Industrial equipment health state evaluation method

A technology for health status and industrial equipment, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as reducing the efficiency of human-computer interaction, failing to understand the overall process status in time, and restricting software development, so as to improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

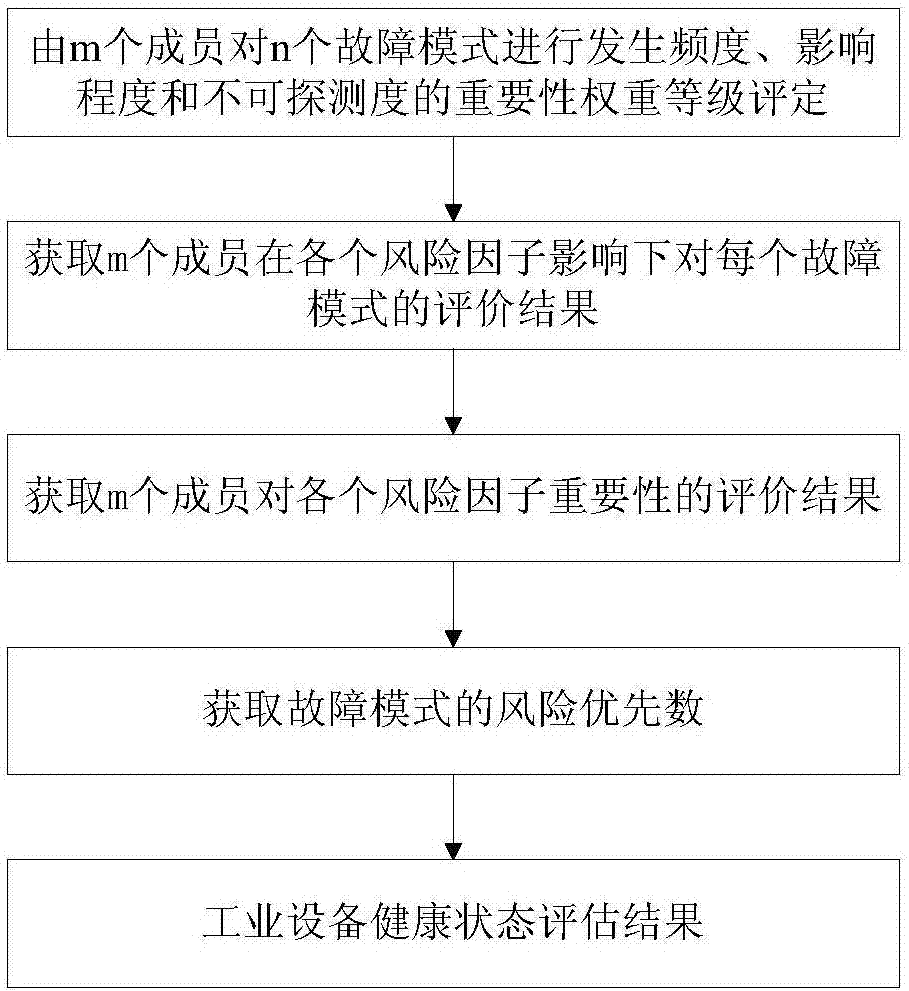

[0034] A method for evaluating the health status of industrial equipment described in this embodiment includes:

[0035] Step 1, FM for n failure modes by m members i (i=1,2,...,n) grade evaluation of occurrence frequency, impact degree and undetectability;

[0036] Step 2, FM for n failure modes by m members i (i=1,2,...,n) evaluate the importance weight grades of frequency of occurrence, degree of influence and degree of undetectability;

[0037] As a preferred method of this step, the specific schemes of steps 1 and 2 include:

[0038] m members form an FMEA team and specify the meanings of various symbols.

[0039] Before the actual calculation of the hazard of the failure mode, it is necessary to abstract the analysis process and calculation method in order to expand the scope of application of this method as much as possible.

[0040] First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com