Glass panel for solar photovoltaic cell and preparation method of glass panel

A photovoltaic cell and glass panel technology, applied in photovoltaic power generation, photovoltaic module support structure, photovoltaic modules and other directions, can solve the problems of sacrificing luminous flux, affecting power generation efficiency, reducing light transmittance, etc., so as not to reduce power generation efficiency and increase production Cost, the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

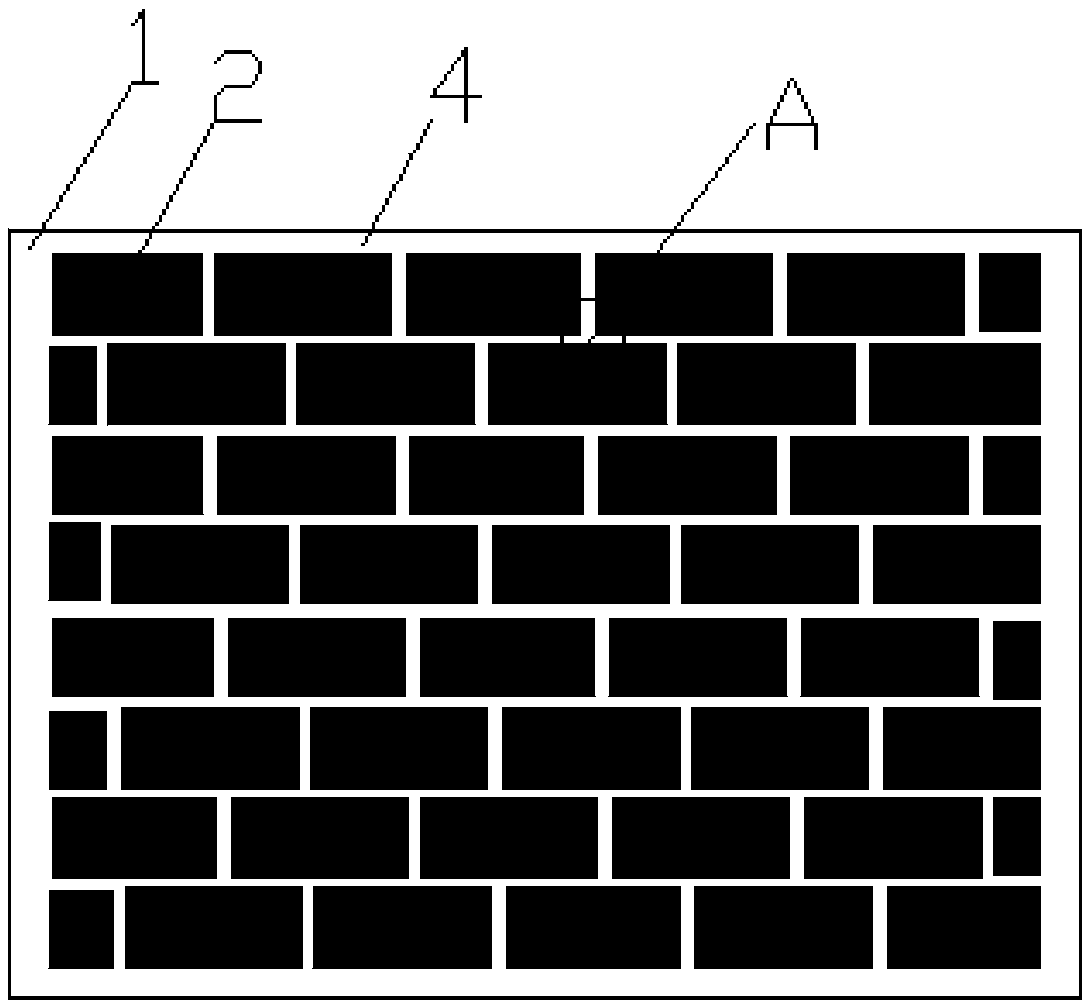

[0039] Such as Figure 1-2 , a panel for solar photovoltaic cells, comprising a substrate 1, on which a pattern area 2 is distributed, and a plurality of pattern area optical structural unit configurations 3 are arranged and fixed on the pattern area 2. The optical structural unit configuration 3 in the pattern area forms a brick-shaped pattern, and there are blank areas 4 between the pattern areas, that is, contrast areas. The optical structural unit configuration 3 in the pattern area is a square (also can be linear, curved, or one or more of circular, elliptical, rhombus, triangle, rectangular, trapezoidal, parallelogram, linear, curved) Regular or irregular shapes composed of shapes, preferably rhombus, triangle.).

Embodiment 2

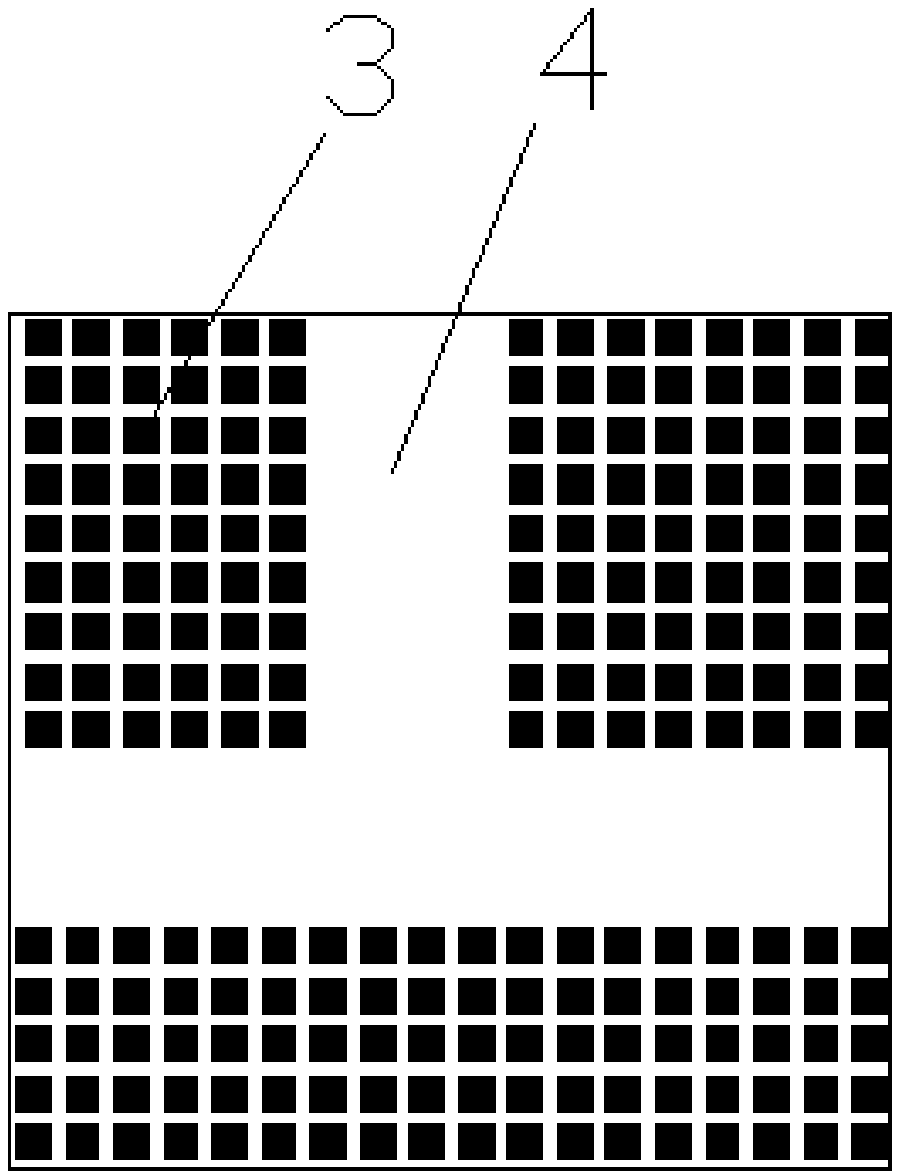

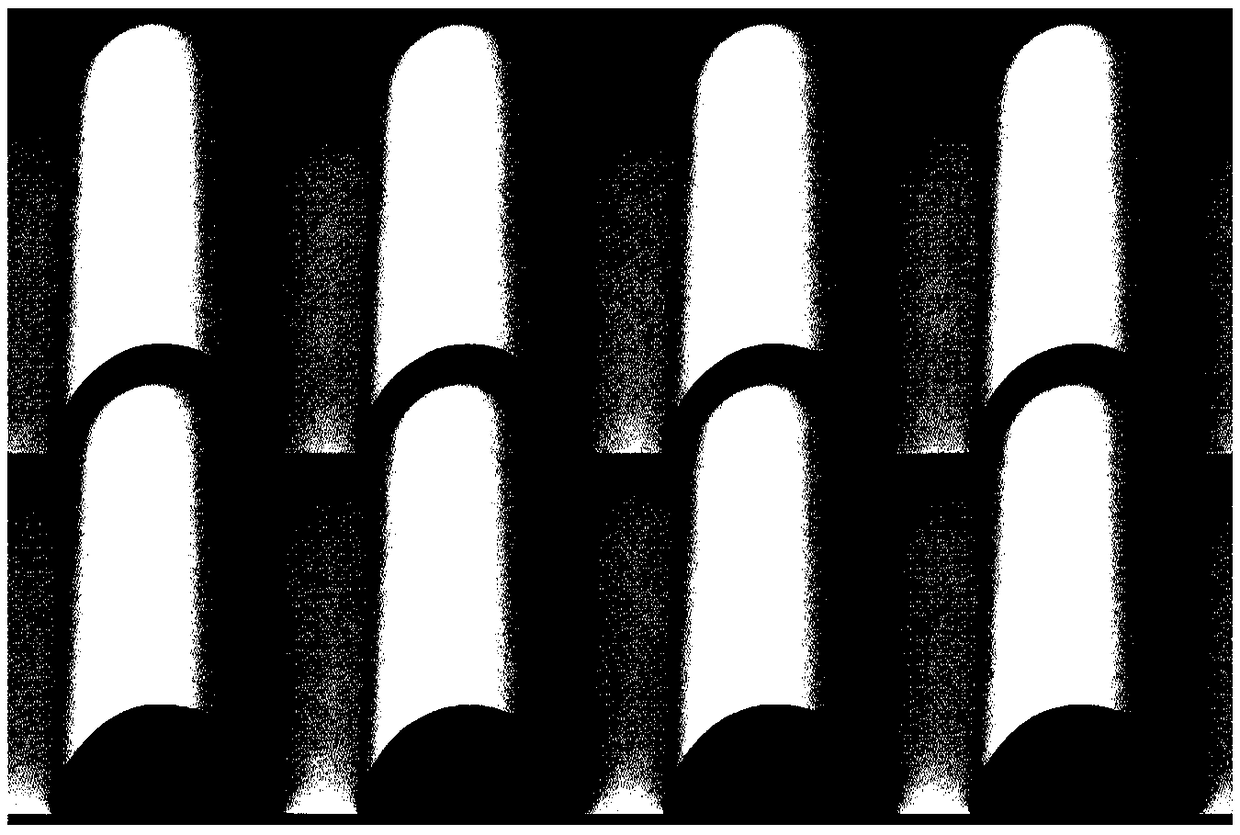

[0041] Such as Figure 3-4 , a panel for solar photovoltaic cells, comprising a substrate 1, a pattern area 2 is distributed on the substrate 1, and a plurality of pattern area optical structural unit configurations 3-1 are arranged and fixed on the pattern area 2. The optical structural unit configuration 3-1 in the pattern area forms a tile-shaped pattern (also can be a marble pattern or a bluestone pattern).

[0042] The optical structure unit configuration 3-1 in the pattern area is a square (also can be linear, curved, or one of circular, elliptical, rhombus, triangular, rectangular, trapezoidal, parallelogram, linear, and curved) Regular or irregular shapes composed of one or more shapes, preferably rhombus, triangle.).

[0043]The optical structural unit configurations 3-1 in the pattern area are closely arranged. The optical structural unit configuration 3-1 in the pattern area achieves the three-dimensional effect of the pattern through the arrangement density and t...

Embodiment 3

[0047] Embodiment 3 The preparation method of the glass panel that solar photovoltaic cell is used

[0048] Transfer UV-curable transparent transfer adhesive on the substrate according to the pattern to form the configuration of the optical structural unit in the pattern area; the transfer UV-curable transparent transfer adhesive includes the following steps:

[0049] Embossing film: use high-precision laser engraving technology to make UV-curable transparent transfer adhesive into embossed transfer film with different texture patterns;

[0050] Lamination film: Cover the transfer film with the pattern to be transferred on the outer surface of the substrate coated with UV-curable transparent transfer adhesive;

[0051] Curing: irradiated with UV lamp;

[0052] Release: the transfer film is peeled off from the substrate to obtain a glass panel with an optical structural unit configuration in the pattern area.

[0053] The substrate is preferably glass coated with a mirror-eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com