Wind turbine rotor blade

一种风力涡轮机、转子叶片的技术,应用在风力发动机、风力发电机组件、与风向一致的的风力发动机等方向,能够解决高负载、高生产成本、运输叶片困难等问题,达到增大塔架负载、增大生产成本、改进空气动力学特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

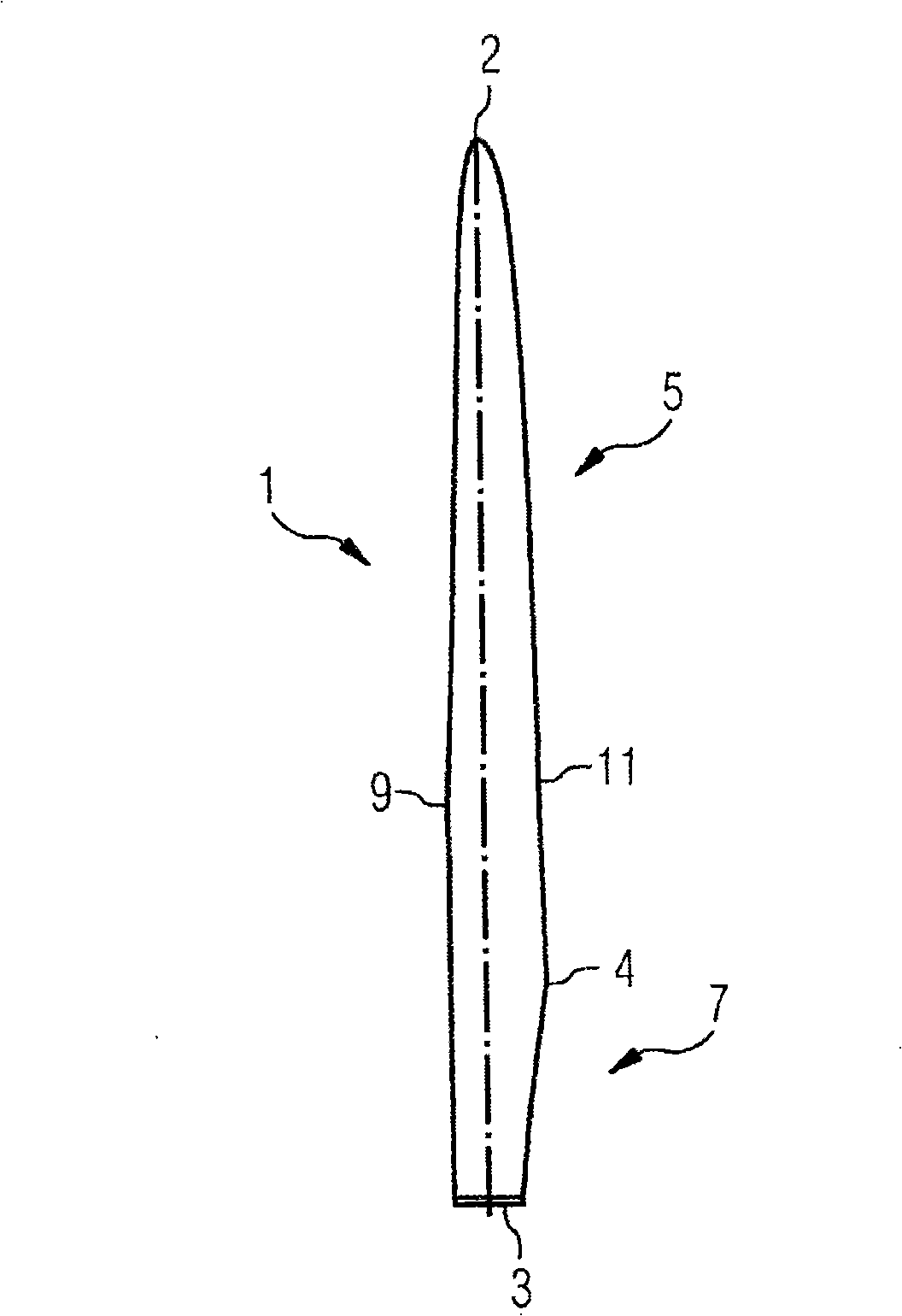

[0021] figure 1 Denotes a wind turbine blade 1 as it is normally used in a three-blade rotor. However, the invention should not be limited to blades for three-blade rotors. In fact, it can also be implemented into other rotors, for example, one-blade rotors or two-blade rotors.

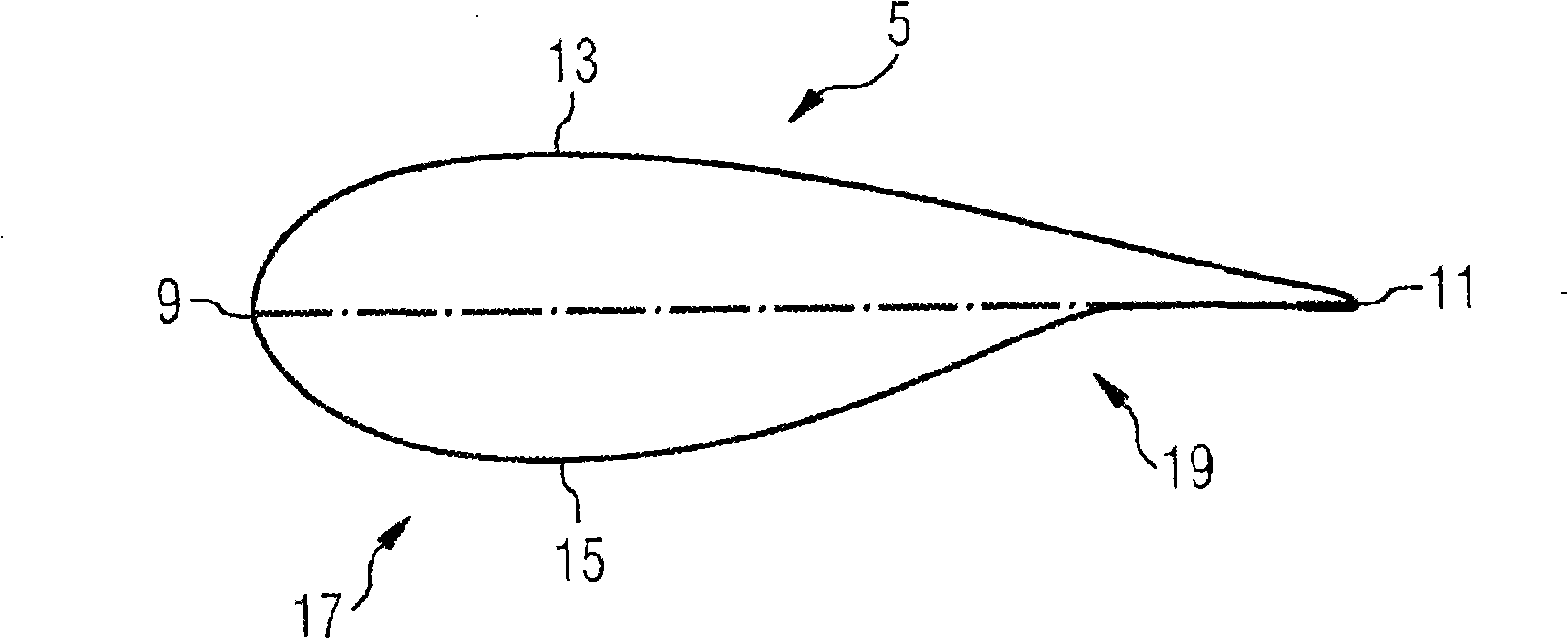

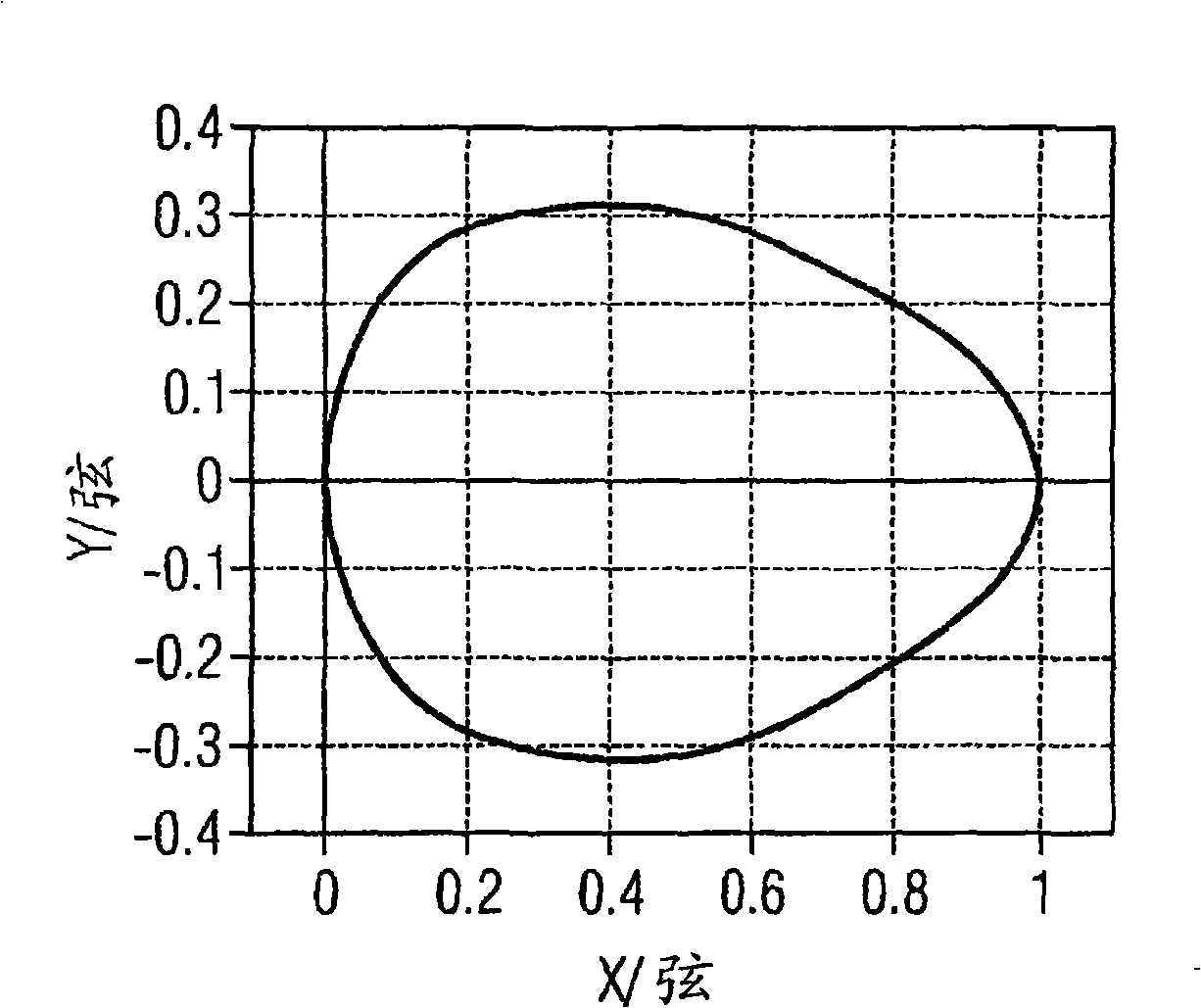

[0022] figure 1 The rotor blade 1 shown comprises a root 3 and a tip 2 with a cylindrical profile. The tip forms the outermost part of the blade. The cylindrical profile of the root 3 is used to fix the blades to the bearings of the rotor hub. The rotor blade 1 also comprises so-called shoulders, which are defined as the portion of the blade where the blade has the greatest profile depth, ie the greatest chord length. A wing 5 extends between the shoulder 4 and the tip 2, said wing having an aerodynamically shaped profile. Between the shoulder 4 and the cylindrical root 3 extends a transition section 7 in which the transition from the aerodynamic profile of the wing 5 to the cylindrical profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com