Solar silicon wafer defect detecting system and method

A defect detection and silicon wafer technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as limited accuracy of detection results, unaccurate calculation of detection data, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: A solar silicon wafer defect detection system.

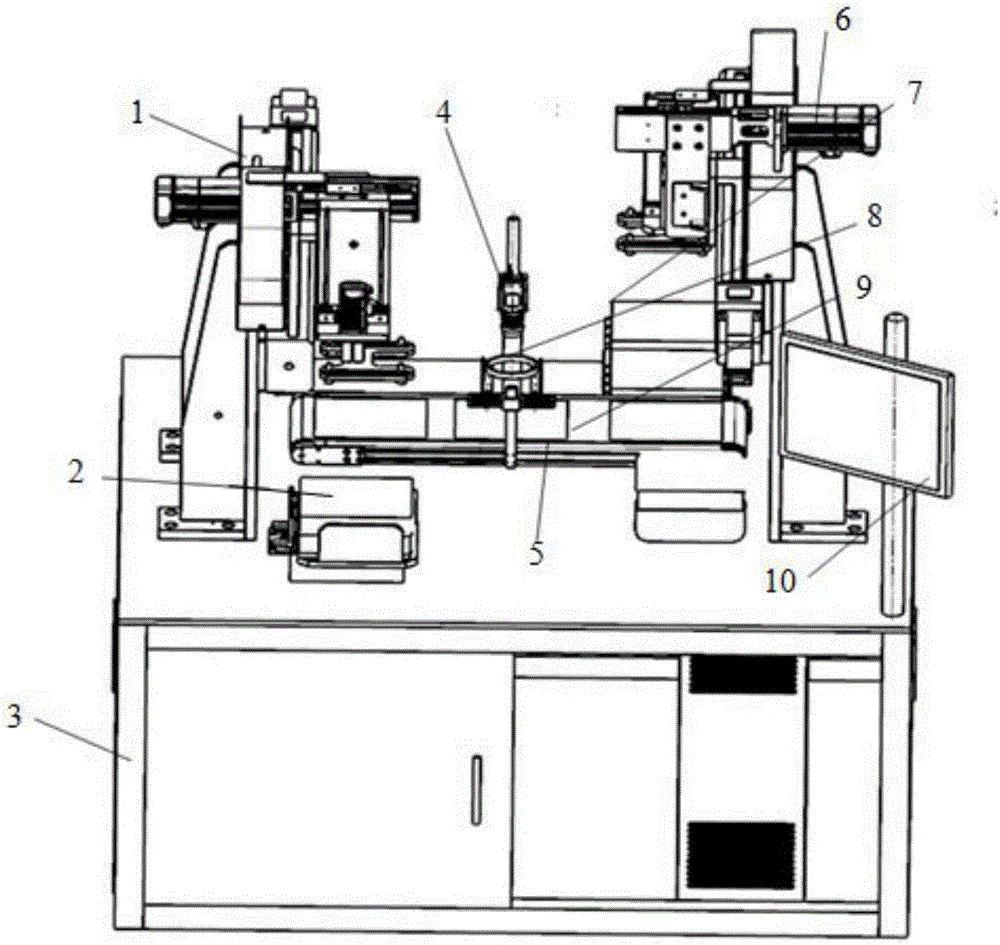

[0081] refer to figure 1 Shown, a kind of solar silicon wafer defect detection system comprises: visual image acquisition system, image processing system and sorting system; Described visual image acquisition system is used for automatically collecting the image of silicon wafer on silicon wafer automatic production line, described The image processing system is used to analyze the collected silicon wafer image, and automatically identify the silicon wafer image, and send the identified signal to the sorting system, and the sorting system is used to execute the signal of the image processing system to sort out the defective Silicon wafers with the same defects are sorted into the same sorting box to achieve precise sorting of silicon wafers.

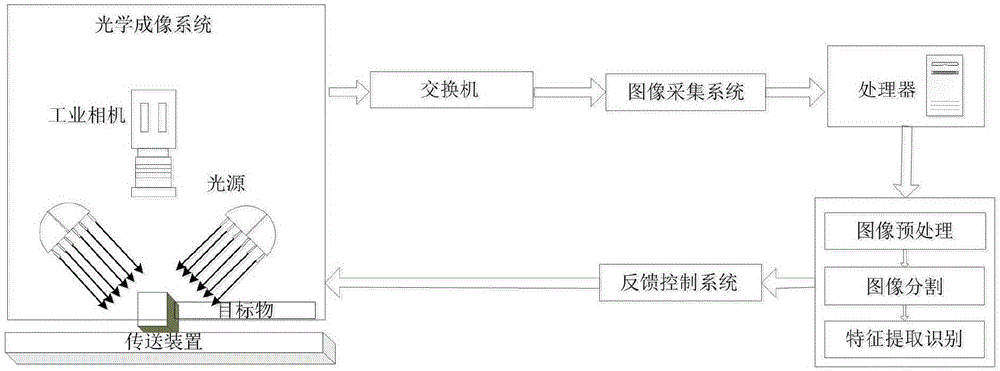

[0082] refer to figure 1 and figure 2 As shown, the visual image acquisition system includes a loading robot arm 1, a material tank 2, a material table 3, an indus...

Embodiment 2

[0084] Embodiment 2: A solar silicon wafer defect detection method.

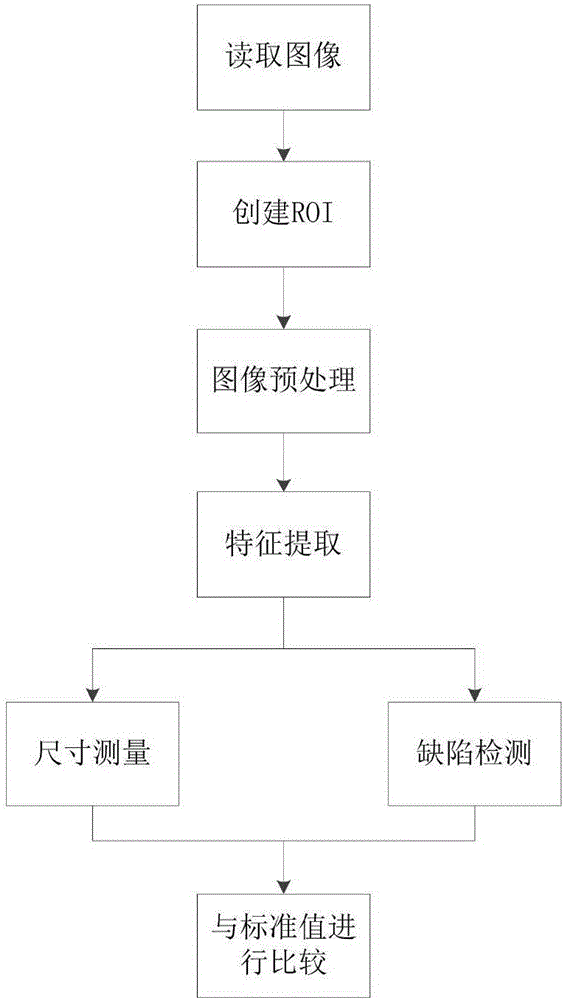

[0085] refer to image 3 As shown, a detection method carried out based on the solar silicon wafer defect detection system provided by the present invention specifically includes the following steps:

[0086] S1. The loading robot arm 1 grabs the silicon wafer 5 from the material tank 2 and puts it on the conveyor belt 9, and the motor controls the conveyor belt 9 to send the silicon wafer 5 to be detected to the detection station directly below the industrial camera 4;

[0087] S2. The PLC controls the industrial camera 4 to take pictures according to the in-place signal, and the lighting source 8 flickers to obtain the silicon wafer image;

[0088] S3. For the obtained silicon wafer image, the image processing software automatically measures the geometric feature value of the silicon wafer, and the silicon wafer geometric feature value includes the length and width of the silicon wafer; compare the geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com