Composite thermistor material, thermistor, thermosensitive lug and lithium-ion battery

A thermistor and tab technology, applied in the field of composite thermistor materials, can solve problems such as protection, affecting battery rate performance and cycle performance, and soft pack batteries cannot pass the overcharge test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

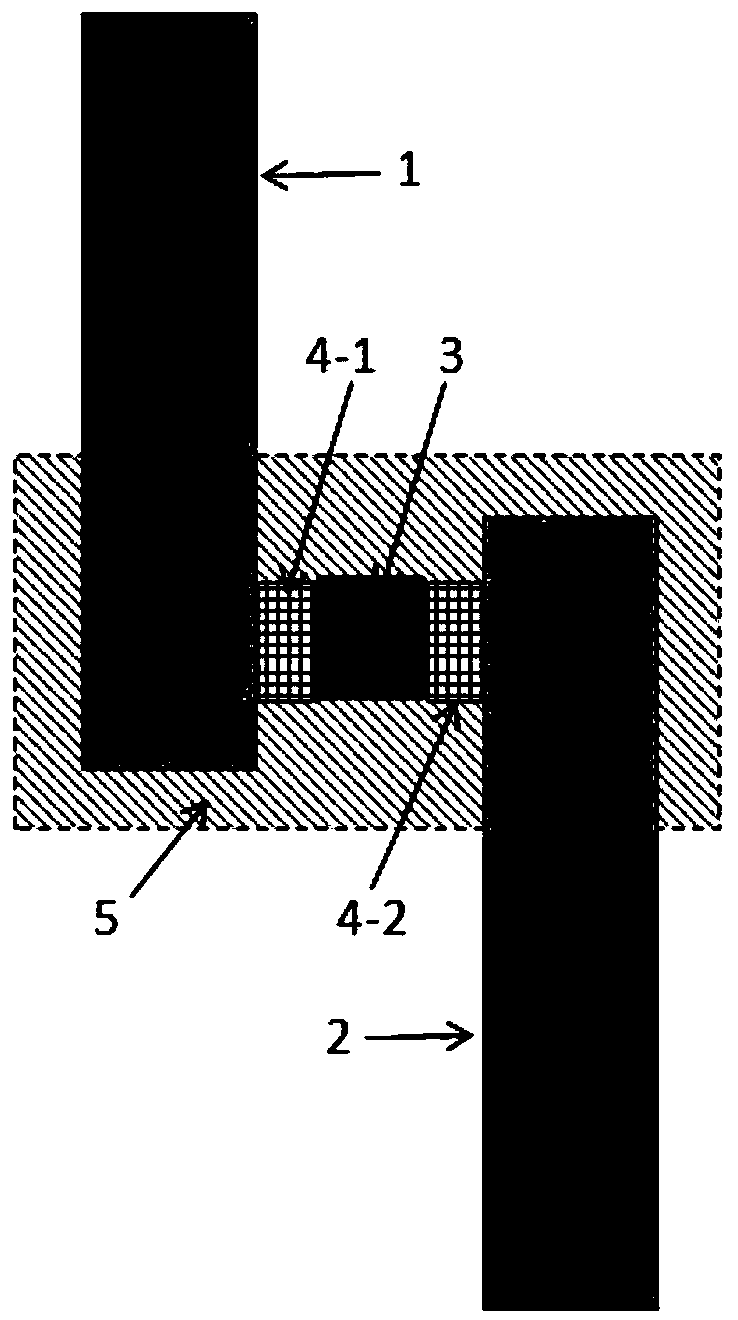

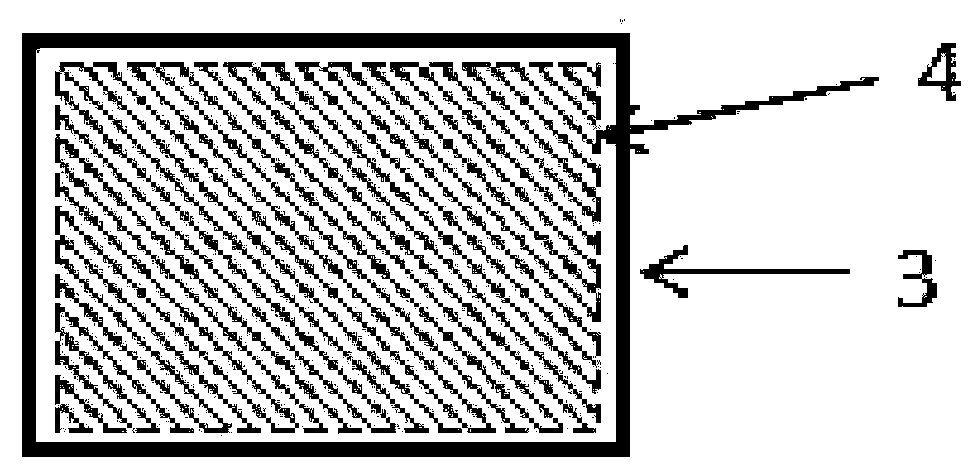

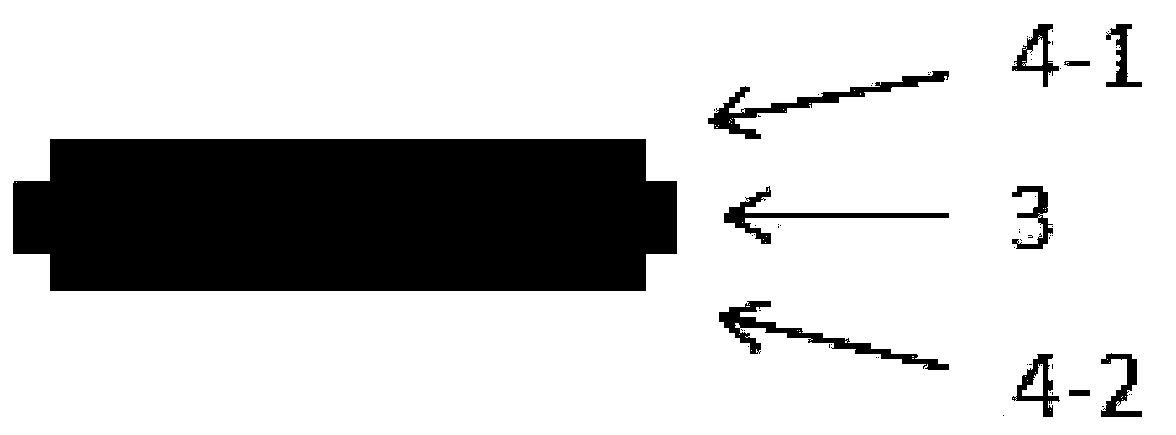

[0072] The invention provides a PTC thermistor containing C60 fullerene, which is composed of two layers of metal foil (aluminum) and a sheet-shaped PTC core material is sandwiched inside. The PTC core material is composed of PTC material, additives, and C60 fullerene. Composition, the parts by weight of each core material raw material are composed as follows:

[0073] PTC material: 70wt%; PTC material is barium titanate;

[0074] Auxiliary agent: 25wt% (auxiliary agent comprises: 5 parts by weight of coupling agent (silane coupling agent), 3 parts by weight of flame retardant (aluminum hydroxide), 3 parts by weight of antioxidant (dilauryl thiodipropionate) , antioxidant (4,4 '-dithiodimorpholine) 3 parts by weight, accelerator (zinc dimethyl dithiocarbamate) 4 parts by weight, crosslinking agent (N N'-methylenebispropylene Amide) 3 parts by weight, dispersant (sodium methylene bis-naphthalene sulfonate) 4 parts by weight);

[0075] C60 fullerene: 5 wt%.

[0076] The prepa...

Embodiment 2

[0087] The invention provides a PTC thermistor containing C60 fullerene, which is composed of two layers of metal foils with a sheet-shaped PTC core material sandwiched inside. The PTC core material is composed of PTC materials, additives, and C60 fullerene. The weight part composition of core material raw material is as follows:

[0088] PTC material: 60wt%; PTC material is iron powder (20wt%), copper powder (20wt%), titanium dioxide (20wt%);

[0089]Auxiliary agent: 30wt% (auxiliary agent comprises: coupling agent (silane coupling agent) 6 weight parts, flame retardant (aluminum hydroxide) 4 weight parts, antioxidant (dilauryl thiodipropionate) 3 weight parts , 4 parts by weight of antioxidant (4,4'-dithiodimorpholine), 4 parts by weight of accelerator (zinc dimethyldithiocarbamate), cross-linking agent (N N'-methylenebispropylene Amide) 4 parts by weight, dispersant (sodium methylene bis-naphthalene sulfonate) 5 parts by weight);;

[0090] C60 fullerene: 10 wt%.

[0091]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com