Method for effectively inhibiting thermal decomposition of phosphorus trichloride in preparation process of monoalkyl phosphine dichloride

A technology of monoalkylphosphine dichloride and phosphorus trichloride, which is applied in the field of preparation of new monoalkylphosphine dichloride, and can solve the problems of thermal decomposition of phosphorus trichloride, flammability and explosion of elemental phosphorus, safety hazards, etc. problems, to achieve efficient inhibition of decomposition, suitable for large-scale industrial production, and excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

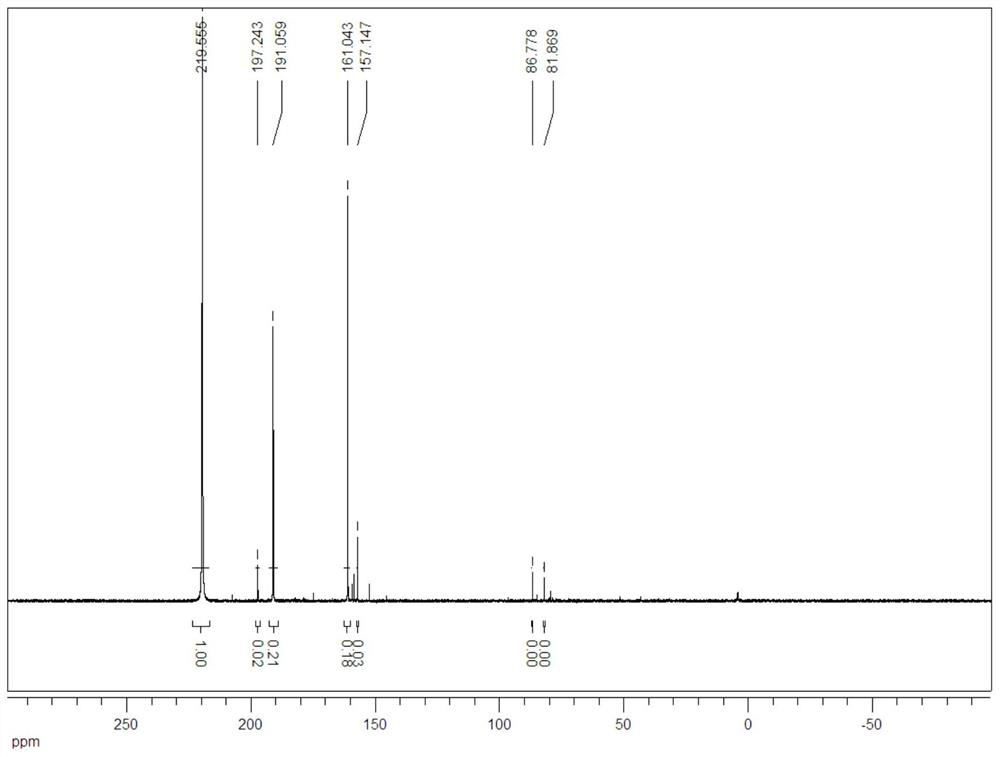

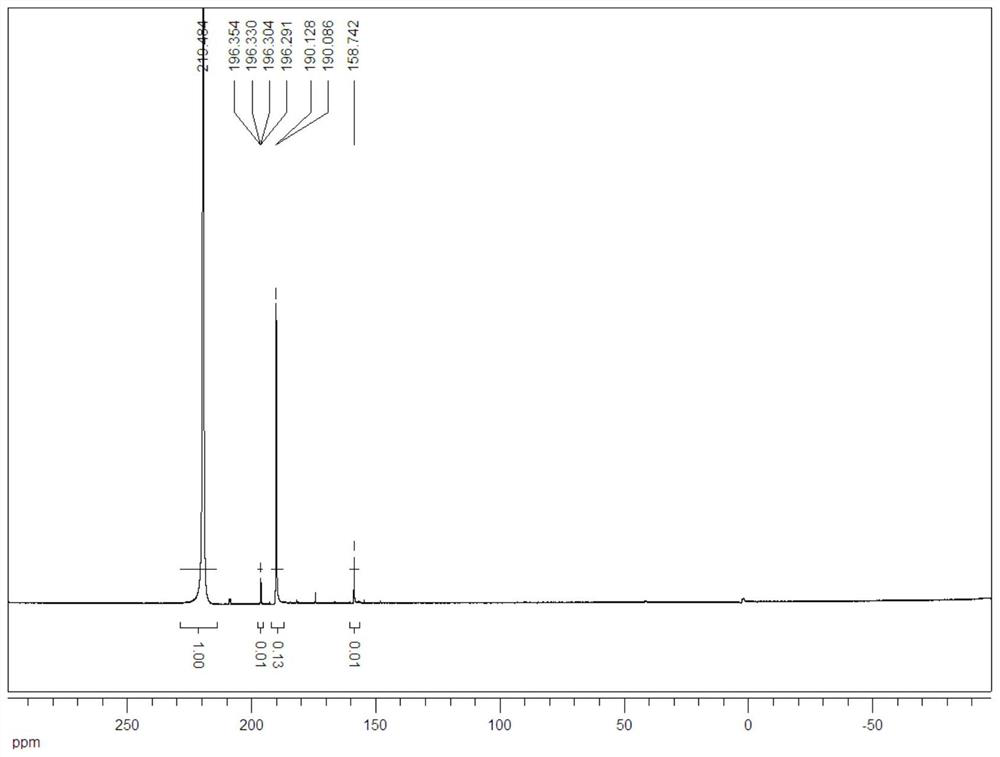

Image

Examples

Embodiment 1

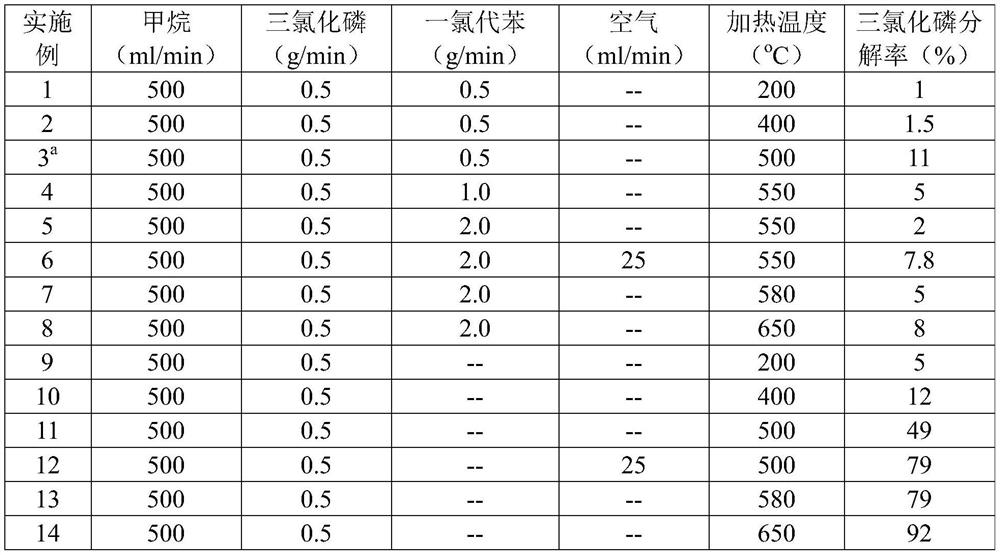

[0031] The reaction was evaluated with a tubular reactor with a diameter of 3 cm and a length of 50 cm. The specific experimental process was as follows: phosphorus trichloride and monochlorobenzene were directly mixed, and injected into a 150 ° C vaporizer at a certain flow rate through a liquid feeding device. The gas, methane and air pass through the high-temperature heating reaction zone and then pass through a tubular cooler with a temperature between 130-160°C. The auxiliary agent is cooled and collected as a liquid. The separation yield exceeds 90%. The gaseous product is further separated by cyclone. The liquid mixture containing the product is obtained after treatment in the cooling section and the final distillation separation to obtain the target product. The liquid material was collected for analysis, and the reaction conditions and results are listed in Table 1 below.

Embodiment 2 to 8

[0033] The experiment was carried out in the same manner as in Example 1 except that the reaction was adjusted according to the reaction conditions in Table 1, and the results are shown in Table 1 below.

Embodiment 9 to 14

[0035] For comparison, the test was carried out in the same manner as in Example 1 except that the reaction was adjusted according to the reaction conditions in Table 1 (without adding chlorobenzene), and the results are shown in Table 1 below.

[0036] Table 1

[0037]

[0038] In addition, experiments have confirmed that the addition of air will significantly aggravate the decomposition of phosphorus trichloride. Comparative Examples 6 and 12 prove that in the presence of air, monochlorobenzene can also well inhibit the decomposition of phosphorus trichloride. Decomposition, indicating that under aerobic or anaerobic conditions, monochlorobenzene can play a good role in inhibiting the decomposition of phosphorus trichloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com