Electrolyte and secondary battery

An electrolyte and compound technology, which is applied in secondary batteries, secondary battery repair/maintenance, organic electrolytes, etc., can solve the problems of secondary battery impedance increase, unusable, secondary battery failure, etc., and improve the anti-overcharge performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of electrolyte

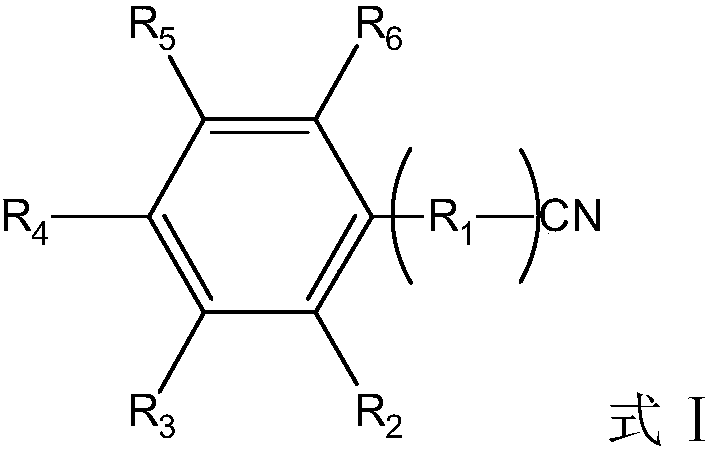

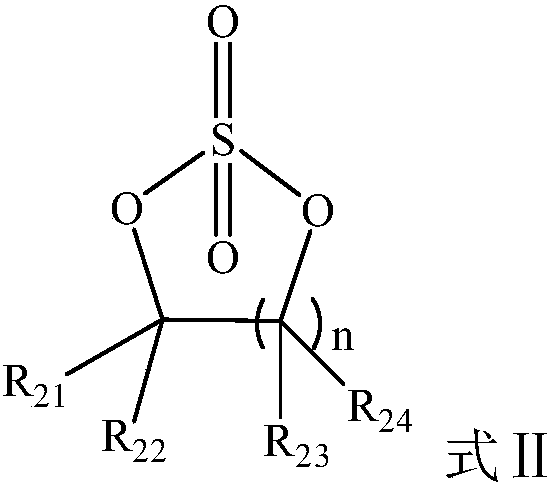

[0038] In the drying room, EC, PC, and DEC are mixed according to the mass ratio of EC:PC:DEC=1:1:1 to obtain a mixed organic solvent, and then fully dried lithium salt LiPF 6 Dissolve in the above-mentioned mixed organic solvent, then add compound 1 (namely benzonitrile), compound 7 (namely vinyl sulfate) and fluoroethylene carbonate (FEC) thereinto, stir evenly, and obtain electrolyte solution. Among them, in the electrolyte, the mass fractions of compound 1, compound 7 and FEC are 1%, 0.2% and 2%, respectively, LiPF 6 The concentration is 1mol / L.

[0039] (2) Preparation of positive electrode sheet

[0040] Weigh 1.42kg of solvent N-methyl-2-pyrrolidone (NMP), 1.2kg of binder polyvinylidene fluoride (PVDF) with a mass fraction of 10%, 0.16kg of conductive graphite and 7.2kg of positive electrode active material LiCoO 2 Thoroughly mix and stir to obtain the positive electrode slurry, then evenly coat the positive electrode slurry on...

Embodiment 2

[0046] The preparation process of the lithium-ion secondary battery is the same as in Example 1, except that in the electrolyte, the mass fraction of compound 1 is 1%, the mass fraction of compound 7 is 0.5%, and the mass fraction of FEC is 2%.

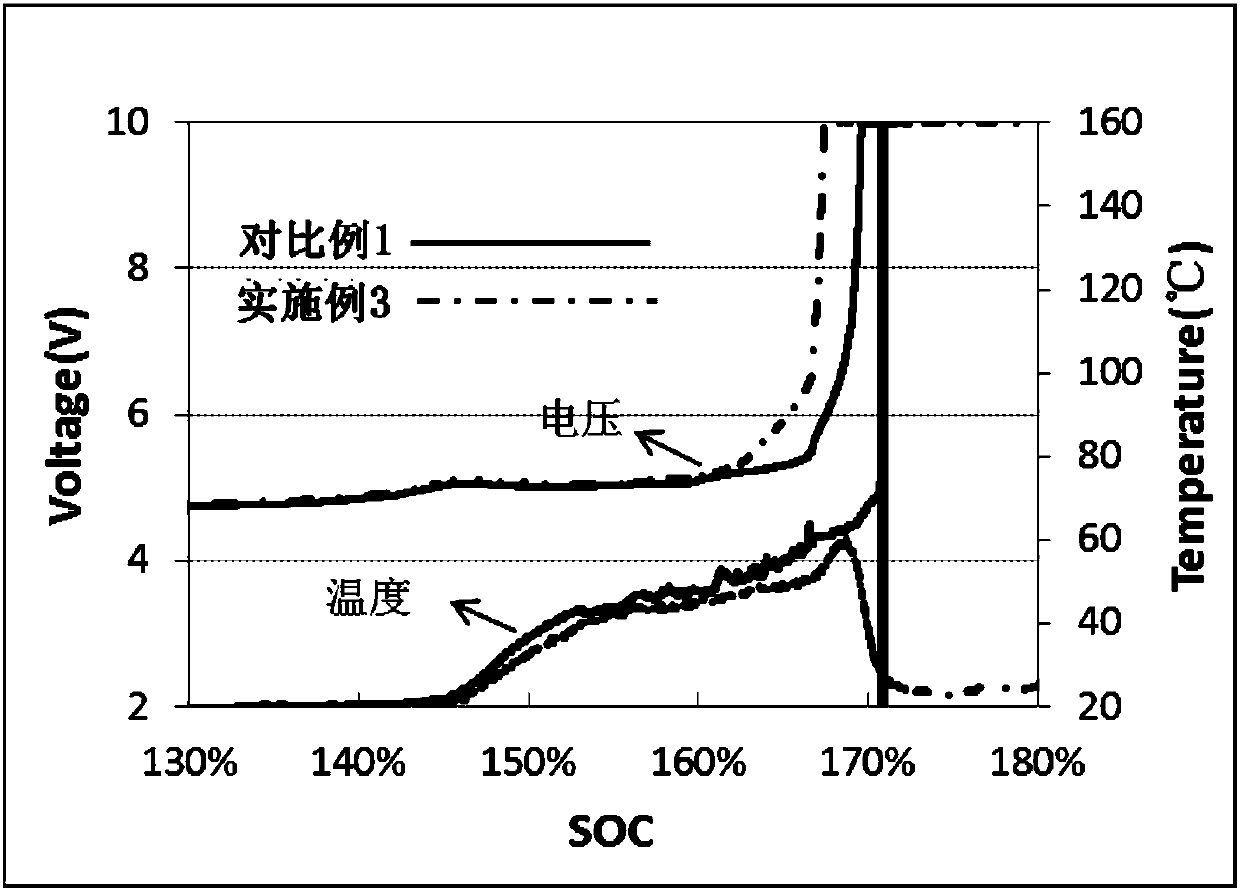

Embodiment 3

[0048] The preparation process of the lithium-ion secondary battery is the same as in Example 1, except that in the electrolyte, the mass fraction of compound 1 is 1%, the mass fraction of compound 7 is 1%, and the mass fraction of FEC is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com