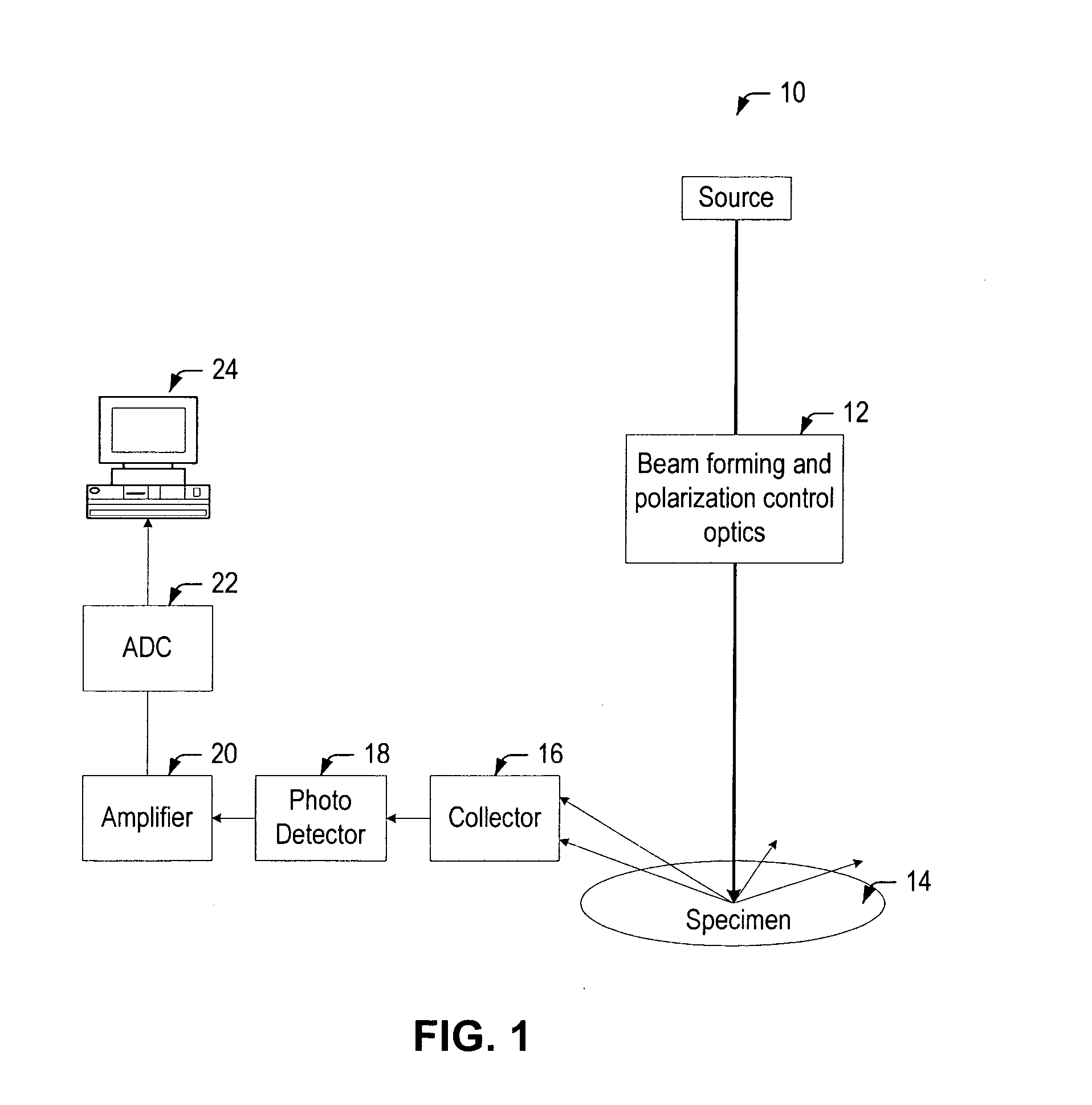

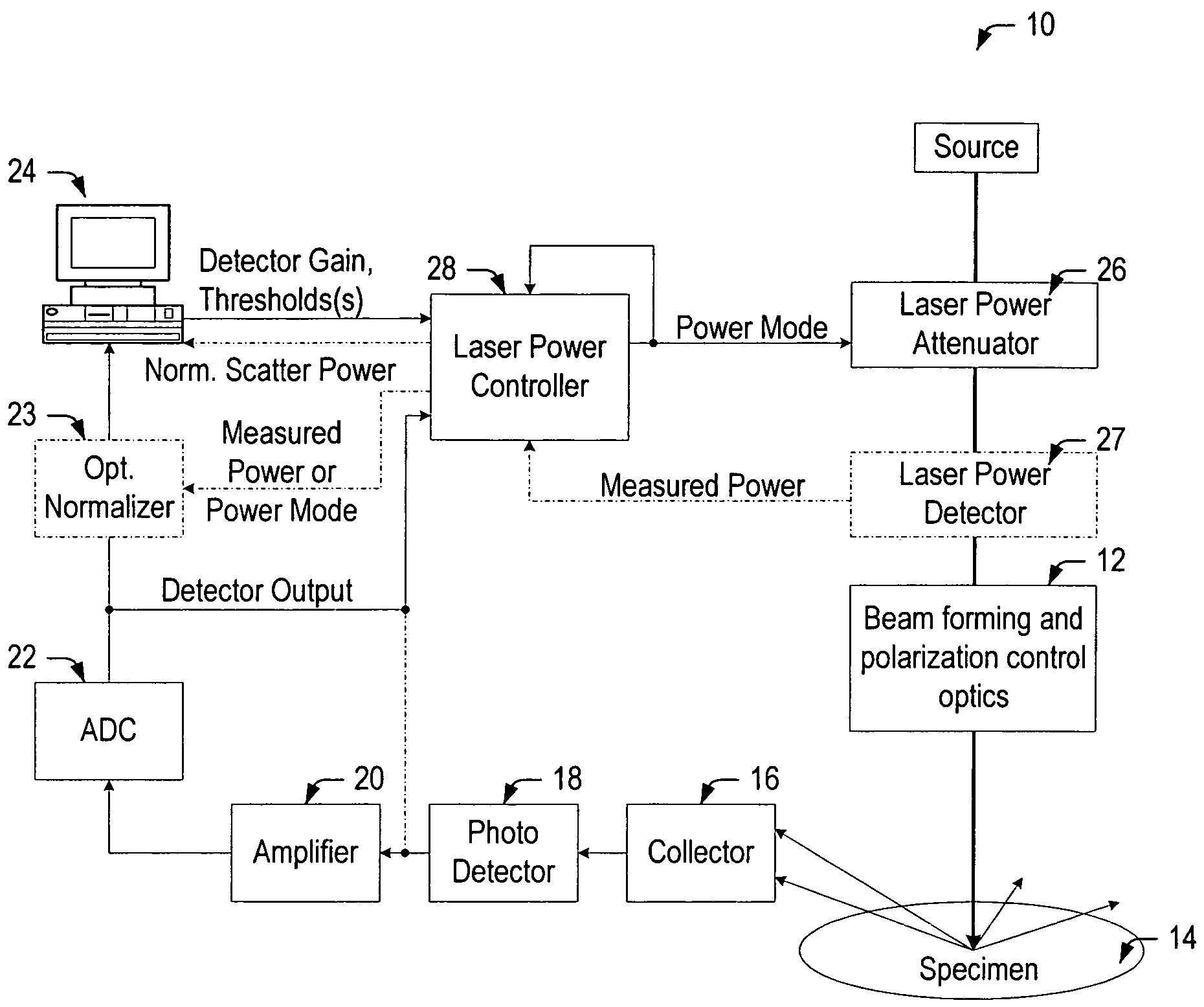

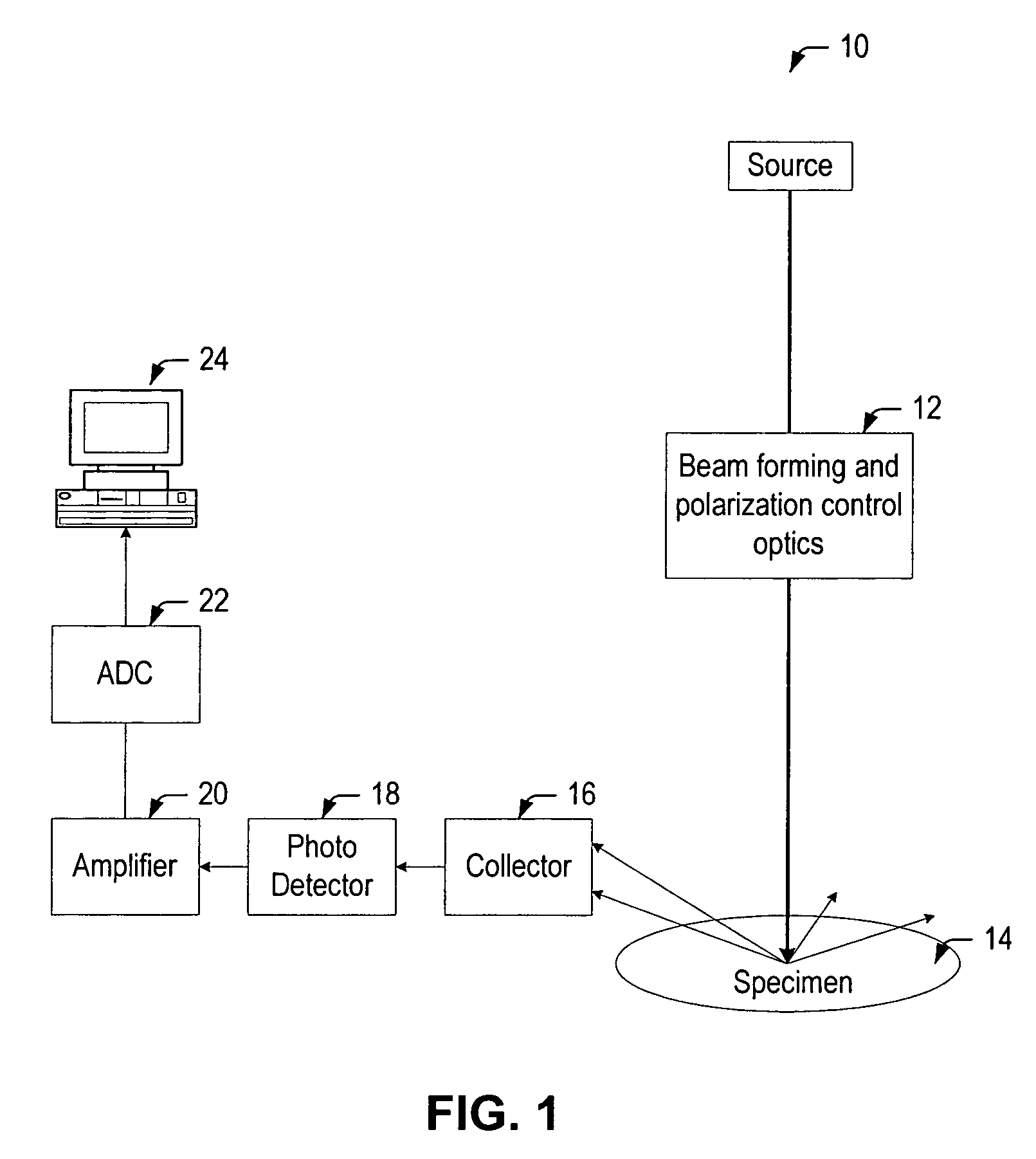

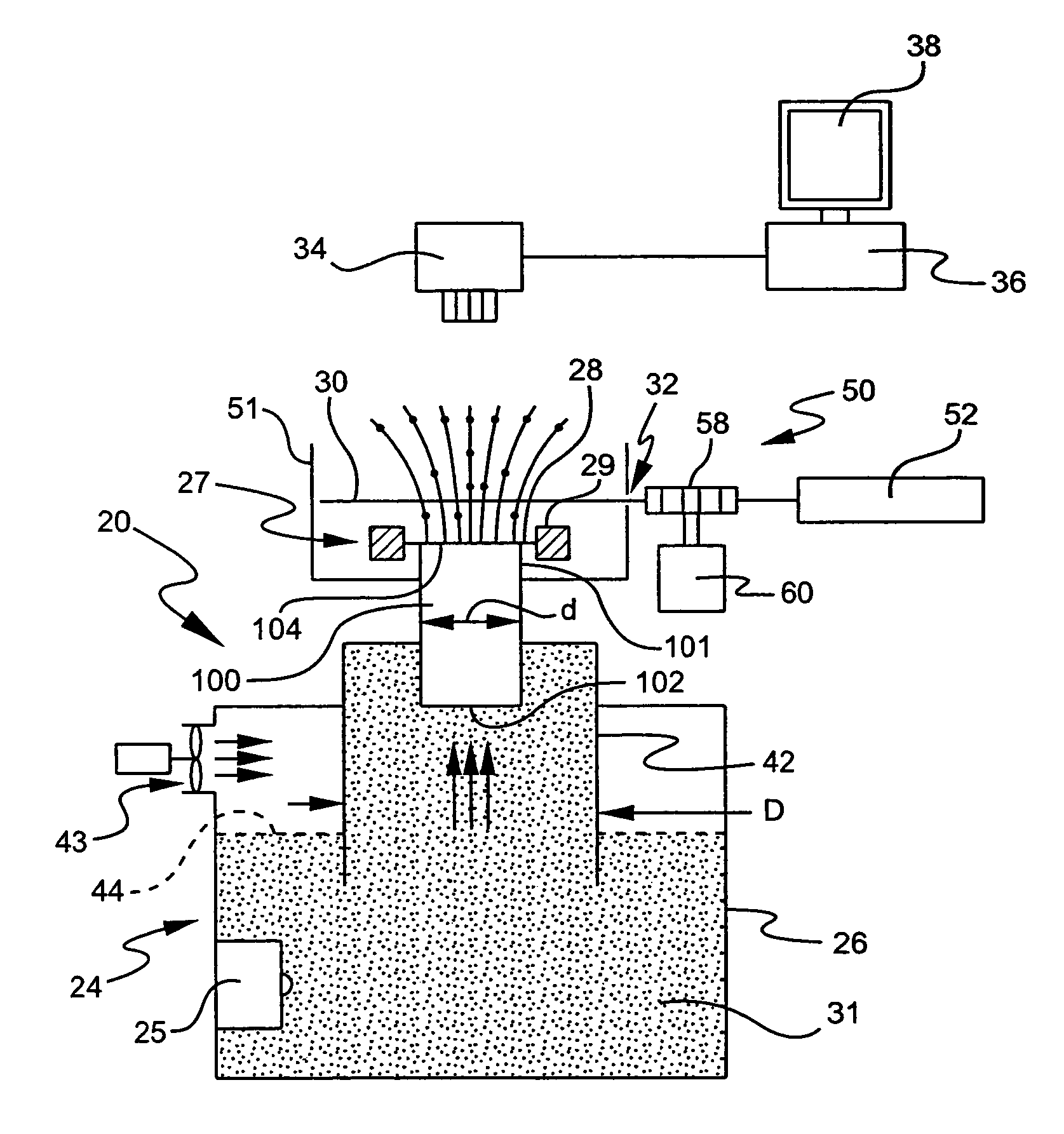

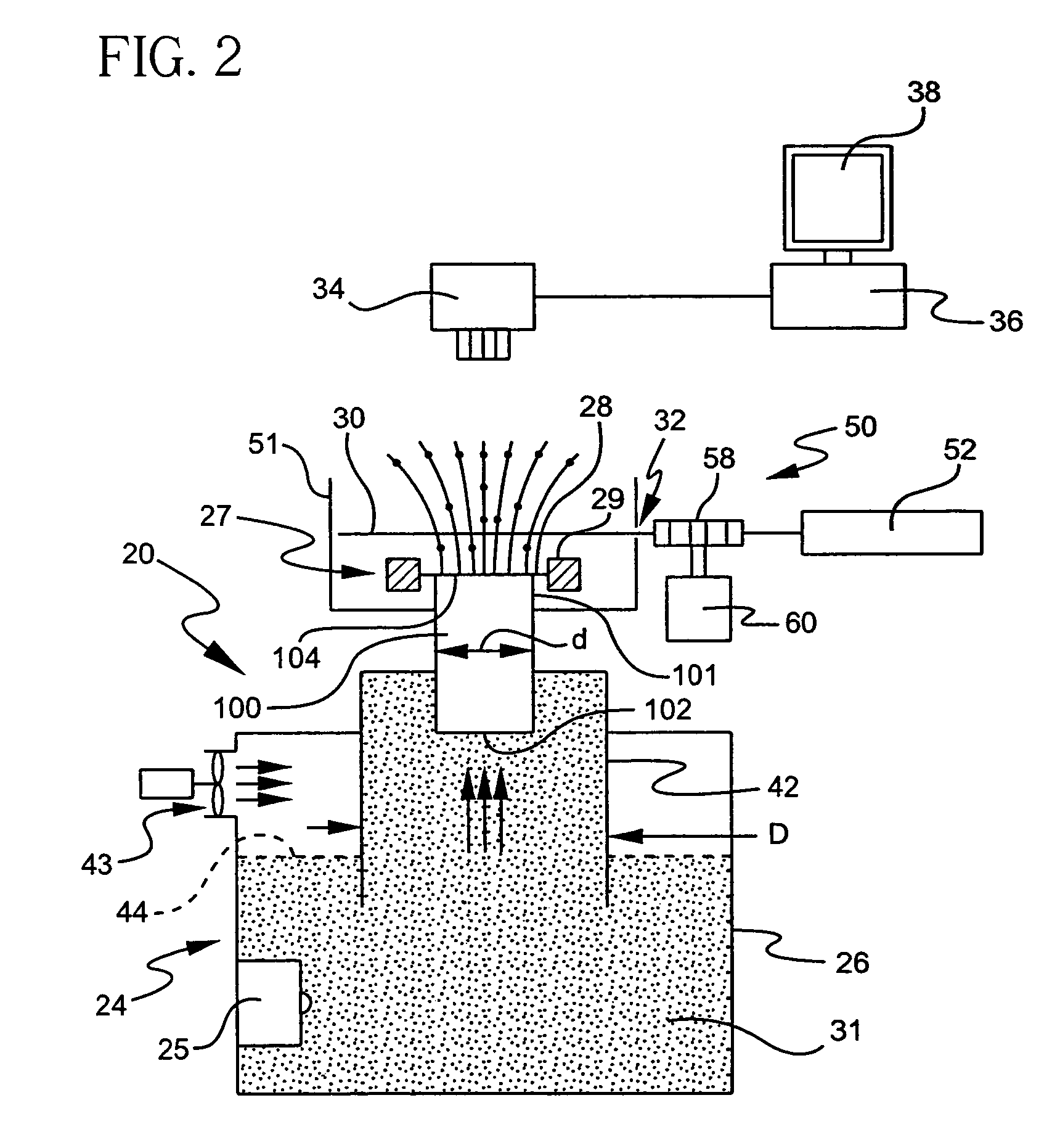

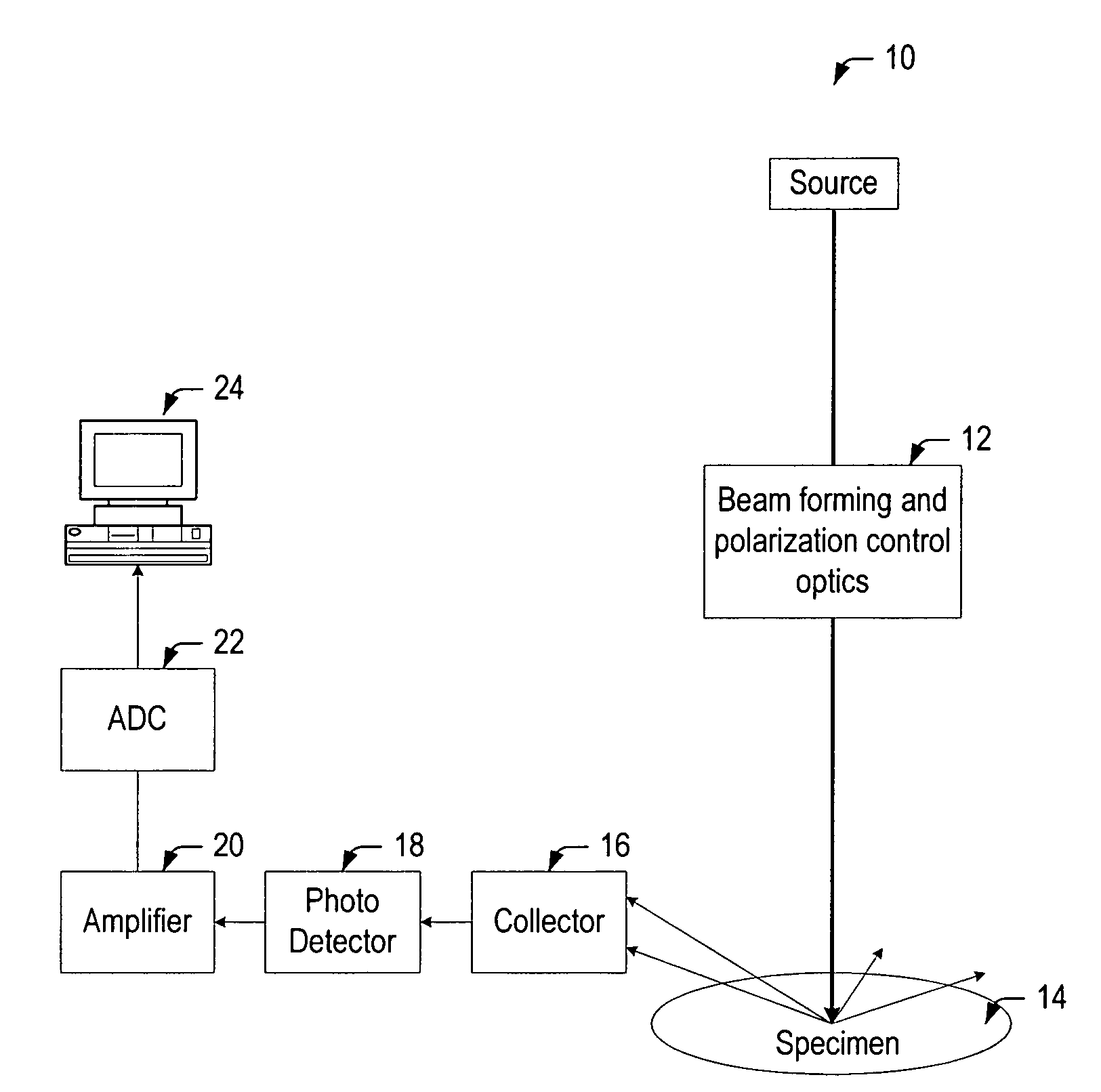

Systems, circuits and methods for reducing thermal damage and extending the detection range of an inspection system

ActiveUS20070013898A1Reduce heat damageEasy defect detectionPolarisation-affecting propertiesScattering properties measurementsEngineeringMechanical engineering

Inspection systems, circuits, and methods are provided to enhance defect detection by reducing thermal damage to large particles by dynamically altering the incident laser beam power level supplied to the specimen during a surface inspection scan. In one embodiment, an inspection system includes an illumination subsystem for directing light to a specimen at a first power level, a detection subsystem for detecting light scattered from the specimen, and a power attenuator subsystem for dynamically altering the power level directed to the specimen based on the scattered light detected from the specimen. For example, the power attenuator subsystem may reduce the directed light to a second power level, which is lower than the first, if the detected scattered light exceeds a predetermined threshold level. In addition reducing thermal damage, the systems and methods described herein may be used to extend the measurement detection range of an inspection system by providing a variable-power inspection system.

Owner:KLA TENCOR TECH CORP

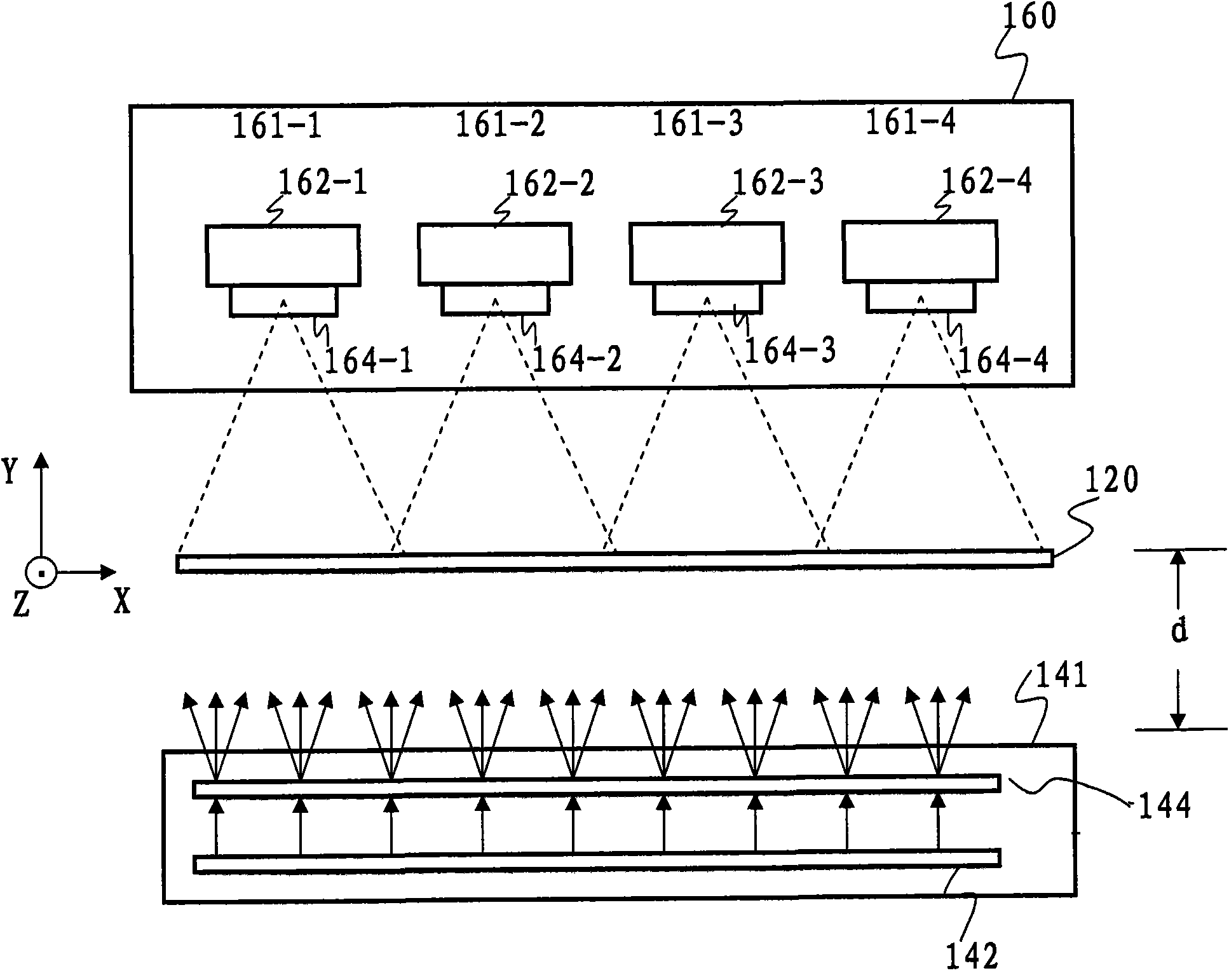

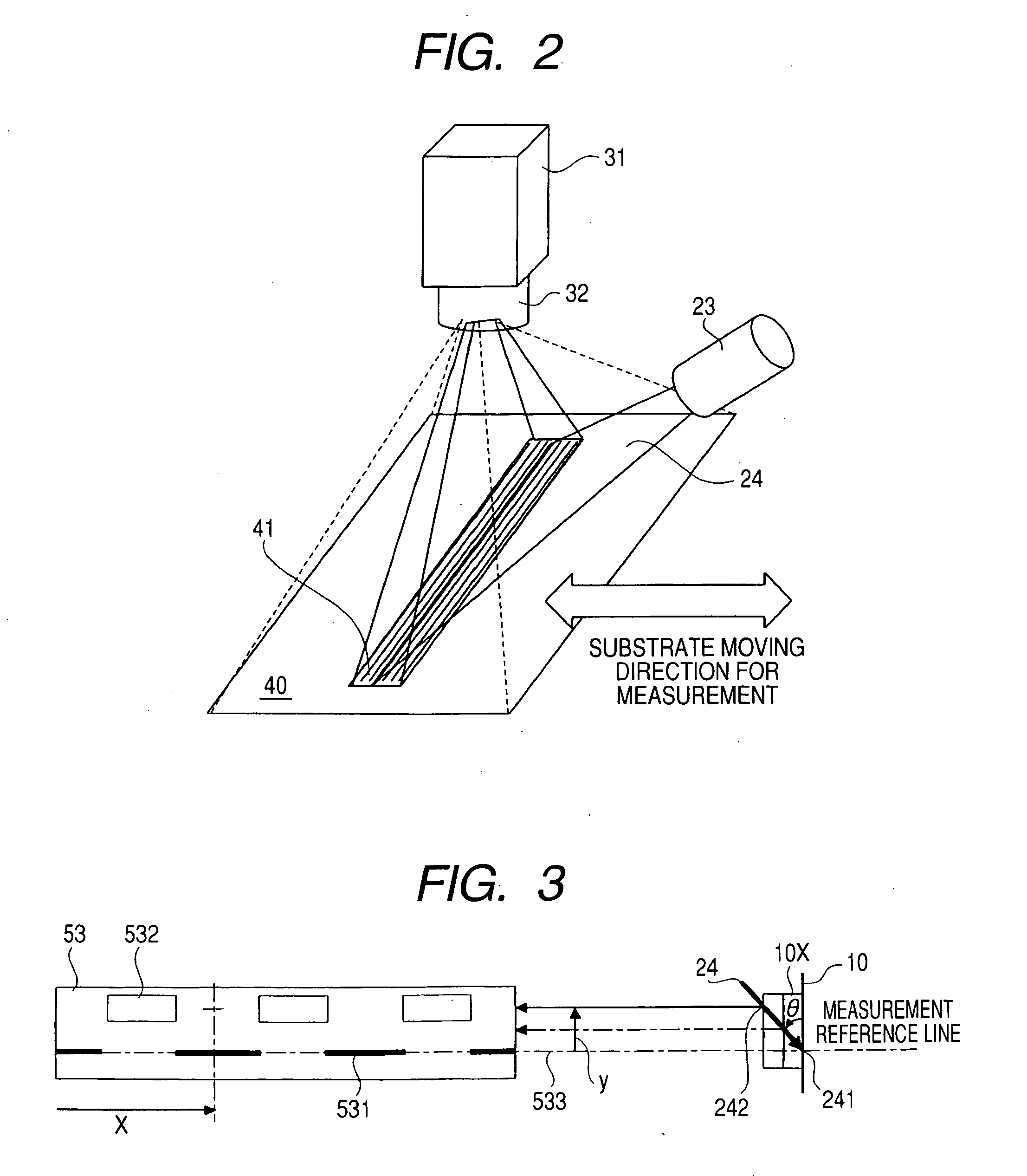

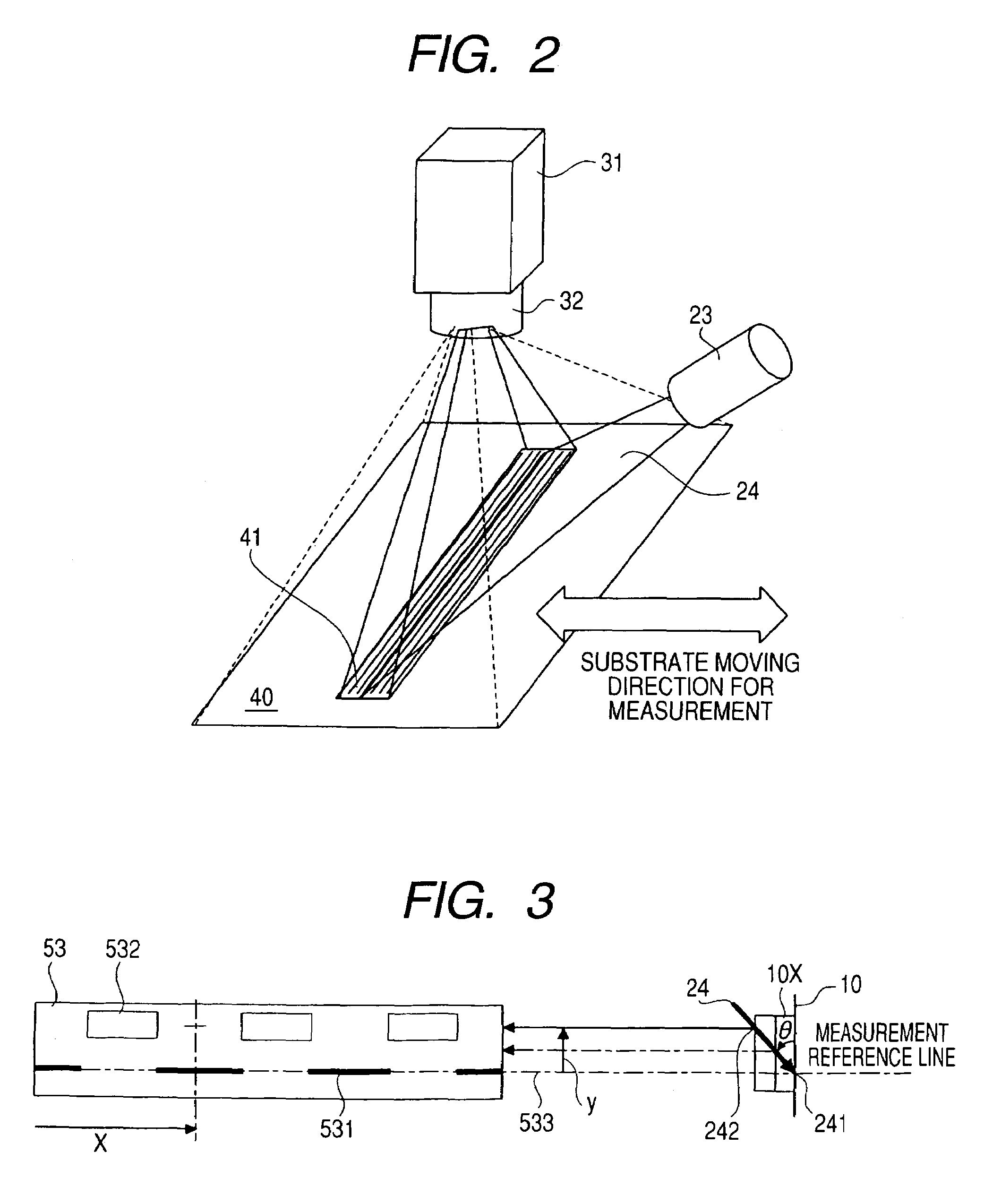

Method and system for detecting defect of patterned substrate

InactiveCN101819165AEliminate the effects ofQuality improvementPhotovoltaic monitoringMaterial analysis by optical meansDiffusionShortest distance

The invention discloses a system and a method for detecting defect on or in a transparent or semitransparent patterned or structured substrate. The system comprises at least one imaging element, a first light source and a conveying device, wherein the at least one imaging element is used for scanning the substrate; the first light source is arranged close to the substrate for irradiating diffusedlight to the substrate; the first light source and the at least one imaging element form a first detection passage about the substrate; and the conveying device is used for producing relative movement between the substrate and the at least one imaging element as well as the first light source. In the invention, the patterned substrate is irradiated by using a short-distance diffusion mode so as to effectively eliminate the influence of the pattern or structure in the substrate on the original image, so that the defect is highlighted so as to easily and accurately identify and classify the local defect.

Owner:SAINT-GOBAIN GLASS FRANCE

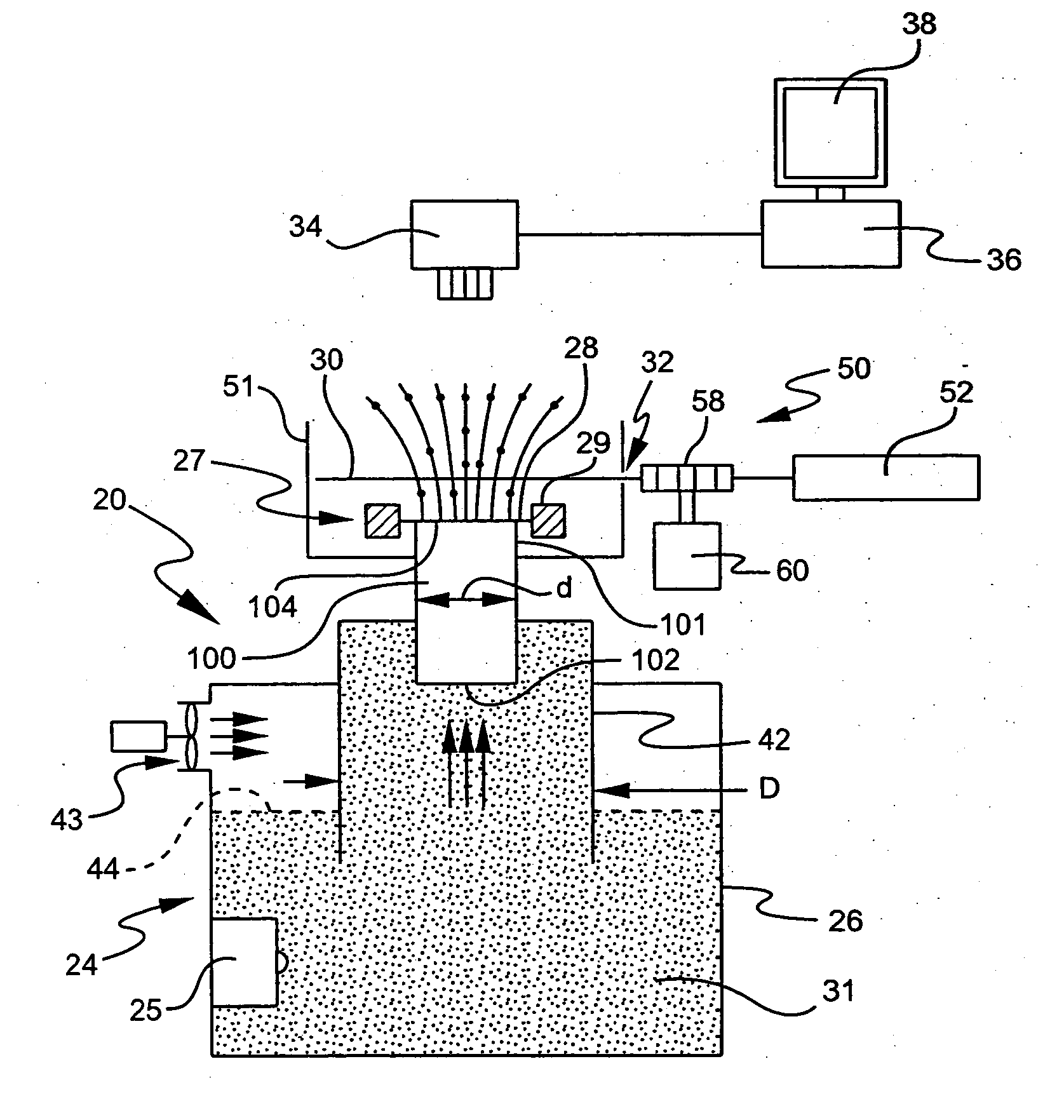

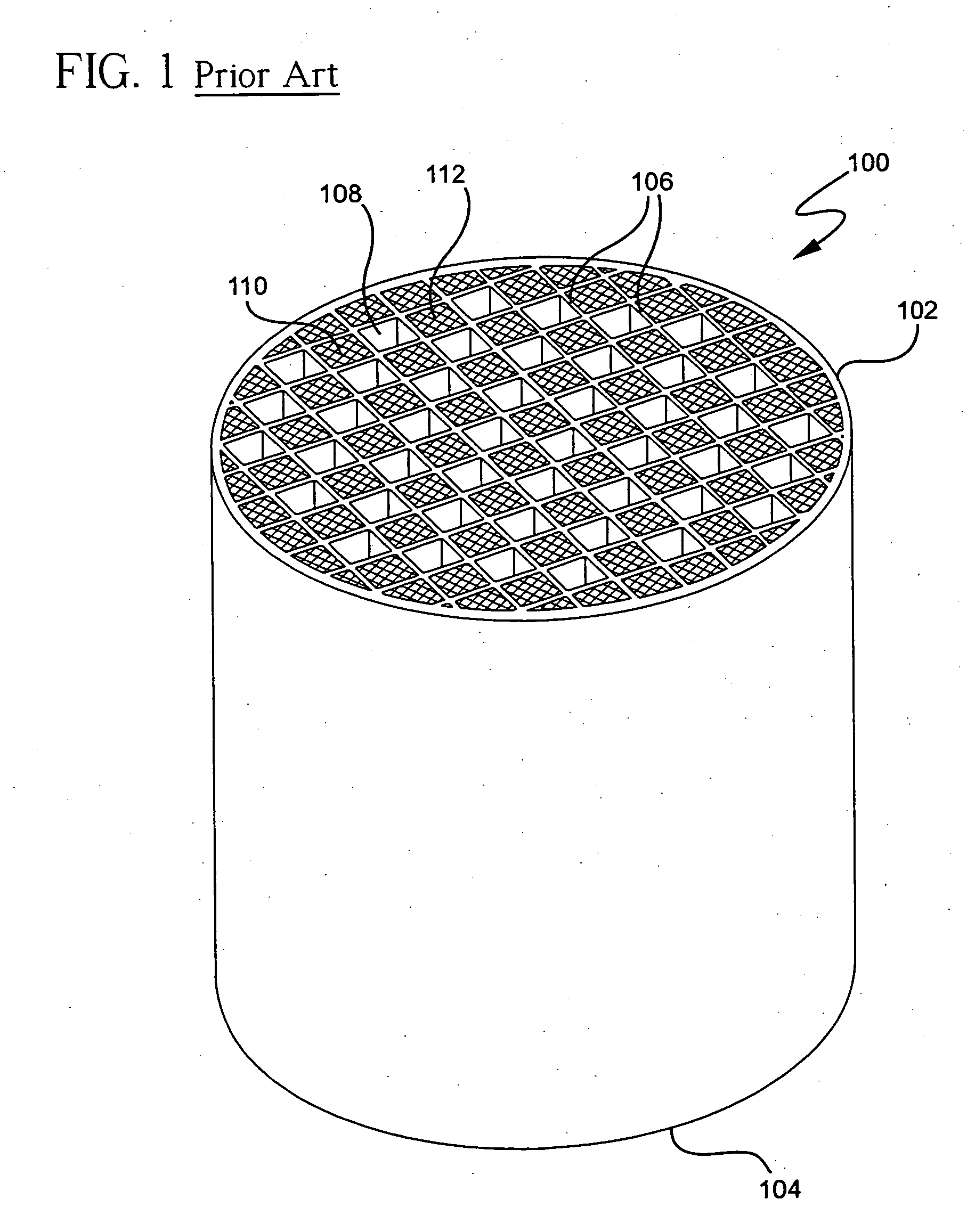

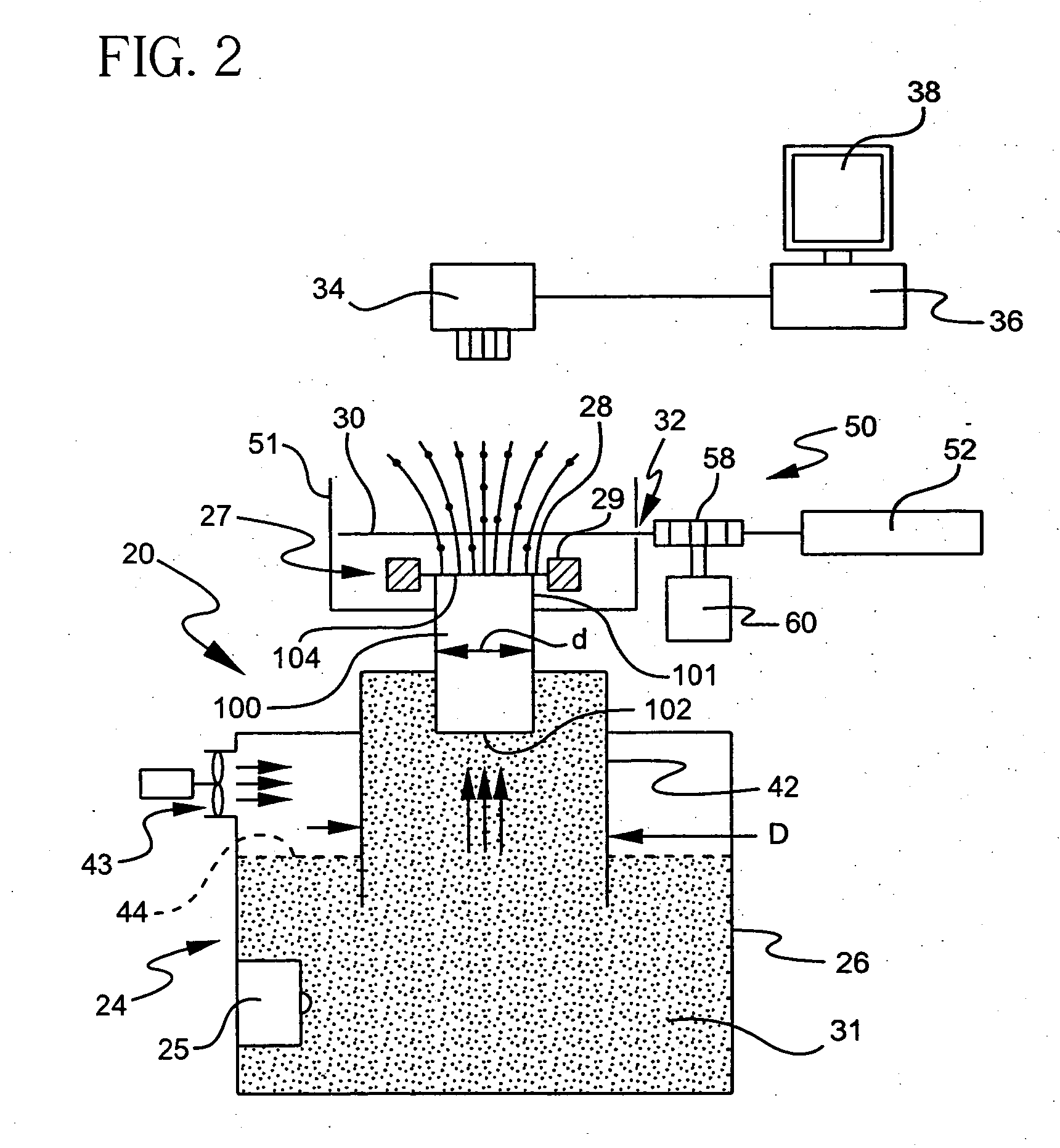

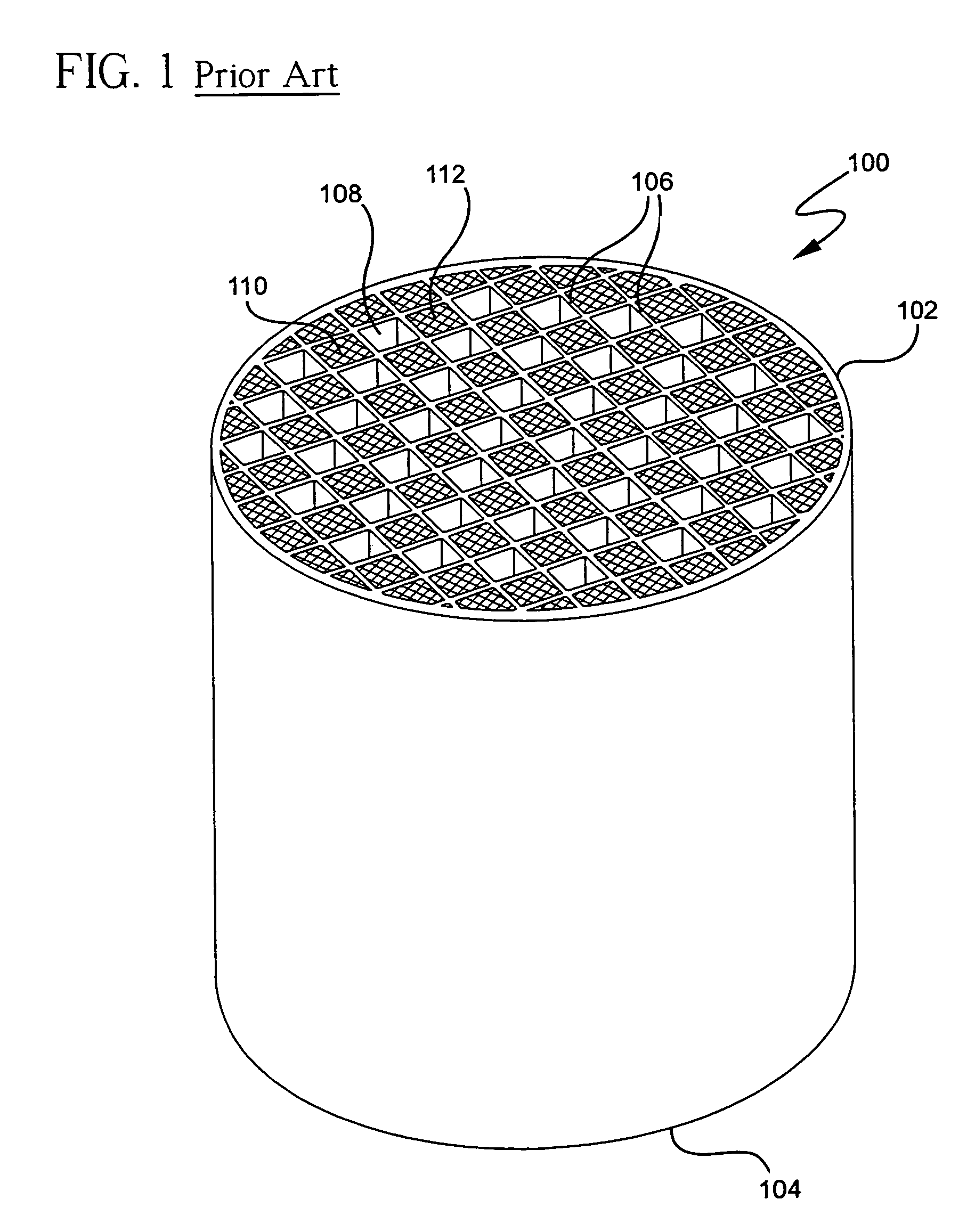

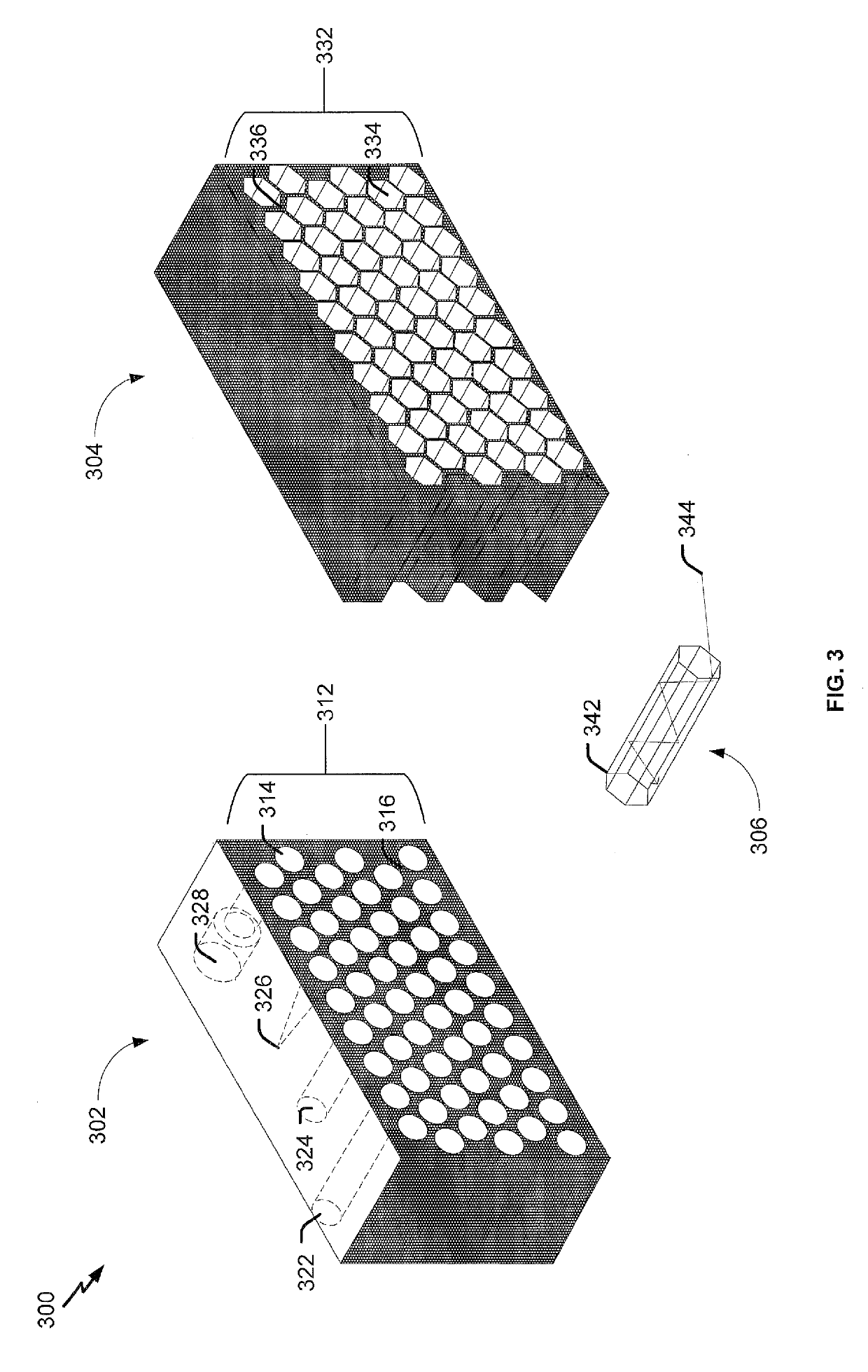

Honeycomb filter defect detecting method and apparatus

ActiveUS20070238191A1Improve signal-to-noise ratioEasy defect detectionDetection of fluid at leakage pointInternal combustion piston enginesParticulatesHoneycomb

A apparatus and method for detecting defects in a honeycomb body. In operation, the particulates emerge at an outlet end face of the honeycomb body through defects, if any, in the honeycomb walls and / or plugs and passes though a permeable member, such as a screen, where they are illuminated. The permeable member is disposed adjacent to and preferably in contact with the outlet end. Use of the permeable member improves the signal-to-noise ratio (SNR) such that defects may be more readily detected. The permeable member preferably includes an anti-reflective surface.

Owner:CORNING INC

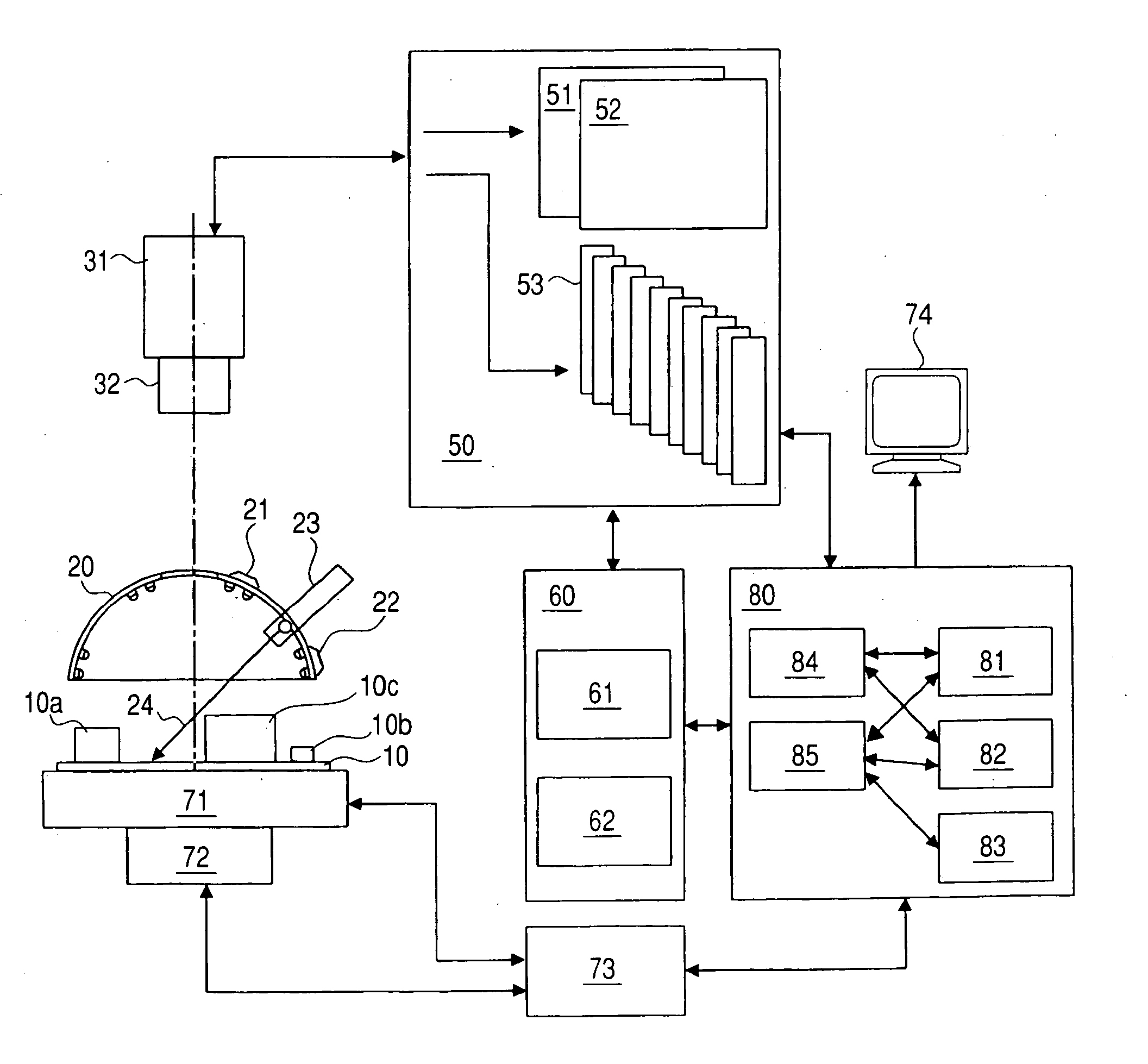

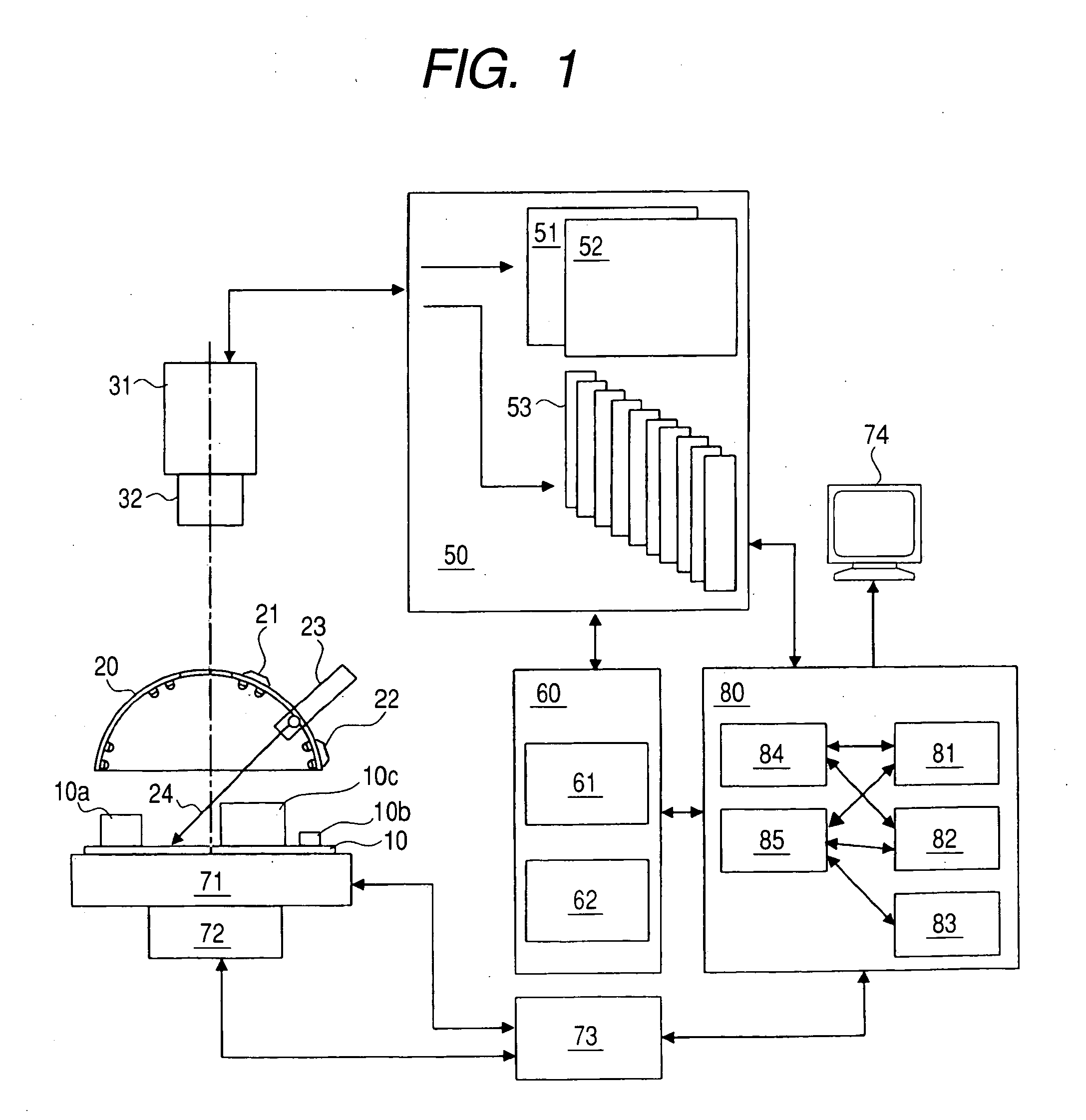

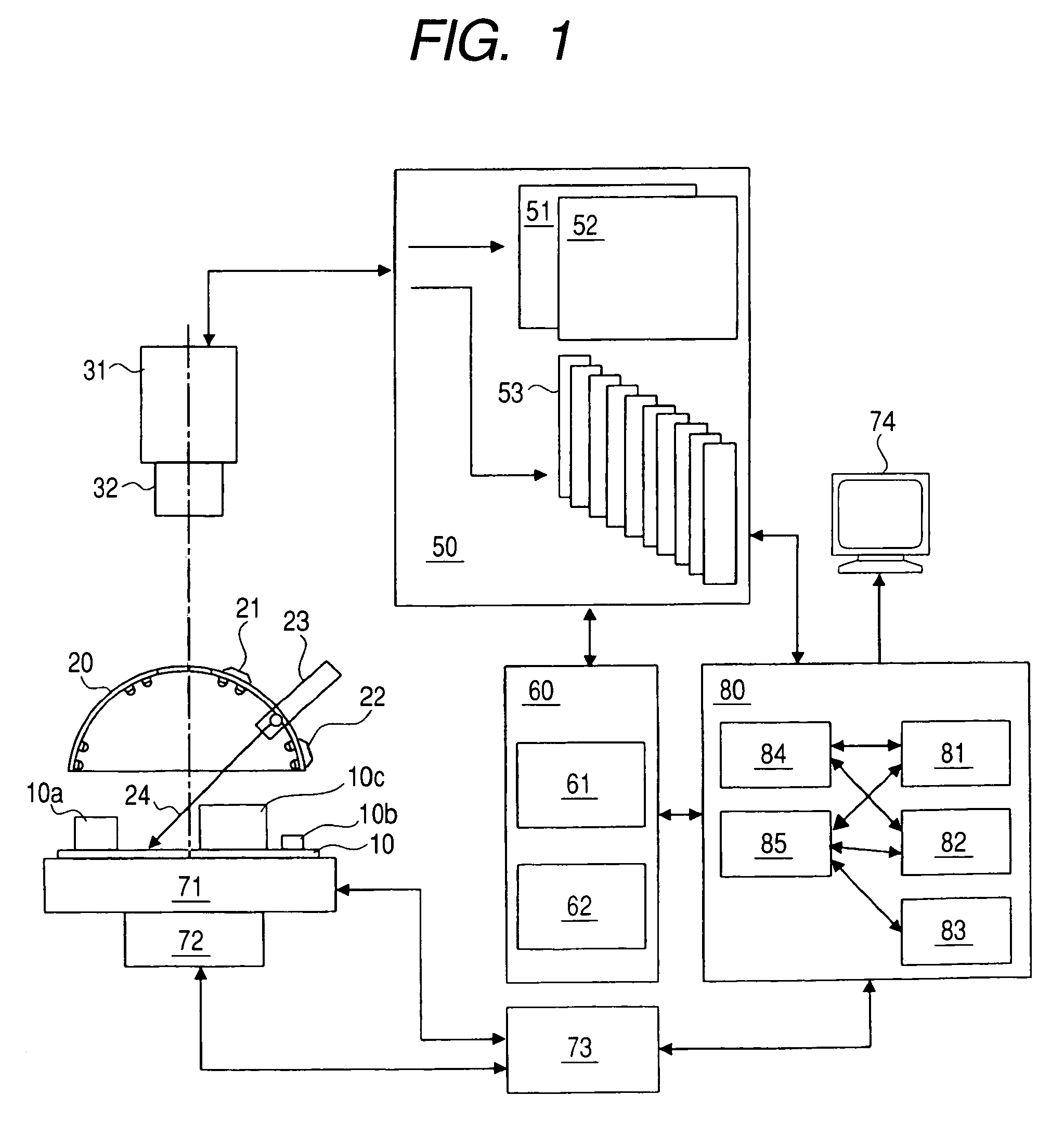

Fabrication method of semiconductor integrated circuit device

ActiveUS20050162644A1Easy to prepareEasy defect detectionPrinted circuit assemblingSolid-state devicesEngineeringVisual perception

In the fabrication of a semiconductor integrated circuit device, a 2D-3D inspection technique for solder printed on a substrate is provided which permits easy preparation of data and easy visual confirmation of a defective portion. In a substrate inspecting step first, a 3D inspection is performed, followed by execution of 2D inspection, whereby a 2D picked-up image of the portion of a pad determined to be defective can be displayed on a larger scale simultaneously with the end of inspection, thereby providing an environment for efficient visual confirmation of the defect. Further, by subjecting a raw substrate to measurement at the time of preparing inspection data, a relation between an original height measurement reference generated automatically by the inspection system and the height of a pad upper surface is checked, whereby it is possible to measure the height and volume of printed solder based on the pad upper surface.

Owner:RENESAS ELECTRONICS CORP

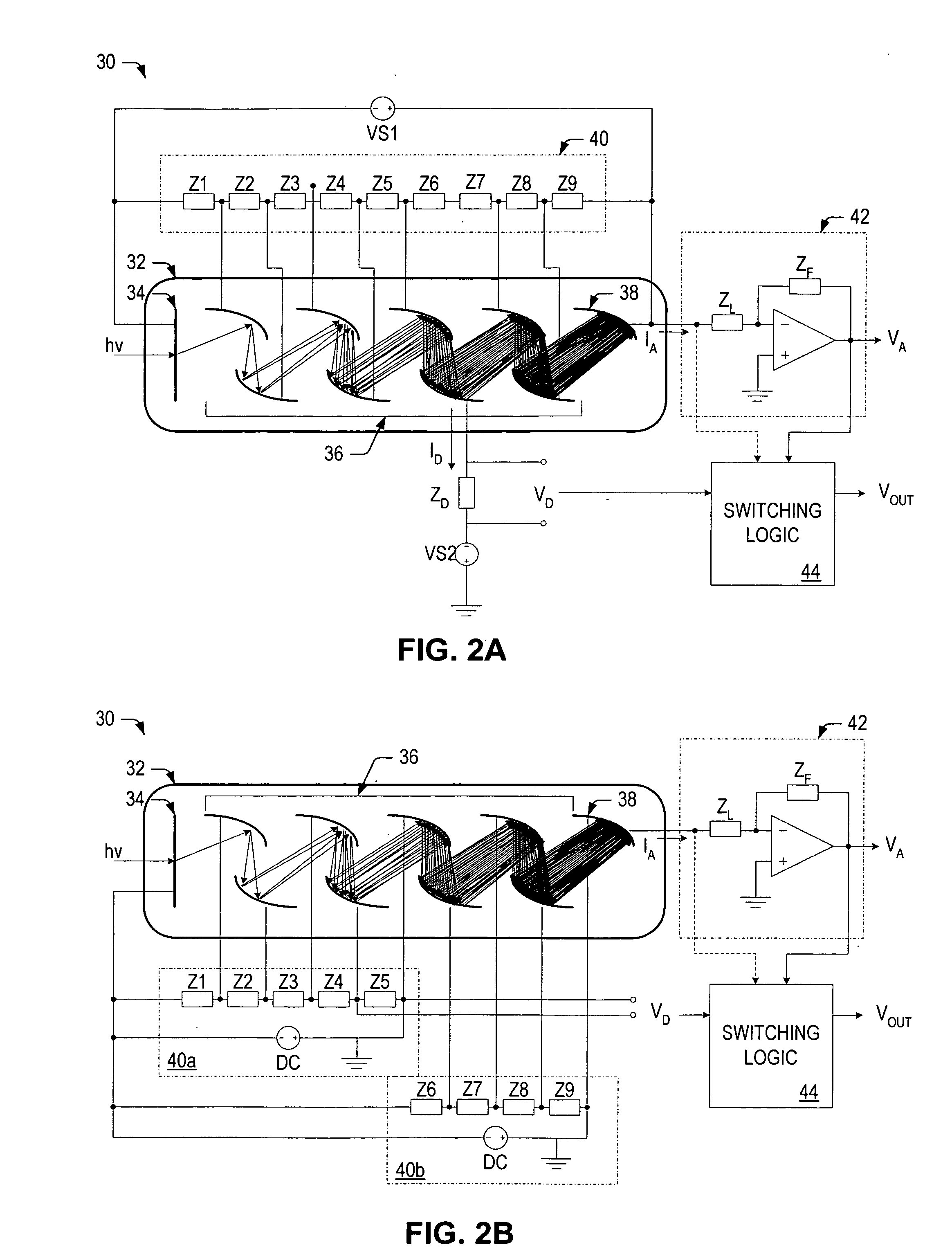

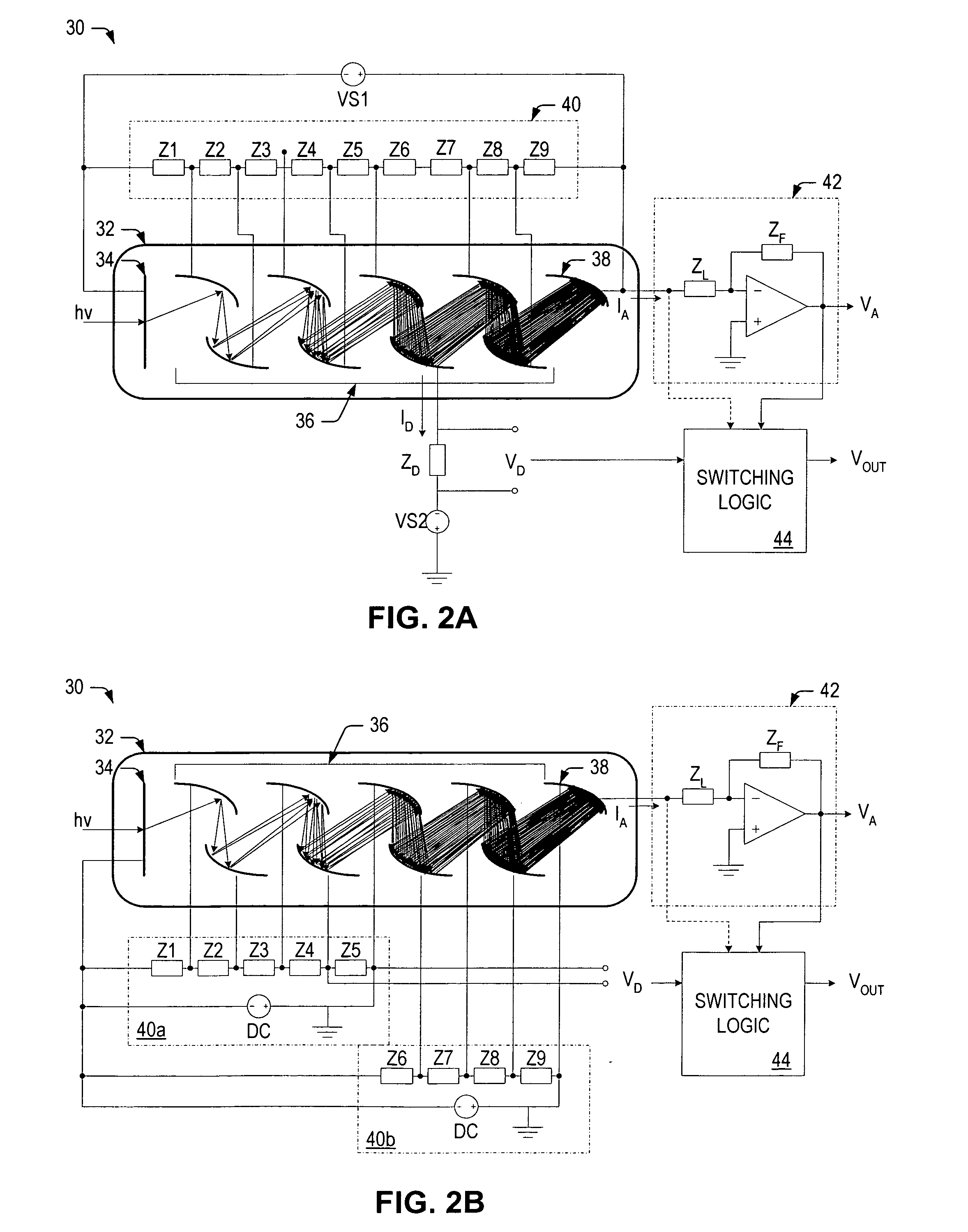

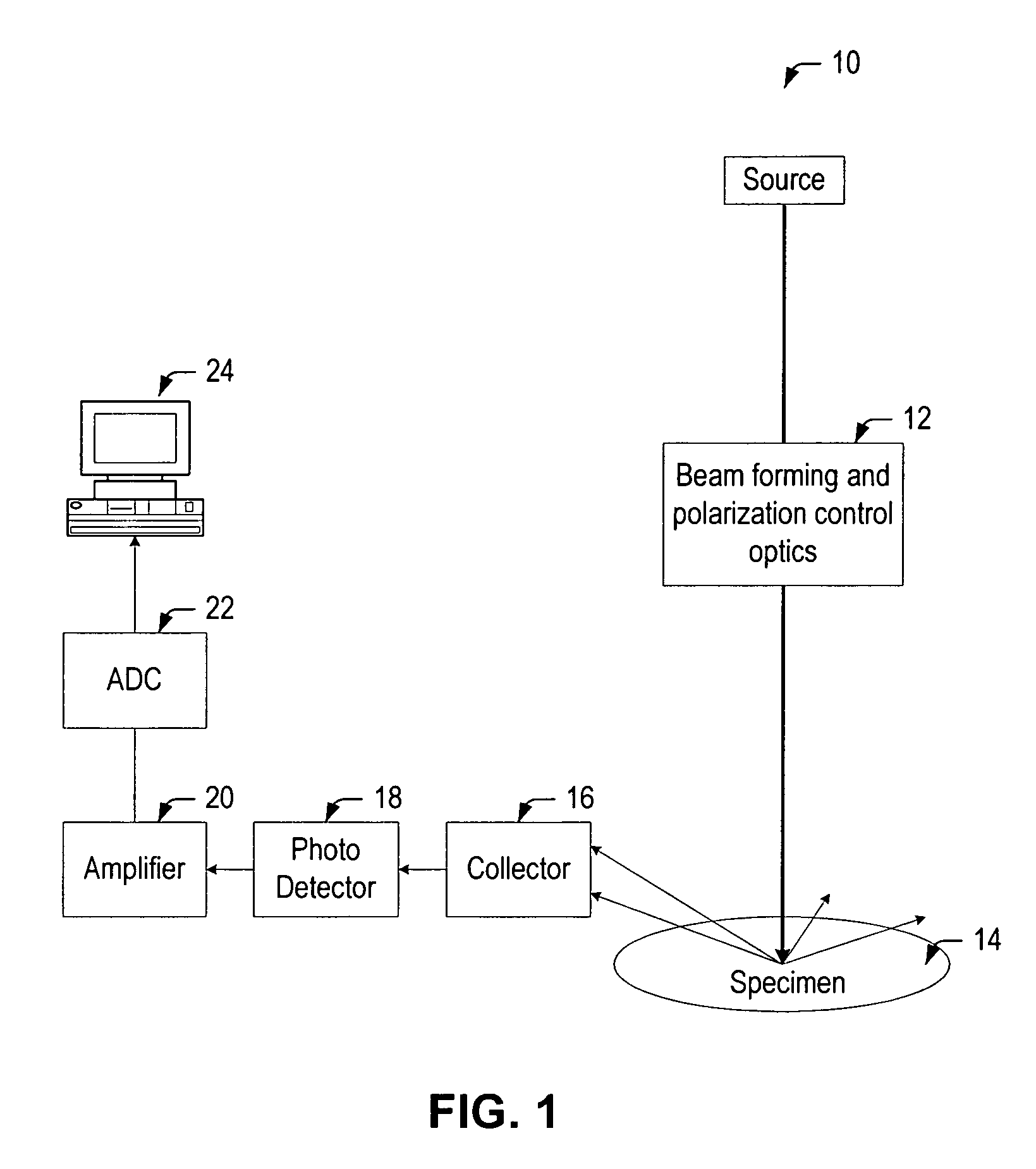

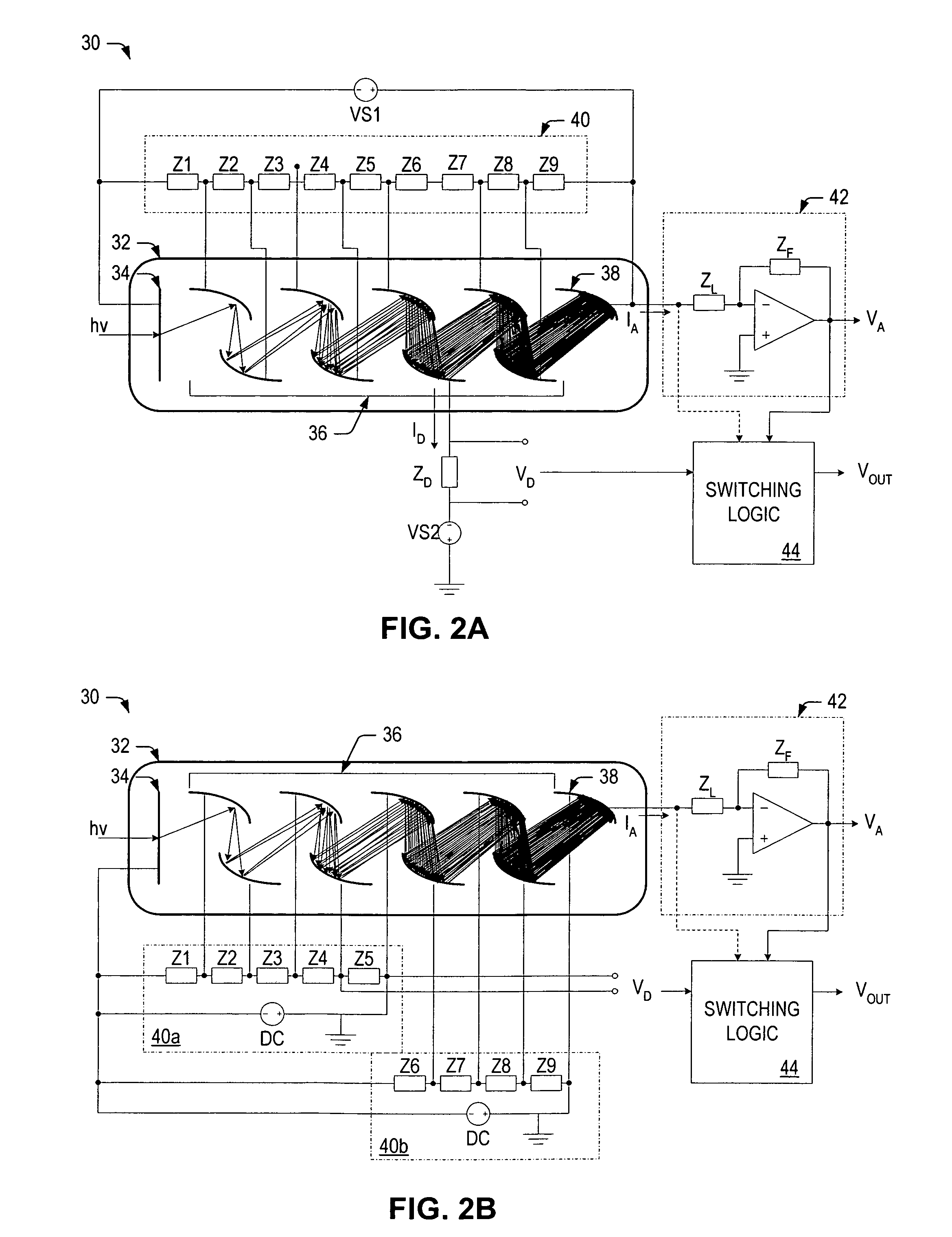

Systems, circuits and methods for extending the detection range of an inspection system by avoiding circuit saturation

ActiveUS20070012867A1Reduce resolutionExpand the scope of detectionMaterial analysis by optical meansMultiplier circuit arrangementsPhotodetectorImage resolution

Inspection systems, circuits and methods are provided to enhance defect detection by addressing saturation levels of the amplifier and analog-digital circuitry as a limiting factor of the measurement detection range of an inspection system. In accordance with one embodiment of the invention, a method for inspecting a specimen includes directing light to the specimen and detecting light scattered from the specimen. However, the step of detecting may use only one photodetector for detecting the light scattered from the specimen and for converting the light into an electrical signal. The step of detecting also includes generating a first signal and a second signal in response to the electrical signal, where the second signal differs from the first. For example, the first signal may be generated to have a higher resolution than the second signal for detecting substantially lower levels of the scattered light. In most cases, the method may use the first signal for detecting features, defects or light scattering properties of the specimen until the first signal reaches a predetermined threshold value. Once the predetermined threshold value is reached, however, the method may use the second signal for said detecting.

Owner:KLA TENCOR TECH CORP

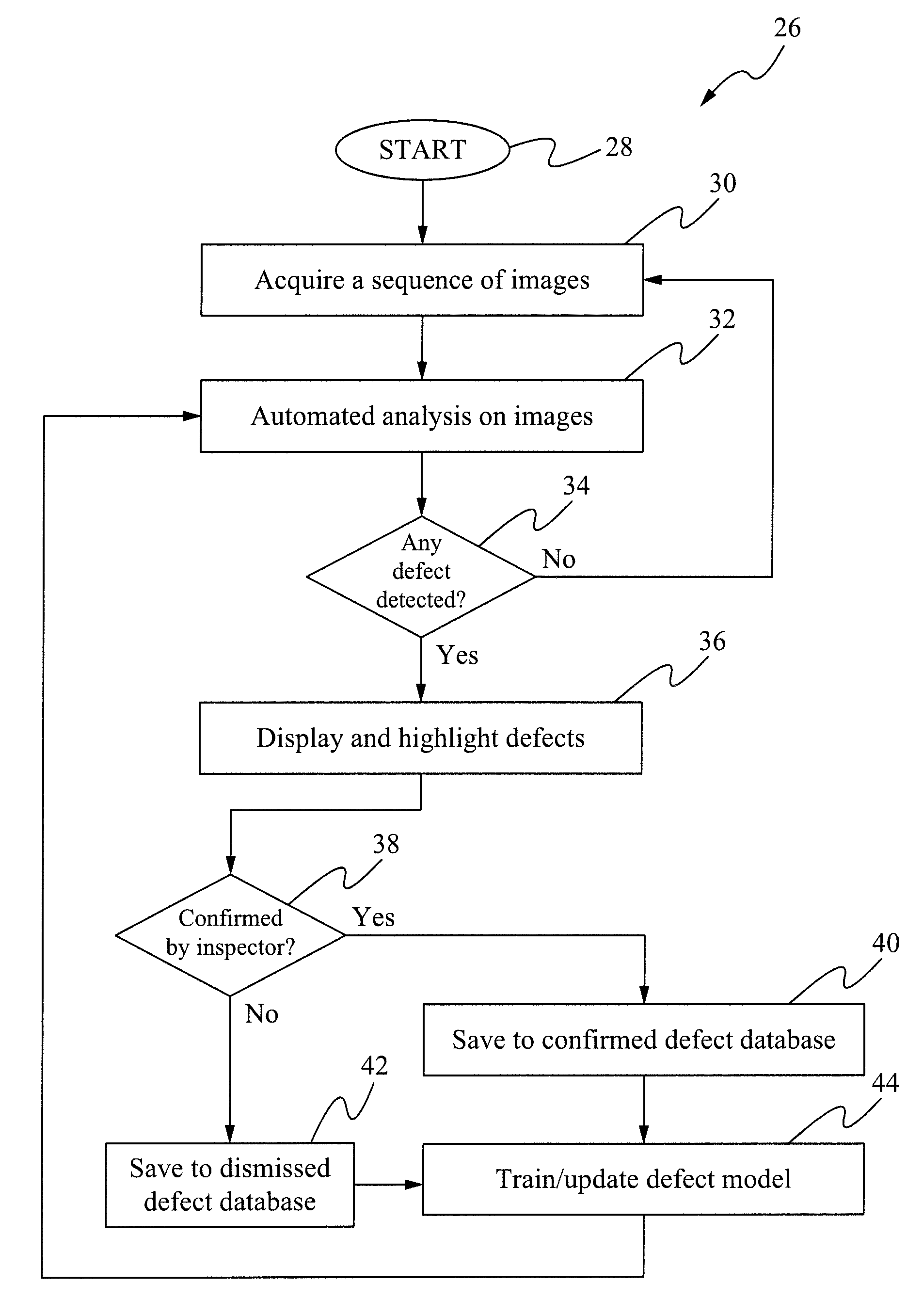

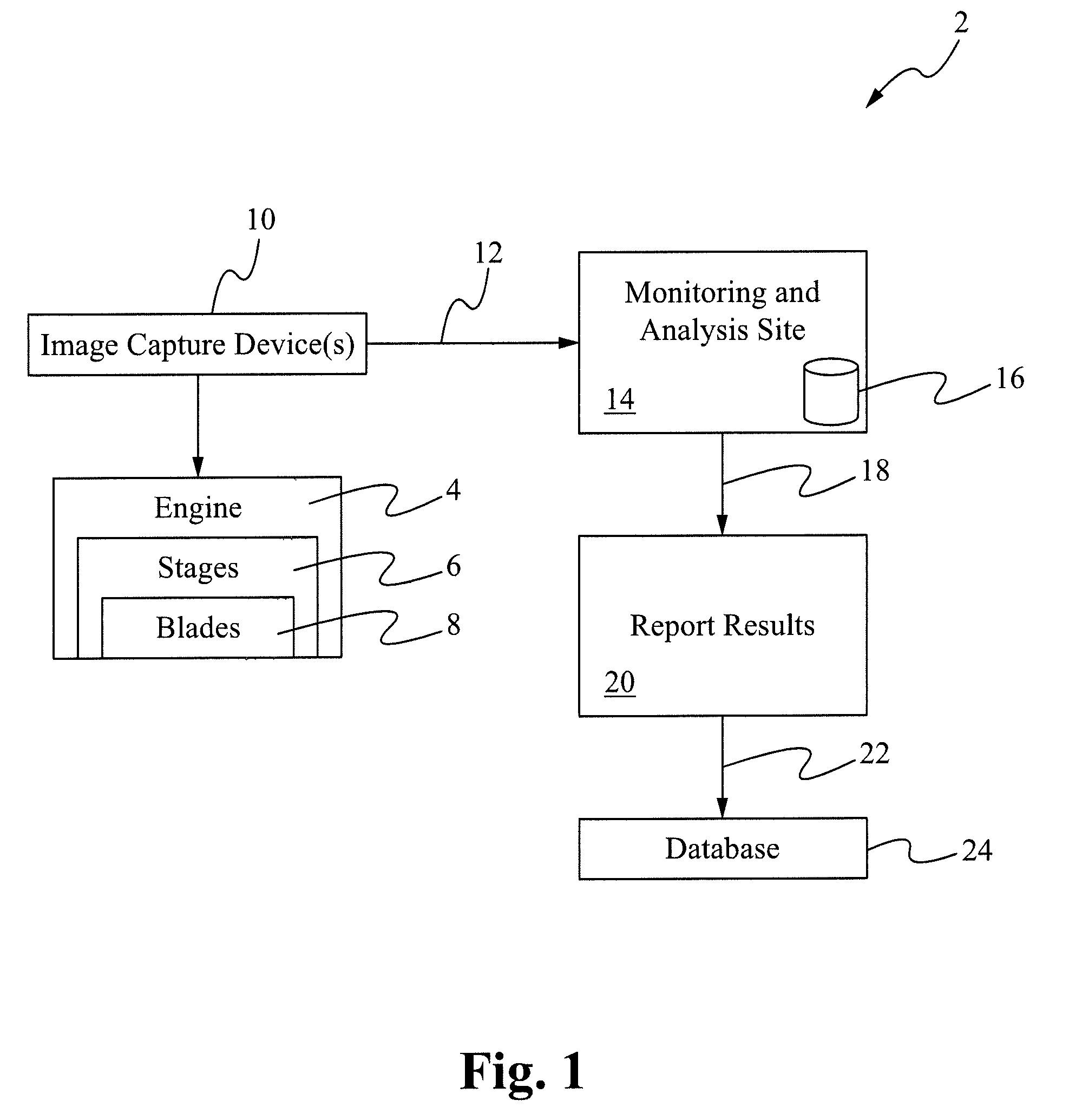

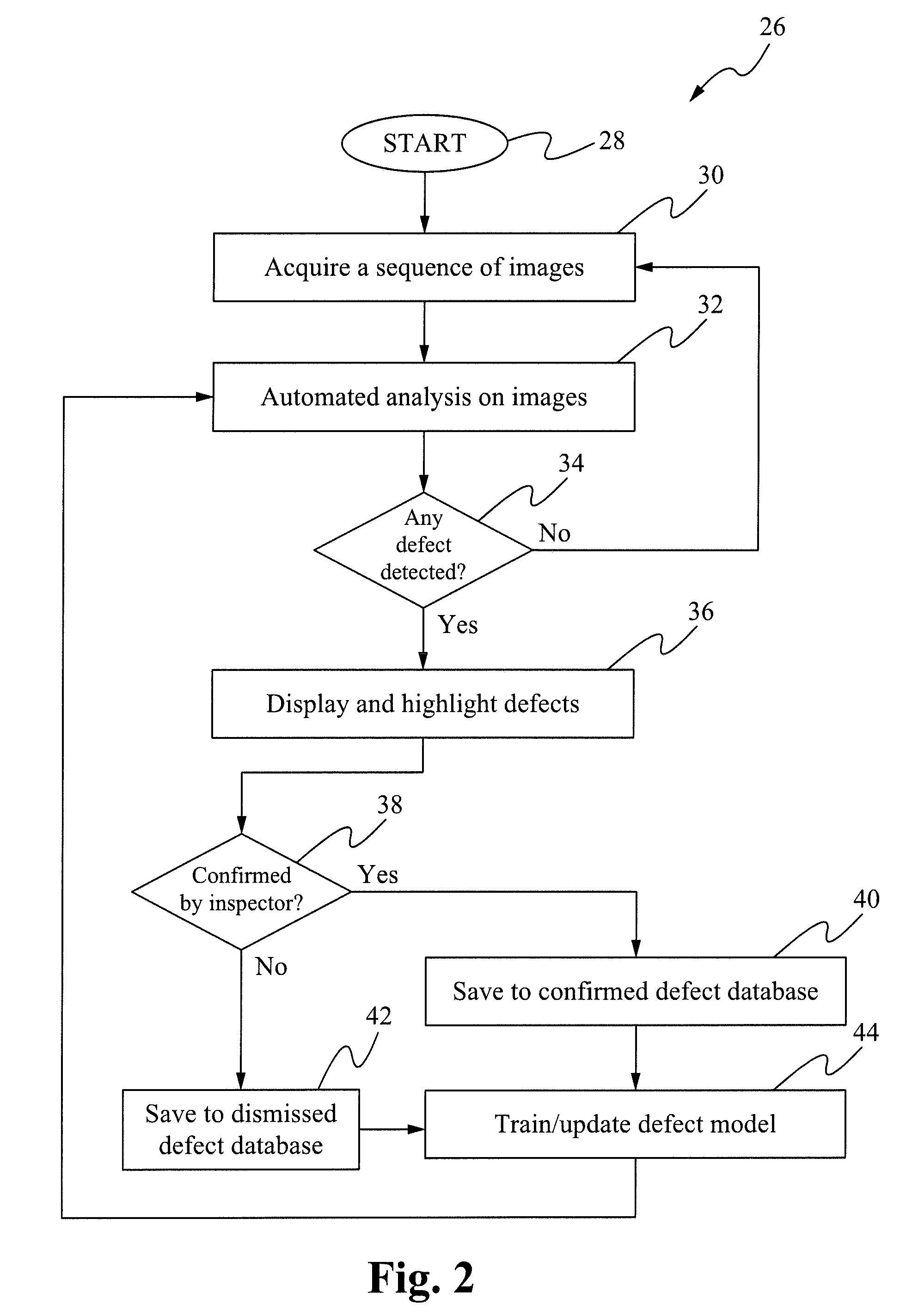

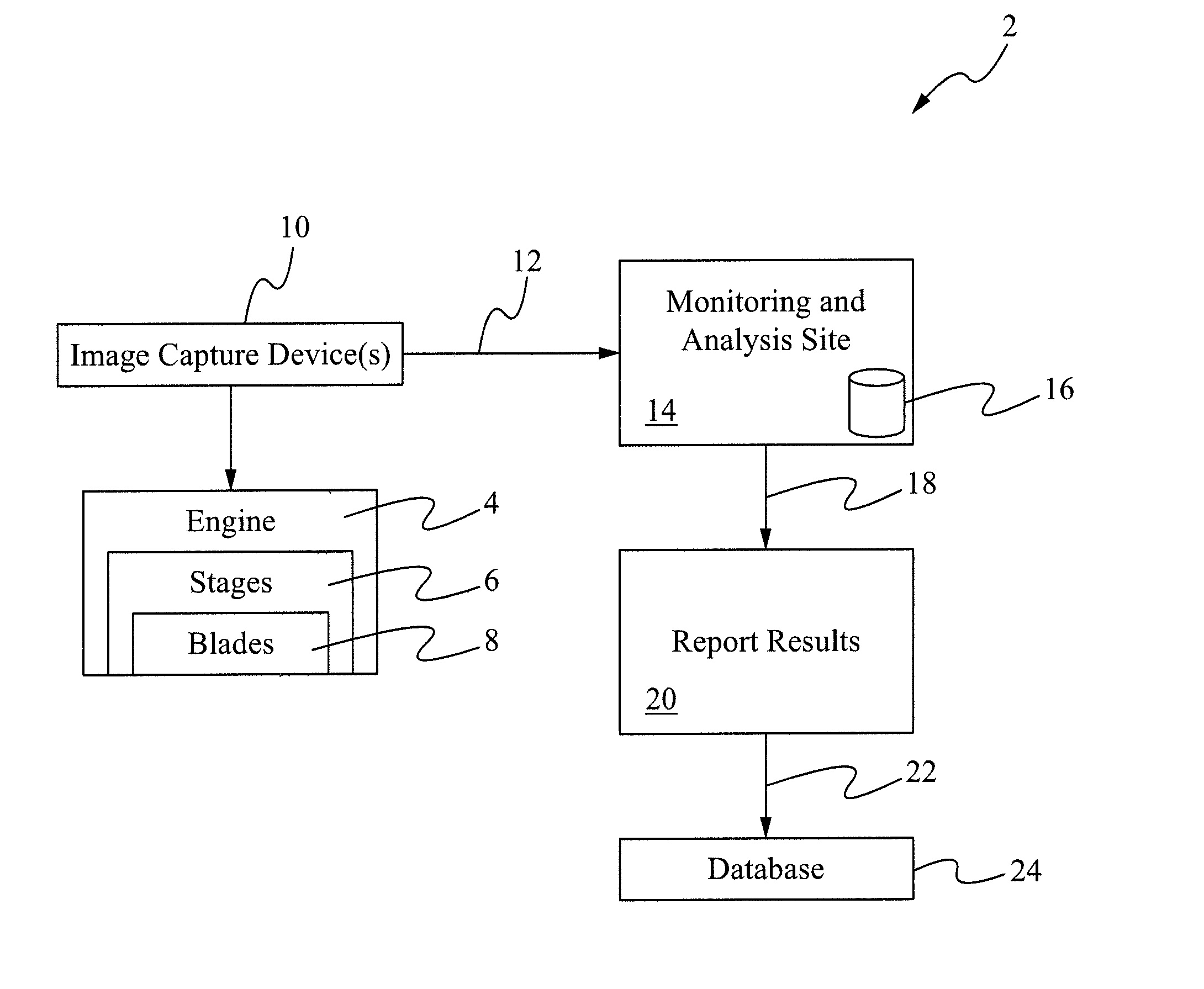

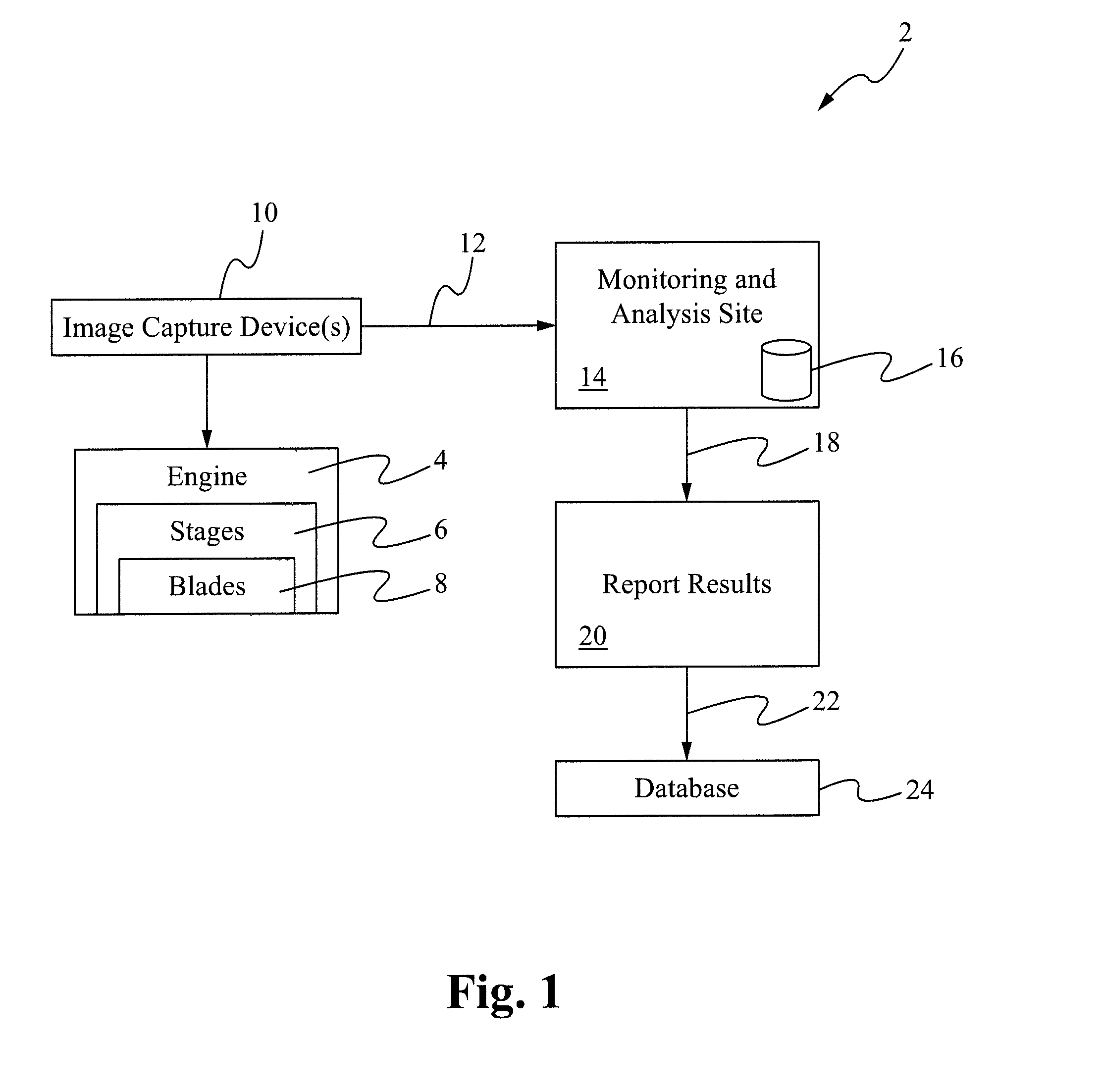

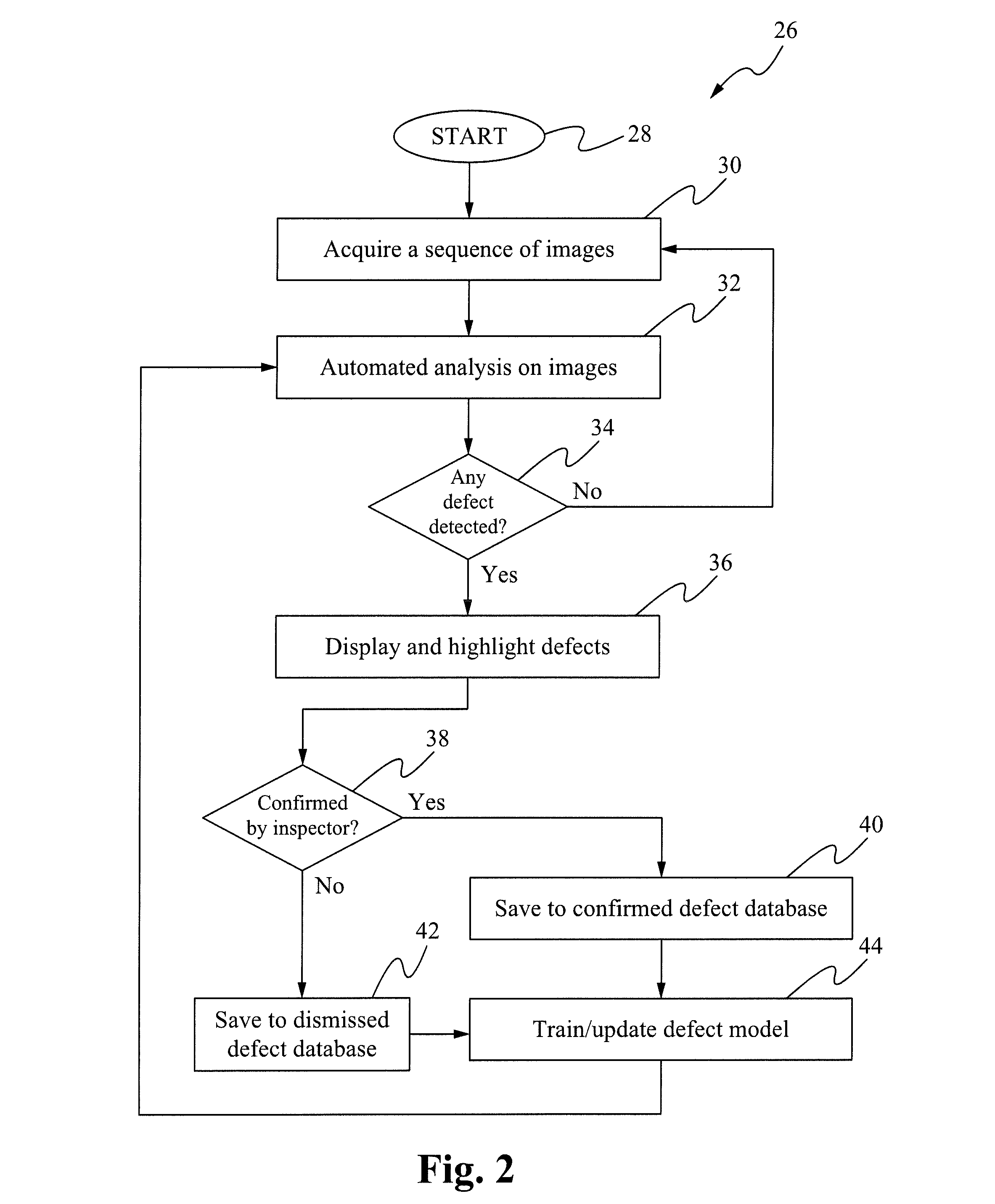

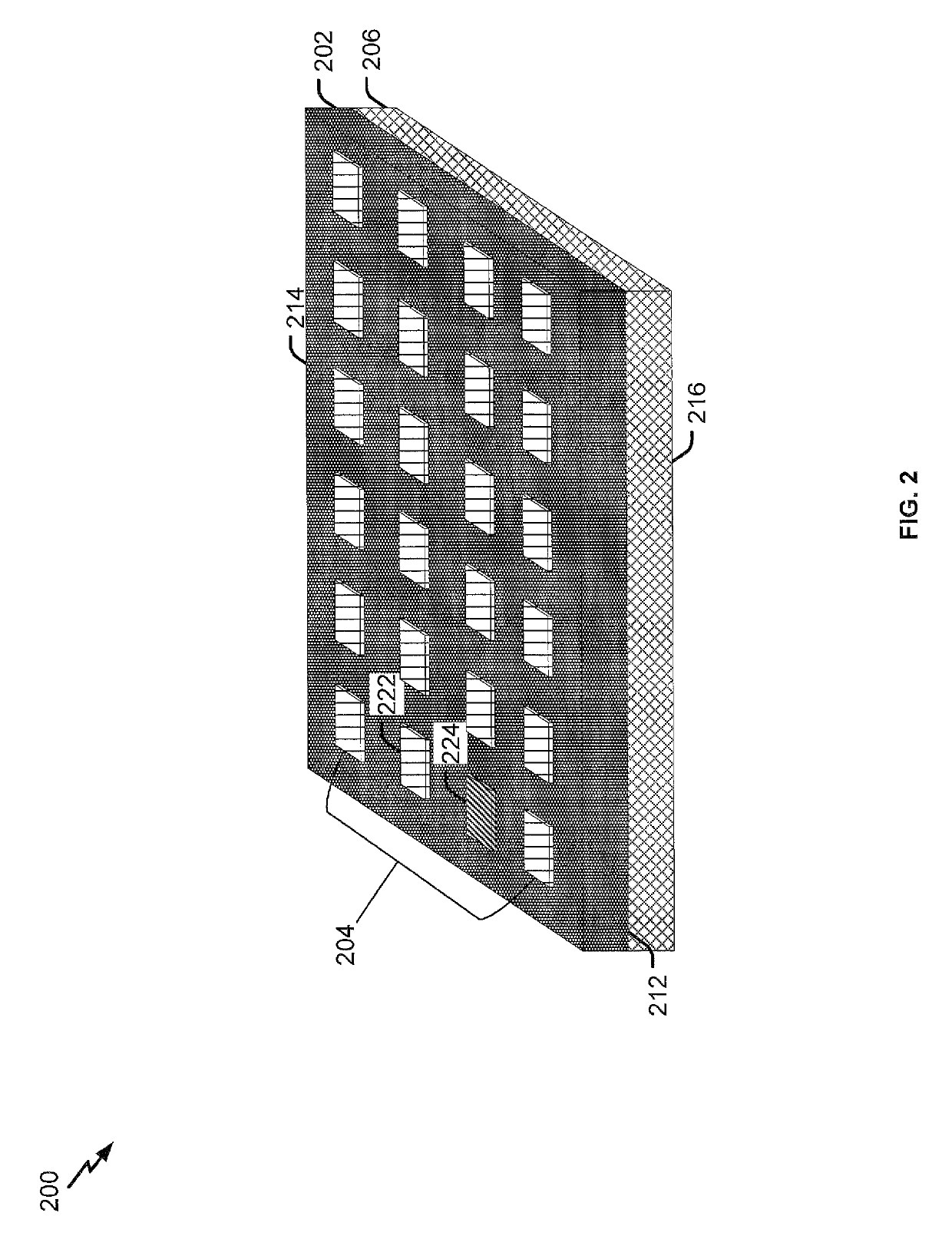

System and method for automated borescope inspection user interface

ActiveUS8761490B2Easy defect detectionMaterial analysis by optical meansCharacter and pattern recognitionHuman–machine interfaceBorescope

A system and method for improving human-machine interface while performing automated defect detection is disclosed. The system and method may include an image capture device for capturing and transmitting data of an object, performing automated analysis of the data and reviewing results of the automated analysis by a human inspector and providing feedback. The system and method may further include refining the automated analysis of the data based upon the feedback of the human inspector.

Owner:PRATT & WHITNEY +1

System and Method for Automated Borescope Inspection User Interface

ActiveUS20130113914A1Easy defect detectionMaterial analysis by optical meansColor television detailsHuman–machine interfaceEngineering

A system and method for improving human-machine interface while performing automated defect detection is disclosed. The system and method may include an image capture device for capturing and transmitting data of an object, performing automated analysis of the data and reviewing results of the automated analysis by a human inspector and providing feedback. The system and method may further include refining the automated analysis of the data based upon the feedback of the human inspector.

Owner:PRATT & WHITNEY +1

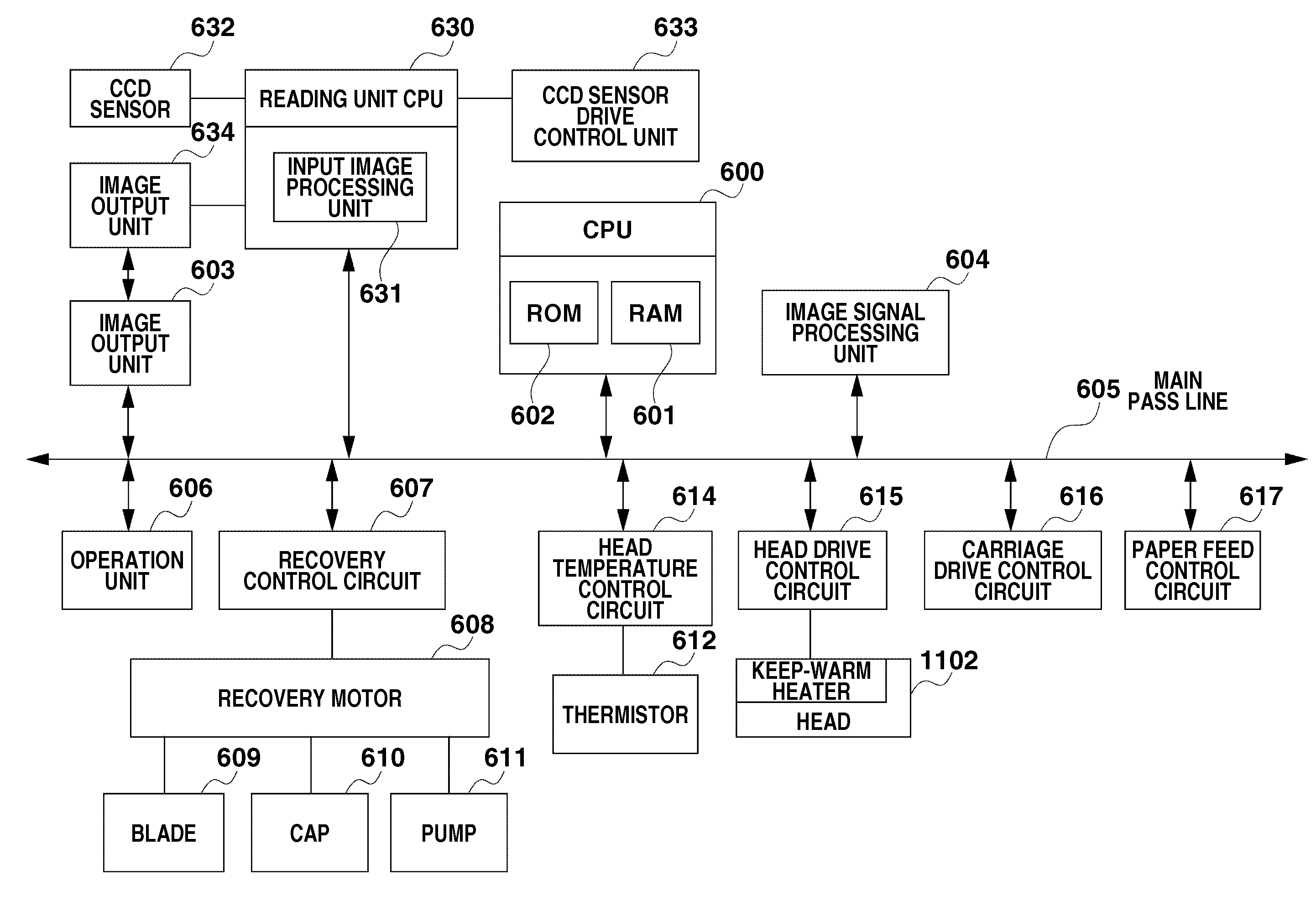

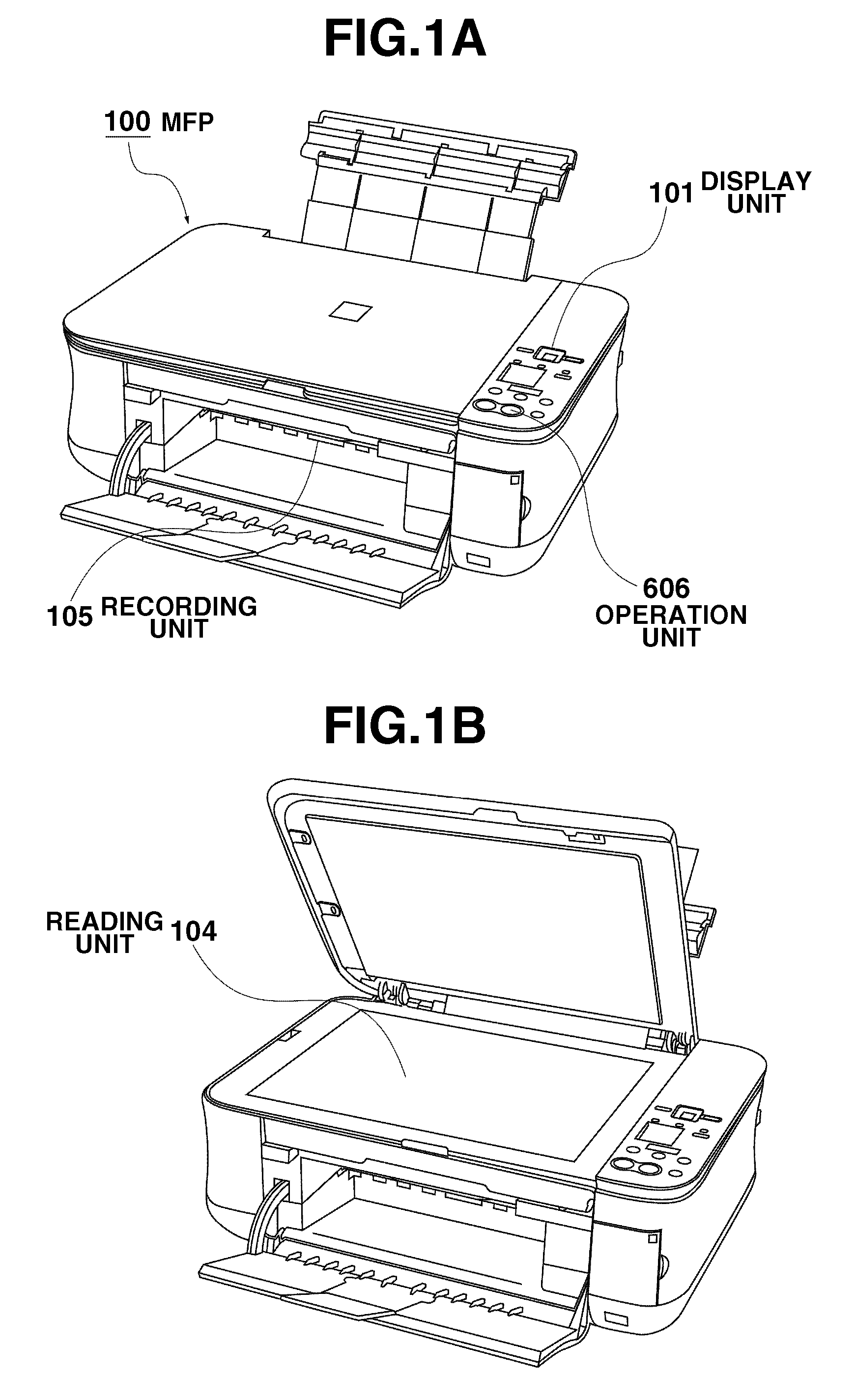

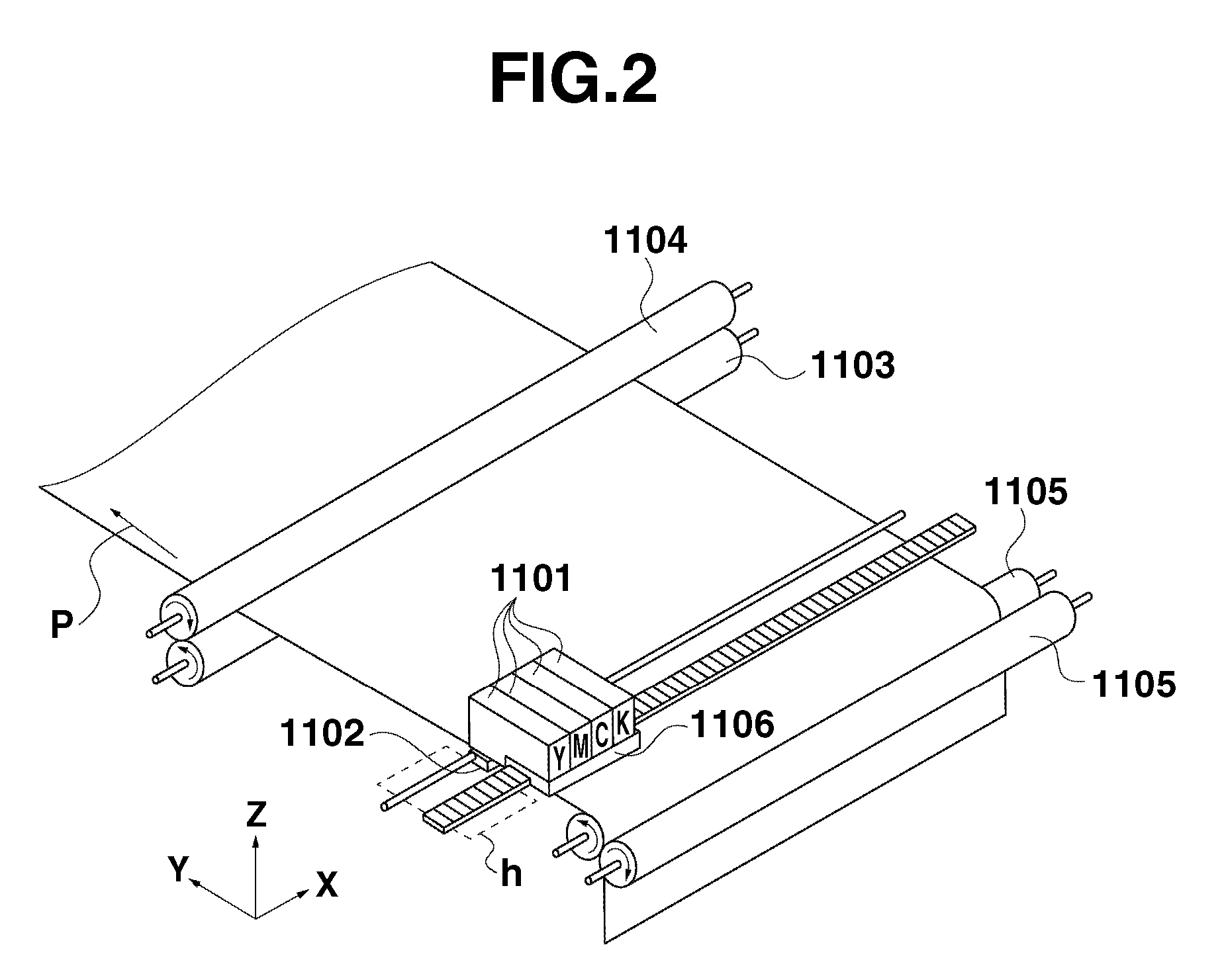

Recording apparatus and pattern forming method

Owner:CANON KK

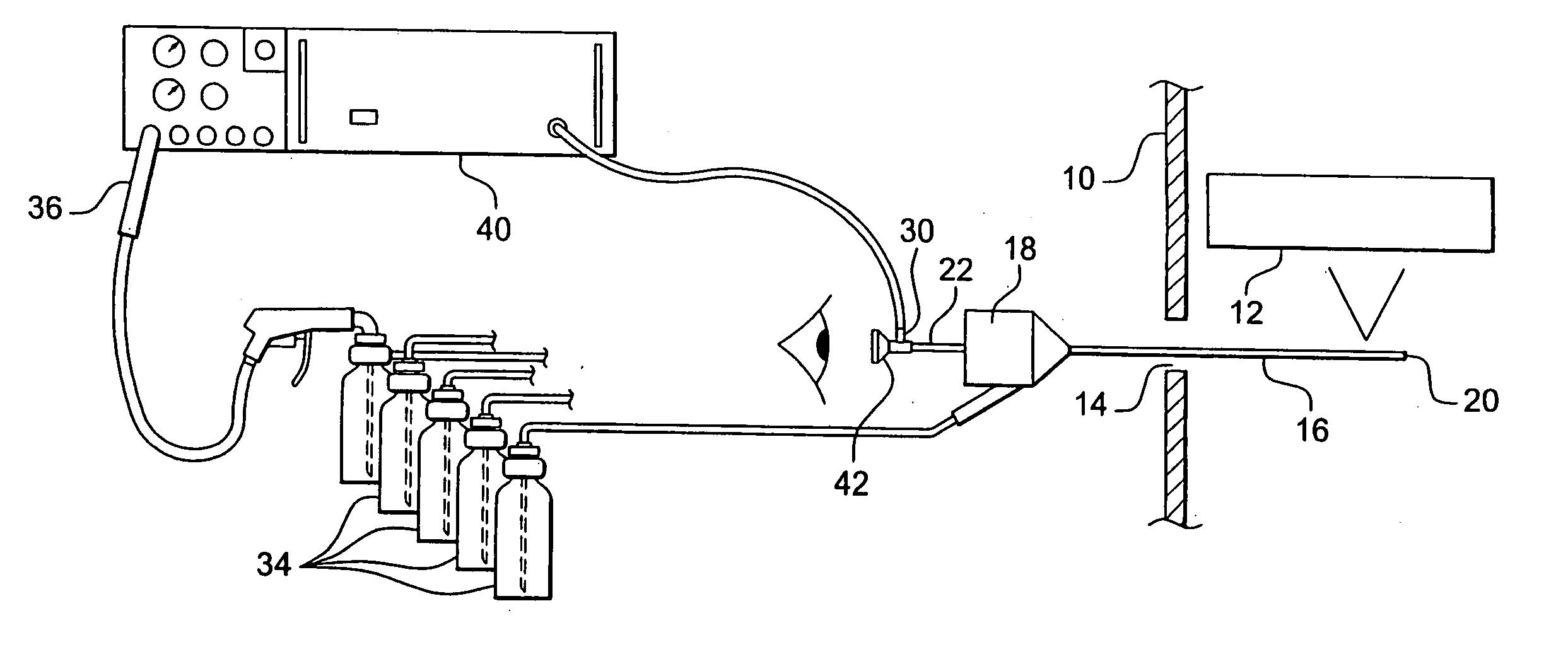

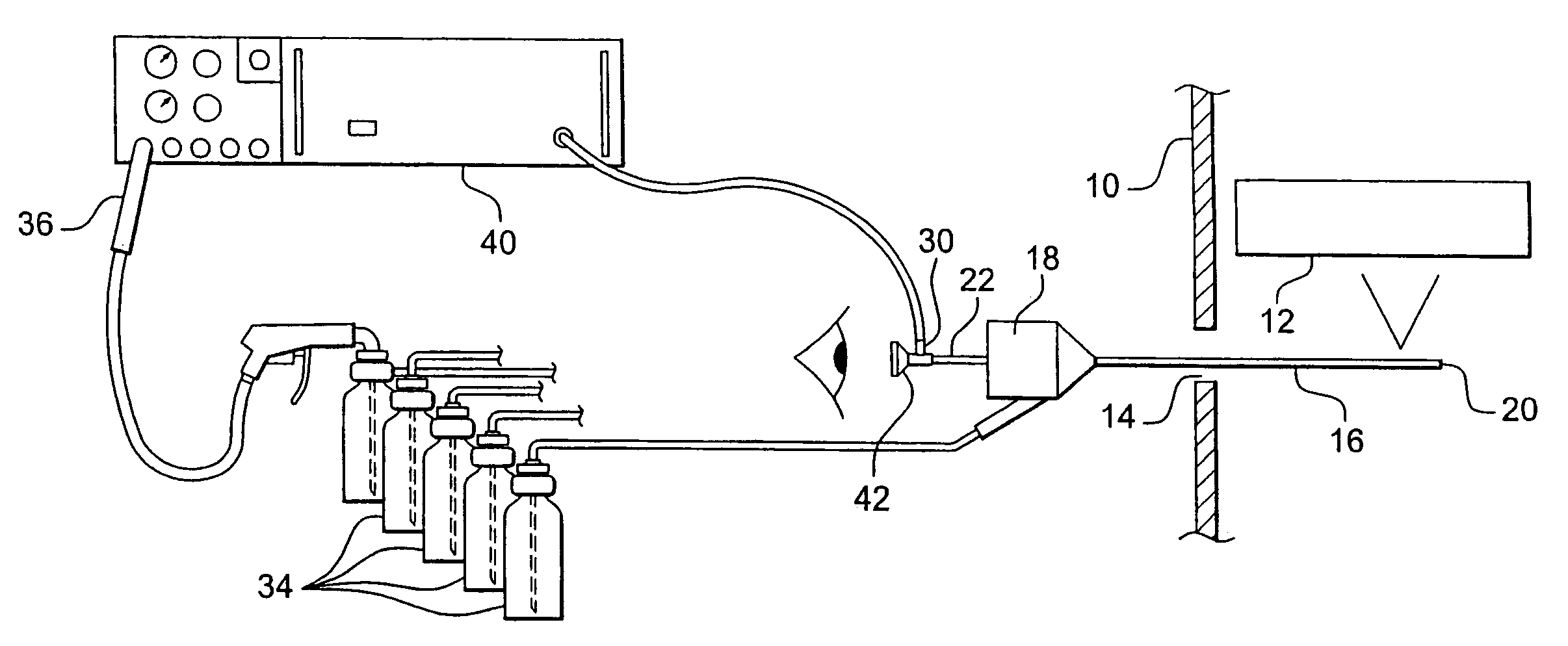

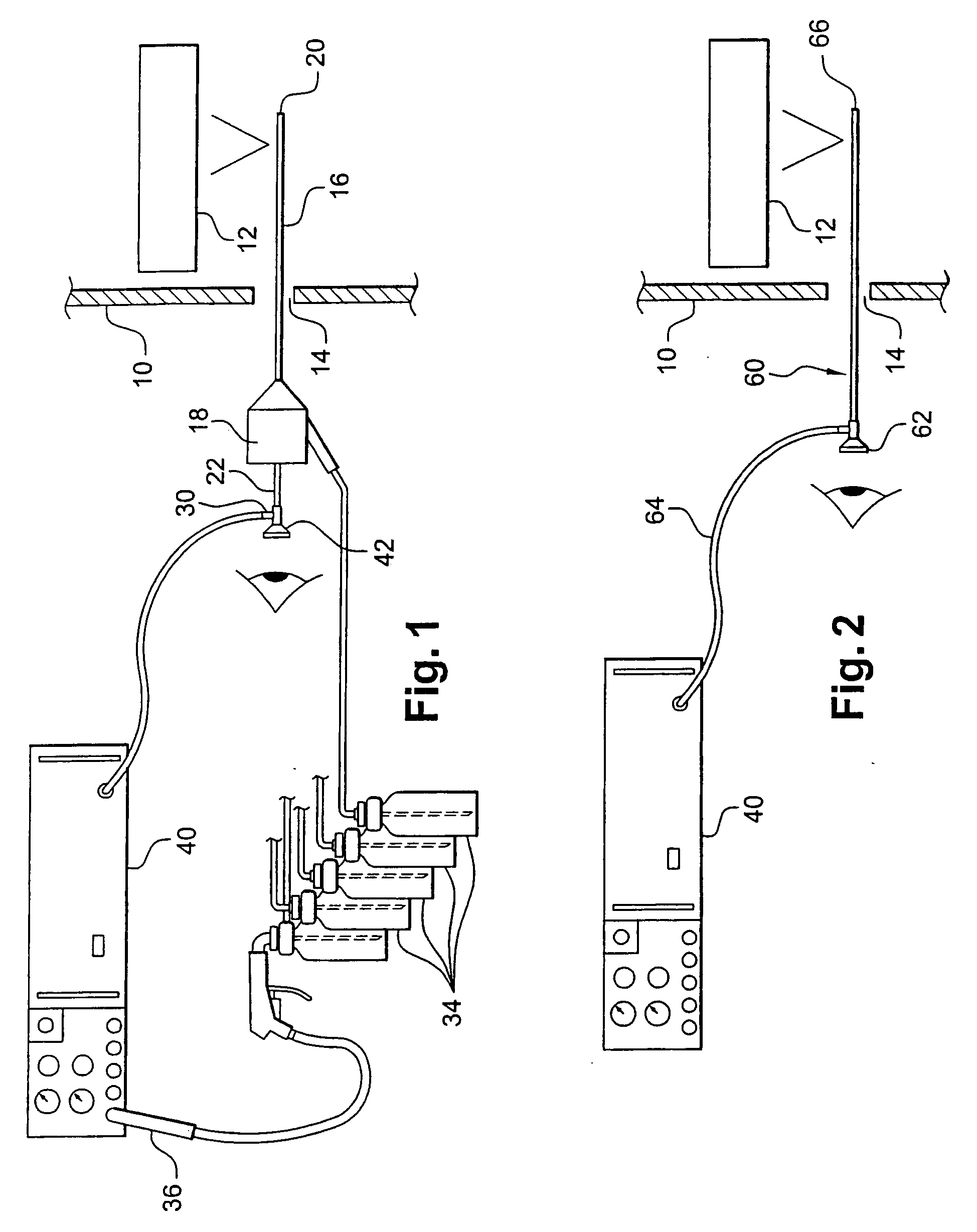

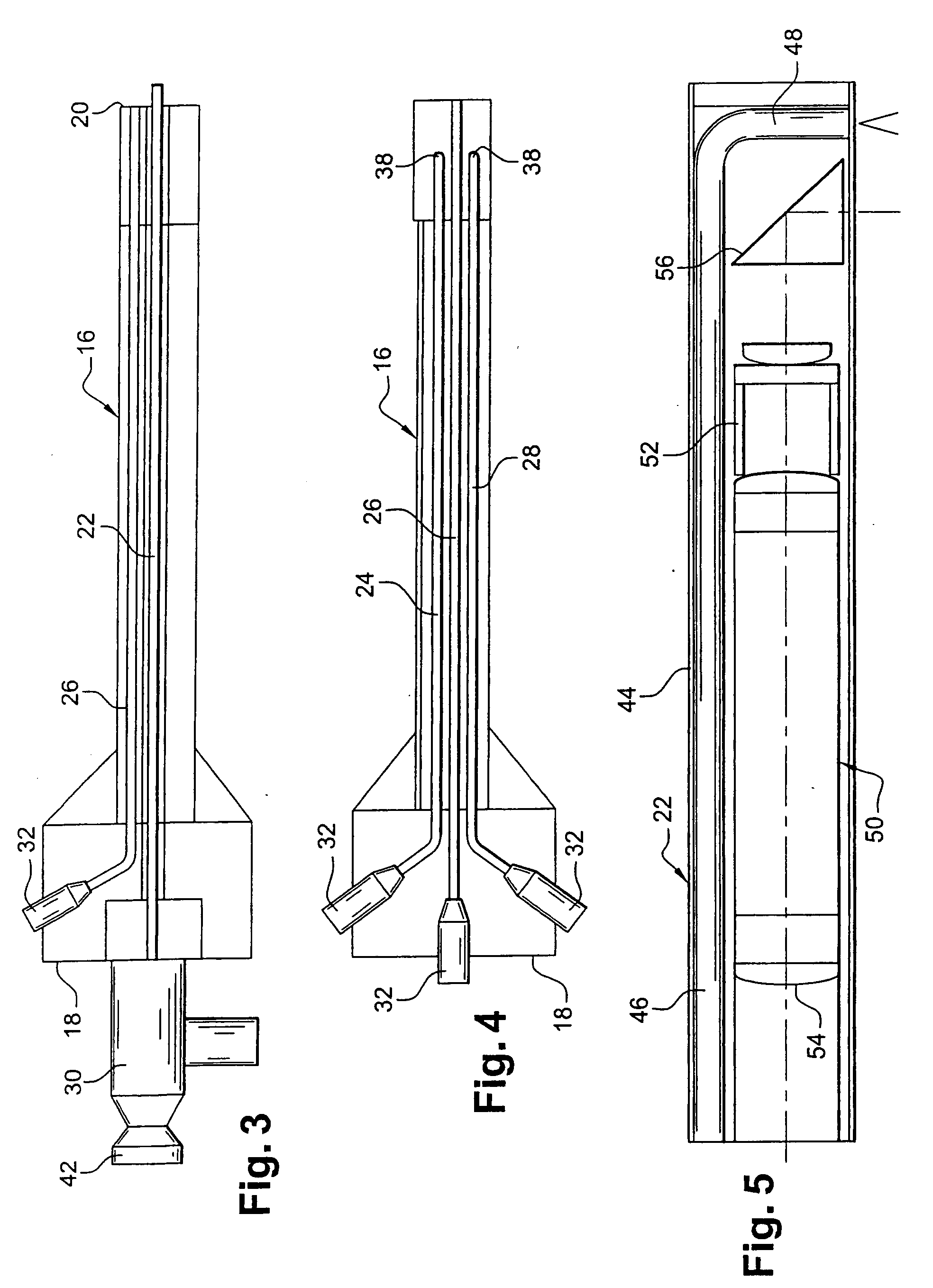

Apparatus for searching for and detecting defects in parts by endoscopy

ActiveUS20050200842A1Improve performanceSimple and satisfactory and inexpensiveRadiation pyrometrySurgeryFlexible endoscopeMedicine

Apparatus for searching for and detecting defects on parts that are substantially inaccessible, being located behind a wall, the apparatus comprising a first endoscope for illumination in visible light and for observation, the first endoscope and pipes for feeding and spraying penetration test substances being housed together in a rod which can be passed through an orifice in the wall in order to examine a part, the apparatus further comprising a second endoscope independent of the first endoscope and the rod for illuminating in ultraviolet light and for observing the portion of the part that has been treated by the penetration test substances.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

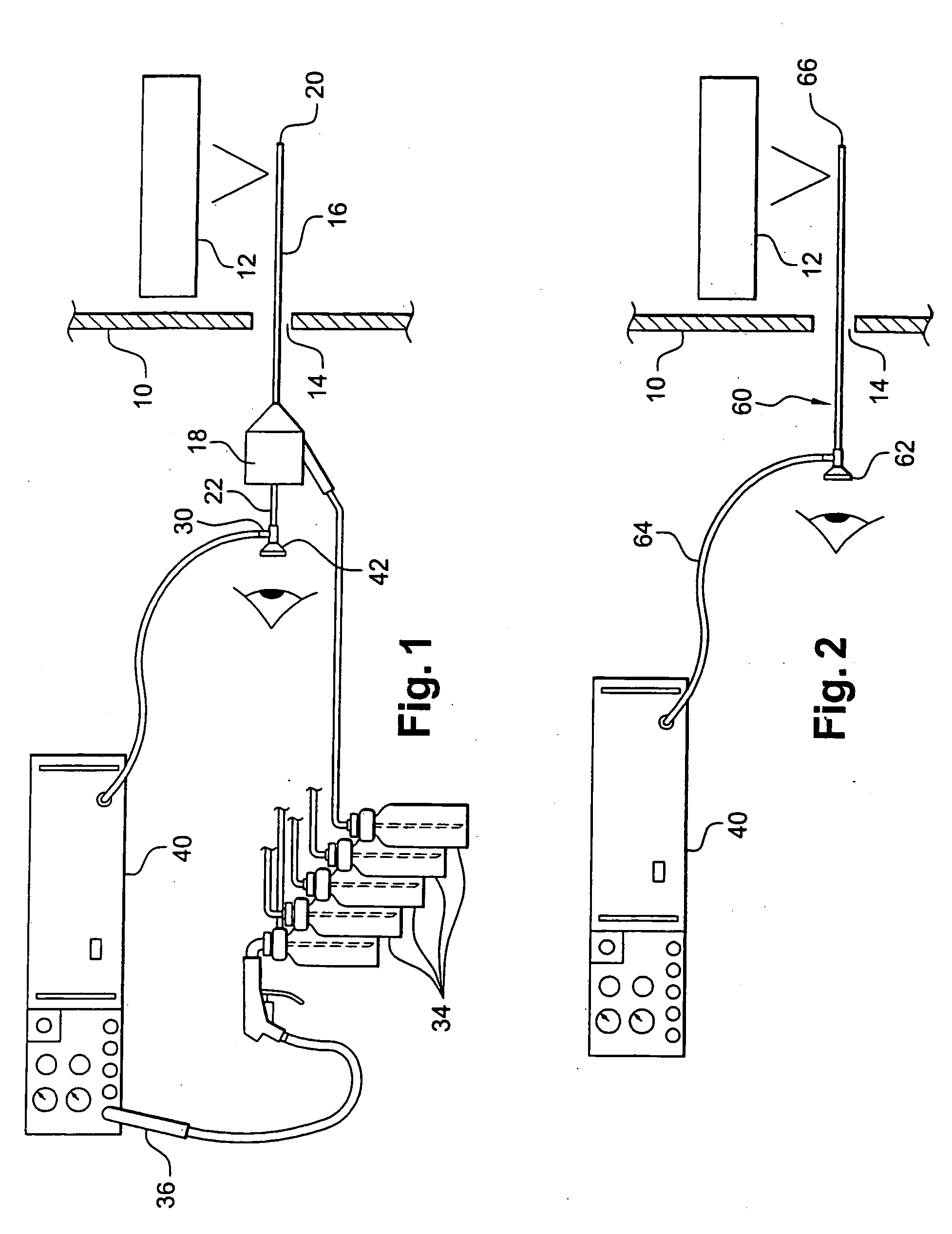

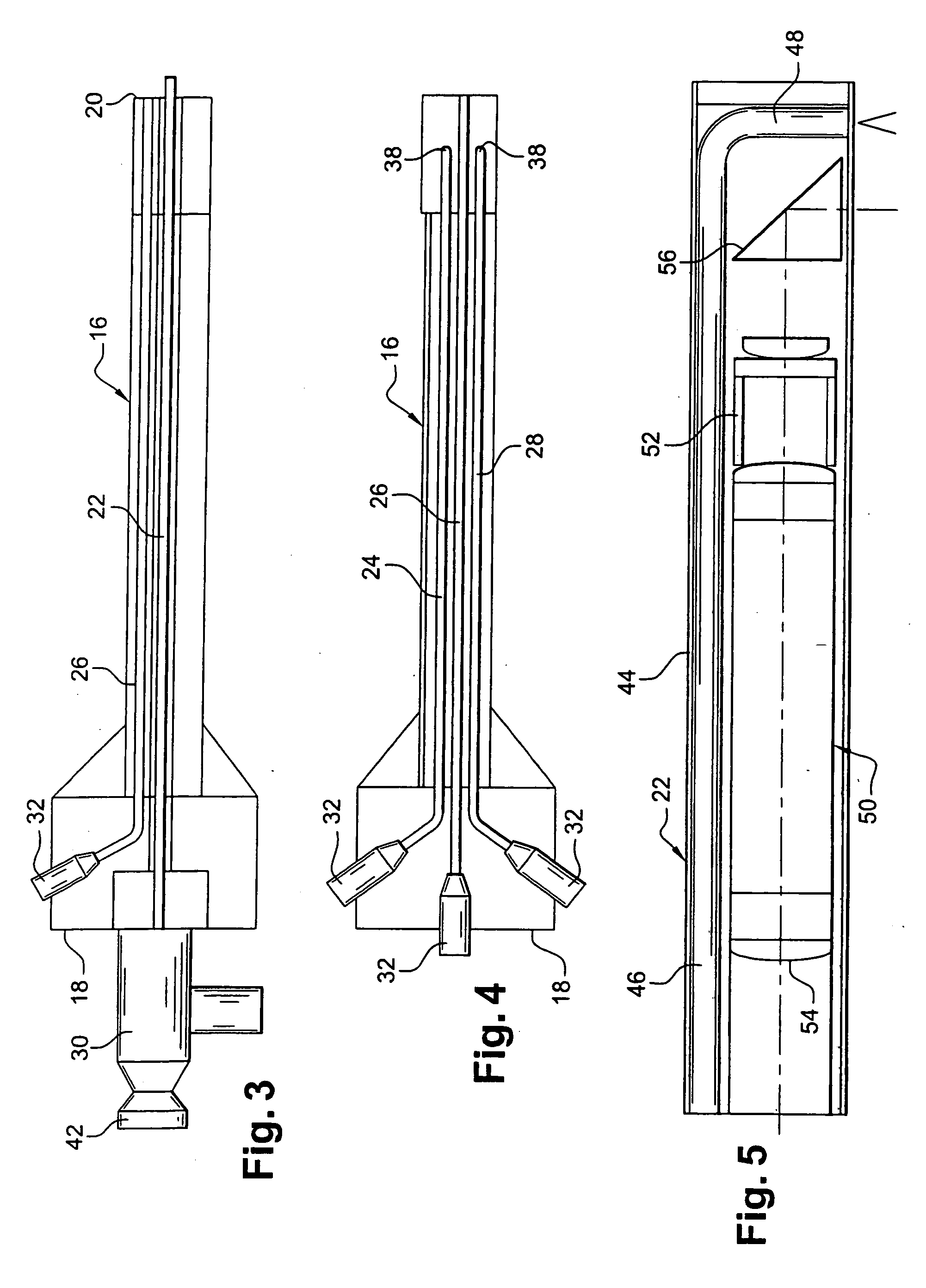

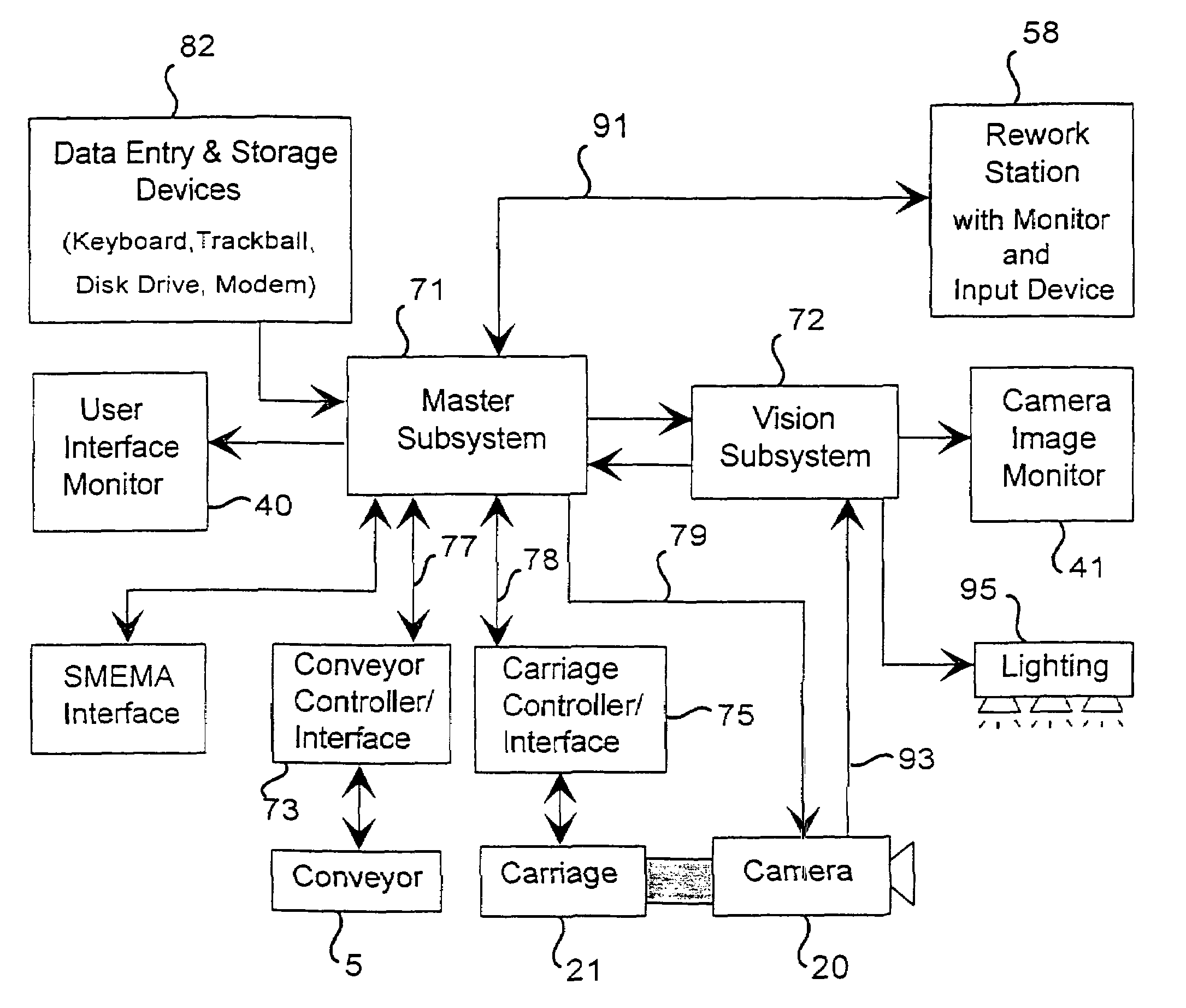

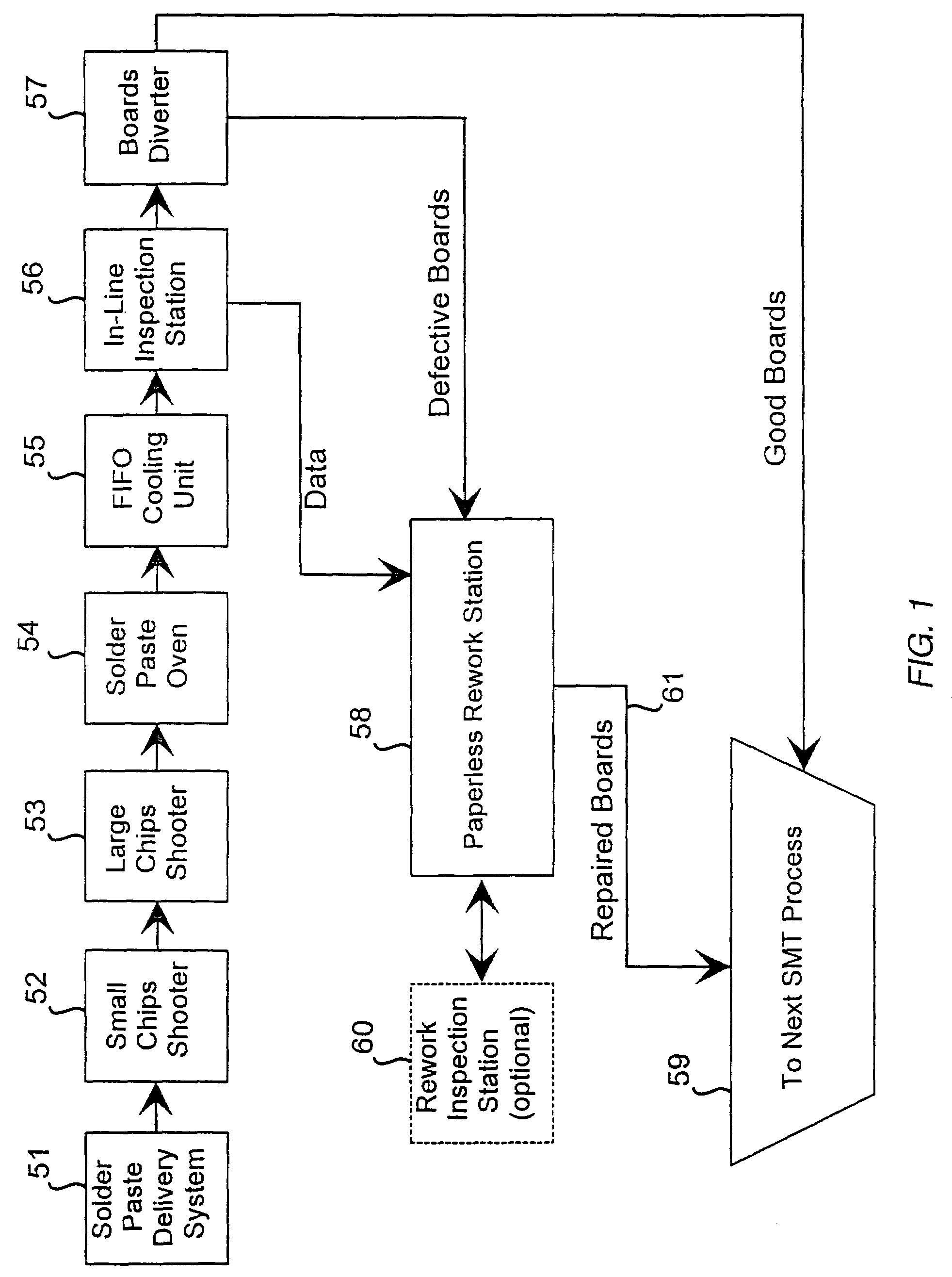

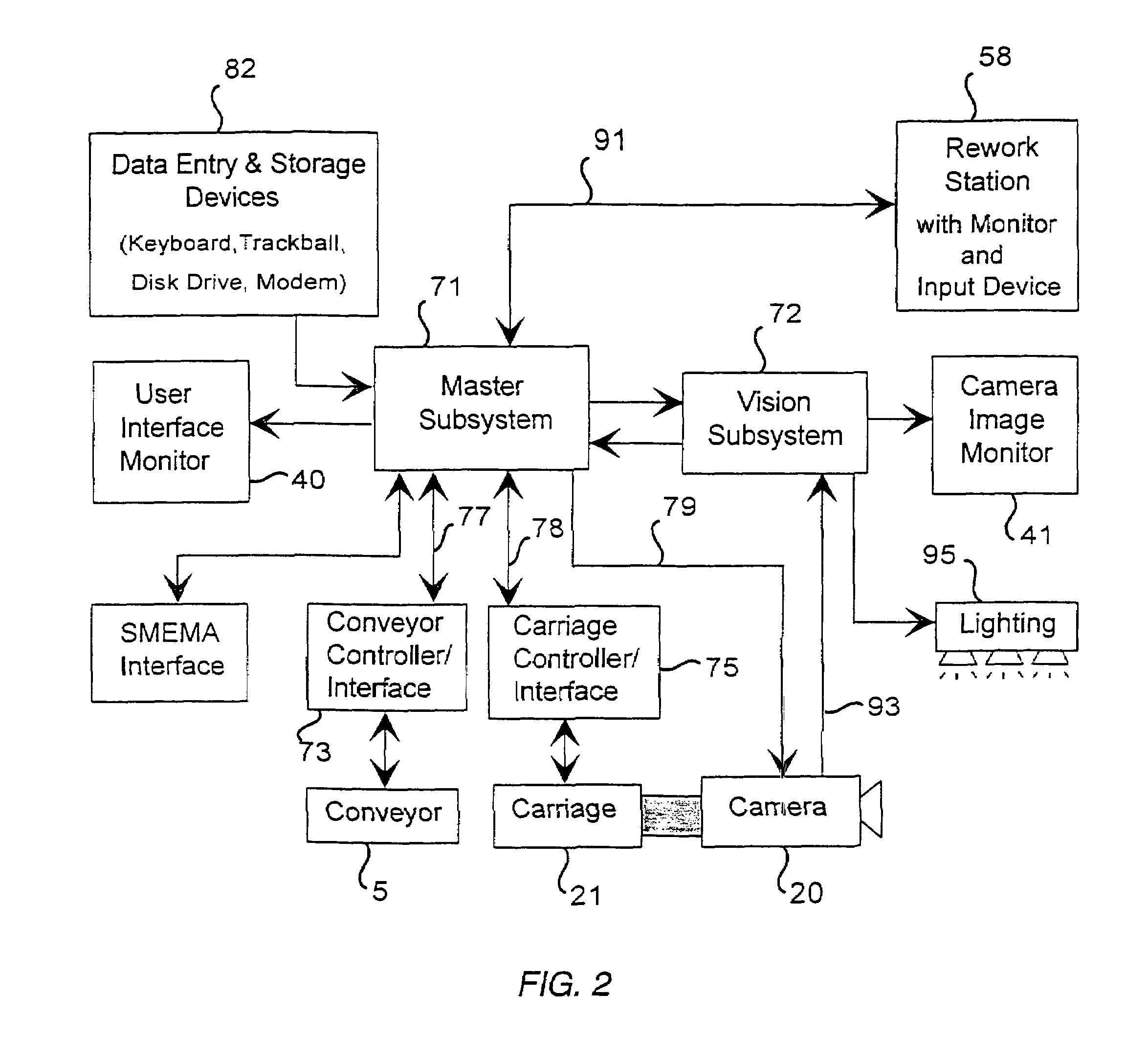

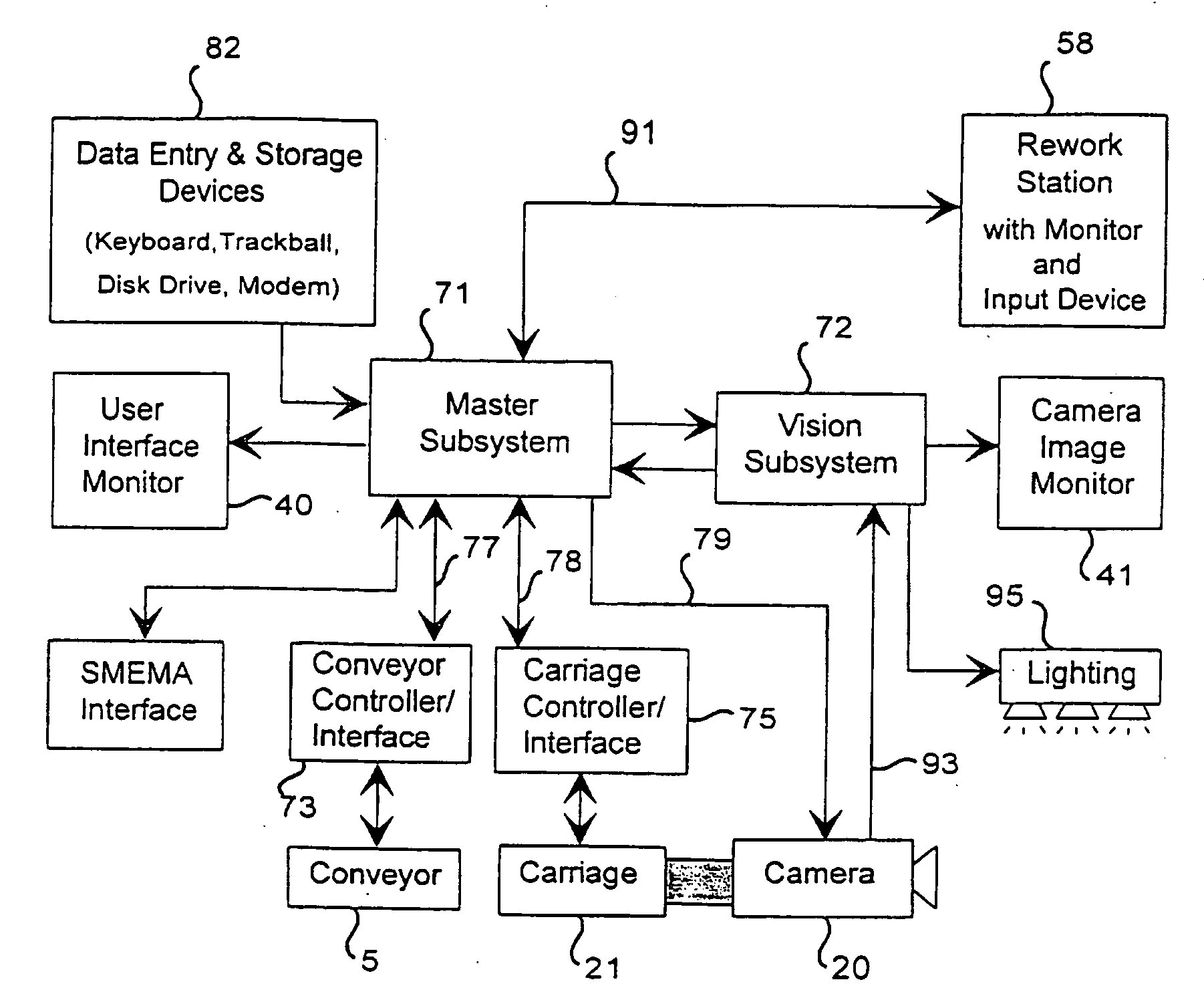

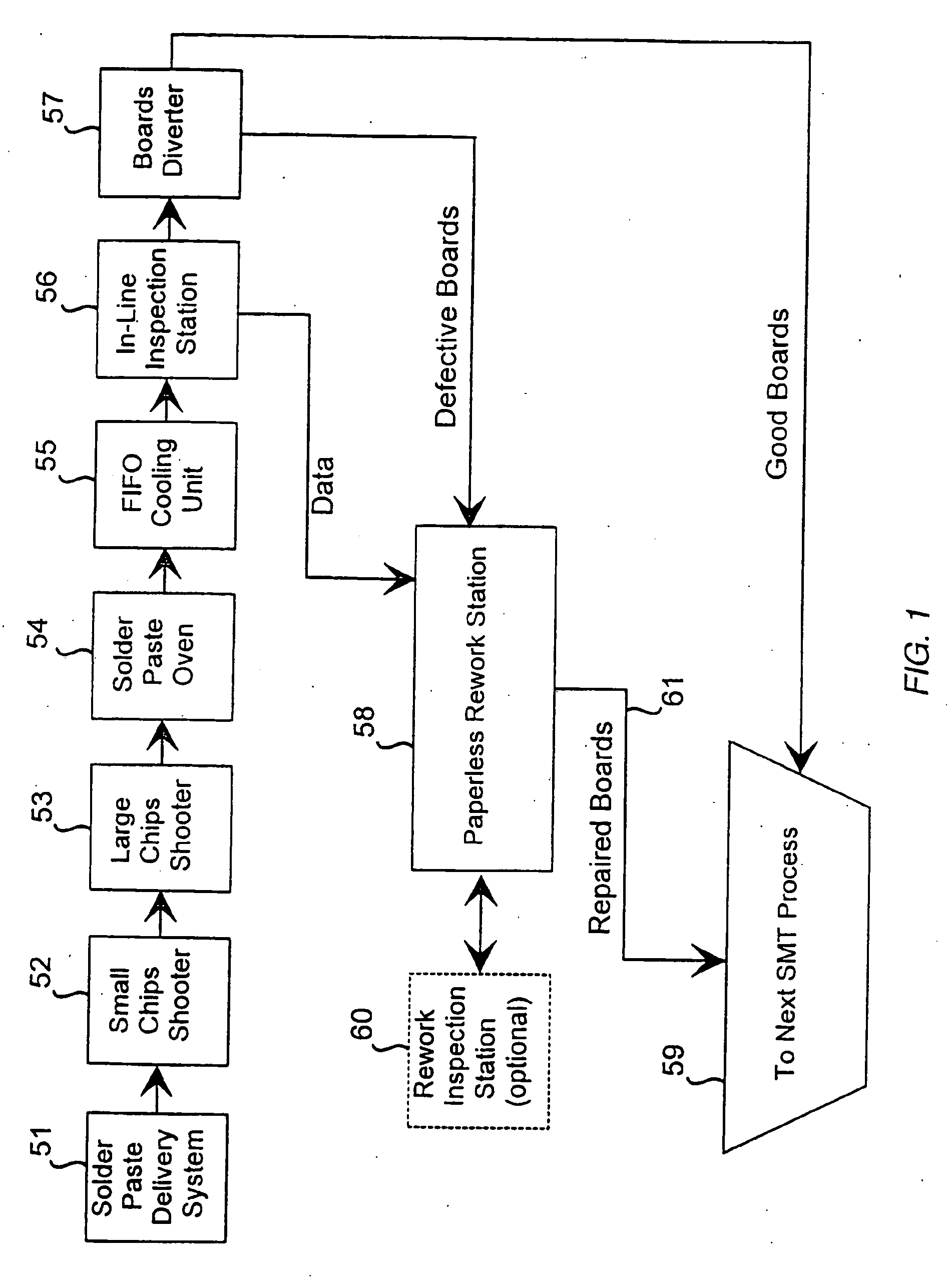

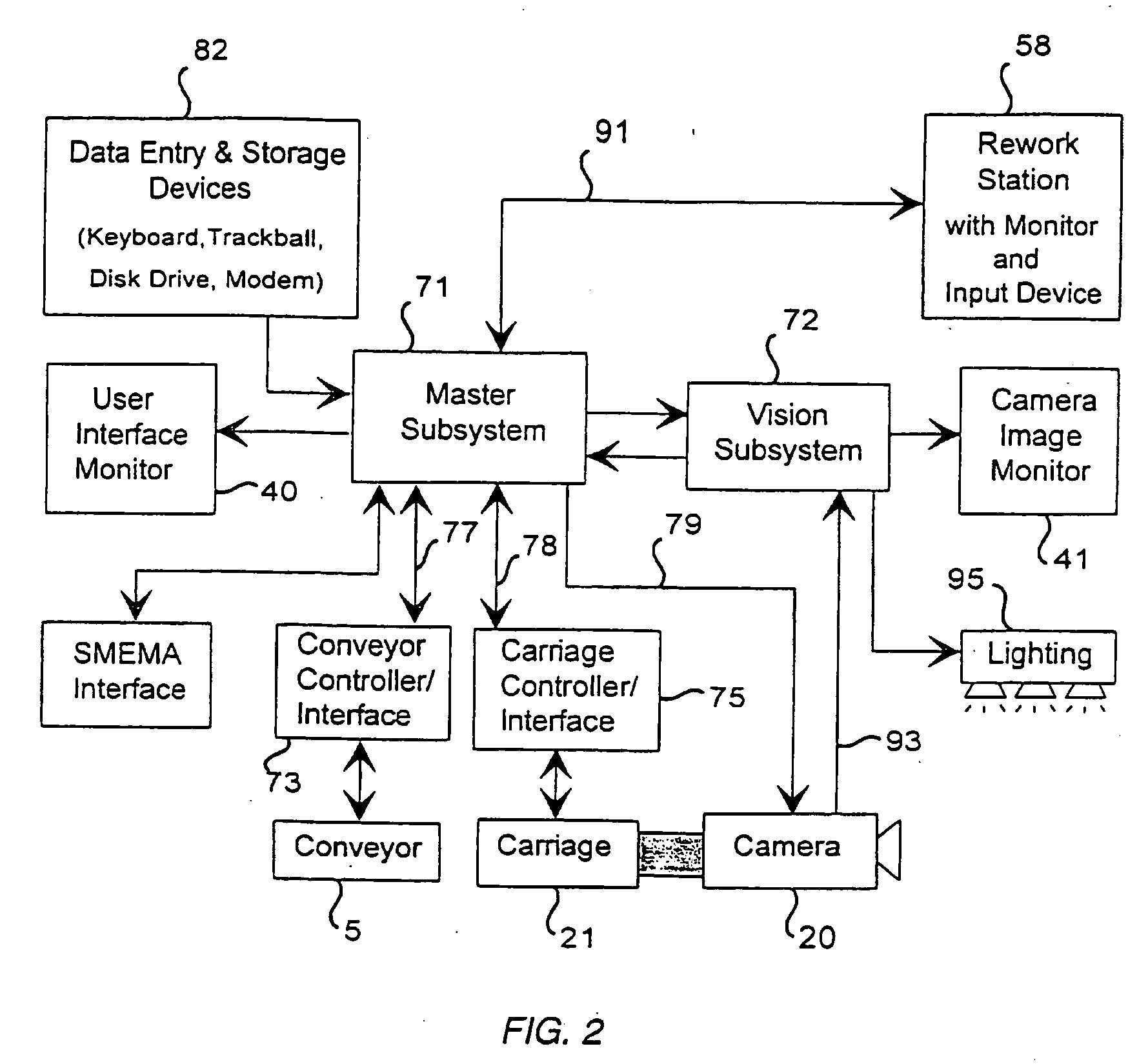

Electronic assembly video inspection system

InactiveUS7043070B2Easy defect detectionEfficiently direct repairImage enhancementImage analysisGraphicsControl signal

An apparatus for automatically assessing the quality of a printed circuit board assembly using digitized video image analysis. The apparatus integrates with existing relatively low precision automated surface mount technology (“SMT”) manufacturing systems as an inspection station insertable at various steps in the assembly process or as a separate manually loaded station. The inspection station includes a high resolution video imaging system and a video image analyzer comprising an onboard master computer that generates control signals to reposition the camera mounted within a screen on a movable carriage and / or reposition the circuit board, and adjust the lighting; and generates individual board status data to be archived, graphically displayed on monitors or otherwise utilized by a rework station.

Owner:EASTON HUNT CAPITAL PARTNERS

Electronic assembly video inspection system

InactiveUS20070047797A1Easy defect detectionEfficient repairImage enhancementImage analysisControl signalEffect light

An apparatus for automatically assessing the quality of a printed circuit board assembly using digitized video image analysis. The apparatus integrates with existing relatively low precision automated surface mount technology (“SMT”) manufacturing systems as an inspection station insertable at various steps in the assembly process or as a separate manually loaded station. The inspection station includes a high resolution video imaging system and a video image analyzer comprising an onboard master computer that generates control signals to reposition the camera mounted within a screen on a movable carriage and / or reposition the circuit board, and adjust the lighting; and generates individual board status data to be archived, graphically displayed on monitors or otherwise utilized by a rework station.

Owner:EASTON HUNT CAPITAL PARTNERS

Systems, circuits and methods for reducing thermal damage and extending the detection range of an inspection system

ActiveUS7436508B2Reduce heat damageEasy defect detectionPolarisation-affecting propertiesScattering properties measurementsEngineeringLaser beams

Inspection systems, circuits, and methods are provided to enhance defect detection by reducing thermal damage to large particles by dynamically altering the incident laser beam power level supplied to the specimen during a surface inspection scan. In one embodiment, an inspection system includes an illumination subsystem for directing light to a specimen at a first power level, a detection subsystem for detecting light scattered from the specimen, and a power attenuator subsystem for dynamically altering the power level directed to the specimen based on the scattered light detected from the specimen. For example, the power attenuator subsystem may reduce the directed light to a second power level, which is lower than the first, if the detected scattered light exceeds a predetermined threshold level. In addition reducing thermal damage, the systems and methods described herein may be used to extend the measurement detection range of an inspection system by providing a variable-power inspection system.

Owner:KLA TENCOR TECH CORP

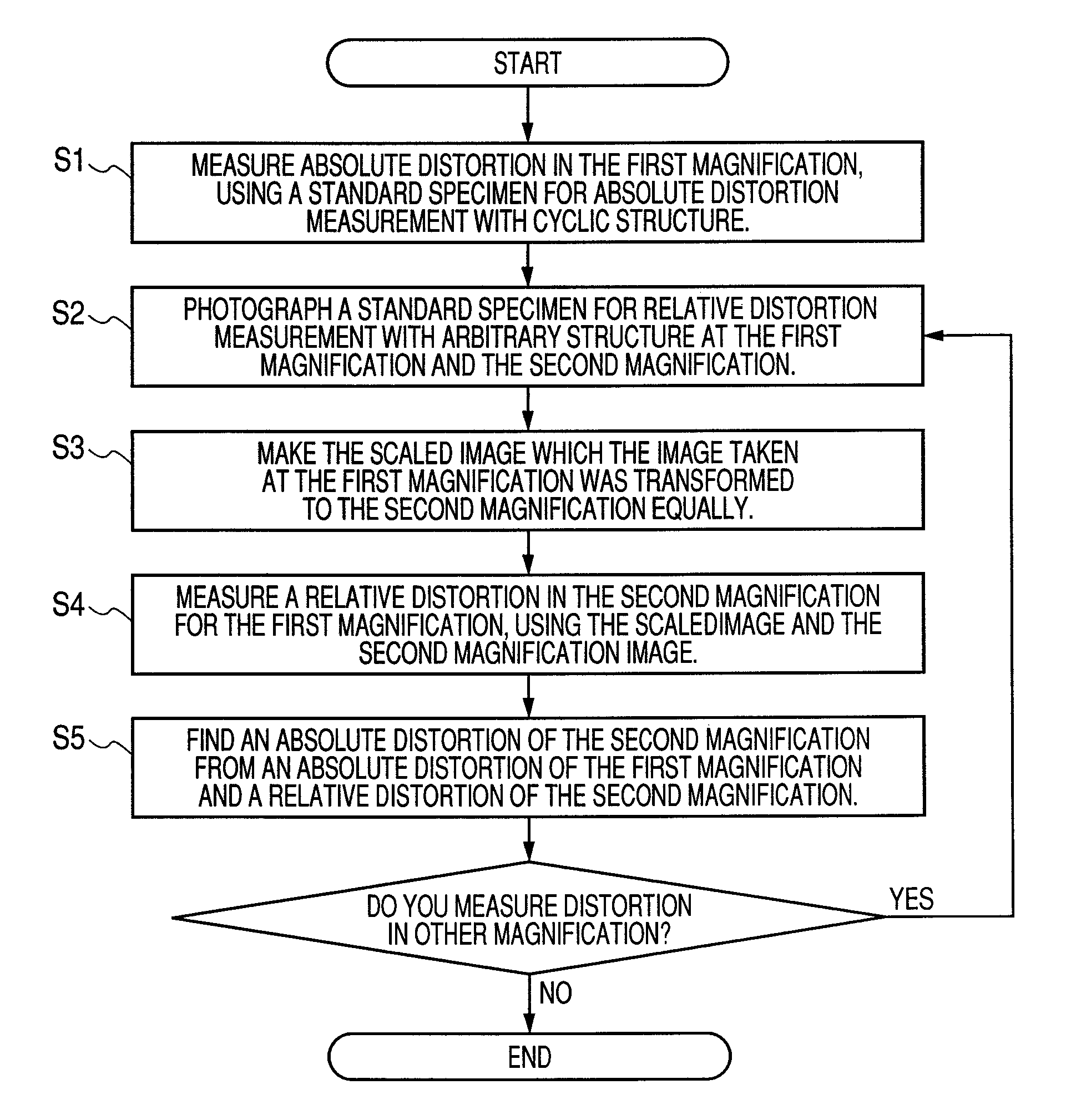

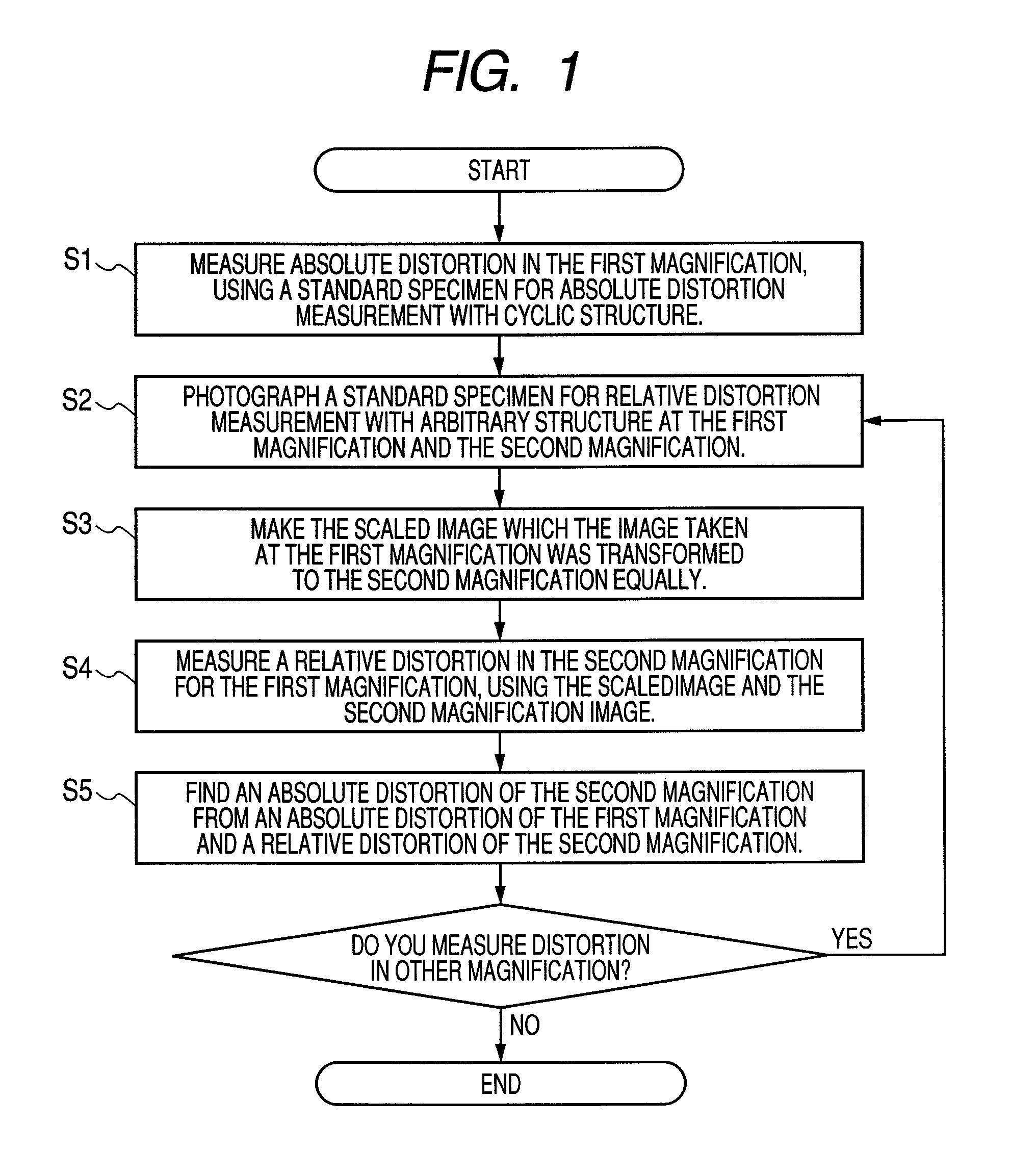

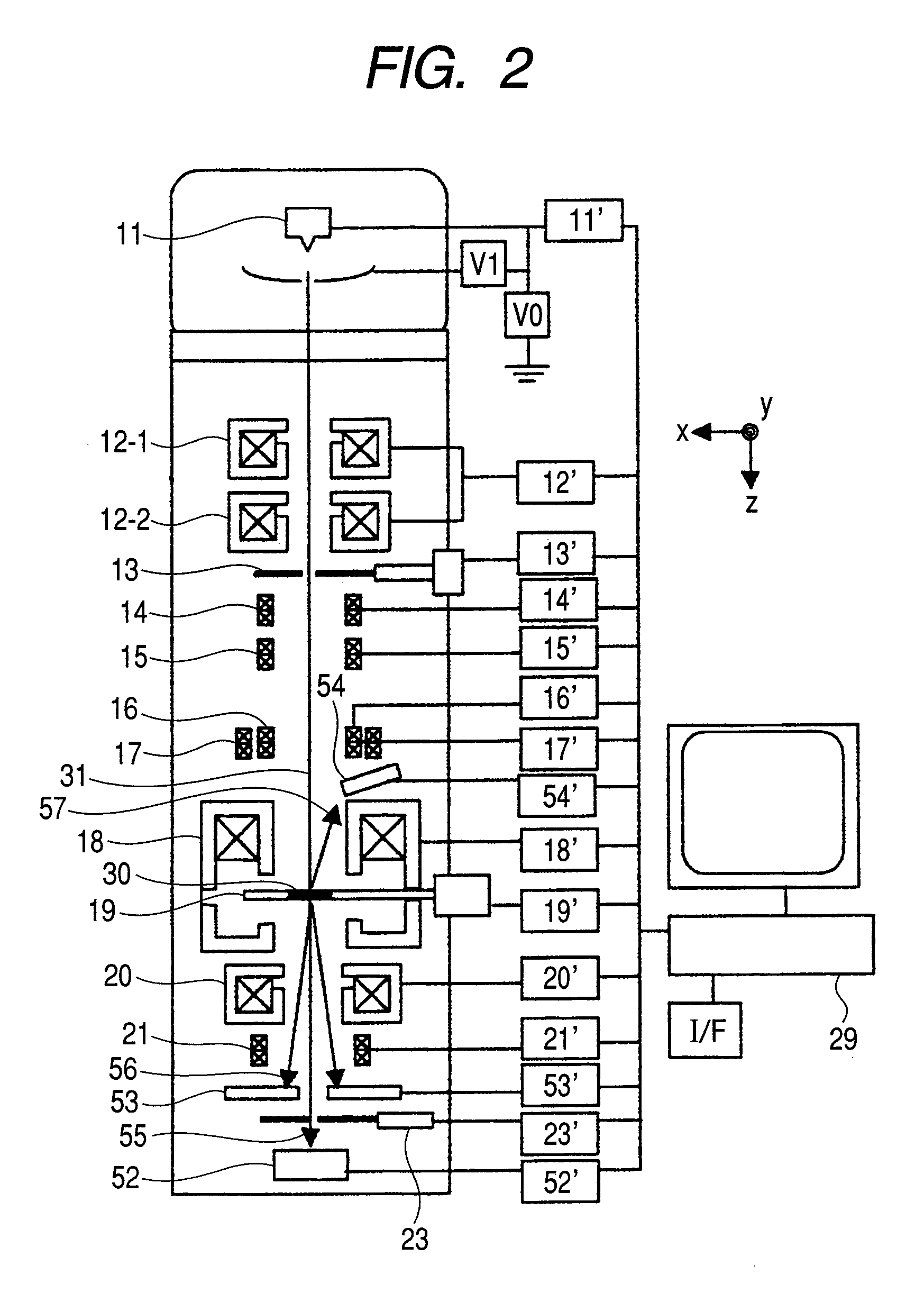

Electric charged particle beam microscopy and electric charged particle beam microscope

InactiveUS7633064B2Improve accuracyEasy to measureImage enhancementMaterial analysis using wave/particle radiationParticle beamMagnification

An electric charged particle beam microscope measures a geometric distortion at an arbitrary magnification with high precision, and corrects the geometric distortion. A geometric distortion at a first magnification is measured as an absolute distortion based on a standard specimen having a cyclic structure. A microscopic structure specimen is photographed at a geometric distortion measured first magnification and at a geometric distortion unmeasured second magnification. The image at the first magnification is equally transformed to the second magnification to generate a scaled image. The geometric distortion at the second magnification is measured as a relative distortion based on the scaled image. The absolute distortion at the second magnification is obtained on the basis of the absolute distortion at the first magnification and the relative distortion at the second magnification. Subsequently, the second magnification is replaced with the first magnification, and the relative distortion measurement is repeated.

Owner:HITACHI HIGH-TECH CORP

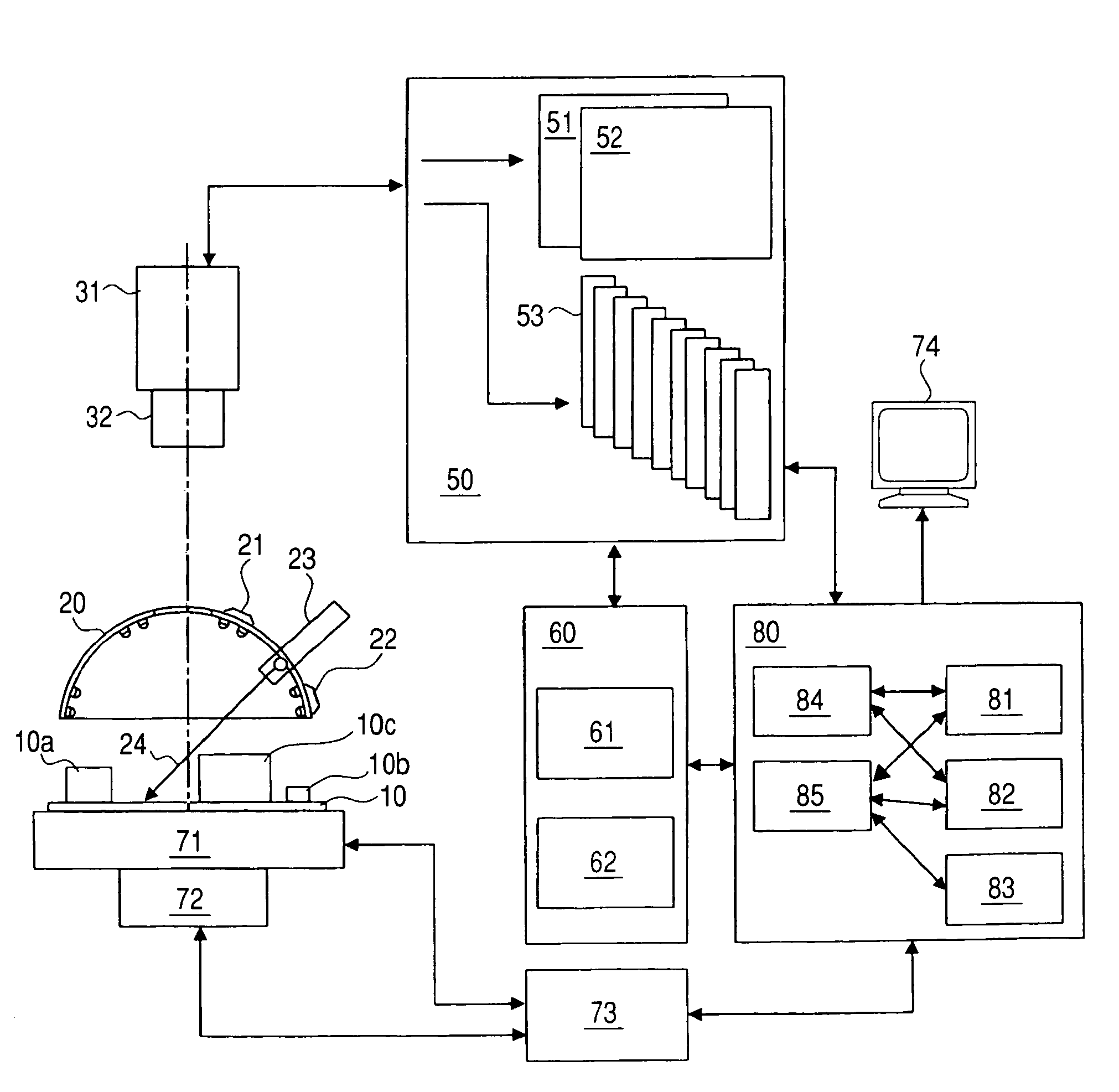

Method of fabrication of semiconductor integrated circuit device

ActiveUS7372555B2Easy to prepareEasy defect detectionPrinted circuit assemblingSolid-state devicesEngineeringSemiconductor

In the fabrication of a semiconductor integrated circuit device, a 2D-3D inspection technique for solder printed on a substrate is provided which permits easy preparation of data and easy visual confirmation of a defective portion. In a substrate inspecting step, first, a 3D inspection is performed, followed by execution of 2D inspection, whereby a 2D picked-up image of the portion of a pad determined to be defective can be displayed on a larger scale simultaneously with the end of inspection, thereby providing an environment for efficient visual confirmation of the defect. Further, by subjecting a raw substrate to measurement at the time of preparing inspection data, a relation between an original height measurement reference generated automatically by the inspection system and the height of a pad upper surface is checked, whereby it is possible to measure the height and volume of printed solder based on the pad upper surface.

Owner:RENESAS ELECTRONICS CORP

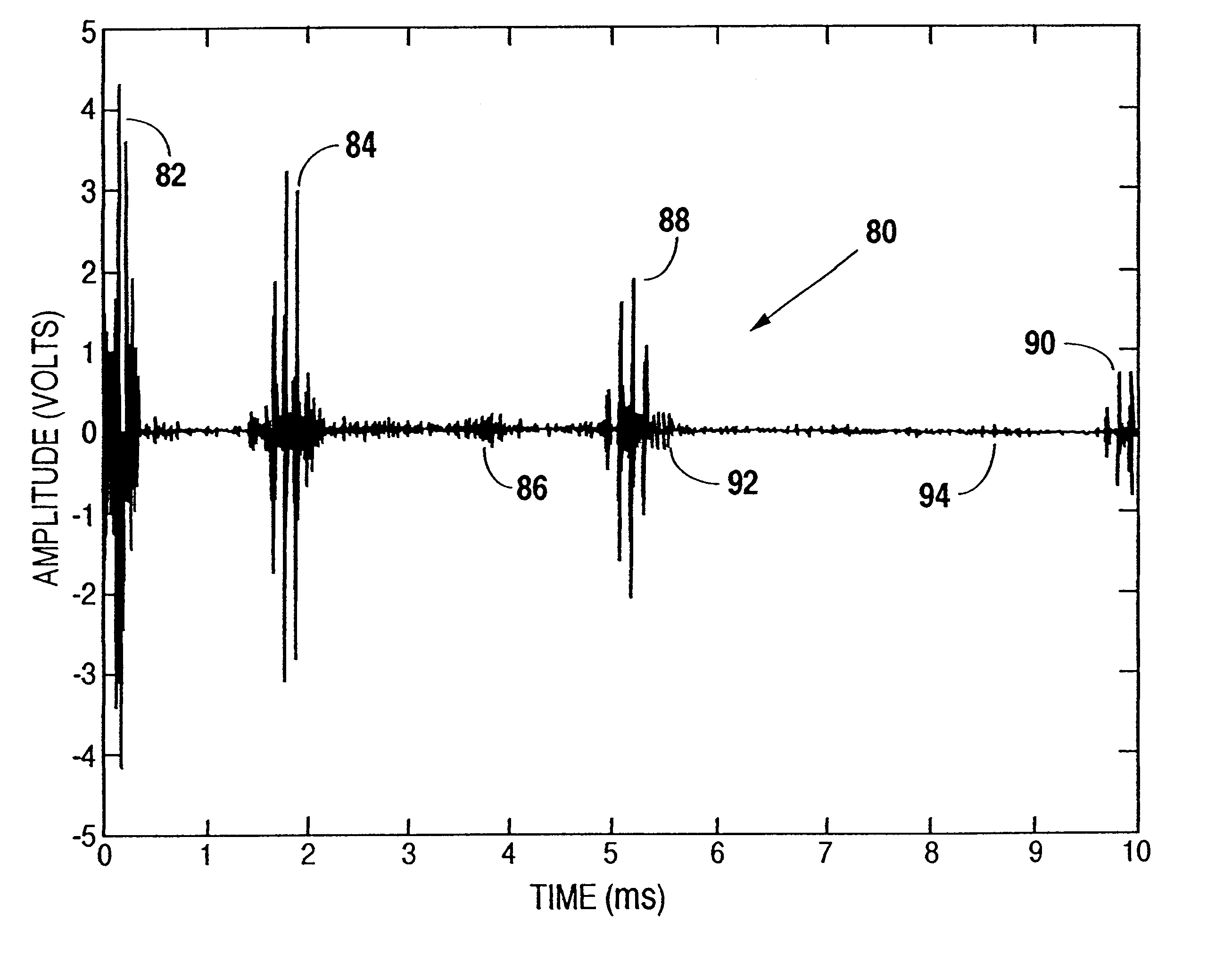

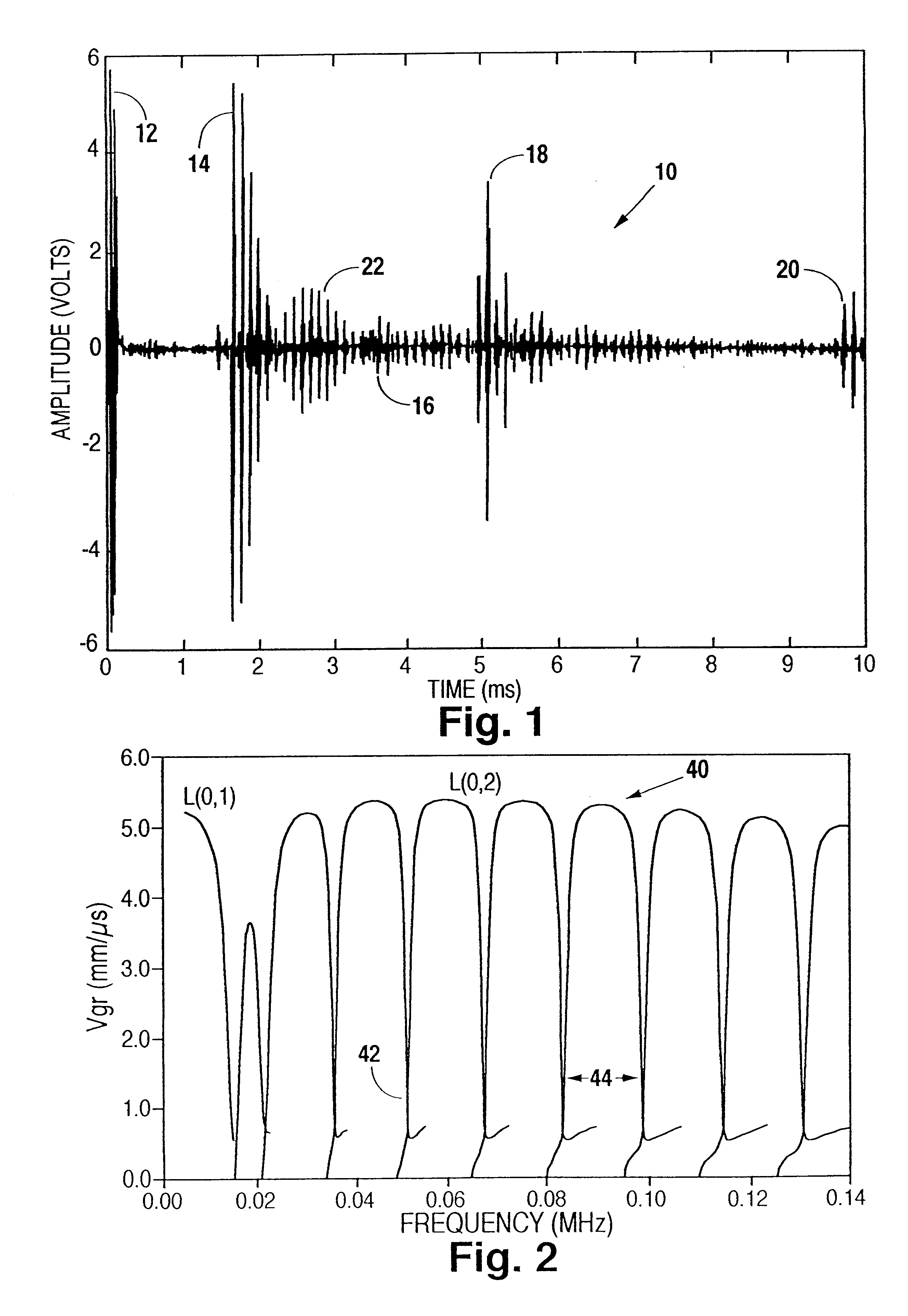

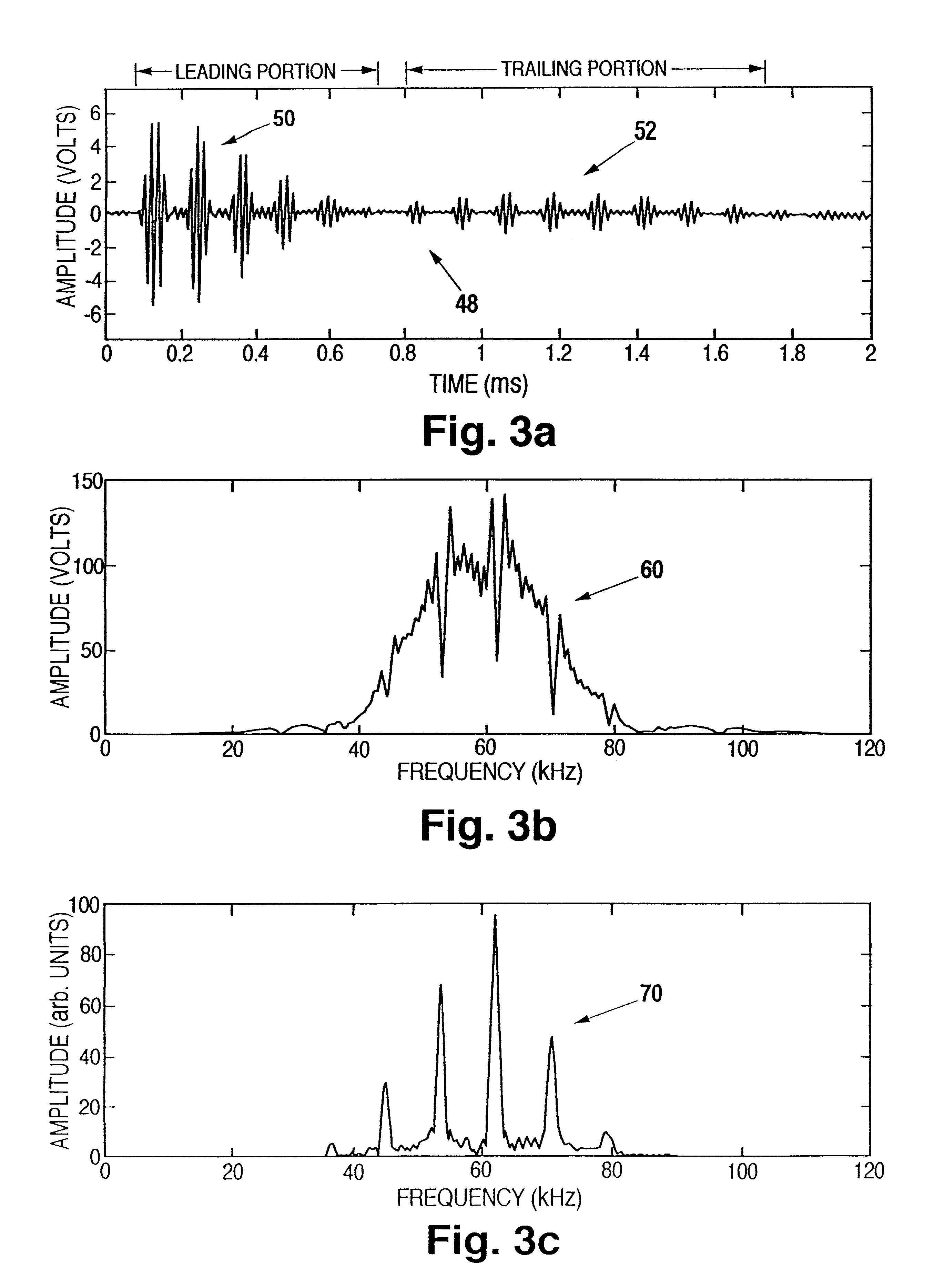

Method for inspecting liquid filled pipes using magnetostrictive sensors

InactiveUS6295677B1Easy to detectEliminates and reduces obscuringAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesDispersion curveLongitudinal wave

An improved method for defect detectability for the inspection of liquid filled pipes using magnetostrictive sensors. The improved method comprises first recognizing the liquid-induced changes in the dispersion properties of the second longitudinal wave mode, L(0,2). These liquid-induced changes include a severe dispersion at periodic branching frequencies that result in a pulse-like characteristic in the extended received signal. A trailing portion of a received signal component associated with a geometric irregularity, is shown to comprise the branching frequency components. The trailing portion of the extended signal may therefore be removed in order to improve defect detection. The removal process comprises one of three alternative methods. A first method includes creating a short duration pulse free of the frequency components that comprise the trailing signals, and applying the pulse to a magnetostrictive transmitter, thereby generating a longitudinal wave signal in the pipe wall free of the trailing signal frequency components. A second method comprises transmitting a broadband signal and processing the detected signal through a digital filter that eliminates those frequency components known to comprise the trailing signals. A third method involves using a signal whose bandwidth lies in the region between two adjacent branching frequencies in the dispersion curve. The result is a detected signal within which components representative of irregularities are less extended and therefore less likely to override subsequent defect components in the detected signal.

Owner:SOUTHWEST RES INST

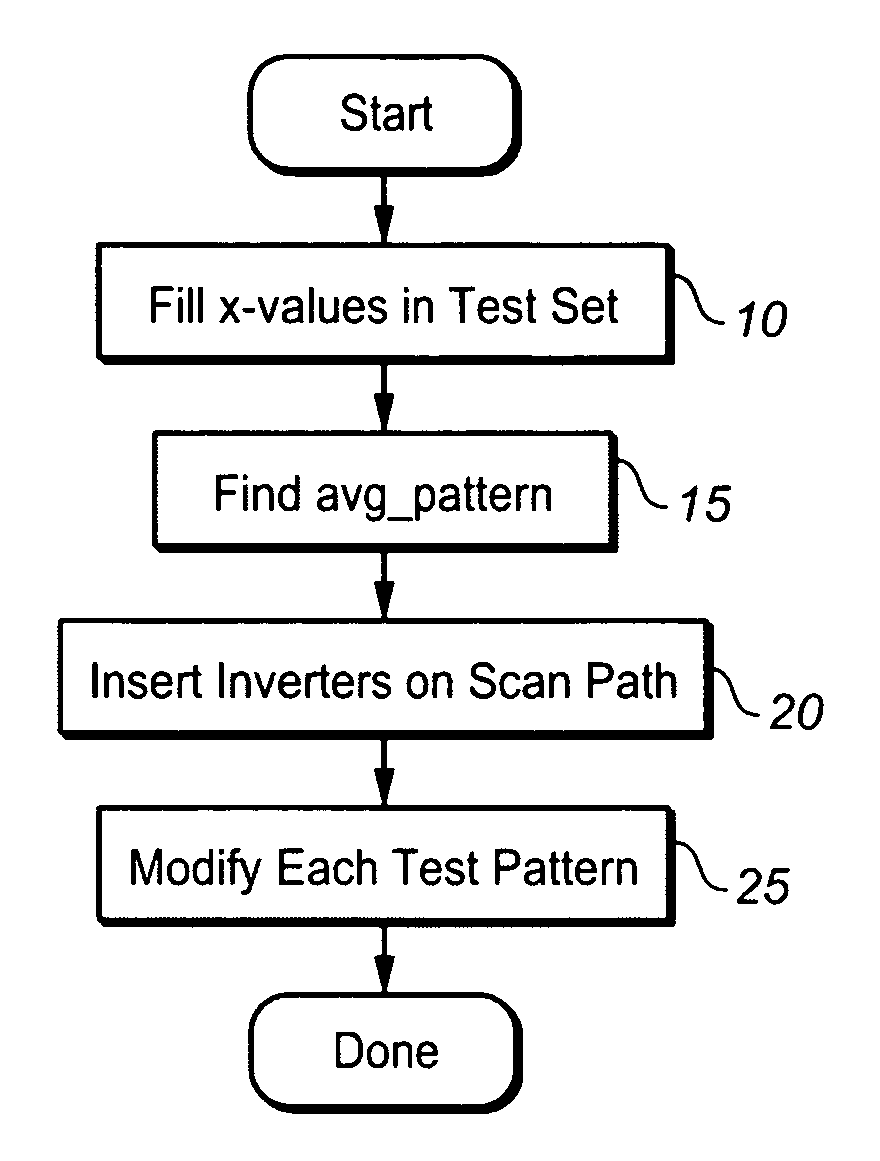

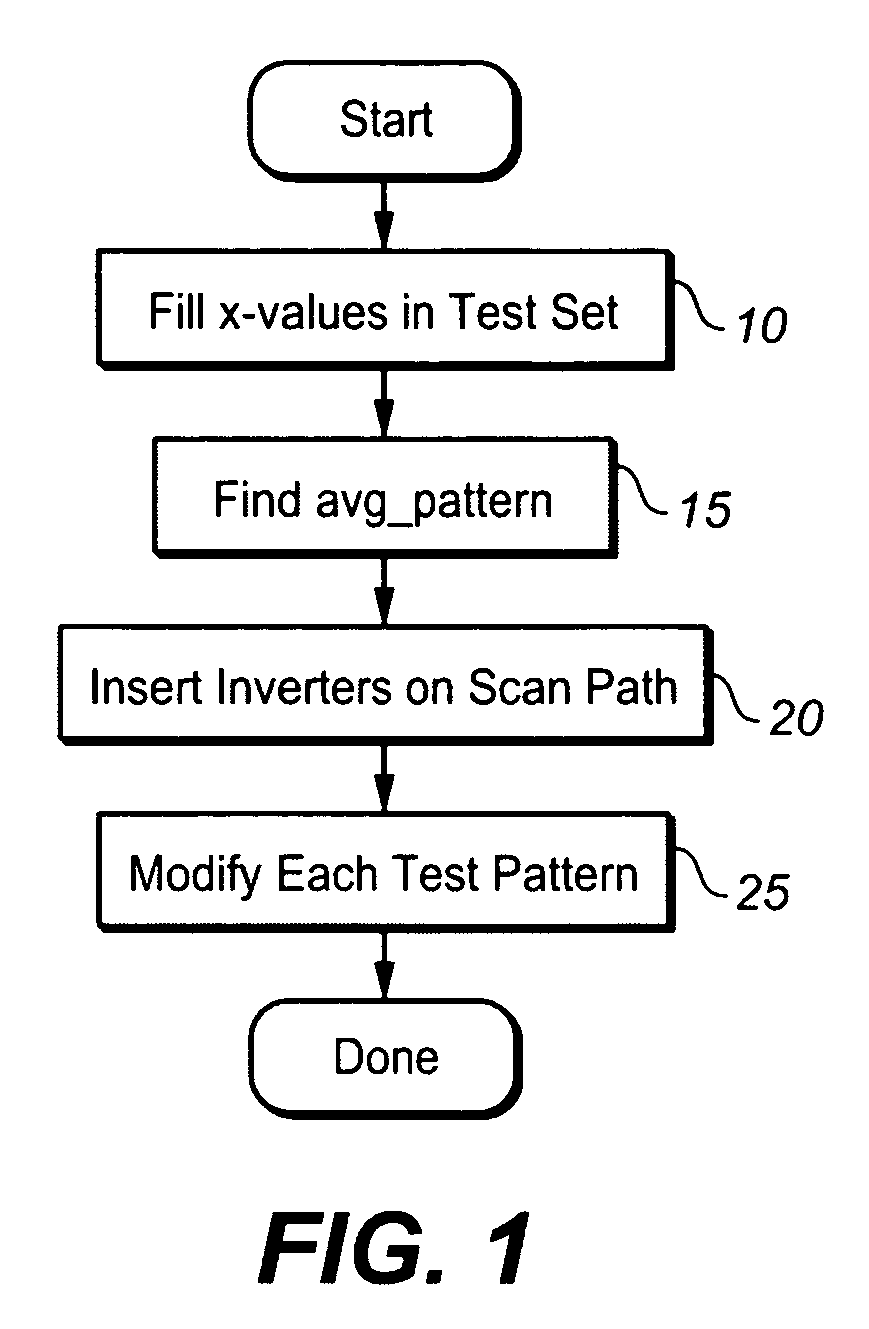

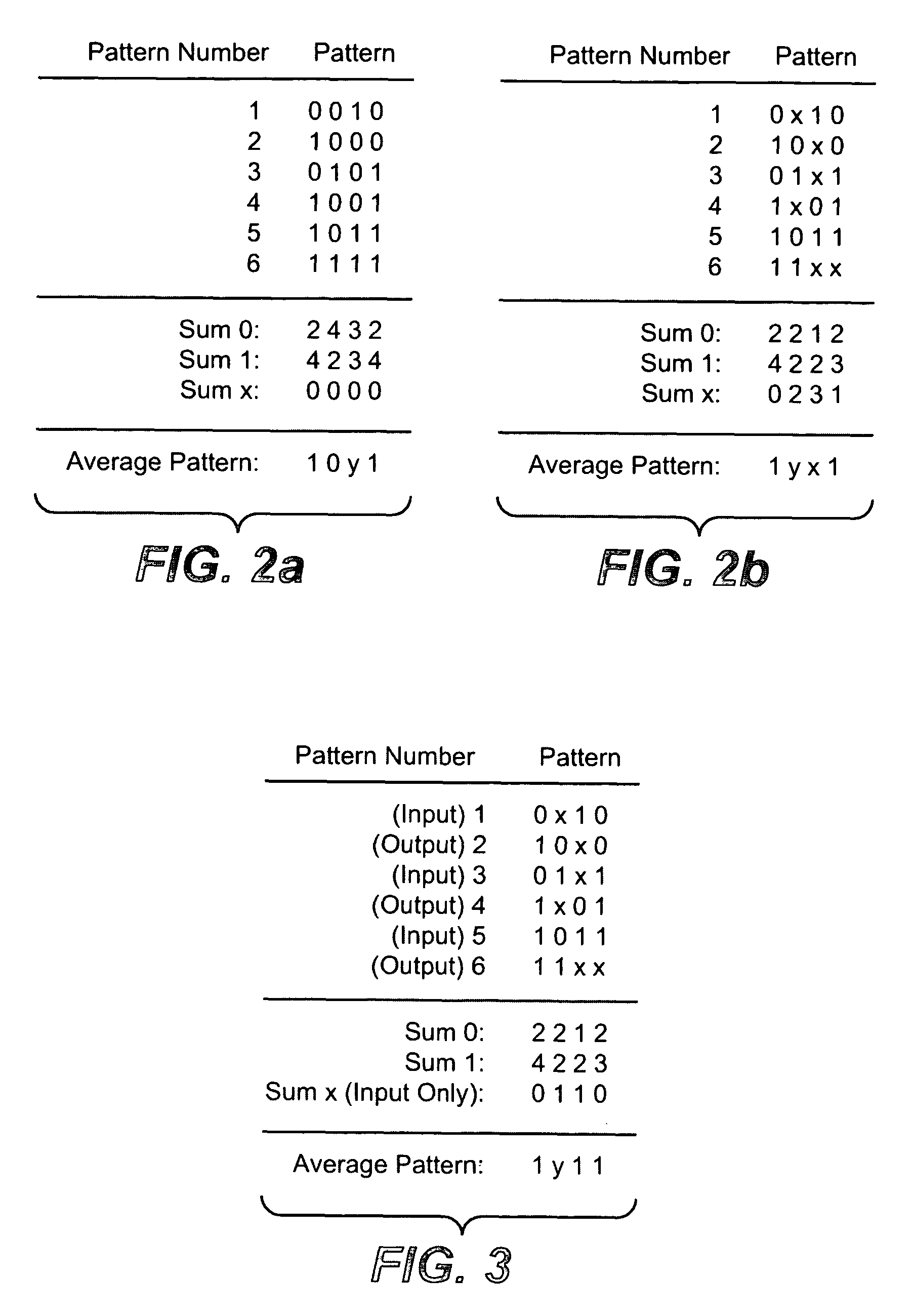

Low power scan shifting with random-like test patterns

InactiveUS7779320B2Minimize togglingReduce switchingElectronic circuit testingError detection/correctionEngineeringTest set

An apparatus and method to design an integrated circuit (IC) to reduce the toggling during shifting in and shifting out of test patterns in a IC having scan chains, while maintaining random-like filling of the “don't cares” of a test set. An average pattern of test patterns of a test set is found for both cases of where the test set is fully specified and not fully specified, inverters are judiciously inserted into the scan path and each test pattern is then modified by XOR-ing it with the average test pattern to produce a modified test pattern, which produces less toggling, translating to less power consumption. Further, the random filling of don't cares, as opposed to 0-fill, 1-fill, or adjacent fill, increases defect detection through collateral coverage.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Honeycomb filter defect detecting method and apparatus

ActiveUS7674309B2Improve signal-to-noise ratioEasy defect detectionDetection of fluid at leakage pointInternal combustion piston enginesParticulatesHoneycomb

A apparatus and method for detecting defects in a honeycomb body. In operation, the particulates emerge at an outlet end face of the honeycomb body through defects, if any, in the honeycomb walls and / or plugs and passes though a permeable member, such as a screen, where they are illuminated. The permeable member is disposed adjacent to and preferably in contact with the outlet end. Use of the permeable member improves the signal-to-noise ratio (SNR) such that defects may be more readily detected. The permeable member preferably includes an anti-reflective surface.

Owner:CORNING INC

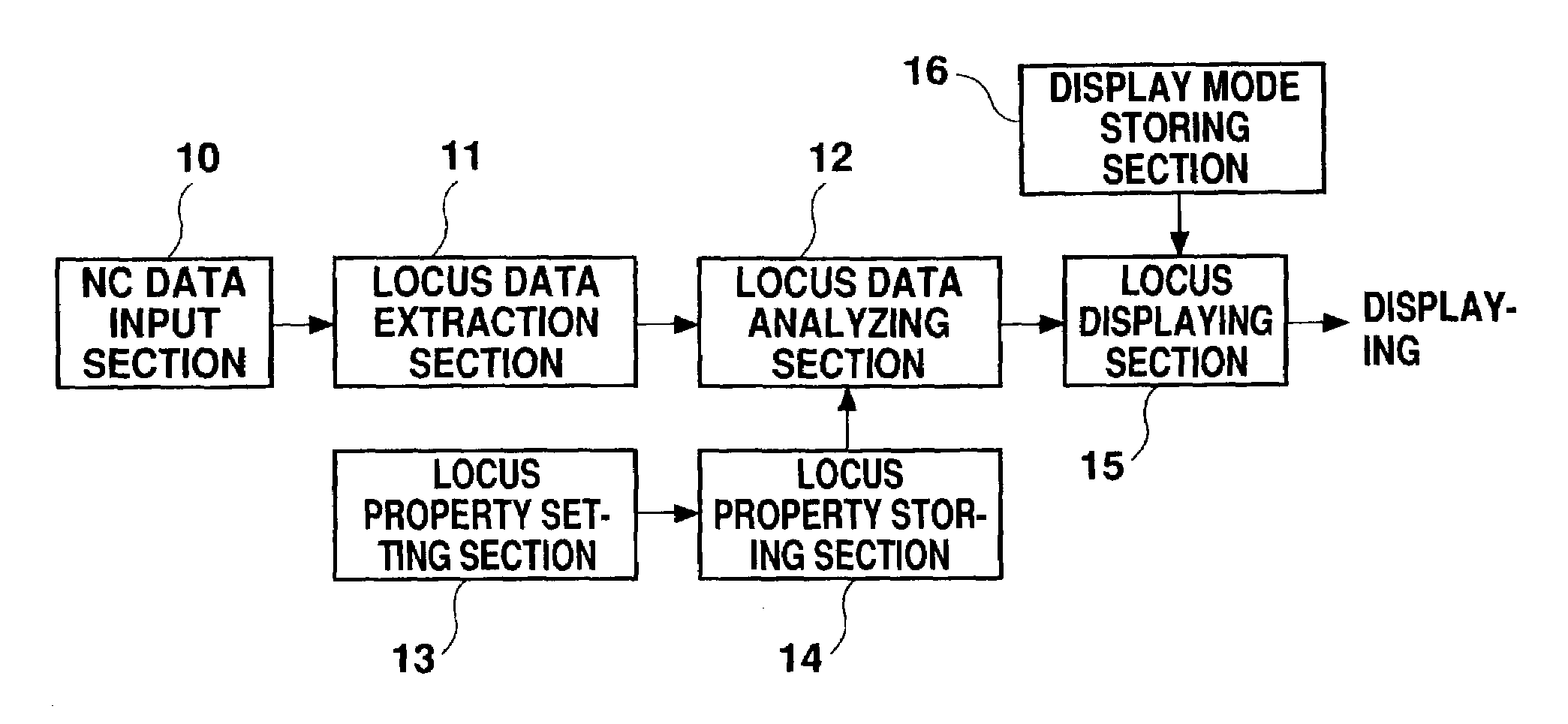

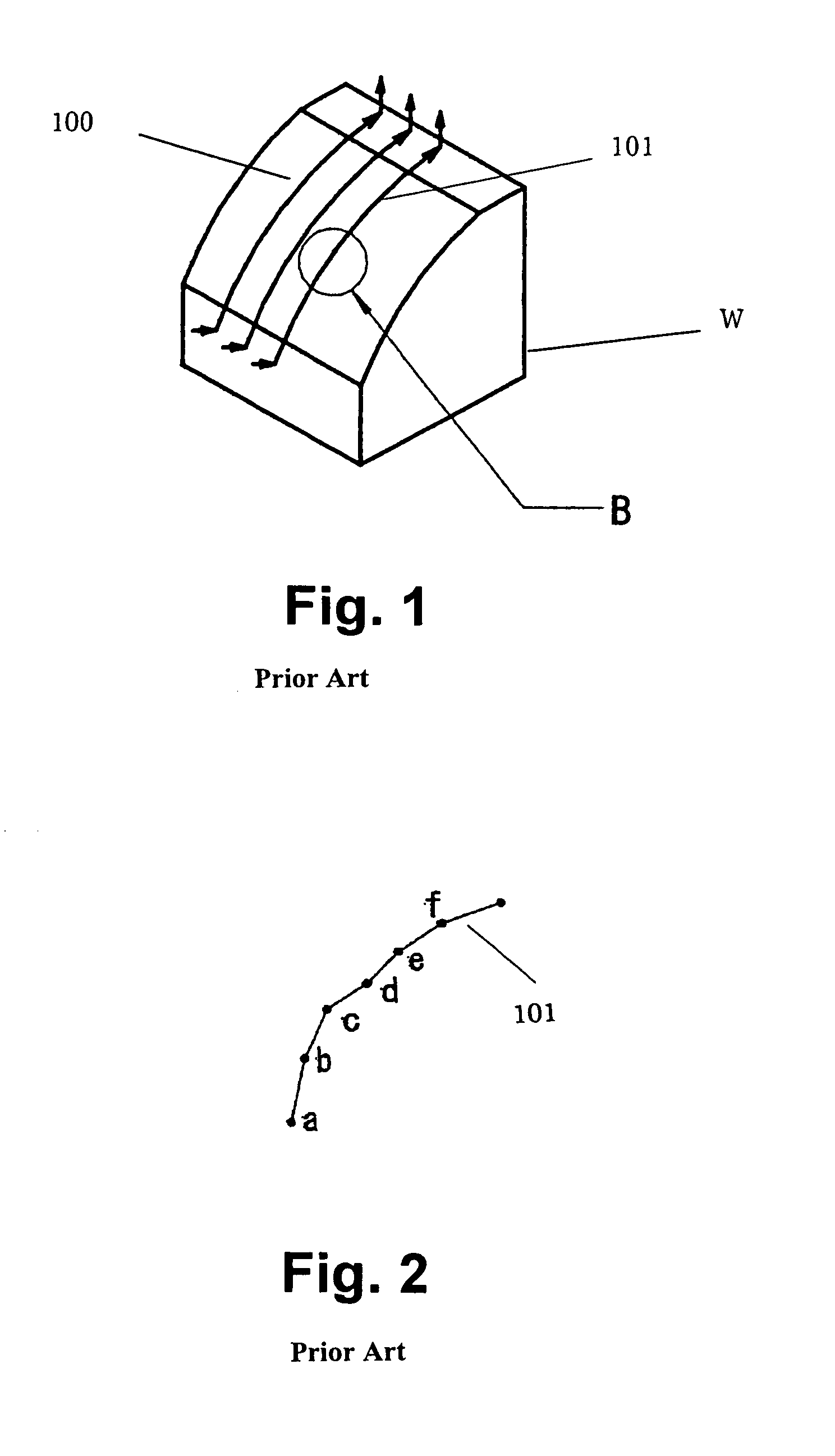

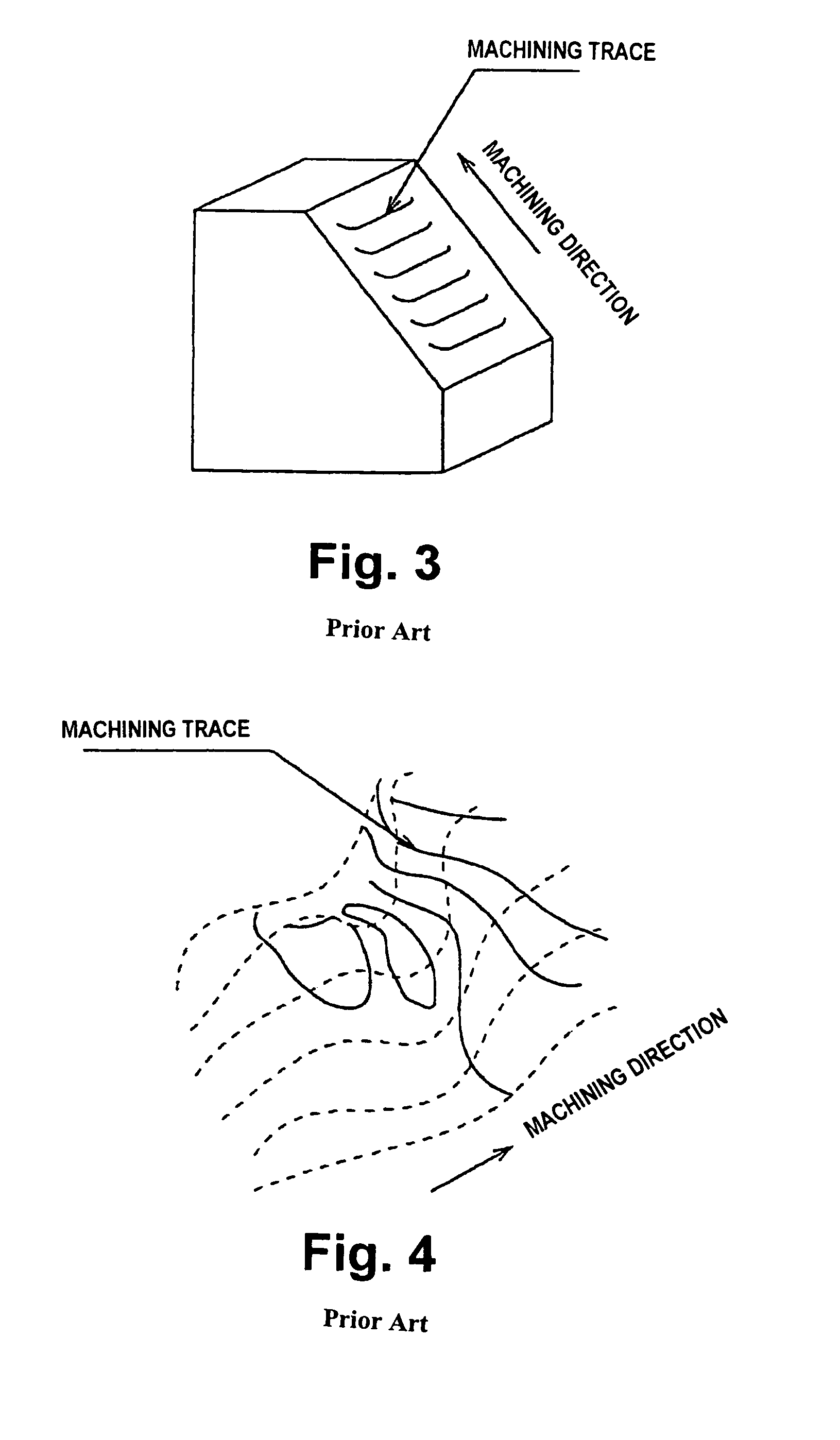

Method for displaying tool locus in NC data and method for analyzing NC data

InactiveUS7062352B2Easy to detectEasy defect detectionComputer controlSimulator controlRoot locusComputer science

With respect to two or more NC data points among a group of dots together representing a tool locus, a curvature radius of the tool locus is determined. Then, the NC data point and its succession with other points is displayed in a display color determined according to the magnitude of the curvature radius. Alternatively, a movement direction of each minute segment relative to a specific axis selected from the three (XYZ) axes is determined as either positive, negative, or zero, and the minute segment or an end point thereof is display with the display property determined according to the movement direction. Still alternatively, after a specific axis is selected from the three (XYZ) axes, a region relative to the selected region is divided along the selected axis, for predetermined dividing width, first beginning with a predetermined reference point, and the resultant divided regions are given predetermined display properties. Then, a tool locus is displayed in the three-axial (XYZ) system according to the display properties given to the respective divided regions.

Owner:OKUMA CORP

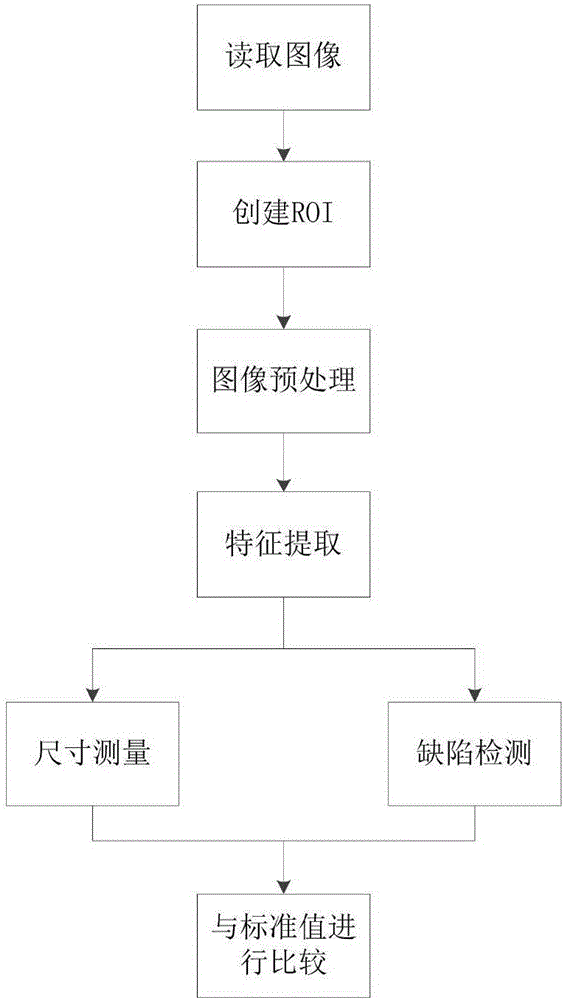

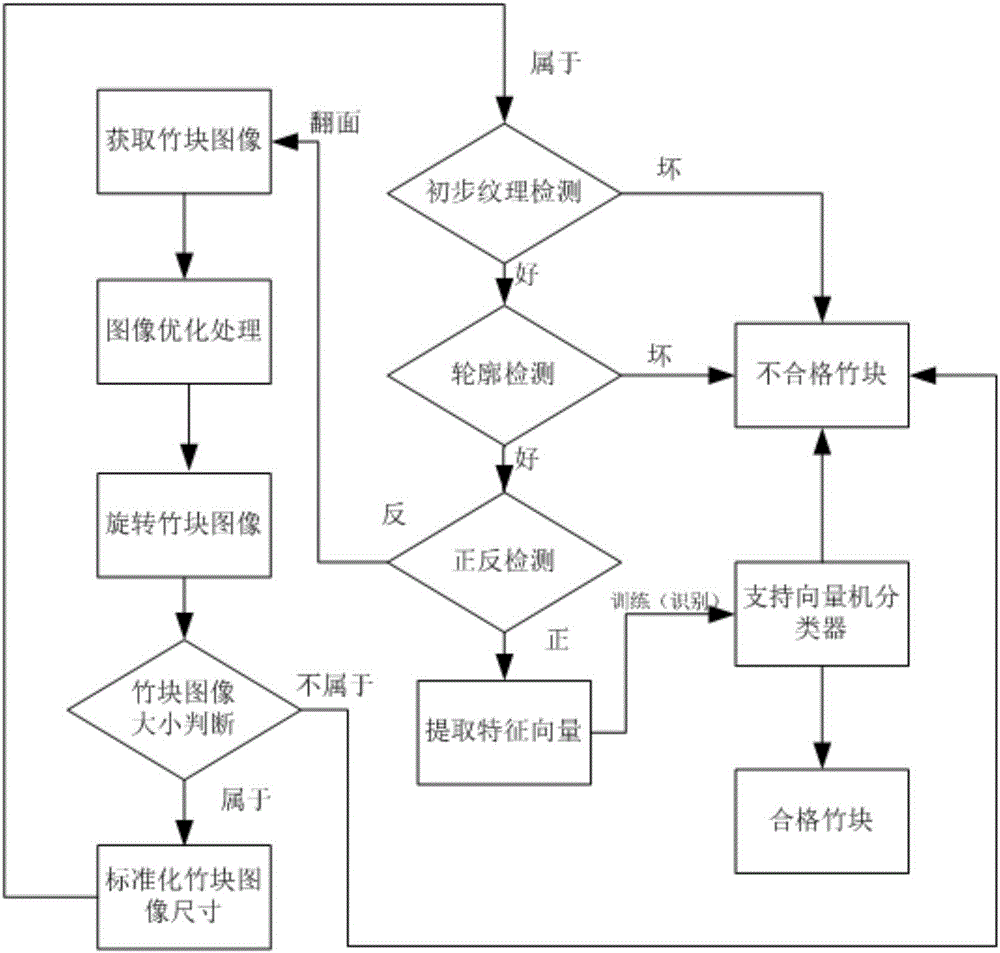

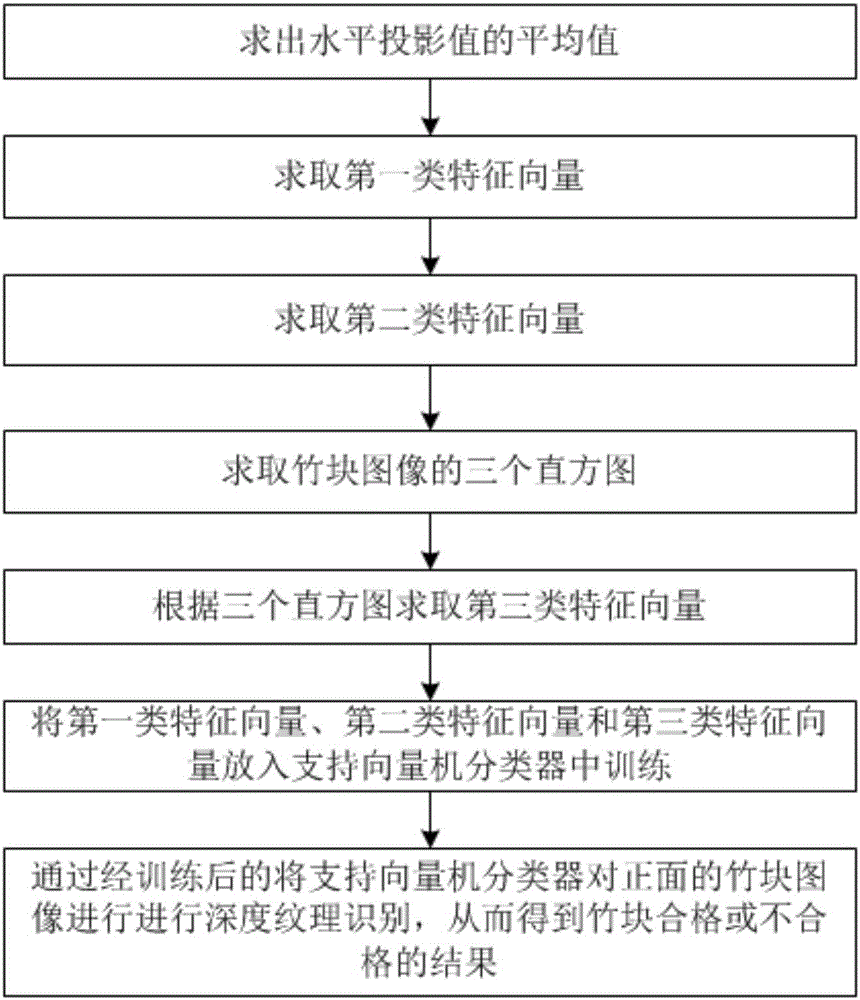

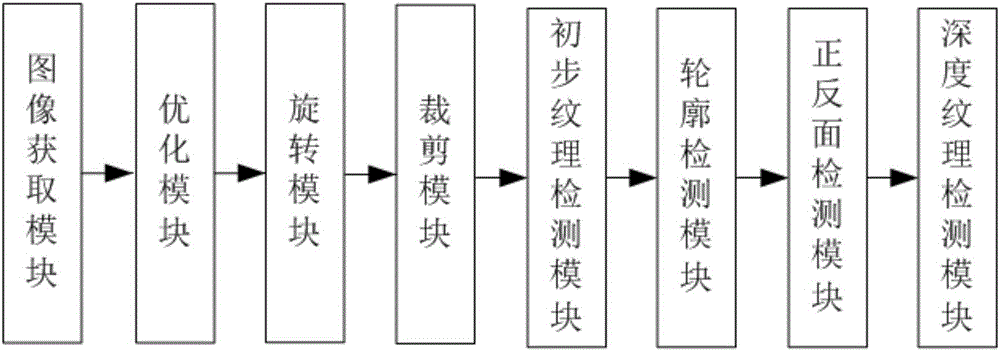

Bamboo piece defect detection method and bamboo piece defect detection system

ActiveCN106651831AIncrease productivityIncrease incomeImage enhancementImage analysisSupport vector machine classifier

The invention provides a bamboo piece defect detection method and a bamboo piece defect detection system. The method comprises the following steps: optimizing the quality of bamboo piece images collected; rotating the bamboo piece images to a horizontal position; cutting the bamboo piece images to a standard size; carrying out preliminary texture detection, contour defect detection and front and back detection on the bamboo piece images; carrying out depth texture identification through a support vector machine classifier; and finally, screening out qualified bamboo pieces. By implementing multiple detection steps on bamboo piece images and carrying out depth texture identification through the support vector machine classifier, qualified bamboo pieces are screened out. The result obtained is accurate. The production efficiency of mahjong mats can be improved, and the profit can be increased for enterprises.

Owner:GUANGXI NORMAL UNIV

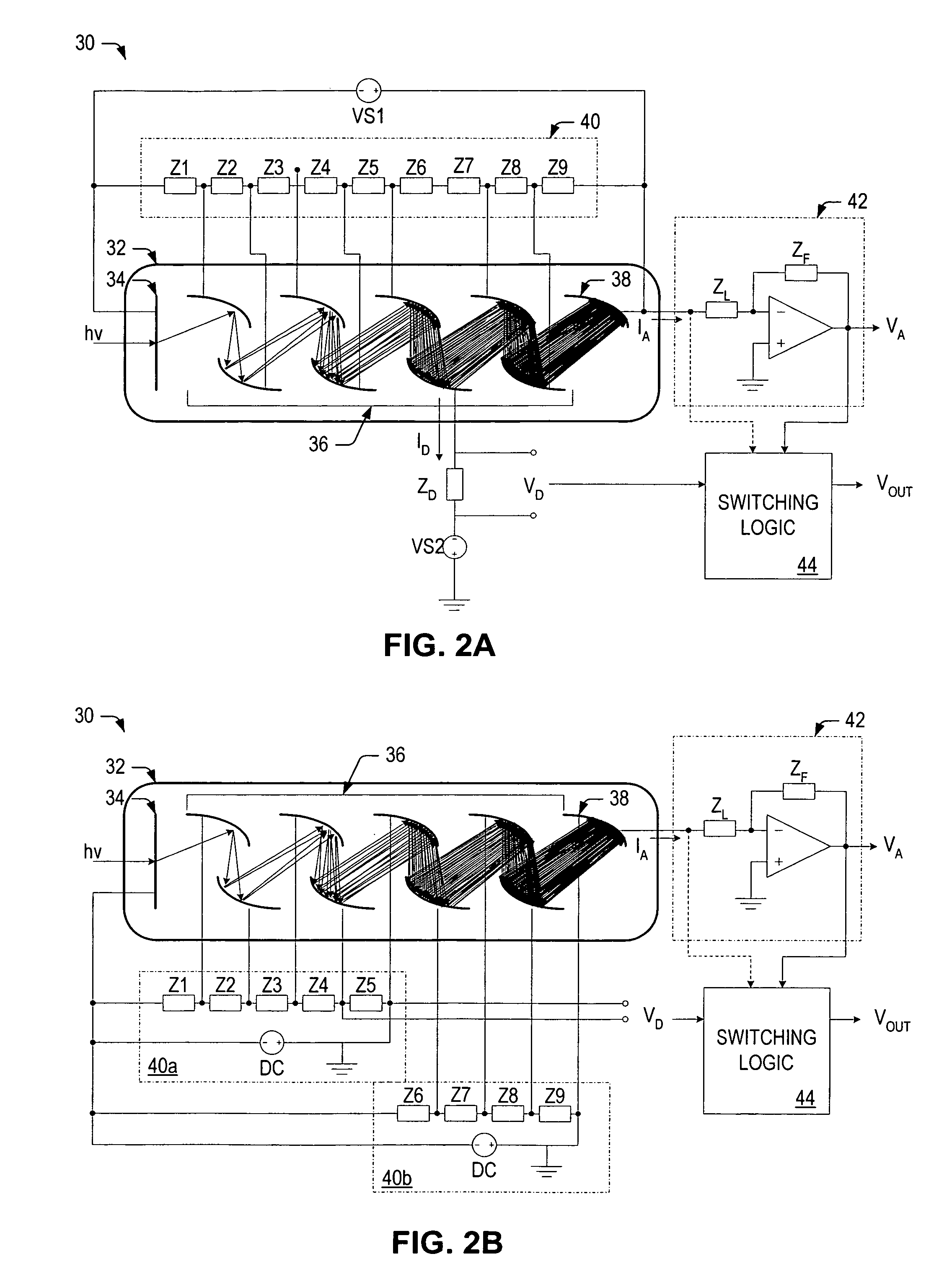

Systems, circuits and methods for extending the detection range of an inspection system by avoiding detector saturation

ActiveUS7414715B2Easy defect detectionPolarisation-affecting propertiesPhotometryPhotomultiplierLight scattering

Inspection systems, circuits and methods are provided to enhance defect detection by addressing anode saturation as a limiting factor of the measurement detection range of a photomultiplier tube (PMT) detector. In accordance with one embodiment of the invention, a method for inspecting a specimen includes directing light to the specimen and detecting light scattered from the specimen. The step of detecting may include monitoring an anode current of the PMT detector, and detecting features, defects or light scattering properties of the specimen using the anode current until the anode current reaches a predetermined threshold. Thereafter, the method may use a dynode current of the PMT for detecting the features, defects or light scattering properties of the specimen.

Owner:KLA TENCOR TECH CORP

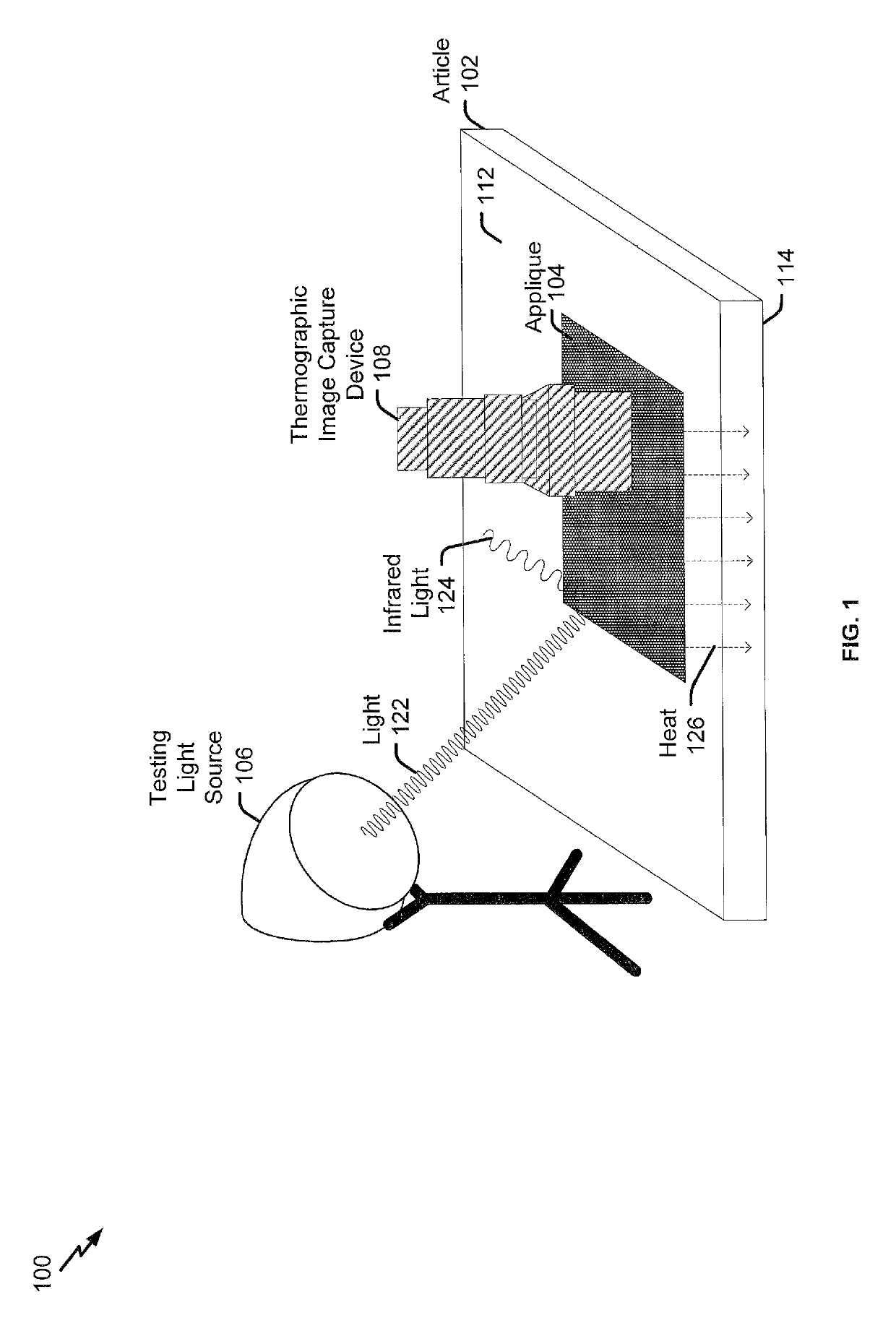

Applique and method for thermographic inspection

ActiveUS10260953B2High quality thermographic imageIncrease absorptivityOptically investigating flaws/contaminationMaterial flaws investigationOptoelectronicsThermal radiation

A method of thermographic inspection includes absorbing, at an applique applied to a test area of an article, light from a testing light source. The method further includes emitting, by the applique, thermal radiation directed to a capture device, the thermal radiation corresponding to at least a portion of the light absorbed by the applique.

Owner:THE BOEING CO

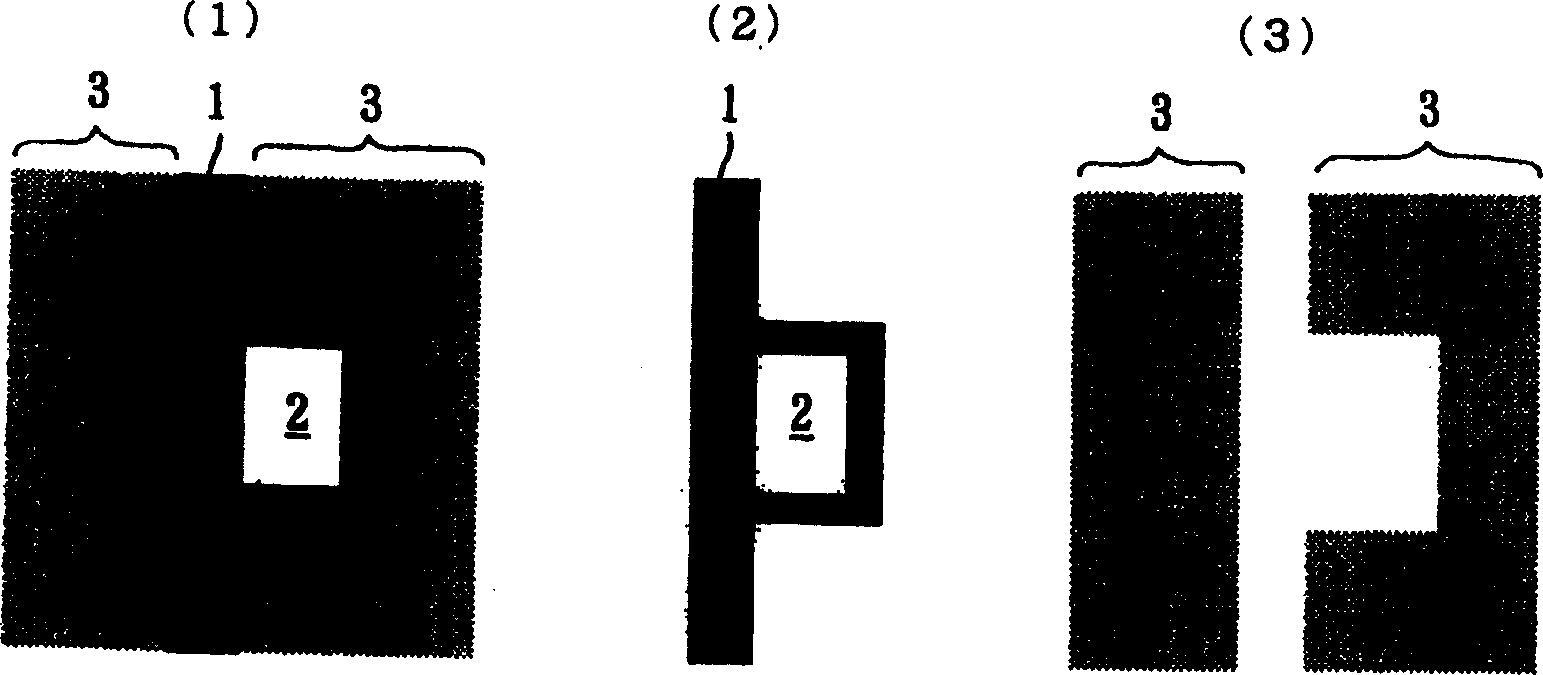

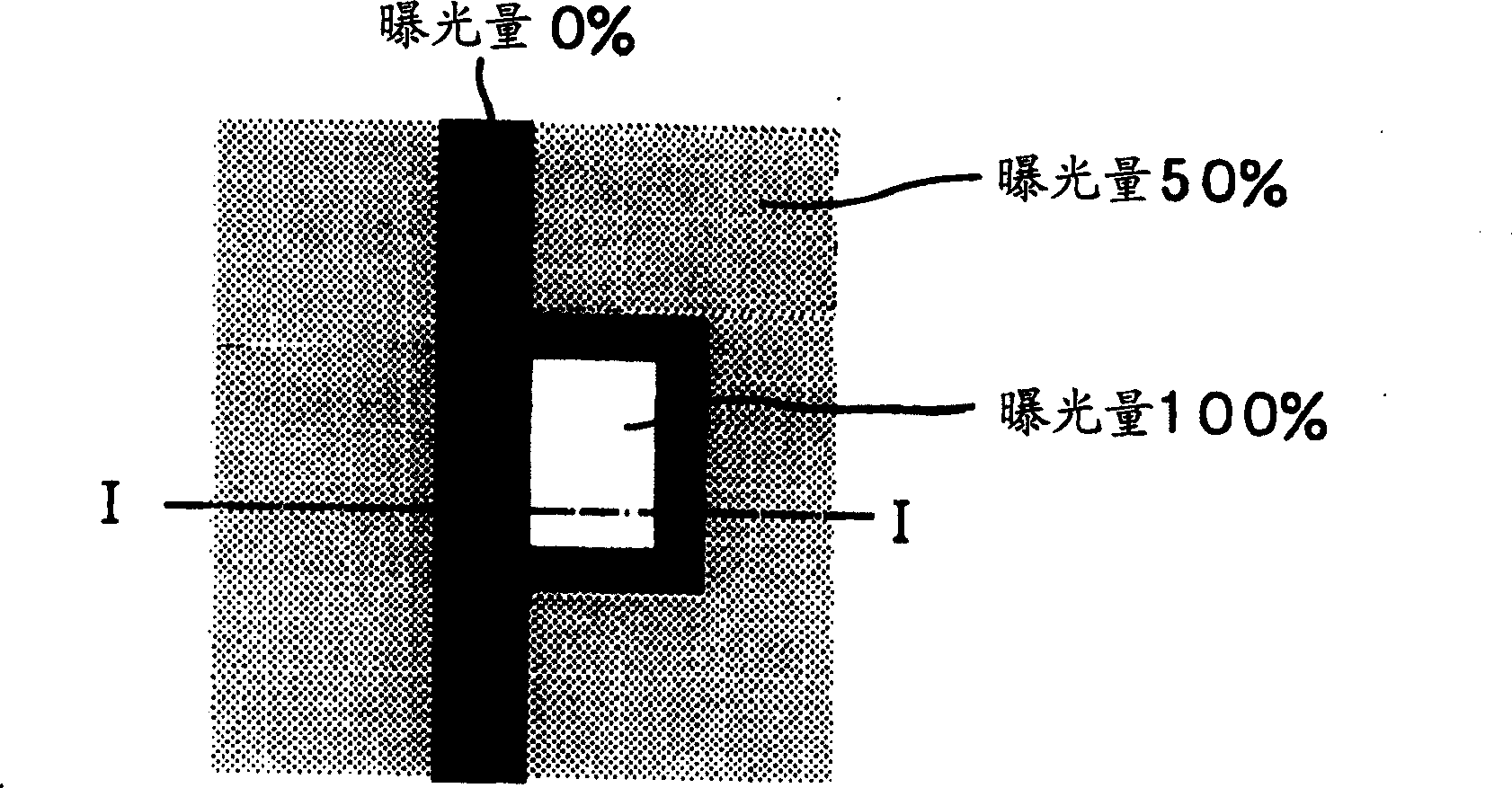

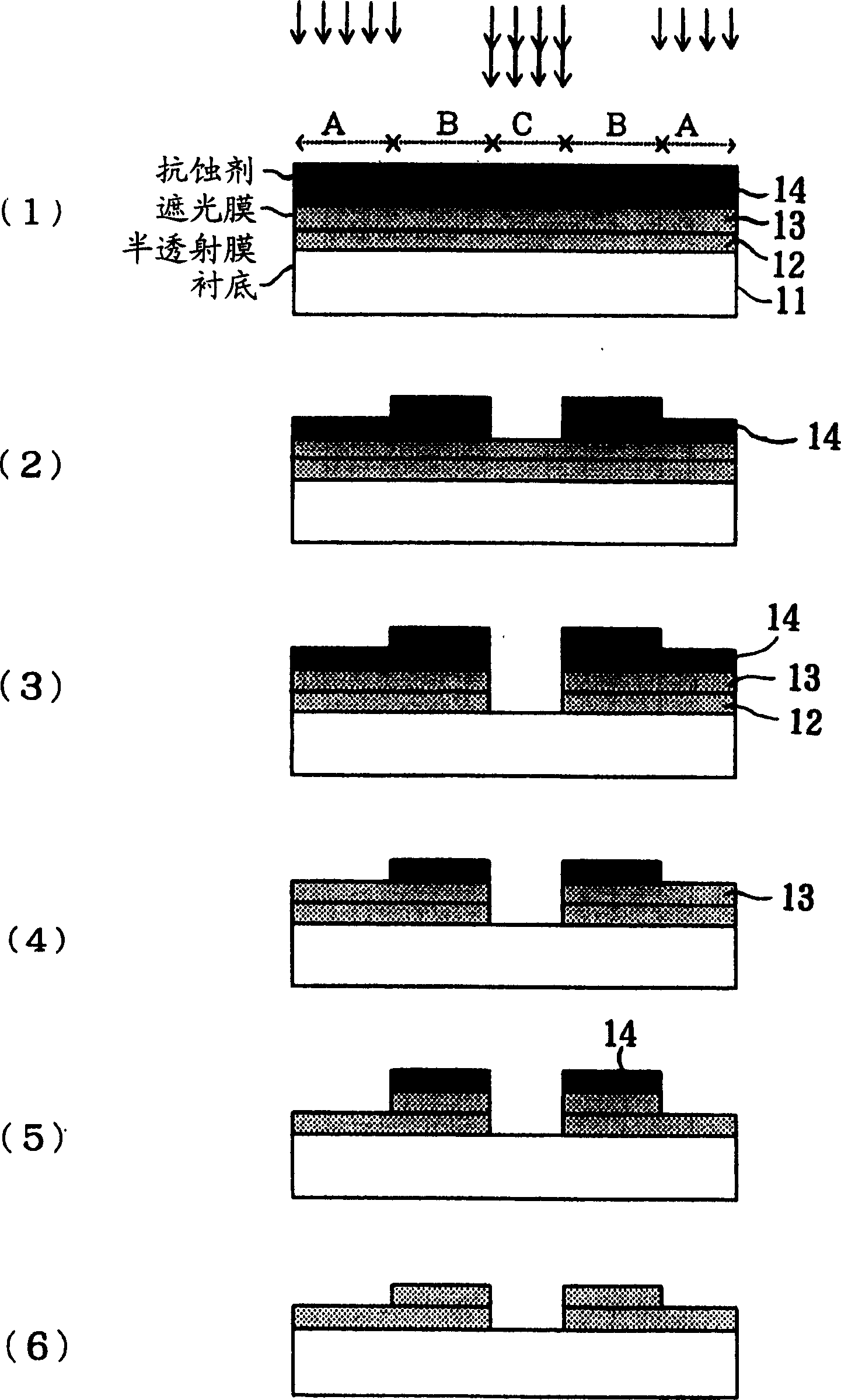

Grey mask and method for making same

InactiveCN1464338ANo problems with machining accuracyEasy defect detectionSemiconductor/solid-state device manufacturingPhotosensitive material processingResistTransmittance

The present invention provides one kind of grey mask capable of making transmissivity controllable and homogeneous film thickness and its making process. For example, on the transparent substrate, transmissivity controllable film, low transmissivity film and photoresist film are formed successively; the photoresist film and the low transmissivity film in some part are eliminated to form transparent part; and the photoresist film and partial low transmissivity film in some other part are eliminated to form grey part and to make grey mask.

Owner:HOYA CORP

Apparatus for searching for and detecting defects in parts by endoscopy

ActiveUS20080297785A1Simple and satisfactory and inexpensiveEasy defect detectionSurgeryOptically investigating flaws/contaminationFlexible endoscopeMedicine

Apparatus for searching for and detecting defects on parts that are substantially inaccessible, being located behind a wall, the apparatus comprising a first endoscope for illumination in visible light and for observation, the first endoscope and pipes for feeding and spraying penetration test substances being housed together in a rod which can be passed through an orifice in the wall in order to examine a part, the apparatus further comprising a second endoscope independent of the first endoscope and the rod for illuminating in ultraviolet light and for observing the portion of the part that has been treated by the penetration test substances.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

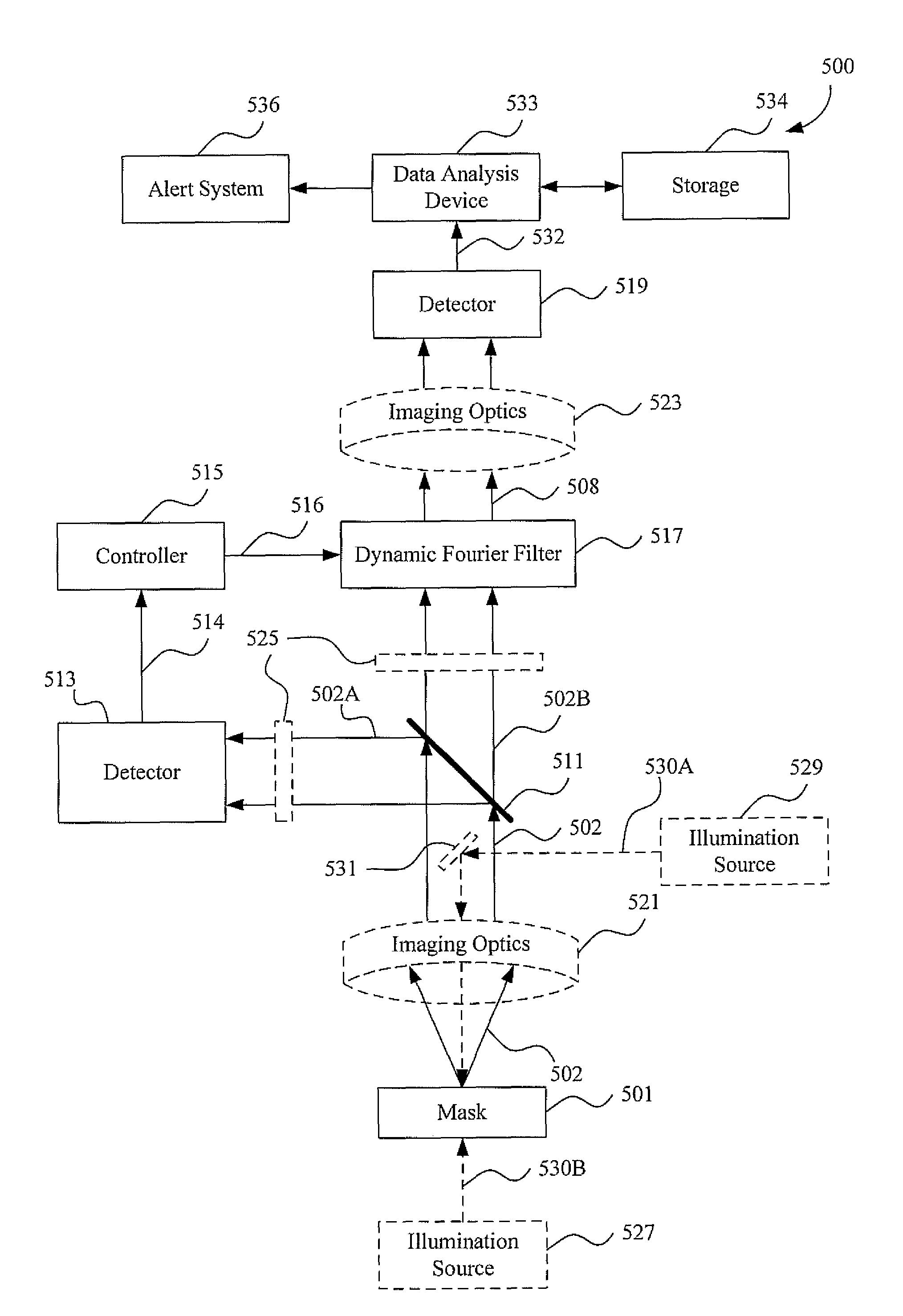

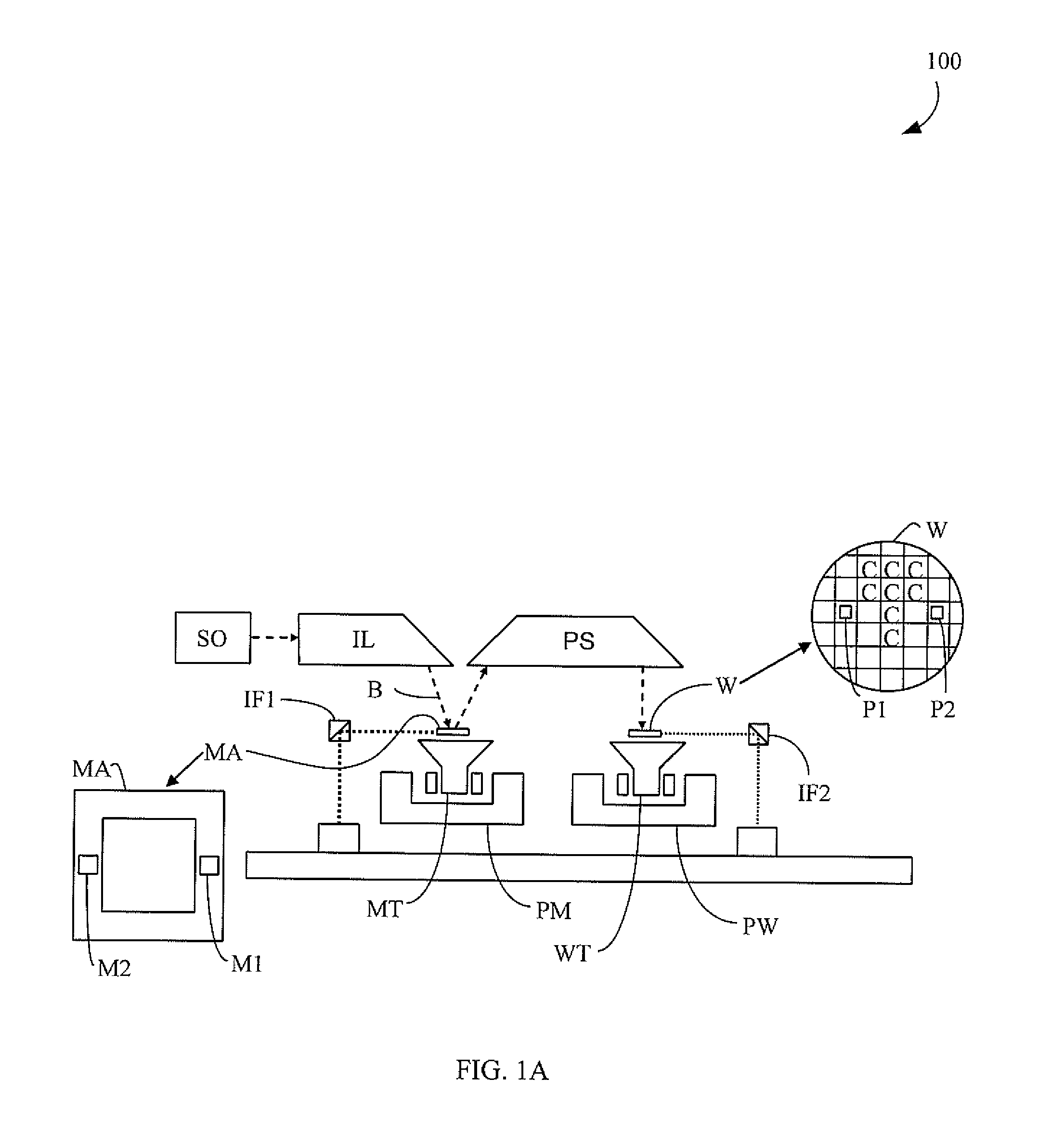

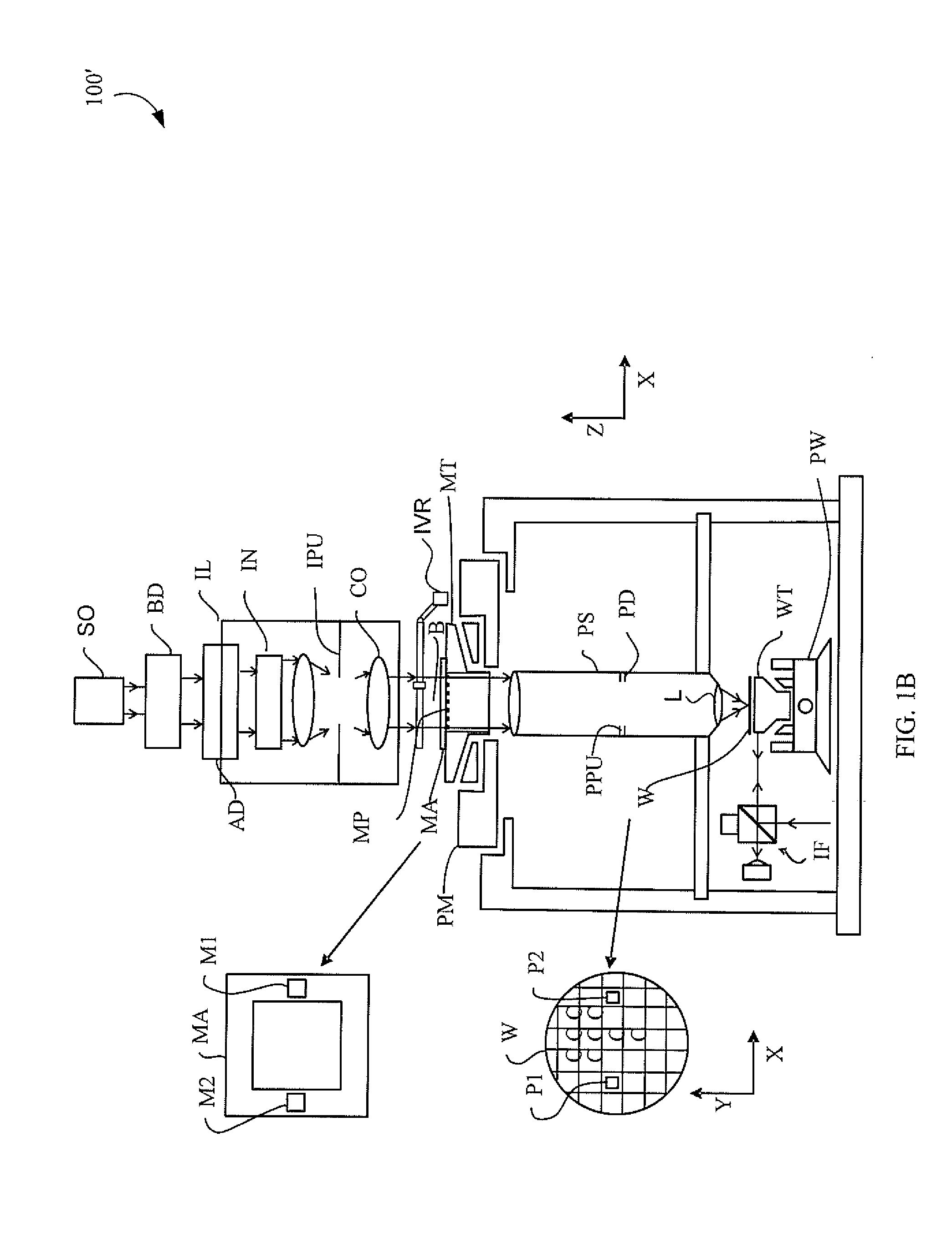

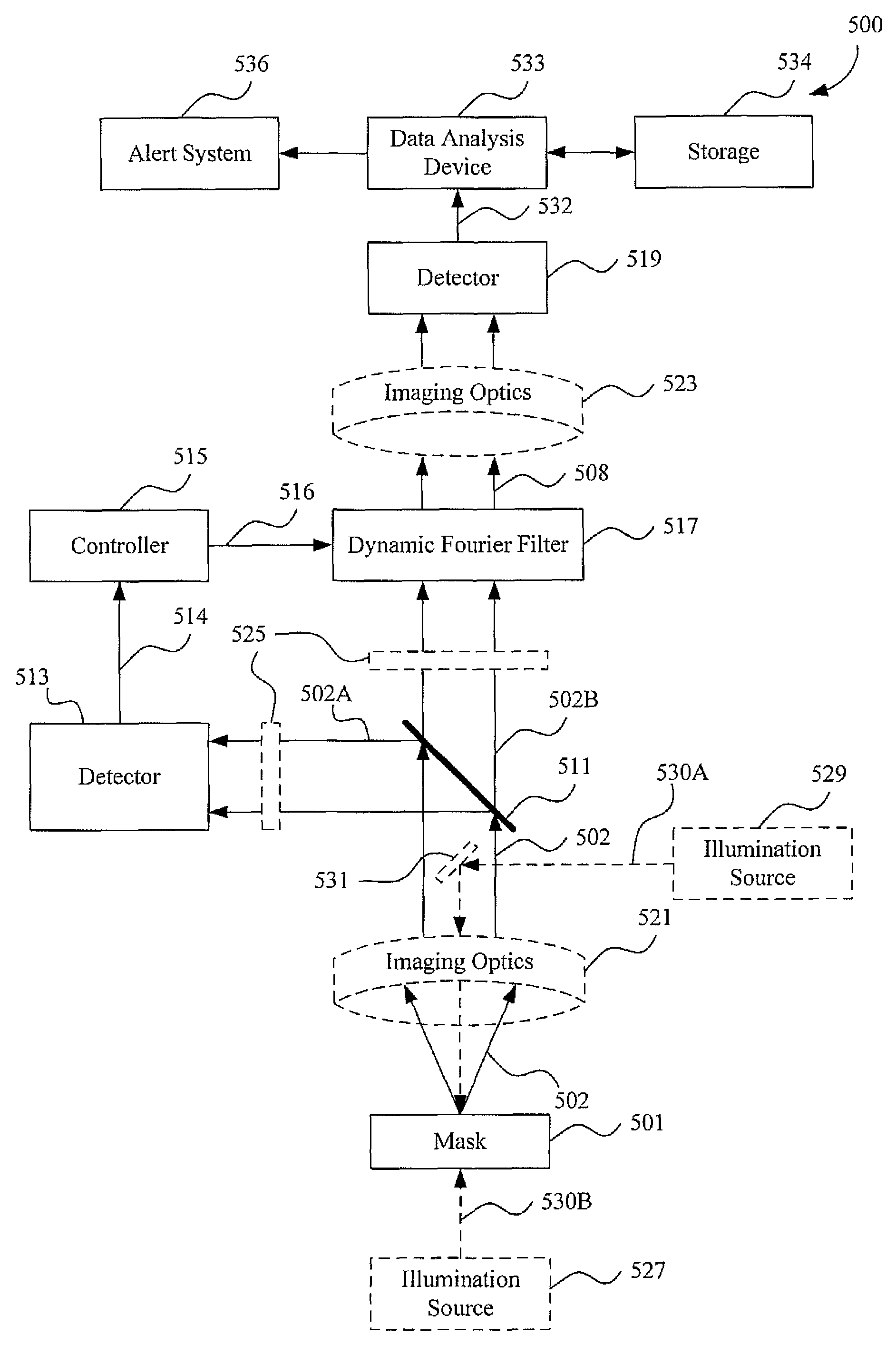

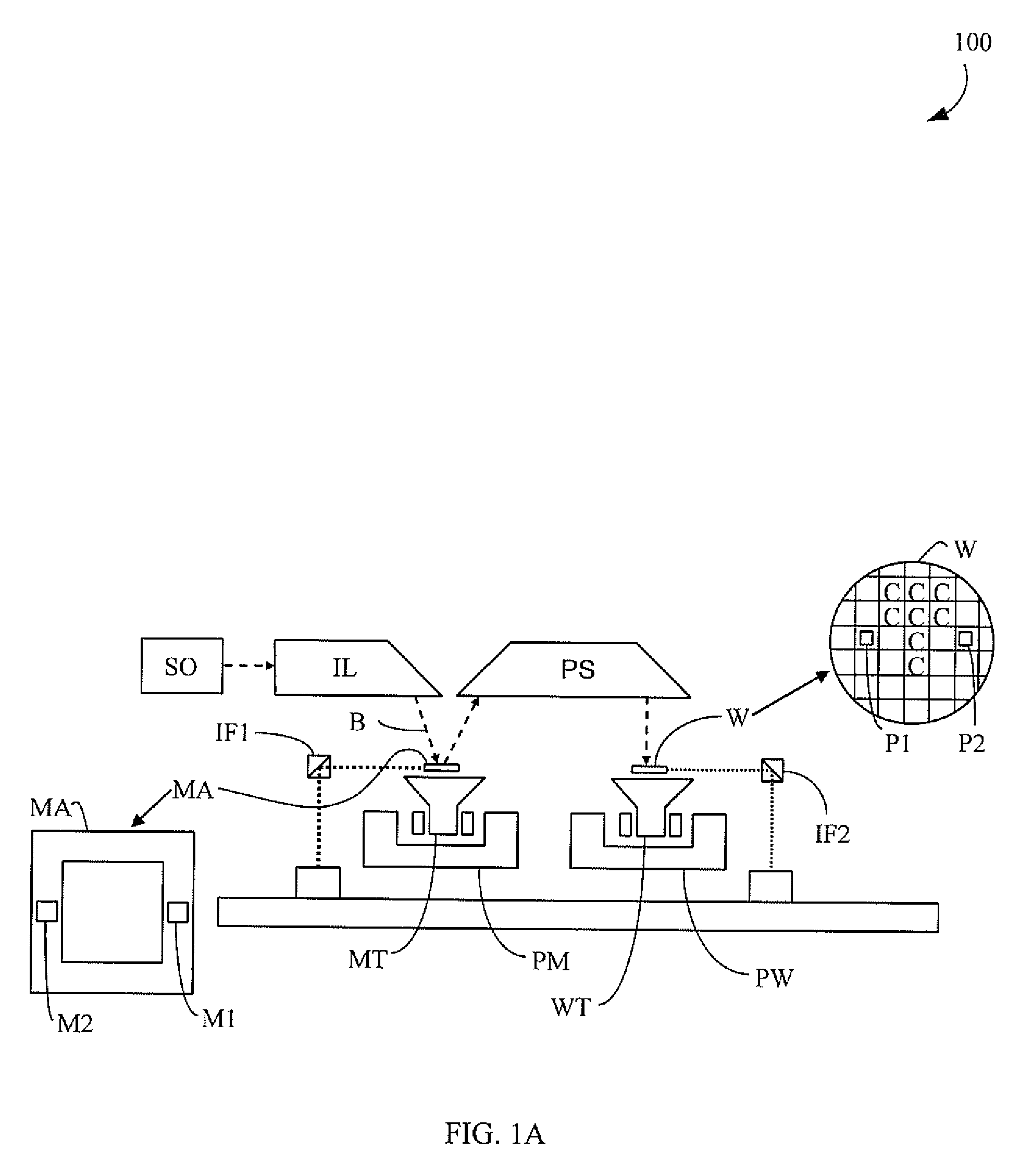

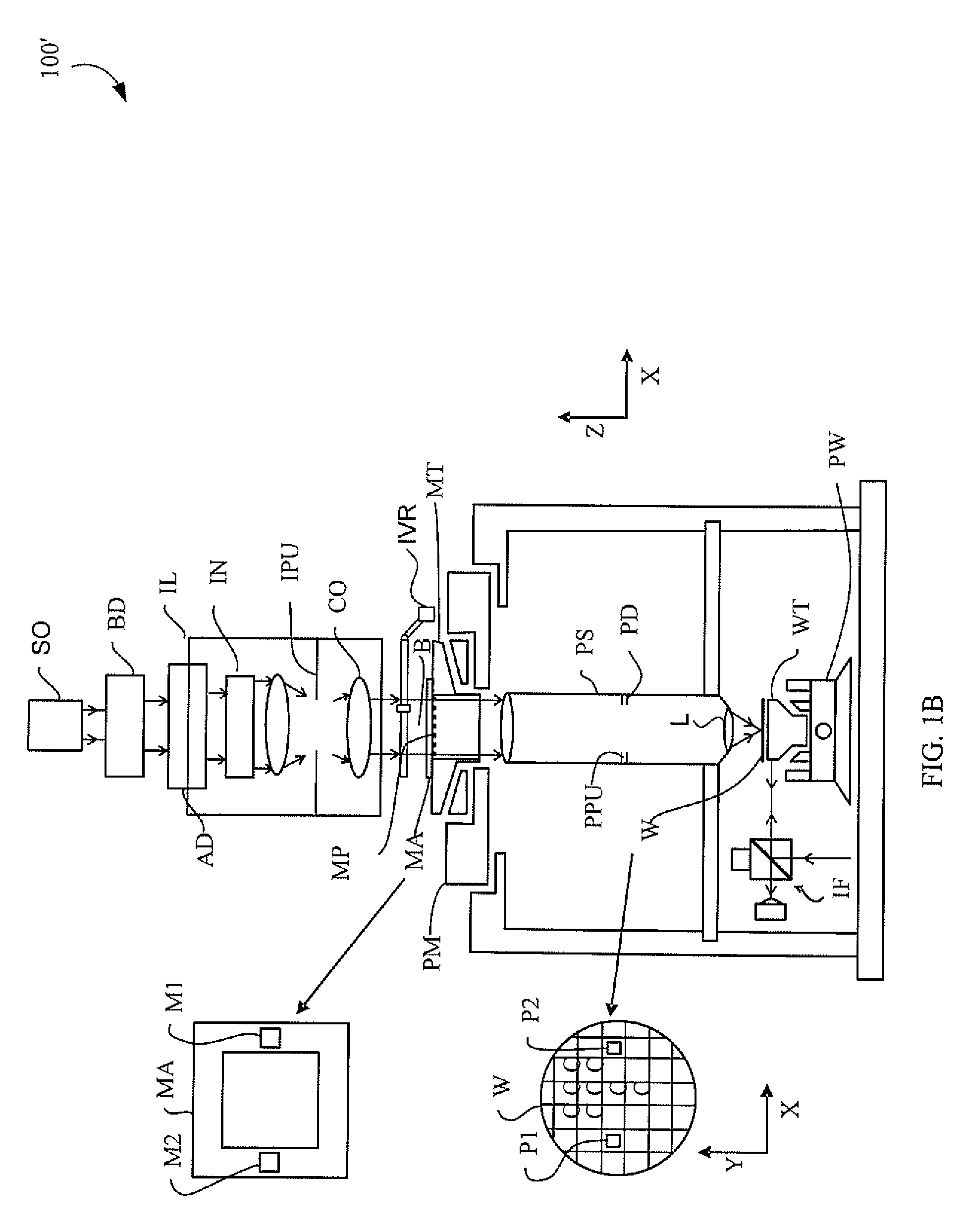

Mask Inspection with Fourier Filtering and Image Compare

ActiveUS20120075606A1Enhance defect detectionImprove detection sensitivityUsing optical meansOriginals for photomechanical treatmentPhysicsMask inspection

A mask inspection system with Fourier filtering and image compare can include a first detector, a dynamic Fourier filter, a controller, and a second detector. The first detector can be located at a Fourier plane of the inspection system and can detect a first portion of patterned light produced by an area of a mask. The dynamic Fourier filter can be controlled by the controller based on the detected first portion of the patterned light. The second detector can detect a second portion of the patterned light produced by the section of the mask and transmitted through the dynamic Fourier filter. Further, the mask inspection system can include a data analysis device to compare the second portion of patterned light with another patterned light. Consequently, the mask inspection system is able to detect any possible defects on the area of the mask more accurately and with higher resolution.

Owner:ASML HLDG NV

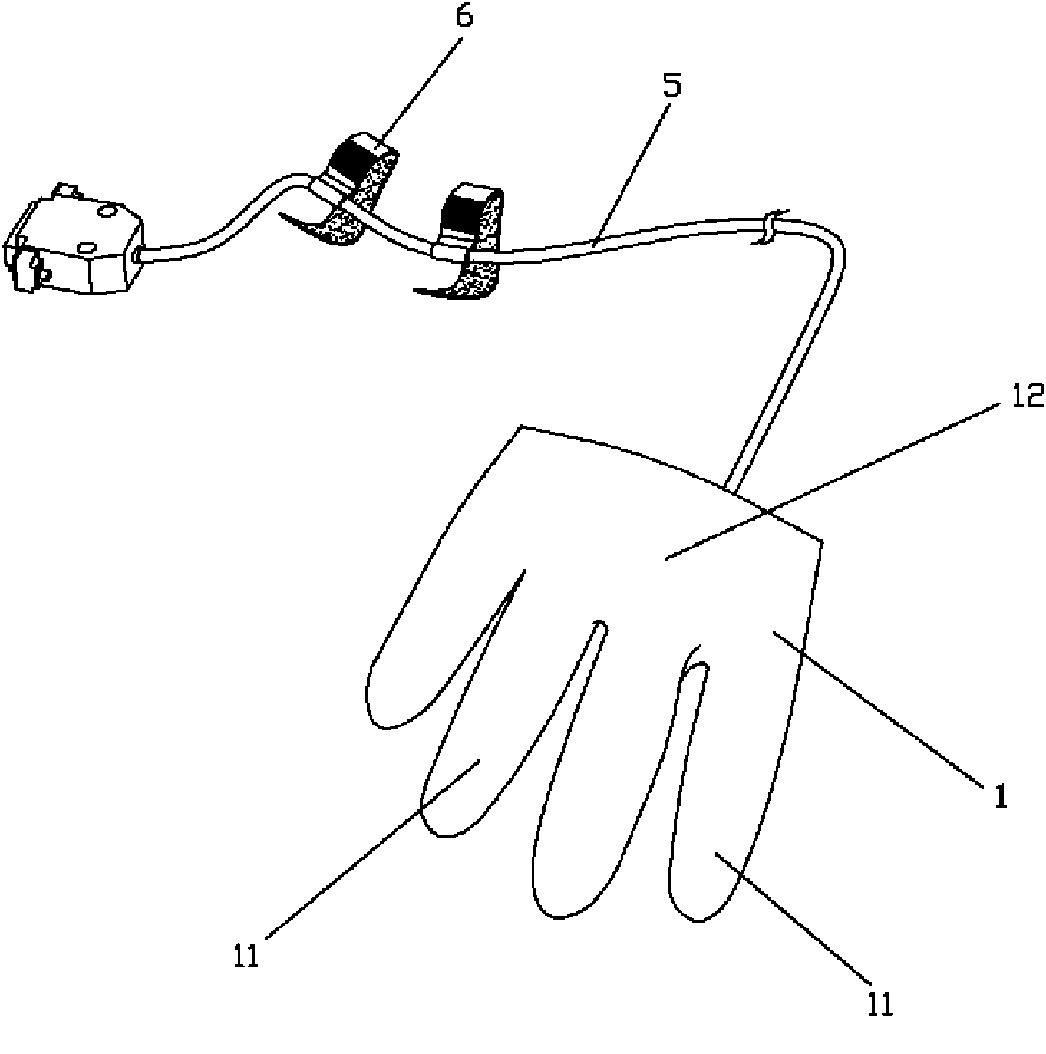

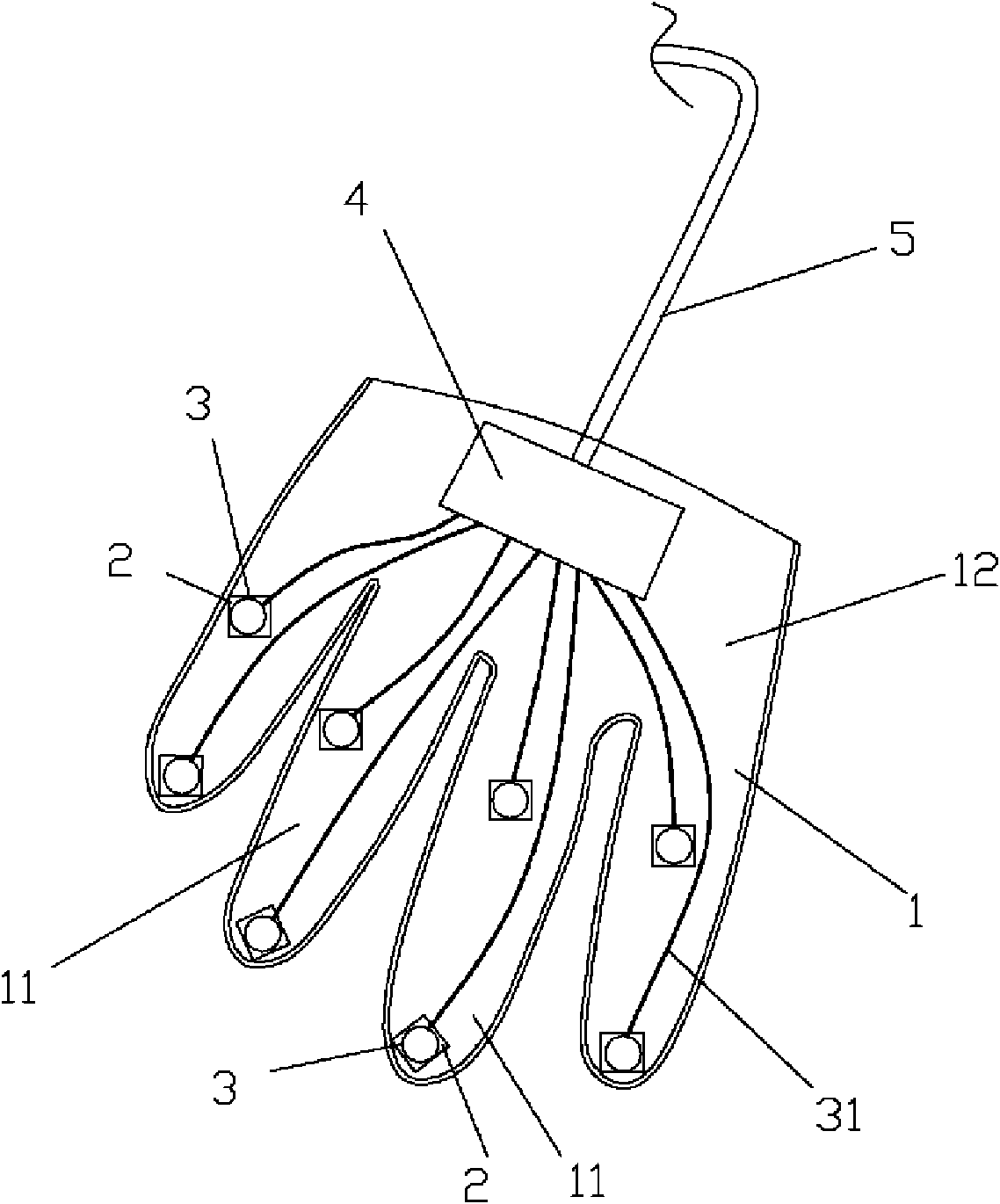

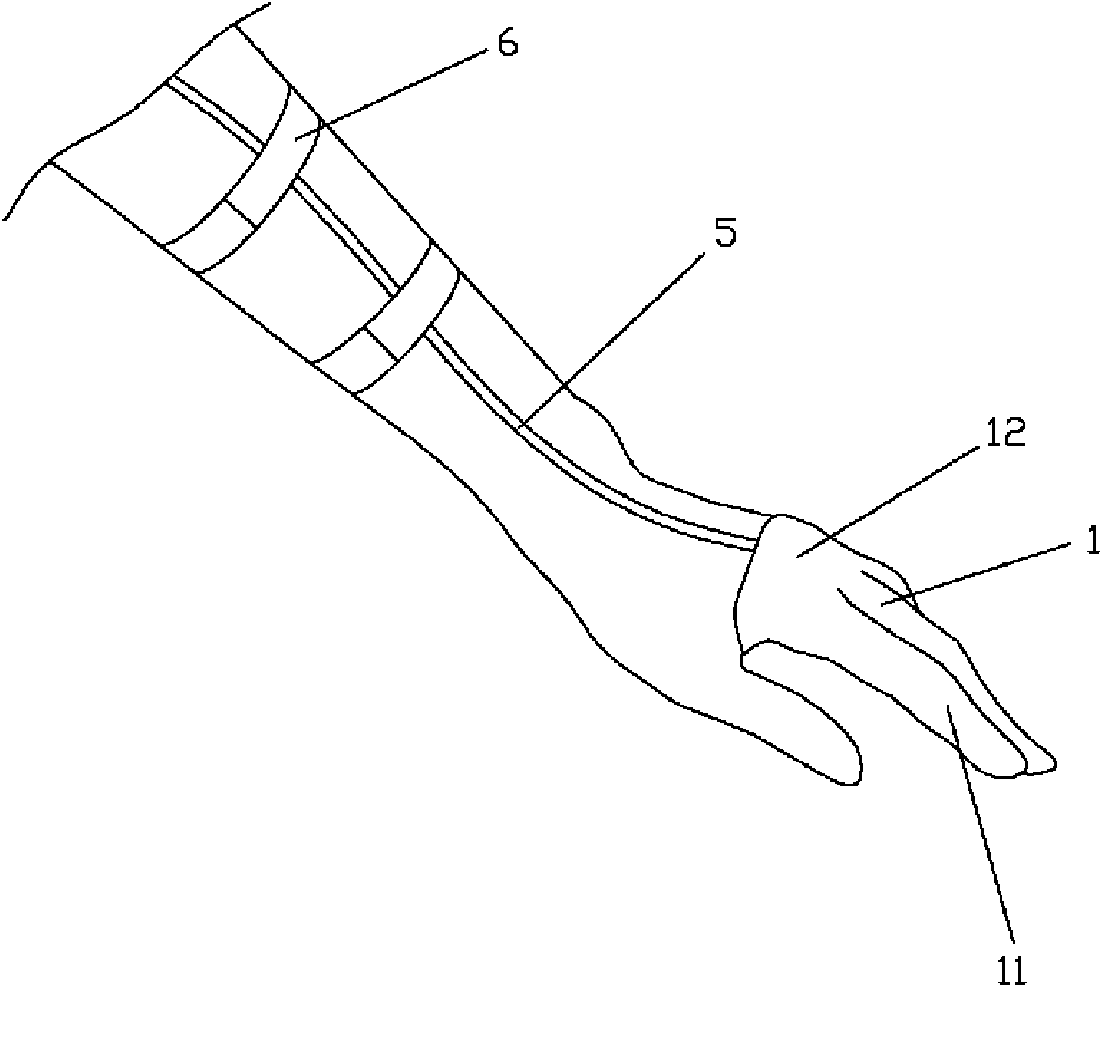

Eddy current detection method using finger touch as supplementary means and device thereof

ActiveCN101576534AEasy to moveImprove accuracyMaterial magnetic variablesFlexible circuitsEngineering

The invention discloses an eddy current detection method using finger touch as supplementary means and a device thereof. A coil capable of being used for realizing eddy current detection is wound in the shape of a pancake or arranged on a flexible circuit board to form a small sensor capable of flexibly bending, then the small sensor is mounted on a finger of a human body (namely an operator), and the finger is used as the framework of the coil. As the small sensor is capable of flexibly bending, the small sensor is adapted to the surface of a metal structural member along with the flexible motion of the surface of the finger. Synchronously, by adopting the sensitivity of human body contact and the flexibility of the finger, the small sensor can conveniently move on the detected surface of the metal structural member without being influenced by all obstacles such as pit, welding beading and the like. The finger touch can be used for supplementary location and judgment so as to improve the accuracy and adaptive capacity of detection result. The method is particularly suitable for defect detection on the complex surface of the metal structural member.

Owner:林俊明

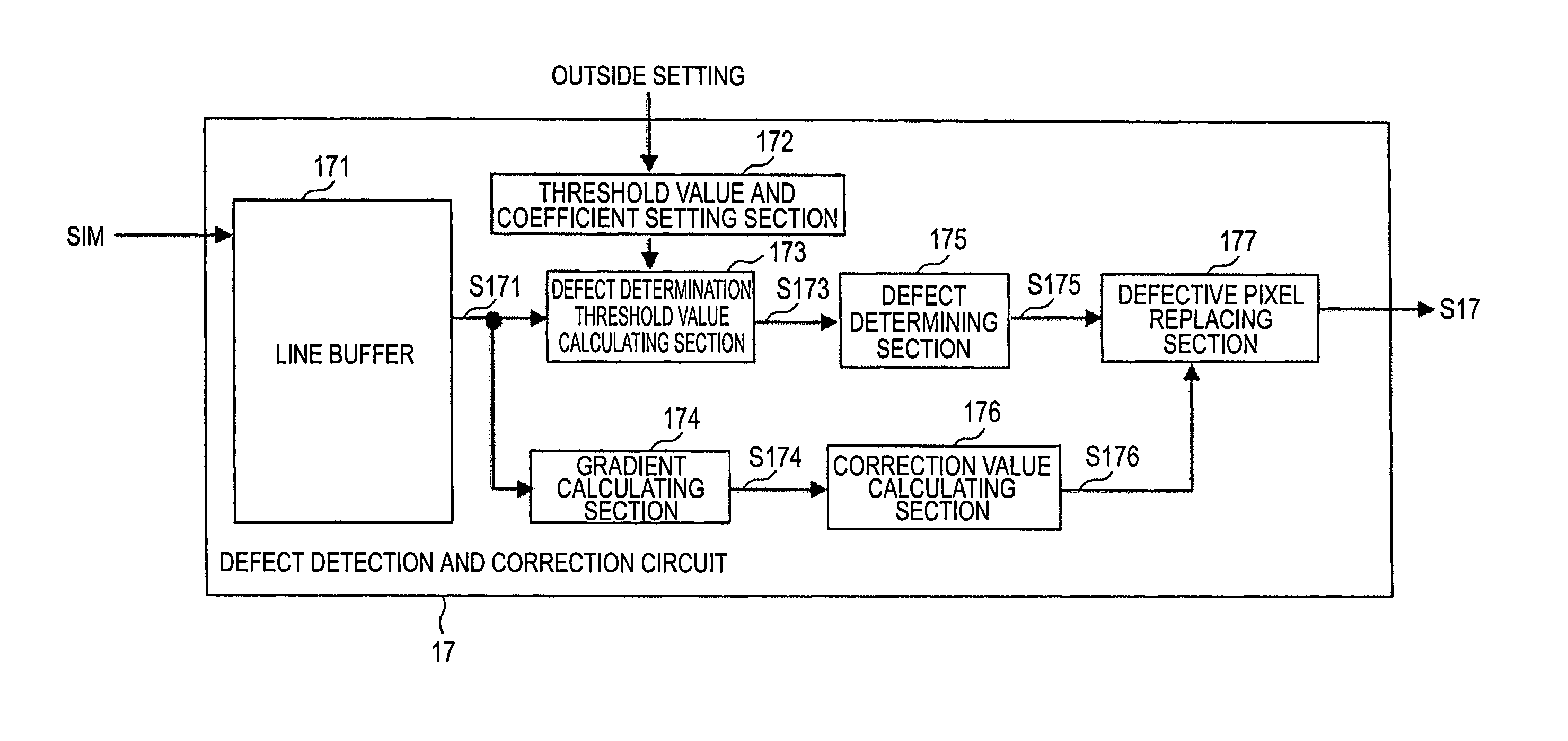

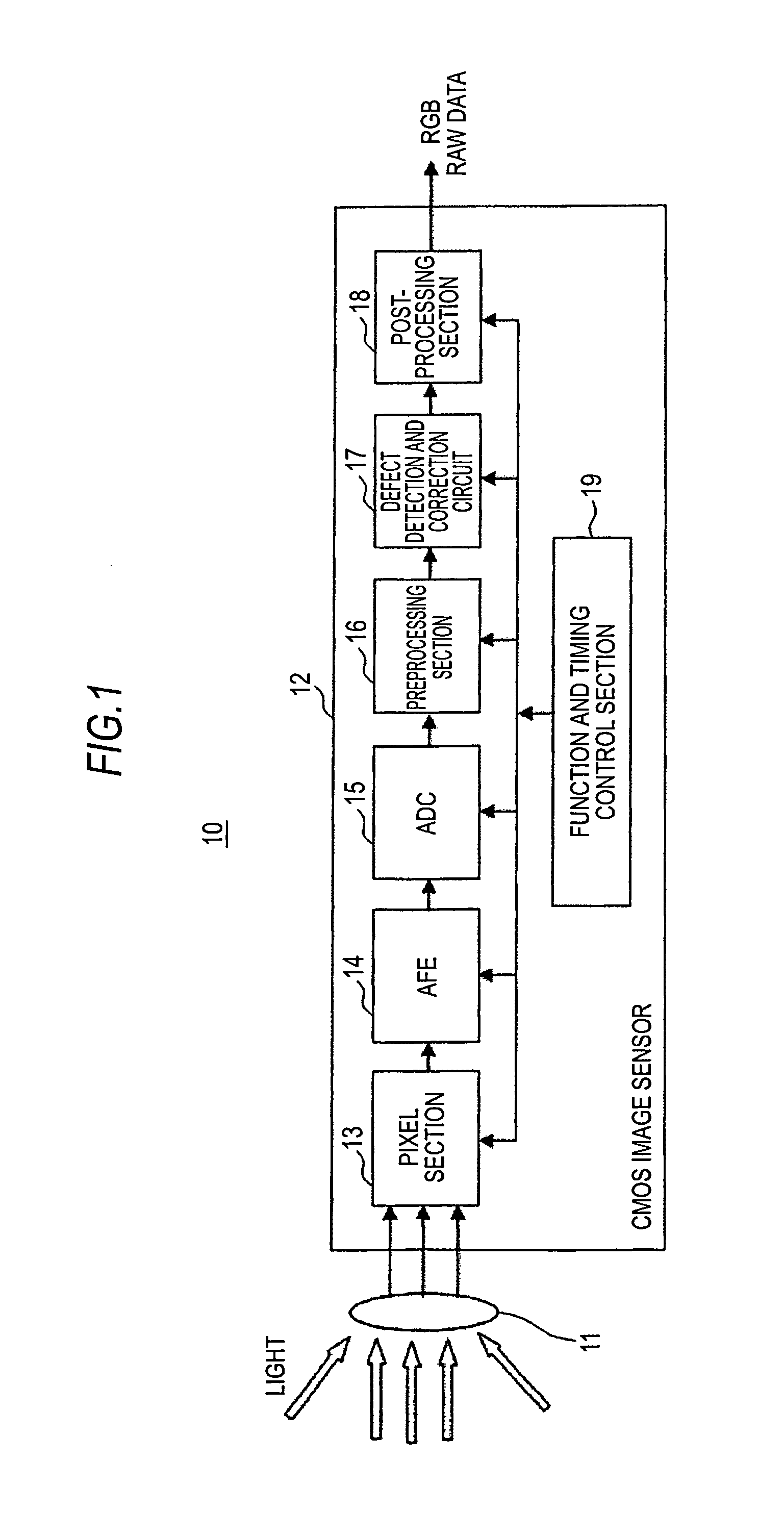

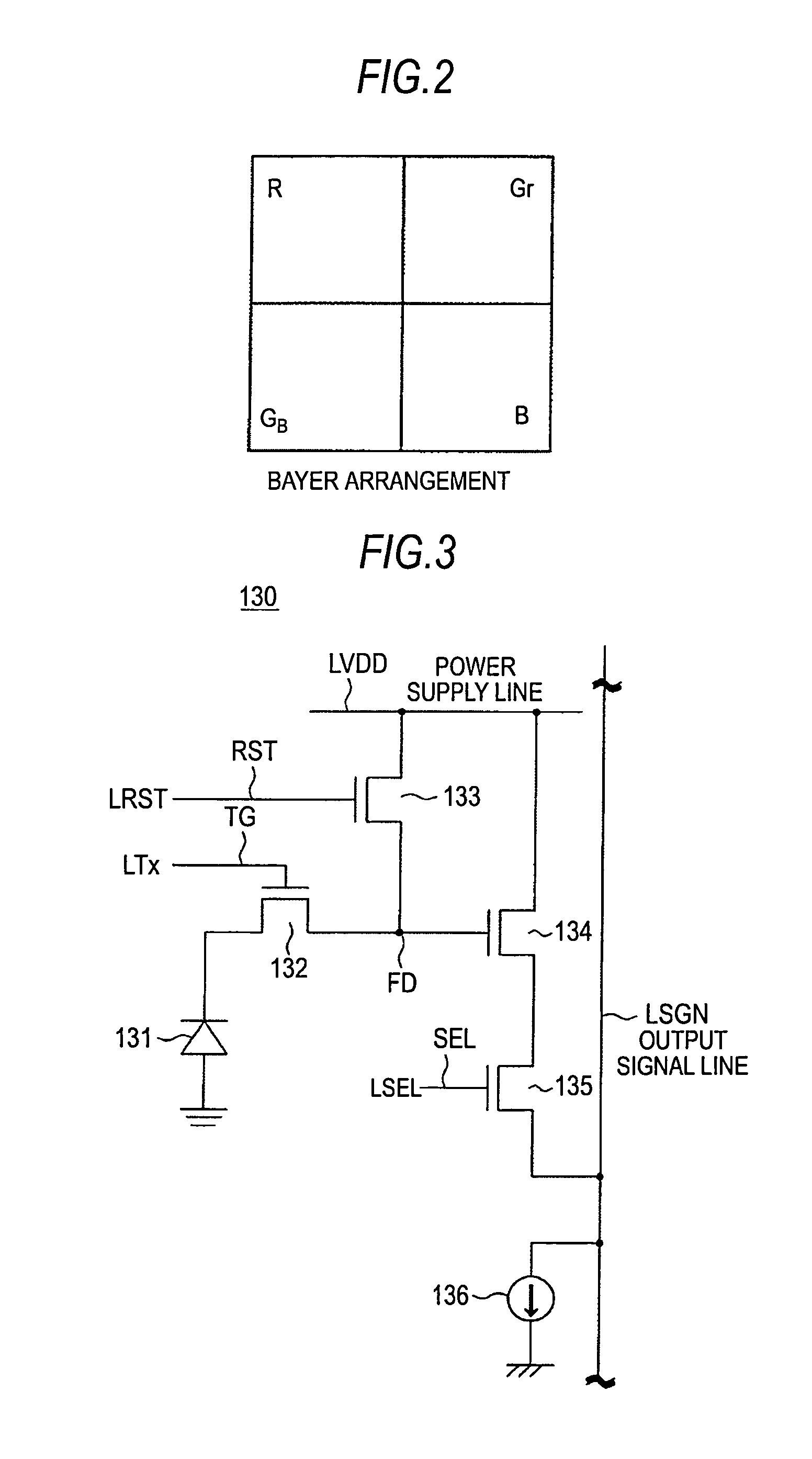

Pixel defect correction device, imaging apparatus, pixel defect correction method, and program

ActiveUS8576309B2Easy to detectEasy defect detectionTelevision system detailsColor signal processing circuitsProcess regionComputer vision

A pixel defect correction device includes: a defect determining section determining whether a pixel of interest of an image, in which pixels each having a pixel value are arrayed in a two-dimensional manner, is a defect of the image; a gradient detecting section detecting a gradient or an edge in a processing region, which includes pixels with the pixel of interest in the middle, based on values of at least peripheral pixels around the pixel of interest which are included in the processing region; a correction value acquisition section selecting a pixel, which is used for acquisition of a correction value of the pixel of interest, according to the detected gradient or edge and acquiring the correction value from a value of the selected pixel; and a defective pixel replacing section replacing the value of the pixel of interest with the correction value when the pixel of interest is determined to be a defect.

Owner:SONY SEMICON SOLUTIONS CORP

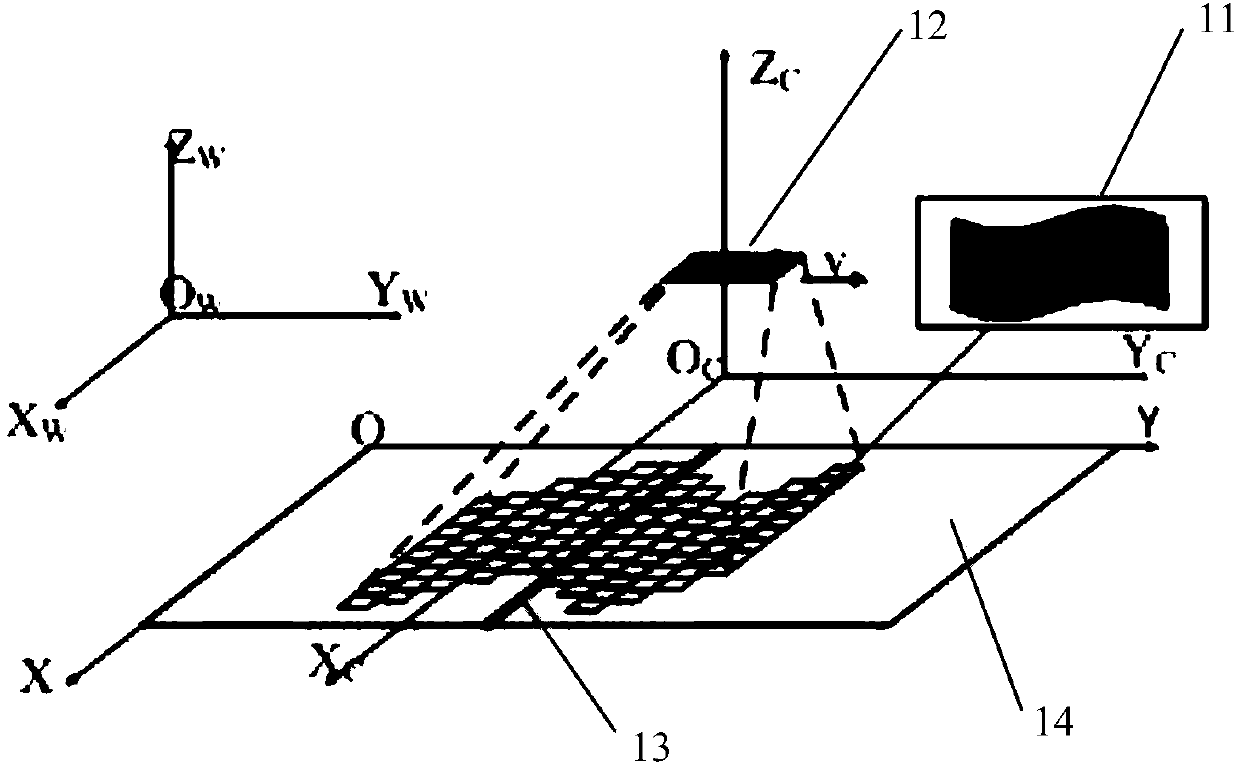

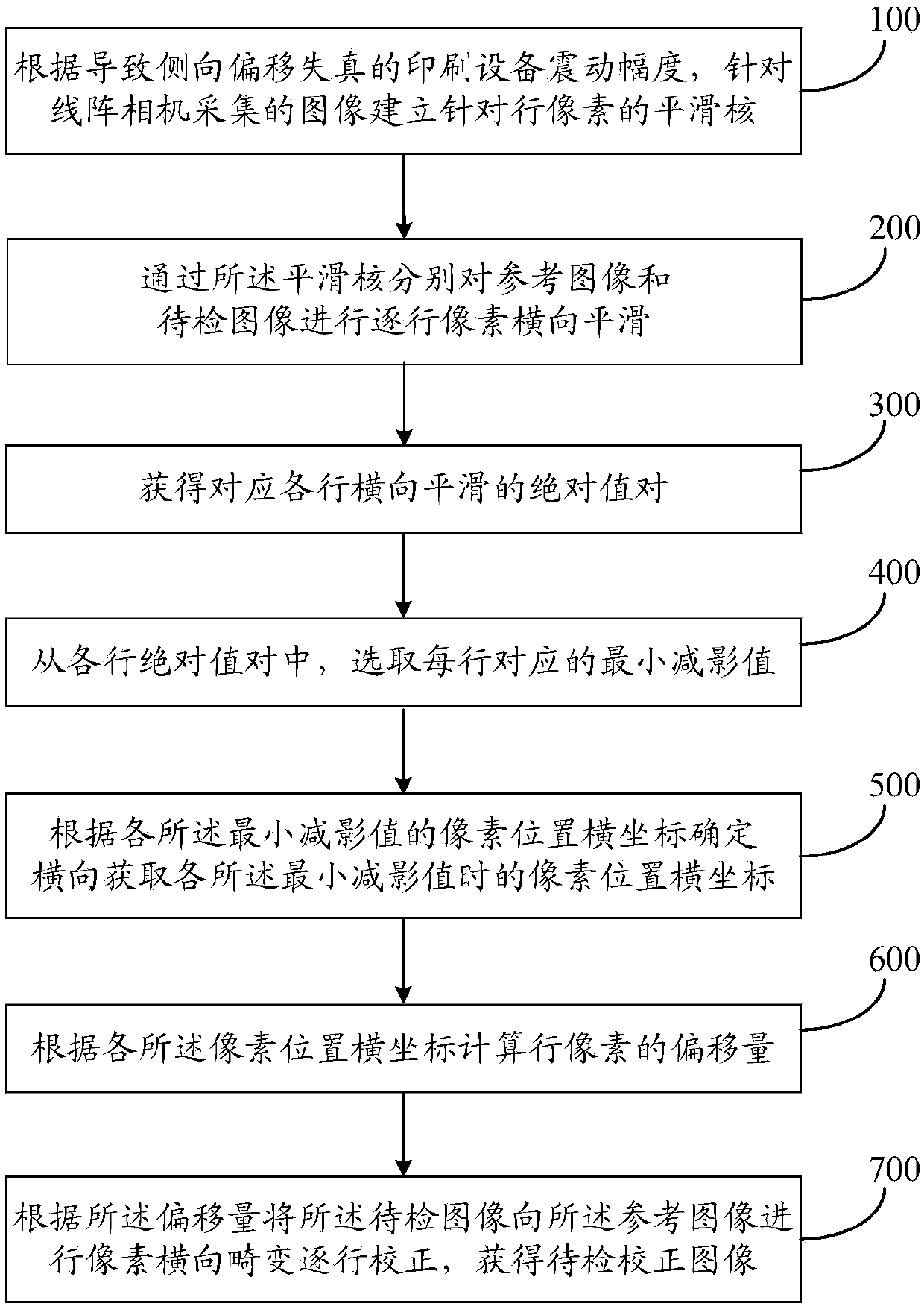

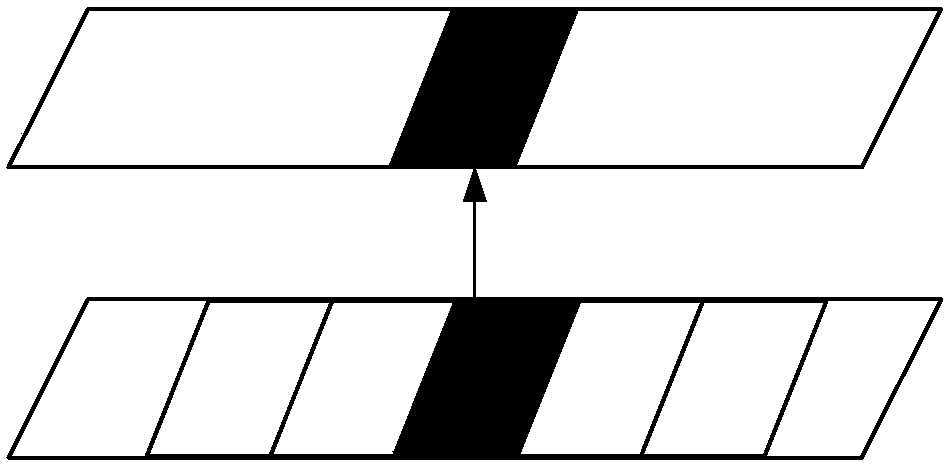

Geometric correction method and system for detecting lateral deviation of image of printed matter

ActiveCN107948464AEasy defect detectionReduce differential artifactsTelevision system detailsImage enhancementVibration amplitudeSmoothing kernel

The invention discloses a geometric correction method and system for detecting the lateral deviation of an image of a printed matter, and the method comprises the steps: building a smoothing kernel for row pixels of an image collected by a linear array camera according to the vibration amplitude, causing the distortion of the lateral deviation, of printing equipment; carrying out the lateral smoothing of the pixels of a reference image and a to-be-detected image row by row through the smoothing kernel; respectively calculating the absolute value pairs for the lateral smoothing of each row; selecting a minimum subtraction value, corresponding to each row, from the absolute value pairs of each row; determining the lateral coordinates of the pixel positions according to the lateral coordinates of the pixel positions of each minimum subtraction value during the obtaining of the minimum subtraction values; calculating the offset of the row pixels according to the lateral coordinates of thepixel positions so as to correct the lateral distortion of the pixels of the to-be-detected image to the reference image, thereby facilitating the subsequent detection of the defects of the printed matter through the to-be-detected image, guaranteeing the comparison premise of a single variable of two images, reducing the differential artifact greatly, and reducing the defect detection error rate.

Owner:LANZHOU JIAOTONG UNIV

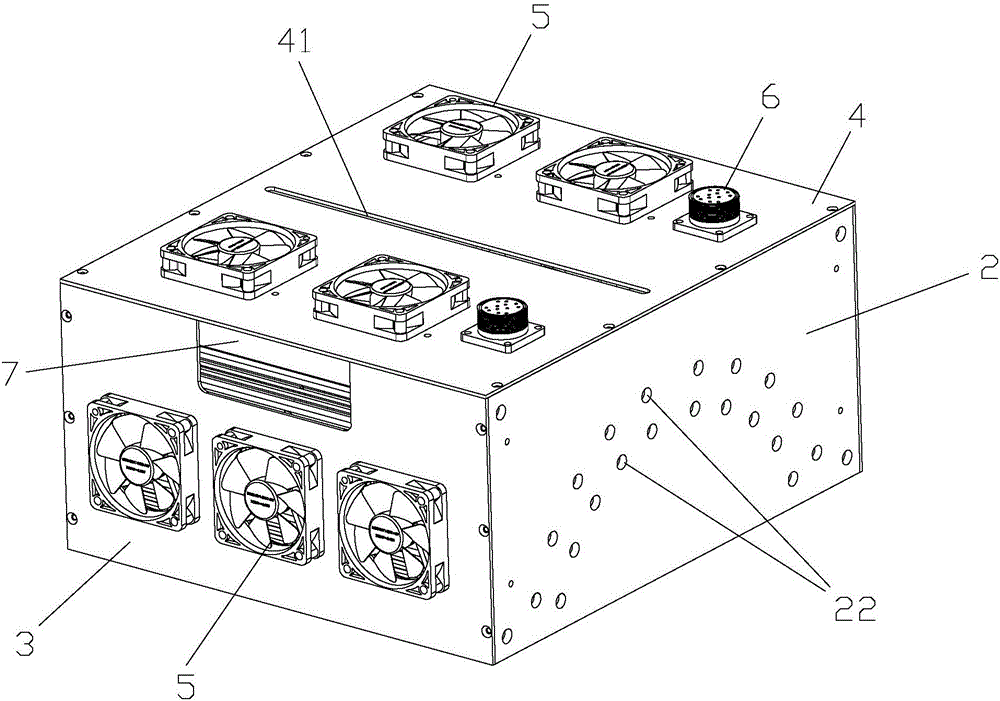

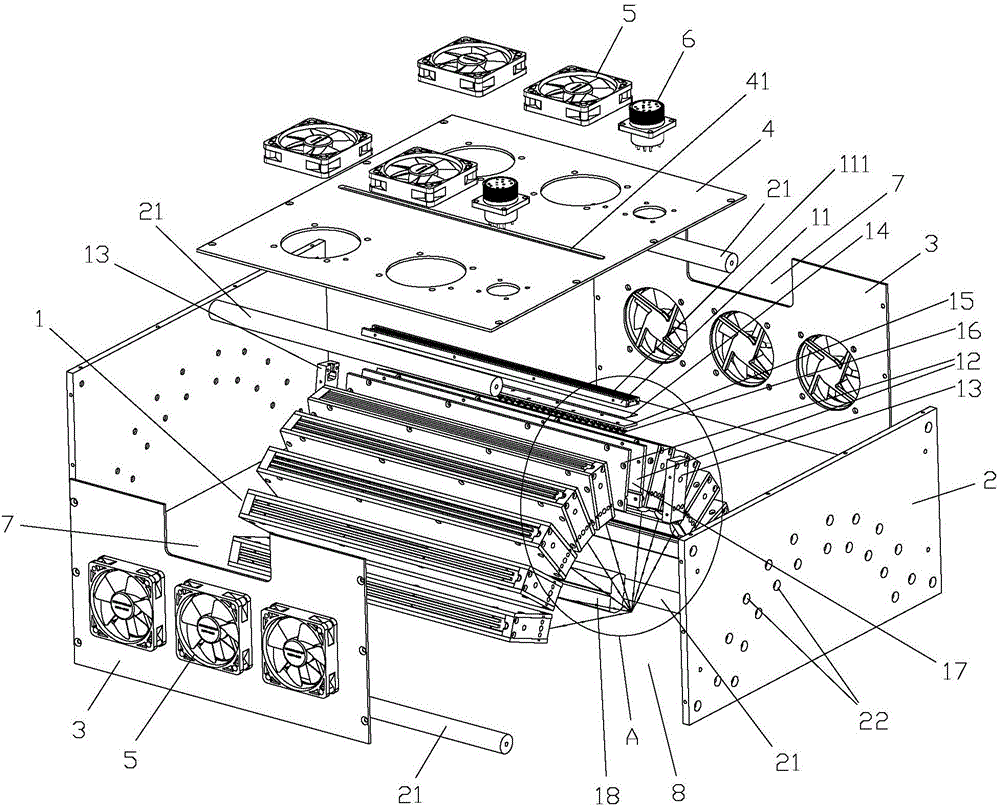

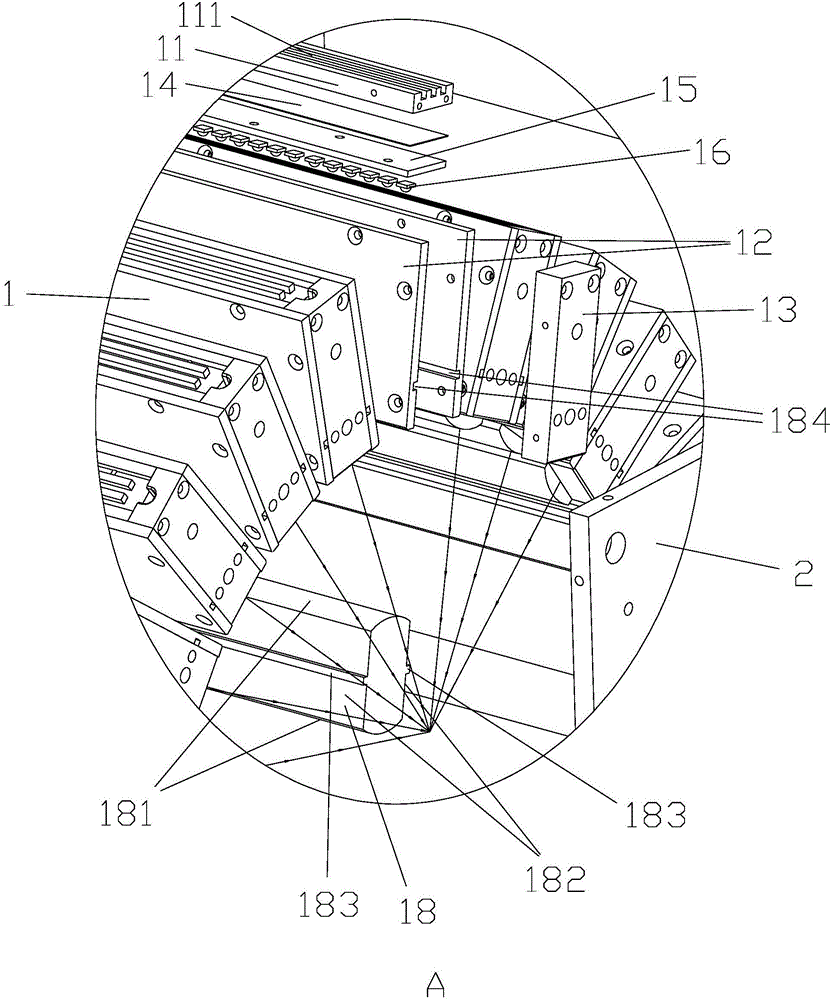

Multi-angle line light source used for detection

InactiveCN106124518AGood spotlight effectStrong lightOptically investigating flaws/contaminationCondensing lensPrinted circuit board

The invention discloses a multi-angle line light source for detection, which comprises a plurality of strip line light sources, line light fixing plates arranged at both ends of the strip line light source for fixing, and fan fixing plates arranged on both sides of the line light fixing plate 1. A cover plate is provided on the top of the line light fixing plate. There are cooling fans on the fan fixing plate and the cover plate. The fan fixing plate and the line light fixing plate form a downward light-emitting gap. Both ends of the board, the base plate is attached with a heat dissipation silicone grease sheet, and the heat dissipation silicone grease sheet is attached to a PCB board. There are many high-power LED lamp beads on the PCB board. The inner cavity of the light source has a cylindrical condenser lens at the opening of the inner cavity of the line light source, the end plate is fixedly connected with the line light fixing plate, and the center line of the cover plate has a camera detection through hole. The invention has better light concentrating effect, stronger light and higher brightness, and is more conducive to the lighting detection of various defects of mobile phone screens and the surface of PCB boards, etc., and has better detection effect.

Owner:DONGGUAN LOTS AUTOMATION

Mask inspection with fourier filtering and image compare

InactiveUS9041903B2Easy defect detectionHigh detection sensitivityUsing optical meansOriginals for photomechanical treatmentMask inspectionImage resolution

A mask inspection system with Fourier filtering and image compare can include a first detector, a dynamic Fourier filter, a controller, and a second detector. The first detector can be located at a Fourier plane of the inspection system and can detect a first portion of patterned light produced by an area of a mask. The dynamic Fourier filter can be controlled by the controller based on the detected first portion of the patterned light. The second detector can detect a second portion of the patterned light produced by the section of the mask and transmitted through the dynamic Fourier filter. Further, the mask inspection system can include a data analysis device to compare the second portion of patterned light with another patterned light. Consequently, the mask inspection system is able to detect any possible defects on the area of the mask more accurately and with higher resolution.

Owner:ASML HLDG NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com