Method for strengthening sintering of high-proportion iron ore concentrate

An iron concentrate, high-proportion technology, applied in the field of strengthening high-proportion iron concentrate sintering, can solve the problems of failure to simultaneously strengthen fine-grained concentrate ore formation, and sinter strength cannot be improved, so as to increase equipment The effect of investment cost, promotion of ball formation and growth, and simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

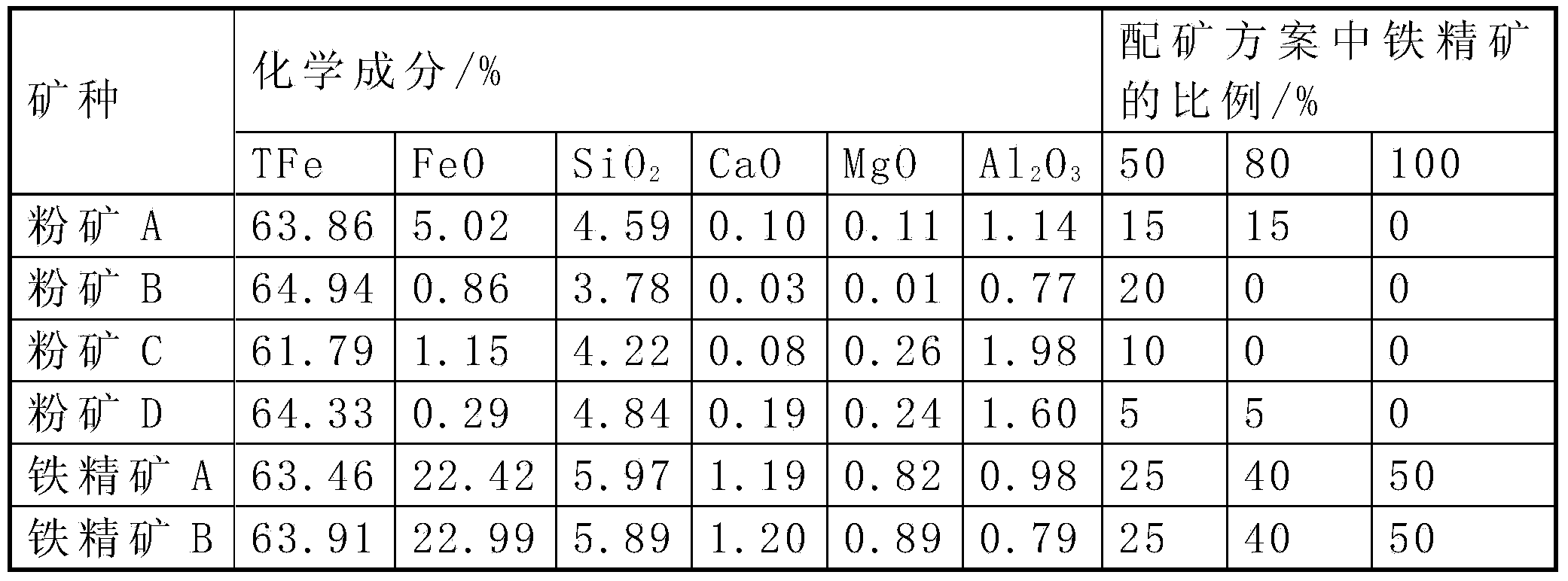

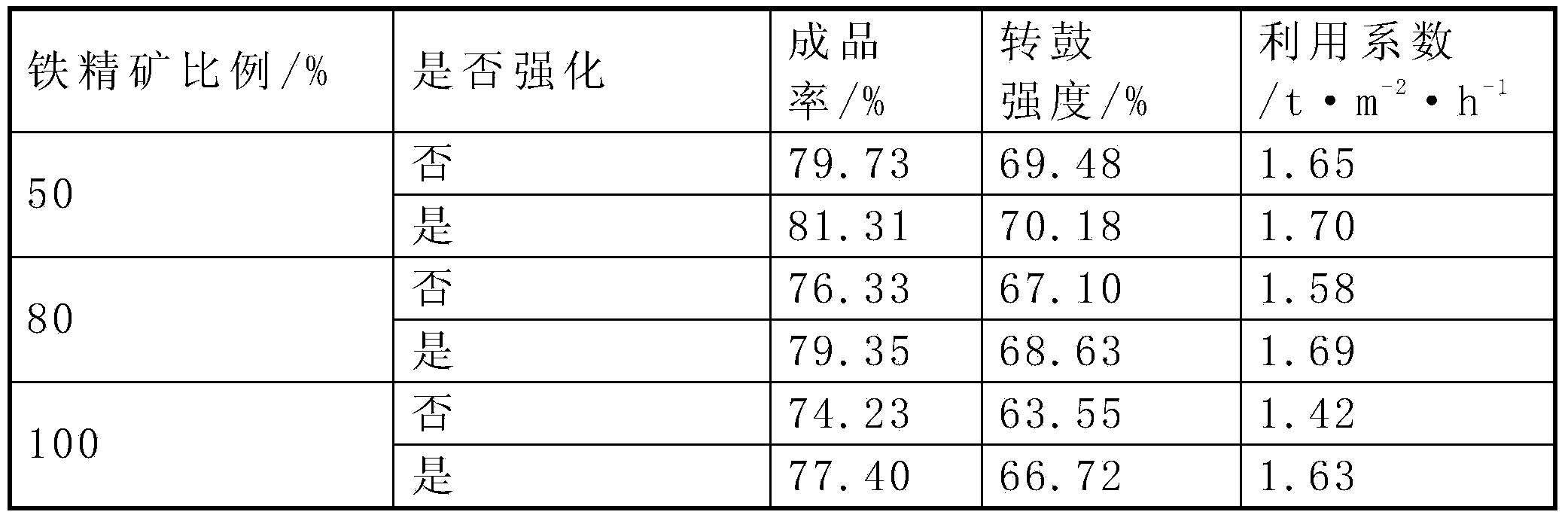

Embodiment 1

[0023] When the total amount of iron ore concentrate accounts for 50% of the total iron ore, the sintering raw material is divided into two parts for granulation. The ore content accounts for 40% of the weight of the material. The Ca / Fe molar ratio of the raw material composed of quicklime, limestone, dolomite, and -0.5mm iron ore in the second part of the material is 0.4. The content of coke powder in the first part of the material is the second 1 / 2 of the coke powder content in the second part of the material. Granulate the first part of the material in a cylinder mixer for 4 minutes to make pellets of 1 to 8 mm; mix the pellets obtained in the first stage of granulation with the second part of the material, and granulate in a cylinder mixer for 3 minutes . After implementing the above strengthening measures, the utilization factor of the sintering machine has increased by 0.05t / (m 2 h), the yield rate increased by 1.58%, and the drum strength increased by 0.7%.

Embodiment 2

[0025] When the total amount of iron ore concentrate accounts for 80% of the total iron ore, the sintering raw material is divided into two parts for granulation. The ore content accounts for 45% of the weight of the material. The Ca / Fe molar ratio of the raw material composed of quicklime, limestone, dolomite, and -0.5mm iron ore in the second part of the material is 0.35. The content of coke powder in the first part of the material is the second 2 / 5 of the coke powder content in the second part of the material. Granulate the first part of the material in a cylinder mixer for 6 minutes to make pellets of 1 to 8 mm; mix the pellets obtained in the first stage of granulation with the second part of the material, and granulate in a cylinder mixer for 5 minutes . After implementing the above strengthening measures, the utilization factor of the sintering machine has increased by 0.11t / (m 2 h), the yield rate increased by 3.02%, and the strength of the drum increased by 1.53%. ...

Embodiment 3

[0027] When the total amount of iron ore concentrate accounts for 100% of the total iron ore, the sintering raw material is divided into two parts for granulation. After separating the first part of the material, the second part of the material The iron ore concentrate content of 0.5mm particle size accounts for 50% of the weight of the material. The Ca / Fe molar ratio of raw materials composed of quicklime, limestone, dolomite and -0.5mm particle size iron ore in the second part of the material is 0.3. The first part of the material The content of the medium coke powder is 1 / 3 of the content of the coke powder in the second part of the material. The first part of the material is made into pellets of 3 to 5 mm in a disc pelletizer; the pellets obtained in the first stage of granulation are mixed with the second part of the material, and granulated in a cylinder mixer for 6 minutes. After implementing the above strengthening measures, the utilization factor of the sintering mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com