Aluminum magnesium fluoride-coated lithium nickel cobalt manganese oxide positive electrode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of gaps in cycle capacity retention and rate performance of manganese-based solid solutions, and achieve good high-temperature cycle performance , Good magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a positive electrode material of nickel-cobalt lithium manganese oxide coated with aluminum magnesium fluoride. The preparation method comprises: a. mixing nickel-cobalt lithium manganate spinel material with water-soluble aluminum salt, water-soluble magnesium salt and After the water is mixed, an aqueous solution of a water-soluble fluoride salt is added to form aluminum fluoride and magnesium fluoride precipitates and coat the surface of the nickel-cobalt lithium manganese oxide spinel material to obtain a solid-liquid mixture; b. The mixture is sequentially subjected to solid-liquid separation, washing, drying and roasting to obtain a nickel-cobalt-lithium-manganese-oxide positive electrode material coated with aluminum-magnesium-fluorine; wherein, the composition of the nickel-cobalt-lithium manganate spinel material is Li x mn 1-a-b Ni a co b o y , a is 0.1-0.4, b is 0.1-0.4, x is 1-2, y is (x+3) / 2, preferably, said...

preparation Embodiment 1

[0032] Preparation Example 1 prepares manganese cobalt nickel cathode material precursor [Mn 4 / 6 Ni 1 / 6 co 1 / 6 ]CO 3

[0033] (1) Configure MnSO separately 4 Solution (0.8mol / L), NiSO 4 Solution (0.8mol / L), CoSO 4 Solution (0.8mol / L), Na 2 CO 3 (0.2mol / L) solution 80ml, 20ml, 20ml and 480ml, keep the molar ratio of Ni, Mn, Co at 4:1:1, then fully stir the prepared solution on a magnetic stirrer to fully dissolve it.

[0034] (2) First, install and clean the reactor, ventilate the air with nitrogen, add 50ml of deionized water into the reactor, and raise the temperature to 50°C. After the temperature stabilized, add 20mlNiSO 4 solution and 5mlCoSO 4 solution. Simultaneously start to stir, and the stirring speed is 900r / m.

[0035] (3) After 5 minutes, use a constant pressure burette to drop 40ml of Na 2 CO 3 solution. The protective gas should be continuously introduced.

[0036] (4) Treat 40ml of Na 2 CO 3 After the dropwise addition of the solution was compl...

preparation Embodiment 2

[0041] Preparation Example 2 Preparation of nickel-cobalt lithium manganese oxide spinel material LiMn 4 / 6 Ni 1 / 6 co 1 / 6 o 2 .

[0042] (1), Li and Mn and weigh Li in molar ratio 1:0.667 2 CO 3 , to compensate for the loss of Li during the sintering process, Li 2 CO 3 Actual weight is 110% of theory.

[0043] (2), fully grind and prepare the obtained manganese-cobalt-nickel cathode material precursor [Mn 4 / 6 Ni 1 / 6 co 1 / 6 ]CO 3 and Li 2 CO 3 About 30min.

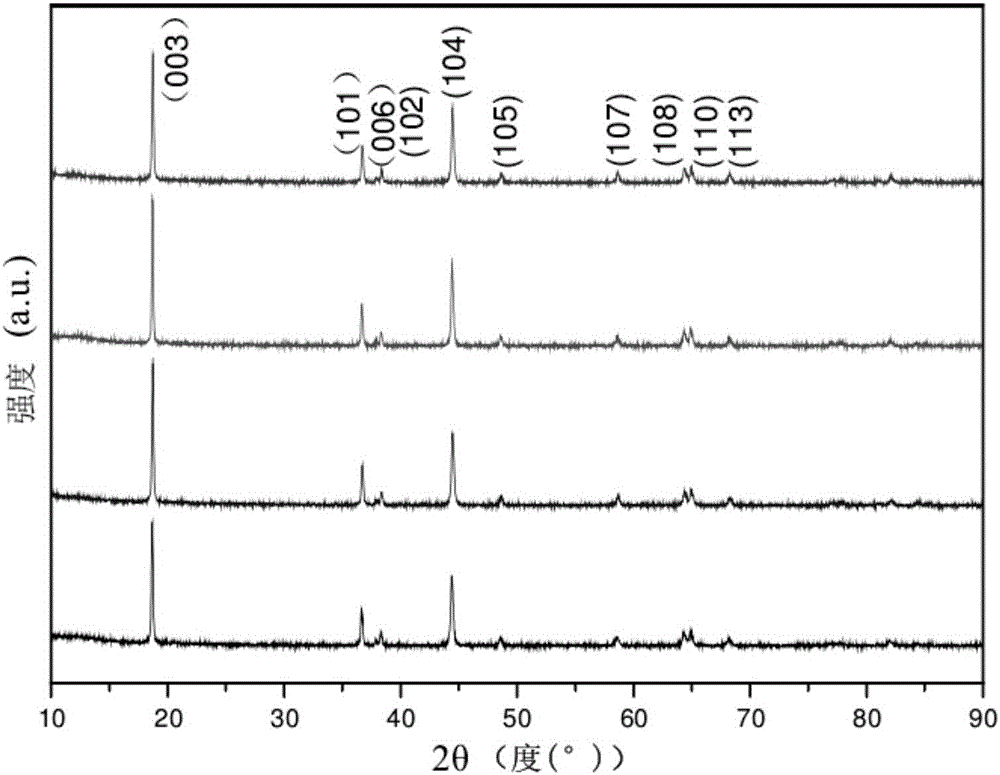

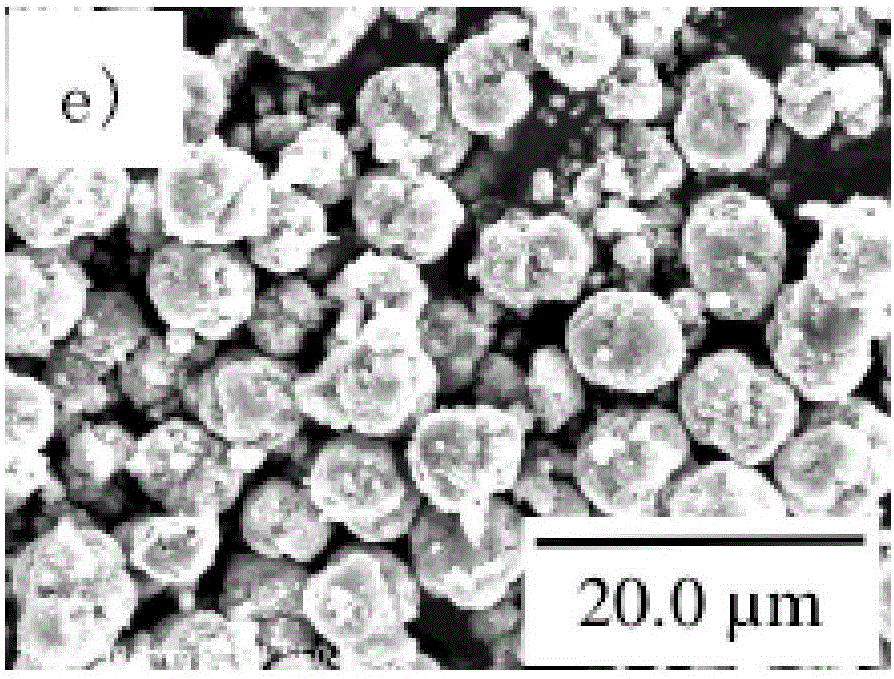

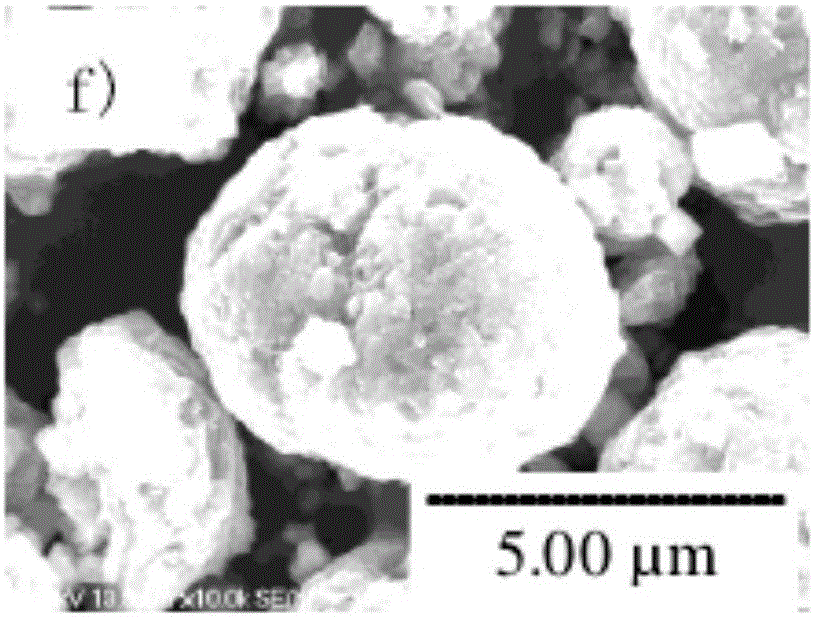

[0044] (3) Use a crucible to hold the ground powder for sintering in a muffle furnace, heat up to 900°C at a rate of 5°C / min and burn for 12 hours, and cool after burning to obtain LiMn, a nickel-cobalt lithium manganese oxide spinel material. 4 / 6 Ni 1 / 6 co 1 / 6 o 2 , the obtained nickel cobalt lithium manganese oxide spinel material LiMn 4 / 6 Ni 1 / 6 co 1 / 6 o 2 Carry out XRD analysis, 50 cycle discharge test, discharge capacity test at different rates, capacity-differential voltage test and AC impedance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com