Eddy current detection method using finger touch as supplementary means and device thereof

A technology of eddy current detection and auxiliary means, applied in the direction of material magnetic variables, etc., can solve the problems of easy missing detection, inconvenient sensor detection, difficult operation of R angle transition position detection, etc., to achieve convenient movement, improve accuracy and judgment ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, an eddy current detection method using finger touch as an auxiliary means of the present invention includes:

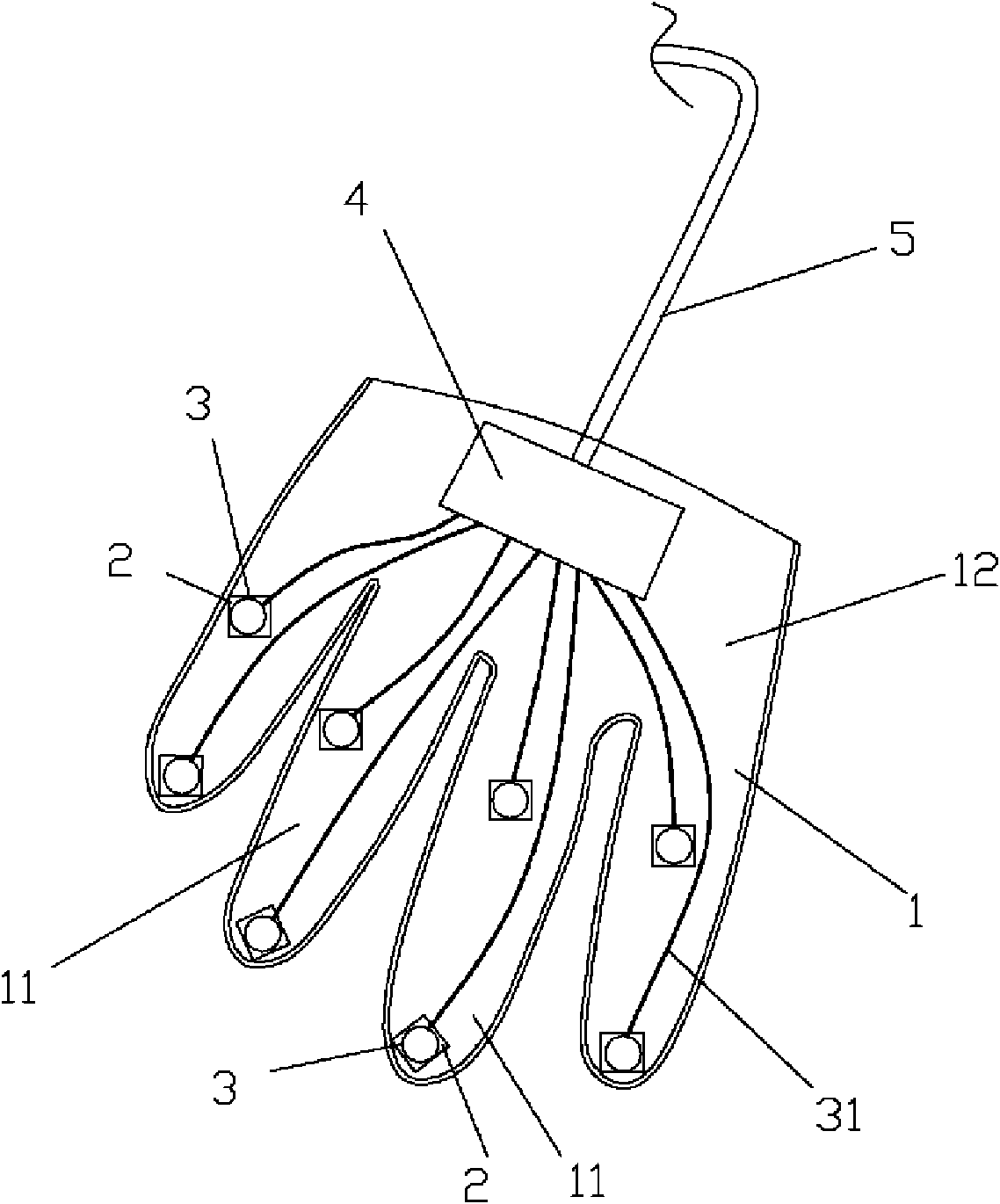

[0033] Wind the coil capable of eddy current detection into a pancake shape or fabricate it on a flexible circuit board in the form of a printed circuit, and connect the outlet end of the coil to the eddy current detector;

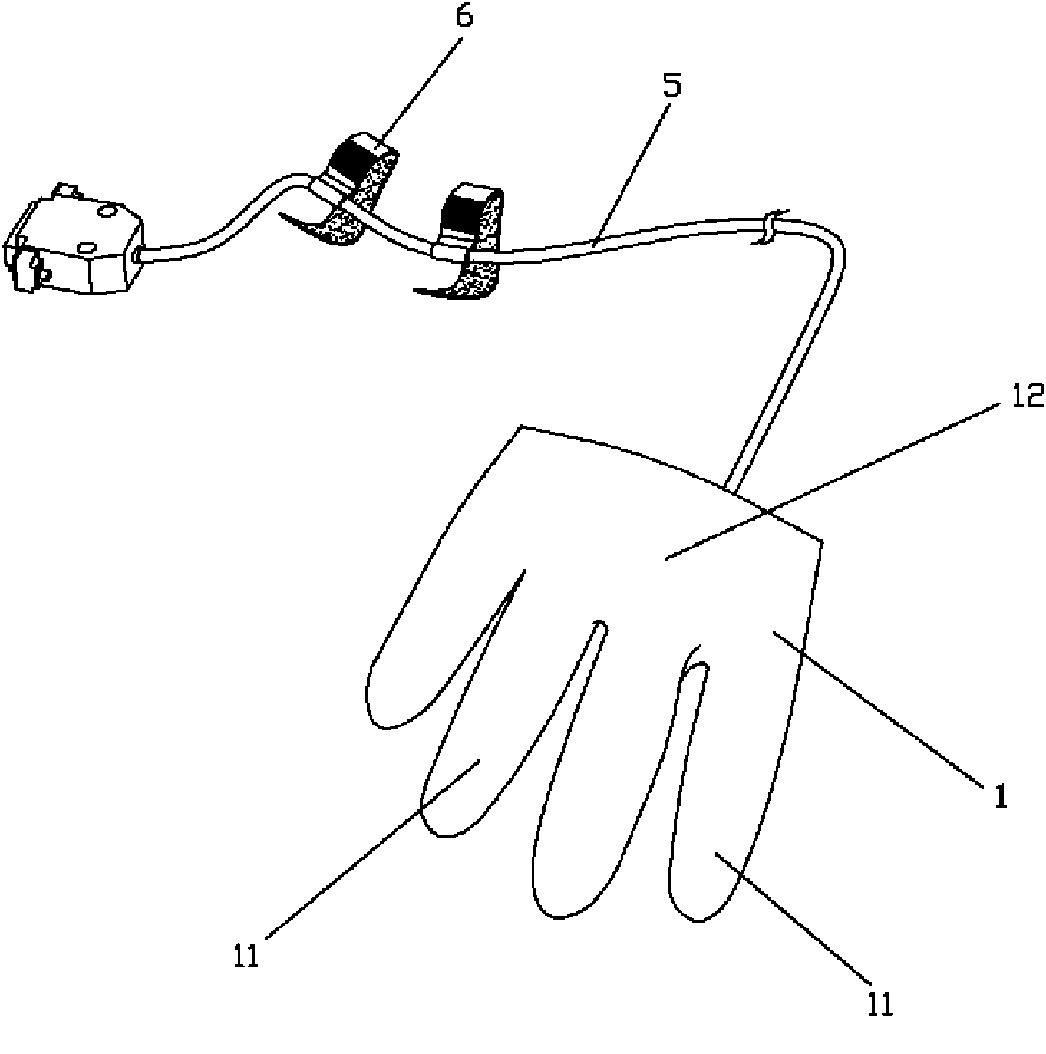

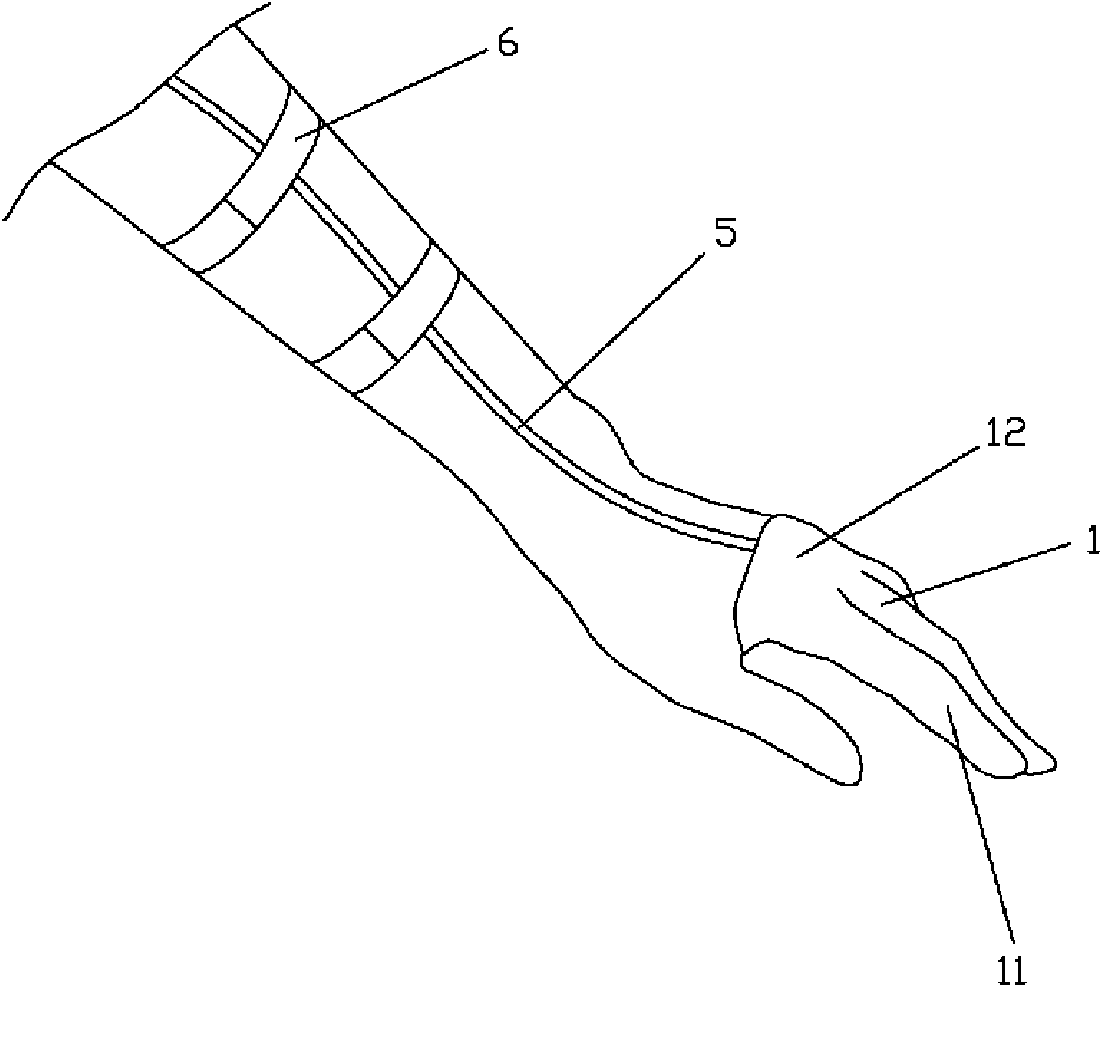

[0034] Install the pancake-shaped coil or the flexible circuit board printed with the coil on the finger surface of the operator;

[0035] Touch the surface of the metal structure with the operator’s finger equipped with a pancake-shaped coil or flexible circuit board;

[0036] The computer system of the eddy current detector sends out a preset excitation signal, the eddy current induction signal generated by the excitation signal on the metal structure is picked up by the coil, and the picked up eddy current induction signal is output to the eddy current detector;

[0037] In the process of picking up the signal by the coil, use ...

Embodiment 2

[0050] Example two, see Figure 4 As shown, an eddy current detection method using finger touch as an auxiliary means of the present invention is different from the first embodiment in that the device used to implement the eddy current detection method using finger touch as an auxiliary means is different. It is also a glove type structure, but the soft finger cuff 1 of the device is two single-finger cuff structures 11 that can be put on two fingers of the human body. Each single finger cuff structure 11 is equipped with a flexible circuit board (in the figure) (Not shown), of course, it can also be a plurality of flexible circuit boards, each flexible circuit board is provided with a spiral printed coil with a one-turn structure or a multi-turn structure, and the lead of each spiral printed coil passes through a wire and a soft Connect the adapter outside the finger cuff.

[0051] Of course, the soft finger cuff can also be a single finger cuff structure that can be placed on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com