Subzero temperature-gust quick semi-unfreezing process of frozen platy meat products

A semi-thawing and meat technology, which is applied in the direction of freezing/cooling to preserve meat/fish, etc., which can solve the problems of insufficient thawing or excessive thawing that are unfavorable to the batching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

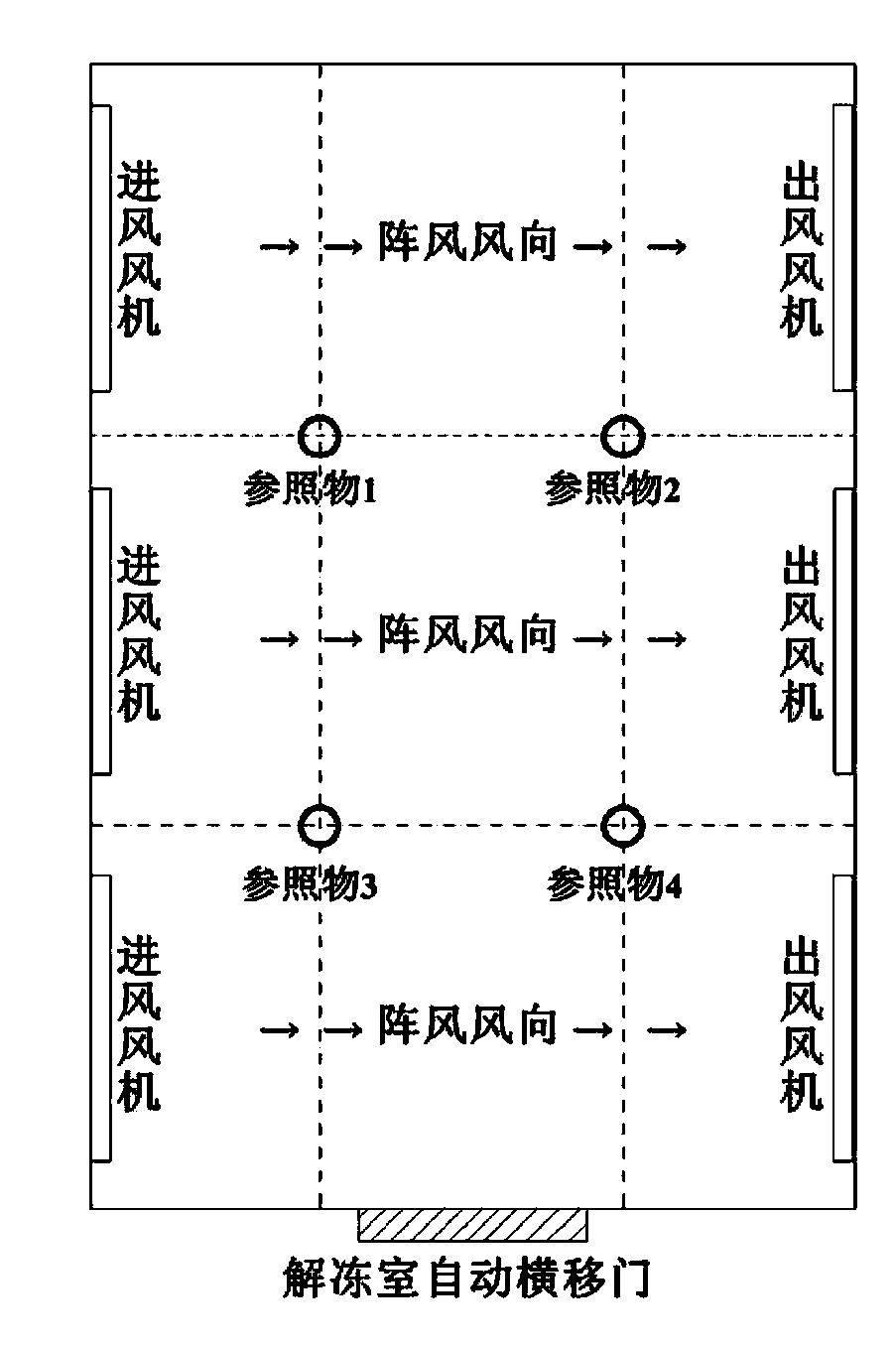

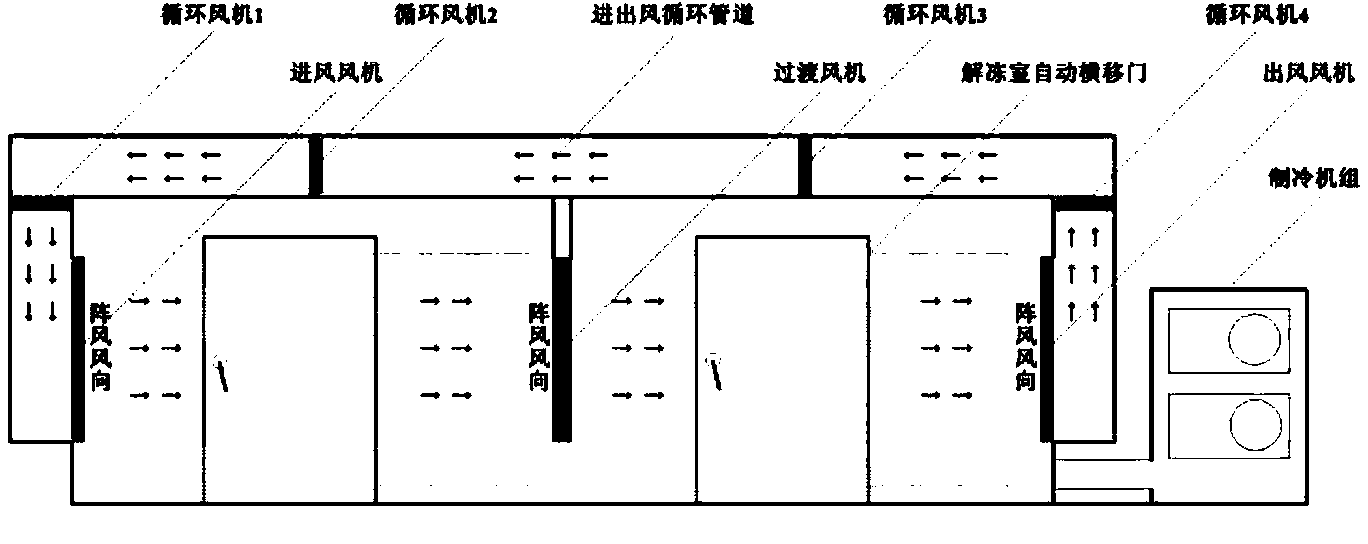

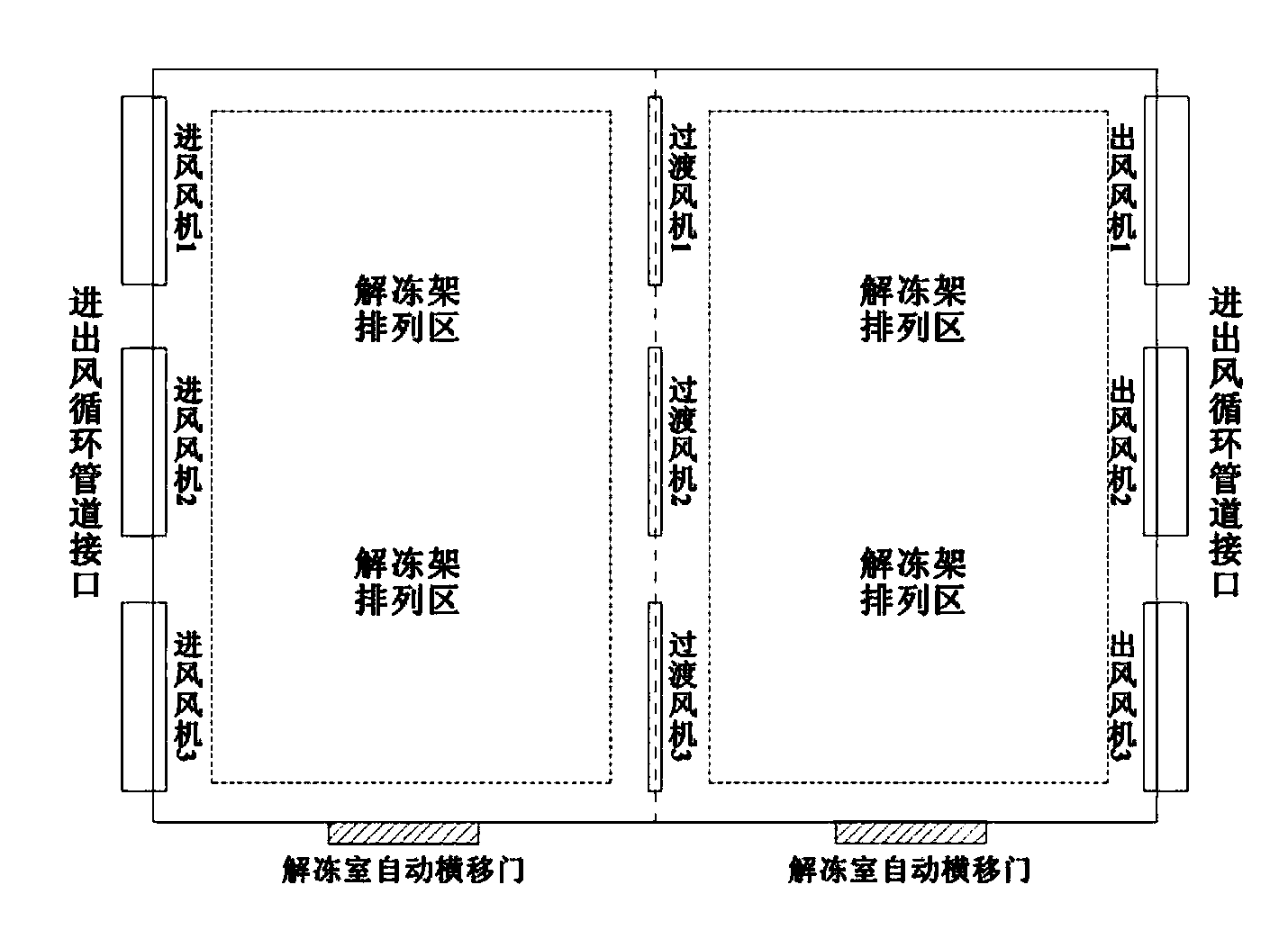

Embodiment 1

[0044] The design of the infrastructure site and fan installation of the negative temperature-gust fast semi-thawing chamber is attached Figure 3A , 3B As shown, 8 tons of frozen minced surimi are removed from the outer carton, and put on the shelves at a loading capacity of 2 boards / layer, and the thawing rack loaded with frozen surimi is pushed into the thawing room pre-cooled to -6°C for arrangement. According to attached figure 1 Select the "frozen product temperature reference object" at the position shown, and place the center / surface temperature probes in the middle of the 2 plates of frozen surimi and on the surface of the frozen surimi. Start the negative temperature-gust fast semi-thawing process control program (the average surface temperature of the "frozen product temperature reference object" reaches -6°C for the first time, then turn off the fan, and then start the fan after the average surface temperature drops to -8°C, and promote thawing through the gust o...

Embodiment 2

[0063] The design of the infrastructure site and fan installation of the negative temperature-gust fast semi-thawing chamber is attached Figure 3A , 3B As shown, 12 tons of frozen minced surimi are removed from the outer carton, and put on the shelves with a loading capacity of 2 boards / layer, and the thawing racks loaded with frozen surimi are pushed into the thawing room pre-cooled to -6°C for arrangement. All the other negative temperature-gust semi-thawing processes are unchanged with reference to Example 1. After the frozen surimi was thawed by negative temperature and gust of wind for 2.7 hours, the actual measurement of the temperature probe showed that the center temperature of the "frozen product temperature reference object" was -8°C, and the surface temperature was -7.2°C, which reached the half-thawing requirement, and the fan was automatically turned off. In order to confirm the overall thawing state of the frozen surimi in the thawing chamber, 15 plates of froz...

Embodiment 3

[0066] The design of the infrastructure site and fan installation of the negative temperature-gust fast semi-thawing chamber is attached Figure 3A , 3B As shown, 8 tons of frozen chicken breasts are removed from the outer cartons, and put on the shelves with a loading capacity of 2 boards / layer (the smooth sides fit together), and the thawing rack loaded with frozen chicken breasts is pushed into the thawing chamber pre-cooled to -6°C to arrange. All the other negative temperature-gust semi-thawing processes are unchanged with reference to Example 1. After the frozen chicken breast was thawed by negative temperature and gust of wind for 2.5 hours, the actual measurement of the temperature probe showed that the center temperature of the "frozen product temperature reference object" was -8°C, and the surface temperature was -7.2°C, which reached the half-thawing requirement, and the fan was automatically turned off. In order to confirm the overall thawing state of the frozen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com