A kind of in-situ preparation method of heat insulation material

A thermal insulation material, in-situ preparation technology, applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problem that thermal insulation materials cannot achieve thermal insulation repair, thermal insulation materials are difficult to meet the structure, complex and other problems, to achieve the effect of excellent heat insulation performance, convenient construction and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

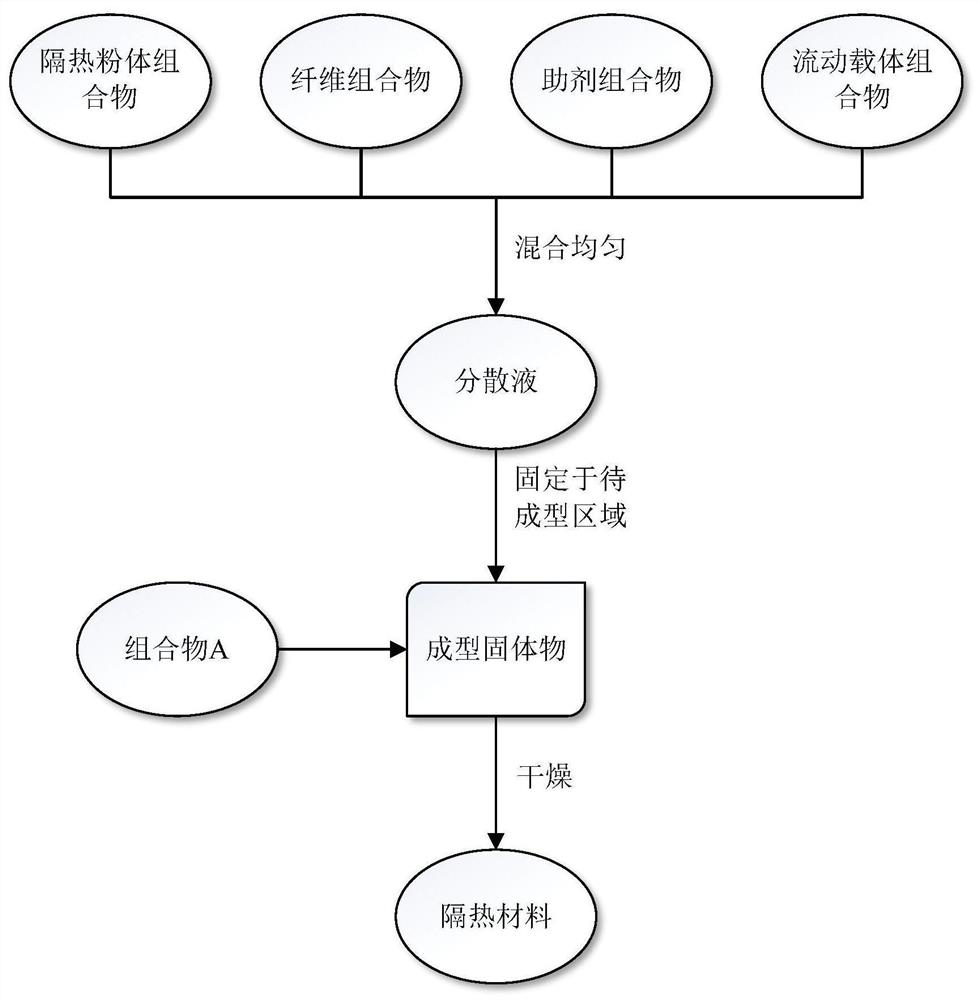

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Mix 10% heat insulation powder composition, 10% fiber composition, 20% auxiliary agent composition and 60% fluid carrier composition and disperse evenly to prepare a dispersion liquid;

[0040] The heat-insulating powder composition is an equal mass ratio composition of phenolic airgel powder and hollow ceramic balls;

[0041] The particle size range of the heat-insulating powder composition is 1-10 microns;

[0042] The fiber composition is an equal mass ratio composition of quartz fiber and mullite fiber;

[0043] The length range of the fiber composition is 50-100 microns;

[0044] The additive composition is a composition of potassium titanate whiskers and zirconium silicate powder;

[0045] The particle size range of the auxiliary composition is 20-50 microns;

[0046] The mobile carrier composition is ethanol;

[0047]Step 2. Scrape-coat the dispersion obtained in step 1 on the pits on the surface of the phenolic resin heat insulating material by spray...

Embodiment 2

[0053] Step 1. Mix 15% of thermal insulation powder composition, 15% of fiber composition, 20% of additive composition and 50% of fluid carrier composition and disperse evenly to prepare a dispersion liquid;

[0054] The heat-insulating powder composition is an equal mass ratio composition of quartz / alumina heat-insulating tile matrix powder, siliceous airgel powder, and hollow ceramic balls;

[0055] The particle size range of the heat-insulating powder composition is 10-30 microns;

[0056] The fiber composition is an equal proportion composition of quartz fiber and alumina fiber;

[0057] The length range of the fiber composition is 100-500 microns;

[0058] The additive composition is an equal mass ratio composition of silicon carbide powder and boron nitride powder;

[0059] The particle size range of the auxiliary composition is 1-20 microns;

[0060] The mobile carrier composition is an equal mass ratio composition of water and ethanol;

[0061] Step 2. The dispersi...

Embodiment 3

[0066] Step 1. Mix 12% heat insulation powder composition, 13% fiber composition, 22% auxiliary agent composition and 53% fluid carrier composition and disperse evenly to prepare a dispersion liquid;

[0067] The heat-insulating powder composition is an equal mass ratio composition of fumed silica powder and hollow ceramic balls;

[0068] The particle size range of the heat-insulating powder composition is 30-100 microns;

[0069] The fiber composition is an equal mass ratio composition of high silica fiber and glass fiber;

[0070] The length range of the fiber composition is 500-2000 microns;

[0071] The additive composition is an equal mass ratio composition of potassium titanate whiskers and titanium oxide powder;

[0072] The particle size range of the auxiliary composition is 15-35 microns;

[0073] The mobile carrier composition is an equal mass ratio composition of water and ethanol;

[0074] Step 2. Brush the dispersion obtained in step 1 on the surface of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com