Method for preparing spinel lithium titanate

A technology of composite lithium titanate and spinel, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve problems such as low energy density, low potential, and reduced research interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

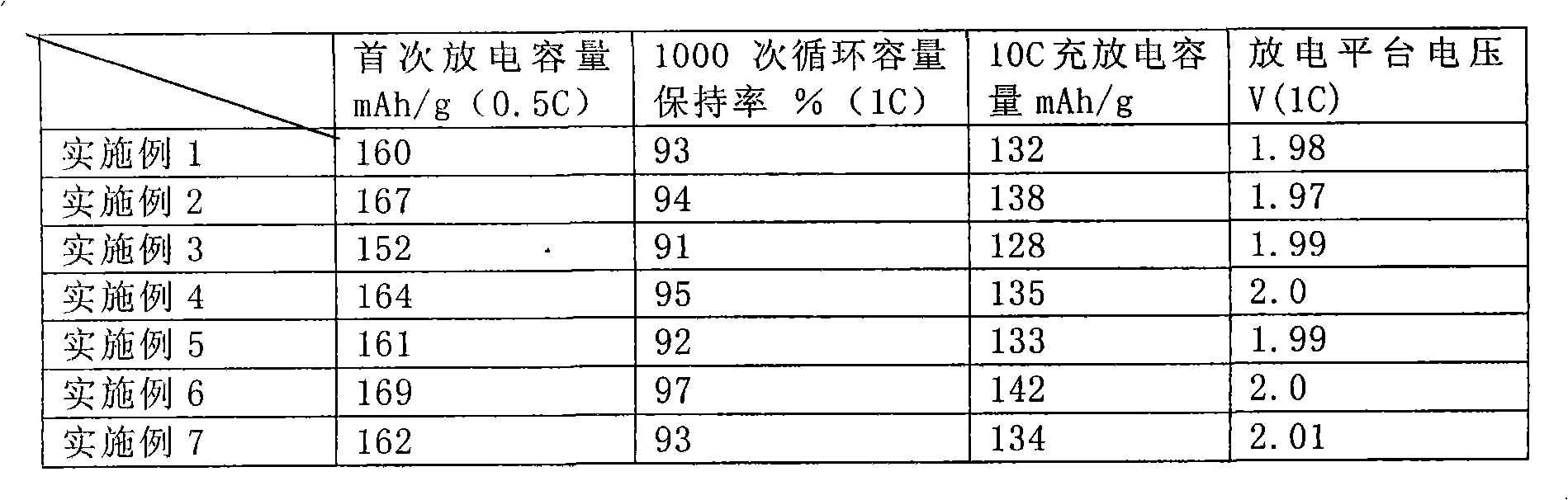

Examples

Embodiment 1

[0006] [Example 1] Li 0.6 Ti 1.2 Cr 0.05 o 3 / w 0.1

[0007] The first treatment step, wherein the atomic ratio of lithium and titanium, that is, Li / Ti is a mixture of lithium carbonate, titanium dioxide and chromium oxide y=0.05, mixed evenly, dispersed in an alcohol solvent, ball milled for 12 hours, and dried.

[0008] A second treatment step, wherein the dried product obtained in the first treatment step is heat-treated at 300° C. for 12 hours.

[0009] The third processing step, wherein the heat-treated material obtained in the second processing step is mixed and ball-milled with glucose z=0.1 for 12 hours, then sintered at 750° C. under nitrogen protection for 12 hours, and cooled through a 300-mesh sieve.

Embodiment 2

[0010] [Example 2] Li 0.6 Ti 1.2 Cr 0.05 o 3 / w 0.2

[0011] The first treatment step, wherein the atomic ratio of lithium and titanium, that is, Li / Ti is a mixture of lithium hydroxide, metatitanic acid and zirconia y=0.1, mixed evenly, dispersed in acetone solvent, ball milled for 18 hours, and dried .

[0012] A second treatment step, wherein the dried product obtained in the first treatment step is heat-treated at 500° C. for 16 hours.

[0013] The third processing step, wherein the heat-treated material obtained in the second processing step and furfural resin z=0.2 are mixed and ball-milled for 10 hours, then sintered at 800° C. under nitrogen protection for 18 hours, and then cooled through a 300-mesh sieve.

Embodiment 3

[0014] [Example 3] Li 0.6 Ti 1.2 Cr 0.05 o 3 / w 0.4

[0015] The first treatment step, wherein the atomic ratio of lithium and titanium, that is, Li / Ti is a mixture of lithium nitrate, titanium tetrachloride and zinc oxide y=0.2, mixed evenly, dispersed in an alcohol solvent, ball milled for 24 hours, and dried .

[0016] A second treatment step, wherein the dried product obtained in the first treatment step is heat-treated at 600° C. for 24 hours.

[0017] The third processing step, wherein the heat-treated material obtained in the second processing step is mixed and ball-milled with pitch z=0.3 for 12 hours, then sintered at 900° C. under nitrogen protection for 12 hours, and cooled through a 300-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com