Additive for lithium ion battery non-aqueous electrolyte and non-aqueous electrolyte made by the same

A non-aqueous electrolyte, lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of difficulty in taking into account the performance of EC-based electrolytes, decreased battery safety performance, and reduced solvent ignition point, etc. Overcharge ability and flame retardancy, small effect of battery internal resistance, effect of inhibiting further decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of phenyl-tris-2-methoxydiethoxysilane containing 10v / v% [C 6 h 5 Si(OCH 2 CH 2 OCH 2 CH 2 OCH 3 ) 3 ]. In an argon atmosphere glove box with a water content 6 Dissolved therein in an amount of 1.0 mol / L, a nonaqueous liquid electrolyte containing 10 v / v% of phenyl-tris-2-methoxydiethoxysilane was prepared.

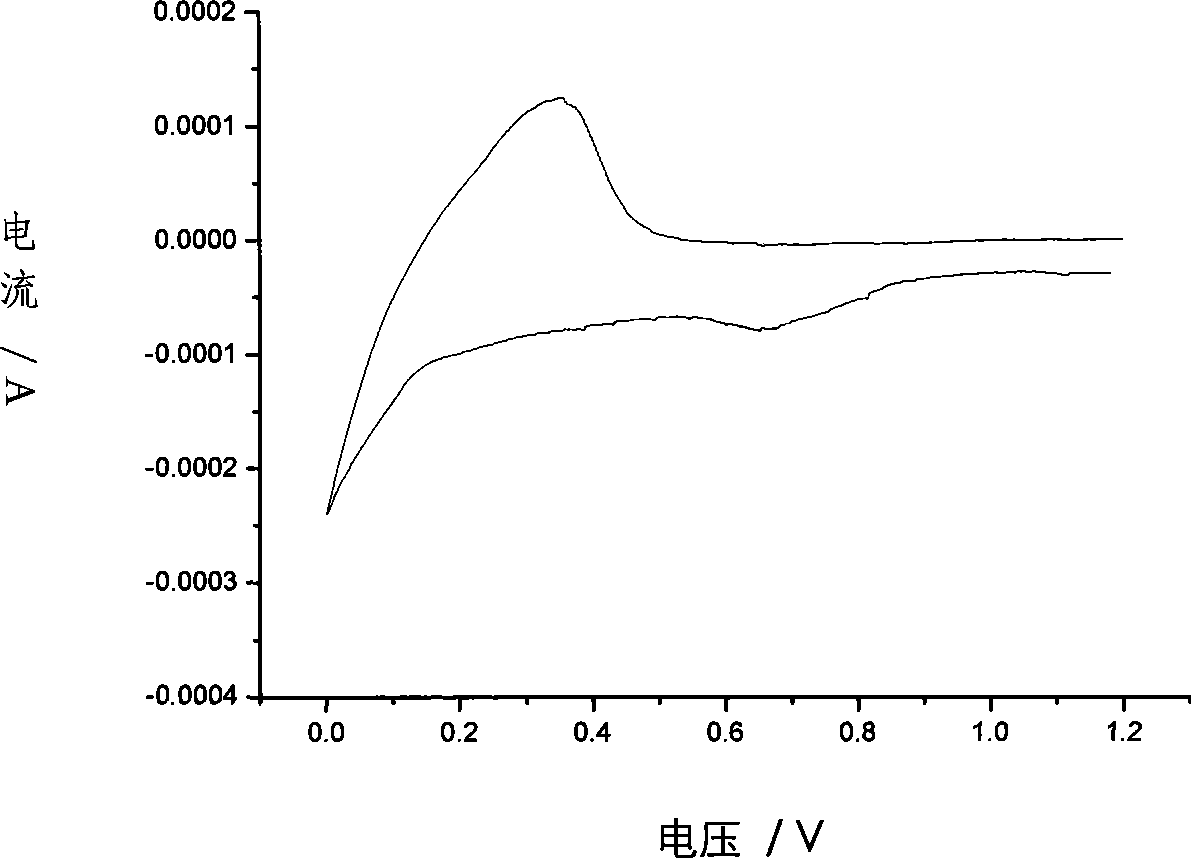

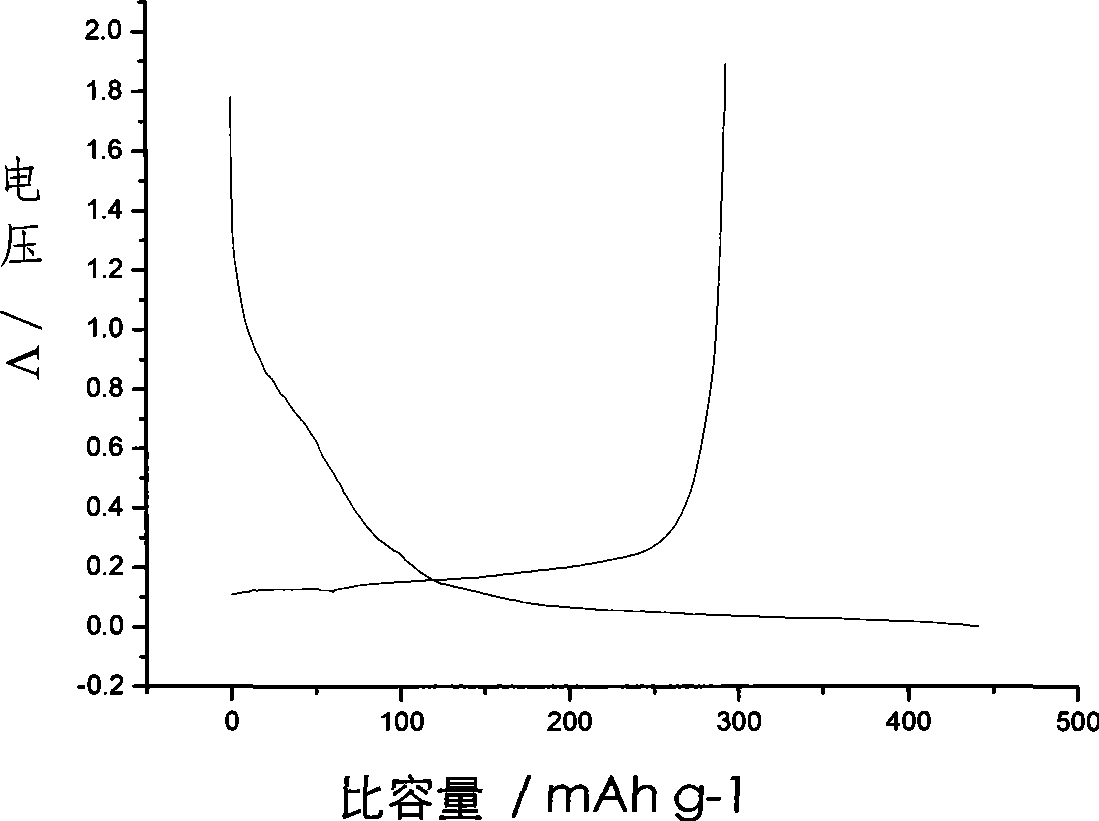

[0029] Mix 90 parts by mass of artificial graphite CMS powder with 5 parts by mass of acetylene black, and 5 parts by mass of polyvinylidene fluoride PVDF plus N-methylpyrrolidone binder to form a uniform paste, which is evenly coated on the negative electrode On the copper foil of the current collector, vacuum-dry at 120°C for 12 hours, cut into electrode sheets of a certain size, as the working electrode, and use the lithium foil as the reference electrode and the counter electrode, in which there is phenyl-tri-2-methoxy Diethoxysilane non-aqueous liquid electrolyte and separator were assembled together into two simulated batteries3,4.

Embodiment 2

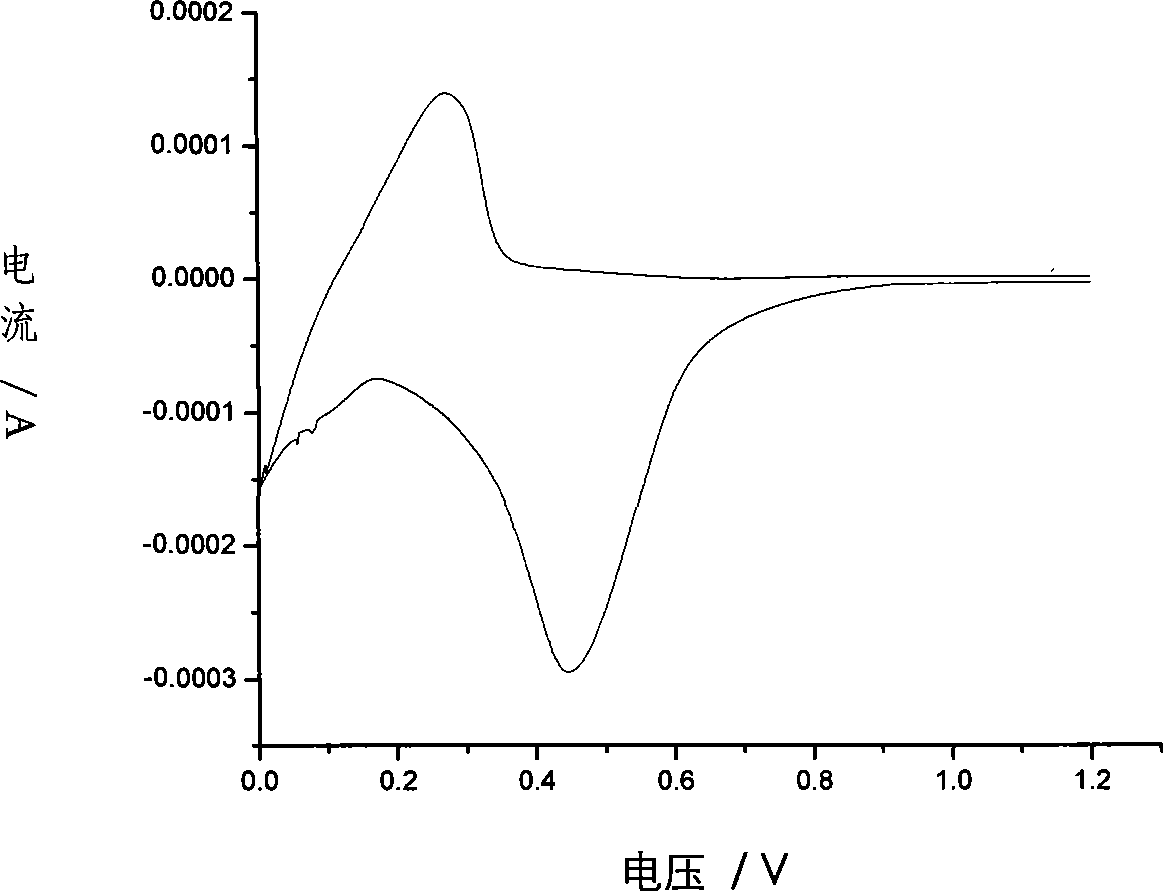

[0031]Preparation of vinyl-tris-2-methoxydiethoxysilane [CH 2 CHSi(OCH 2 CH 2 OCH 2 CH 2 OCH 3 ) 3 ] Non-aqueous liquid electrolyte and simulated battery 5,6. According to the method in Example 1, 5v / v% of vinyl-tri-2-methoxydiethoxysilane was mixed with propylene carbonate and dimethyl carbonate at a volume ratio of 1:1, and then Fully dry LiPF 6 Dissolved therein in an amount of 1.0 mol / L, a non-aqueous liquid electrolyte containing 5 v / v % of vinyl-tris-2-methoxydiethoxysilane was prepared. According to the method of Example 1, two simulated batteries 5 and 6 were assembled.

Embodiment 3

[0033] Tris-2-methoxyethoxy-2-thiocyanatoethylsilane [NCSCH 2 CH 2 Si(OCH 2 CH 2 OCH 3 ) 3 ] Non-aqueous liquid electrolyte. According to the method of Example 1, 3v / v% of tri-2-methoxyethoxy-2-thiocyanatoethylsilane was mixed with ethylene carbonate and dimethyl carbonate at a volume ratio of 1:1 Mix well, and then fully dry LiPF 6 Dissolved therein in an amount of 1.0 mol / L, a nonaqueous liquid electrolyte containing 3 v / v% of tris-2-methoxyethoxy-2-thiocyanatoethylsilane was prepared. According to the method of Example 1, two simulated batteries 7 and 8 were assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com