Method for increasing interlayer binding force of high-temperature superconducting narrow-headed wire

A technology of interlayer bonding and high-temperature superconductivity, which is applied in the usage of superconductor elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of inconspicuous effect, insufficient bonding force, and inability to satisfy lateral twisting and other problems, to achieve the effect of reducing the possibility of quenching, increasing production costs, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

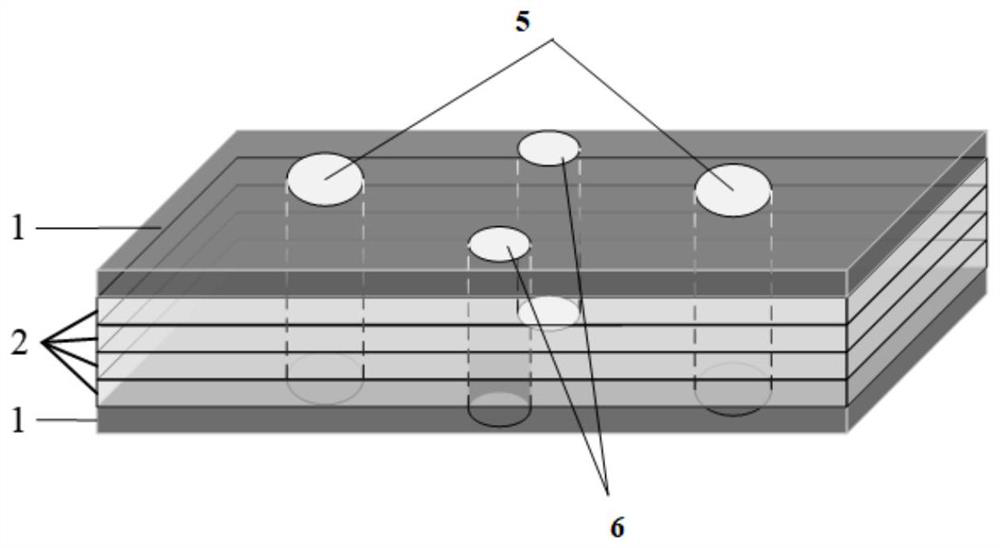

[0042] For 4 second-generation high-temperature superconducting strips 2 with a width of 2mm and a length of 30mm and 2 copper strips 1 with a width of 2mm and a length of 30mm, prepare a high-temperature superconducting narrow stack containing "soldering tin columns" according to the following steps Wire:

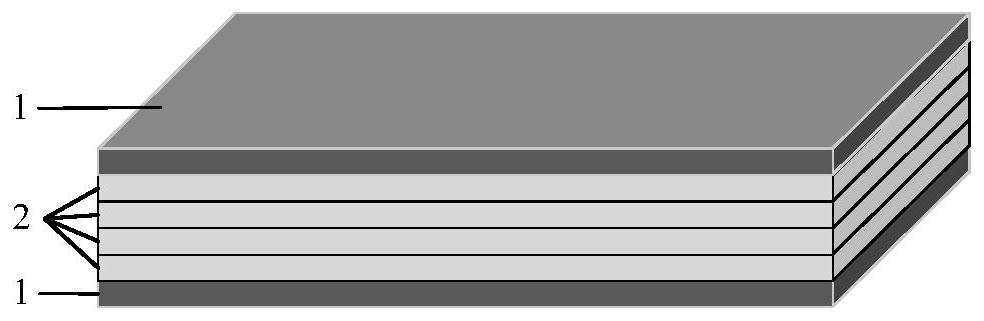

[0043] (1) The second-generation high-temperature superconducting strip 2 and the copper strip 1 are stacked and packaged into a high-temperature superconducting narrow stack line after being tinned in a tin furnace; figure 1 It is a schematic diagram of a high-temperature superconducting narrow stack line, wherein the second-generation high-temperature superconducting strip 2 is located between the copper strips 1 and 1 .

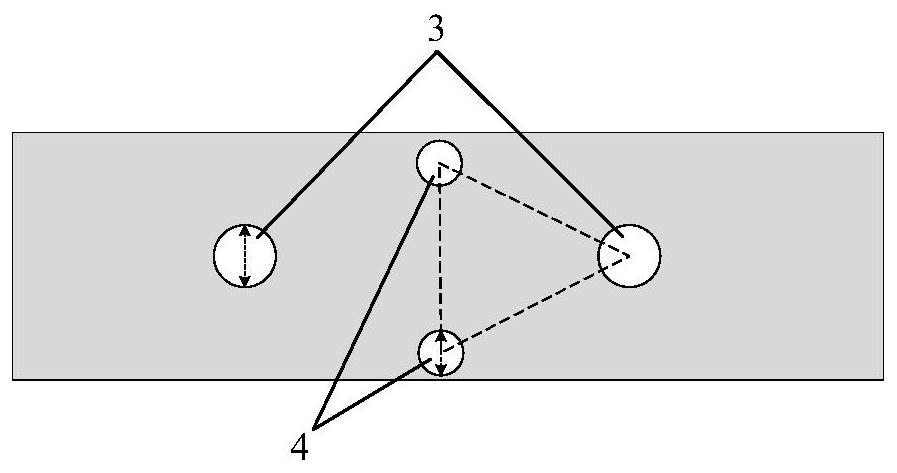

[0044] (2) Make circular through holes through all layers on the surface of the narrow pile line, and the through holes are divided into the first through hole 3 (9 pieces) and the second through hole 4 (16 pieces). figure 2 It is a top view of the h...

Embodiment 2

[0059] For 4 second-generation high-temperature superconducting strips 2 with a width of 2mm and a length of 30mm and 2 copper strips 1 with a width of 2mm and a length of 30mm, prepare a high-temperature superconducting narrow stack containing "soldering tin columns" according to the following steps Wire:

[0060] (1) The second-generation high-temperature superconducting strip 2 and the copper strip 1 are stacked and packaged into a high-temperature superconducting narrow stack line after being tinned in a tin furnace;

[0061] (2) Make circular through holes through all layers on the surface of the narrow pile line, and the through holes are divided into the first through hole 3 (9) and the second through hole 4 (16), and the first through hole 3 has an aperture of 0.5 mm; the diameter of the second through hole 4 is 0.2mm. The second through hole is located on the perpendicular bisector of the connecting line of two adjacent first through holes, and the second through hol...

Embodiment 3

[0067] The present embodiment is the same as the embodiment, and the difference is only that: the first through hole 3 aperture is 0.44mm (22% of the strip width); the second through hole 4 aperture is 0.36mm (18% of the strip width). ).

[0068] The performance test result of this embodiment is as follows:

[0069] table 3

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com