Patents

Literature

38results about How to "Does not significantly increase production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

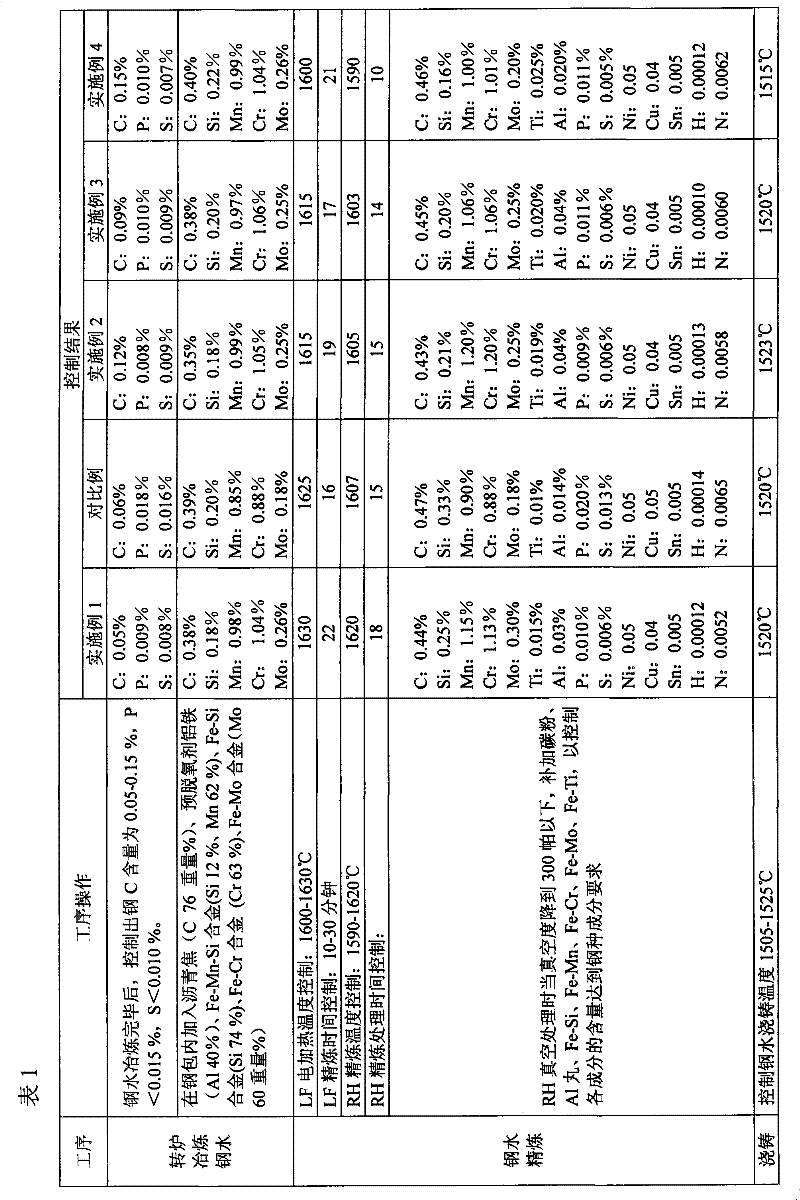

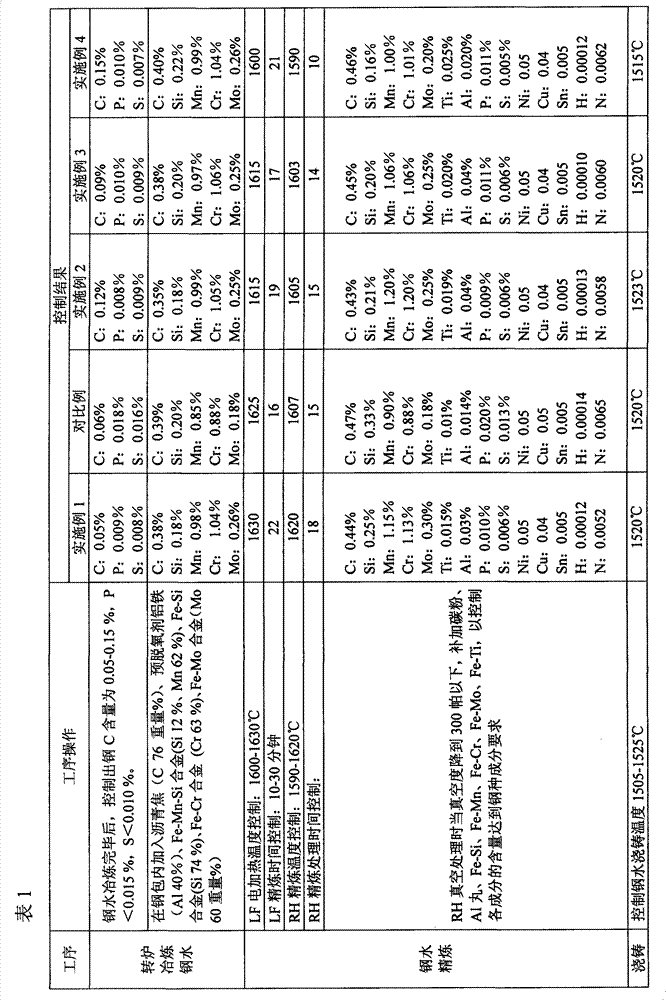

A kind of drill collar steel and its preparation method

The invention relates to drill collar steel and a preparation method thereof. The drill collar steel comprises the following components based on the total weight of drill collar steel: 0.41-0.47wt% of C, 0.15-0.3wt% of Si, 0.95-1.2wt% of Mn, 0.95-1.2wt% of Cr, 0.15-0.3wt% of Mo, 0.02-0.04wt% of Al, 0.01-0.03wt% of Ti, less than or equal to 0.02wt% of P, less than or equal to 0.015wt% of S, less than or equal to 0.2wt% of Ni, less than or equal to 0.2wt% of Cu, less than or equal to 0.05wt% of Sn, less than or equal to 0.0002 wt% of H, less than or equal to 0.007wt% of N and the balance of Fe;and T[O] is less than or equal to 0.0020wt%, and the A,B,C and D impurities are less than or equal to 1.5 levels. By using the preparation method, the problem that the strength of the drill collar steel is not matched with plastic toughness is solved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

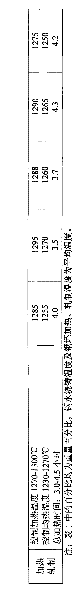

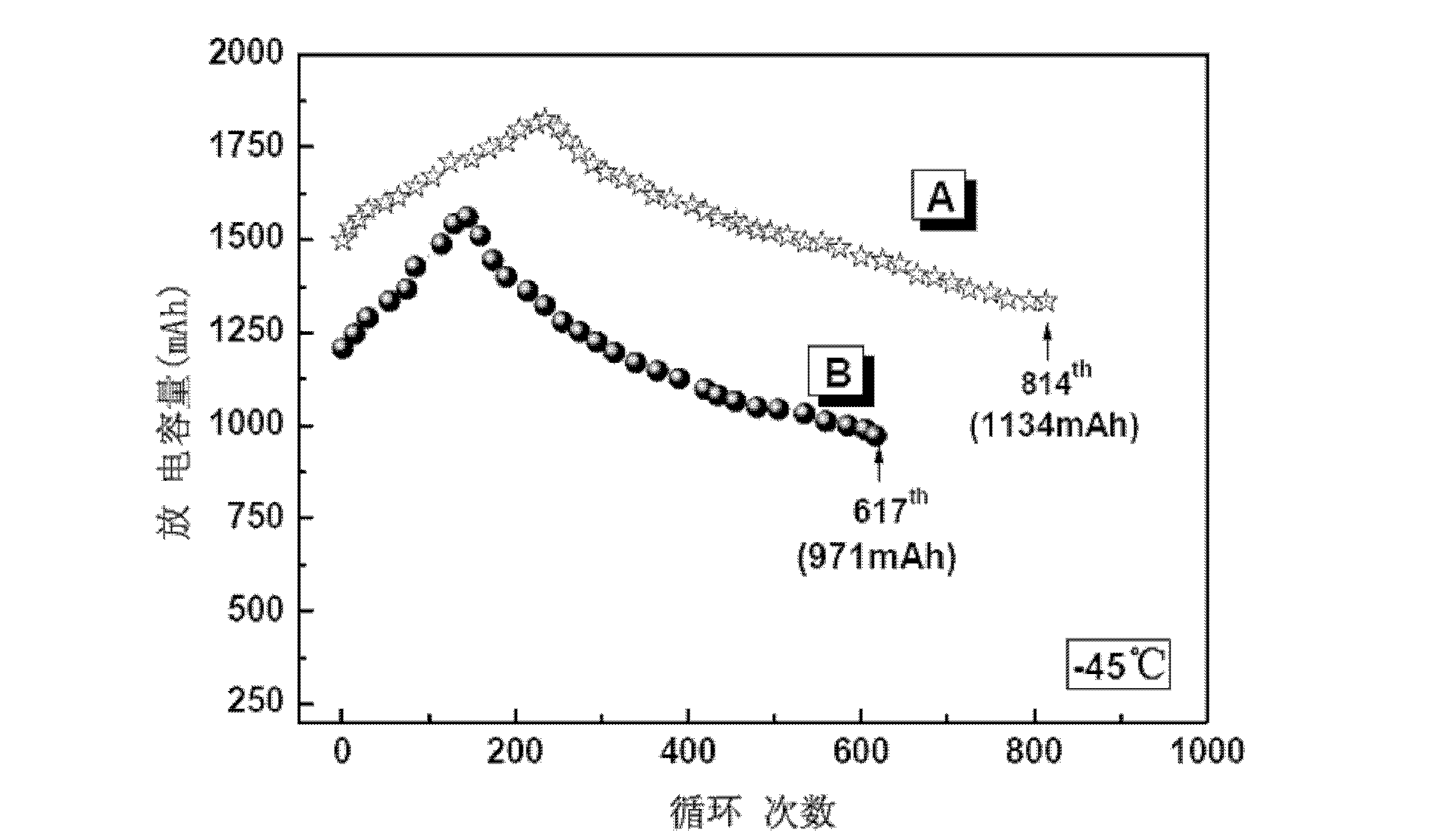

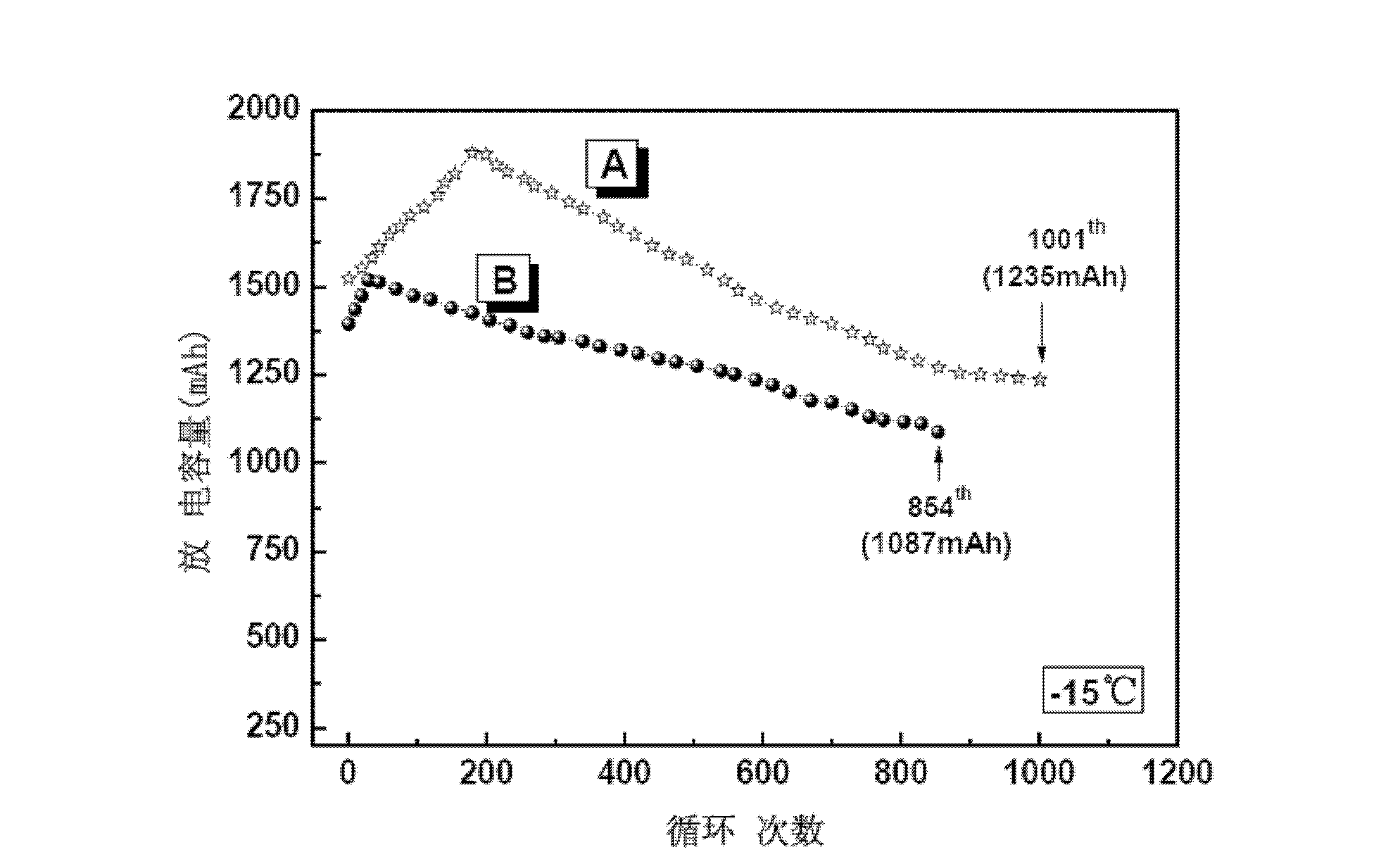

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

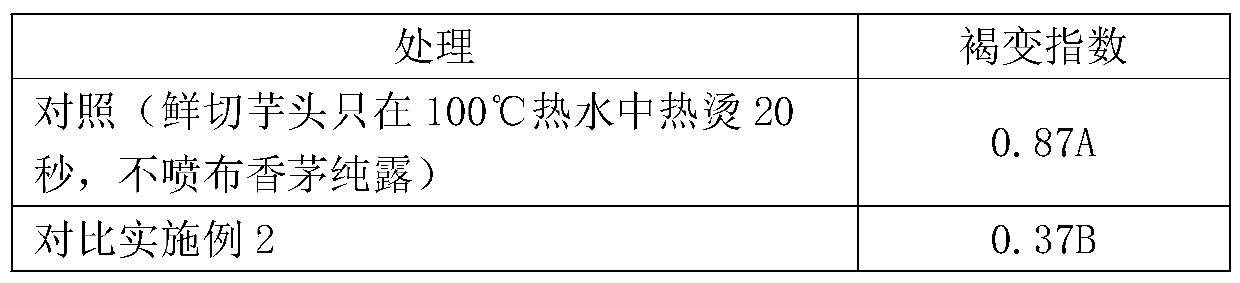

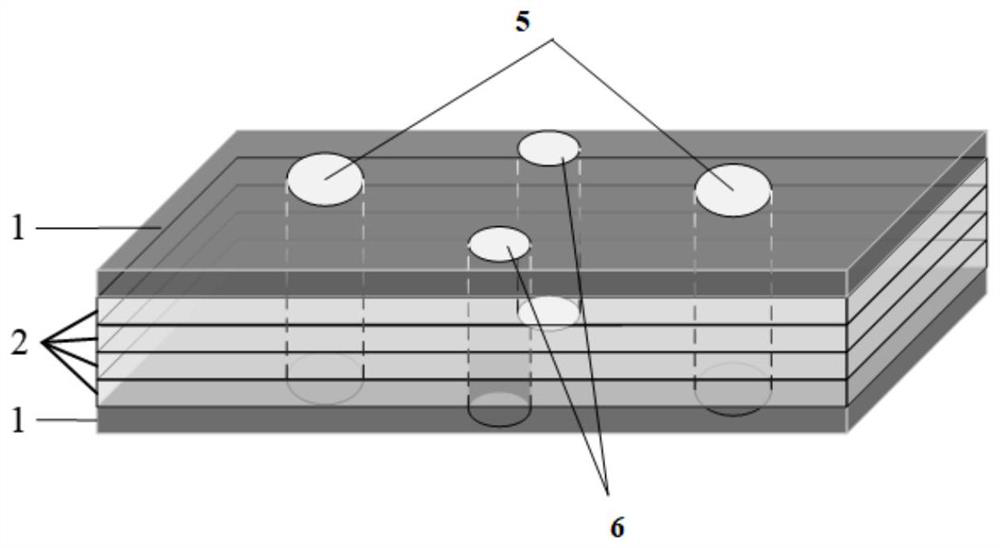

Production process of ultrathin aluminum nitride ceramic substrate

ActiveCN112876260AHigh degree of densificationDoes not significantly increase production costsAl powderSlurry

The invention relates to the technical field of aluminum nitride ceramics, and provides a production process of an ultrathin aluminum nitride ceramic substrate. The process comprises the following steps: (1) uniformly mixing aluminum nitride powder, a composite sintering aid, a UV monomer, a reactive diluent, a photoinitiator, a dispersant and a silane coupling agent to obtain ceramic slurry; (2) subjecting the ceramic slurry to tape casting on a tape casting machine, initiating a polymerization reaction through ultraviolet radiation, subjecting the slurry to in-situ curing molding to obtain a ceramic green body, and then cutting the ceramic green body into required shapes and sizes through a mold to obtain ceramic green sheets; (3) laminating the ceramic green sheets, and putting the laminated ceramic green sheets into a glue discharging furnace for glue discharging; and (4) carrying out hot pressed sintering on the ceramic blank sheet after glue discharging under the protection of nitrogen atmosphere, cooling to room temperature after the sintering, and then carrying out powder removal and polishing processes to obtain the ultrathin aluminum nitride ceramic substrate. The prepared aluminum nitride ceramic substrate is ultrathin, good in thermal conductivity and high in bending strength.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

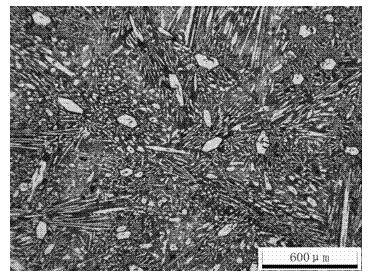

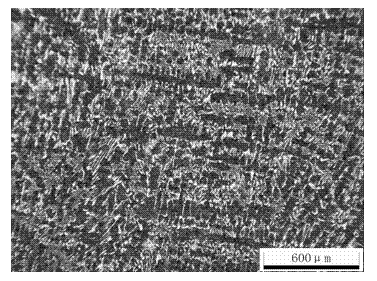

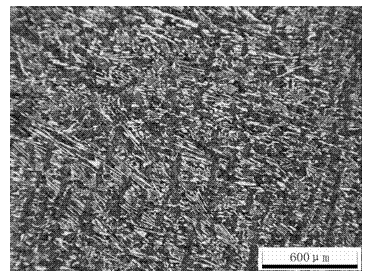

High wear resistance high chromium cast iron used for bimetallic composite tube and preparation method thereof

The invention discloses a high wear resistance high chromium cast iron used for a bimetallic composite tube and a preparation method thereof. The high wear resistance high chromium cast iron comprises the following chemical components by weight percentage: 2.0-3.5% of C, 1.0-3.0% of Si, 0.5-1.5% of Mn, less than or equal to 0.10% of P, less than or equal to 0.05% of S, 9.0-14.0% of Cr, 0.10% of 1.0% of V, 0.10-0.30% of Ti, and the remains are Fe and ineluctable impurities. The high chromium cast iron is based on V and Ti alloyage improvement, tissue is refined, and a hard carbide is precipitated, furthermore high wear resistance is realized; by adding a few of V and Ti elements and properly adjusting the Si content, tissue state of the high chromium cast iron can be obviously improved, excellent comprehensive mechanical property can be obtained, and impact toughness and wear resistance are obviously increased. The method has the advantages of simple process and strong operationality, compared with a composite tube lined high chromium cast iron prepared by the current technology, impact toughness is better, hardness is high, and abrasion resistance performance is greatly increased.

Owner:TANGSHAN COLLEGE

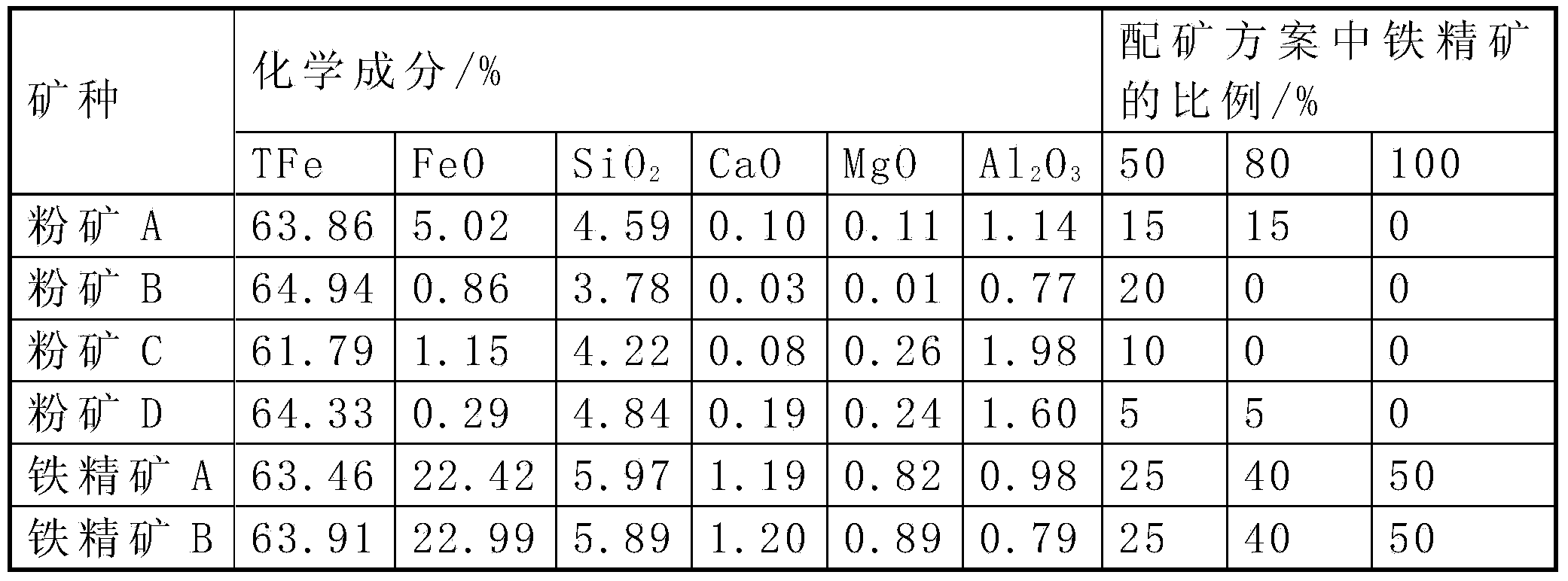

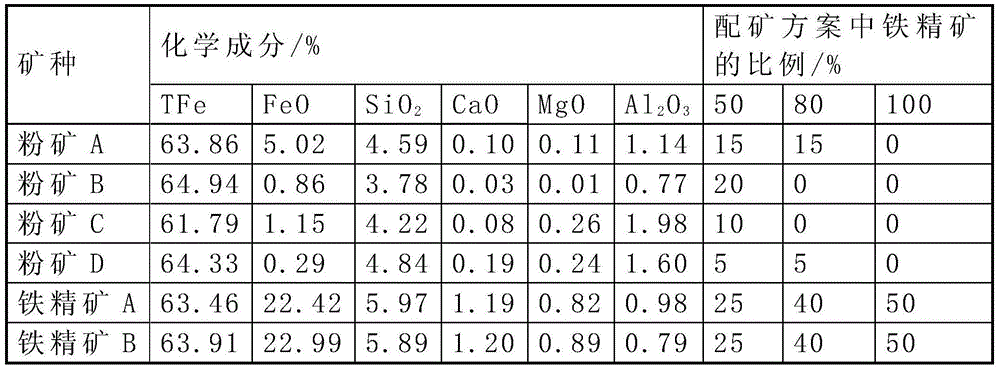

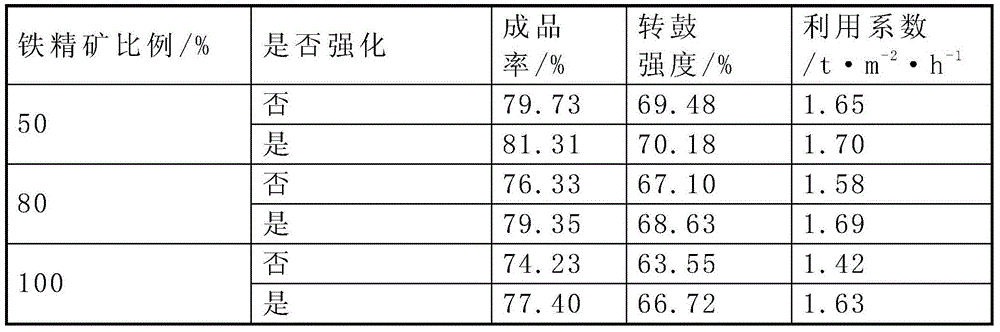

Method for strengthening sintering of high-proportion iron ore concentrate

The invention discloses a method for strengthening sintering of high-proportion iron ore concentrate. The sintering raw material is divided into two materials and then palletized. The first material comprises a part of the iron ore concentrate, quick lime and coke powder separated from the sintering raw material, first-stage palletizing is carried out on the first material, then second-stage palletizing is carried out on the first material and the second material, and the second material comprises a part of the iron ore concentrate, quick lime, coke powder, ore fines, lime stone, dolomite and return fines. By distributing the concentrate, the quick lime and the coke powder in the two materials reasonably, the purposes of palletizing strengthening and sintering mineralizing are achieved. For sintering of an iron mine with the iron ore concentrate accounting for 50-70 percent of the total mass of the iron core, after the strengthening technology is utilized, the utilization factor of a sintering machine is improved by 0.05-0.3t / (m<2>.h), the sinter yield is improved by 1-4 percent, the drum strength is improved by 0.5-4 percent, and the output index and the quality index of sintering of the high-proportion iron ore concentrate are improved.

Owner:CENT SOUTH UNIV

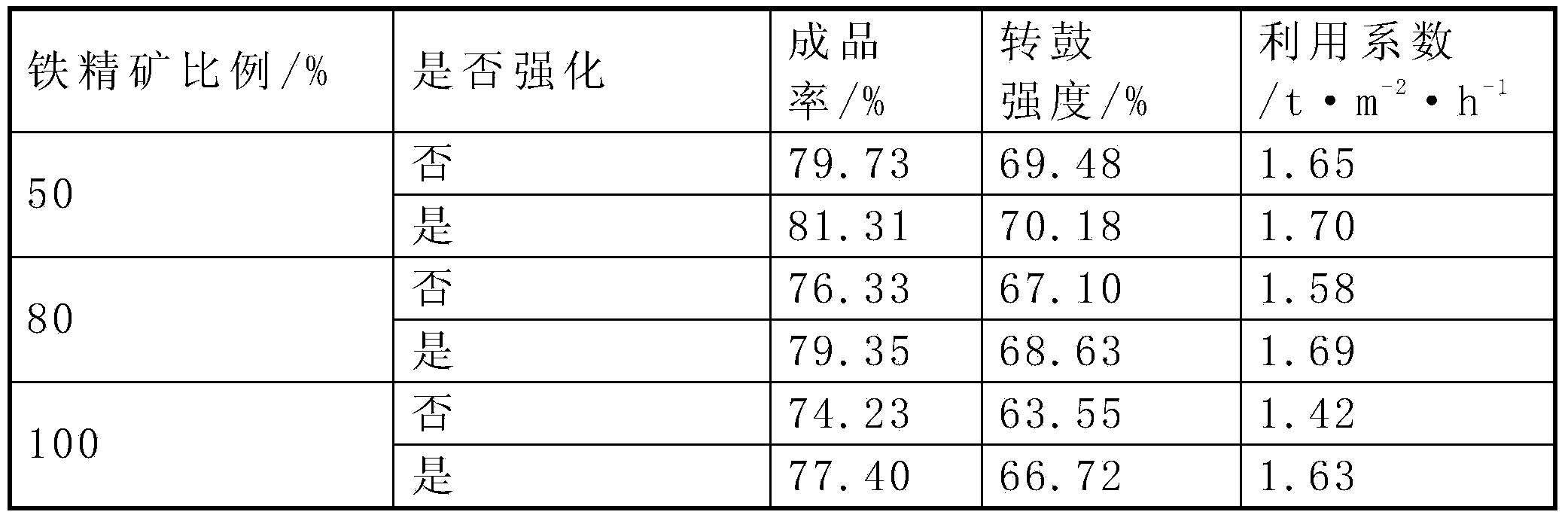

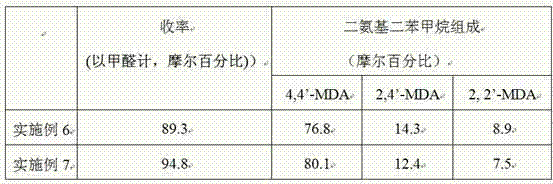

Solid super acid and application thereof in preparing 4,4'-diaminodiphenylmethane

InactiveCN102059129ALow costEasy to prepareMolecular sieve catalystsOrganic compound preparationPulverized fuel ashNuclear chemistry

The invention discloses a solid super acid and application thereof in preparing 4,4'-diaminodiphenylmethane. The solid super acid is prepared from waste pulverized fuel ash of a coal fired power plant. A preparation method of the solid super acid comprises the steps of: treating the pulverized fuel ash, treating screenings, dipping the screenings into in a 10mol / l sulfuric acid solution for 1-10 hours, carrying out suction filter, and sintering filter residues at 450-650 DEG C for 4 hours to obtain the solid super acid. The invention not only provides a new approach to the utilization of the waste pulverized fuel ash, but also solves the problem of environmental pollution caused by the pulverized fuel ash, and has important social and economic significance. Since the solid super acid provided by the invention has an extremely low cost and a simple preparation method, the prepared solid super acid has low price and good marketization prospect.

Owner:河南省华鼎高分子股份有限公司

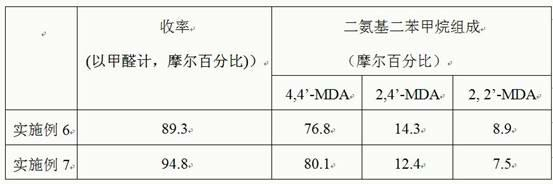

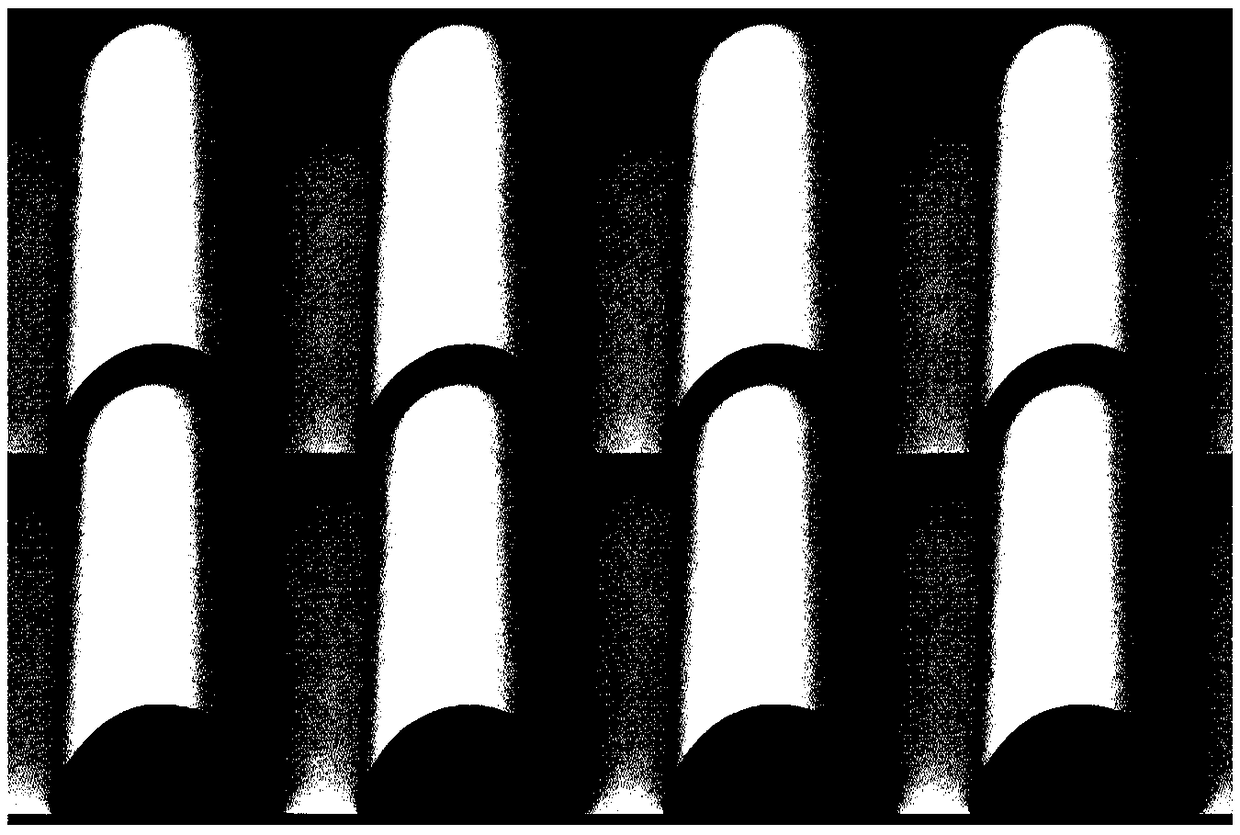

Wind turbine rotor blade

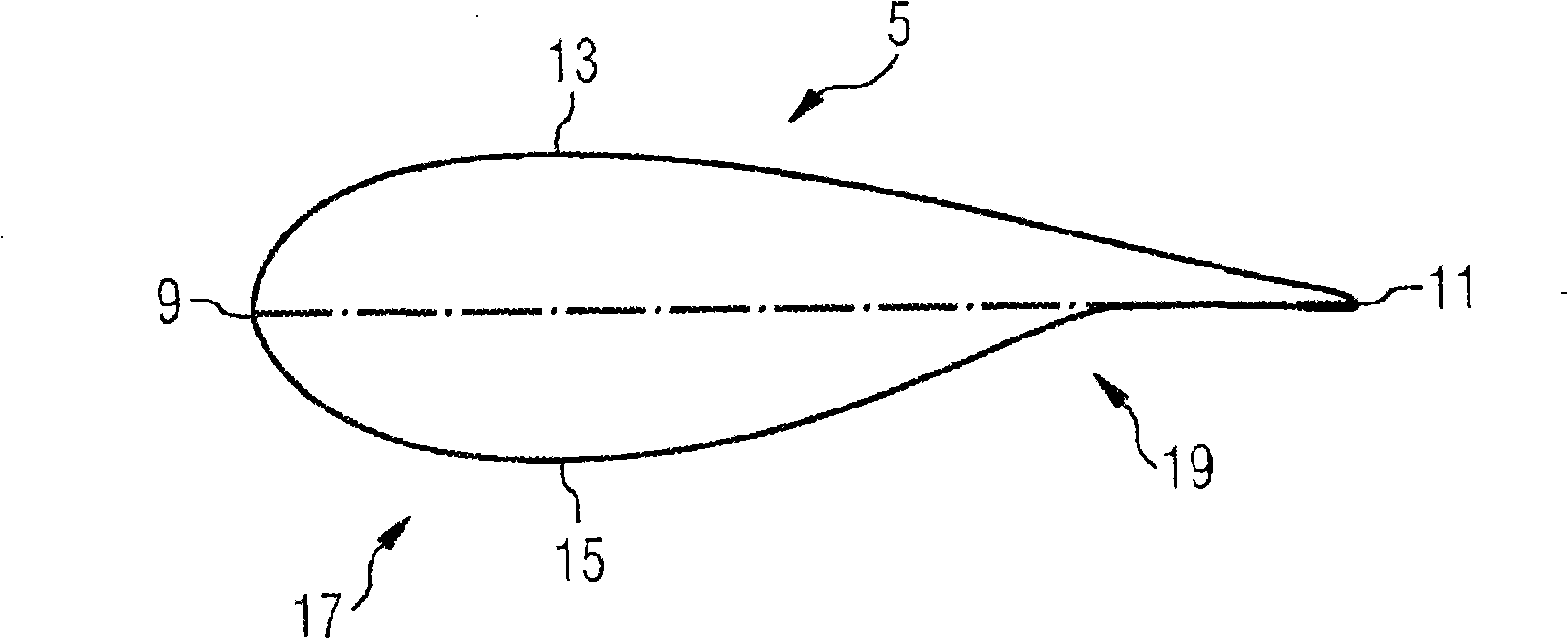

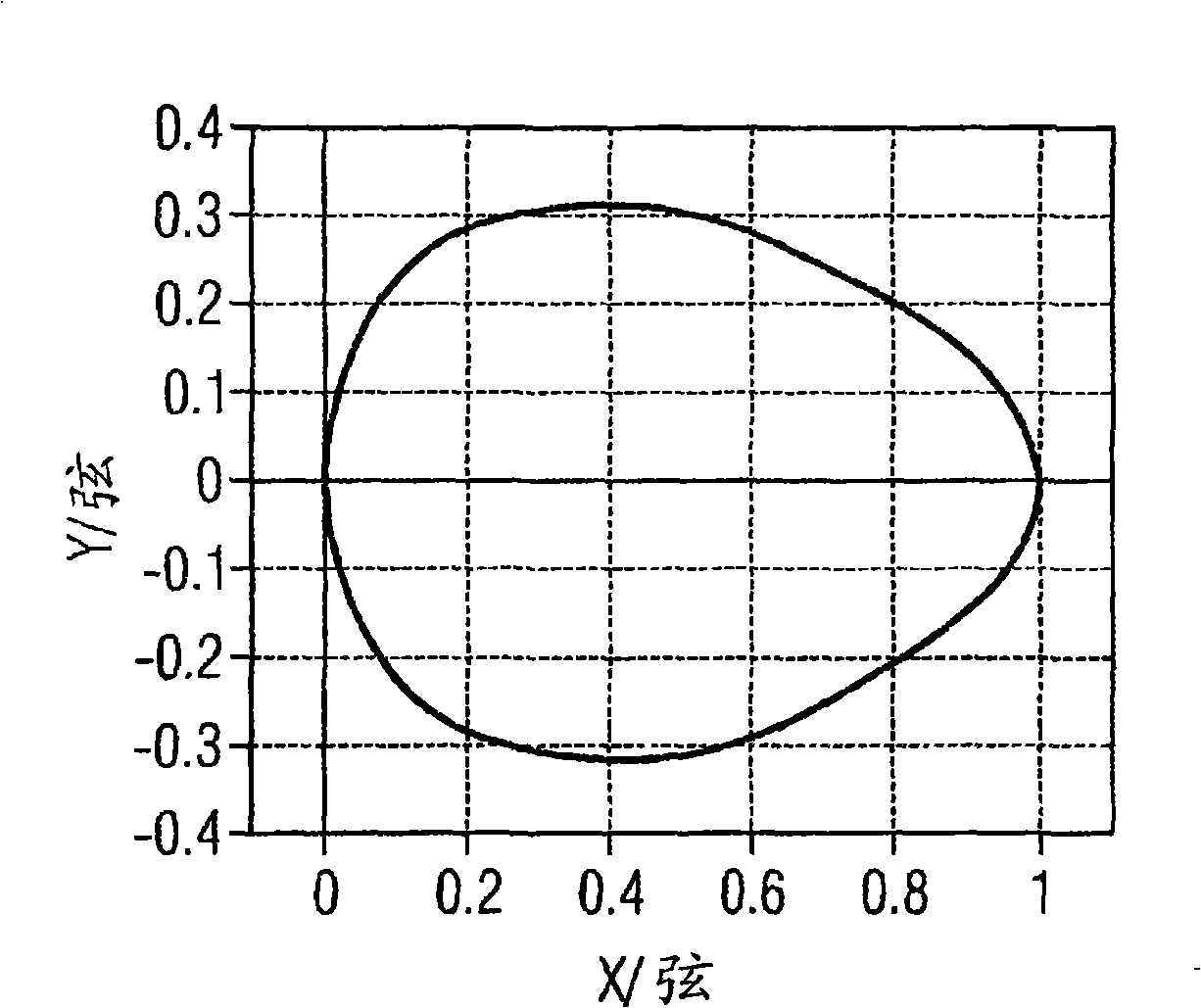

ActiveCN101405504AImproved aerodynamicsDoes not significantly increase the loadMachines/enginesEngine componentsEngineeringWind force

A wind turbine rotor blade (1) with a suction side (13) and a pressure side (15) is provided. It comprises a cylindrical root portion (3) an airfoil portion (5) defining the suction side (13) and the pressure side (15), and a transition portion (7) which is located between the airfoil portion (5) and the root portion (3). The transition portion (7) has a transition profile changing from the airfoil of the airfoil portion (5) to the cylindrical profile of the root portion (3). The leading section of the transition profile is cylindrical and the trailing section of the transition profile is elongated. In the rotor blade, the maximum chord length of the airfoil portion (5) is at least the maximum chord length of the transition portion (7). In addition, the transition profile comprises a section with a concave curvature (25) on the pressure side (15) of the rotor blade (1).

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

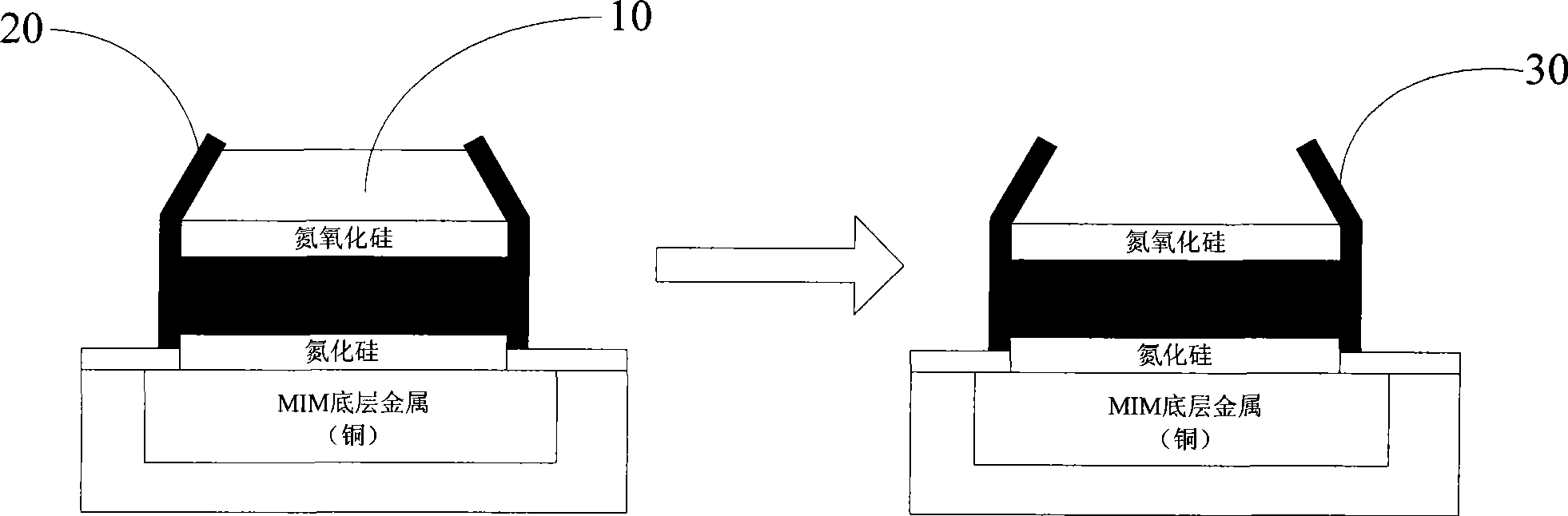

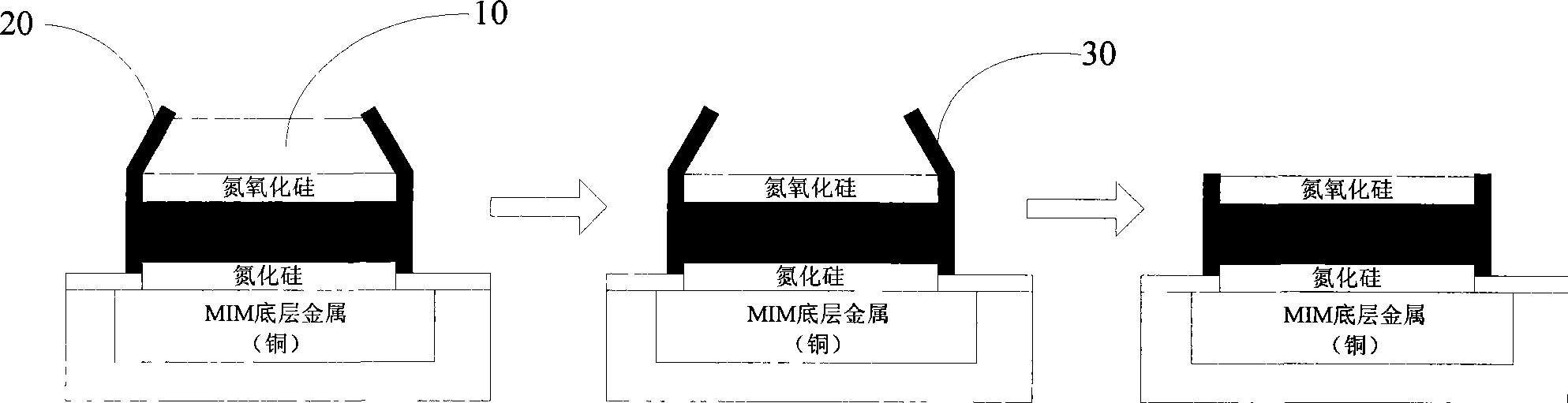

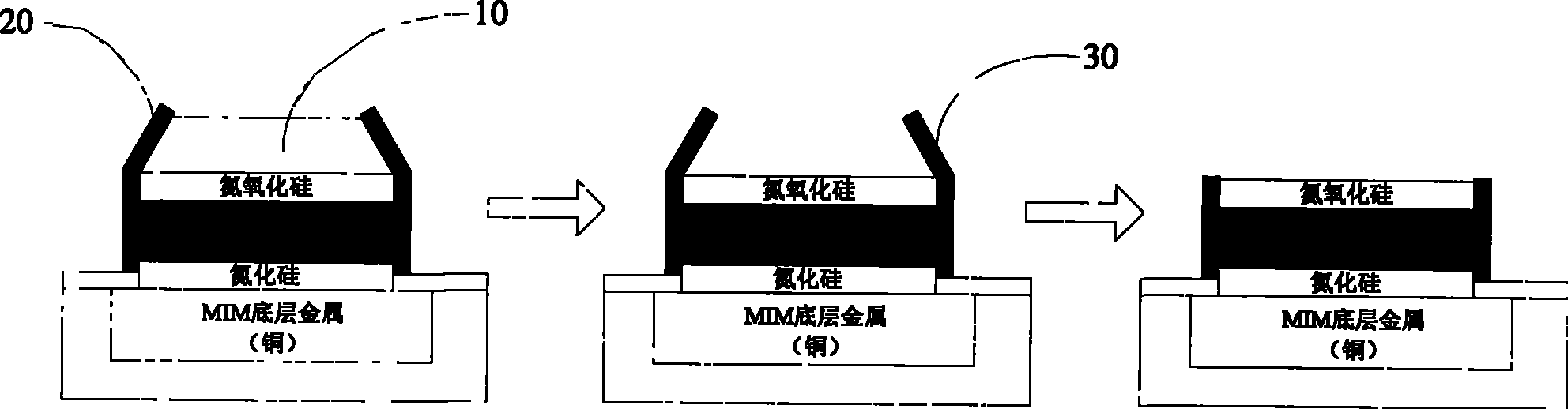

Method for eliminating residual polymer of etching procedure

InactiveCN101308764AEliminate Coronary DefectsDoes not significantly increase production costsSemiconductor/solid-state device manufacturingState of artPolymer science

The invention provides a method to remove residual polymer during etching process. Firstly, a wafer is processed with dry etching in a main etching chamber; then the anticorrosion protective film of the wafer is removed in a decoating chamber; finally, the wafer is again disposed into the main etching chamber for dry etching for the second time; in this way, the residual polymer in the etching process can be gotten rid of. Compared with prior art, the method described by the invention is easy to realize and can thoroughly remove the residual polymer and eliminate coronary defects without increasing production cost by a large margin.

Owner:SEMICON MFG INT (SHANGHAI) CORP

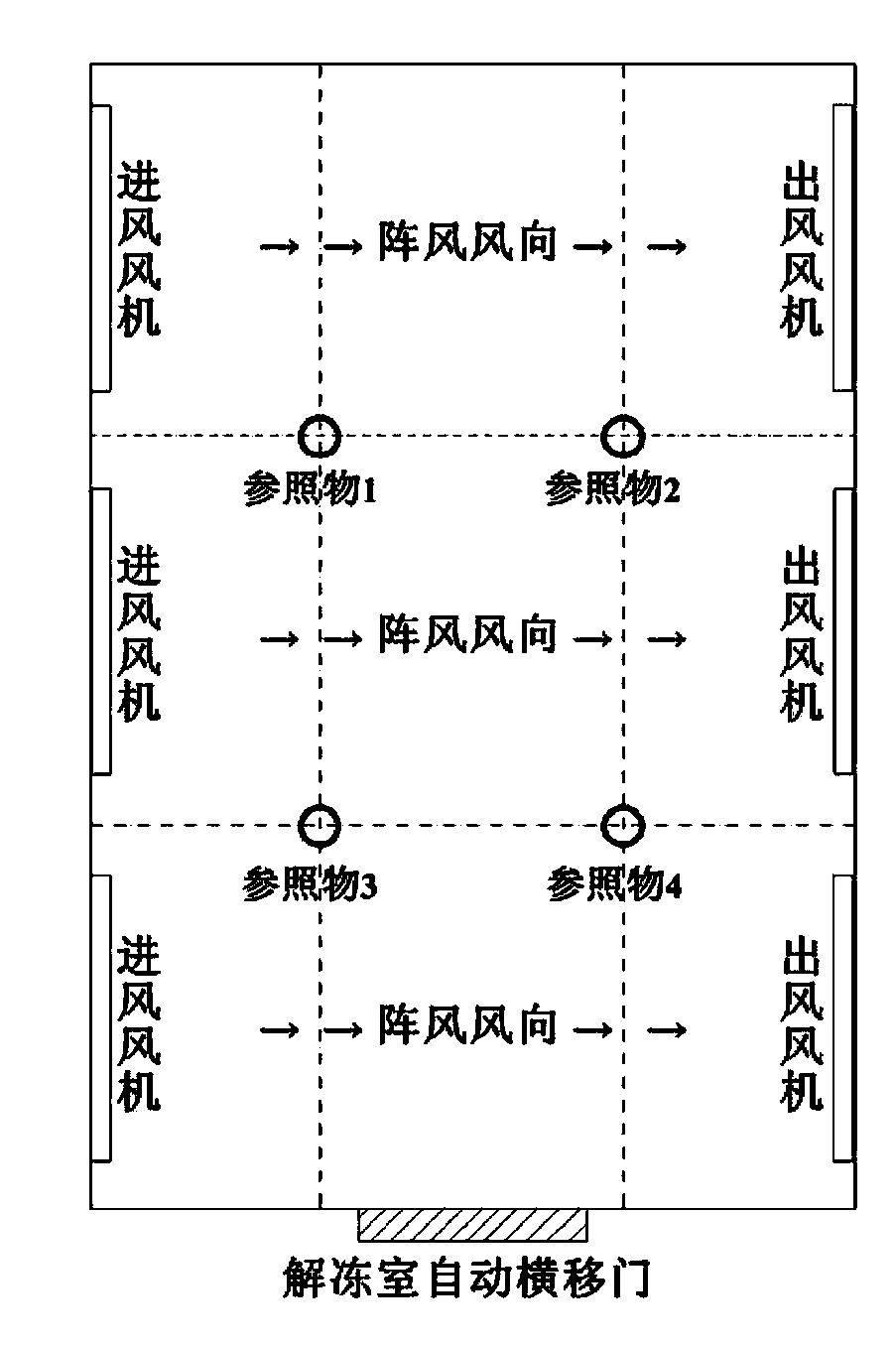

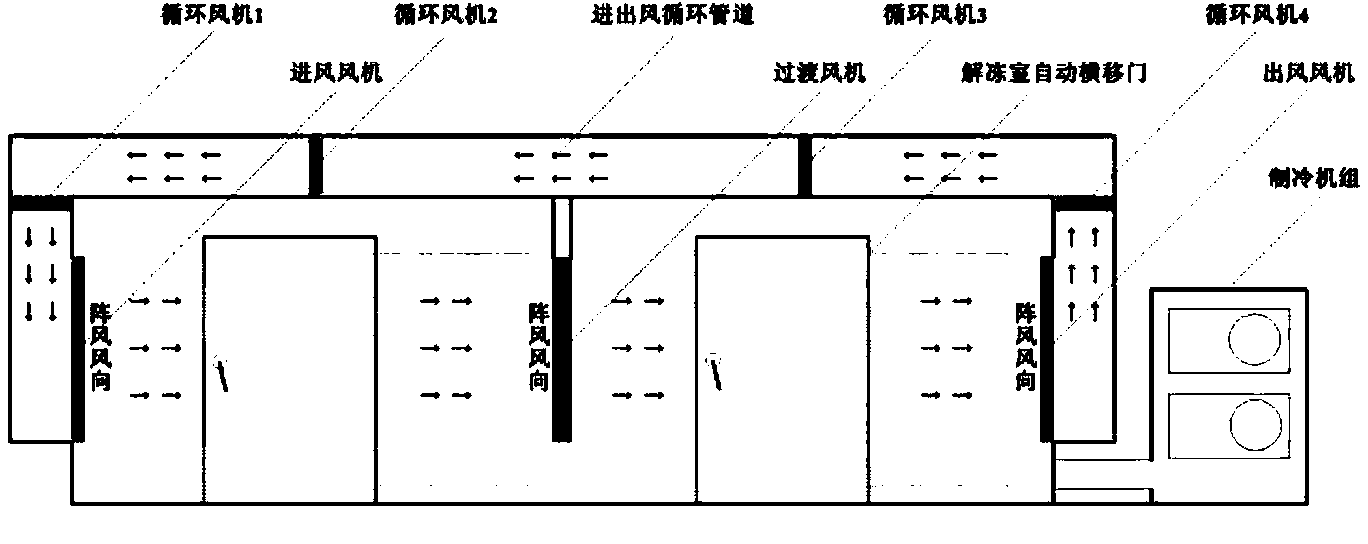

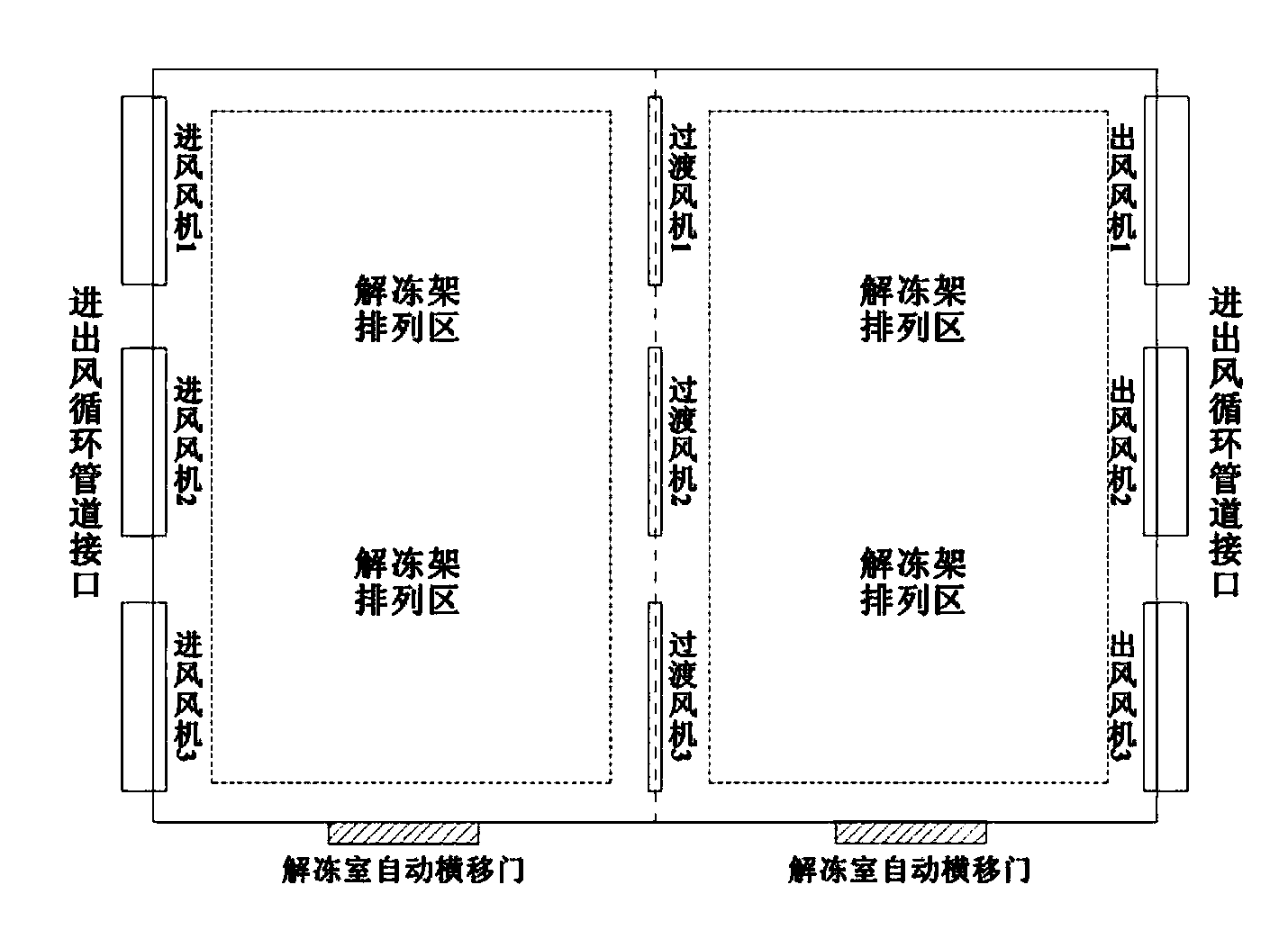

Subzero temperature-gust quick semi-unfreezing process of frozen platy meat products

InactiveCN104273208AReach the target half-thawed degreeUniform qualityMeat/fish preservation by freezing/coolingProcess engineeringFood products

The invention discloses a subzero temperature-gust quick semi-unfreezing process of frozen platy meat products. The subzero temperature-gust quick semi-unfreezing process comprises the following steps: loading the frozen platy meat products on unfreezing racks, placing the unfreezing racks in a subzero temperature unfreezing room with the room temperature being not higher than -6 DEG C, monitoring the center temperature and the surface temperature of the meat products by setting four frozen meat products as references, and enabling the center temperature of the frozen platy meat products to be -8+ / -1 DEG C by taking the center temperatures and the surface temperatures of the references as control nodes of a gust opening / closing procedure and at the air speed of (3-6)+ / -0.9m / s during opening, so that the state of internal / external balanced semi-unfreezing is achieved under the subzero temperature-gust unfreezing condition that the center / surface temperature difference is 0.5-1.5 DEG C. The subzero temperature-gust semi-unfreezing process has the positive effects that 1, the frozen platy meat products can quickly achieve the unfreezing state needed for quickly-frozen prepared foods; 2, the center / surface temperature difference after semi-unfreezing is less and the internal / external unfreezing degree is balanced; 3, the subzero temperature-gust quick semi-unfreezing process can be applied to quick unfreezing of large batches of frozen meat products; and 4, the energy consumption of semi-unfreezing is less and the production cost cannot be greatly increased.

Owner:TAIZHOU ANJOY FOODS +1

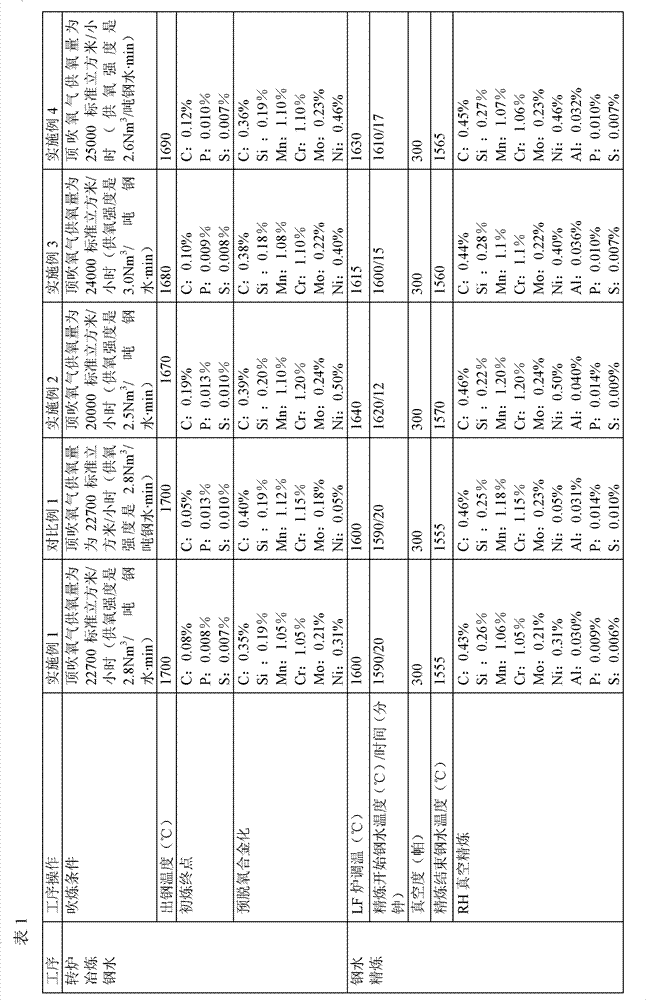

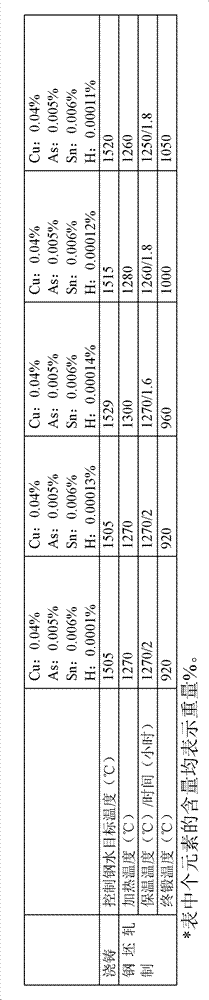

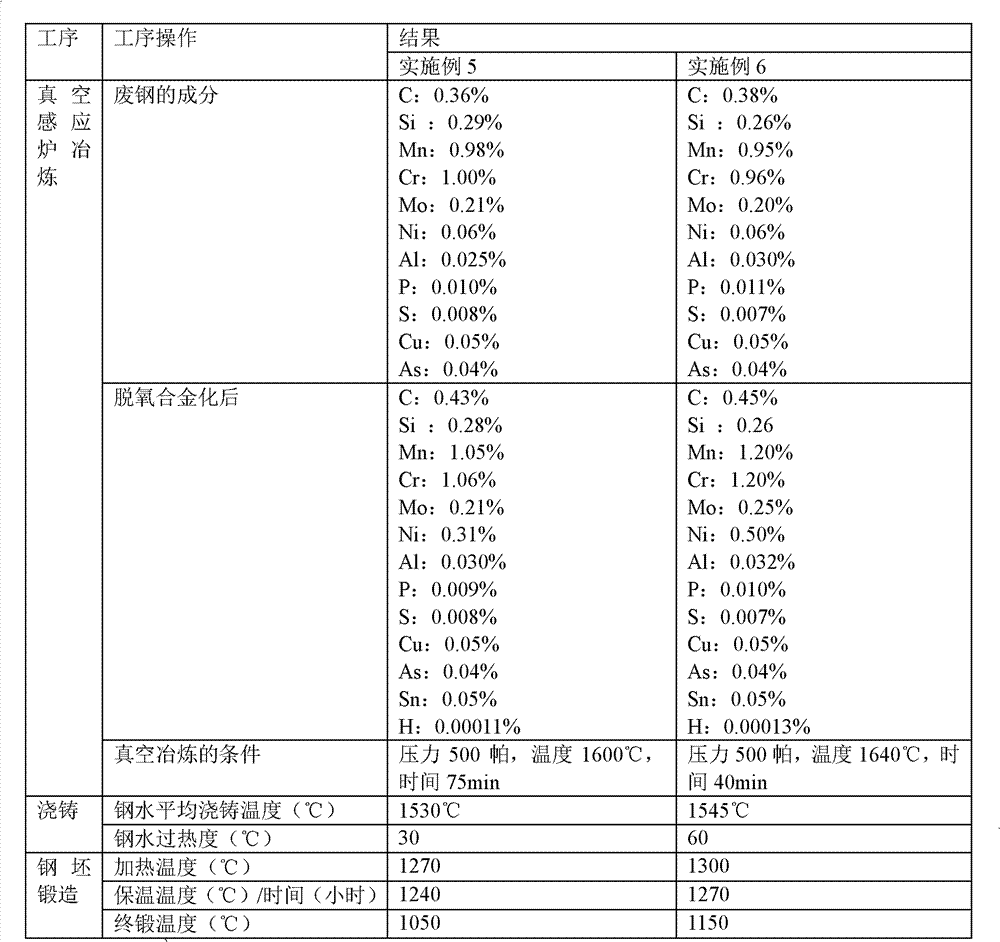

Steel for drilling tools and method for smelting steel for drilling tools

The invention discloses a steel for drilling tools and a method for smelting steel for drilling tools. On the basis of the total weight of the steel for drilling tools, the steel comprises 0.4-0.49 wt% of C, 0.15-0.37 wt% of Si, 1-1.3 wt% of Mn, 1-1.3 wt% of Cr, 0.2-0.3 wt% of Mo, 0.02-0.04 wt% of Al, 0.25-0.5 wt% of Ni, at most 0.015 wt% of P, at most 0.015 wt% of S, at most 0.2 wt% of Cu, at most 0.05 wt% of Sn, at most 0.05 wt% of As, at most 0.0002 wt% of H, at most 0.009 wt% of N and the balance of iron. The T[O] content in the steel for drilling tools is at most 0.002 wt%. The steel for drilling tools disclosed by the invention has higher strength, ductility and toughness than the steel for drilling tools provided by the prior art. Thus, the invention provides the steel for drilling tools with high strength, high toughness and favorable fatigue resistance on the premise of not greatly increasing the steel product production cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

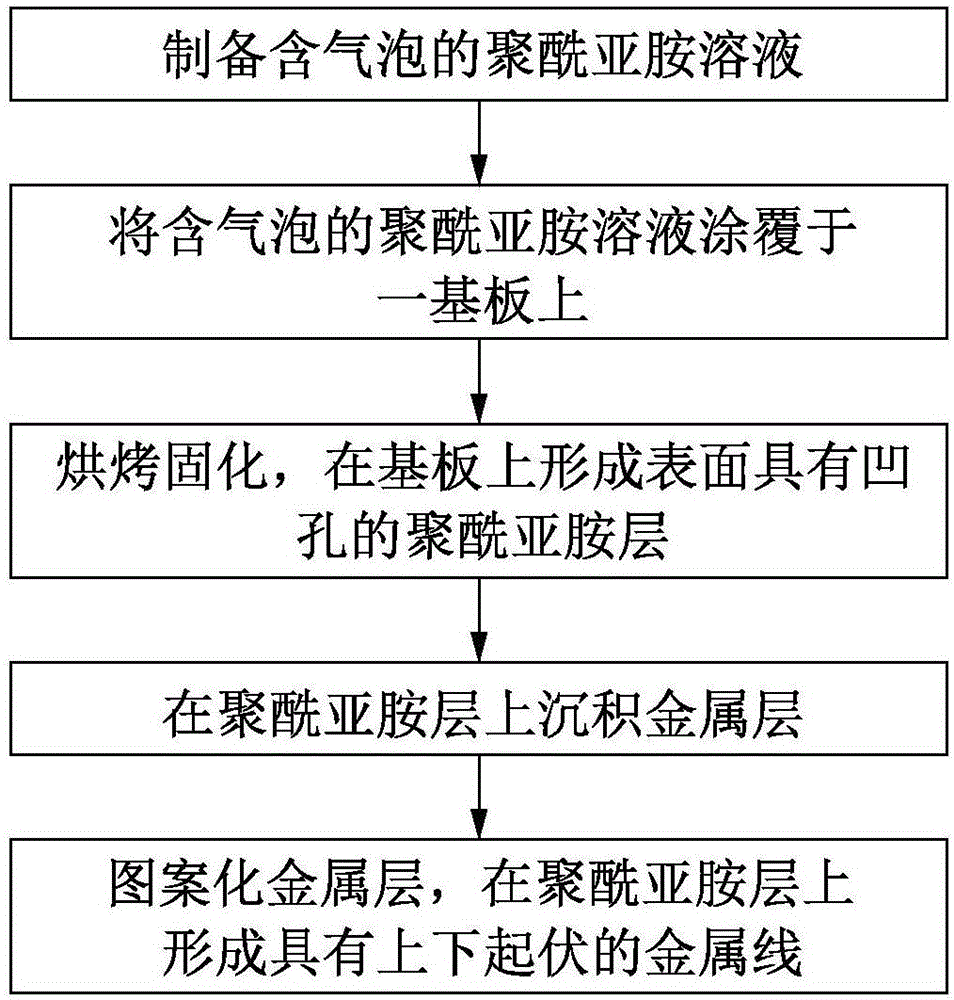

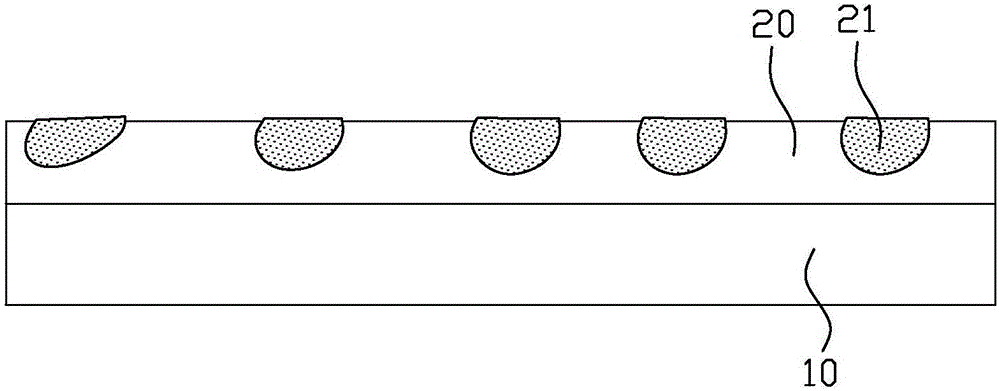

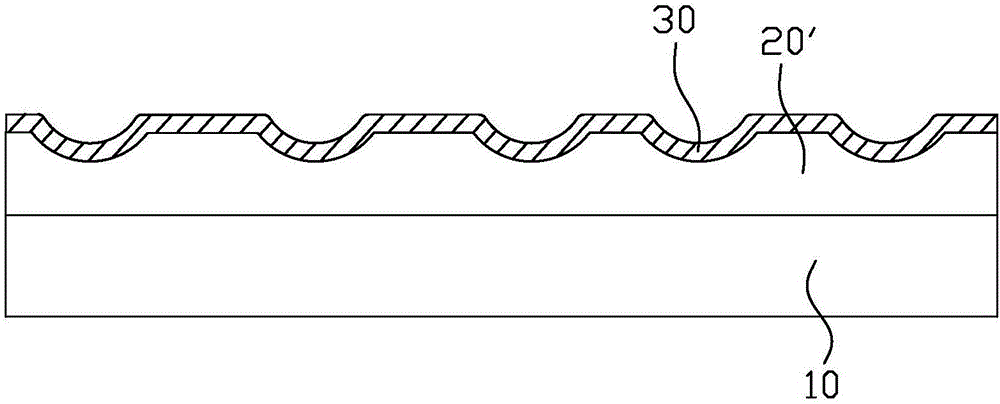

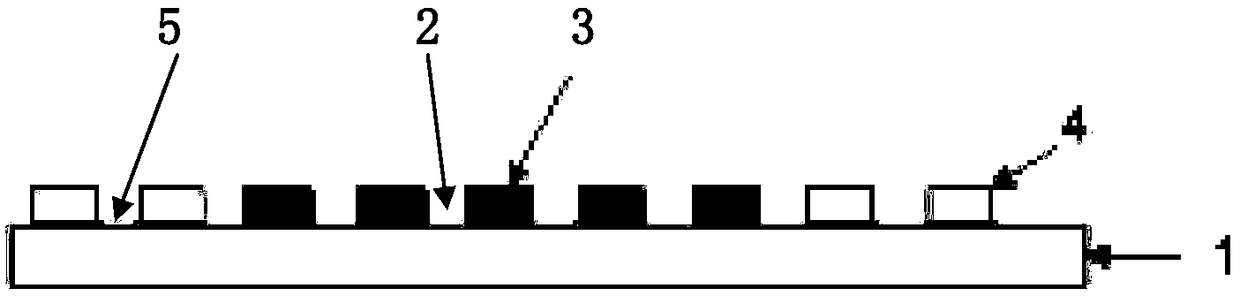

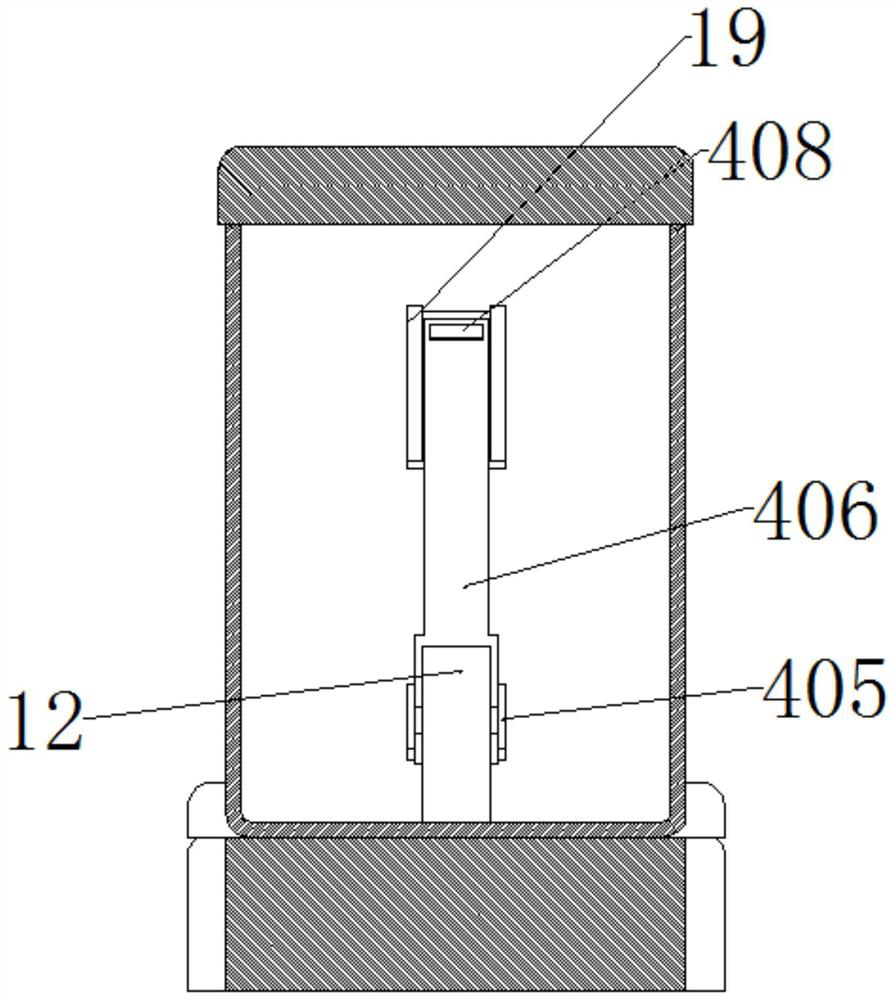

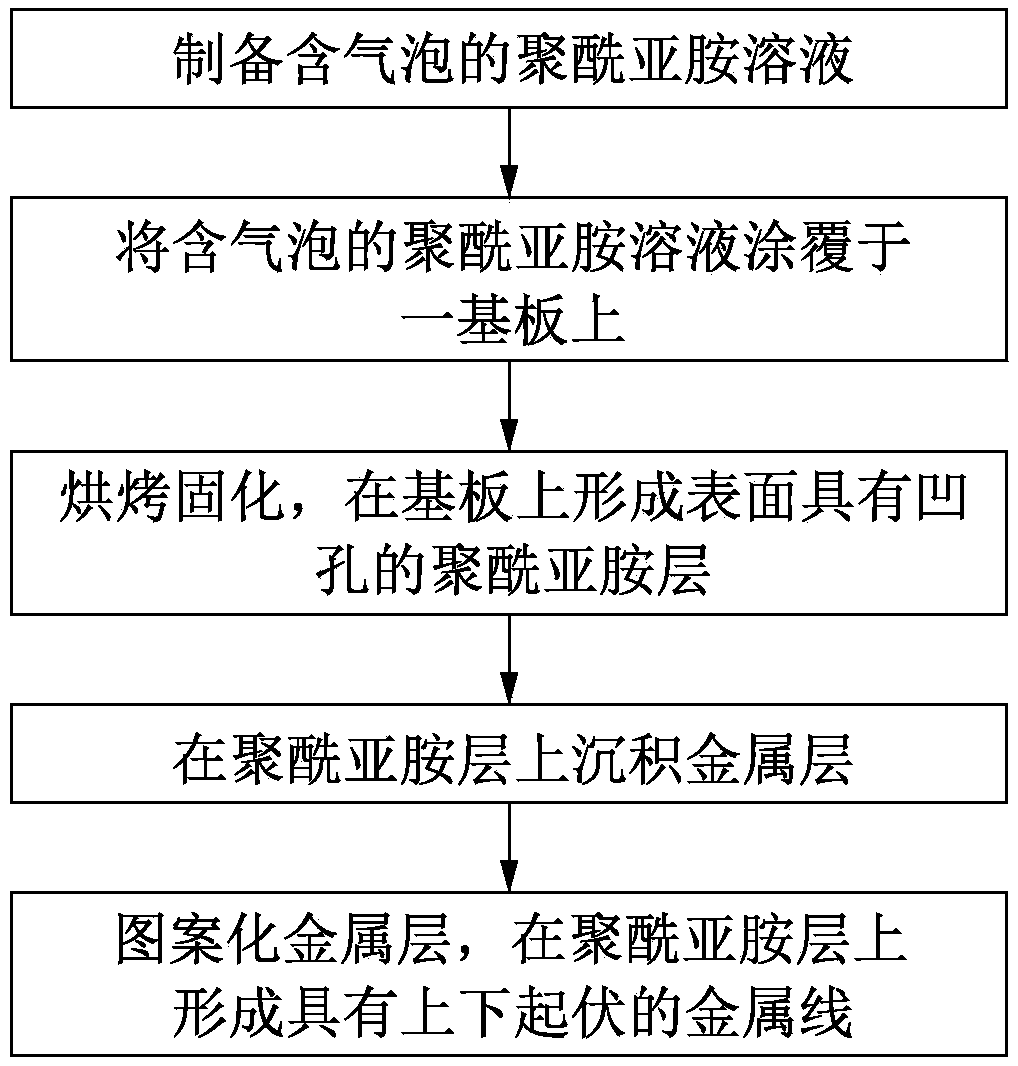

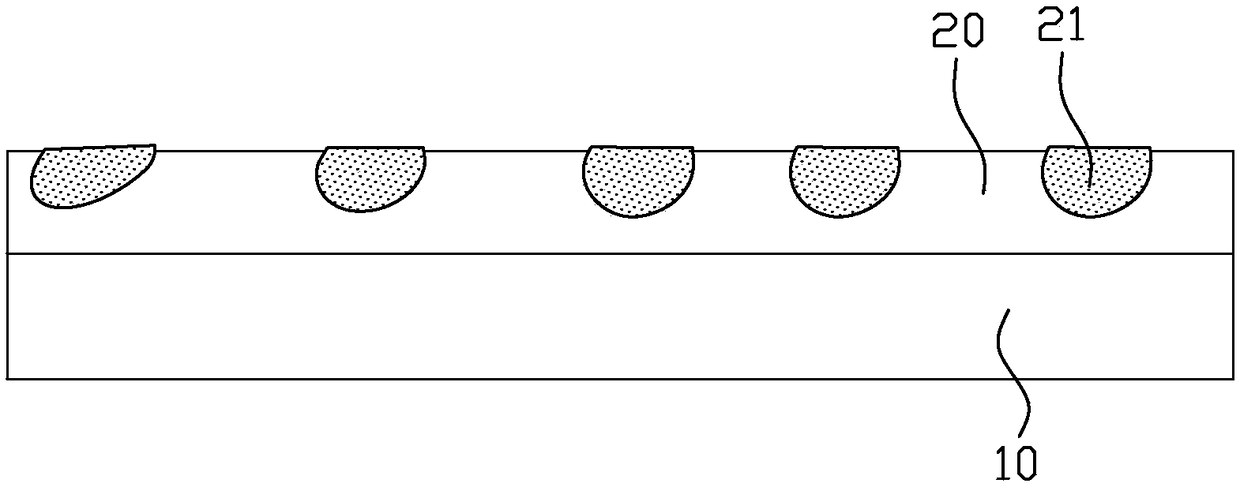

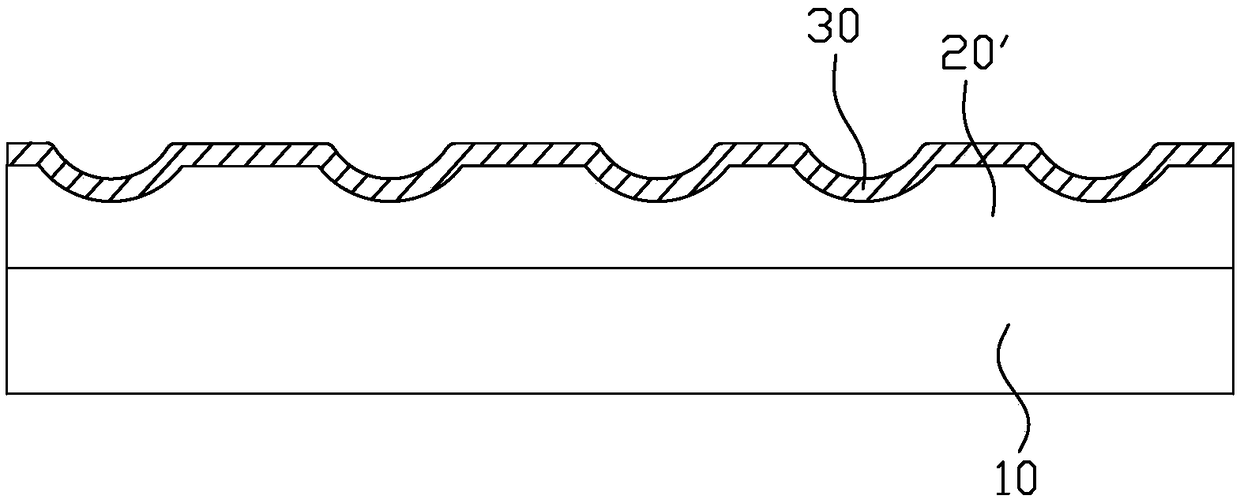

Metal wire manufacturing method of flexible substrate

ActiveCN106340460AIncreased durabilityEffective stress reliefSemiconductor/solid-state device detailsSolid-state devicesCooking & bakingOptoelectronics

The invention provides a metal wire manufacturing method of a flexible substrate. The method comprises a step of preparing a polyimide solution containing bubbles, a step of coating a substrate with the polyimide solution containing bubbles, a step of carrying out baking-curing and forming a polyimide layer with concave holes on the substrate, a step of depositing a metal layer on the polyimide layer, and a step of patterning the metal layer and forming wavy metal wires on the polyimide layer. According to the method, through simple steps, the wavy metal wires are formed on the substrate, the formed metal wires can release the stress of the formed metal wires in the bending of the flexible substrate, and the bending resistance and reliability of the flexible substrate are improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Solid super acid and application thereof in preparing 4,4'-diaminodiphenylmethane

InactiveCN102059129BLow costEasy to prepareMolecular sieve catalystsOrganic compound preparationPulverized fuel ashNuclear chemistry

The invention discloses a solid super acid and application thereof in preparing 4,4'-diaminodiphenylmethane. The solid super acid is prepared from waste pulverized fuel ash of a coal fired power plant. A preparation method of the solid super acid comprises the steps of: treating the pulverized fuel ash, treating screenings, dipping the screenings into in a 10mol / l sulfuric acid solution for 1-10 hours, carrying out suction filter, and sintering filter residues at 450-650 DEG C for 4 hours to obtain the solid super acid. The invention not only provides a new approach to the utilization of the waste pulverized fuel ash, but also solves the problem of environmental pollution caused by the pulverized fuel ash, and has important social and economic significance. Since the solid super acid provided by the invention has an extremely low cost and a simple preparation method, the prepared solid super acid has low price and good marketization prospect.

Owner:河南省华鼎高分子股份有限公司

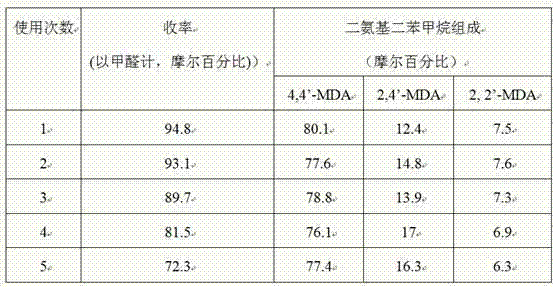

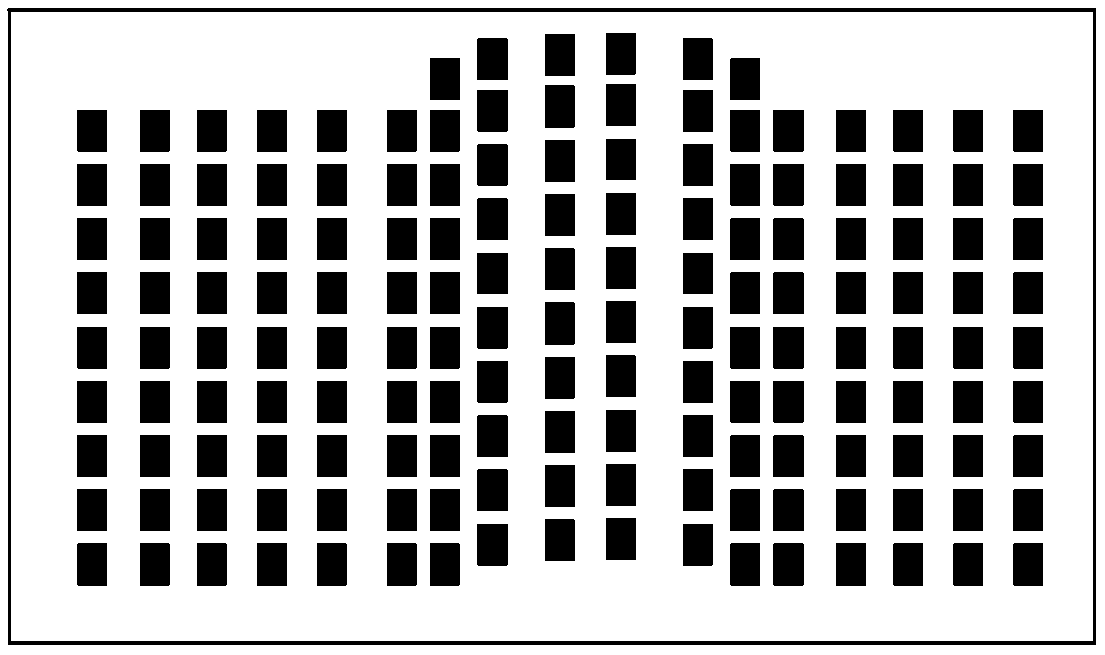

Glass panel for solar photovoltaic cell and preparation method thereof

PendingCN109390426AWith surface protectionImprove energy efficiencyPhotovoltaic supportsWallsOptical transmittanceLuminous flux

The invention belongs to the technical field of an assembling type environment-friendly energy-saving building and solar energy comprehensive utilization, and particularly to a glass panel in the thinfilm power generation field of a glass curtain wall or a glass roof for a building external fa ade, and particularly to a glass panel for a solar photovoltaic cell and a preparation method thereof. The glass panel for the solar photovoltaic cell comprises a substrate. The substrate is divided into a pattern area and a contrasting area. A plurality of pattern area optical structure unit configurations are arranged and fixed in the pattern area. A plurality of contrasting area optical structure unit configurations are arranged and fixed in the contrasting area. The glass panel and the preparation method thereof have advantages of (1), no luminous flux is changed, great light transmittance reduction of incident light is prevented, and high power generation efficiency is ensured; (2), throughstructure change of the geometric configuration, color brightness change is generated, thereby improving visual impact of a decorative pattern; and (3), decorative performance of the photovoltaic glass curtain wall and the roof is improved, and furthermore great increase of manufacturing cost is prevented.

Owner:GUANGZHOU LONGZHU CHEM CO LTD

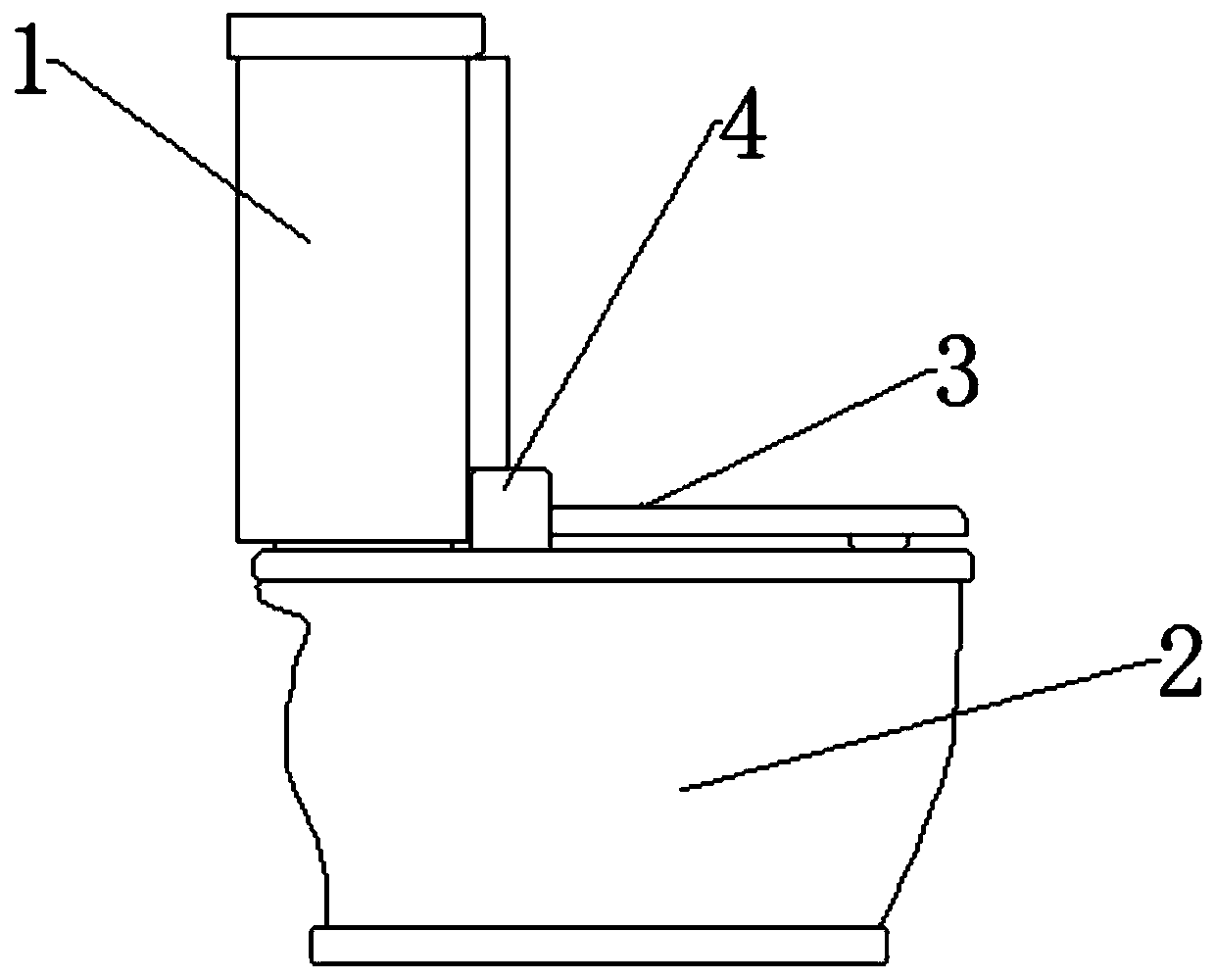

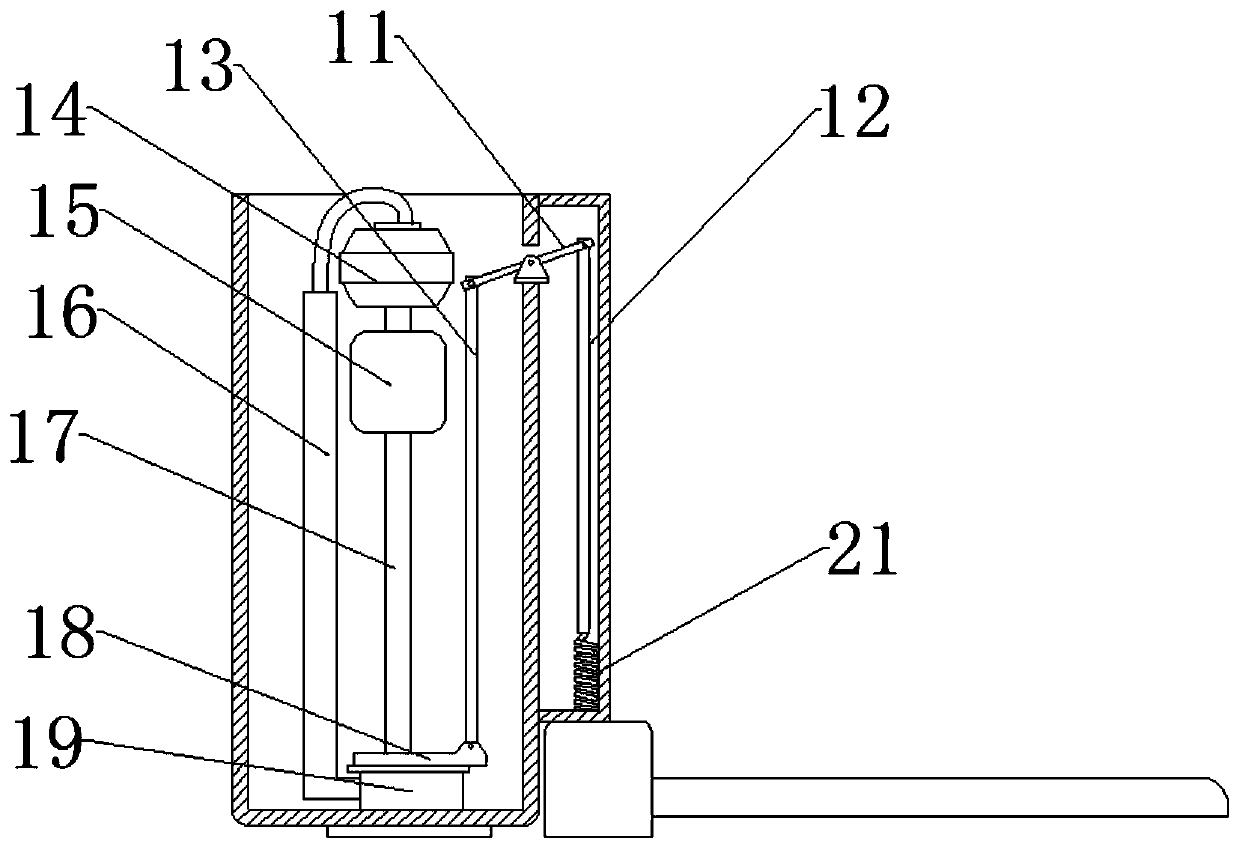

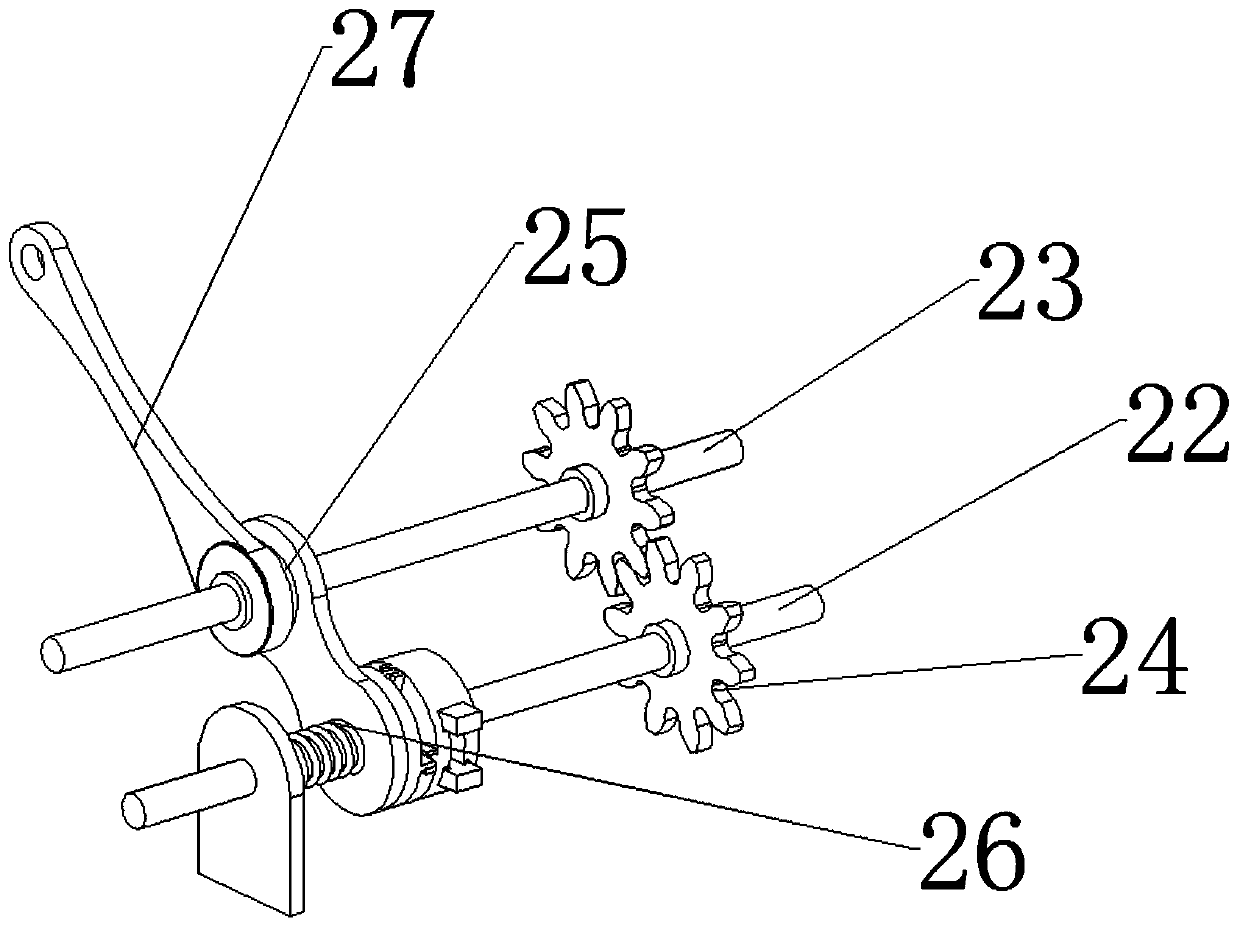

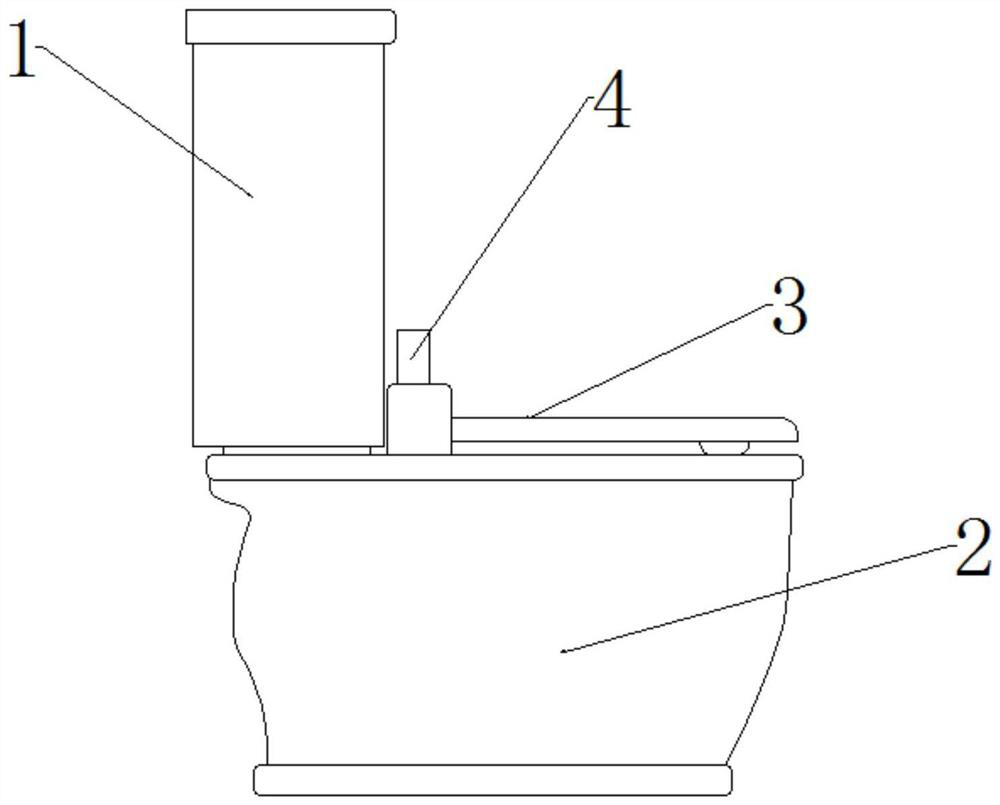

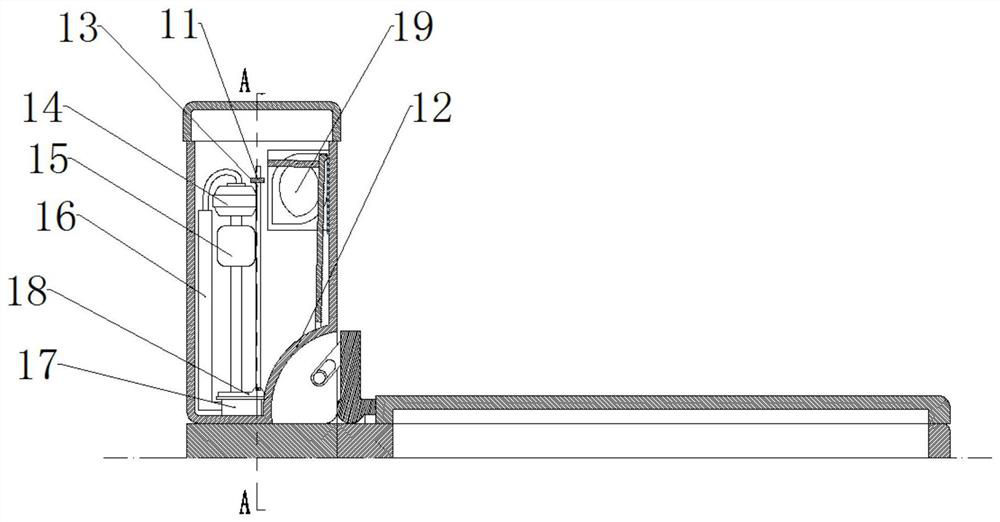

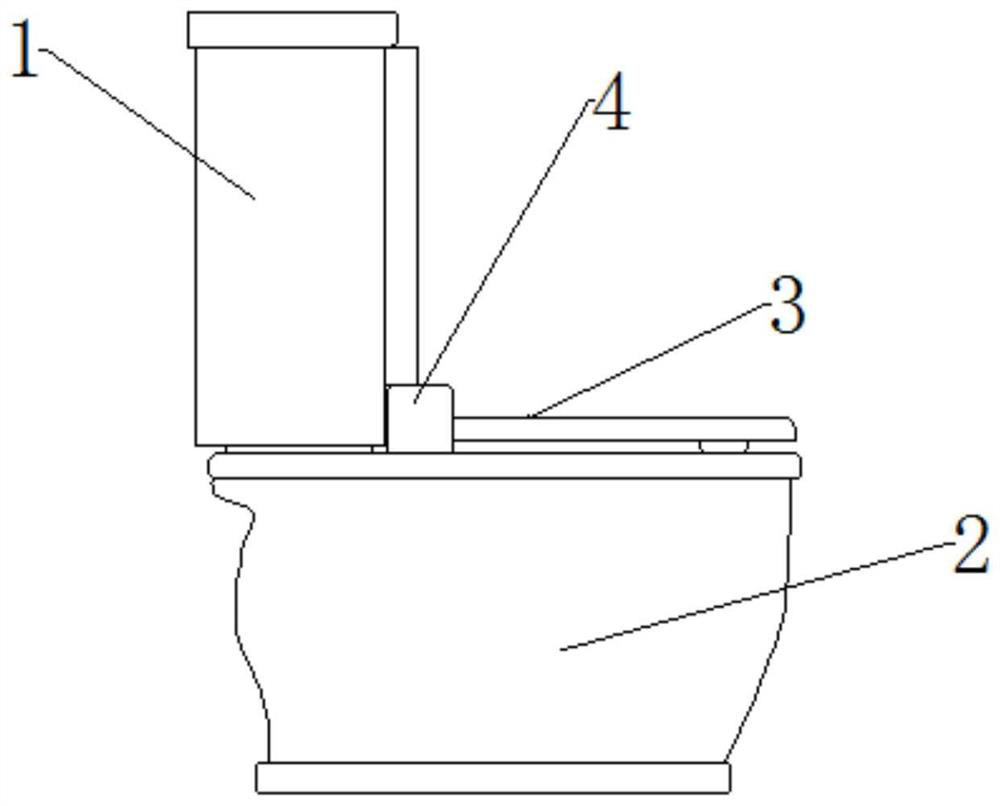

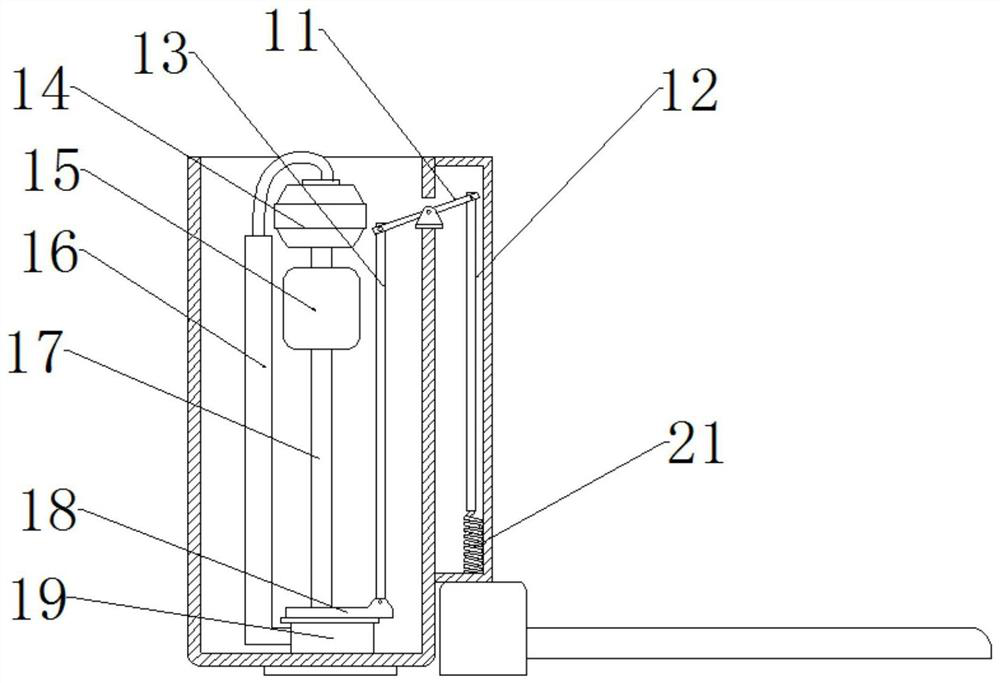

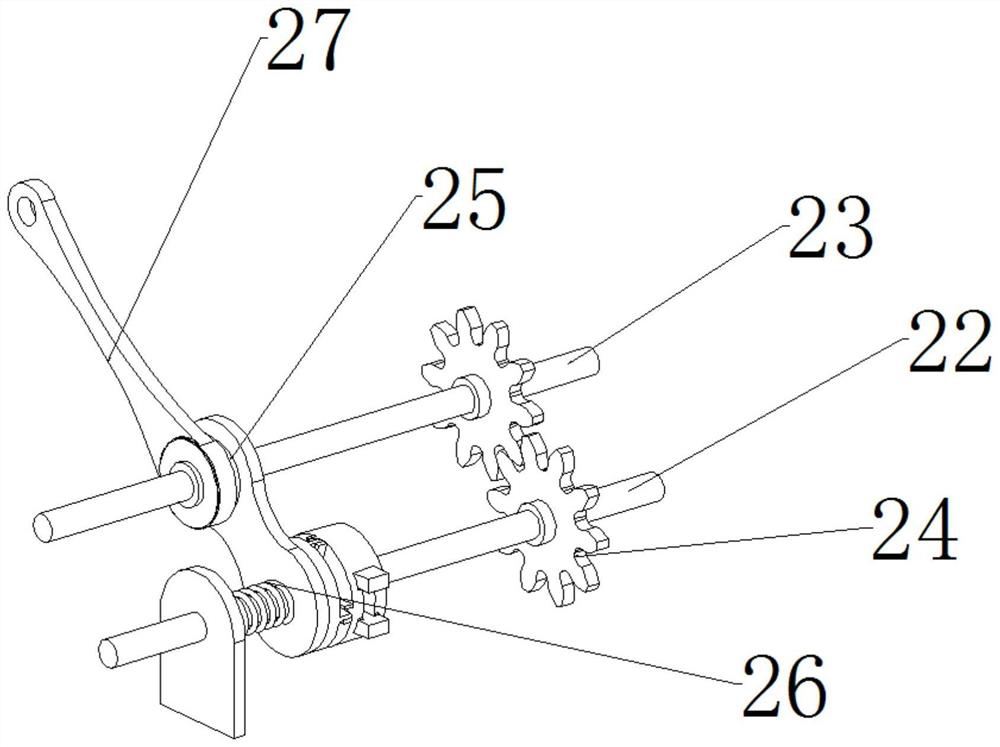

Lever type flip automatic flushing closestool

ActiveCN110924493AOff does not affectGuaranteed water useWater closetsFlushing devicesGear wheelControl theory

The invention discloses a lever type flip automatic flushing closestool. The lever type flip automatic flushing closestool comprises a closestool body, a closestool cover and a water tank; a flushingvalve in the water tank is opened through a lifting connecting rod; a lever mechanism is arranged in the water tank; a starting mechanism and a linkage switching mechanism are arranged at the joint ofthe closestool cover and the closestool body; the lever mechanism is arranged on the front wall of the water tank to connect the lifting connecting rod with the gear starting mechanism; the startingmechanism comprises a starting arm rotating shaft, a gear mechanism and a starting arm; the t closestool cover rotating shaft is in transmission with the starting arm rotating shaft through the gear mechanism, the starting arm rotating shaft is rotationally installed on the closestool body, the linkage switching mechanism controls the transmission relation between the starting arm and the startingarm rotating shaft, and the tail end of the starting arm is connected with the lever mechanism through a tension spring. The flushing valve is started to flush water while the closestool cover is closed, and design and transformation on the basis of the prior art are facilitated.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Preparation method for solar battery emitting electrode

InactiveCN105226111AImproved shortwave spectral responseImprove battery efficiencyPhotovoltaic energy generationSemiconductor devicesChemistryOxide

The invention provides a preparation method for a solar battery emitting electrode, comprising the steps of (A), texturing, diffusing and etching a silicon wafer to obtain a pretreated silicon wafer; and B) oxidizing the pretreated silicon wafer by ozone to form an oxide layer on the surface, and then removing the oxide layer by a hydrofluoric acid solution to obtain the solar battery emitting electrode. Compared with the prior art, the preparation method uses ozone to oxidize the pretreated silicon wafer to form the oxide layer on the surface at the normal temperature, and then the hydrofluoric acid solution is used to remove the oxide layer, so that the dead layer of the emitting electrode can be effectively removed, the short-wave spectral response of the solar battery is accelerated, and the battery efficiency is improved; and in addition, the preparation method is simple and controllable without dramatically increasing the production cost, so that the preparation method is suitable for large-scale production.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

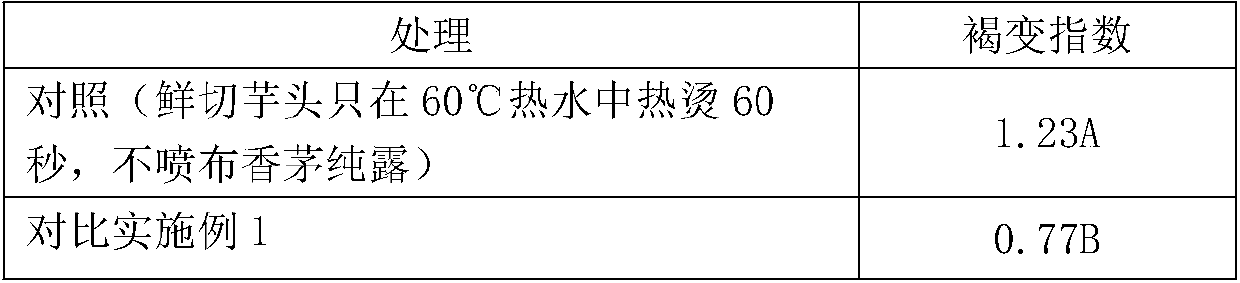

Treatment method for controlling browning of fresh-cut taros

InactiveCN110063365AImprove freshnessExtended shelf lifeFruit and vegetables preservationFood thermal treatmentEconomic benefitsCitrus medica

Disclosed is a treatment method for controlling browning of fresh-cut taros. The method comprises the following operation steps that the taros are peeled, cut into halves, blanched with hot water at 60-100 DEG C for 20-60 seconds, fished out and drained; then citronella hydrolat is sprayed onto the surfaces of the fresh-cut taros, moisture is drained off, and the taros are packaged with a 0.01mm polyethylene plastic thin film and stored in a constant-temperature box at 4-8 DEG C. The method has the advantages that a chemical anti-browning agent is not adopted, the method is safe and efficient,and the shelf life at least can be prolonged by 9 days; the operation is simple and easy to implement, the production cost is not significantly increased, and the method has significant economic benefits.

Owner:SHAOGUAN COLLEGE

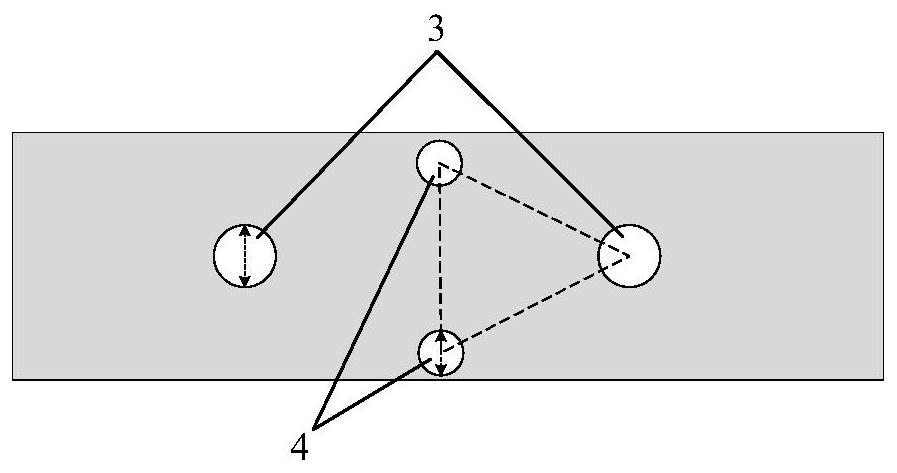

Method for increasing interlayer binding force of high-temperature superconducting narrow-headed wire

ActiveCN113327716AReduce usageDoes not significantly increase production costsSuperconductors/hyperconductorsSuperconductor devicesTinningMetal strips

The invention relates to a method for increasing the interlayer binding force of a superconducting narrow headed wire. The method comprises the following steps: S1, stacking a superconducting strip and other metal strips which are equal in width, and then tinning and packaging the stacked superconducting strip and other metal strips into a high-temperature superconducting narrow headed wire through a tinning furnace; S2, punching holes in the surface of the narrow-headed wire obtained in the step S1, wherein the holes are through holes; S3, re-packaging the through holes of the narrow pile lines obtained in the step S2. According to the invention, a tin-plated packaging mode is adopted after the narrow headed wire is punched, and a'soldering tin column 'is formed by penetrating through all upper and lower layers of the narrow headed wire, so the weight and the size of the narrow headed wire are not influenced, the manufacturing cost is not greatly increased, and the feasibility is provided for practical engineering application; in mechanical operations of twisting, bending and the like, compared with a metal sheath, the soldering tin column is smaller in size, higher in toughness and capable of better meeting application requirements under working conditions.

Owner:SHANGHAI JIAO TONG UNIV

A flip-type buckle linkage automatic flush toilet

ActiveCN110924499BFew exposed partsOff does not affectWater closetsFlushing devicesStructural engineeringFlush toilet

The invention discloses a flip type snap-linked automatic flushing toilet, comprising a toilet body, a toilet cover and a water tank. There is a starting mechanism, the starting mechanism includes a starting lever and a starting shaft, the bottom of the front side of the water tank is provided with a starting groove for installing the starting shaft, and the starting rod is fixed on the hinged end of the toilet cover and passes through the transmission structure. It is connected with the starting shaft, the two ends of the starting shaft extend into the water tank, and the buckle linkage mechanism includes rotating arms symmetrically installed at both ends of the starting shaft, horizontally arranged on the upper end of the lifting link A flat plate, a pick plate and a guide piece are provided, the pick board is slidably connected with the guide piece, and the pick board is fixed with a linkage plate whose lower end is hinged at the end of the rotating arm. The invention realizes that the toilet lid is closed and the flush valve is activated to flush the water, which is convenient for design and modification in the prior art.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Manufacturing method of metal wire for flexible substrate

ActiveCN106340460BIncreased durabilityEffective stress reliefSemiconductor/solid-state device detailsSolid-state devicesCooking & bakingMetal

The invention provides a metal wire manufacturing method of a flexible substrate. The method comprises a step of preparing a polyimide solution containing bubbles, a step of coating a substrate with the polyimide solution containing bubbles, a step of carrying out baking-curing and forming a polyimide layer with concave holes on the substrate, a step of depositing a metal layer on the polyimide layer, and a step of patterning the metal layer and forming wavy metal wires on the polyimide layer. According to the method, through simple steps, the wavy metal wires are formed on the substrate, the formed metal wires can release the stress of the formed metal wires in the bending of the flexible substrate, and the bending resistance and reliability of the flexible substrate are improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

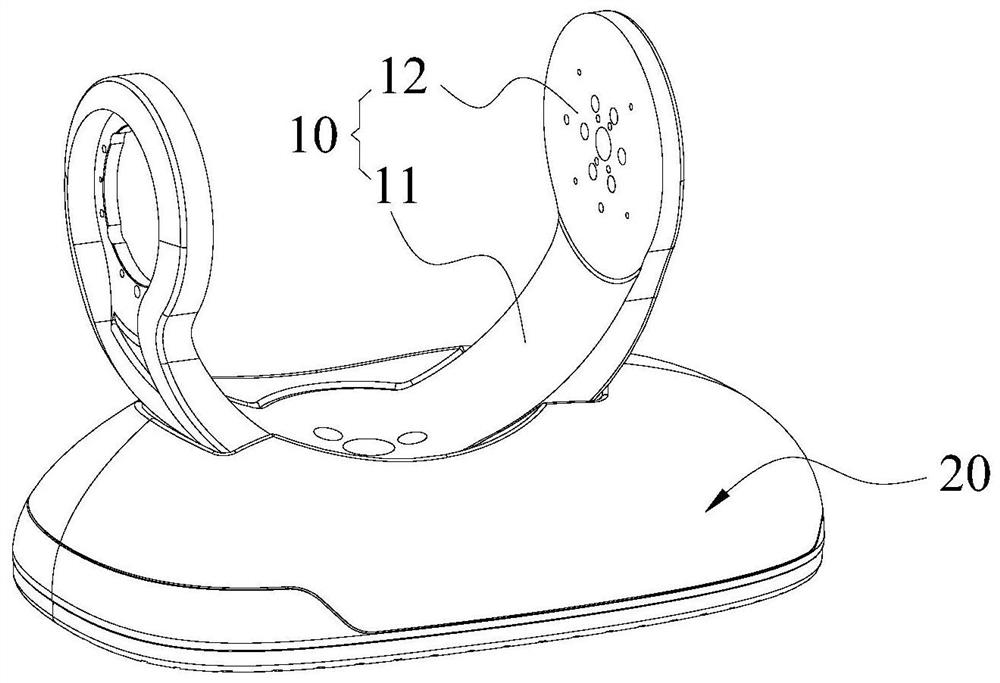

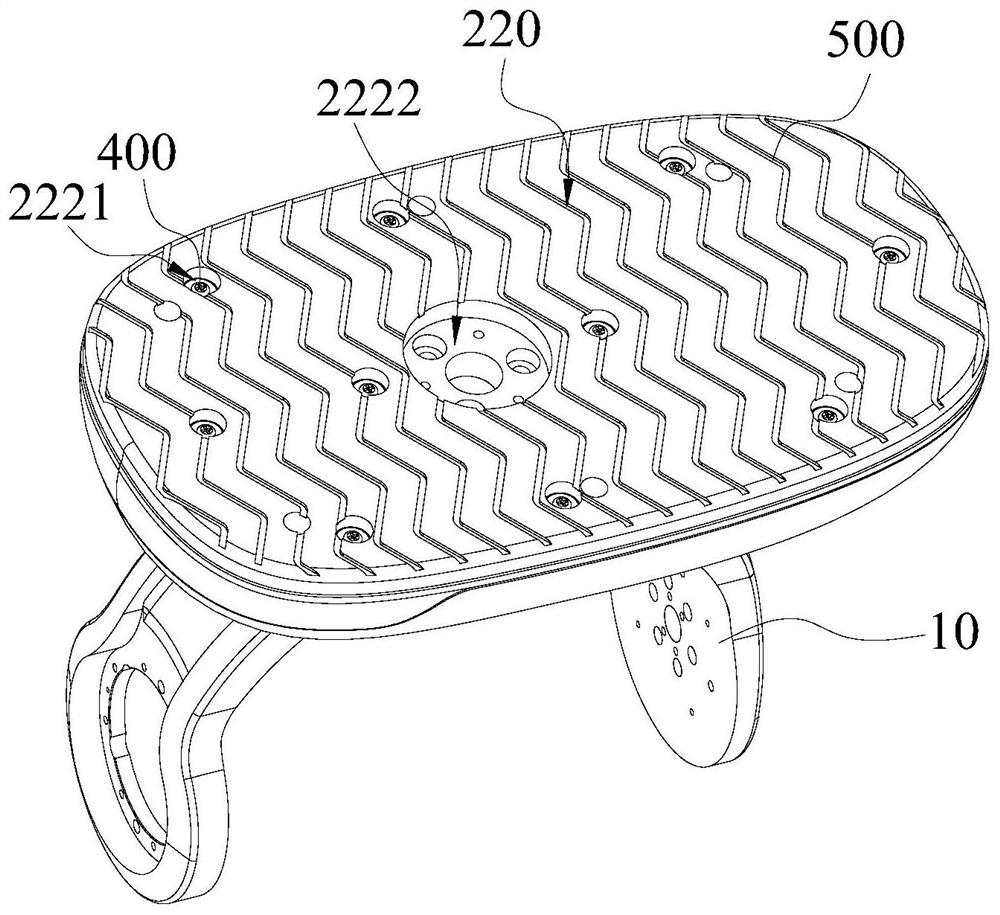

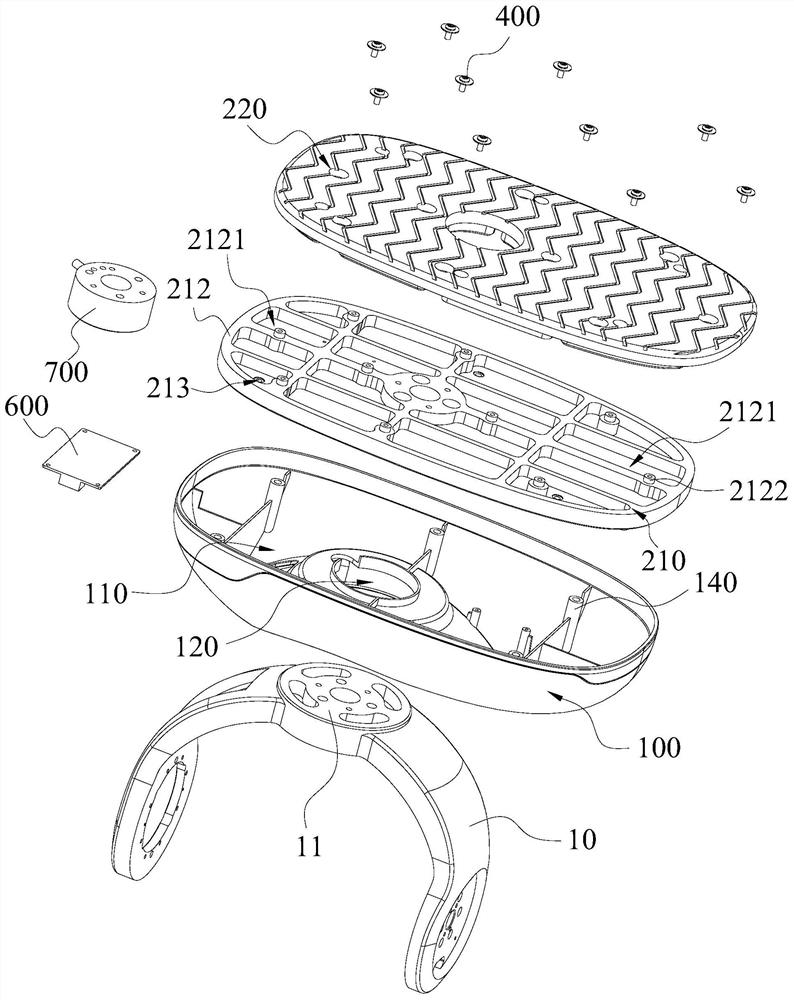

Robot and its foot structure

ActiveCN109533081BWalking balanceWalk smoothly and naturallyJointsVehiclesEngineeringMechanical engineering

The invention belongs to the technical field of robots and aims to provide a robot and a foot structure thereof. The foot structure of the robot comprises a foot main body and an adapter bracket usedfor driving the foot main body to move, wherein the foot main body comprises an instep shell the middle part of which is connected with the adapter bracket, a bottom plate the the bearing wall of which is connected to the instep shell and covers the cavity of the instep shell, and a pad plate the buffer wall of which is connected to a connecting wall of the bottom plate and has a buffer function.According to the invention, on the premise that the production cost is not greatly increased and the foot structure is not complicated, the buffer wall of the pad plate is arranged to be a middle concave structure, so that the middle part of the buffer wall of the pad plate is not contacted with the connecting wall of the bottom plate, so that the pad plate is correspondingly deformed in the walking process of the foot main body to further enhance the absorption or buffering of the reaction impact force to the ground. According to the robot and the foot structure thereof, the absorption capacity of impact force is enhanced, and the walking posture is more stable and natural.

Owner:UBTECH ROBOTICS CORP LTD

A kind of crosslinking modified soybean protein adhesive

ActiveCN103865477BSimple and fast operationEase of industrial productionProtein adhesivesMacromolecular adhesive additivesEpoxyMelamine formaldehyde resin

The invention provides a crosslinked modified soybean protein adhesive and a preparing method thereof. The preparing method includes: adding defatted soybean powder, water, sodium dodecyl benzene sulfonate and an alkali into a reactor, stirring for 5 min, adding glycol and silicone oil, raising the temperature to 90 DEG C, maintaining the temperature and stirring for 3 h, cooling and discharging. Before the adhesive is used, two or more of epoxy resin, melamine-formaldehyde resin, urea-formaldehyde resin and phenolic resin are added into the adhesive, adopted as crosslinking agents and uniformly mixed. The soybean protein adhesive is simple in preparation process, moderate in viscosity and strong in operationality. The adhesive is excellent in water resistance. After a poplar adhered board test piece is boiled in boiling water for 2 h and dipped in water having a temperature of 63+-3 DEG C for 1 h, the bonding strength of the test piece is not less than 0.7 MPa and is free of tackless phenomena.

Owner:SOUTHWEST FORESTRY UNIVERSITY

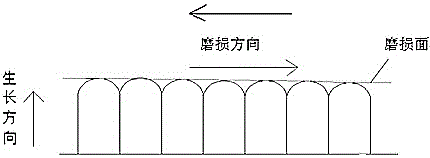

Method for casting antiwear shot blasting machine blade

InactiveCN106734898ADoes not significantly increase production costsImprove wear resistanceFoundry mouldsFoundry coresBottom gateAlloy

The invention provides a method for casting an antiwear shot blasting machine blade. The method comprises the following steps that S1, green sand is utilized for carrying out modeling on a casting of the antiwear shot blasting machine blade, and dry sand is utilized for carrying out core making on the casting of the antiwear shot blasting machine blade; S2, casting lower surface parting of the antiwear shot blasting machine blade is selected, and a bottom gating system is selected; S3, the dimensional tolerance, the casting weight tolerance, the shrinking percentage, the pattern draft and the air outlet hole dimension during casting are determined; S4, an alloy is subjected to smelting and casting; and S5, after the casting is put in the temperature being 900 DEG C for heat preservation for 0.5 h after casting is carried out, the casting is taken out of a furnace to be cooled, and the casting is cooled after being subjected to heat preservation tempering for 0.5 h at the temperature being 220 DEG C. The method for casting the antiwear shot blasting machine blade has the following beneficial effects that by means of the method, a structure growing perpendicularly to the direction of the wear face of the blade can be obtained, on the premise of no greatly improving production cost, the wear resistance of the structure is greatly improved, and application is wider.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

Method for preparing drill collar steel

The invention relates to drill collar steel and a preparation method thereof. The drill collar steel comprises the following components based on the total weight of drill collar steel: 0.41-0.47wt% of C, 0.15-0.3wt% of Si, 0.95-1.2wt% of Mn, 0.95-1.2wt% of Cr, 0.15-0.3wt% of Mo, 0.02-0.04wt% of Al, 0.01-0.03wt% of Ti, less than or equal to 0.02wt% of P, less than or equal to 0.015wt% of S, less than or equal to 0.2wt% of Ni, less than or equal to 0.2wt% of Cu, less than or equal to 0.05wt% of Sn, less than or equal to 0.0002 wt% of H, less than or equal to 0.007wt% of N and the balance of Fe;and T[O] is less than or equal to 0.0020wt%, and the A,B,C and D impurities are less than or equal to 1.5 levels. By using the preparation method, the problem that the strength of the drill collar steel is not matched with plastic toughness is solved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

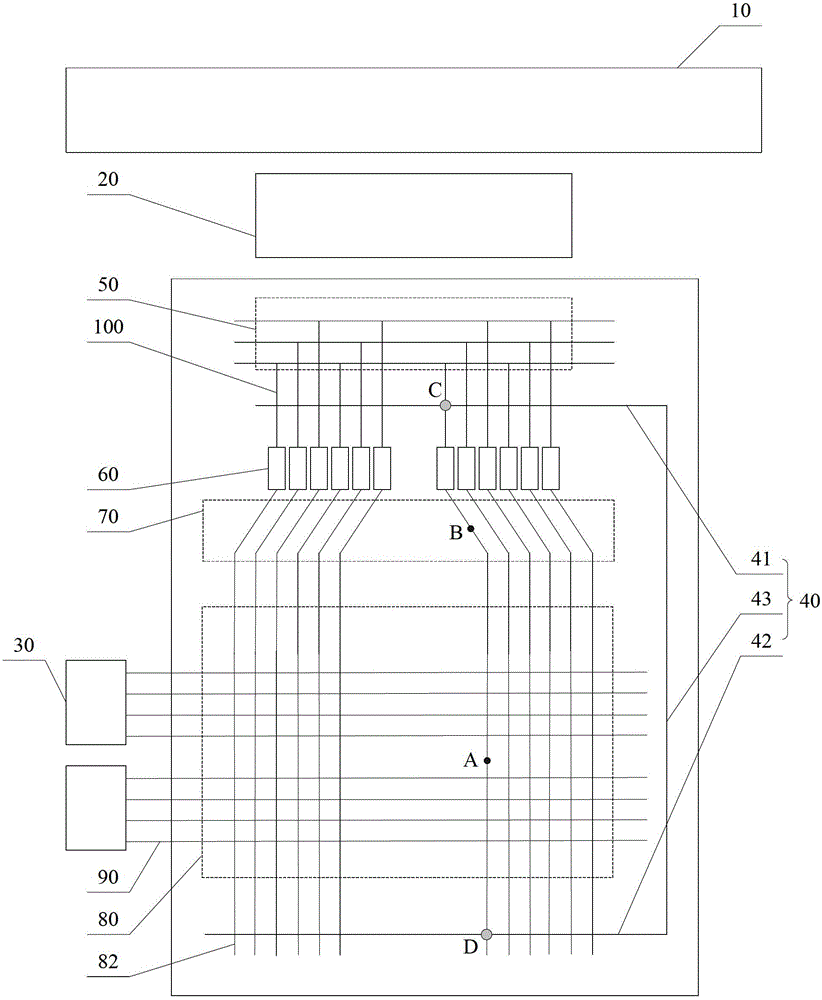

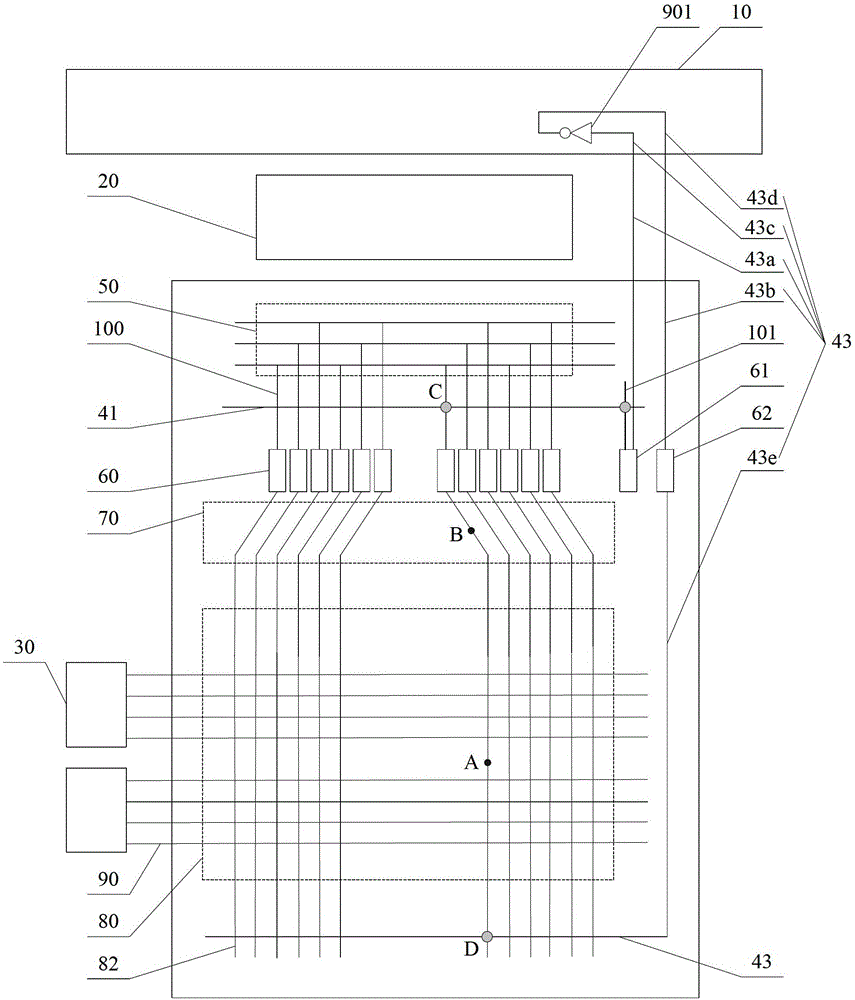

LCD Monitor

ActiveCN103048837BDoes not significantly increase production costsStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

Provided is a liquid crystal display comprising at least a repairing wire (40), a shorting bar area (50), a data line bonding pad (60), a plurality of test lines (100) connected with shorting bars in the shorting bar area (50) and the data line bonding pad (60) during testing, a wiring area (70), a display area (80), a plurality of data lines (82) passing through the wiring area (70) and the display area (80). First ends of the data lines (82) are electrically connected with the data line bonding pad (60) and second ends of the data lines (82) extend below the display area (80). The repairing wire (40) comprises a first portion (41), a second portion (42) and a third portion (43). The first portion (41) is insulatingly crossed with the test lines (100), the second portion (42) is insulatingly crossed with the second ends of the data lines (82), and the third portion (43) is connected with the first portion (41) and the second portion (42) during repairing. Broken line repairing of the data lines (82) in the display area (80) and the wiring area (70) of a liquid crystal panel for the liquid crystal display can be achieved without greatly increasing the production cost of the liquid crystal display.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for eliminating residual polymer of etching procedure

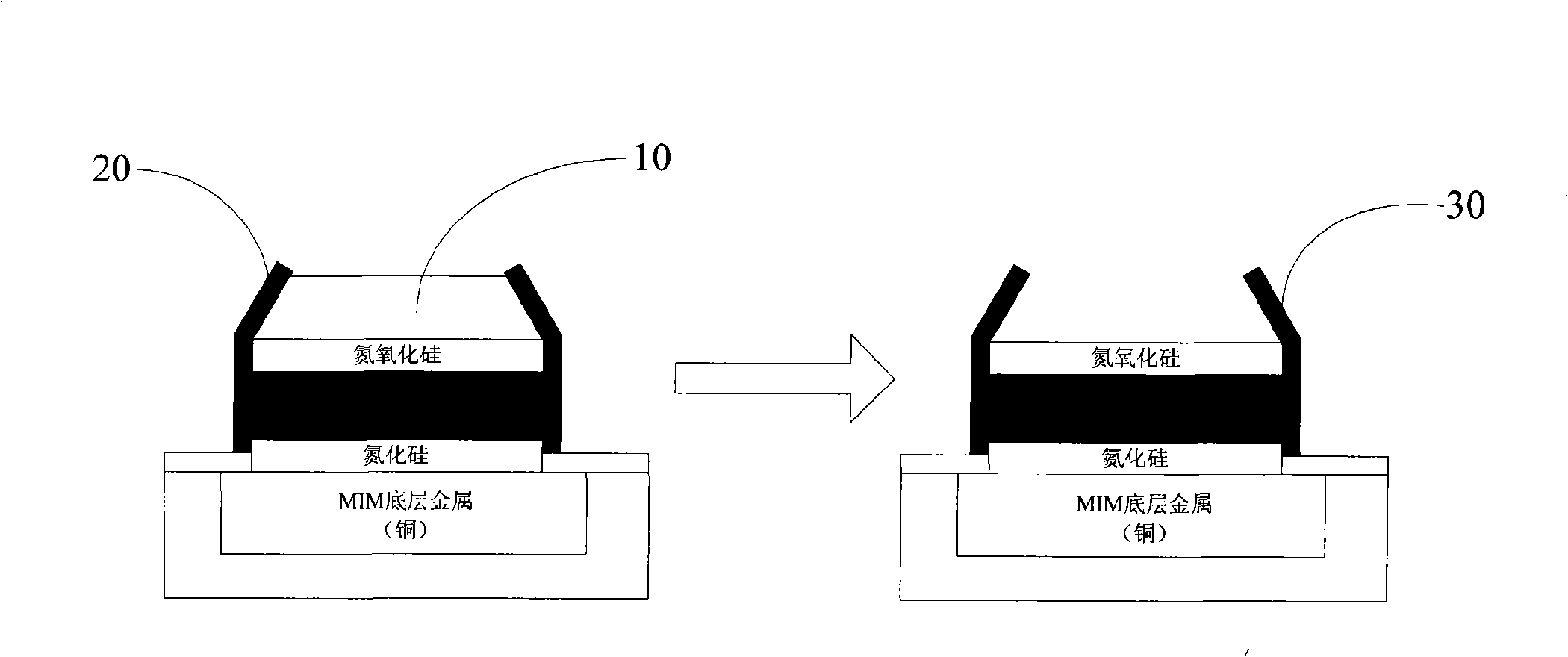

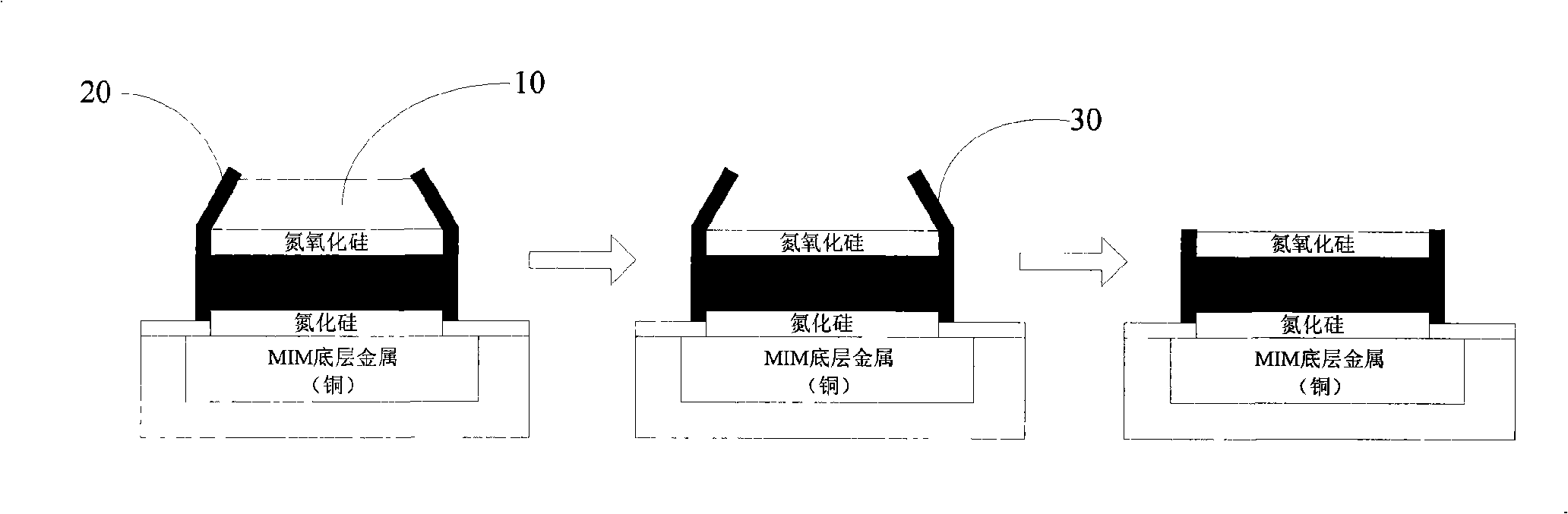

InactiveCN101308764BEliminate Coronary DefectsDoes not significantly increase production costsSemiconductor/solid-state device manufacturingWaferingEngineering

The invention provides a method to remove residual polymer during etching process. Firstly, a wafer is processed with dry etching in a main etching chamber; then the anticorrosion protective film of the wafer is removed in a decoating chamber; finally, the wafer is again disposed into the main etching chamber for dry etching for the second time; in this way, the residual polymer in the etching process can be gotten rid of. Compared with prior art, the method described by the invention is easy to realize and can thoroughly remove the residual polymer and eliminate coronary defects without increasing production cost by a large margin.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Glass panel for solar photovoltaic cell and preparation method of glass panel

PendingCN109510569AWith surface protectionImprove energy efficiencyPhotovoltaic supportsWallsOptical transmittanceEngineering

The invention belongs to the field of assembled green energy-saving building and solar energy comprehensive utilization technologies and relates to a glass panel for the thin film power generation field of glass curtain walls or glass roofs for building facades, in particular to a glass panel for a solar photovoltaic cell and a preparation method of the glass panel. The panel for the solar photovoltaic cell comprises a substrate; a pattern area is distributed on the substrate; a plurality of pattern area optical structure unit configurations are arranged and fixed on the pattern area. With theglass panel for the solar photovoltaic cell and a preparation method of the glass panel of the invention adopted, luminous flux is not changed, and the sharp decrease of the light transmittance of incident light can be avoided, and power generation efficiency can be ensured; the change of the degree of color shading is generated by means of the structural change of the geometric configurations, and therefore, the visual impact of decorative patterns can be highlighted; and the decorativeness of photovoltaic glass curtain walls and roofs can be enhanced, and production costs will not be significantly increased.

Owner:GUANGZHOU LONGZHU CHEM CO LTD

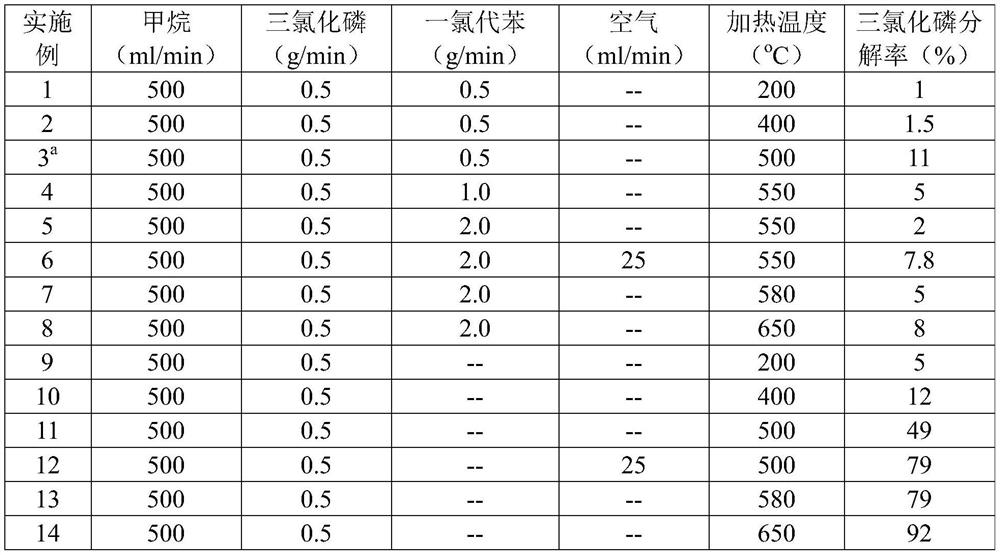

Method for effectively inhibiting thermal decomposition of phosphorus trichloride in preparation process of monoalkyl phosphine dichloride

InactiveCN113105503AAvoid decompositionIncrease profitGroup 5/15 element organic compoundsAromatizationPhosphorus trichloride

The invention discloses a method for effectively inhibiting thermal decomposition of phosphorus trichloride in the preparation process of monoalkyl phosphine dichloride. The method comprises the following steps: adding an auxiliary agent together with phosphorus trichloride in the preparation process of monoalkyl phosphine dichloride, wherein the auxiliary agent is a chlorobenzene aromatic compound, and the mass ratio of the auxiliary agent to phosphorus trichloride is 20: 1-0.1: 1. The method is simple and effective, and decomposition of phosphorus trichloride can be efficiently inhibited by adding a small amount of auxiliaries, so that the utilization rate and conversion rate of phosphorus trichloride are improved. Meanwhile, after the reaction is finished, thorough separation of the auxiliary agent can be realized by simply controlling the temperature of a reaction mixture. According to the method, the effect is excellent, the production cost is not greatly increased, and meanwhile, the addition of the auxiliary agent does not cause side reaction, so that the method is suitable for large-scale industrial production requirements.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

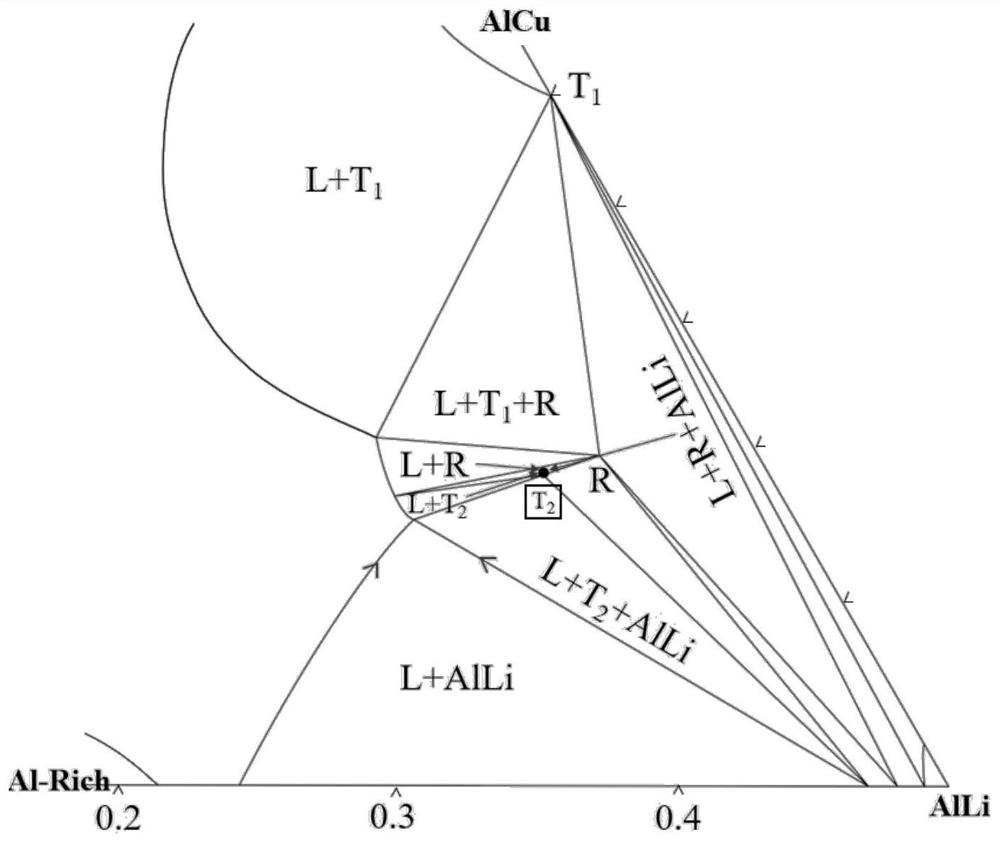

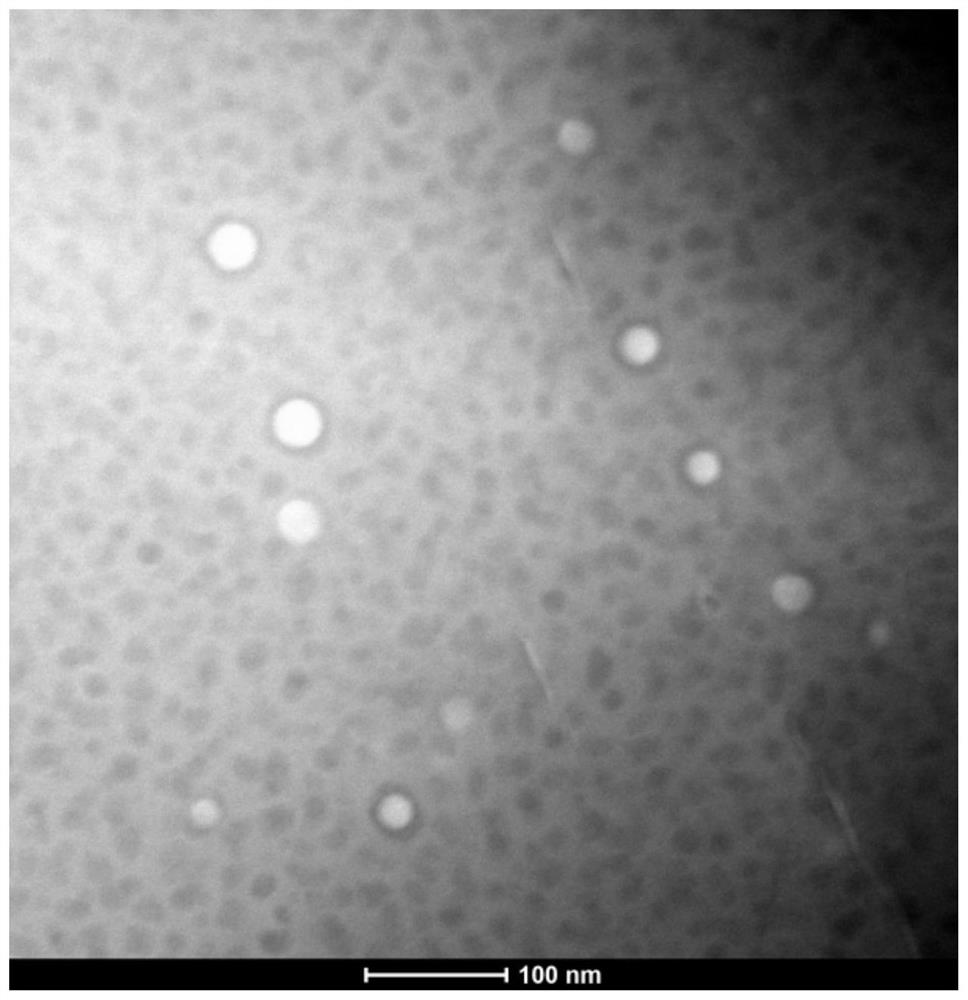

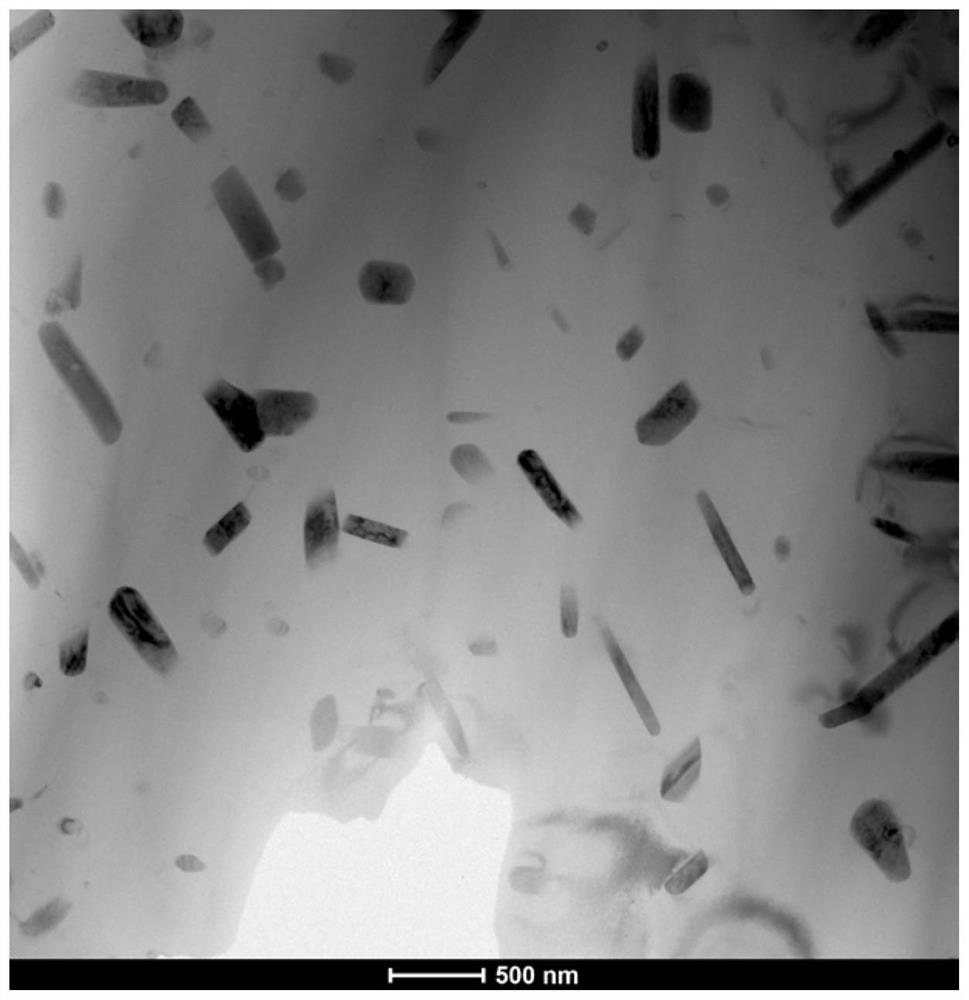

Alloying method for inducing icosahedron quasicrystal phase to be subjected to in-situ synthesis to reinforce cast aluminum-lithium alloy

The invention discloses an alloying method for inducing an icosahedron quasicrystal phase to be subjected to in-situ synthesis to reinforce cast aluminum-lithium alloy, and relates to the method for inducing the quasicrystal phase to be subjected to in-situ synthesis to reinforce the cast aluminum-lithium alloy. The method aims to solve the technical problems that in the existing aluminum-lithium alloy casting process, a large number of delta'-Al3Li particles are separated out, the coplanar slippage tendency is intensified, the stress concentration phenomenon at the grain boundary is more obvious, and the obdurability of the alloy is obviously reduced. The invention relates to the alloying method for inducing the quasicrystal phase to be subjected to in-situ synthesis to reinforce the cast aluminum-lithium alloy, the separation-out number of Al3Li reinforcing particles in the quasicrystal reinforced cast aluminum-lithium alloy is inhibited, meanwhile, the separation-out number of icosahedron quasicrystal phases T2-Al6CuLi3 is greatly increased, and the product of strength and ductility of alloy is improved by more than five times.

Owner:HARBIN INST OF TECH

A lever-type flip-top automatic flush toilet

ActiveCN110924493BOff does not affectGuaranteed water useWater closetsFlushing devicesGear wheelFlush toilet

The invention discloses a lever-type reversible automatic flushing toilet, which comprises a toilet body, a toilet cover and a water tank. The flushing valve in the water tank is opened by lifting a connecting rod. The joint of the toilet body is provided with a starting mechanism and a linkage switching mechanism. The lever mechanism is arranged on the front wall of the water tank to connect the lifting link and the gear starting mechanism. The starting mechanism includes a starting mechanism. Arm rotating shaft, gear mechanism and starting arm, the rotating shaft of the toilet lid is transmitted with the rotating shaft of the starting arm through the gear mechanism, the rotating shaft of the starting arm is installed on the body of the toilet, and the linkage switching mechanism controls the starting arm The transmission relationship between the arm and the rotating shaft of the starting arm, the end of the starting arm is connected with the lever mechanism through a tension spring. The invention realizes closing the toilet lid and simultaneously starting the flushing valve for flushing, which is convenient for design and modification in the prior art.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A method of strengthening sintering of high-proportion iron concentrate

The invention discloses a method for strengthening sintering of high-proportion iron ore concentrate. The sintering raw material is divided into two materials and then palletized. The first material comprises a part of the iron ore concentrate, quick lime and coke powder separated from the sintering raw material, first-stage palletizing is carried out on the first material, then second-stage palletizing is carried out on the first material and the second material, and the second material comprises a part of the iron ore concentrate, quick lime, coke powder, ore fines, lime stone, dolomite and return fines. By distributing the concentrate, the quick lime and the coke powder in the two materials reasonably, the purposes of palletizing strengthening and sintering mineralizing are achieved. For sintering of an iron mine with the iron ore concentrate accounting for 50-70 percent of the total mass of the iron core, after the strengthening technology is utilized, the utilization factor of a sintering machine is improved by 0.05-0.3t / (m<2>.h), the sinter yield is improved by 1-4 percent, the drum strength is improved by 0.5-4 percent, and the output index and the quality index of sintering of the high-proportion iron ore concentrate are improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com