Method for preparing drill collar steel

A drill collar and molten steel technology, applied in the field of drill collar steel and its preparation, can solve the problems of drill collar steel strength and plastic toughness mismatch, drill collar steel plastic toughness, increase steel production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

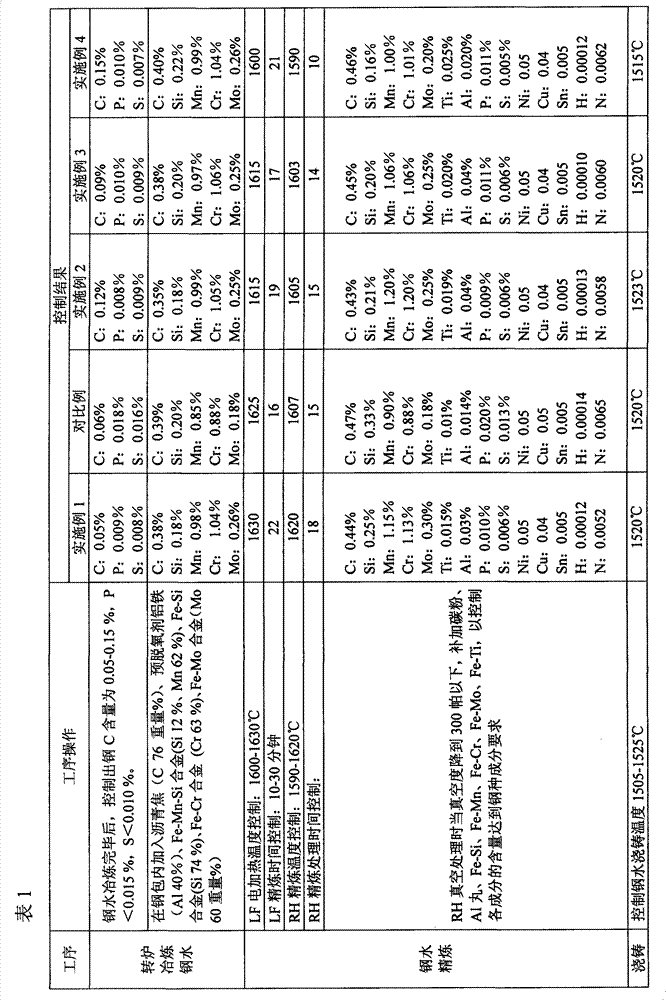

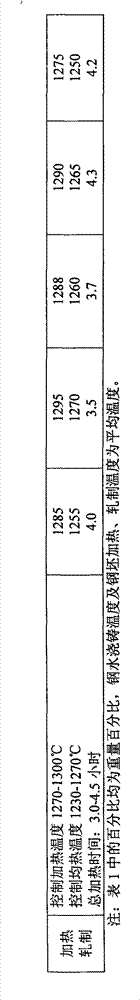

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing drill collar steel, the method comprising:

[0033] (1) adopting the molten iron after desulfurization to carry out blowing;

[0034] (2) tapping molten steel after blowing into the ladle, and carrying out carburization and alloying in the process of tapping into the ladle;

[0035] (3) carrying out refining outside the furnace with the molten steel after alloying, the method of refining outside the furnace comprises argon blowing refining, LF refining and vacuum refining;

[0036] (4) Pouring the molten steel refined outside the furnace.

[0037] In order to control the content of impurities Ni, Cu and Sn in the drill collar steel provided by the present invention, the C content of the steelmaking raw material can be selected to be > 3.5% by weight, Ni content < 0.2% by weight, Cu content < 0.2% by weight, Hot metal or steel scrap with Sn content < 0.05% by weight is used as raw material. In addition, in ord...

Embodiment 1

[0050] This embodiment is used to illustrate the drill collar steel provided by the present invention and its preparation method.

[0051] The desulfurized molten steel is subjected to blowing. Based on the total weight of the molten steel, when the C content in the molten steel is 0.05% by weight, the P content is 0.009% by weight, and the S content is 0.008% by weight, the steel is immediately tapped into the ladle. When tapping, first add 3.2 kg of pitch coke (the C content is 76% by weight, Panzhihua Yangcheng Metallurgical Auxiliary Materials Co., Ltd.) for each ton of molten steel to increase carbon. Add 3.7 kilograms of pre-deoxidizer aluminum-iron alloy (Al content is 40% by weight, Anyang Hengwang Metallurgical Refractories Co., Ltd.) in the ladle, then add 6.0 kilograms of refining slag, Fe-Mn-Si (Si content of 18% by weight, Mn content of 68% by weight, Anyang Hengwang Metallurgical Refractory Co., Ltd.) 6.8 kg, Fe-Mn (Mn content of 81% by weight, Anyang Hengwang Me...

Embodiment 2

[0057] This embodiment is used to illustrate the drill collar steel provided by the present invention and its preparation method.

[0058] Melting iron-containing raw materials into molten steel, then desulfurizing, blowing the desulfurized molten steel, based on the total weight of molten steel, when the C content in the molten steel is 0.12% by weight, the P content is 0.008% by weight, and the S content is 0.009% by weight % when the steel is tapped into the ladle immediately. When tapping, first add 2.1 kilograms of pitch coke (the C content is 76% by weight, Panzhihua Yangcheng Metallurgical Auxiliary Materials Co., Ltd.) for each ton of molten steel to increase carbon. Add 2.8 kilograms of pre-deoxidizer aluminum-iron alloy (Al content is 40% by weight, Anyang Hengwang Metallurgical Refractories Co., Ltd.) in the ladle, then add 6.0 kilograms of refining slag, Fe-Mn-Si (Si content of 18% by weight, Mn content of 68% by weight, Anyang Hengwang Metallurgical Refractory Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com