Patents

Literature

56results about How to "Improve anti-overcharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode material of lithium ion cell and preparation method

InactiveCN1627550AGood cycle performanceGood high temperature performanceElectrode thermal treatmentActive material electrodesAnodeMetallurgy

The anode material is prepared from oxidation material layer of covering surface of at least one anode active material among LiCoO2, LiNi1-xCOxO2, LiNi1 / 3Mn1 / 3O2 and LiMn2O4. Weight of non-oxygen element in oxidation material layer can be 0.01-10 weight% of anode active material. Advantages of the anode material are: good cycle performance, favorable high temp property and high power discharge property, and anti over change property as well as simple technique and easy of production.

Owner:BYD CO LTD

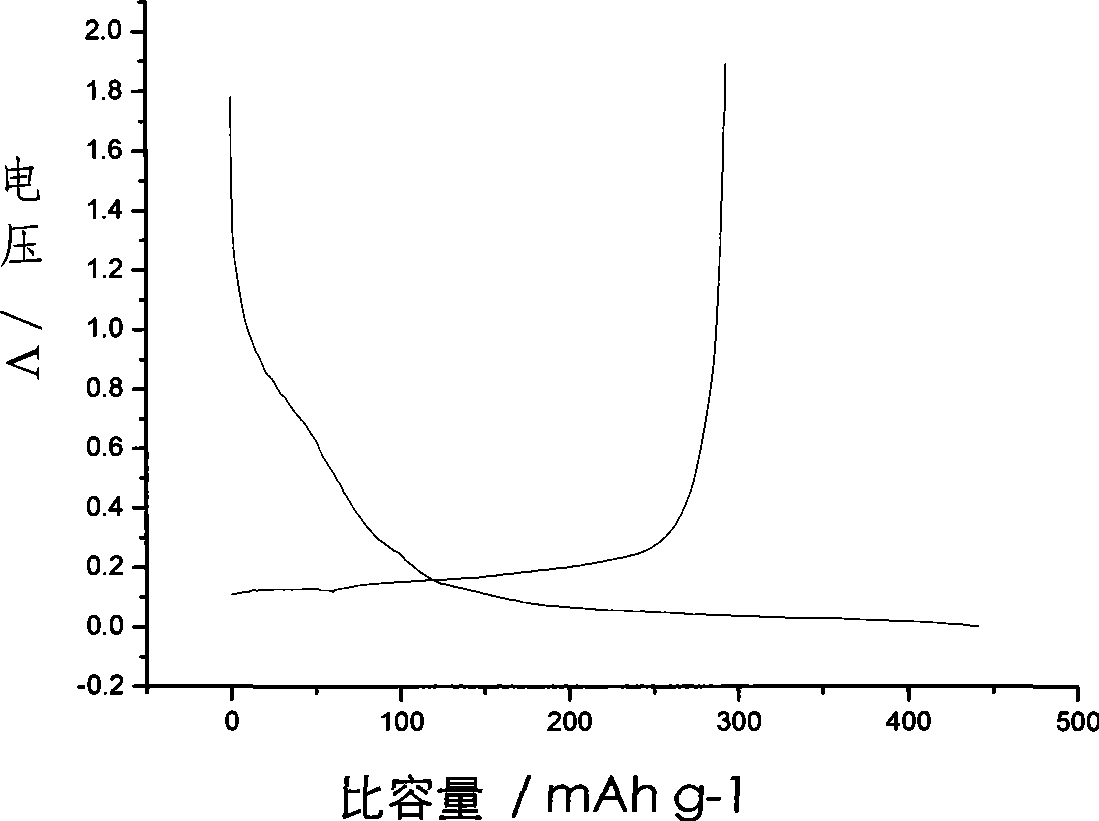

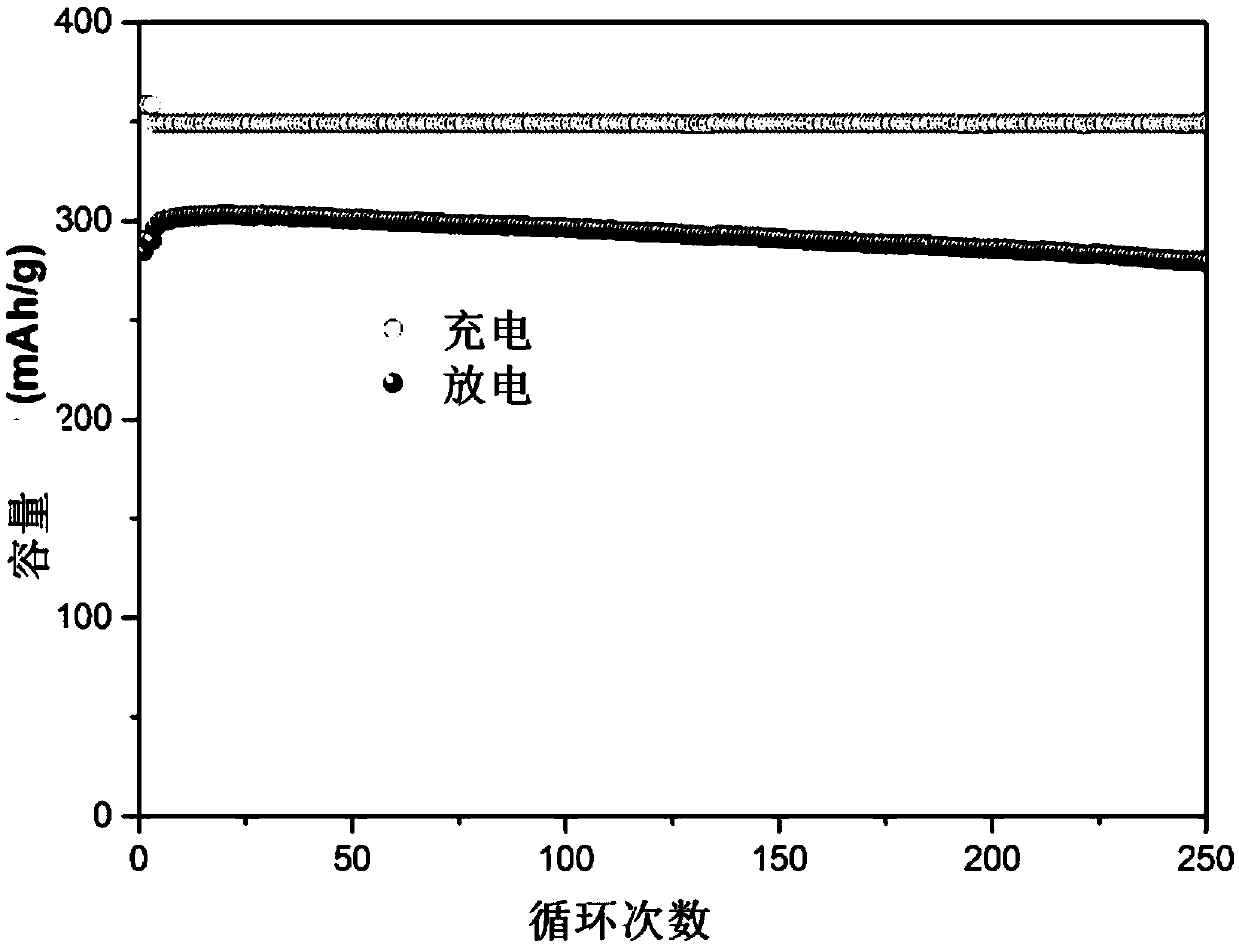

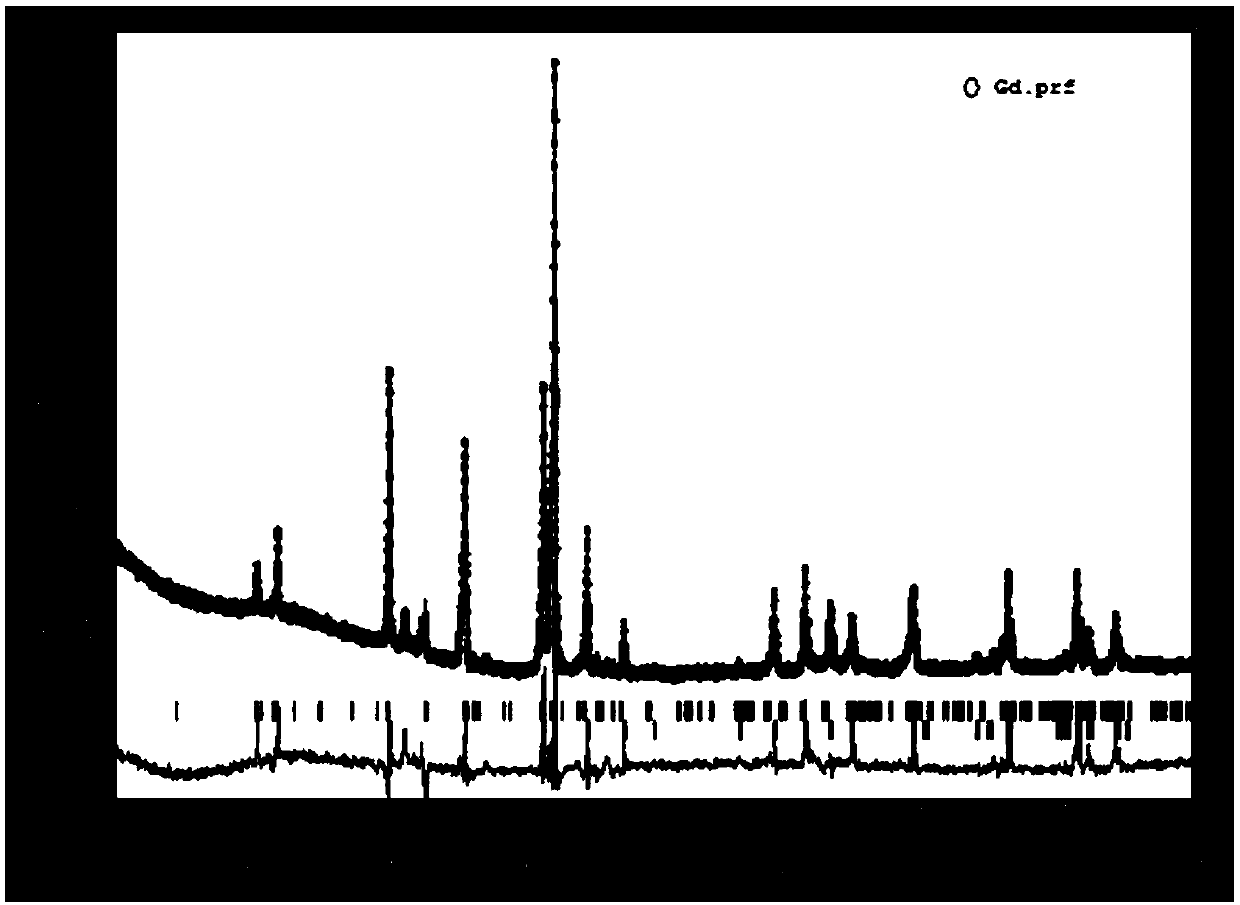

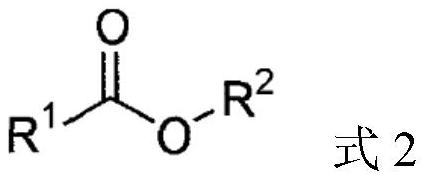

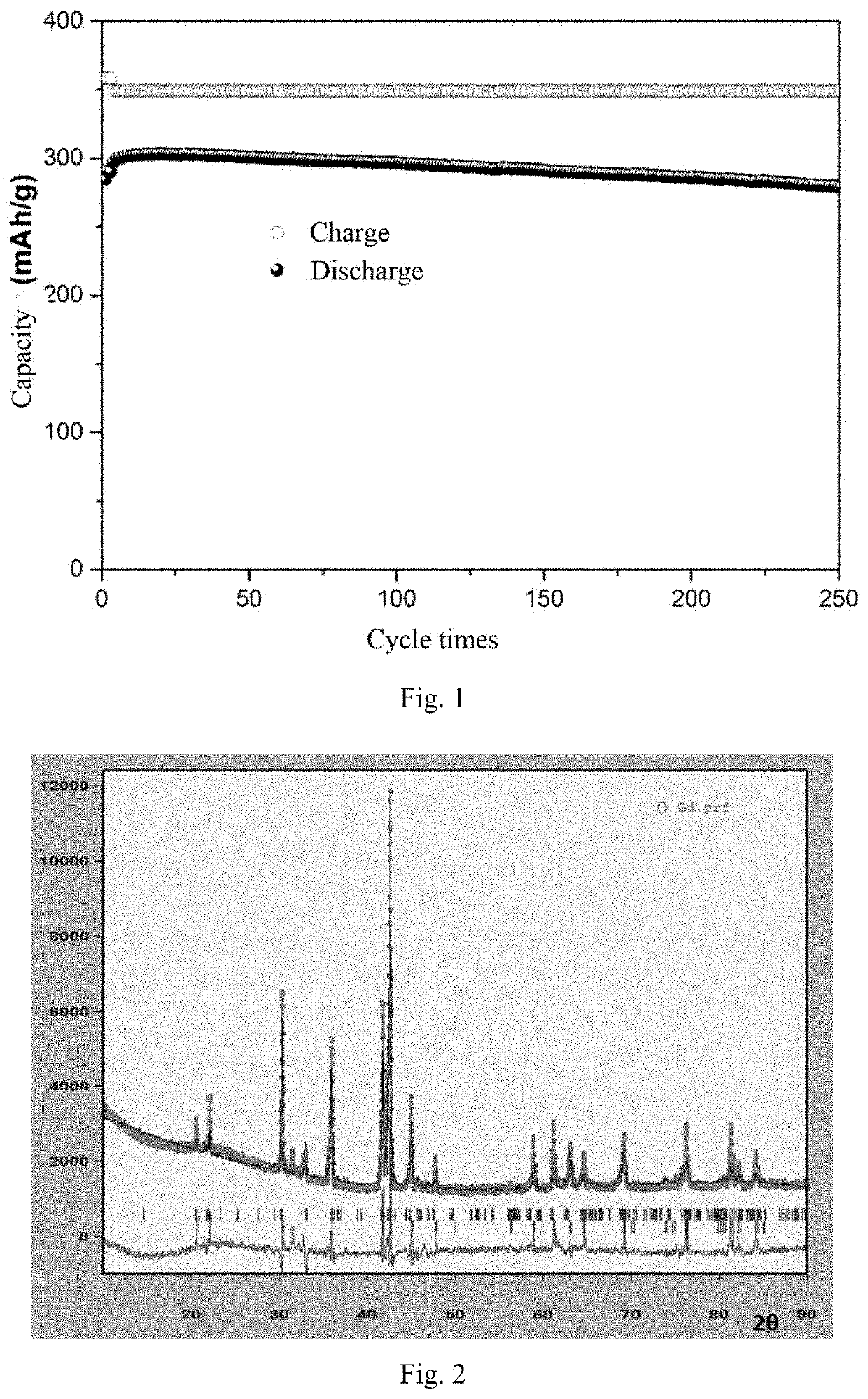

Method for preparing spinel lithium titanate

InactiveCN101567442AImprove cycle stabilityFast charge and dischargeElectrode manufacturing processesNitrogen gasHeat treated

A method for preparing the spinel lithium titanate belongs to the field of the battery. The aim of the invention is to provide a method for preparing the spinel lithium titanate. The essential point of the technical scheme of the invention is that the molecular formula of the spinel lithium titanate is LixTi1.25-yMyO3 / wz according to the method for preparing the spinel lithium titanate. The method for preparing comprises the following steps: (1) after mixing a lithium source and a titanium source with the atomic ratio between lithium and titanium for 0.6-1 into an organic solvent for executing ball milling for 8-24 hours, drying; (2) executing heat treatment to the dried object prepared in the step (1) at the temperature of 300-600 DEG C for 10-24 hours, cooling by radiation; and (3) mixing and executing ball milling to the material obtained in the step (2) and the coating material for 8-24 hours, and after sintering under the protection of nitrogen in the temperature of 700-1000 DEG C for 10-24 hours, cooling and sieving for obtaining the spinel lithium titanate of the invention. The method of the invention is used for preparing the lithium cell.

Owner:XINXIANG ZHONGKE SCI&TECH

Additive for lithium ion battery non-aqueous electrolyte and non-aqueous electrolyte made by the same

InactiveCN101471455AImprove anti-overcharge performanceImprove flame retardant performanceSecondary cellsIonDecomposition

The invention discloses an additive used in the nonaqueous electrolyte of a Li-ion battery for achieving good circle performance, safety performance and low-temperature performance of the Li-ion battery. The additive is a silane compound represented by formula (1): R1R2R3Si(OCH2CH2)nOCH3. The invention also discloses a nonaqueous electrolyte containing the additive. The nonaqueous electrolyte contains a Li salt, a nonaqueous organic solvent, and the silane compound represented by formula (1), wherein the silane compound accounts for 0.1 to 0.3 v / v% the nonaqueous organic solvent. The nonaqueous electrolyte in the Li-ion battery can form a dense and stable solid electrolyte interface membrane on the surface of negative electrodes, such as graphite so as to maximally suppress the decomposition of the electrolyte, thereby improving the charge / discharge efficiency and the circle property of the Li-ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Separators for nonaqueous-electrolyte secondary battery, and nonaqueous-electrolyte secondary battery

InactiveUS20120208070A1Avoid explodingPrevented short-circuitingPrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersLithiumEngineering

The invention relates to a separator for use in a nonaqueous-electrolyte secondary battery, and a nonaqueous-electrolyte secondary battery employing the separator, the separator comprising a positive electrode and a negative electrode which are capable of occluding and releasing lithium, a separator, and a nonaqueous electrolytic solution comprising a nonaqueous solvent and an electrolyte, the separator for use in the battery having an electroconductive layer, the electroconductive layer having (1) an apparent volume resistivity of 1×10−4 Ω·cm to 1×106 Ω·cm, or (2) a volume resistivity of 1×10−6 Ω·cm to 1×106 Ω·cm, or (3) a surface electrical resistance of 1×10−2Ω to 1×109Ω, and the electroconductive layer having a film thickness less than 5 μm. The invention further relates to.

Owner:MITSUBISHI CHEM CORP +1

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

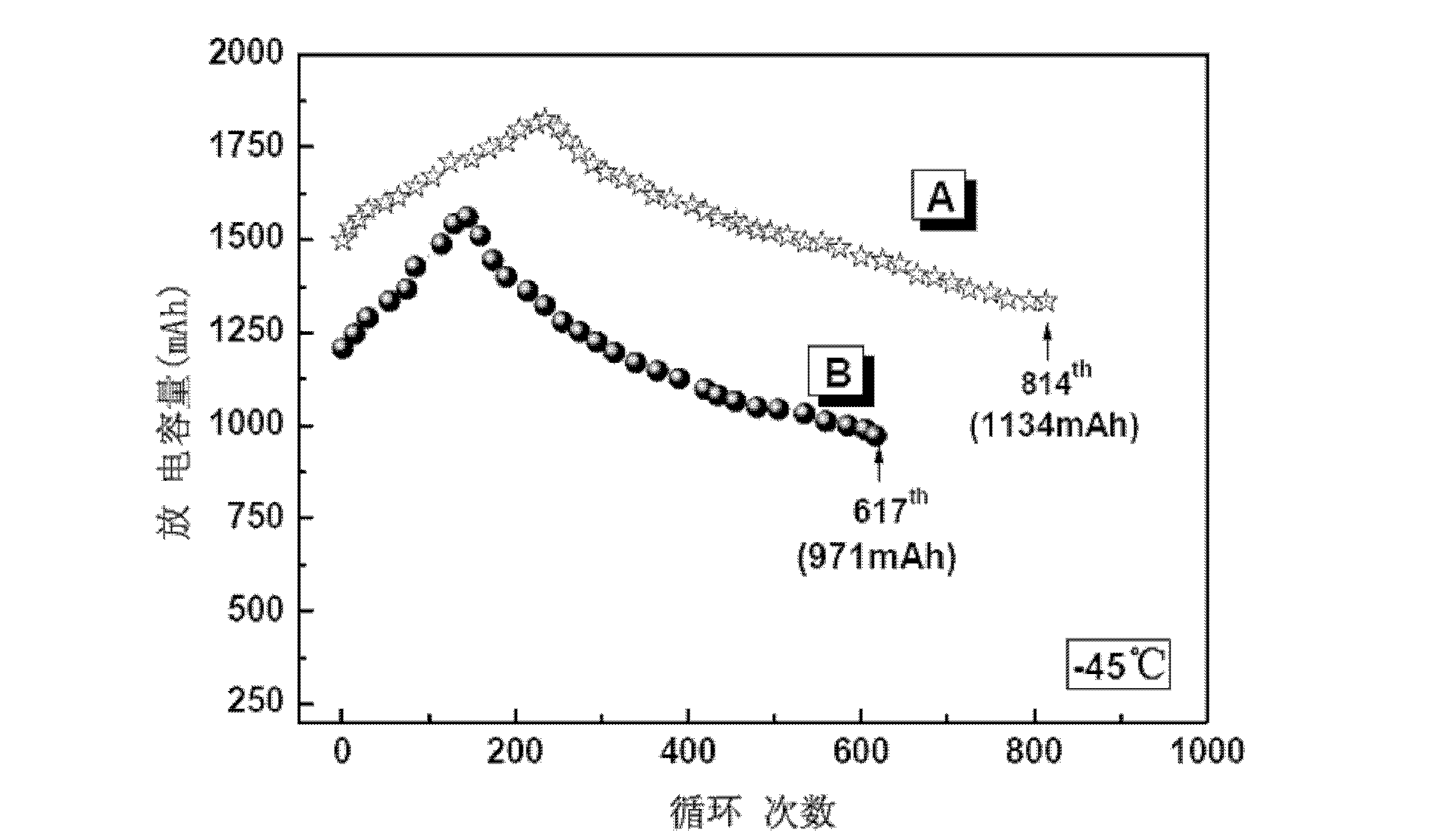

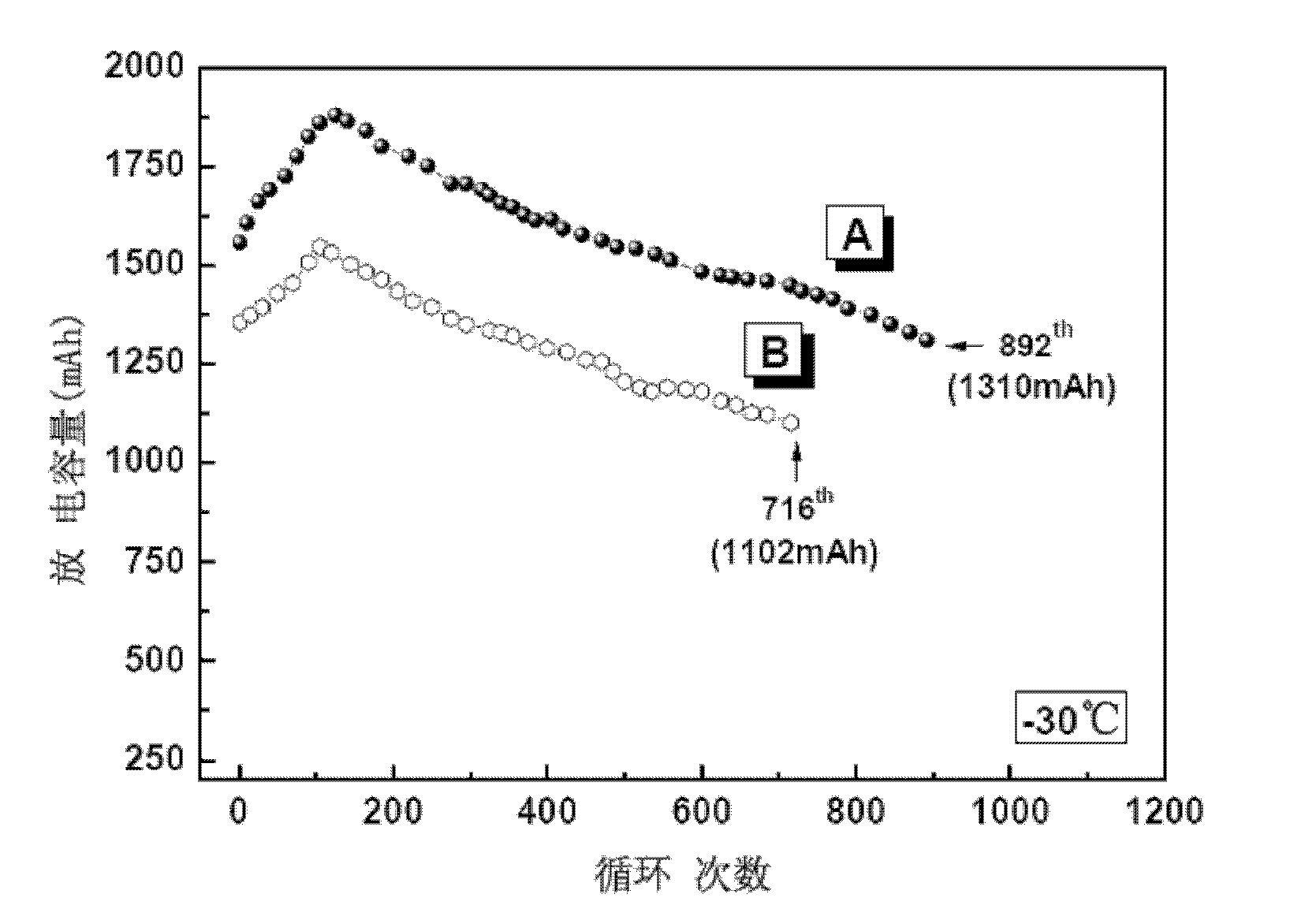

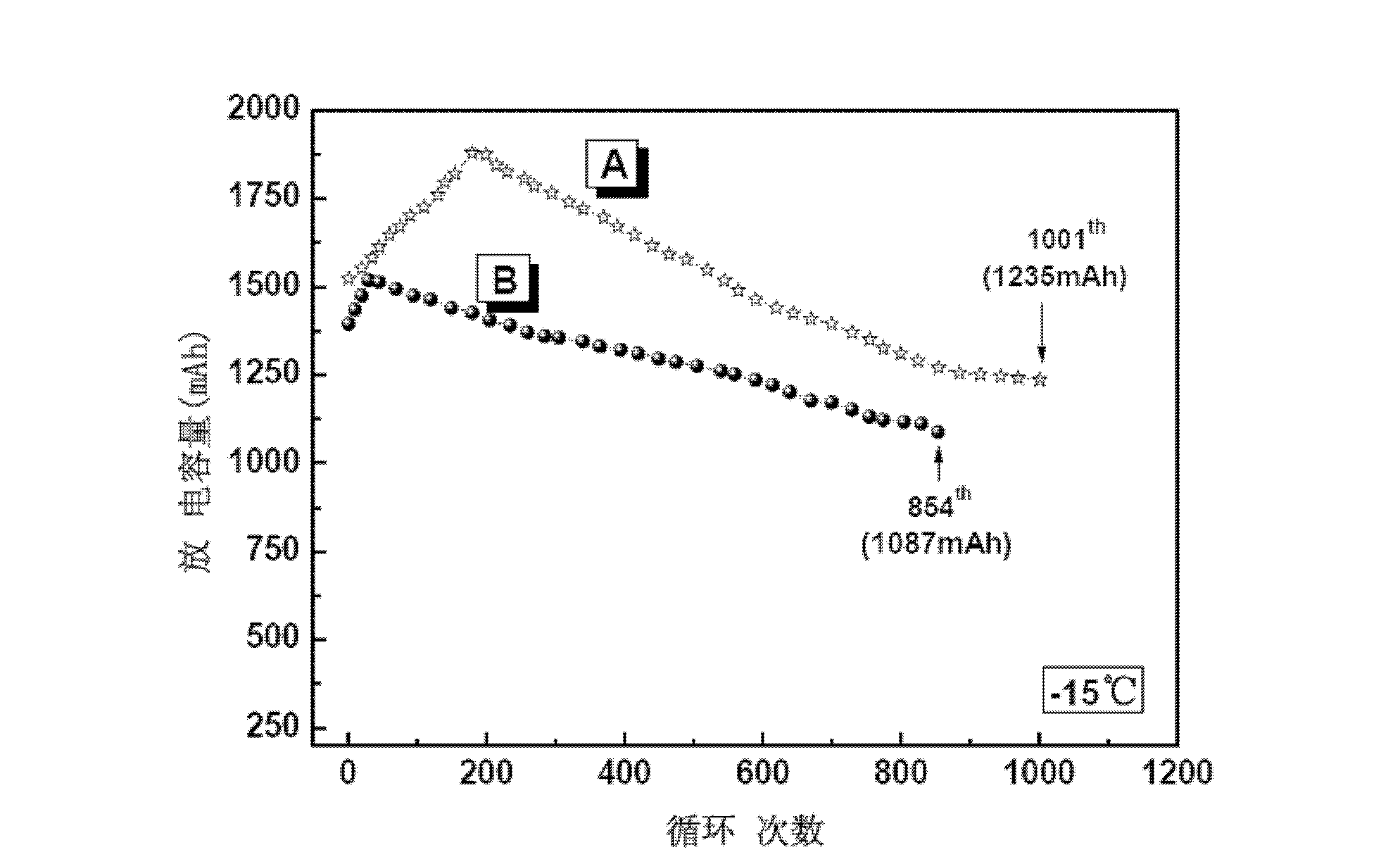

AB5-base hydrogen storage alloy, electrode for Ni-MH battery, secondary battery and method for preparing hydrogen storage alloy

ActiveCN109585790AMeet overcharge performanceSatisfy the charging and discharging dynamic performanceNegative electrodesAlkaline accumulator electrodesHigh rateCerium

The invention relates to a hydrogen storage alloy, an electrode for a Ni-MH battery, a secondary battery and a method for preparing the hydrogen storage alloy. The chemical composition of the hydrogenstorage alloy is represented by the general formula La(3.0-3.2)x CexZrySm (1- (4.0~4.2)x-y)NizCouMnvAlw, wherein x, y, z, u, v, w are molar ratios; 0.14 <= x <= 0.17; 0.02 <= y <= 0 .03; 4.60 <= z +u + v + w <= 5.33; 0.10 <= u <= 0.20; 0.25 <= v <= 0.30; and 0.30 <= w <= 0.40. The overcharge performance of the electrode material is satisfied by fixing a ratio of lanthanum (La) to cerium (Ce) to3.0 - 3.2. A large number of samarium (Sm) elements on a side A are replaced, namely, the ratio of Sm atoms accounts for 25.6 to 42% of the side A to overcome a decrease in service life caused by lowcobalt (Co). The equilibrium pressure is adjusted by changing the ratios of Sm and La to Ce in order to satisfy the charge and discharge dynamics performance of the electrode material. The nucleationrate of a solidification process is increased by adding zirconium (Zr) having an atomic ratio of 2 to 3% relative to the elements at the side A to the elements at the side A. The Ni-MH battery anode material obtained by using the hydrogen storage alloy has high overcharge resistance, high rate discharge performance and good cycle stability.

Owner:SOUTH CHINA UNIV OF TECH +2

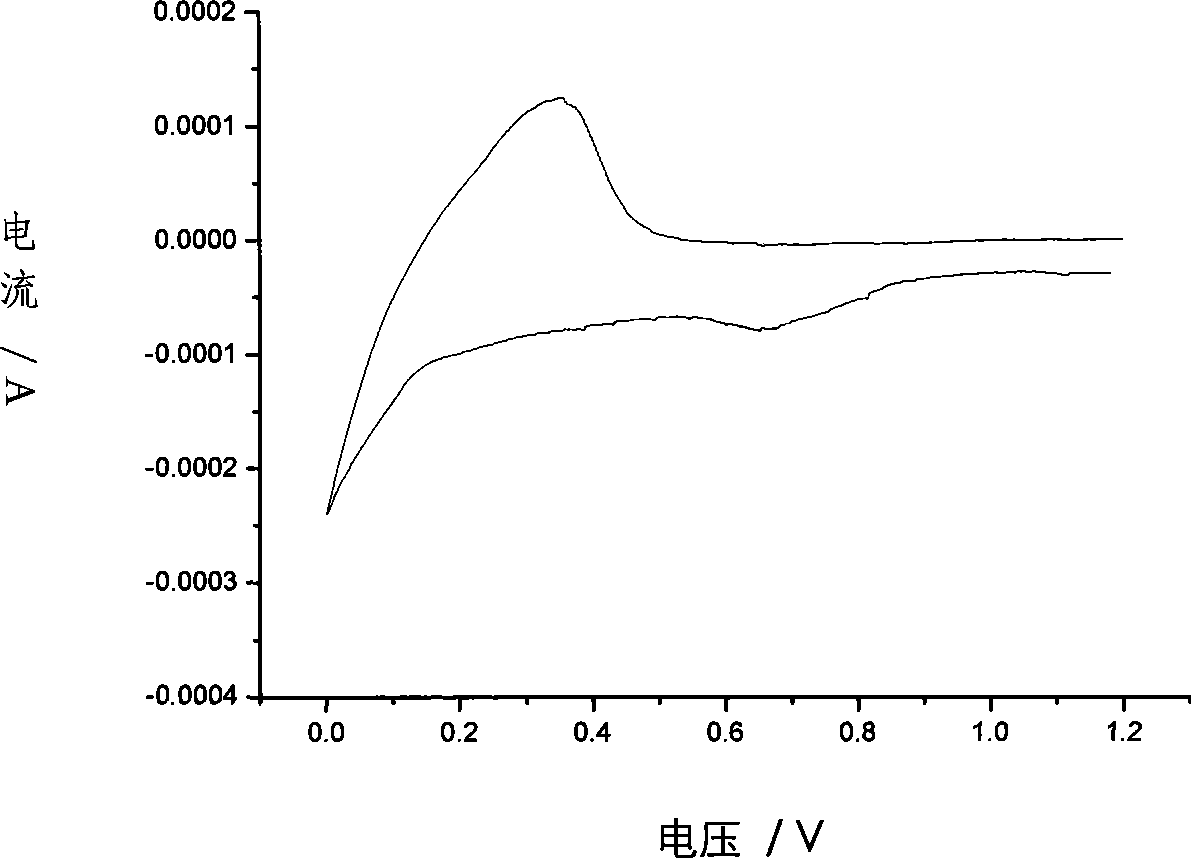

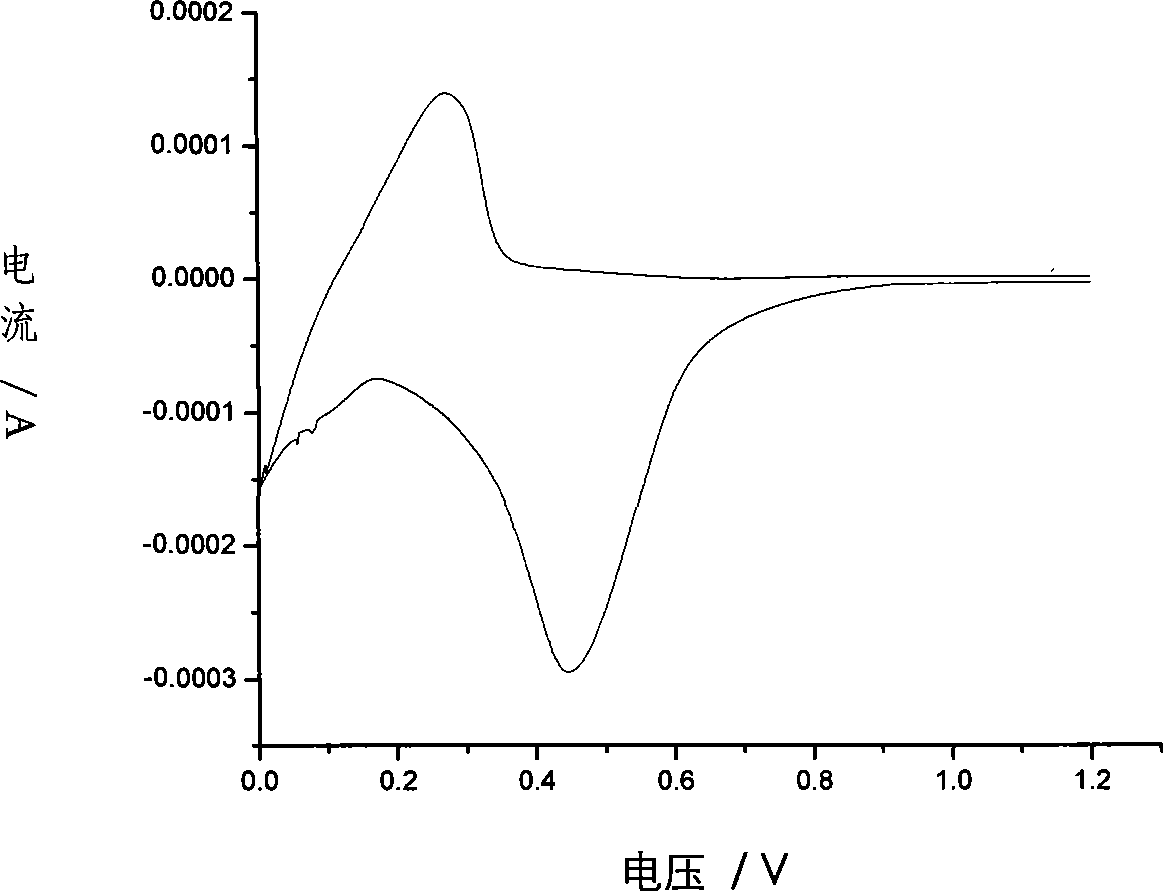

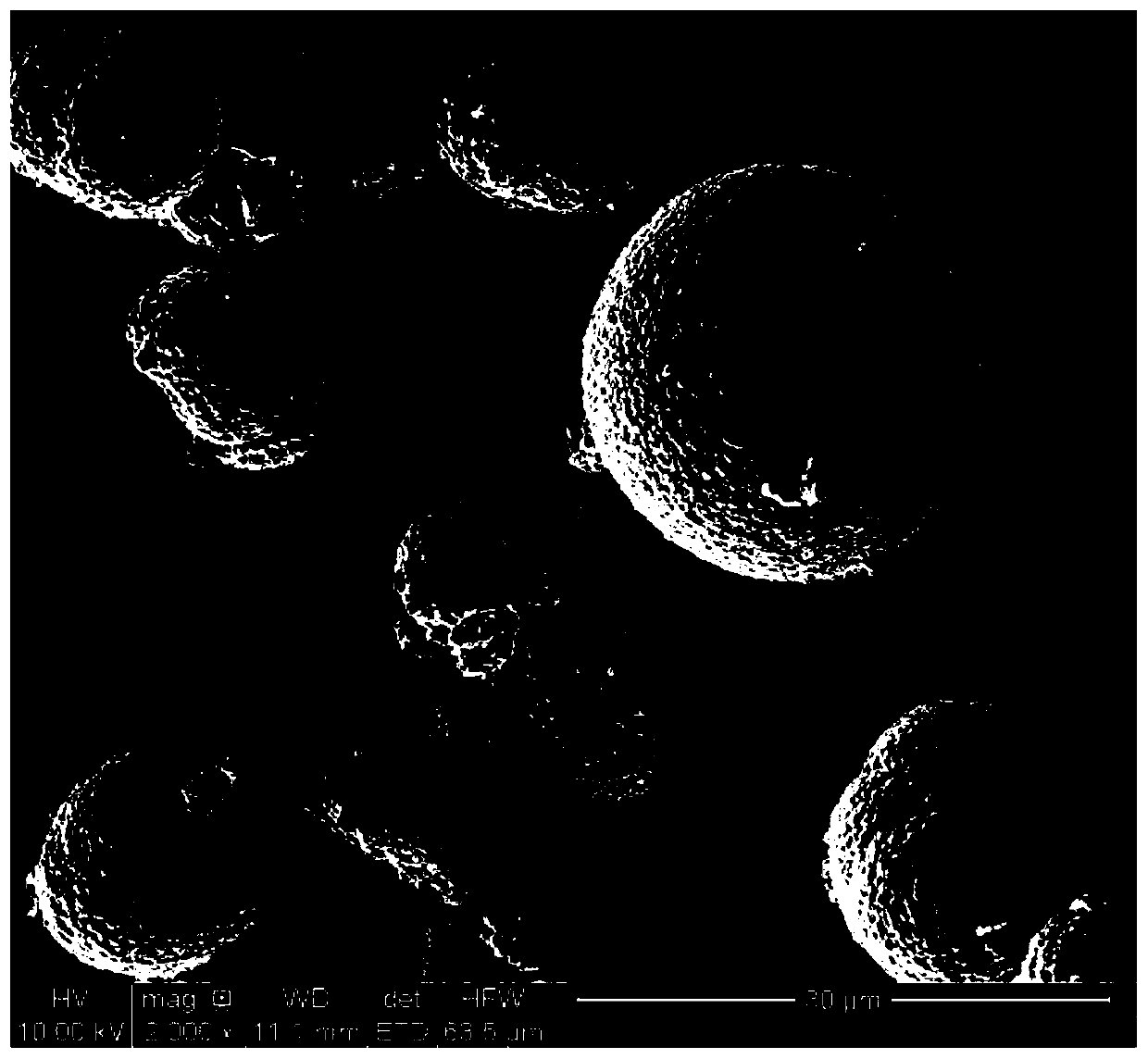

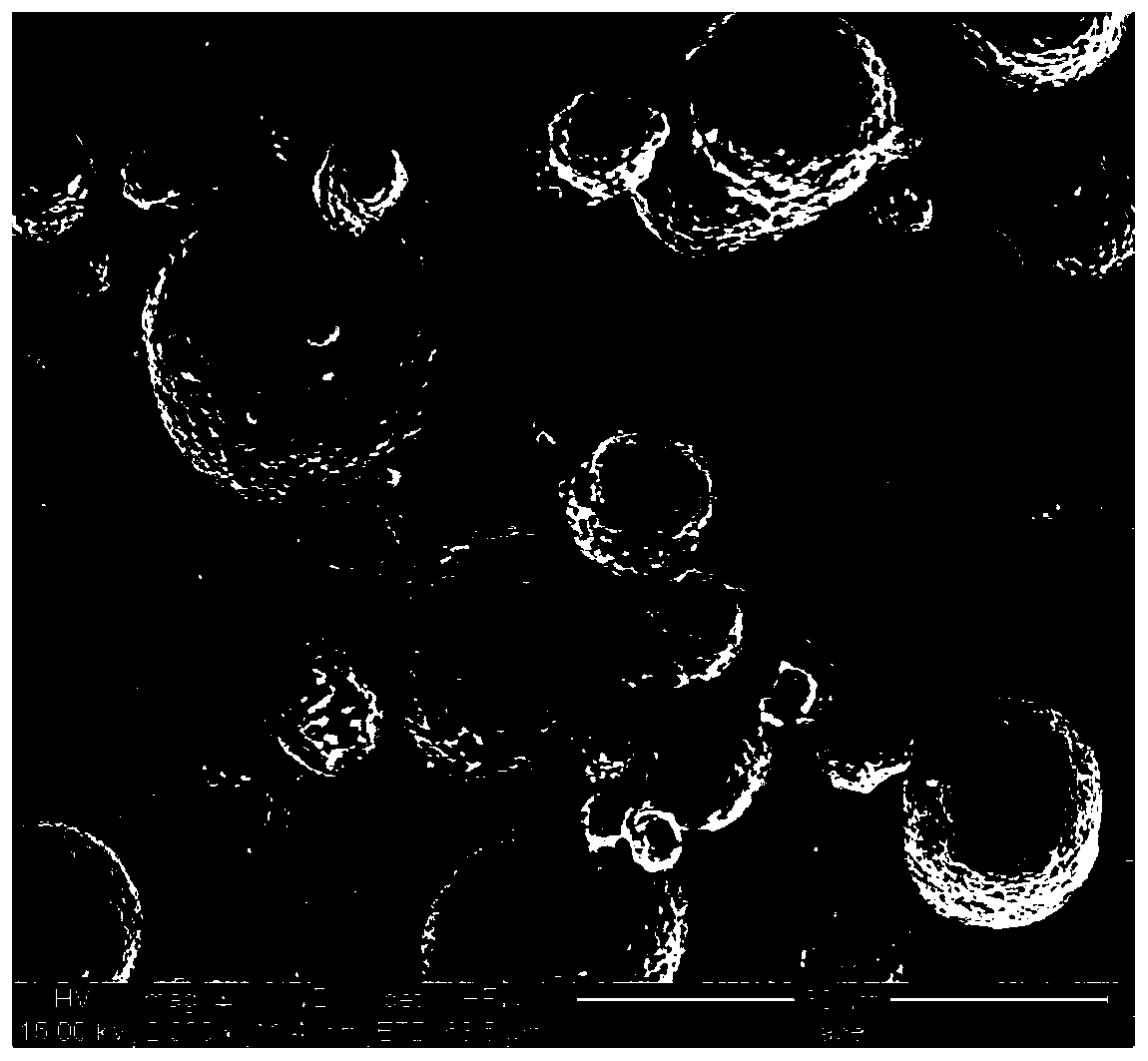

Cobalt acid lithium battery material adulterated alkaline-earth metal between layers and its preparing method

InactiveCN1763997AInitial capacity reductionStable structureCell electrodesLithium compoundsAlkaline earth metalCITRATE ESTER

The invention relates to a new anode material with interlaminar doping Li(1-2beta)(AE) (beta)CoO2 (AEú¢Mgú¼Ca) by substituting lithium ion by alkaline-earth metal ion and opposite fused salt ion exchange reaction preparation method. Wherein, the preparation method comprises: preparing layer-shape LiCoO2 predecessor with little and even size with citrate sol-gel method; substituting part lithium ion with Mg2+ or Ca2+ by fused salt ion exchange reaction; baking to distribute lithium ion and alkaline-earth metal ion evenly in main body layer constructed by CoO2. This product has more stable structure, better anti-overcharge performance, higher specific capacity and super electrochemical circulation property.

Owner:BEIJING UNIV OF CHEM TECH

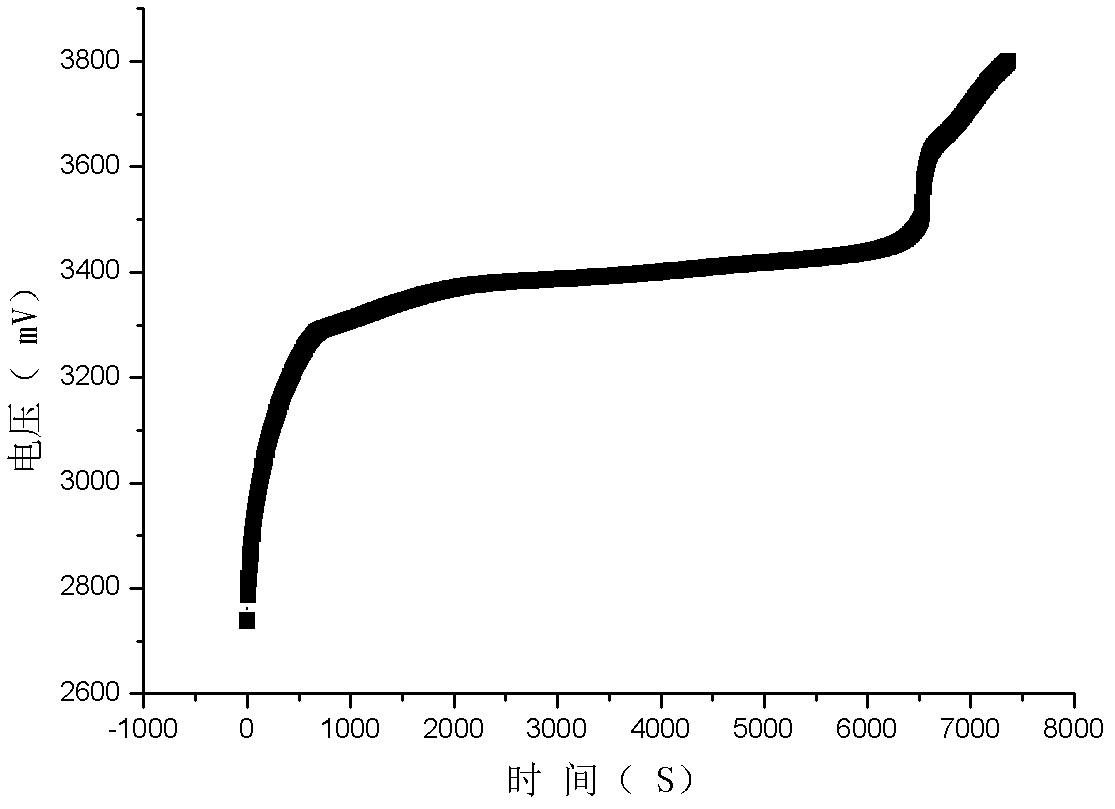

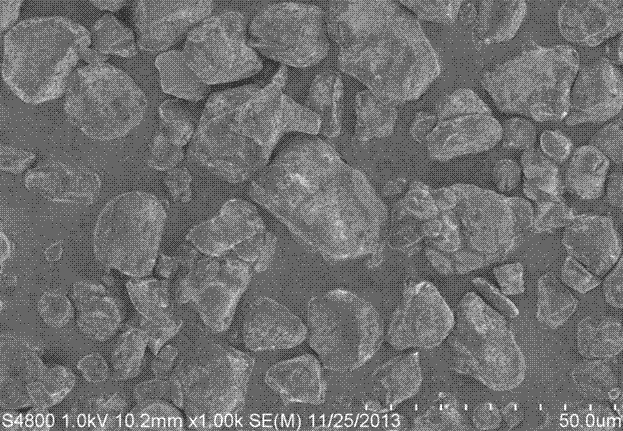

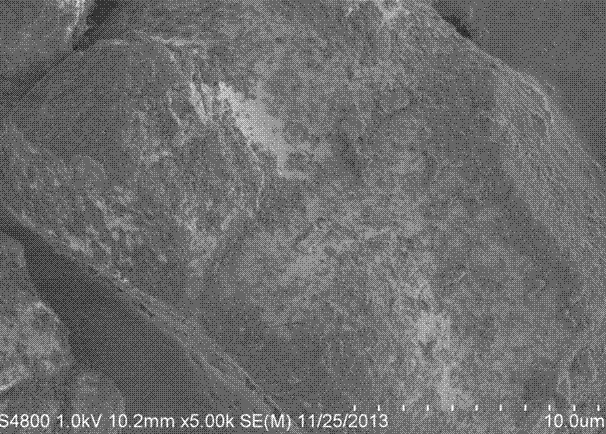

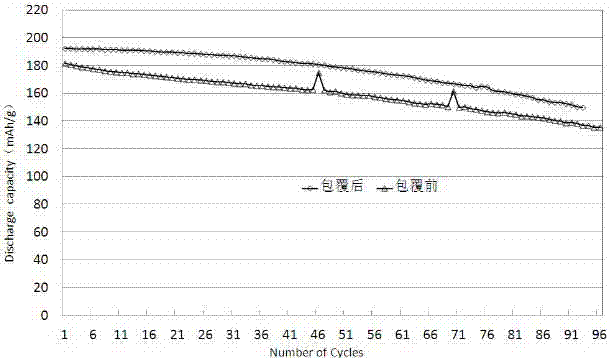

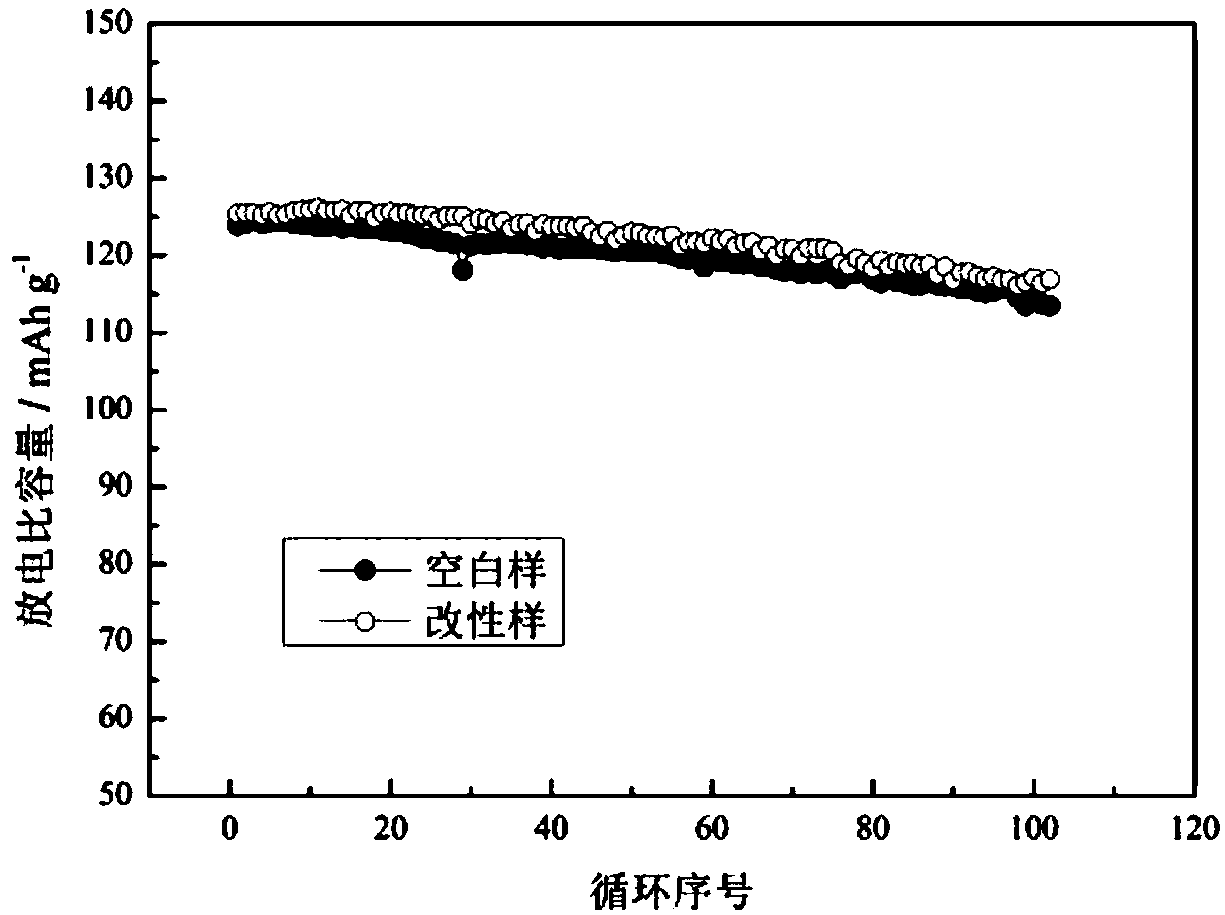

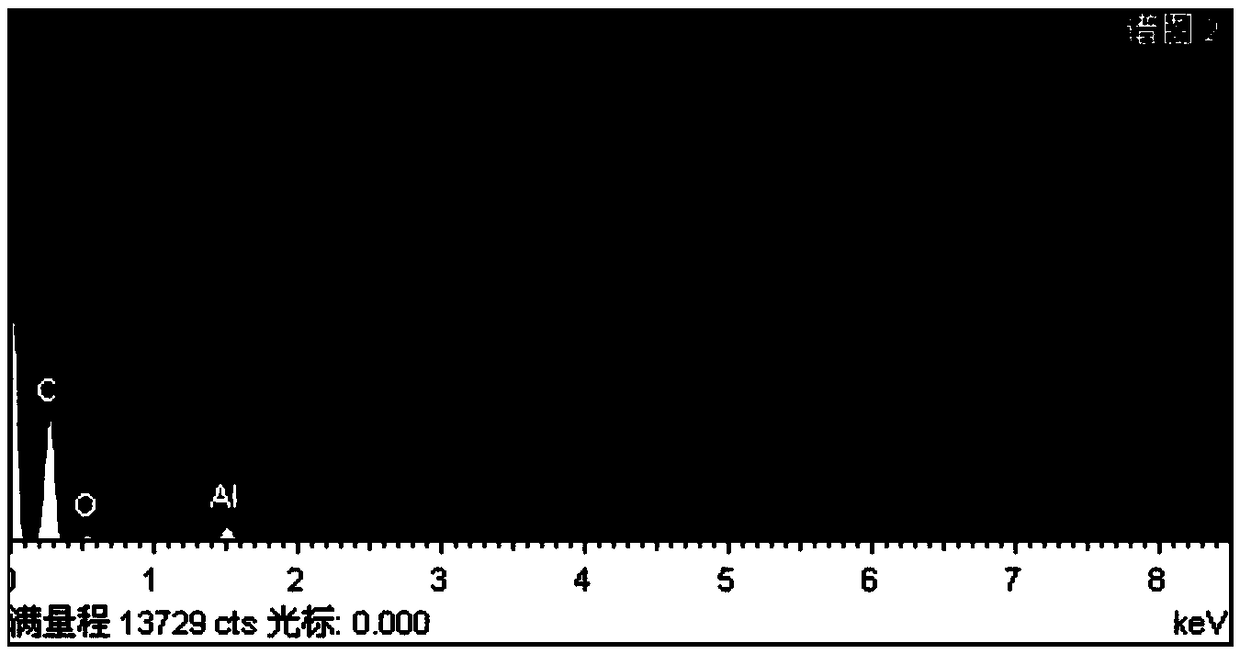

Aluminum magnesium fluoride-coated lithium nickel cobalt manganese oxide positive electrode material and preparation method thereof

InactiveCN106025212AImprove anti-overcharge performanceImprove structural stabilityCell electrodesSecondary cellsAluminum fluorideMagnesium salt

The invention discloses an aluminum magnesium fluoride-coated lithium nickel cobalt manganese oxide positive electrode material and a preparation method thereof. The preparation method comprises the steps of (a) mixing a lithium nickel cobalt manganese oxide spinel material with a water-soluble aluminum salt, a water-soluble magnesium salt and water, adding a water solution of a water-soluble fluoride salt, generating an aluminum fluoride sediment and a magnesium fluoride sediment and coating the surface of the lithium nickel cobalt manganese oxide spinel material to obtain a solid-liquid mixture; and (b) sequentially carrying out solid-liquid separation, washing, drying and roasting on the obtained solid-liquid mixture to obtain the aluminum magnesium fluoride-coated lithium nickel cobalt manganese oxide positive electrode material. The aluminum magnesium fluoride-coated lithium nickel cobalt manganese oxide positive electrode material has good cycle performance and rate capability.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

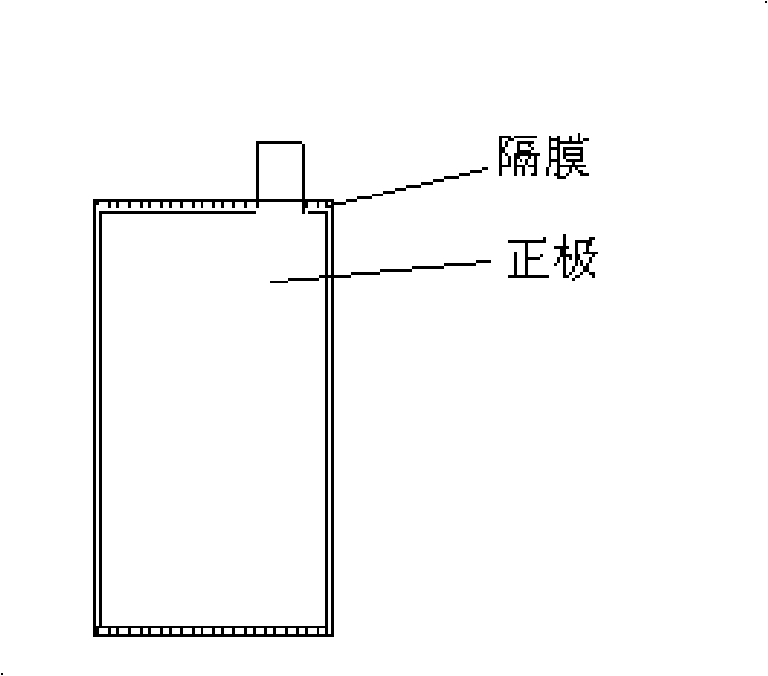

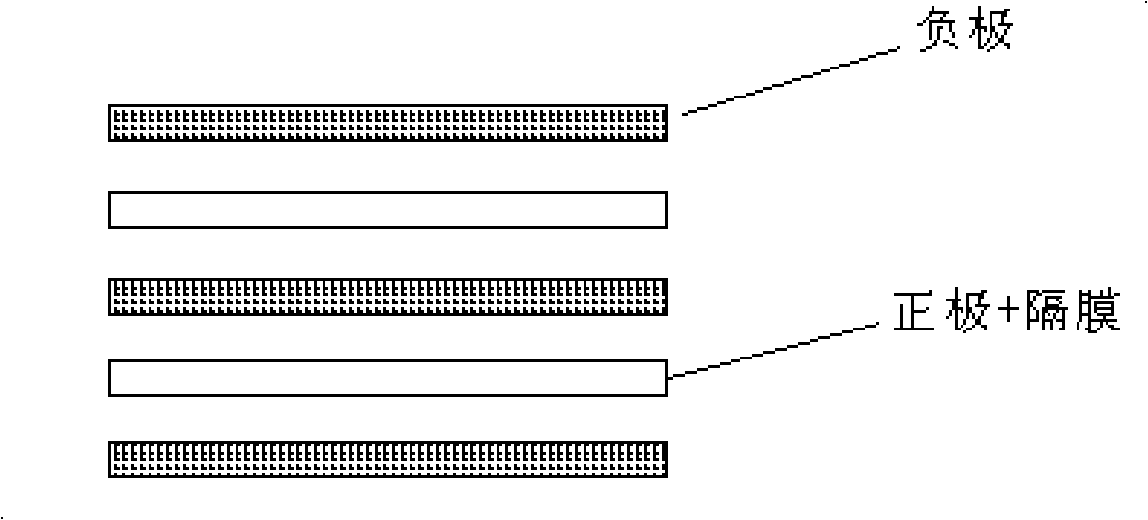

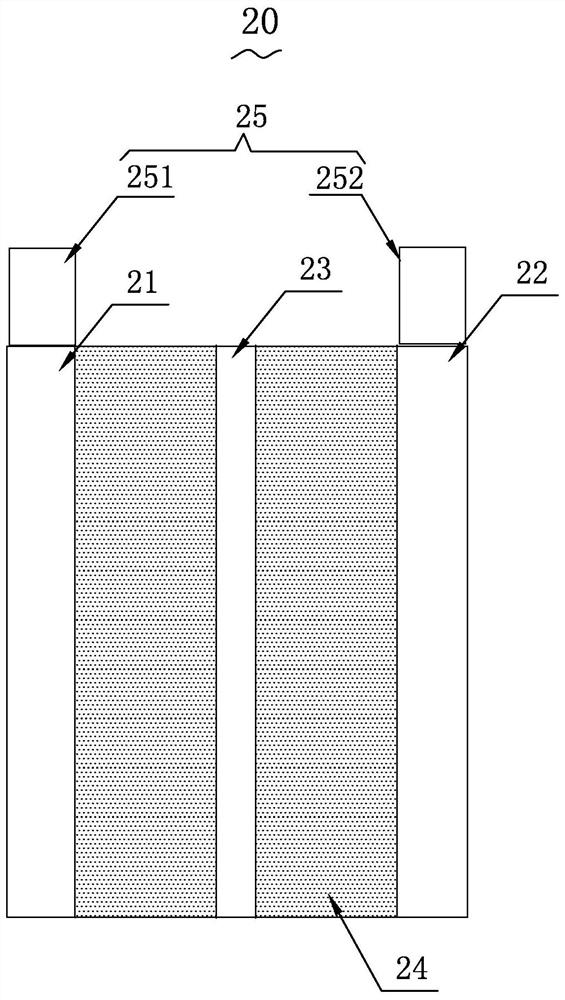

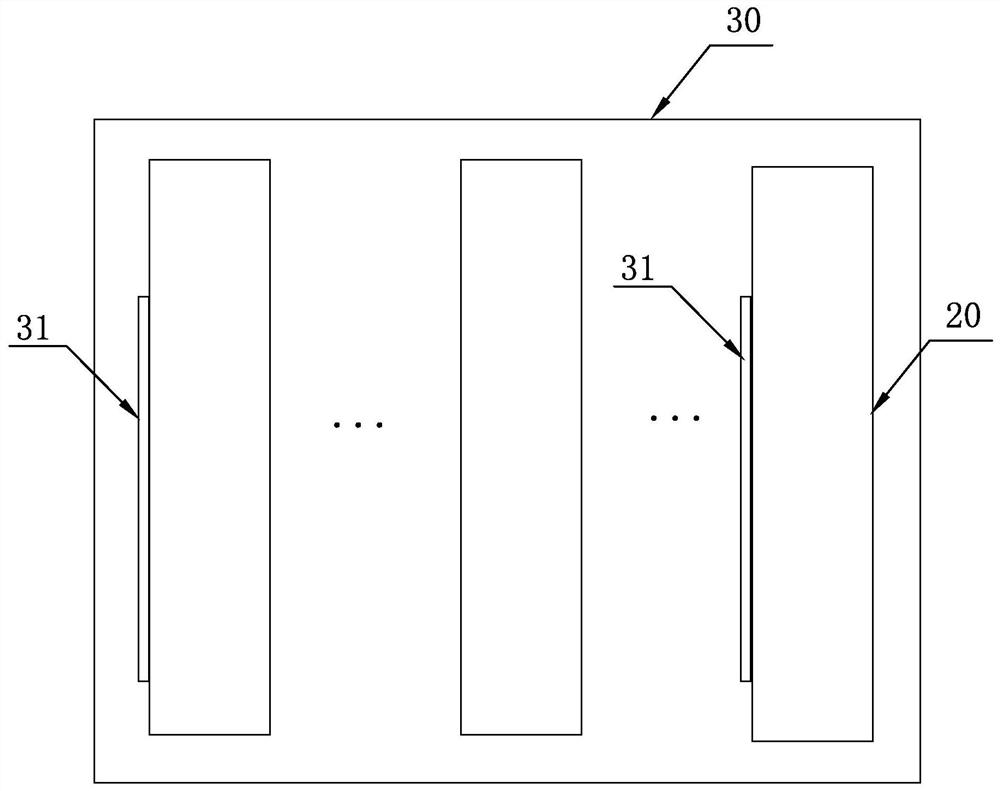

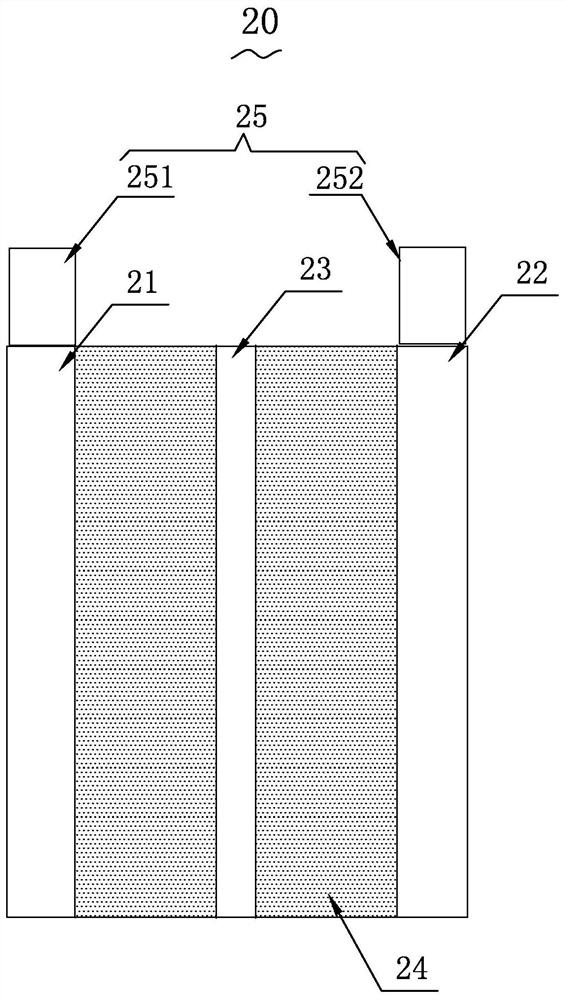

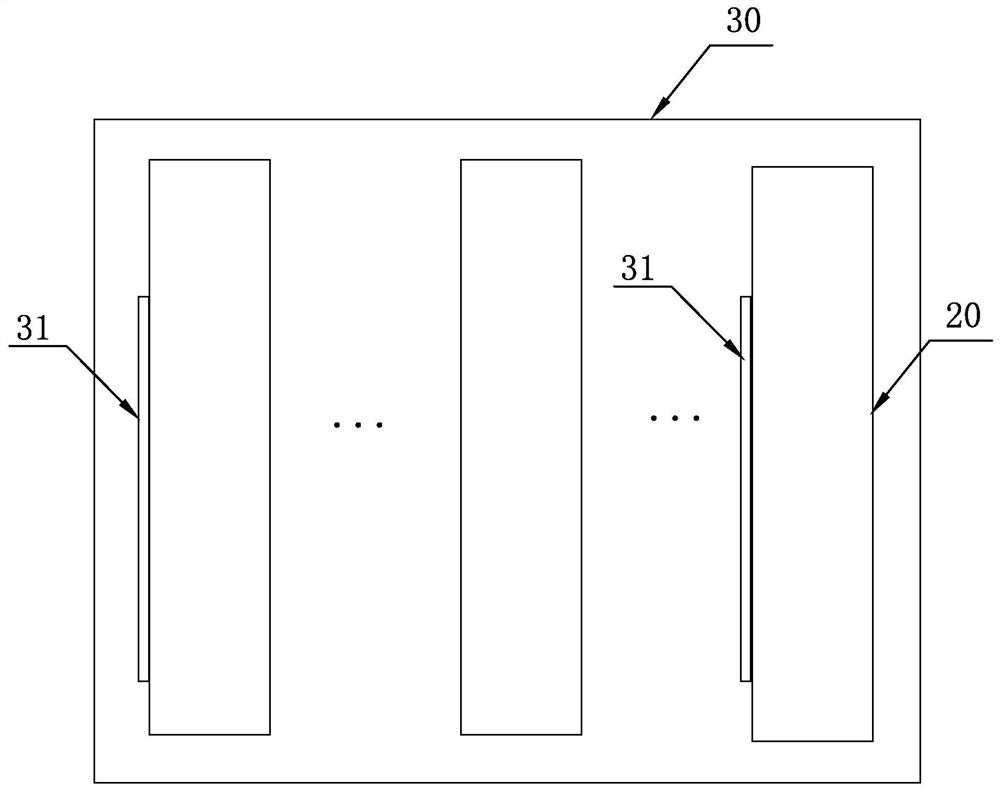

Composite cathode material lithium ion battery

InactiveCN101409361AReduced chance of lithium dendritesSimple processing technologyCell electrodesSecondary cellsComposite cathodeAdhesive

The invention discloses a lithium ion cell of a compound cathode material. A polar plate unit consists of an anode, a spacing membrane and a cathode; the anode is sealed in the bag of the spacing membrane; the cathode comprises the compound material of lithium titanate and black lead. The bag of the spacing membrane provided with the anode and the cathode are spaced by another layer of spacing membrane; an 'S'-shaped lamination mode is adopted; or the bag of a double-layer spacing membrane provided with the anode and the cathode are directly overlapped. The width of the cathode is equal to the width of the bag of the spacing membrane. The cathode comprises the following material components as per weight percentage: 80 to 87 portions of the compound material of lithium titanate and black lead, 4 to 7 portions of adhesive, 6 to 7 portions of conductive agent as well as 3 to 6 portions of liquid imbibing agent. The compound material of lithium titanate and black lead comprises the following components as per weight percentage: 85 to 90 portions of lithium titanate as well as 10 to 15 portions of black lead. The compound material of lithium titanate and black lead is manufactured by a mechanical alloy method. The lithium ion cell of a compound cathode material has simple structure, is easy to be processed and manufactured, is safer and is suitable for electric motor cars and special power sources.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

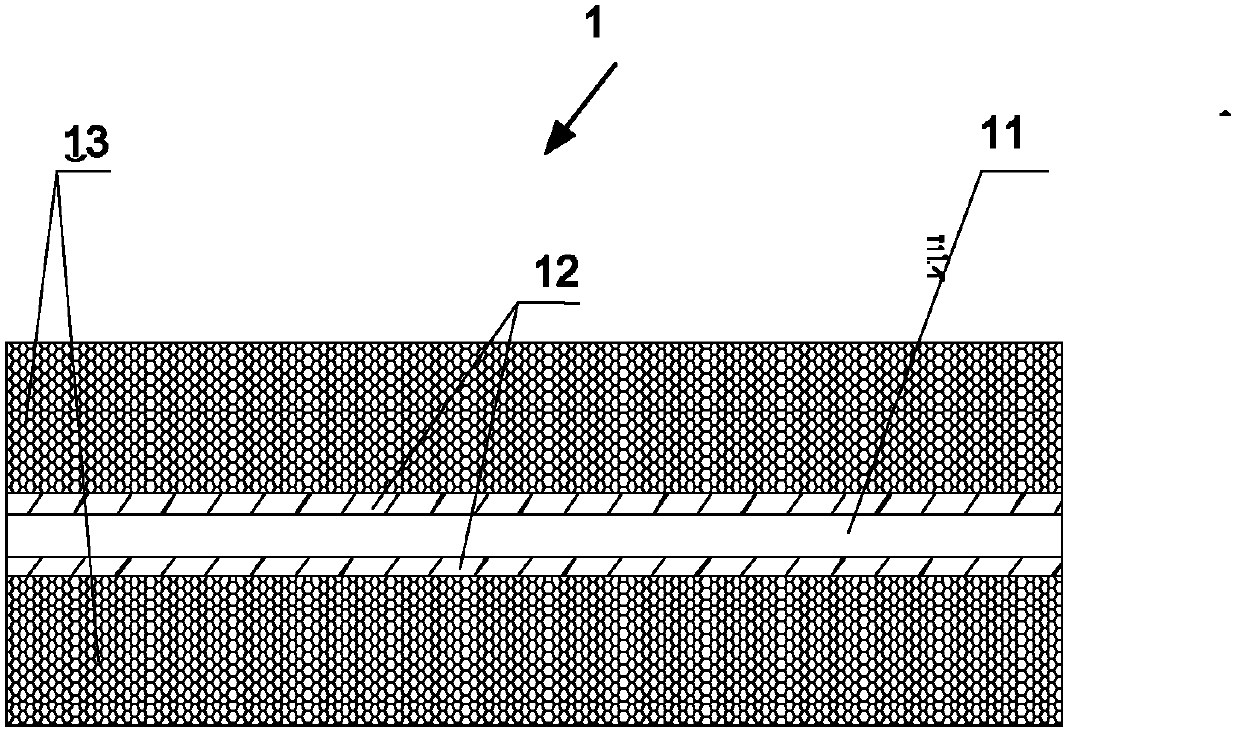

Battery positive pole piece and preparation method

InactiveCN103378351AImprove anti-overcharge performanceExtend your lifeCell electrodesLithium iron phosphatePhysical chemistry

The invention provides a battery positive pole piece and a preparation method. The battery positive pole piece at least comprises a substrate layer, a lithium-containing coating and a lithium iron phosphate active substance coating, wherein the lithium-containing coating is formed on at least one surface of the substrate layer; the lithium iron phosphate active substance coating is formed on the surface of the lithium-containing layer; the material of the lithium-containing coating comprises at least one of lithium nickel cobalt manganate, lithium manganate and lithium cobalt oxide. The battery positive pole piece has the advantages of being capable of effectively improving the over-charging prevention capacity of a battery and prolonging the service life of the battery.

Owner:协鑫动力新材料(盐城)有限公司

Lithium ion batteries cathode material and preparation method thereof

InactiveCN104752685AAchieve reversible exchangeAvoid decompositionCell electrodesChemical compositionPhysical chemistry

The invention discloses a lithium ion batteries cathode material and a preparation method thereof, and more specifically relates to the lithium ion batteries cathode material coated by orthosilicate and the preparation method thereof. A coating layer comprises the chemical composition of Li1+aMnbMcSiO4(M=Co, Ni, Fe, Mg, Al, Ti, Zr, and a is greater than or equal to -0.1 and less than or equal to 0.1, b is greater than 0 and less than or equal to 1.0, c is greater than or equal to 0 and less than or equal to 1.0). The cathode material has good overcharge resistance performance and thermostability. The preparation method is characterized in that orthosilicate and a salting liquid containing Mn(and M) are mixed to form sol, then a cathode material core is added, an orthosilicate coating layer containing Mn(and M) is formed on at least part of the surface of the cathode material core, and the lithium ion batteries cathode material can be obtained after heat treatment.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

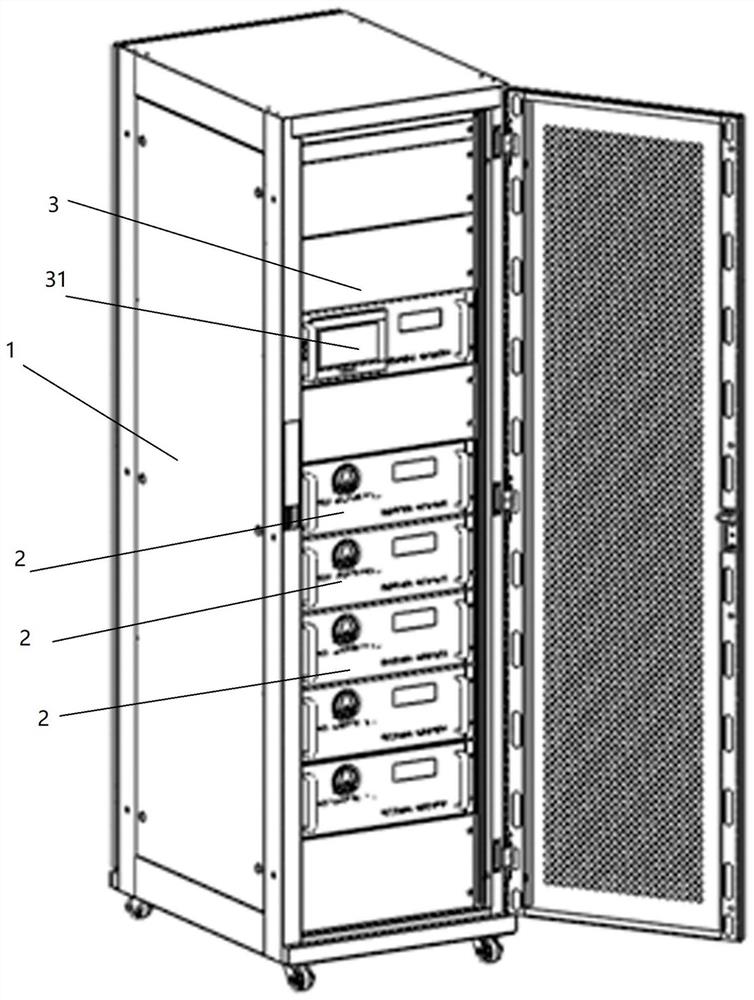

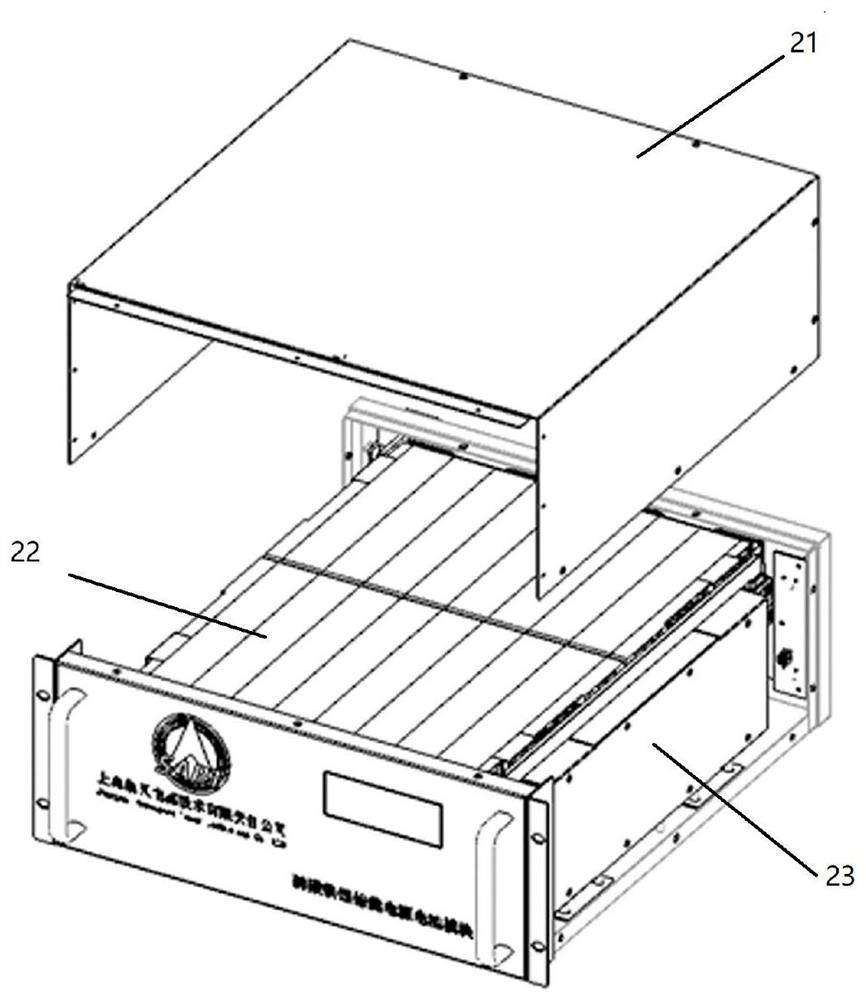

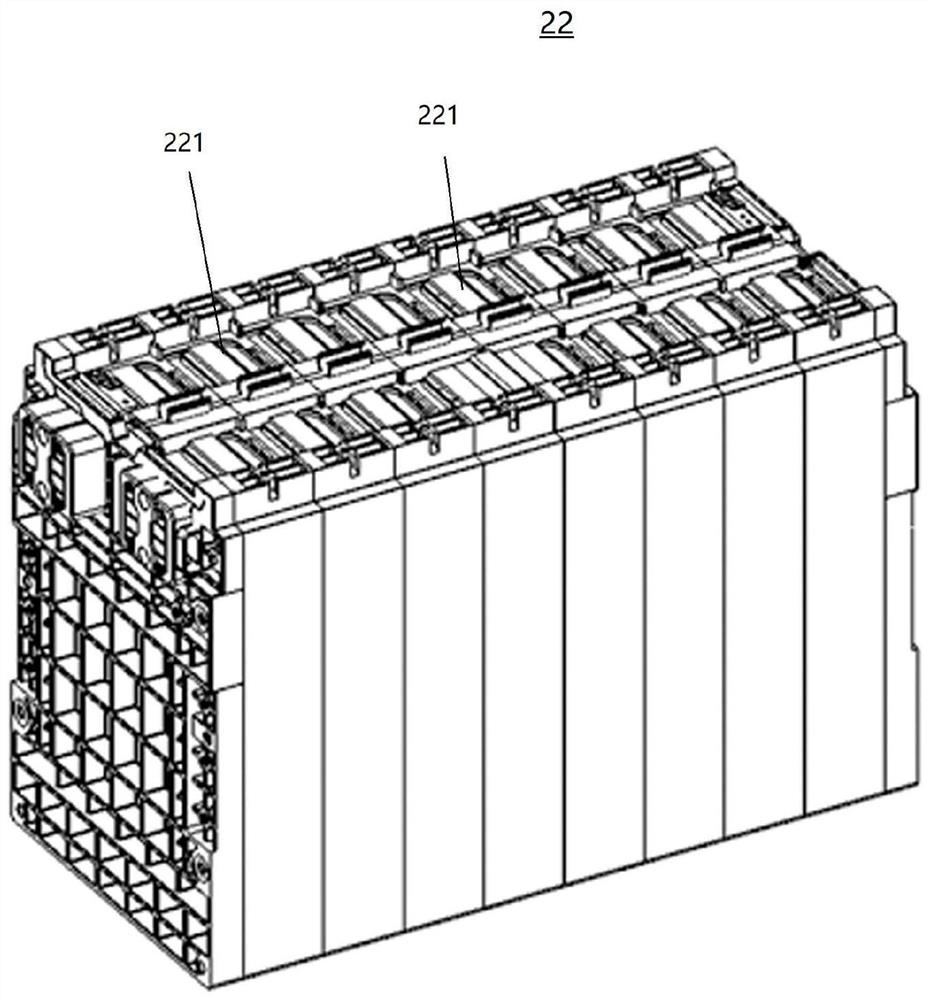

Servo power supply

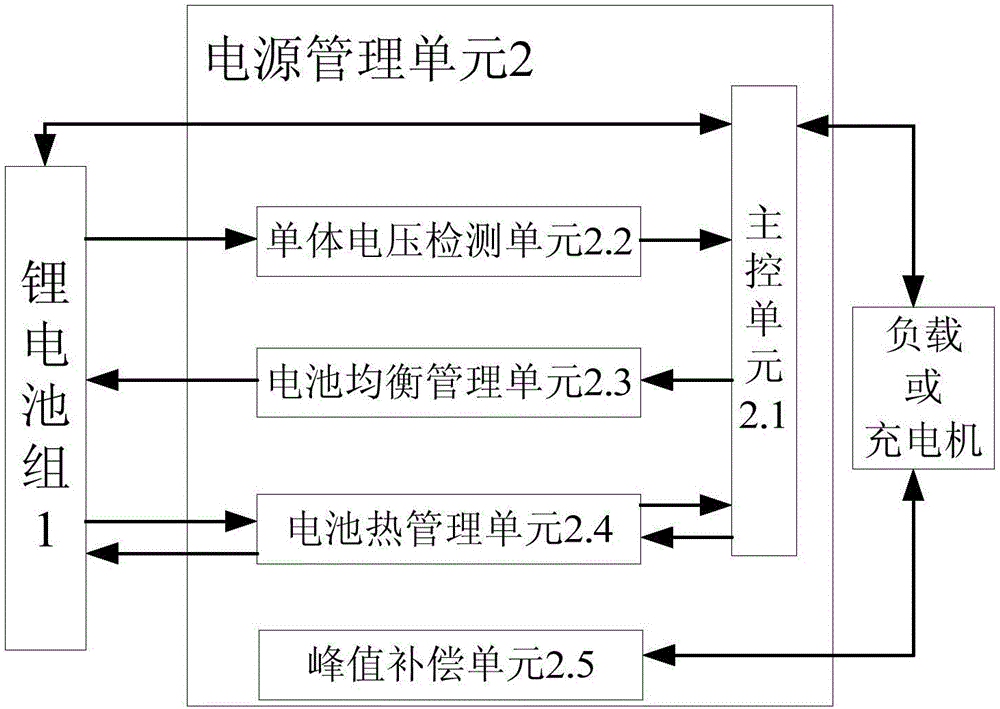

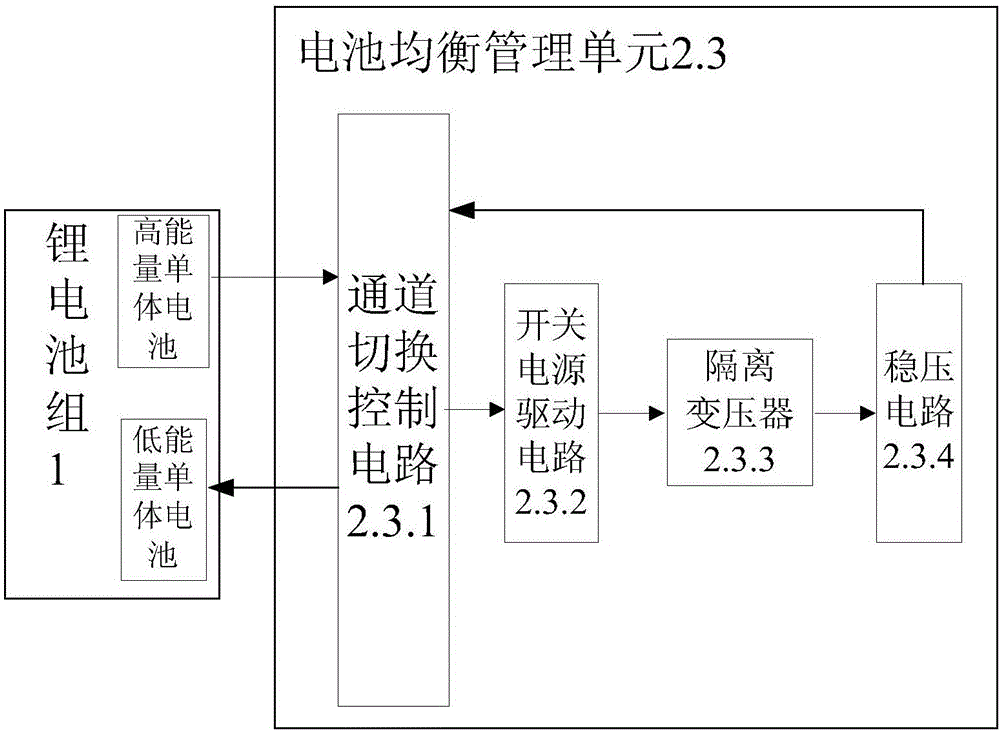

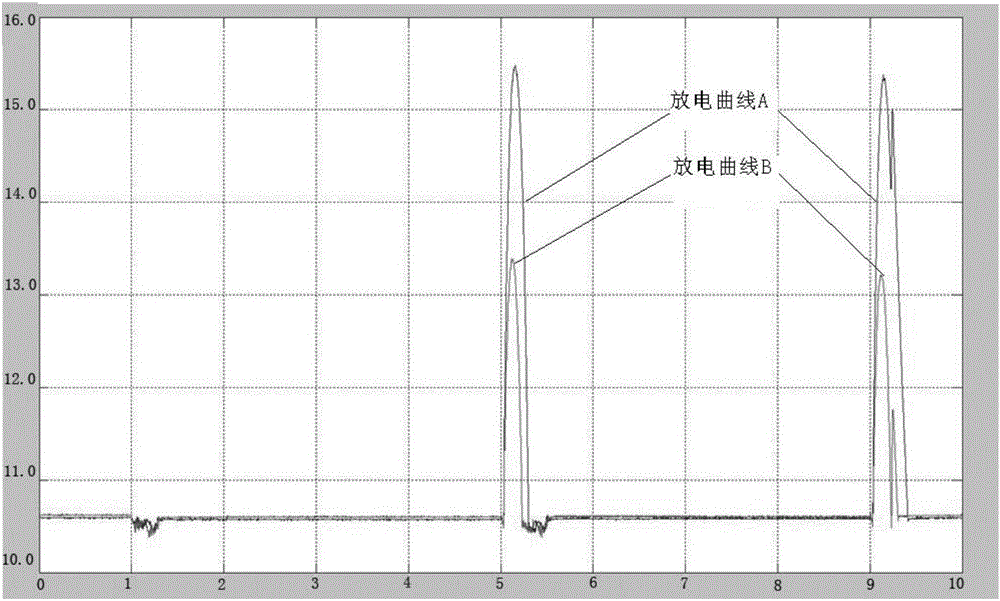

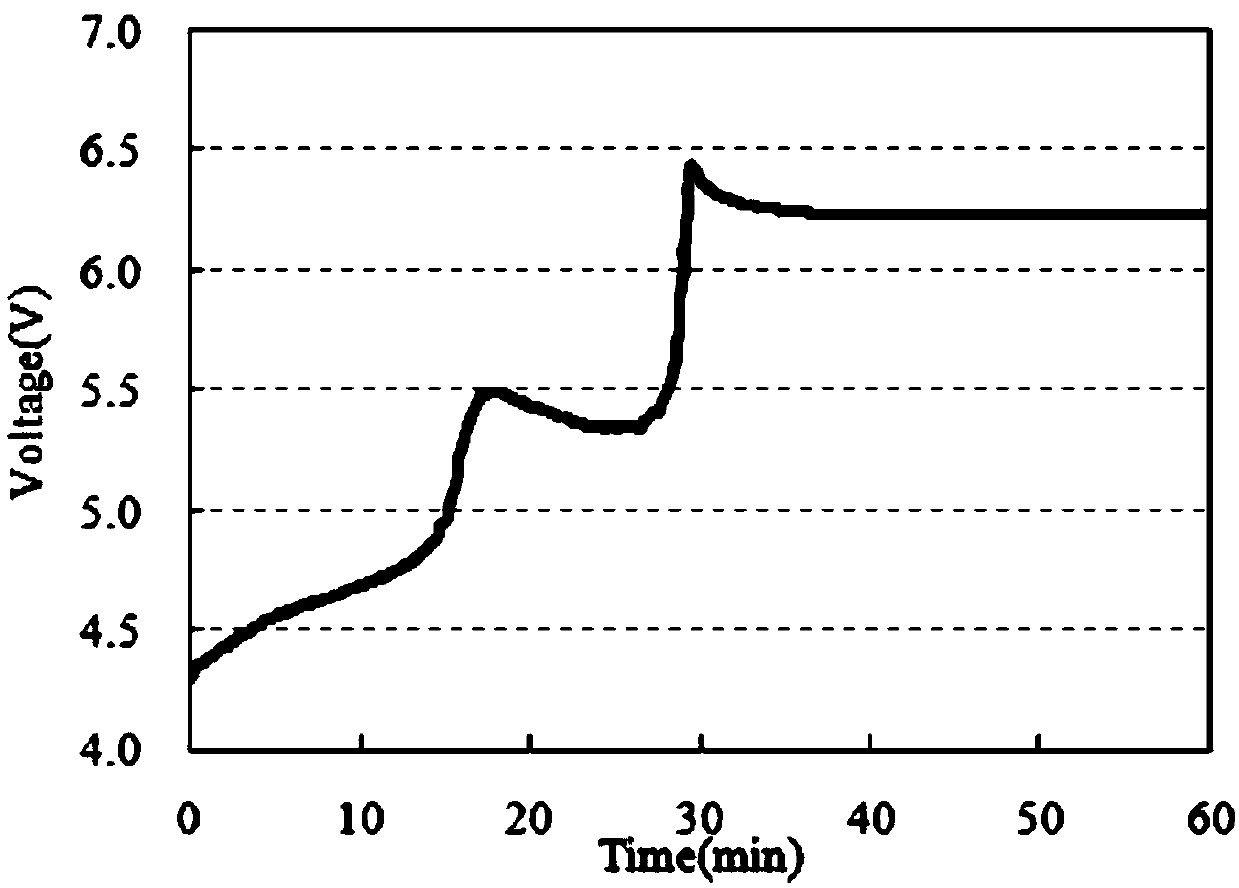

ActiveCN106130123AMeet electricity demandGood chemical stabilityCharge equalisation circuitIndicating/monitoring circuitsSystems managementEnergy absorption

The invention provides a servo power supply which is applied to an electromechanical servo system and belongs to the electromechanical field. The servo power supply source comprises a lithium battery pack (1) and a power supply management unit (2). The power supply management unit (2) is composed of a main control unit (2.1), a monomer voltage detection unit (2.2), a battery equalization management unit (2.3), a battery thermal management unit (2.4) and a peak compensation unit (2.5). The lithium battery pack (1) provides a power supply required by the electromechanical servo system. The power supply management unit (2) carries out peak current compensation and regeneration energy absorption, and carries out system management and equalization on the lithium battery pack (1). The servo power supply provided by the invention can work for a long time, can be reused, has the advantages of large capacity, high reliability, low cost and small volume, can absorb regeneration energy, can carry out large pulse discharge, and is especially suitable for an aerospace servo power supply system.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

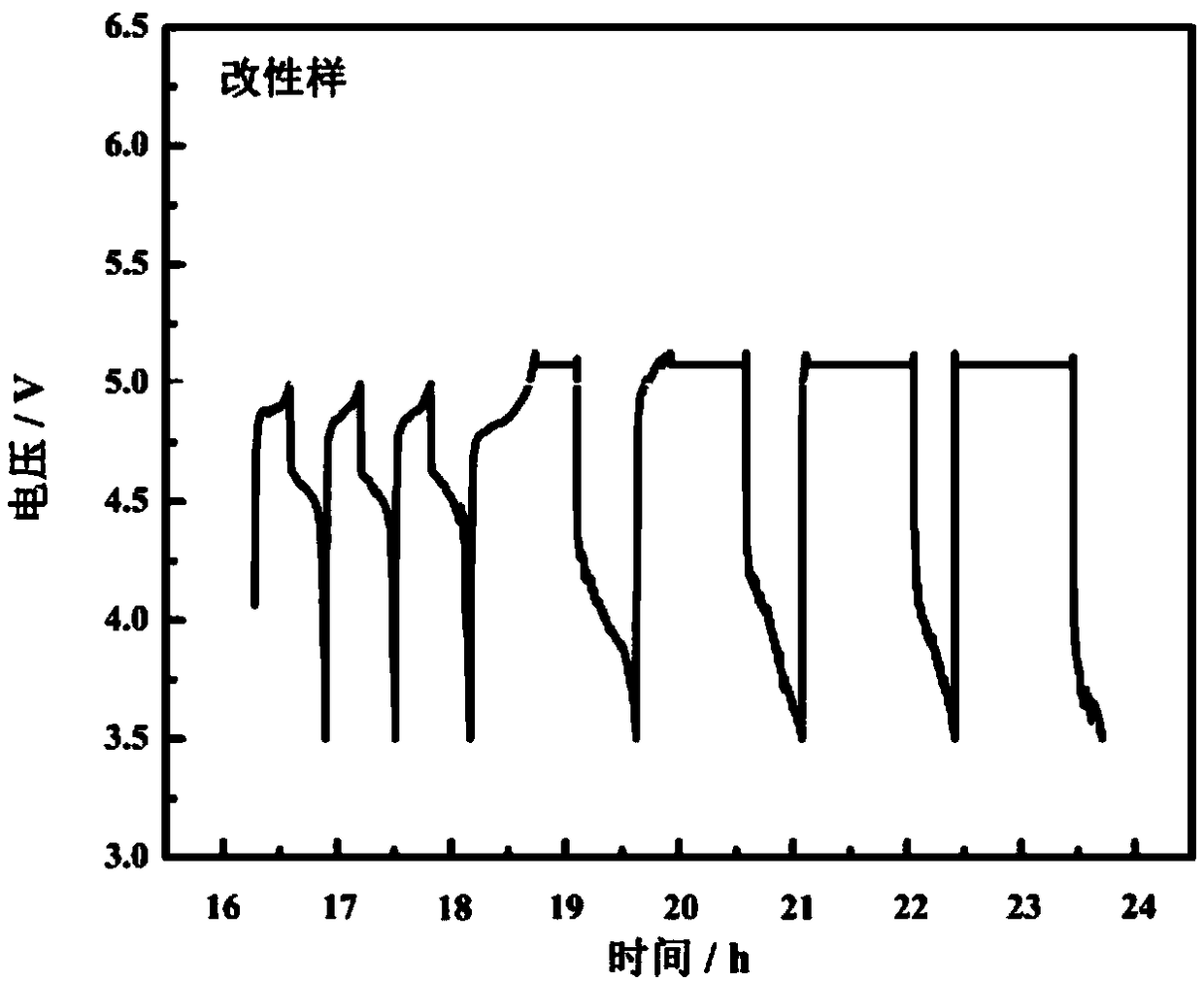

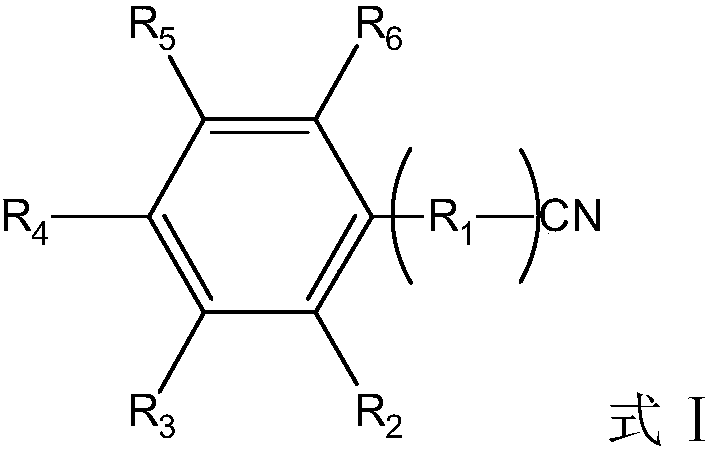

Lithium-ion battery electrolyte and lithium-ion battery

ActiveCN108054430AImprove anti-overcharge performanceEnsure safetySecondary cells servicing/maintenanceOrganic electrolytesInternal pressureHydrogen

The invention provides a lithium-ion battery and electrolyte thereof. By adding a cyano anti-overcharge additive to the electrolyte, anti-overcharge capacity of the lithium-ion battery is improved, and safety of the lithium-ion battery is guaranteed. The cyano anti-overcharge additive has acting level of about 5.25 V. When the lithium-ion battery experiences overcharge and level rises over 5.25 V,the cyano anti-overcharge additive polymerizes and produces massive hydrogen, the hydrogen increases inner pressure of the lithium-ion battery, safety devices such as an anti-explosion device are broken through, gas and heat are released, and battery safety is guaranteed accordingly. In addition, cyano group in the anti-overcharge additive can well adsorbs on the surface of cathodic material transition metal ions, changes in cathode level are quickly sensed, responding occurs quickly, no delay or untimely response occurs, and battery safety is guaranteed.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

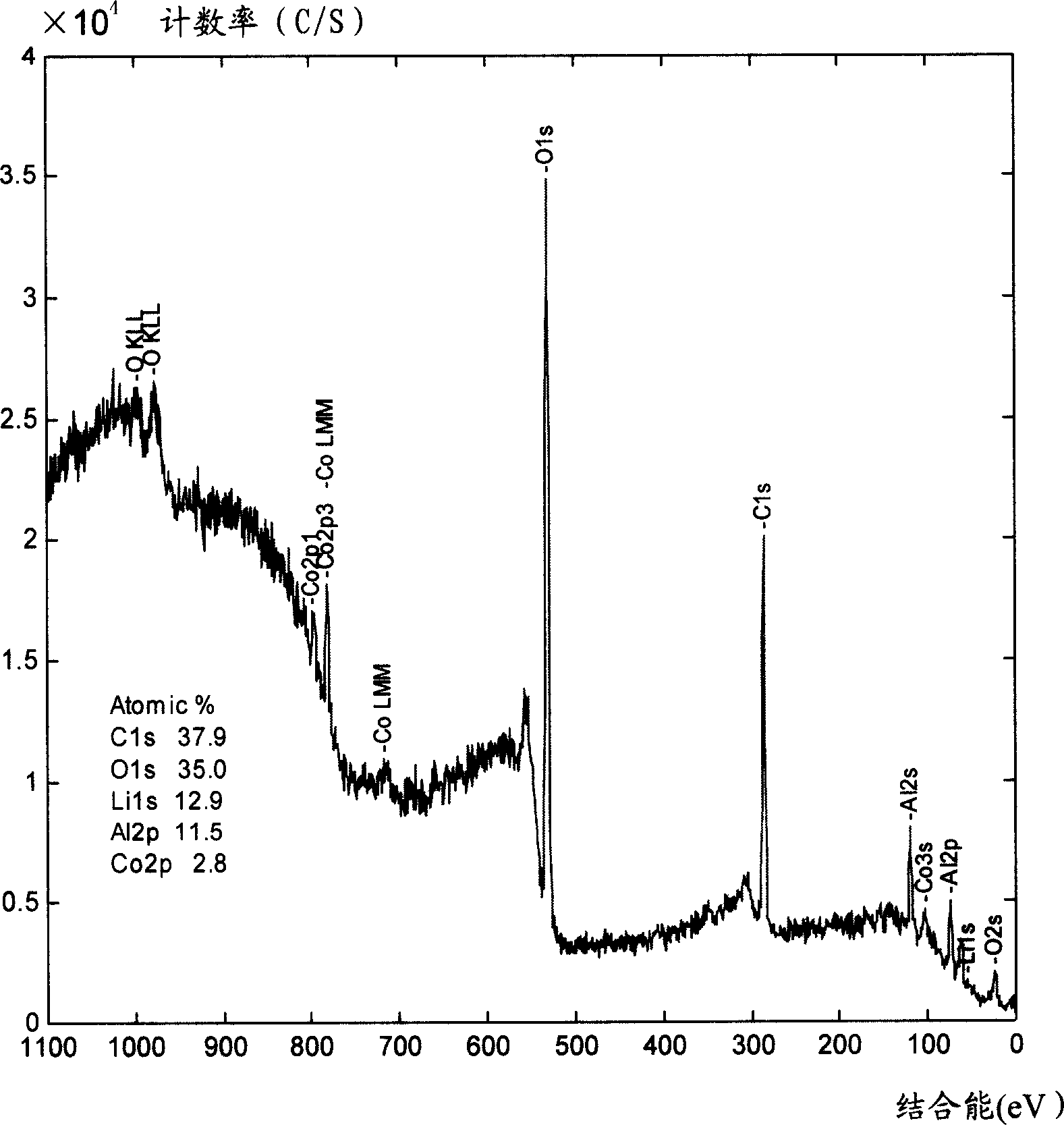

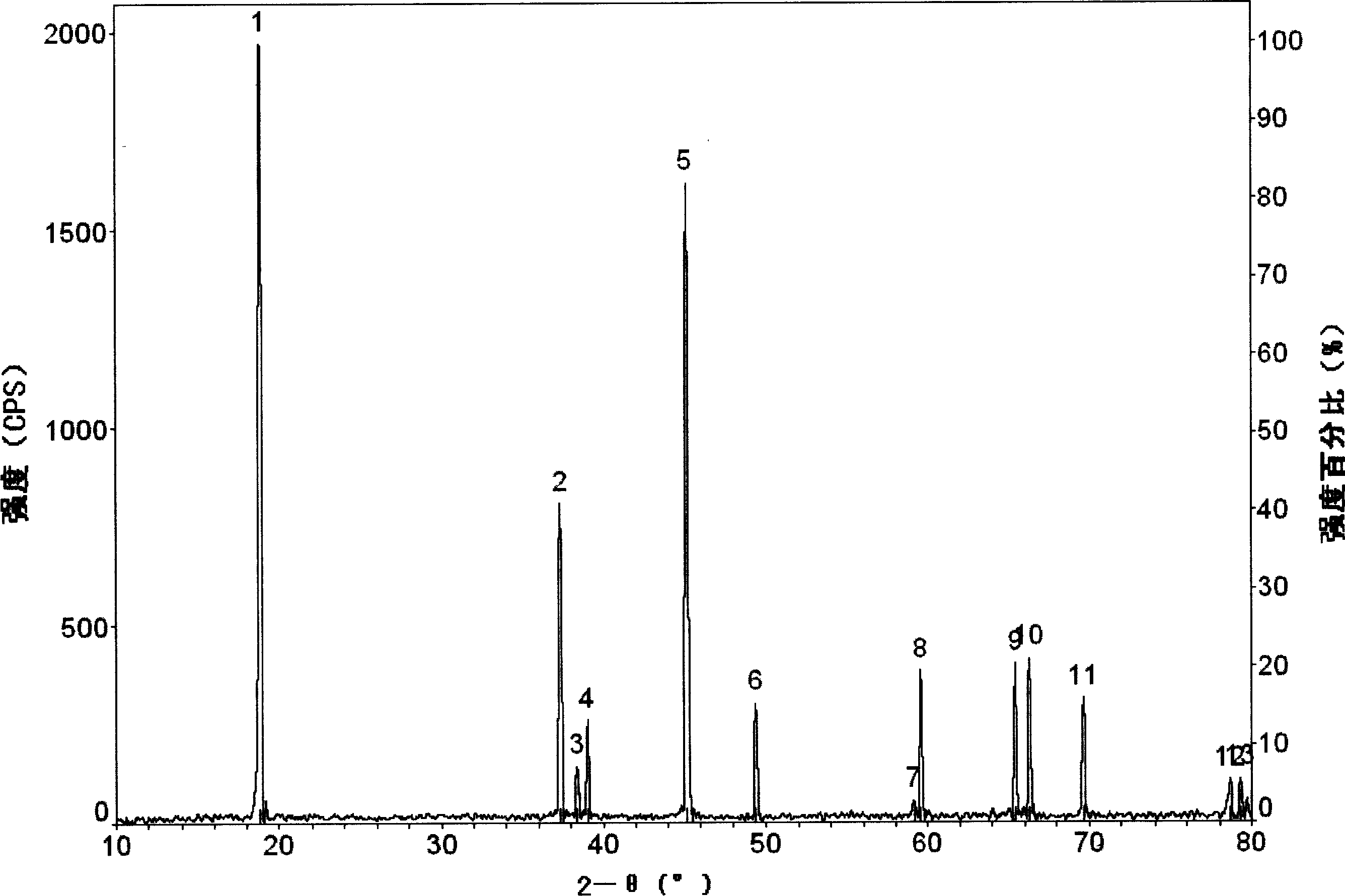

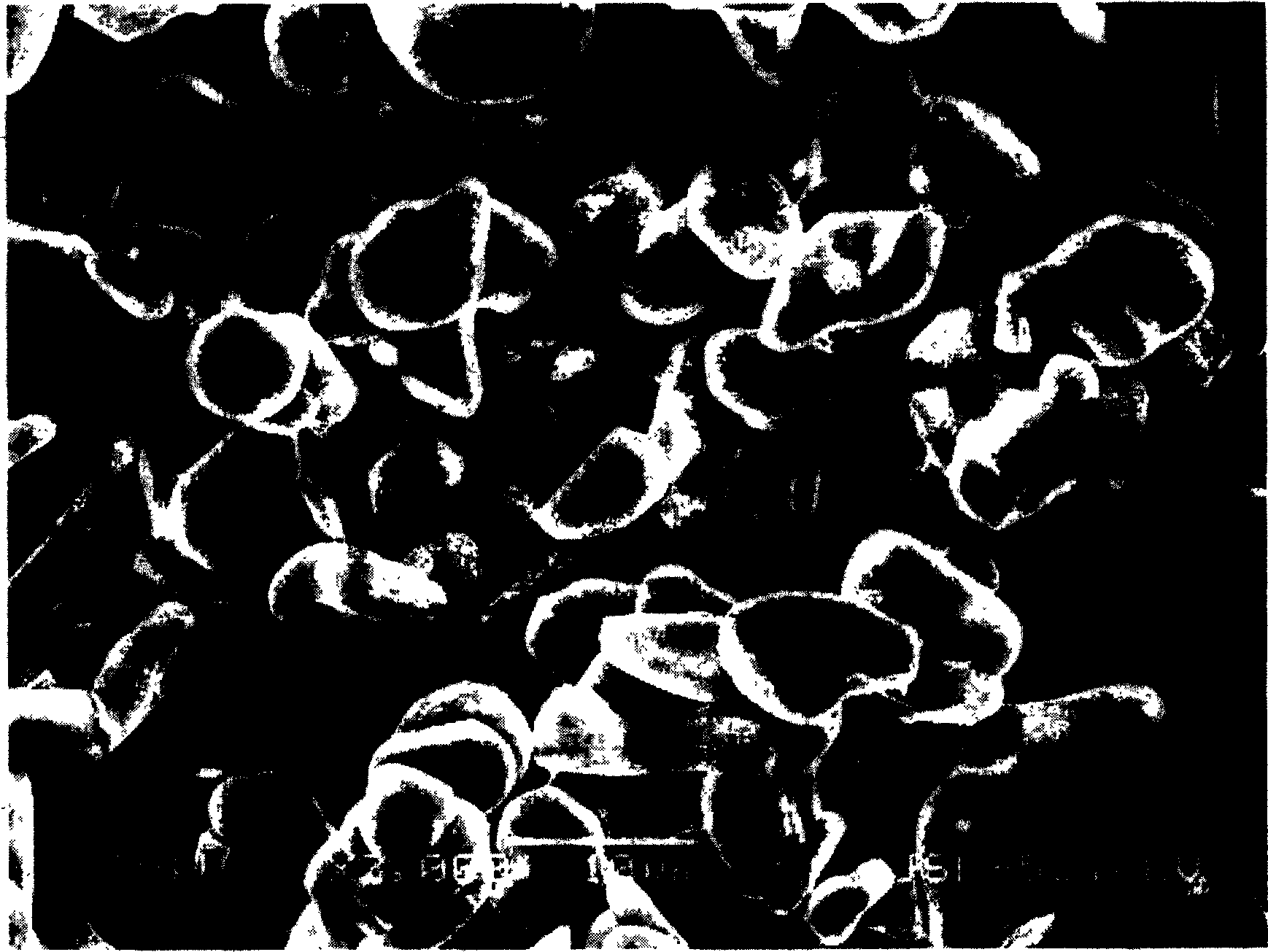

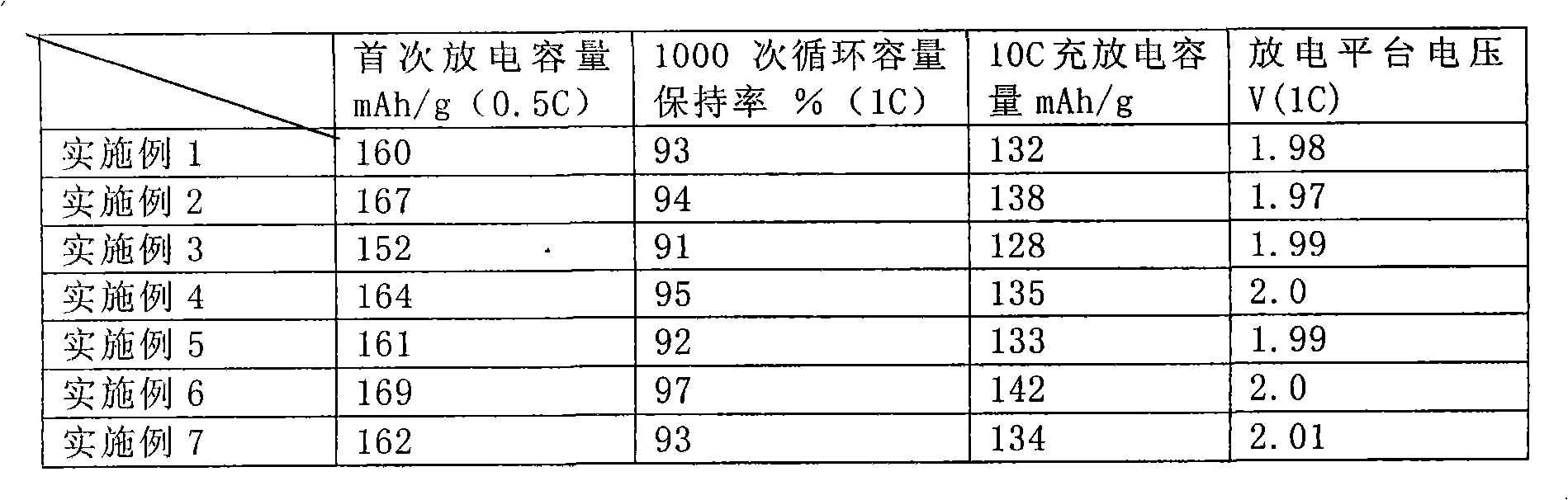

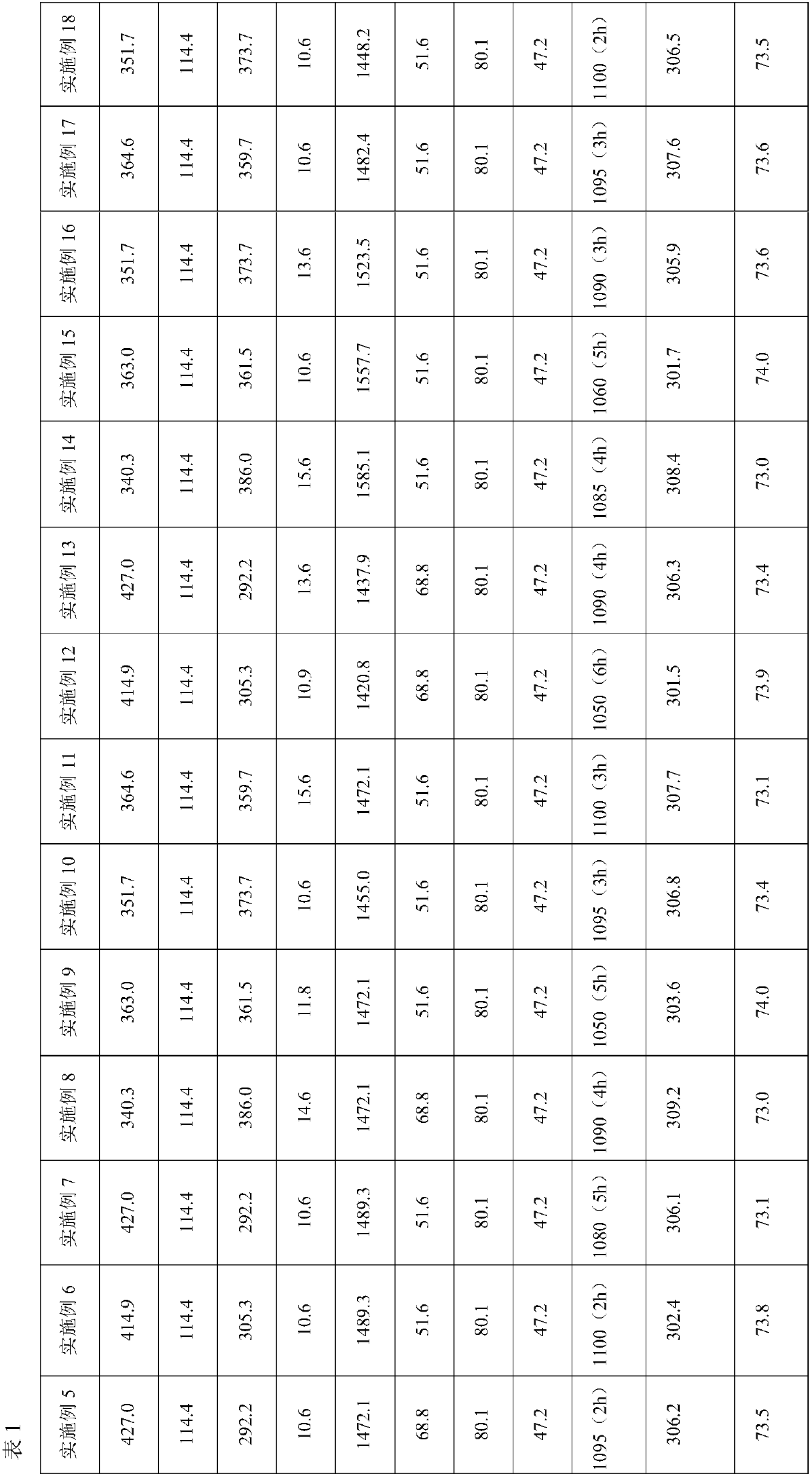

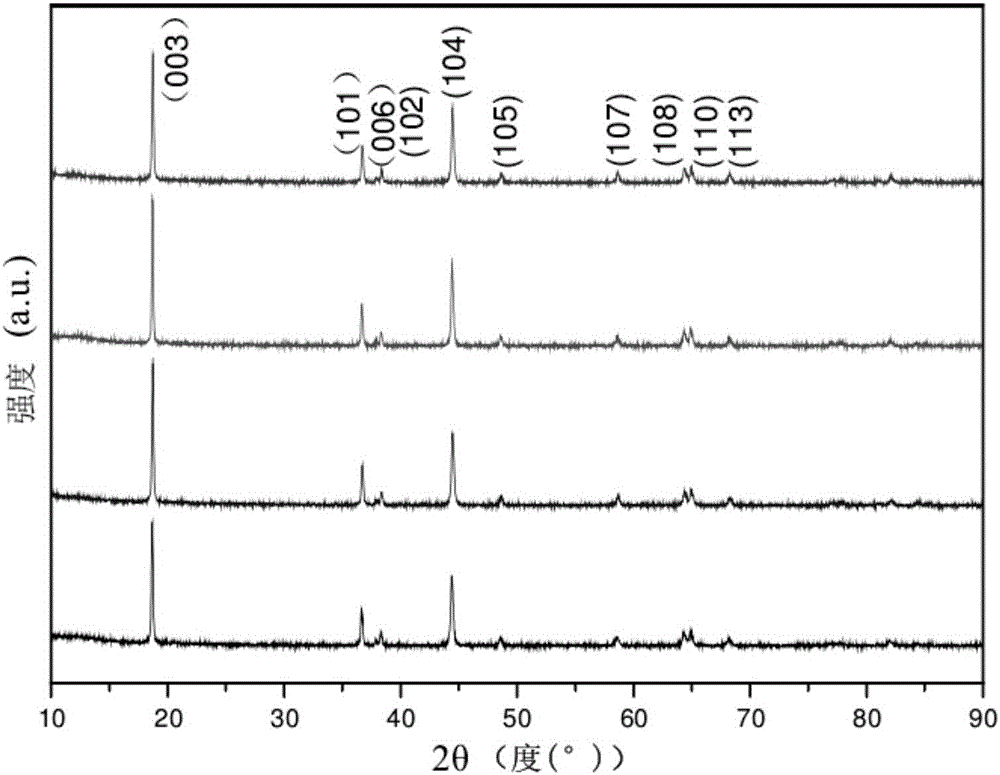

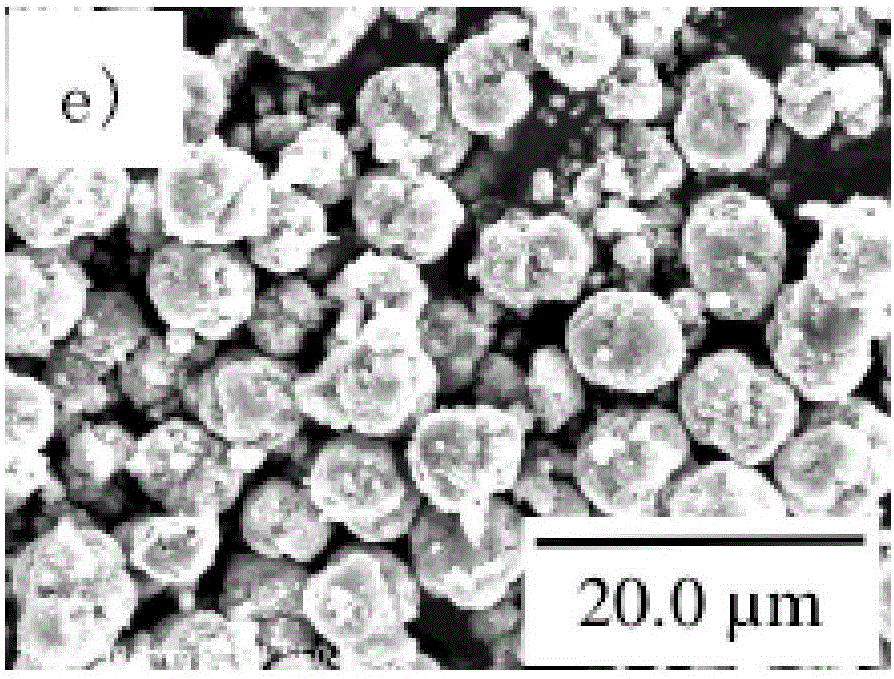

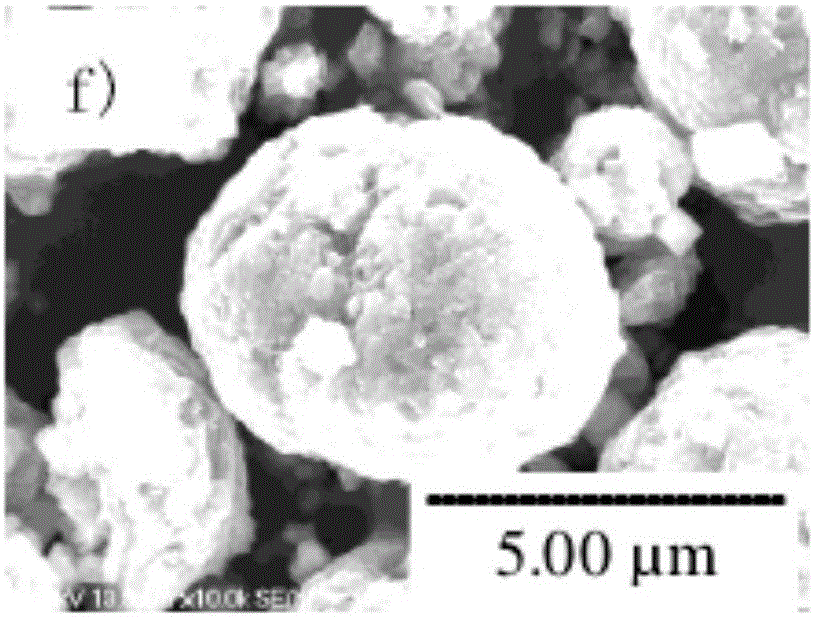

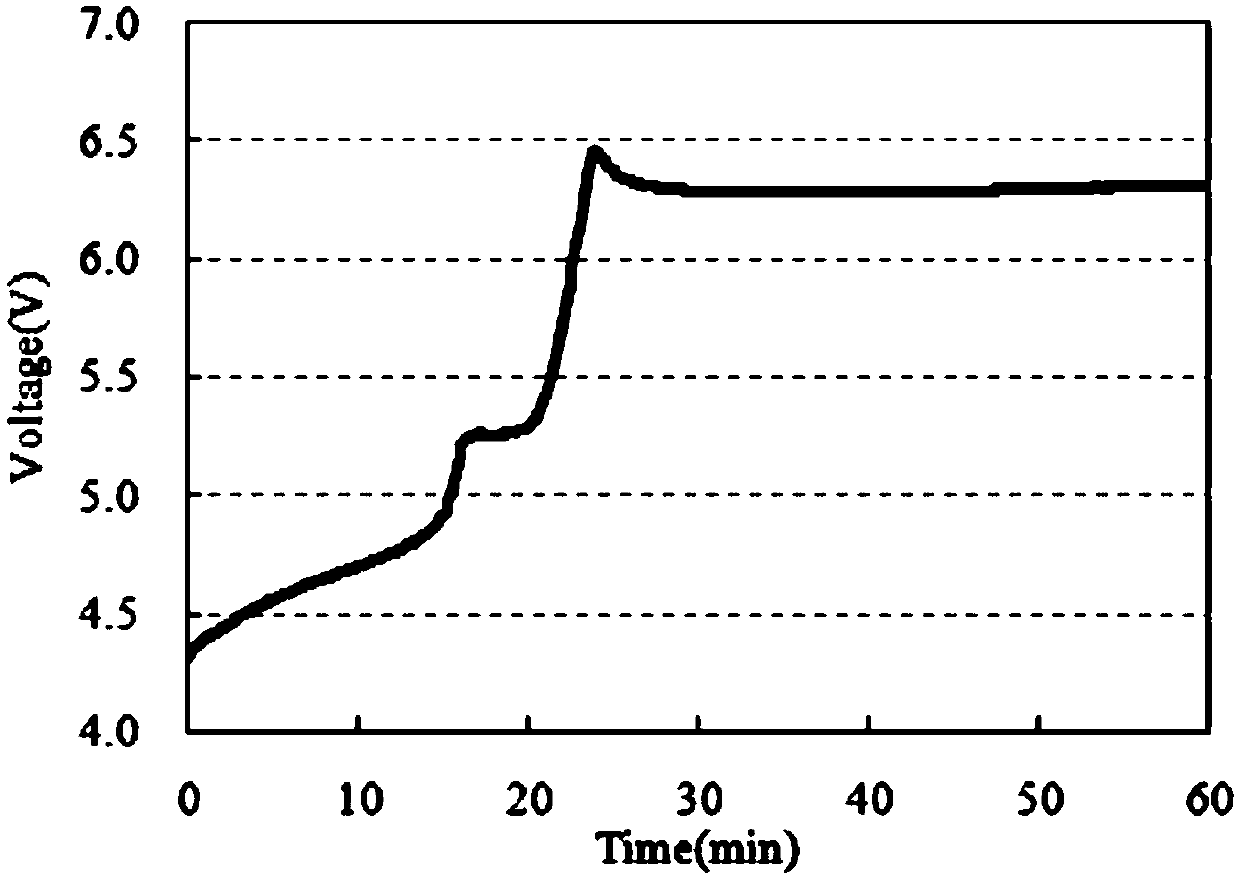

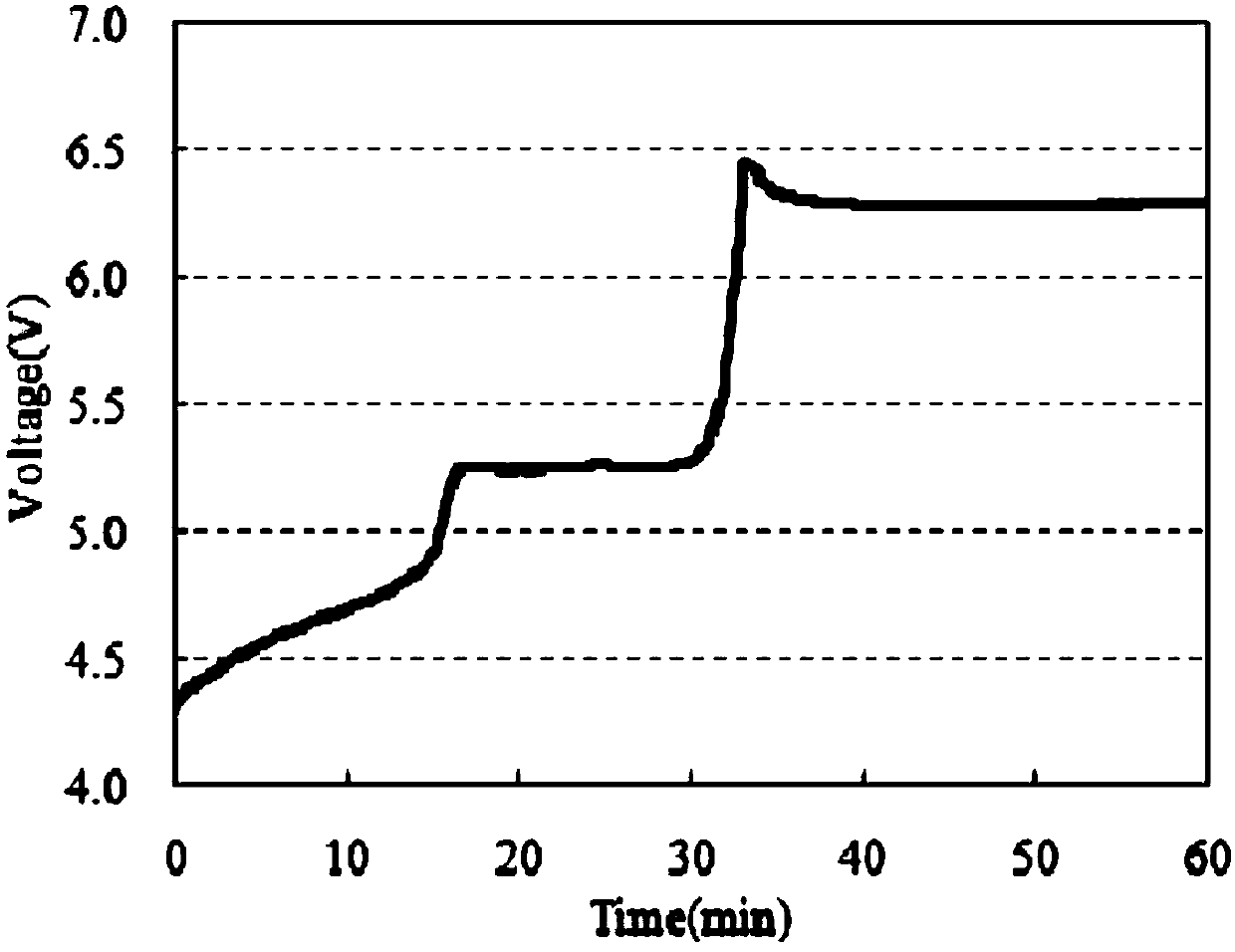

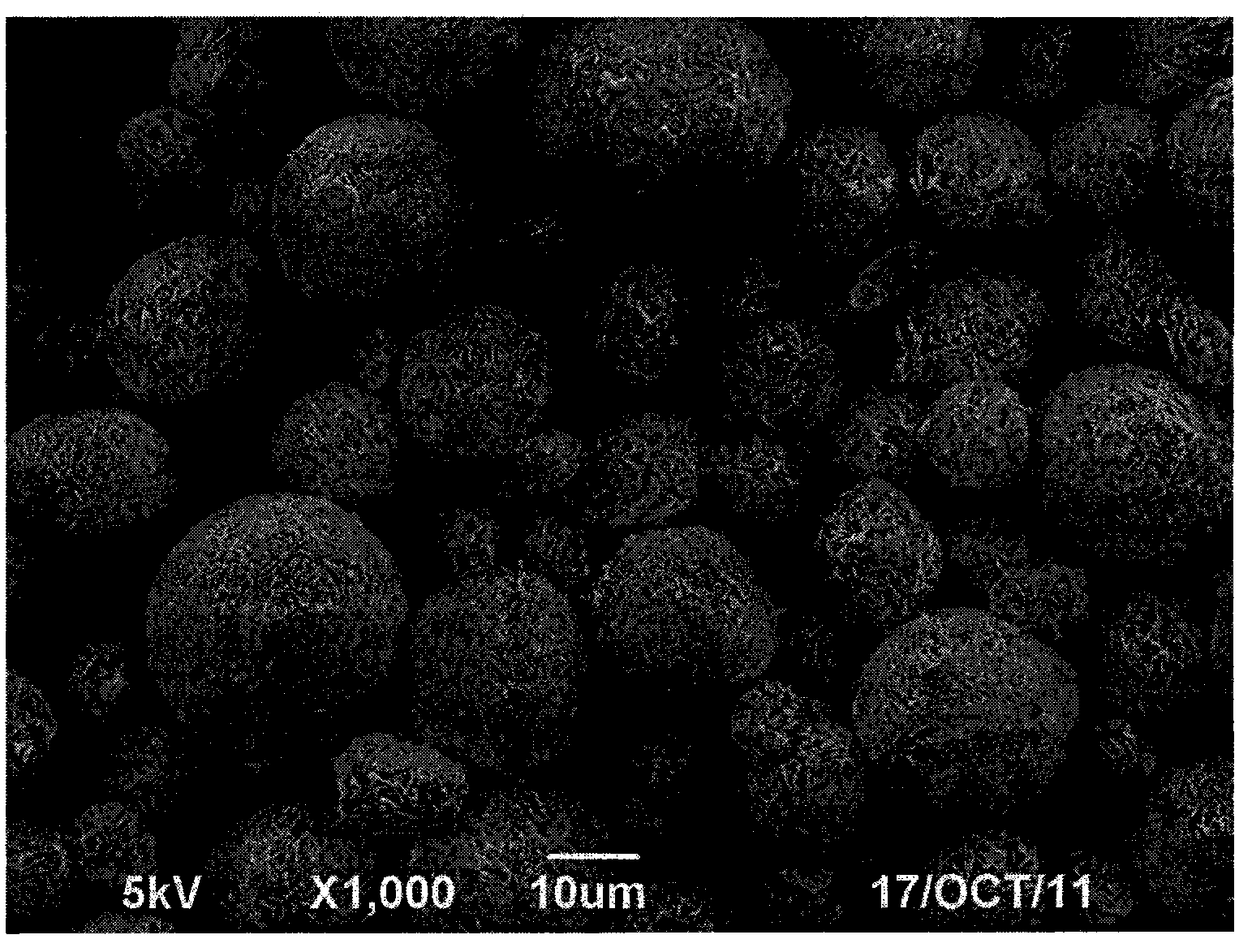

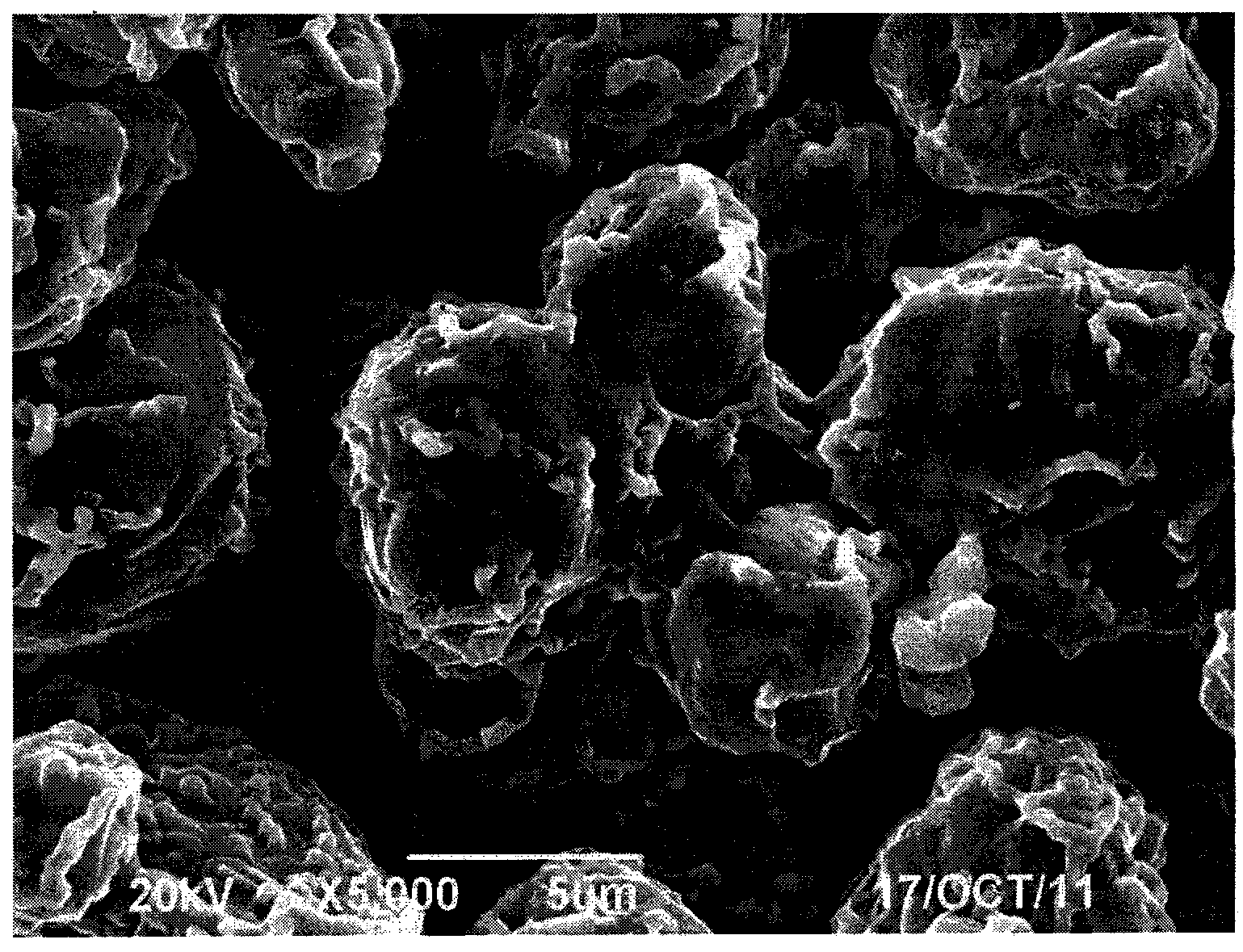

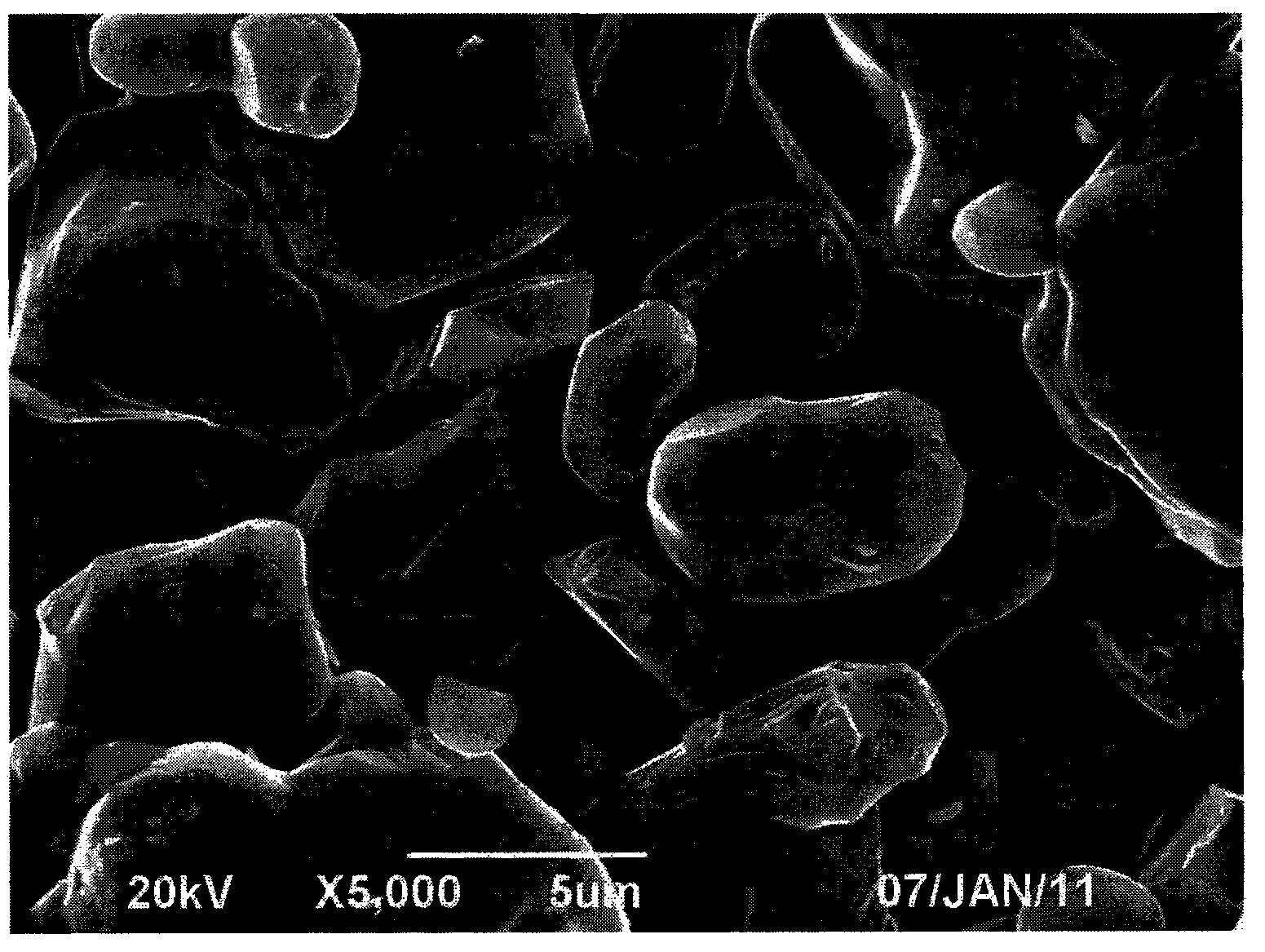

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

InactiveCN102583585BSimple processReaction is easy to controlCell electrodesCobalt carbonatesAlkalinityCobalt(II,III) oxide

The invention relates to the field of lithium ion battery materials and particularly relates to a preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the preparation technology, pure water serves as base solution under the conditions that temperature ranges from 40 DEG C to 80 DEG C and a stirring speed is controlled to 60-180 r / min, ammonium bicarbonate is added into the base solution to adjust the alkalinity of the base solution to range from 5 to 30, cobalt-salt mixed solution and ammonium bicarbonate solution are continuously pumped into the base solution in parallel flow and are subjected to sedimentation reaction under the temperature of 40-80 DEG C, the solid content and the alkalinity of slurry in a reaction system are controlled, reaction feed liquid flows out continuously from an overflow gate at the upper part of a reaction kettle to enter into an ageing kettle and then is washed by a washing press and dried by a vacuum drier, spherical cobalt carbonate is subjected to primary calcination to obtain cobaltosic oxide, and the cobaltosic oxide and a lithium source are subjected to secondary calcination to obtain the spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the invention, the process is simple, the reaction is easy to control, the production cost is low, the product application range is wide, and thus, the method is relatively large in production value; and the spherical lithium cobalt oxide is stable in performance and better in overcharging prevention performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

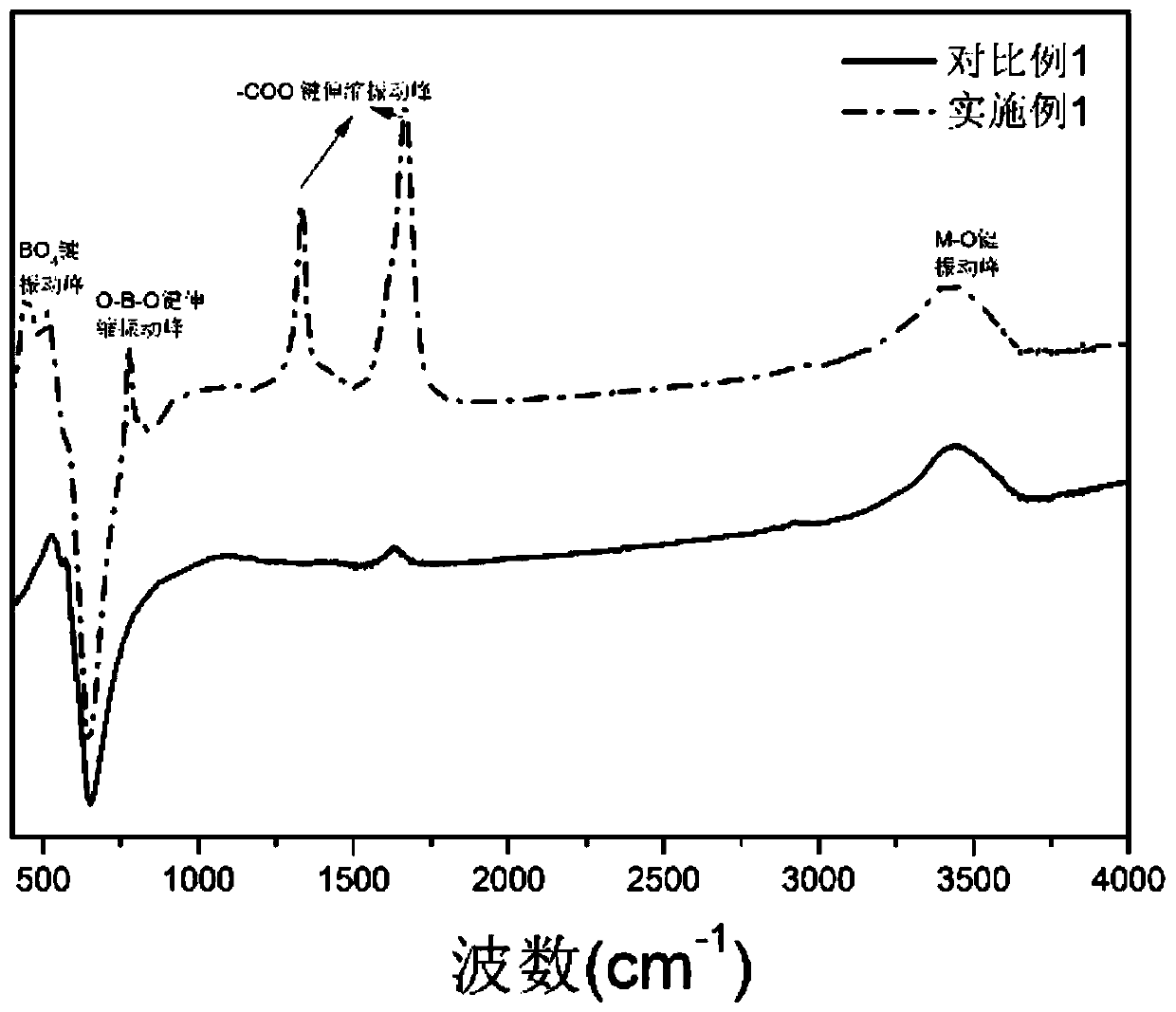

Positive electrode material with low surface residual alkali as well as preparation method and application thereof

InactiveCN109817914AImprove electrochemical performanceImprove conductivityCell electrodesSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a positive electrode material with low surface residual alkali. The positive electrode material is obtained by reacting an original positive electrode material with a boron compound and / or organic weak acid, wherein the original positive electrode material comprises any one or more of LiNi<y>Co<z>DM<1-y-z-u>O2, LiCo<1-w>T<w>O2, Li2Mn<1-j / 2>Q<j / 2>O4 and LiFe<1-s>R<s>PO4.According to the invention, the electrochemical performance of the positive electrode material can be improved, a coating material generated by the reaction has good thermal stability, chemical stability and high conductivity, a stable and compact solid electrolyte interface film can be formed on the surface of the electrode, the overcharge resistance and the rate capability of the lithium ion battery can be effectively improved, and the cycle life of the lithium ion battery is remarkably prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrochemical device and electronic device

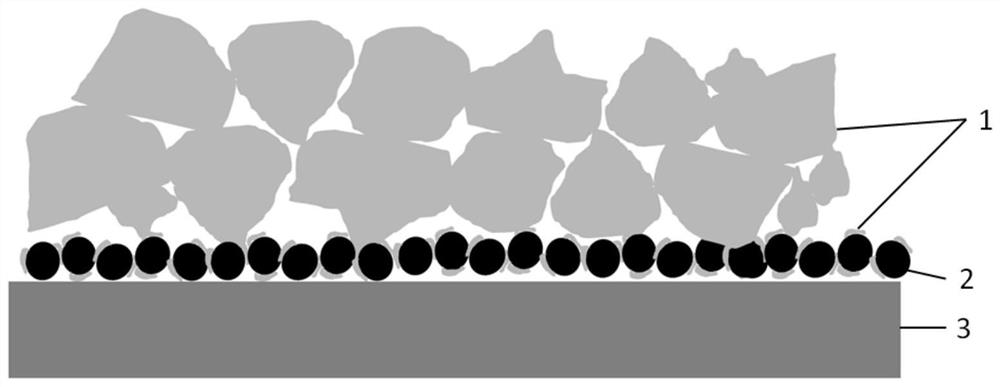

PendingCN112151750AImprove anti-overcharge performanceFix security issuesElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentConductive materials

The invention relates to an electrochemical device and an electronic device, and specifically provides an electrochemical device, which comprises a positive electrode, a negative electrode and an electrolytic solution, wherein the negative electrode comprises a negative electrode current collector and a negative electrode active material layer formed on the negative electrode current collector, the negative electrode active material layer containing a negative electrode active material, a conductive material is provided between the negative electrode active material layer and the negative electrode current collector, an average particle diameter of the conductive material is smaller than an average particle diameter of the negative electrode active material, and the negative electrode active material layer has a specific weight. The electrochemical device provided by the invention has improved high-temperature cycle expansion performance and overcharge resistance.

Owner:NINGDE AMPEREX TECH

Lithium ion battery electrolyte and preparation method thereof, lithium ion battery and electric vehicle

PendingCN112909341AImproved magnification performanceImprove cycle performancePropulsion by batteries/cellsSecondary cells servicing/maintenanceElectrolytic agentElectric cars

The invention relates to the technical field of energy storage, and provides a lithium ion battery electrolyte and preparation thereof. A composite lithium salt is dissolved in an organic solvent, the composite lithium salt comprises a lithium salt additive and lithium hexafluorophosphate, and the molar concentration of final lithium ions is 0.8-2.5 mol / L when the composite lithium salt is dissolved in an electrolyte solvent. The bis (trifluoromethylsulfonyl) lithium imide obviously improves the low-temperature performance and the high-temperature performance of the battery, and the bis (trifluoromethylsulfonyl) lithium imide is used as a main lithium salt additive and is matched with lithium hexafluorophosphate, so that the ionic conductivity of the electrolyte can be further improved, the component proportion of an SEI film can be improved, the conduction of Li<+> is facilitated. The positive electrode structure is stabilized, and the dissolution of transition metal ions is inhibited, so that the rate capability and the cycle performance of the lithium ion battery are improved. The invention also provides an electric vehicle with the lithium ion battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

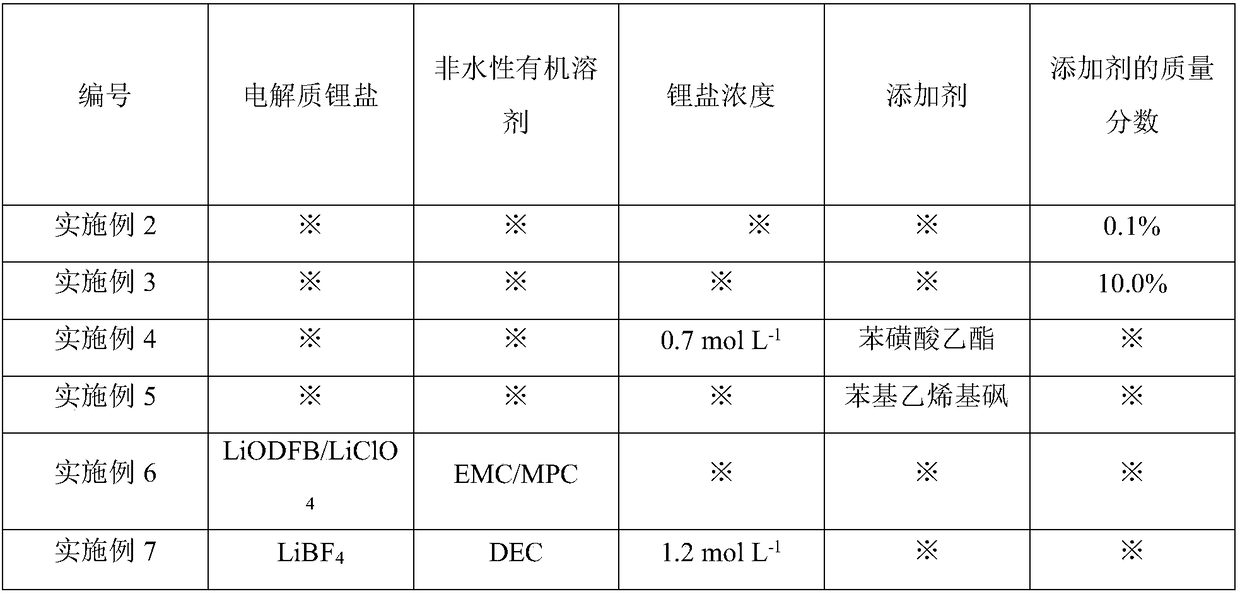

Lithium ion battery electrolyte

InactiveCN108598576AImprove anti-overcharge performanceIncrease transfer rateSecondary cells servicing/maintenanceOrganic electrolytesBenzeneLithium electrode

The invention discloses a lithium ion battery electrolyte. The electrolyte comprises electrolyte lithium salt, non-aqueous organic solvent and additive, wherein a major constituent of the additive isbenzene-containing sulfide, the benzene-containing sulfide specifically is at least one or more of phenyl vinyl sulfone, methyl benzenesulfinate, ethyl benzenesulfonate and methyl benzenesulfonate, mass of the additive is 0.1-10.0% of total mass of the electrolyte. The additive used in the electrolyte provided by the invention contains an aromatic nucleus and a sulfur-containing functional group,a special conjugated system of a benzene ring is liable to generate electric polymerization and consequently produces an insulating polymer film, thus, overcharging resisting performance of the lithium ion battery can be improved; the sulfur-containing functional group is beneficial for improving transmission rate of lithium ions between positive electrode interfacial films and reducing interfaceimpedance of the lithium ion battery. By modifying the positive electrode interfacial films with such additive, circulating performance and overcharging resisting performance of a high-voltage seriespositive electrode material can be promoted effectively.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

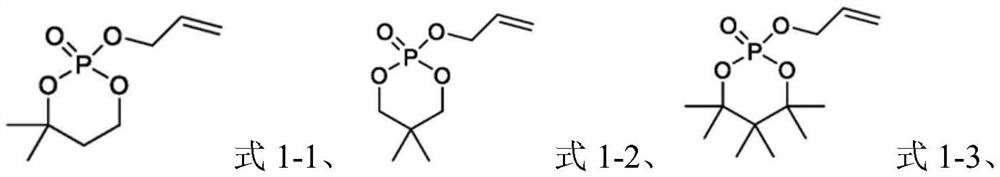

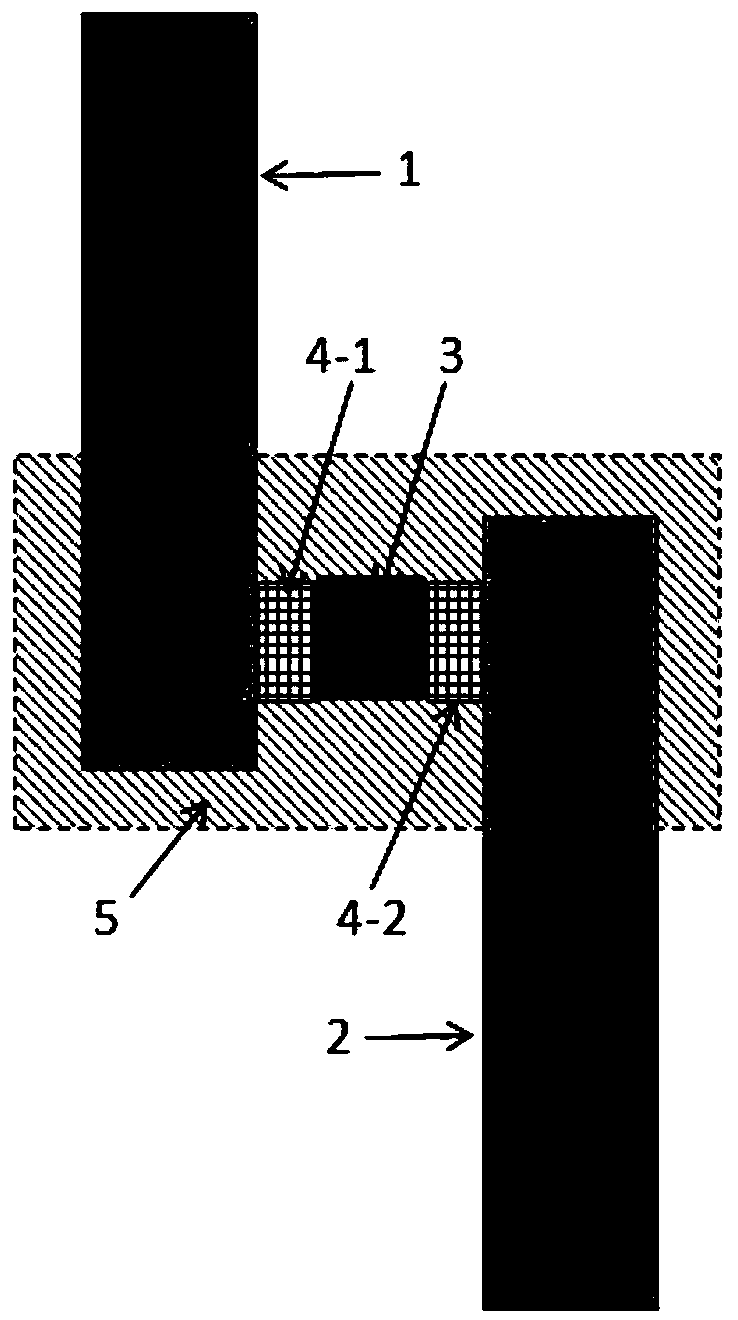

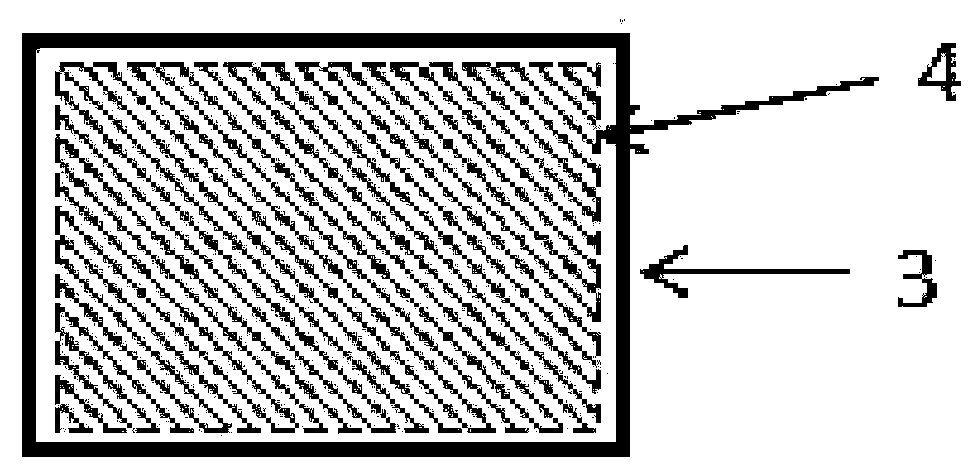

Composite thermistor material, thermistor, thermosensitive lug and lithium-ion battery

ActiveCN108615590ASuppress dangerHigh impedanceFinal product manufactureCell component detailsThermistorLithium electrode

The invention belongs to the field of lithium battery materials and particularly discloses a composite thermistor material. The composite thermistor material is characterized by comprising a fullerenematerial, a PTC material and an assistant. The invention further provides a thermistor compounded with the composite thermistor material, a thermosensitive lug assembled by the thermistor and a lithium-ion battery assembled by the thermosensitive lug. The inventor accidentally finds that the performance can be collaboratively improved through combined use of the fullerene material and the PTC material through a large number of studies. The lithium-ion battery with excellent overcharge resistance can be obtained through applying the lug provided by the invention into assembly of the lithium-ion battery; and especially a PTC thermistor containing the fullerene material is added between lugs of a soft package battery, so that the internal resistance of the whole battery can be reduced through reducing the room-temperature internal resistance rate of a PTC, and the overcharge performance of the soft package lithium-ion battery can be effectively improved to enhance the safety performanceof the battery.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Anti-overcharge battery pack device

PendingCN112615042APrevent overchargingImprove anti-overcharge performanceSecondary cells charging/dischargingBattery cellBattery pack

The invention discloses an anti-overcharge battery pack device, which comprises a battery box and a battery management system, wherein the battery box is electrically connected with the battery management system, the battery box comprises a plurality of single batteries, the battery management system acquires state information of the battery box in real time and controls charging and discharging of the battery box according to the state information, and an anti-overcharging additive is added into electrolyte of the single batteries. According to the anti-overcharge battery pack device, the overcharge safety of the battery pack device is ensured from multiple aspects of electrolyte components of the single batteries, functions of a battery management system and the like, and fire and explosion during overcharge of one or more single batteries are prevented.

Owner:SHANGHAI AEROSPACE POWER TECH

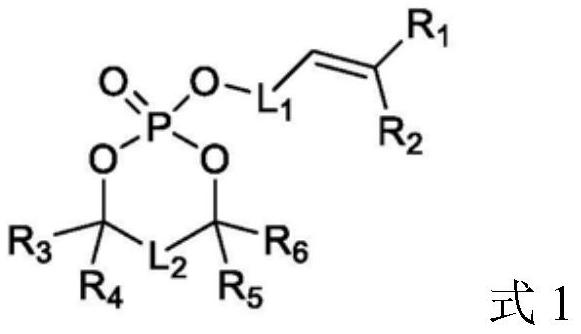

High-safety diaphragm material and preparation method and application thereof

ActiveCN108878737AImproved dimension stabilityIncreasing the thicknessSecondary cellsCell component detailsLithium-ion batteryAtomic layer deposition

The invention is mainly applied to the field of batteries, and particularly relates to a high-safety battery diaphragm and a preparation method thereof; more particularly, the high-safety battery diaphragm is formed by depositing a layer of inorganic oxide through an atomic layer deposition technology in advance on the surfaces of pores of a microporous diaphragm base material, and grafting voltage-sensitive organic monomers on the surface of the inorganic oxide through surface modification; the invention further relates to the high-safety battery diaphragm obtained by the method and an application of the high-safety battery diaphragm in a chemical power supply system such as a lithium ion battery and the like. The high-safety diaphragm provided by the invention not only has relatively high-temperature dimension stability, but also has the function of preventing overcharge of the battery, and has high ion conduction performance, so that the battery rate performance can be improved. Thepreparation process is simple to operate and the method is very suitable for large-scale production and application.

Owner:力源(广州)新能源科技有限公司

Electrolyte and preparation method thereof, lithium ion battery and electric vehicle

ActiveCN112993408AImproved magnification performanceImprove cycle performancePropulsion by batteries/cellsSecondary cells servicing/maintenanceElectrolytic agentElectric cars

The invention relates to the technical field of energy storage, and provides an electrolyte for a lithium ion battery, the electrolyte comprises an electrolyte solvent and a composite lithium salt, the composite lithium salt can be dissolved in the electrolyte solvent, and the electrolyte solvent comprises an organic solvent and an additive; wherein the volume percentage content of the organic solvent in the electrolyte solvent is 80%-99%, the volume percentage content of the additive in the electrolyte solvent is 0.5%-5%, and the additive comprises tris (trimethylsilane) phosphite. According to the multiplying power type electrolyte for the lithium ion battery, the solvent composition is optimized, and the novel electrolyte salt and the additive are matched, so that the ionic conductivity of the electrolyte is improved, the component proportion of an SEI film is improved, Li < + > conduction is facilitated, a positive electrode structure is stabilized, and dissolution of transition metal ions is inhibited; therefore, the rate capability and the cycle performance of the lithium ion battery are improved, and the running stability of an electric vehicle using the lithium ion battery can also be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

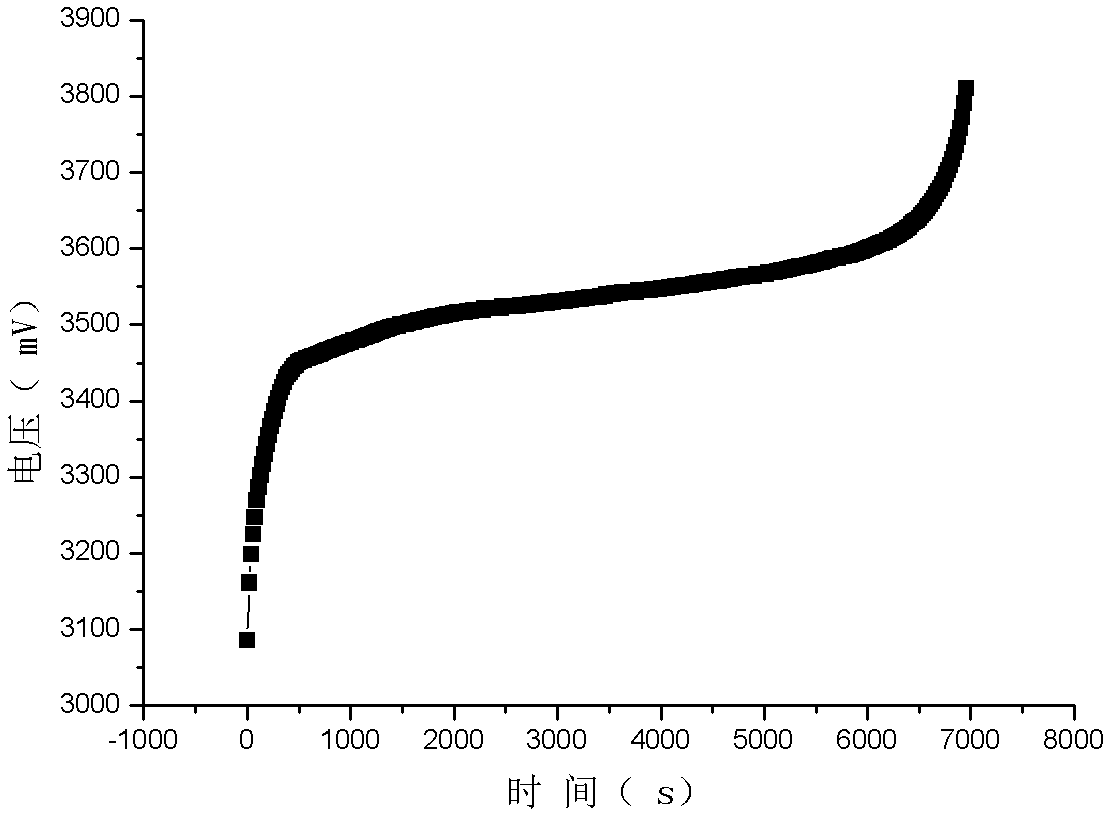

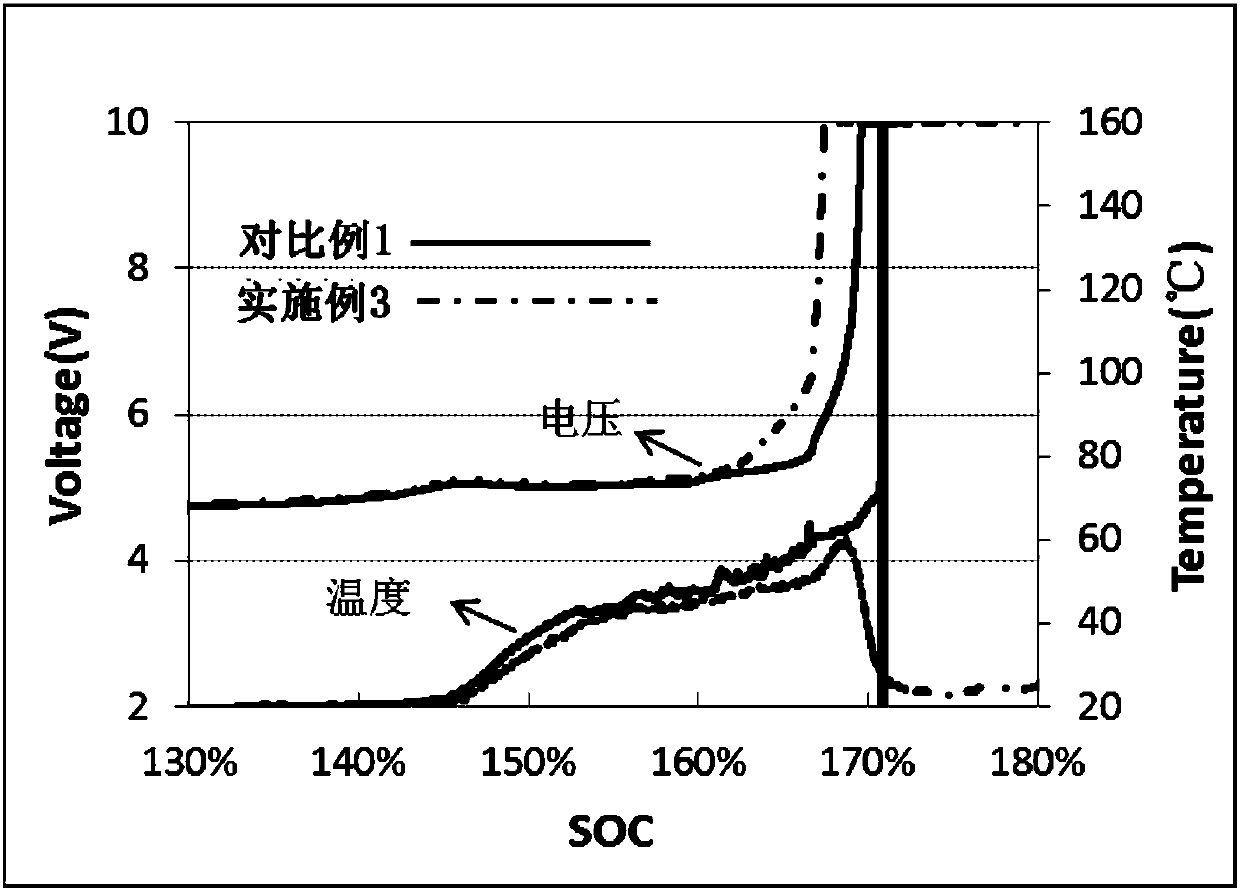

Electrolyte for flexible packaging lithium-ion secondary battery and battery containing same

ActiveCN103208648BImprove cycle performanceImprove high temperature storage performanceSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

The invention belongs to the technical field of lithium ion secondary batteries, and particularly relates to electrolyte for flexible-package lithium ion secondary batteries. The electrolyte comprises organic solvent, lithium salt and additives. The additives include additive A, additive B and additive C. The additive A is tert-amylbenzene and / or tert-butylbenzene, and the weight percentage of the additives A in the electrolyte is 5-10%. The additive B is at least one of malononitrile, succinonitrile, glutaronitrile, adiponitrile, pimelonitrile, suberonitrile, azelaic dinitrile and sebaconitrile, and the weight percentage of the additive B in the electrolyte is 1-8%. The additive C is fluoroethylene carbonate, and the weight percentage of the additive C in the electrolyte is 2-10%. Compared with the prior art, the electrolyte has the advantages that the additive A, the additive B and the additive C are combined in the high-voltage-design flexible-package lithium ion secondary batteries, good circulating performance and high temperature storage performance of the batteries are guaranteed, and meanwhile, the batteries are enabled to have good anti-overcharge performance.

Owner:DONGGUAN AMPEREX TECH

Electrochemical device and electronic device

ActiveCN112151751AImprove anti-overcharge performanceAvoid security issuesElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesPhysicsCurrent collector

The invention relates to an electrochemical device and an electronic device, and specifically provides an electrochemical device, which comprises a positive electrode, a negative electrode and an electrolytic solution, wherein the negative electrode comprises a negative electrode current collector and a negative electrode mixture layer formed on the negative electrode current collector, the negative electrode current collector contains tin, and the electrolytic solution comprises a compound containing a sulfur-oxygen double bond. The electrochemical device provided by the invention has improved high-temperature cycle performance and anti-overcharge performance.

Owner:NINGDE AMPEREX TECH

AB5-BASED HYDROGEN STORAGE ALLOY, ELECTRODE FOR Ni-MH BATTERY, SECONDARY BATTERY, AND PREPARATION METHOD OF HYDROGEN STORAGE ALLOY

PendingUS20220006070A1Low cycle lifeIncrease nucleation rateNegative electrodesAlkaline accumulator electrodesChemical compositionMetallurgy

The present invention relates to a hydrogen storage alloy, an electrode for a Ni-MH battery, a secondary battery, and a method for preparing the hydrogen storage alloy. The chemical composition of the hydrogen storage alloy is expressed by the general formula La(3.0˜3.2)xCexZrySm(1−(4.11˜4.2)x−y)NizCouMnvAlw, where x, y, z, u, v, w are molar ratios, and 0.14≤x≤0.17, 0.02≤y≤0.03, 4.60≤z+u+v+w≤5.33, 0.10≤u≤0.20, 0.25≤v≤0.30, and 0.30≤w≤0.40. The atomic ratio of the metal lanthanum (La) to the metal cerium (Ce) is fixed at 3.0 to 3.2, which satisfies the requirements of the overcharge performance of the electrode material. A side elements are largely substituted by samarium (Sin) element, that is, the atomic ratio of Sin on the A side is 25.6% to 42%, so as to solve the problem of shortened cycle life caused by the small amount of cobalt (Co) atoms. The equilibrium pressure is adjusted by the change in the ratio of Sin to La and Ce to satisfy the requirements of the charge and discharge dynamic performance of the electrode material. The nucleation rate of the solidification process is improved by the addition of zirconium (Zr) to the A side at an atomic ratio of 2% to 3%. The Ni-MH battery negative-electrode material obtained from the hydrogen storage alloy has high overcharge resistance, and good high-rate discharge performance and cycle stability.

Owner:SOUTH CHINA UNIV OF TECH +2

Lithium-ion power battery material

InactiveCN105261747AFast dischargeGood anti-overchargeCell electrodesSecondary cellsCell materialHeat stability

The invention aims at providing a lithium-ion power battery material. Spinel lithium titanate is adopted as a negative electrode; and the lithium-ion power battery material is high in discharge speed, good in overcharge resistance, excellent in heat stability and excellent in safety. A positive electrode of the lithium-ion power battery material comprises a main material, namely a lithium iron phosphate and lithium vanadium phosphate composite material; a positive electrode material and a negative electrode material can be used cooperatively; and the lithium-ion power battery material has the advantages of high current charge-discharge capability, extremely high safety and excellent circulating discharge performance, and is suitable for the field of electric automobiles.

Owner:WUHU KAIER ELECTRICAL TECH

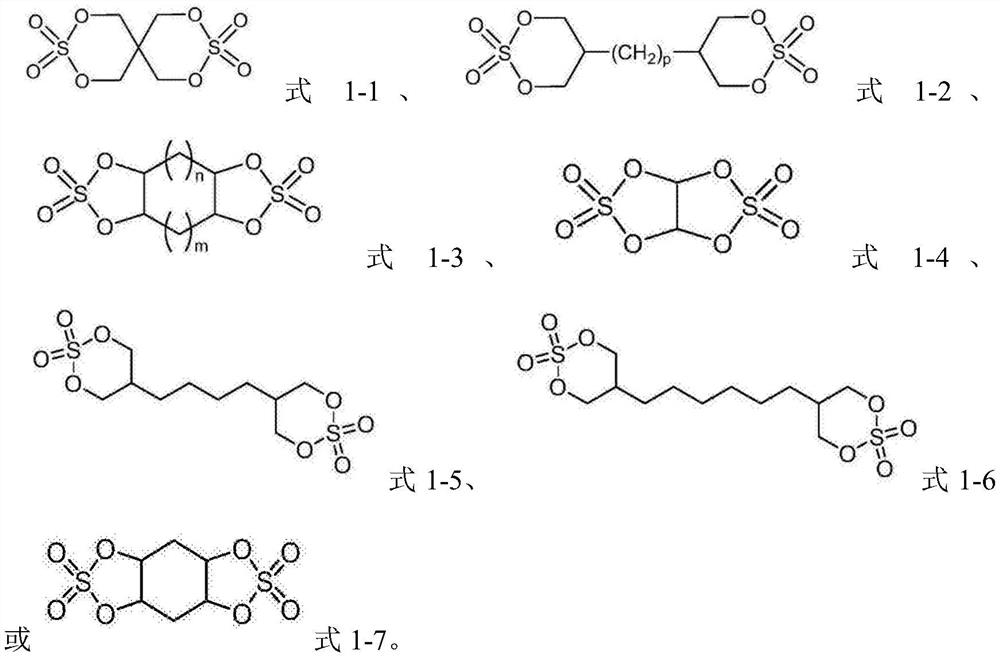

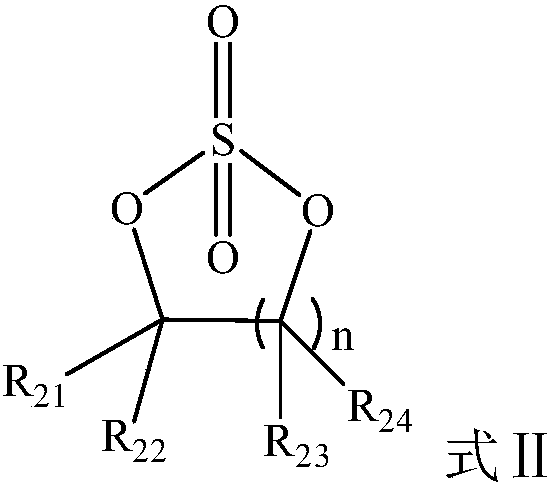

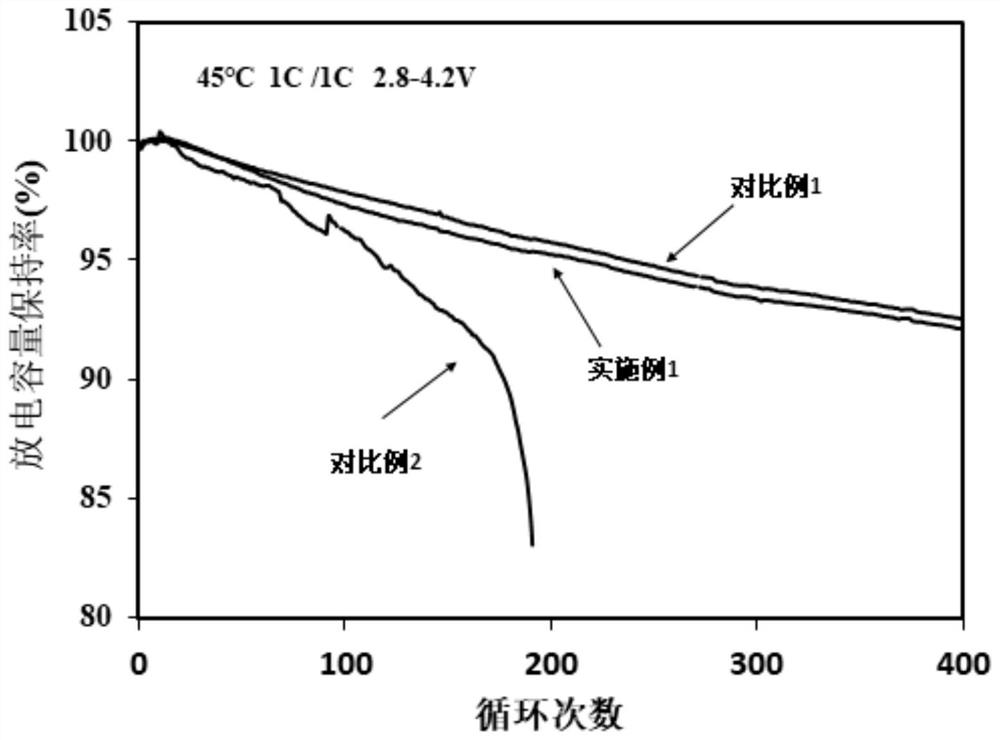

Electrolyte and secondary battery

InactiveCN107919497AImproved anti-overcharge performanceImprove anti-overcharge performanceSecondary cells servicing/maintenanceOrganic electrolytesRetention ratioOrganic solvent

The invention provides an electrolyte and a secondary battery. The electrolyte comprises an electrolyte salt, an organic solvent and additives, wherein the additives comprise a benzene single nitrilecompound, cyclic sulfate and fluoroethylene carbonate. When the electrolyte disclosed in the invention is applied to the secondary battery, the anti-overcharging performance of the secondary battery can be obviously improved; and meanwhile, the secondary battery also has relatively low cycle impedance and relatively high cycle capacity retention ratio.

Owner:NINGDE AMPEREX TECH

Cobalt acid lithium battery material adulterated alkaline-earth metal between layers and its preparing method

InactiveCN1316652CInitial capacity reductionStable structureElectrode manufacturing processesLithium compoundsAlkaline earth metalCITRATE ESTER

Owner:BEIJING UNIV OF CHEM TECH

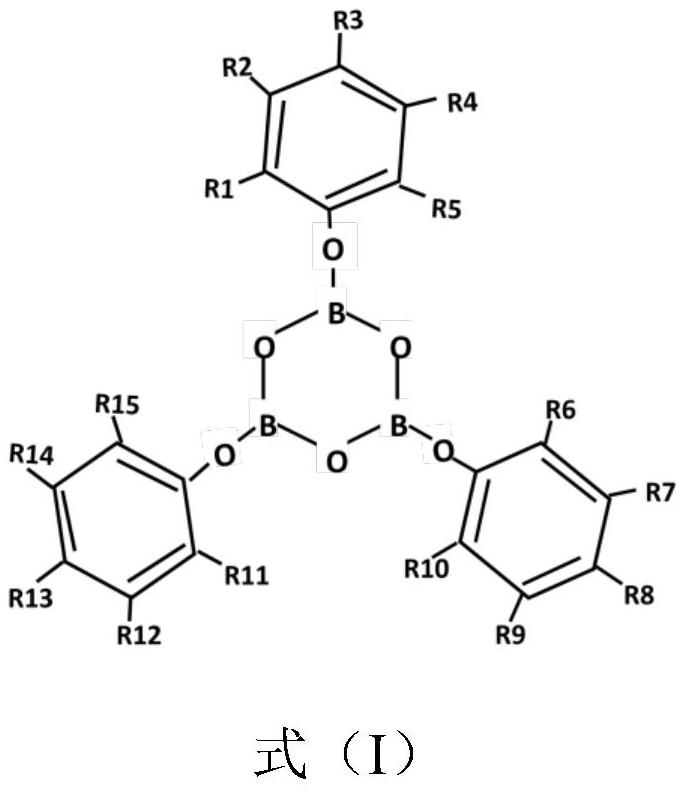

Anti-overcharge electrolyte and lithium ion battery containing electrolyte

InactiveCN112186245ALittle impact on electrochemical performanceImprove securitySecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentElectrical battery

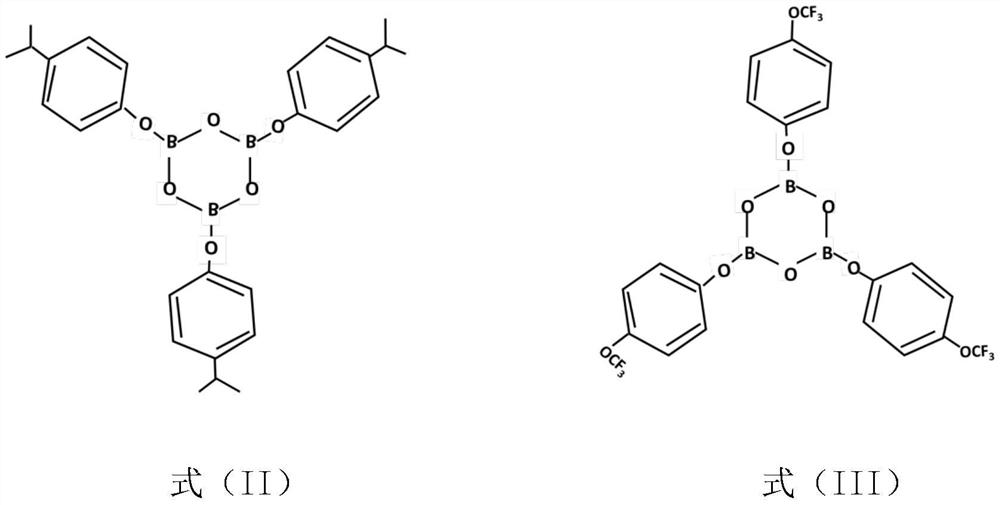

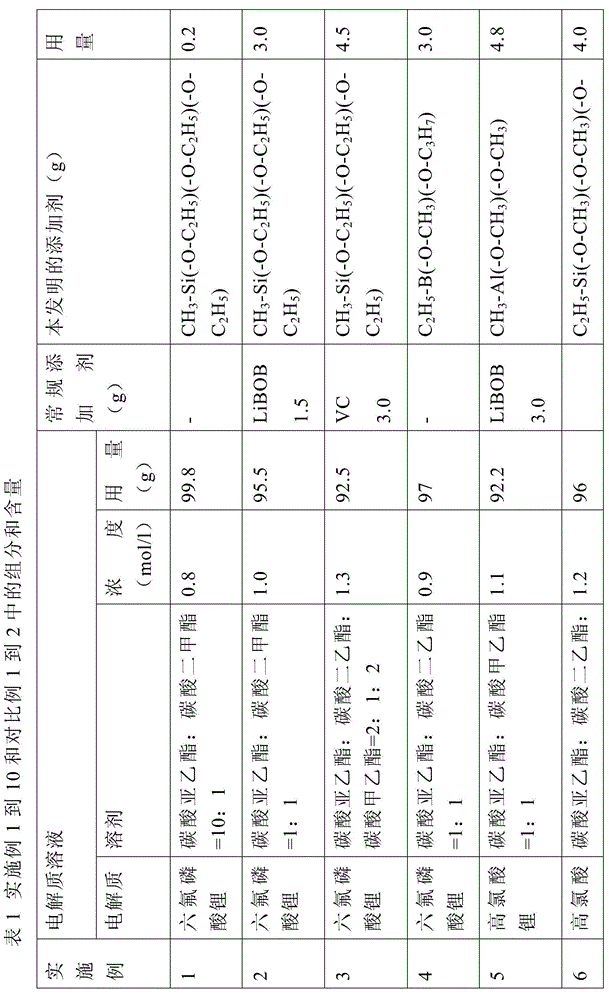

The invention discloses an anti-overcharge electrolyte and a lithium ion battery containing the electrolyte and relates to the technical field of lithium ion batteries. The anti-overcharge electrolytecomprises an anti-overcharge additive, wherein the anti-overcharge additive is composed of at least one of triphenoxy cyclotriboroxane and derivatives thereof, and the structural formula of the anti-overcharge additive is shown in the specification, triphenoxy cyclotriboroxane or derivatives thereof are adopted as the anti-overcharge additive, the anti-overcharge additive is added into an electrolyte, and polymerization reaction occurs only at a relatively high voltage of 4.5 V or above. The electrolyte is suitable for the lithium ion battery of a high-voltage material system, has less influence on the cycle performance, impedance and other electrochemical properties of the lithium ion battery, has very good overcharge prevention performance, and improves the safety performance of the lithium battery, especially the lithium battery of the high-voltage material system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

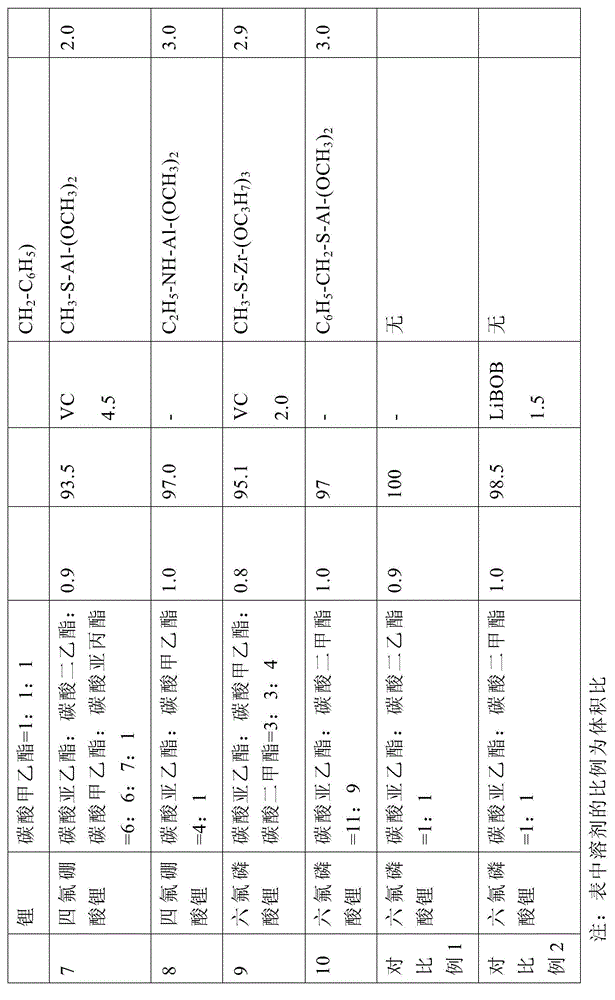

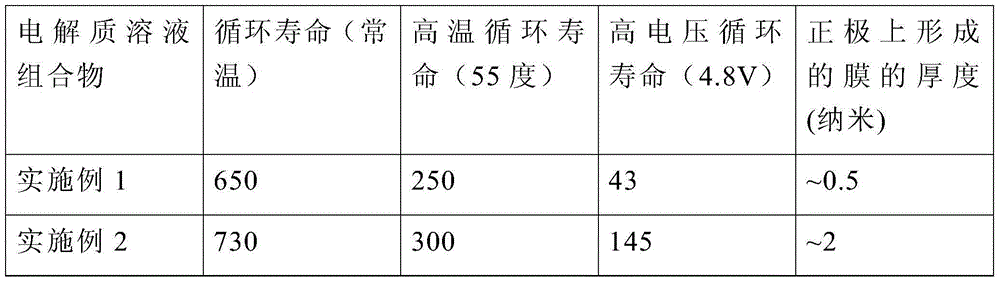

Lithium ion battery electrolyte solution composition

InactiveCN104466245AImprove battery performanceImprove charge and discharge efficiencySecondary cellsArylPhysical chemistry

The invention relates to a lithium ion battery electrolyte solution composition, which comprises an electrolyte solution and an additive. The additive is selected from one or more of formula (I) compound: RaM(-X1R1) (-X2R2)...... (-XZRZ) (I), wherein Ra optionally can be C1-C10, preferably C1-C6 alkyl, C3-C6 cycloalkyl, and C6-C10 aryl substituted C1-C10, preferably C1-C6 alkyl, C3-C6 cycloalkyl, or C2-C6 alkenyl or does not exist; R1, R2,... RZ independently and optionally can be C1-C10, preferably C1-C6 alkyl, C3-C6 cycloalkyl, and C6-C10 aryl substituted C1-C10, preferably C1-C6 alkyl, C3-C6 cycloalkyl, or C2-C6 alkenyl; X1, X2,....XZ can independently be O, S, N or P or does not exist; Z is an integer keeping the formula (I) compound electroneutral; and M is Al, B, Be, Mg, Si, Ca, Sr, Ba, Ra or Zr. The invention also relates to a lithium ion battery containing the electrolyte solution composition.

Owner:SUZHOU SINLION BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com