Patents

Literature

86 results about "Evaporation duct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

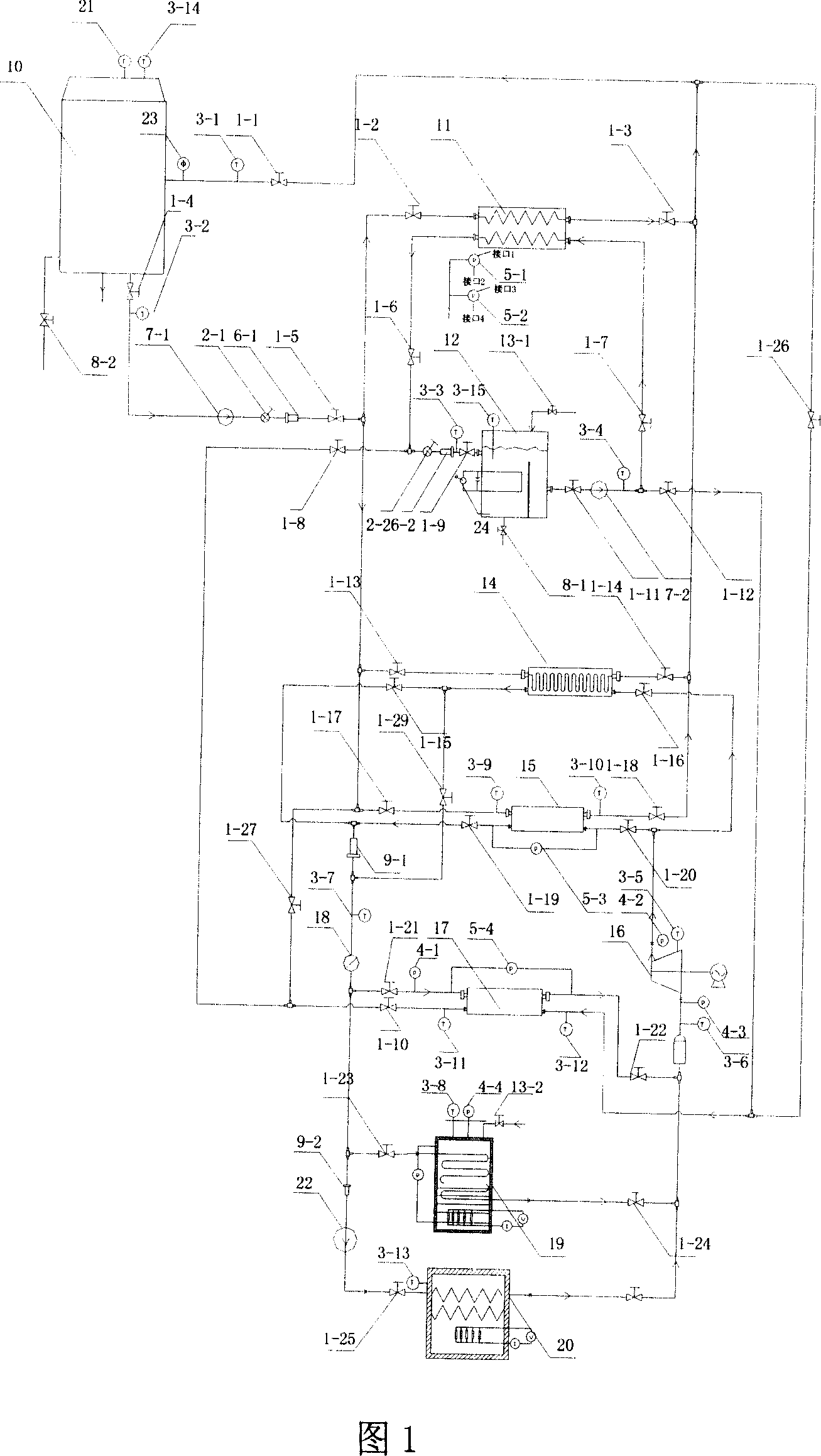

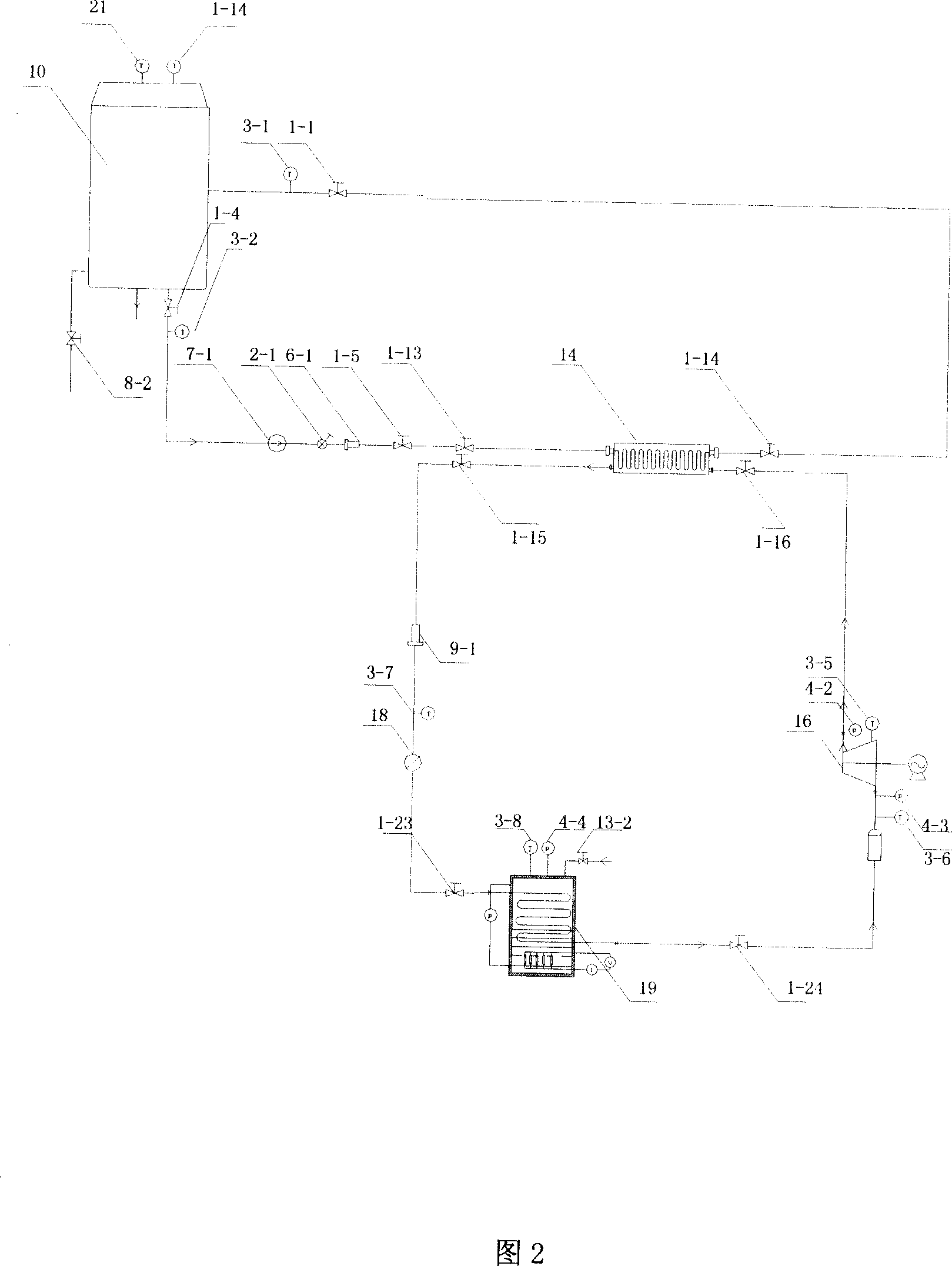

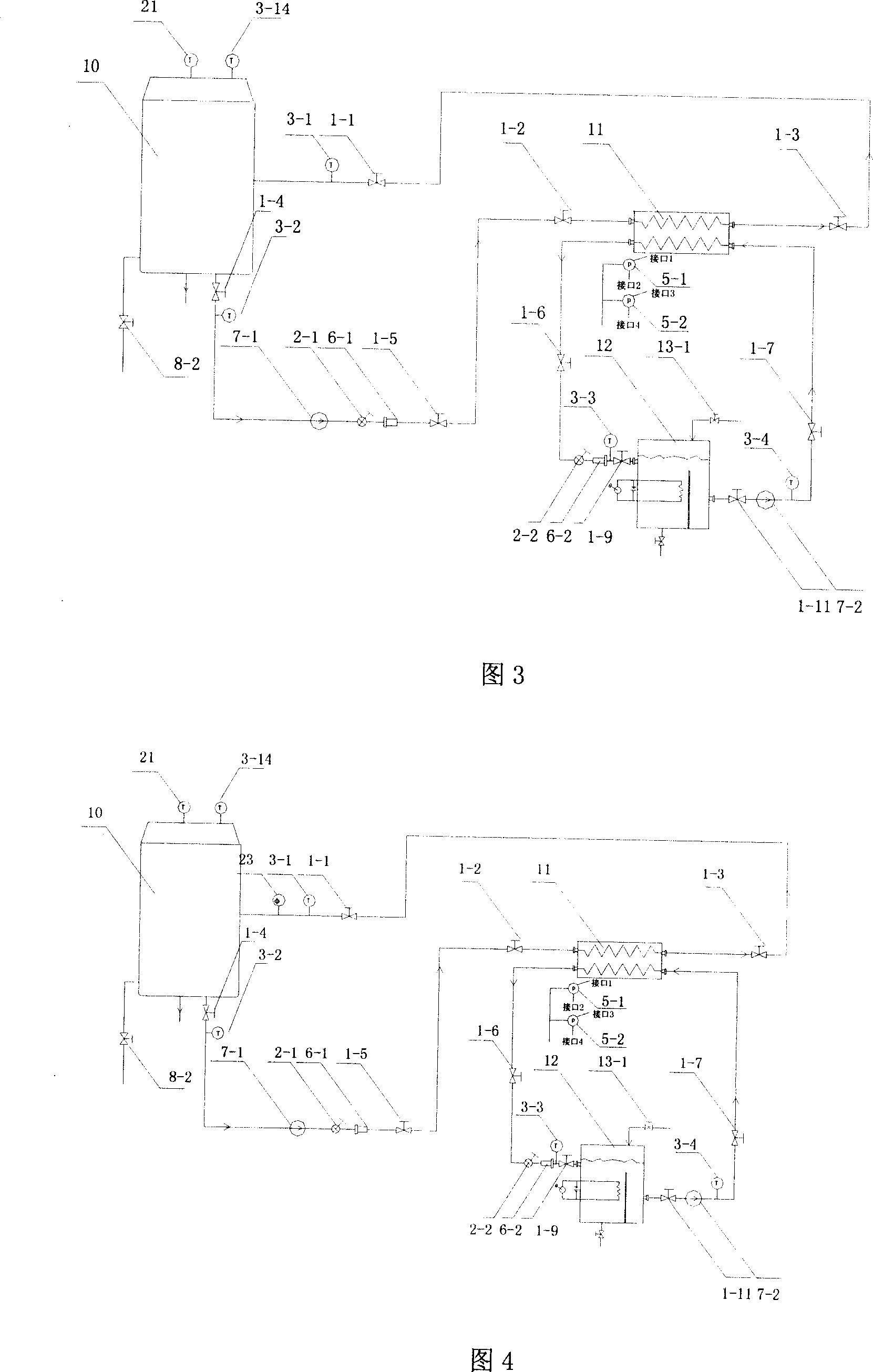

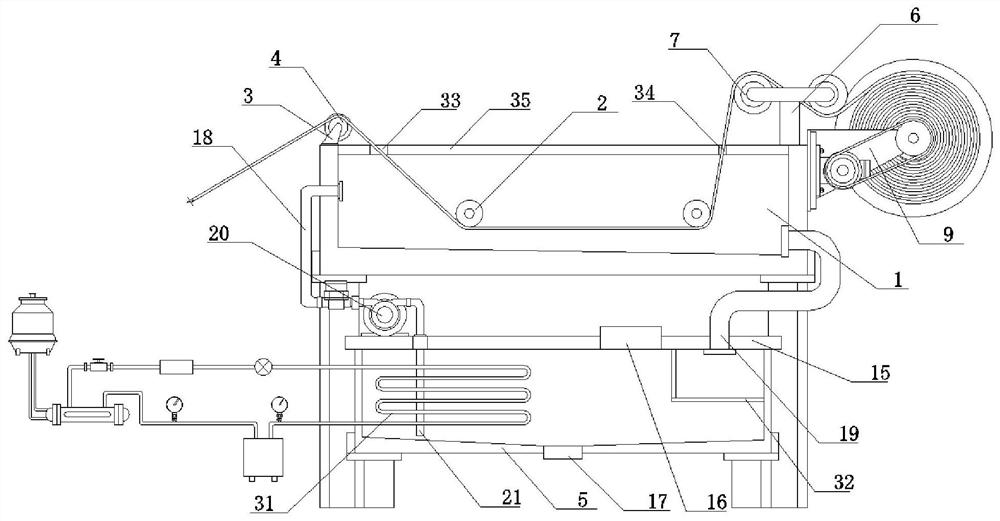

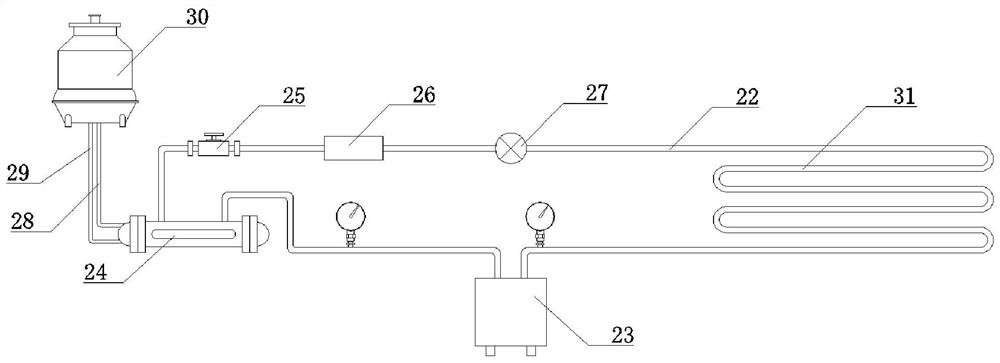

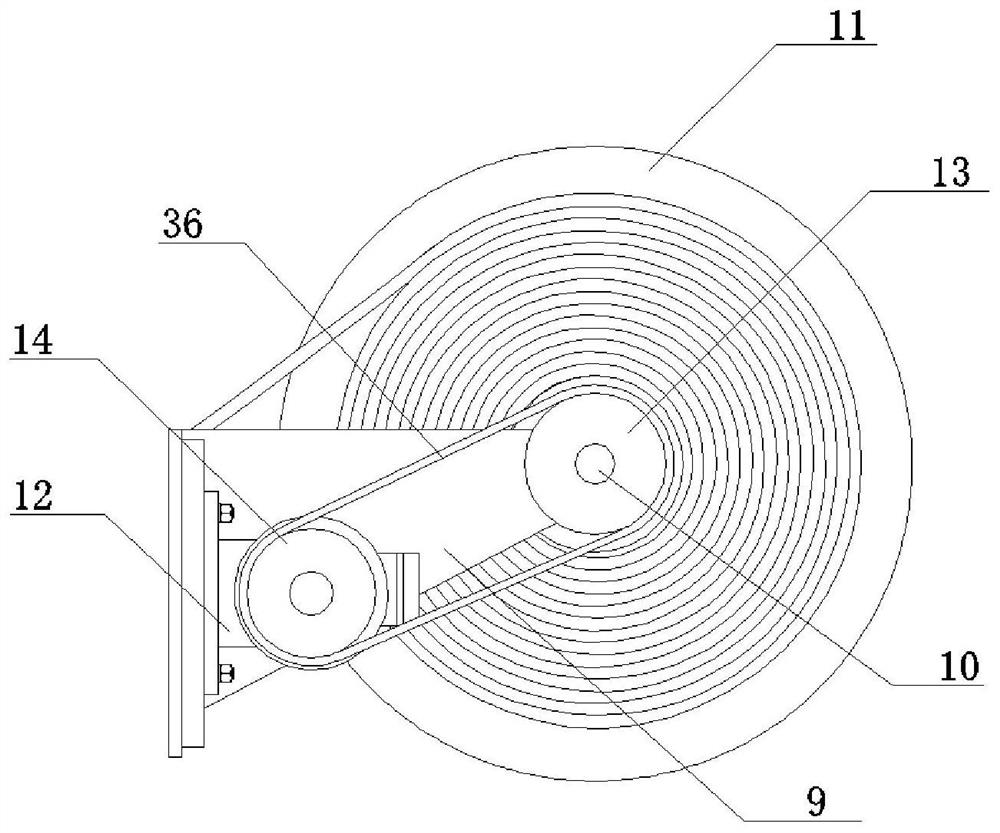

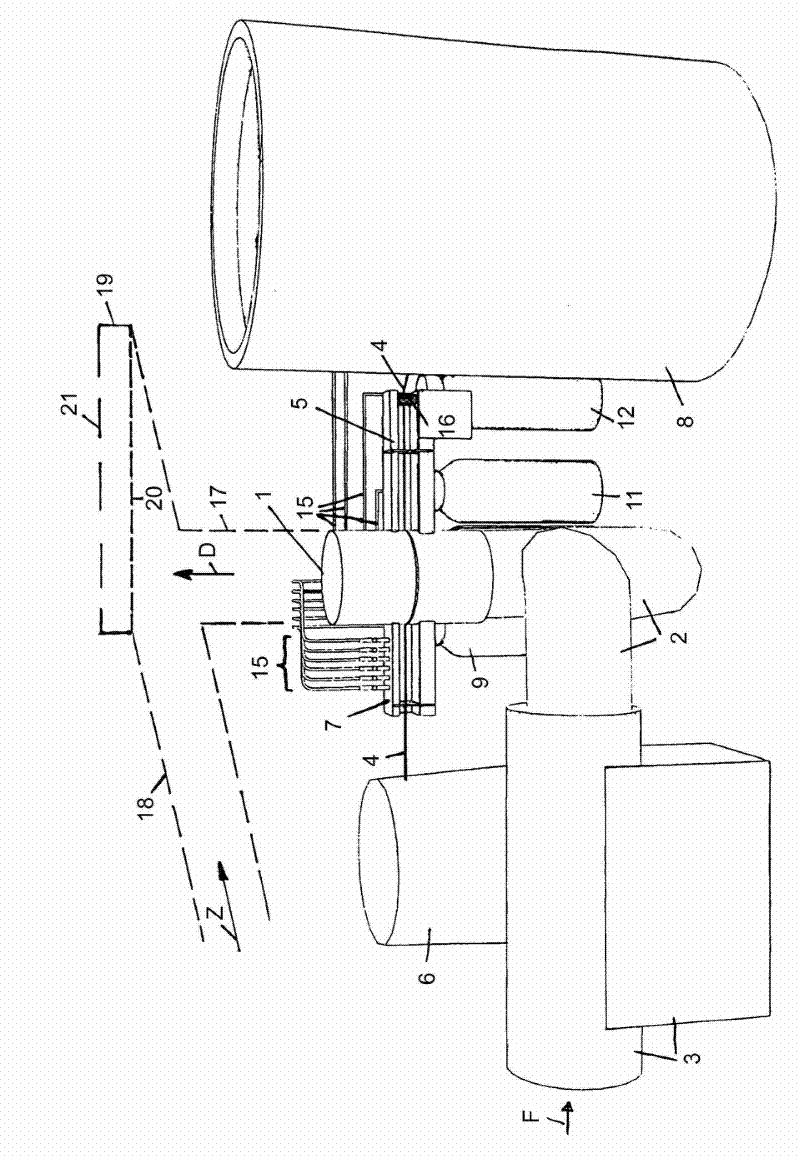

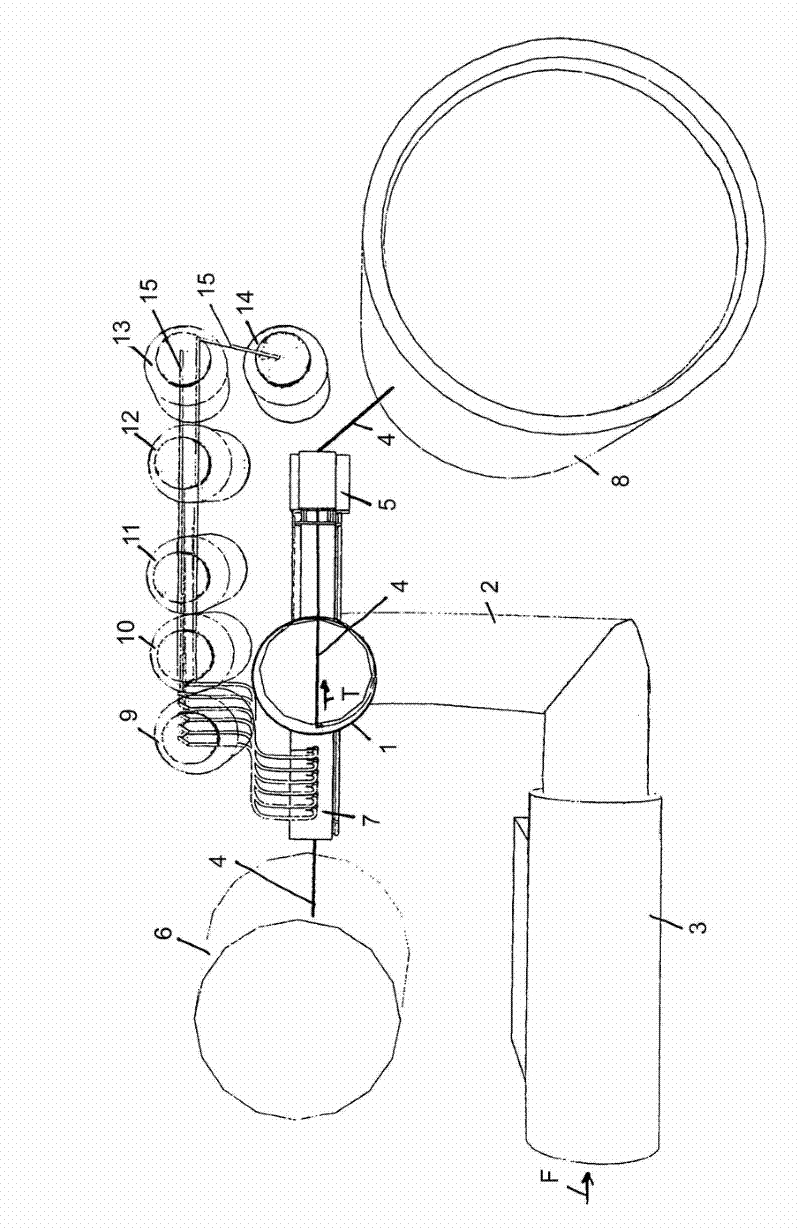

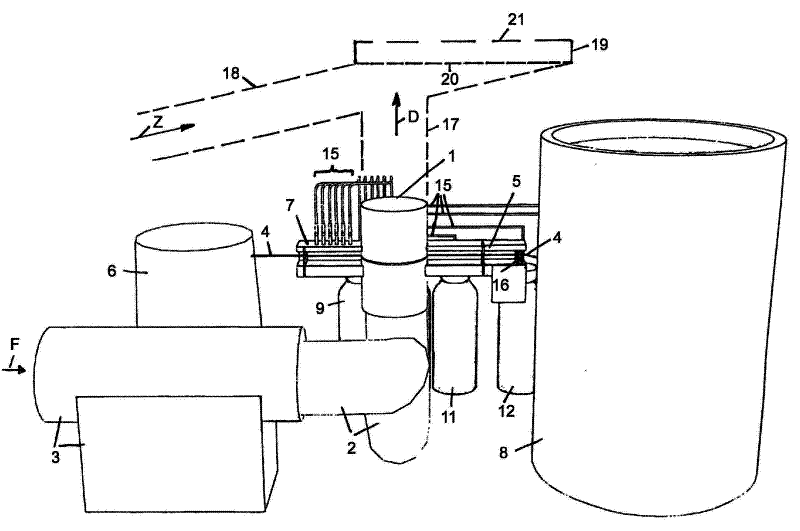

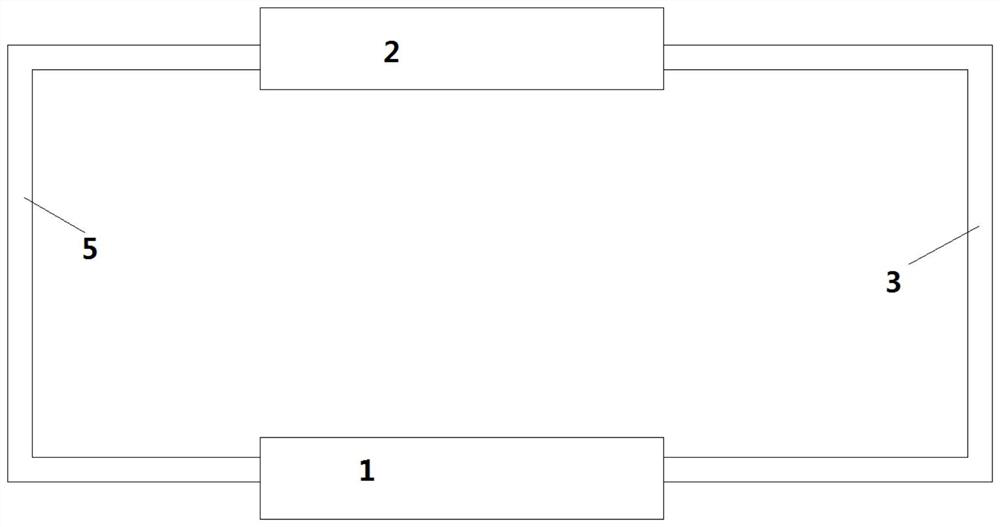

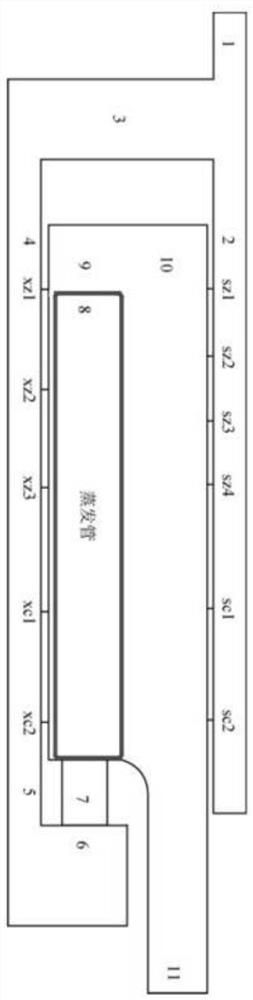

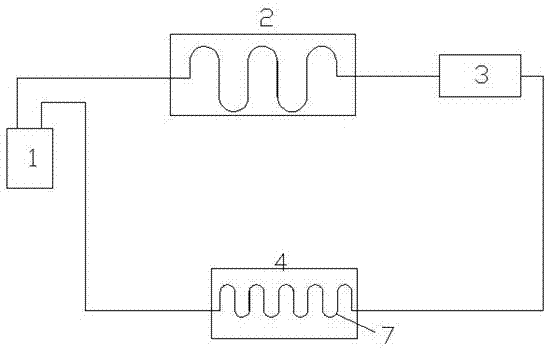

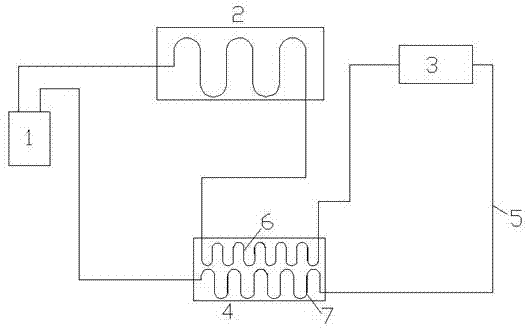

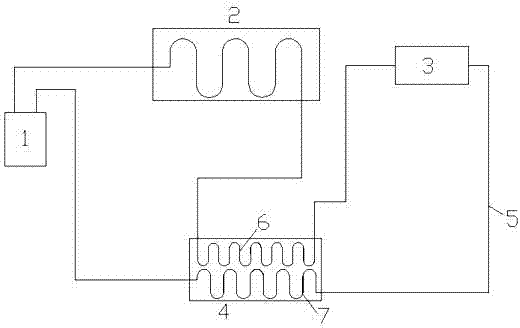

Combining method for multiple thermotechnical complex performance detection test

InactiveCN1987440AIntelligent temperature controlGood control effectMaterial heat developmentStructural/machines measurementCooling towerEngineering

Carrying out building block type alternant combination for multifunctional heat engineering integrative performance test unit, the method can be in use for carrying out following 8 items of relevant heat engineering experiment: mensurating performance coefficient of refrigeration cycle; available energy loss in heat transfer of temperature difference in heat exchanger; performance of cooling tower; intelligent controlling temperature of hot water tank; performance of condenser, performance of evaporating pipe, performance of cooling pipe, and performance of compressor. Full automatic computer test means are adopted in the invention so that dynamic changes of parameters to be tested can be observed visually. The method excitates students' interest in experiment to test parameters, process data, and accomplish whole procedure for measuring each performances.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

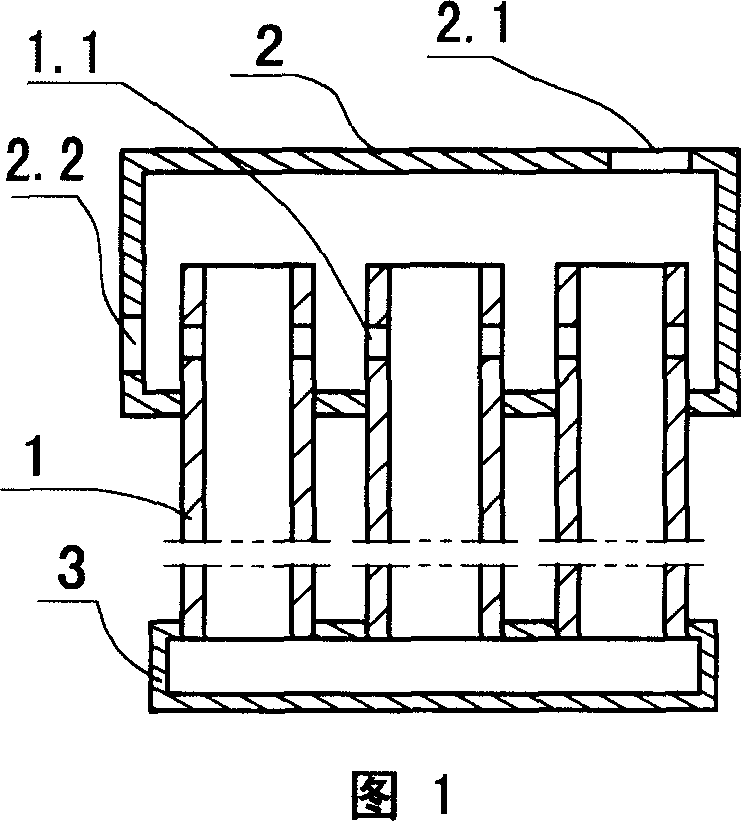

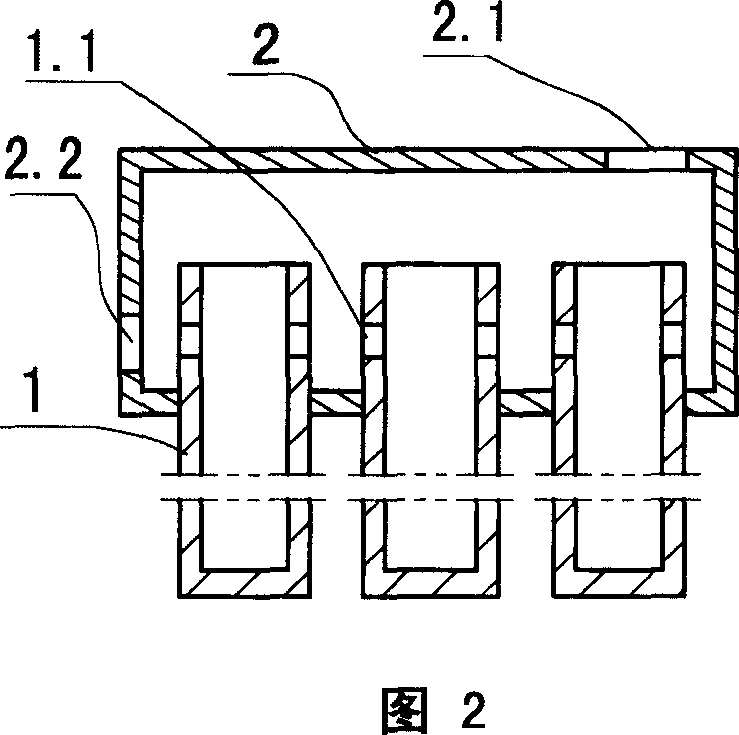

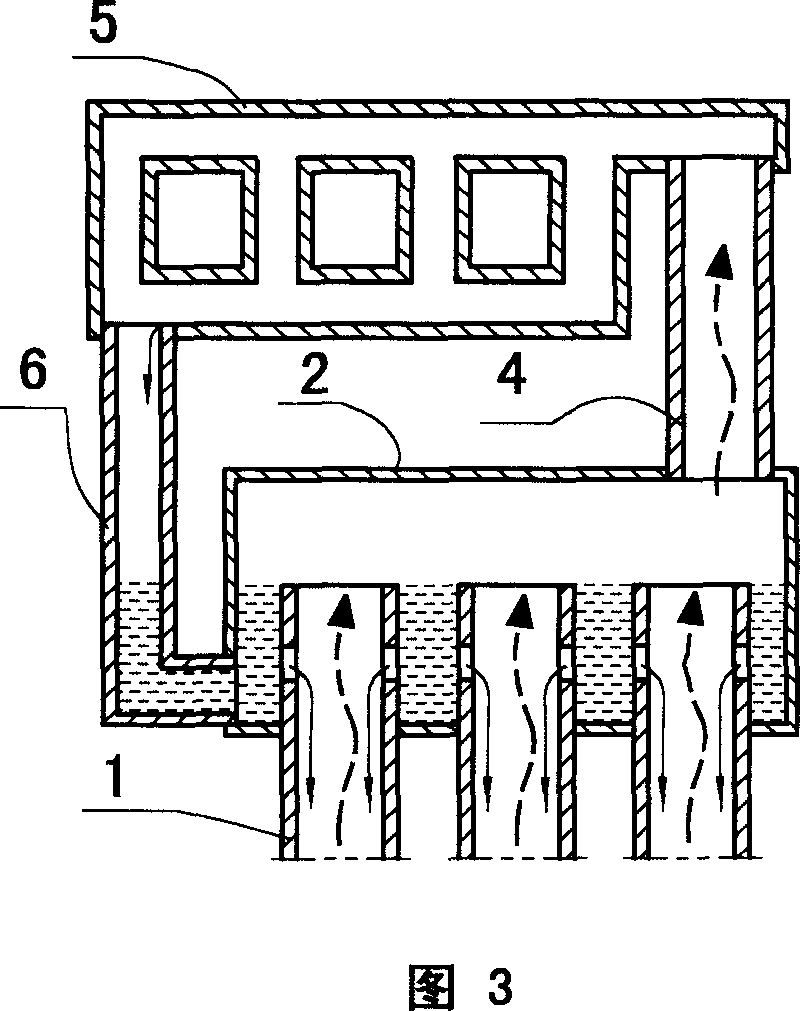

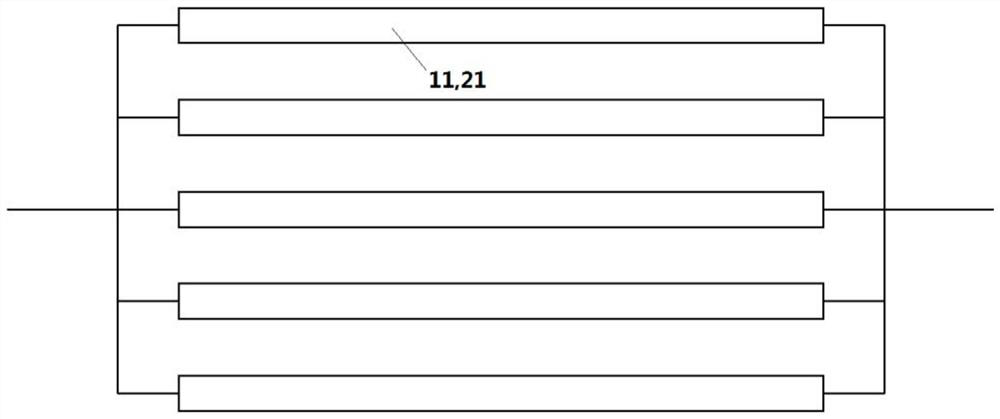

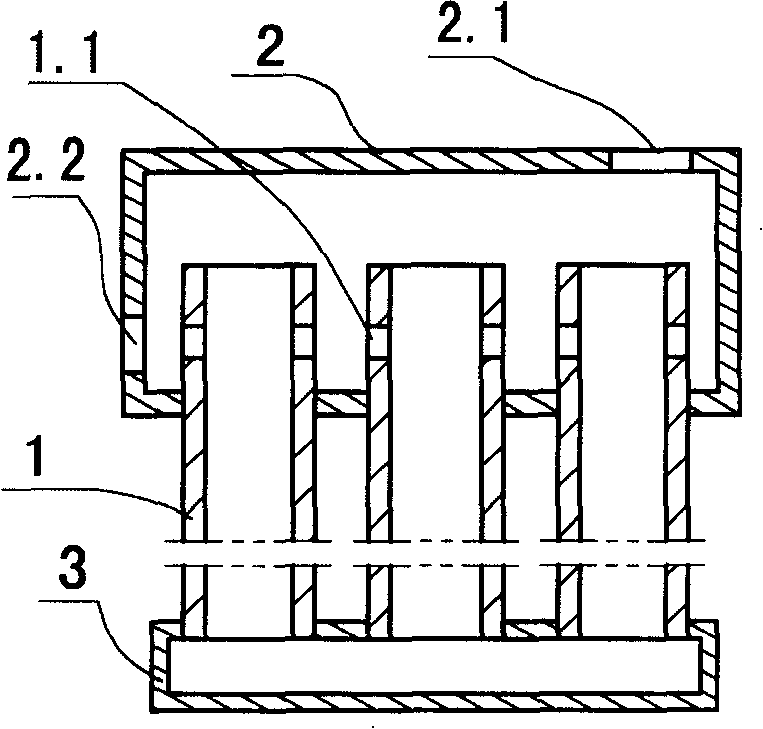

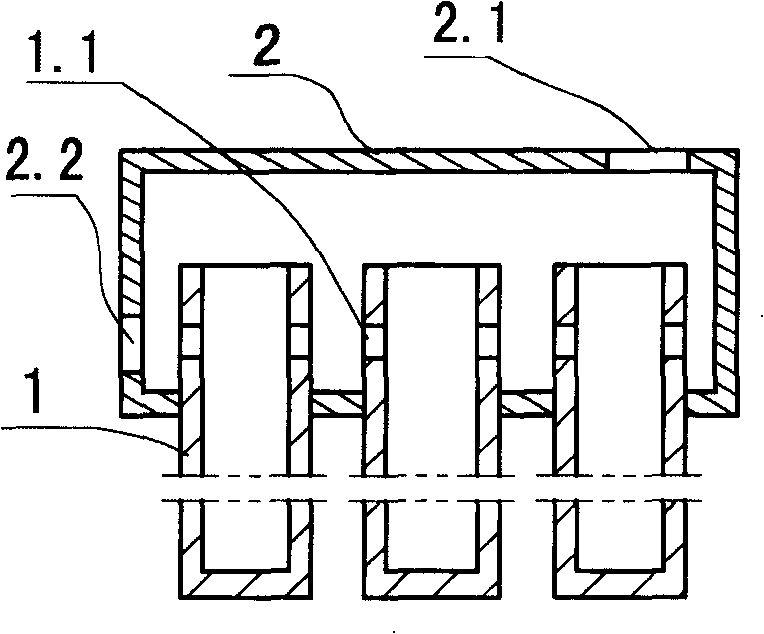

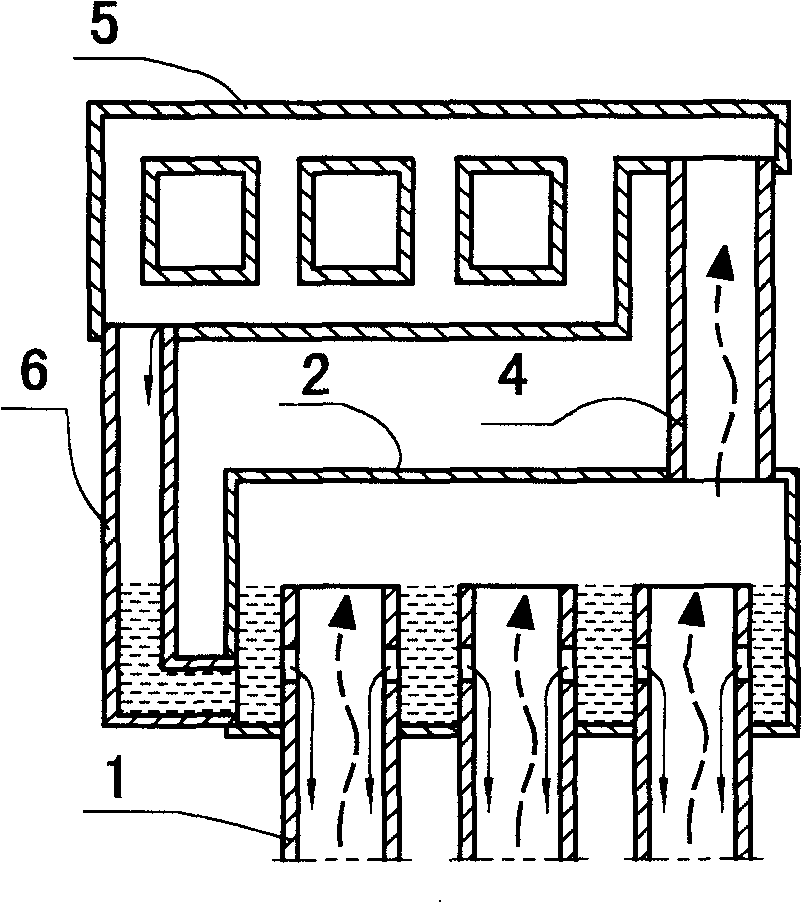

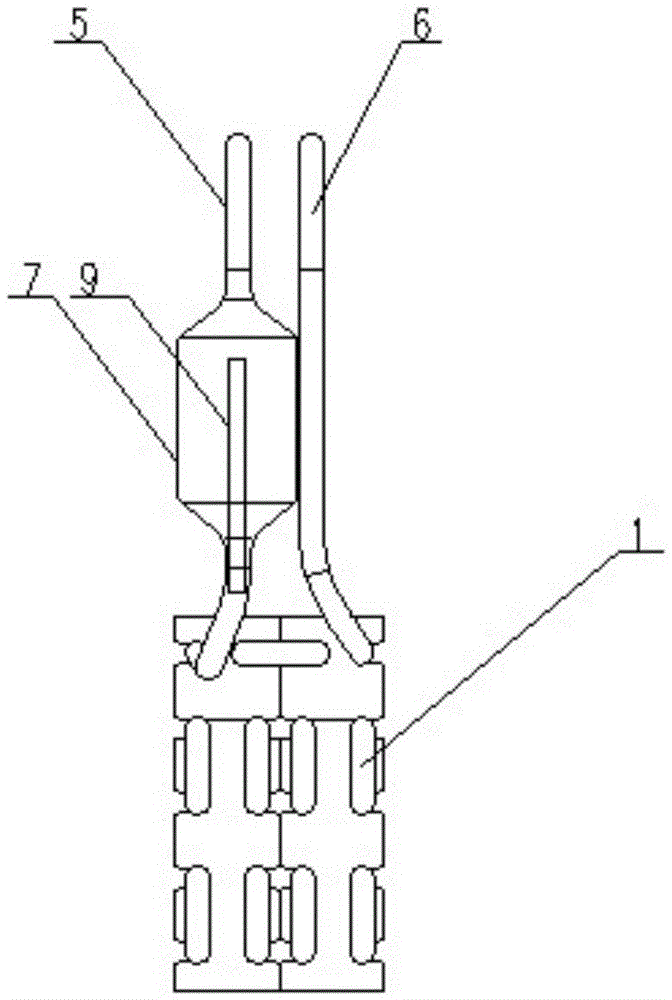

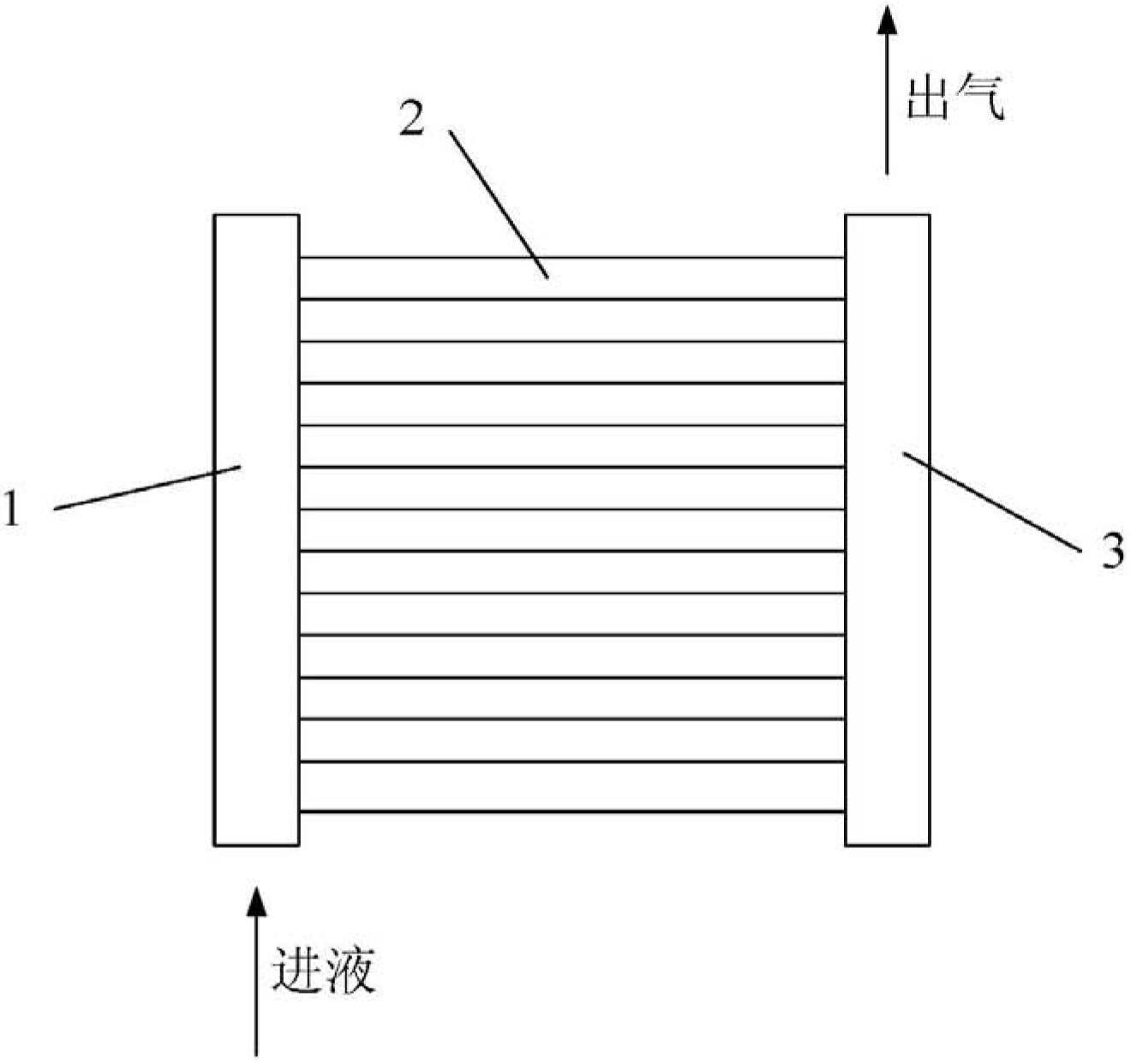

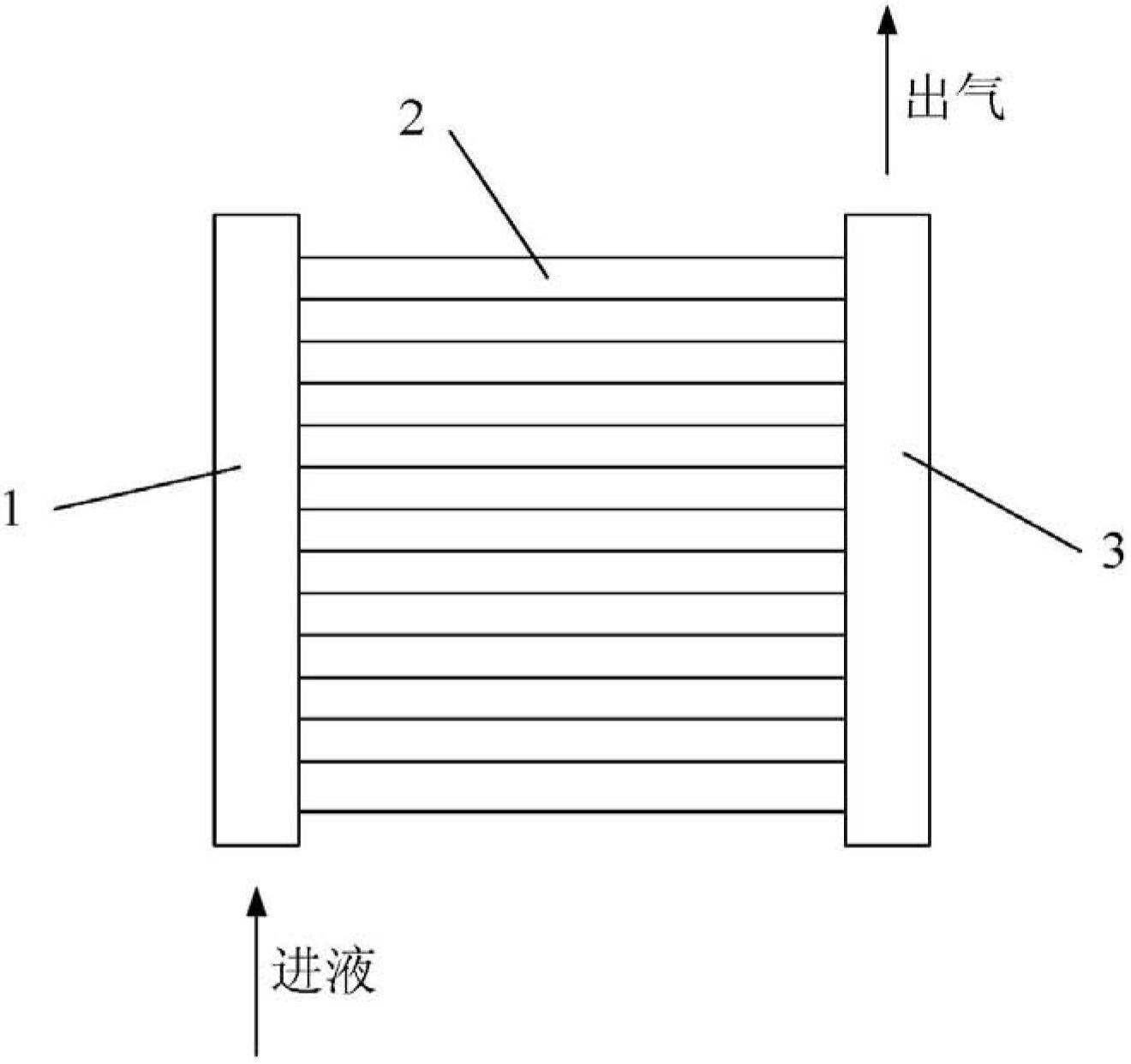

Evaporator and heat absorber of separated gravity hot pipe

InactiveCN101029803ALarge heat transfer capacity coefficientImprove heat transfer effectIndirect heat exchangersEvaporationEngineering

It's a kind of evaporator of separating gravity heat pipe, which can make reflux condensed fluid in the hot pipe distribute uniformly on the evaporating pipe, and form falling film evaporation. The essentials of technological scheme are that the evaporator includes at least two evaporation tubes (1) and a upper header, and the part of the evaporation tube (1) in which there are liquid inlet holes (1.1) trends into the upper header (2), the upper ends of evaporators are the same height, so are the liquid inlet holes (1.1); outlet steam (2.1) and liquid inlet opening (2.2) are installed on the upper header; the openings of the evaporator (1) can be in its lower end, and all connect with sub-header; the evaporator (1) can be sealed in its lower end.

Owner:庞立升

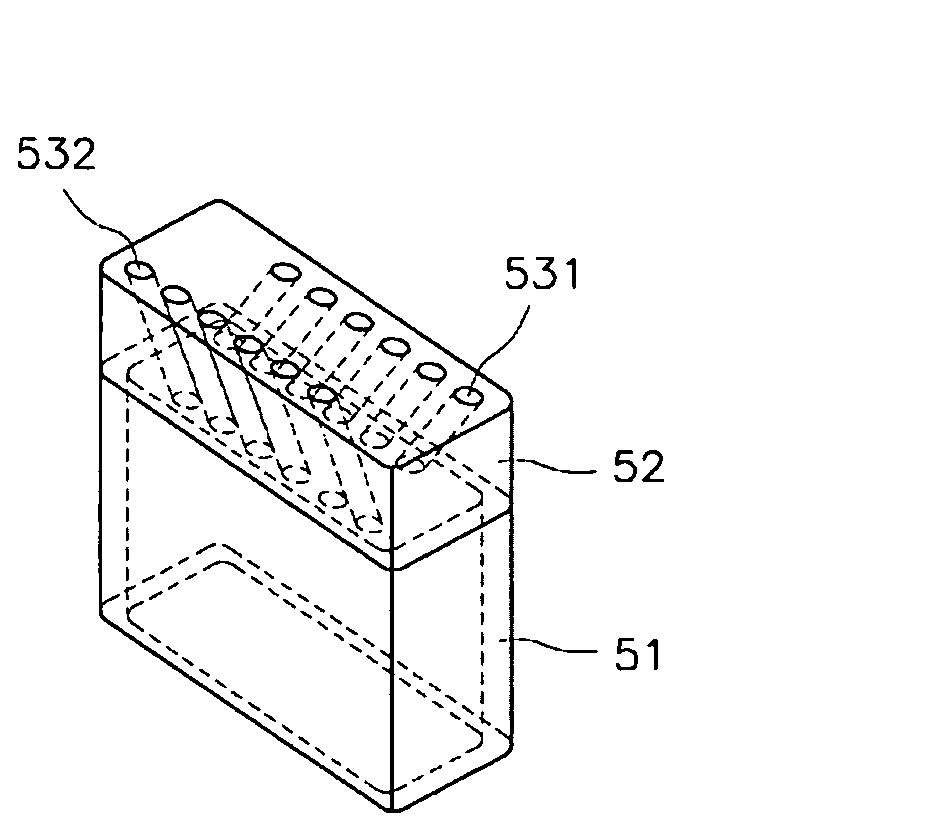

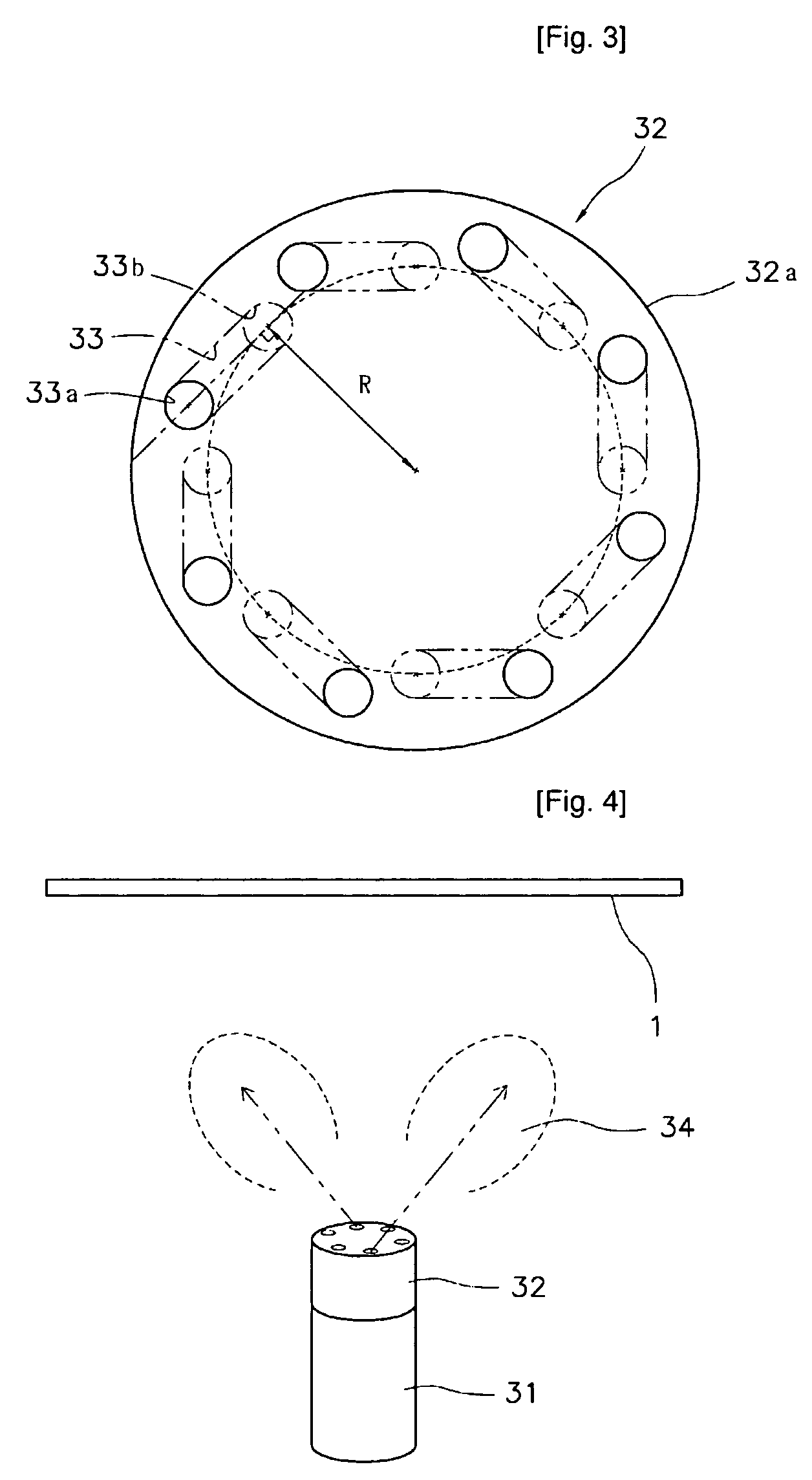

Multiple nozzle evaporator for vacuum thermal evaporation

ActiveUS7833354B2Improve efficiencyVacuum evaporation coatingSputtering coatingCrucibleEvaporation duct

Disclosed is a multiple nozzle evaporator in which a material to be evaporated in the evaporator can be deposited on a substrate with an improved efficiency of use of the material, thereby forming a large-area uniform thin film. The evaporator includes a cylindrical or rectangular post-shaped crucible 31 or 51 with an open top face; and a nozzle unit 32 having a body portion having a cylindrical or rectangular post-like shape with a height smaller than that of the crucible 31 or 51 and assembled to an upper portion of the crucible, and a plurality of evaporation tubes formed at an angle while penetrating through the body portion between top and bottom faces of the body portion. An evaporated material spouts toward peripheral areas of a substrate due to the inclined evaporation tubes, thereby improving the uniformity of a thin film to be deposited and the efficiency of use of the evaporated material, and preventing condensation of the evaporated material at a spouting portion.

Owner:YAS

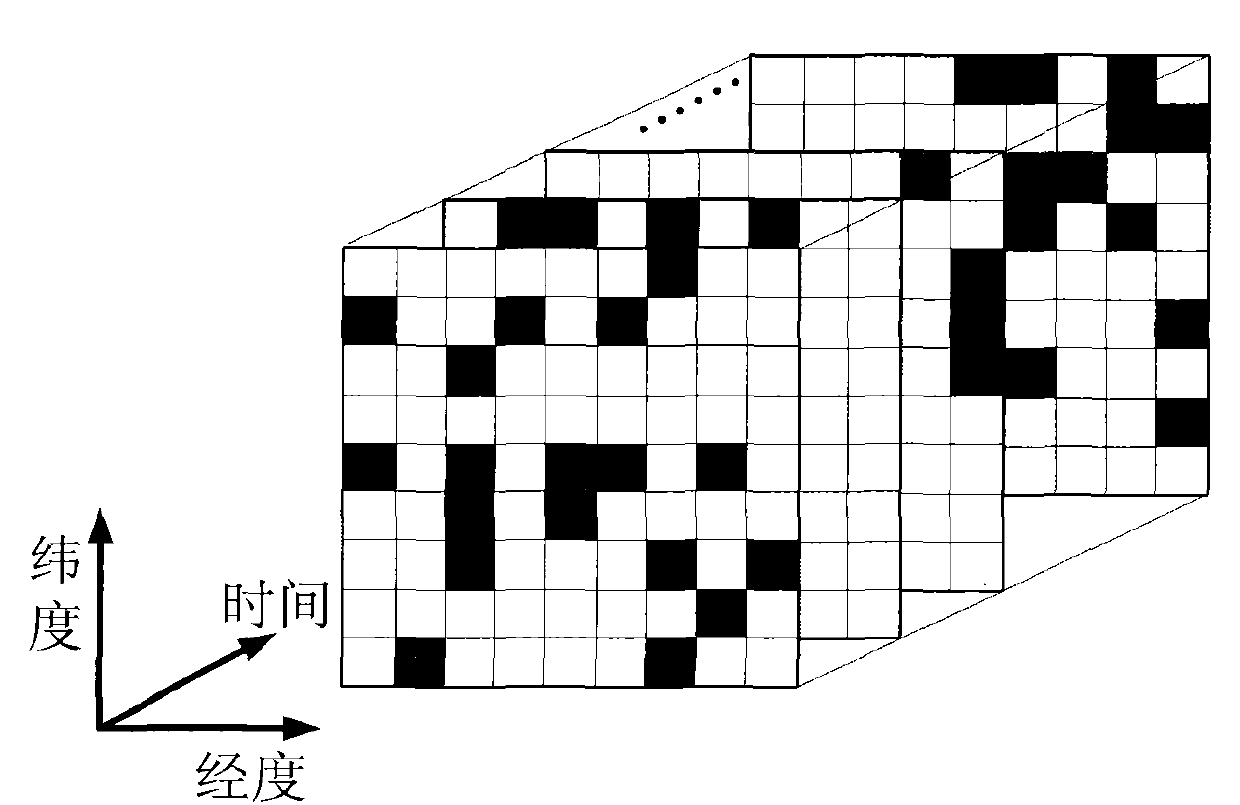

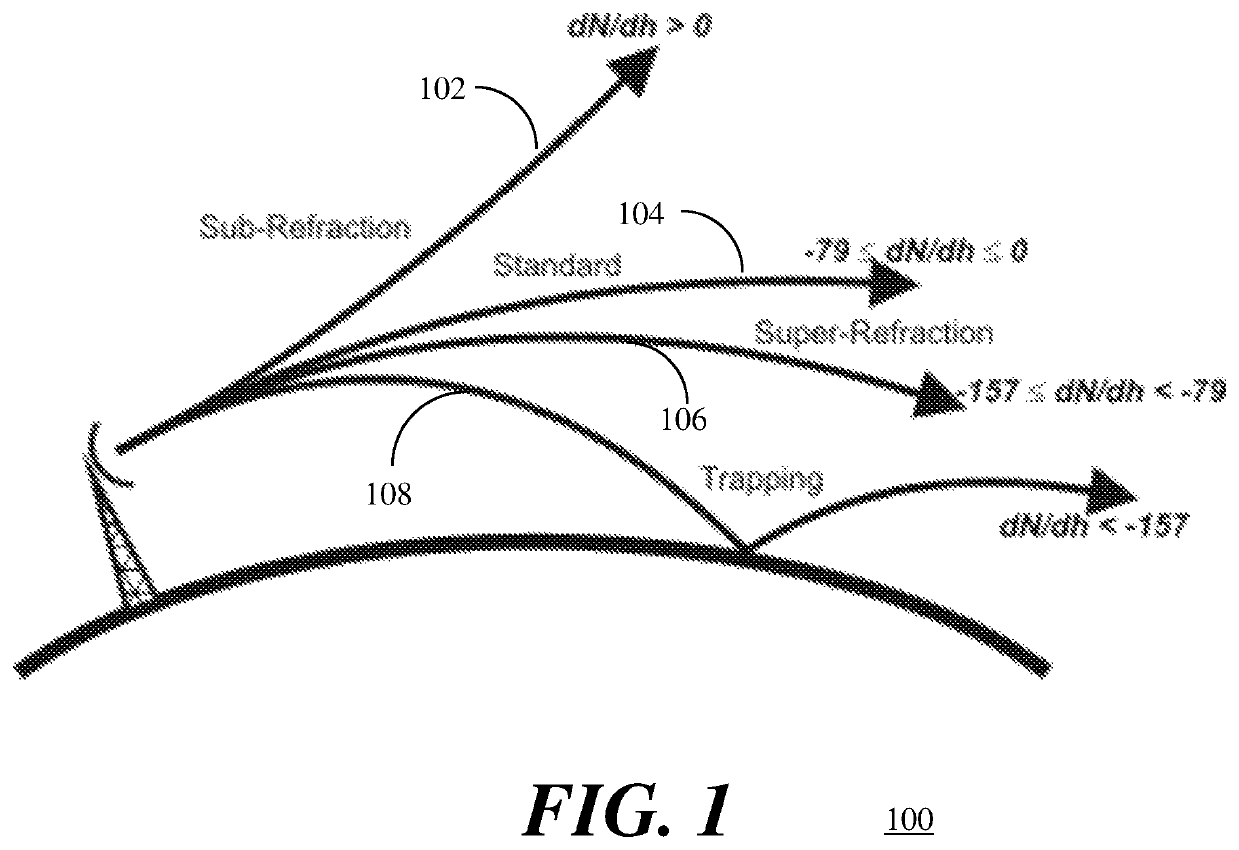

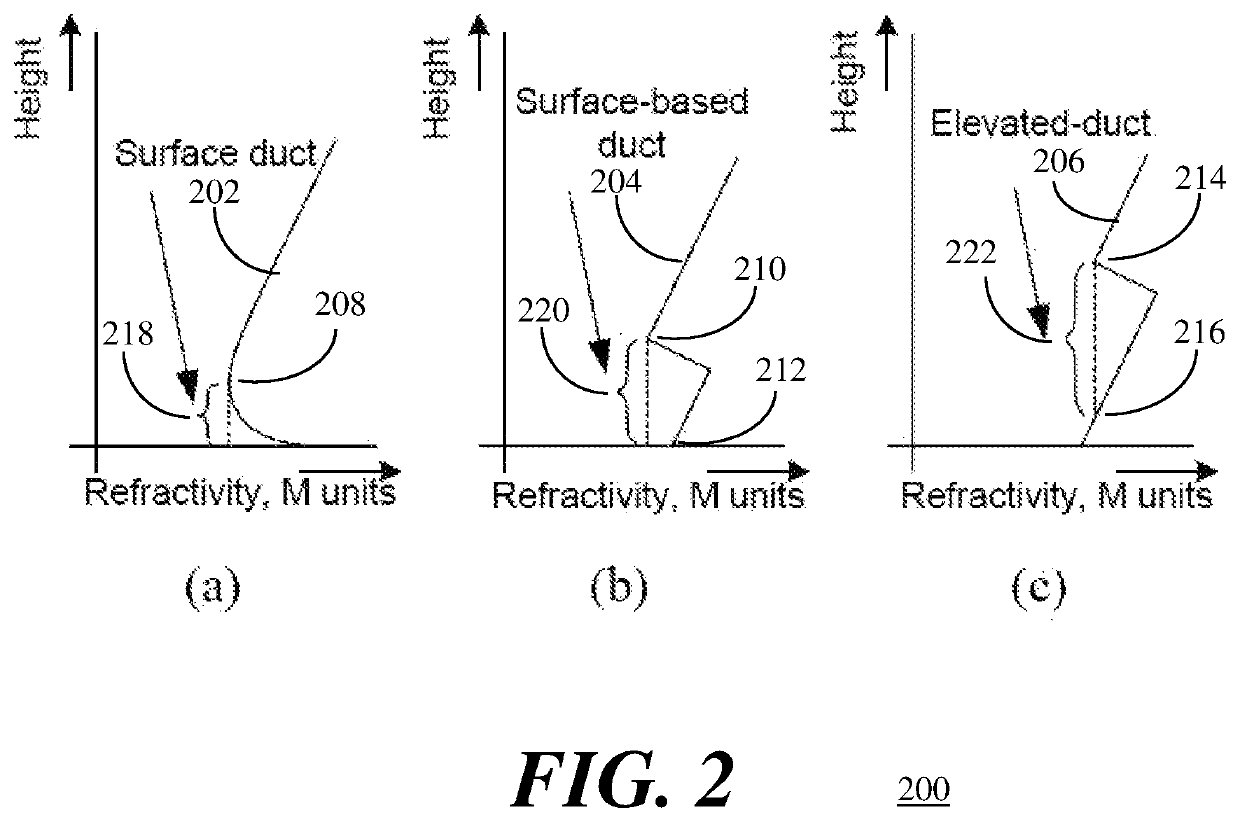

Compressed sensing method for space-time situation of evaporation duct

ActiveCN103399361AImprove perceived efficiencyReduce energy consumptionInstrumentsComputation complexitySparse constraint

The invention relates to a compressed sensing method for space-time situation of an evaporation duct, and discloses a three-dimensional observation model and a reconstruction method aimed at reducing data bulk and computation complexity stored and acquired in the space-time situation sensing process of the evaporation duct. Time dimension and space dimension are simultaneously observed via an equivalent three-dimensional sensing matrix, and a smooth zero norm is used as sparse constraint, so that the whole construction is considered, and artificial effect on effect introduced by independent space or time dimension is alleviated. Under the same compression ratio, time-space three-dimensional result closest approaches the true value.

Owner:NAVAL AVIATION UNIV

Novel refrigerator refrigerating evaporator

InactiveCN102759229AIncrease contact areaImprove heat exchange efficiencyEvaporators/condensersRefrigeration devicesEvaporation ductEngineering

The invention discloses a novel refrigerator refrigerating evaporator which comprises an evaporation pipe and a heat conduction board, wherein an inlet and an outlet are arranged on the evaporation pipe and respectively connected with other parts of a refrigerator refrigerating system, the evaporation pipe is H-shaped, and an H-shaped groove matched with the H-shaped evaporation pipe is arranged on the heat conduction board. The H-shaped evaporation pipe is placed in the H-shaped groove on the heat conduction board and is contacted with an inner container surface of a refrigerating chamber. The H-shaped groove is arranged on the heat conduction board of the evaporator, and three surfaces of the H-shaped evaporation pipe are respectively contacted with three surfaces of the H-shaped groove on the heat conduction board for heat conduction, so that contact area of the evaporation pipe and the heat conduction board is enlarged, and heat exchange efficiency is improved.

Owner:SHUNDE POLYTECHNIC

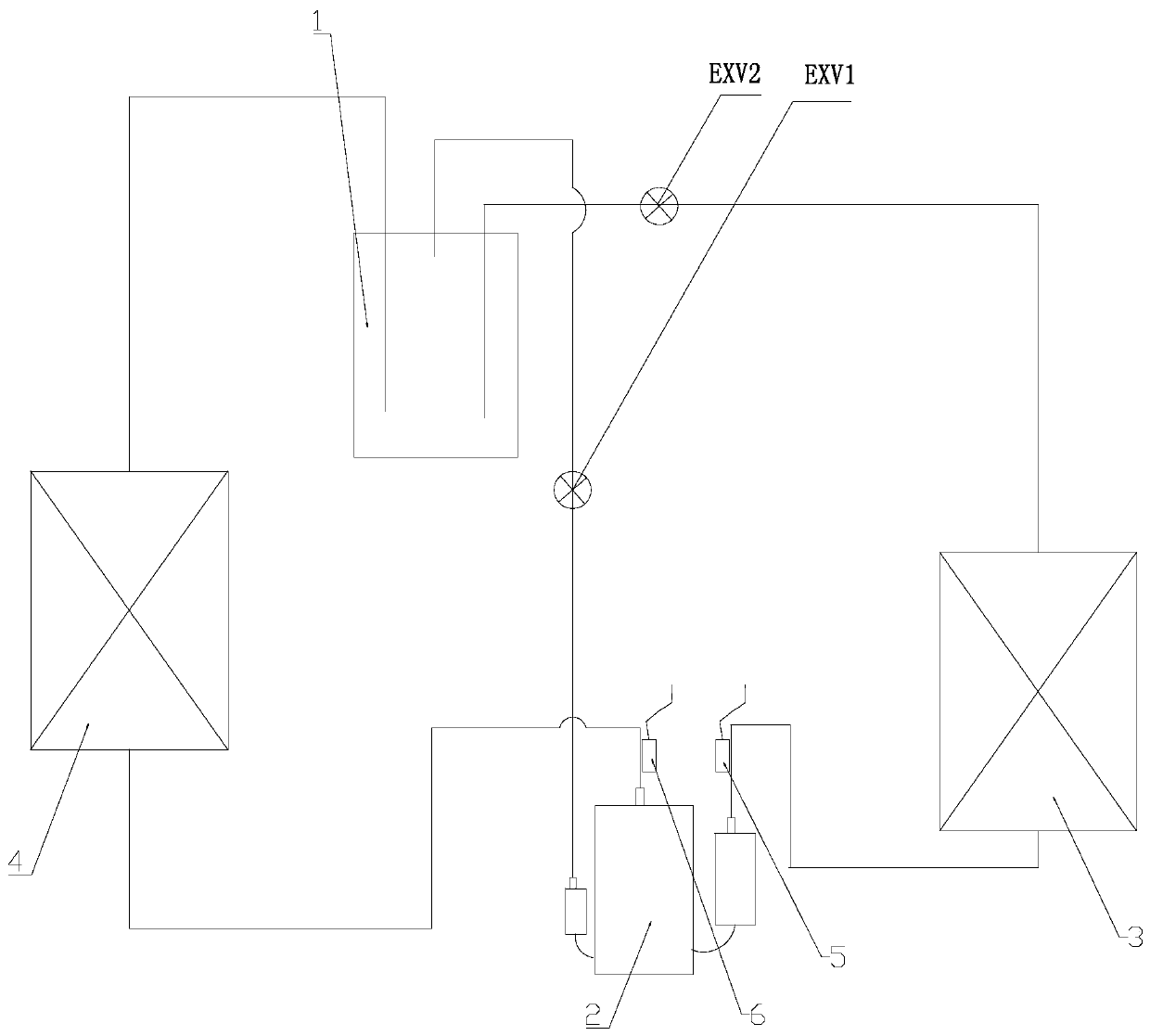

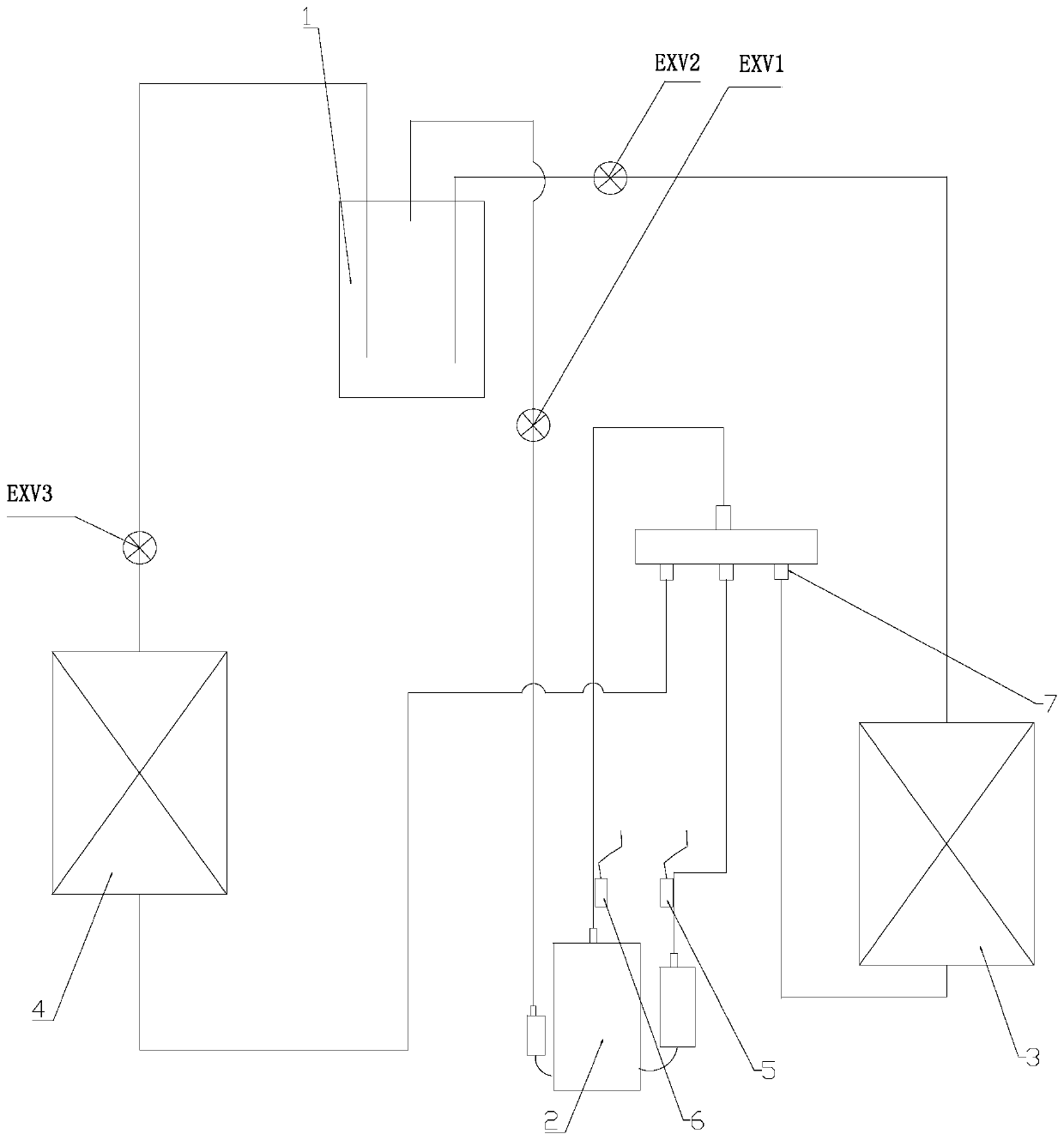

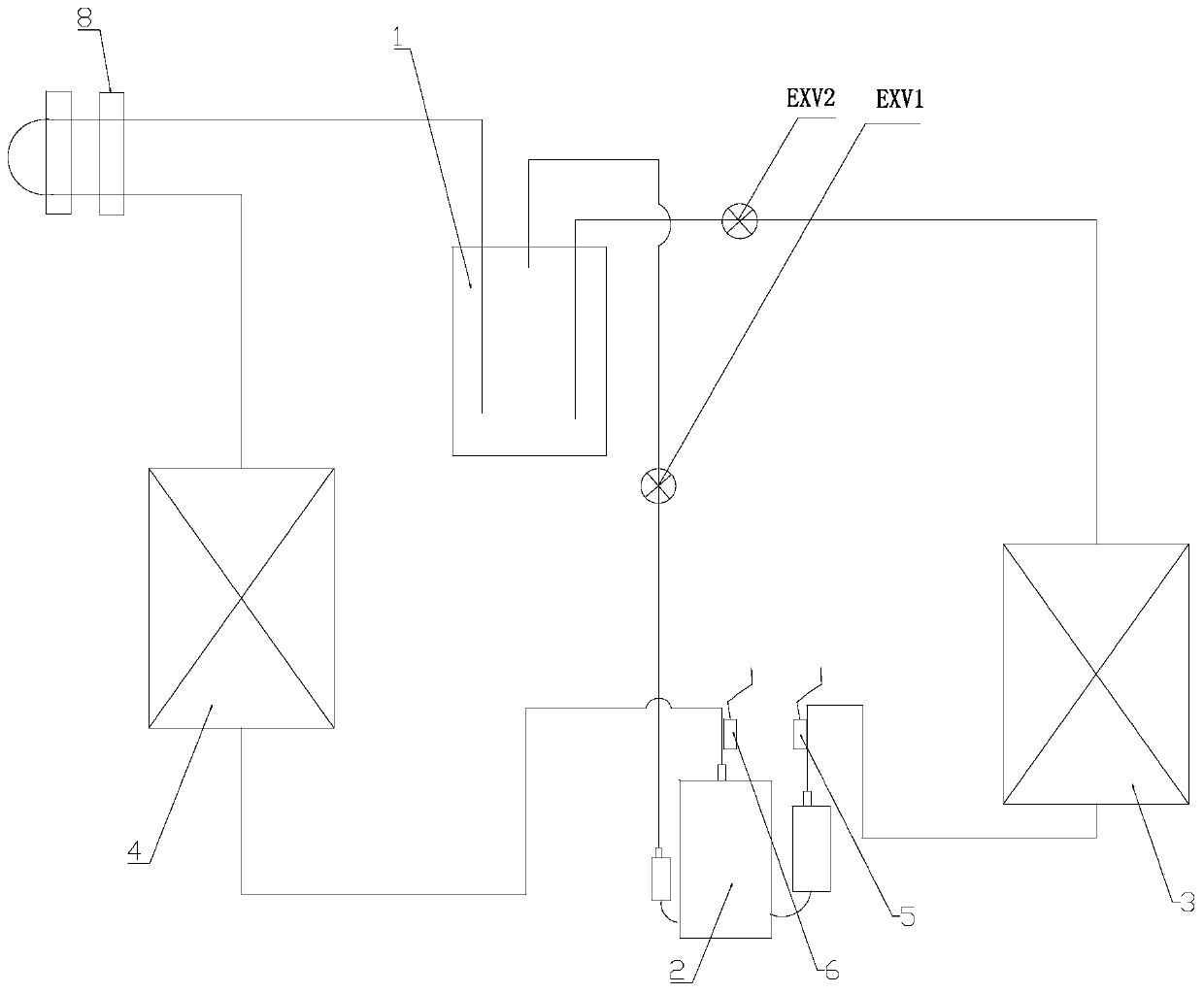

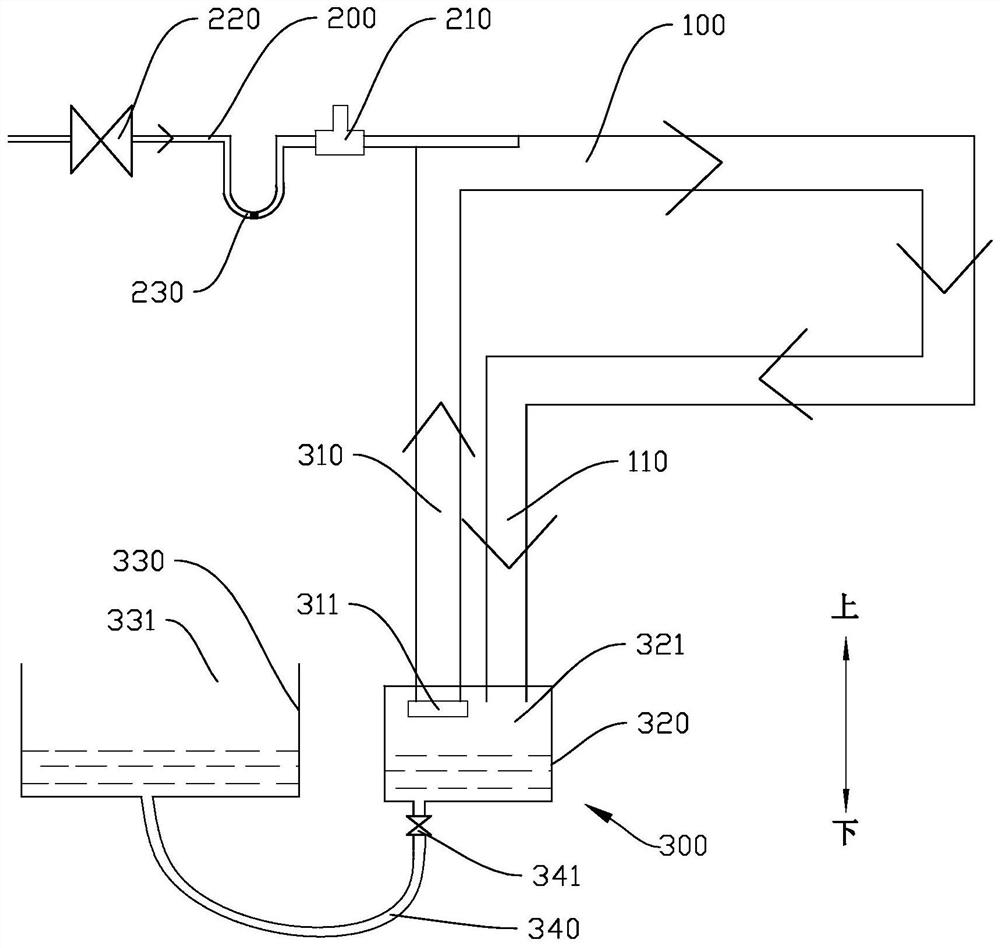

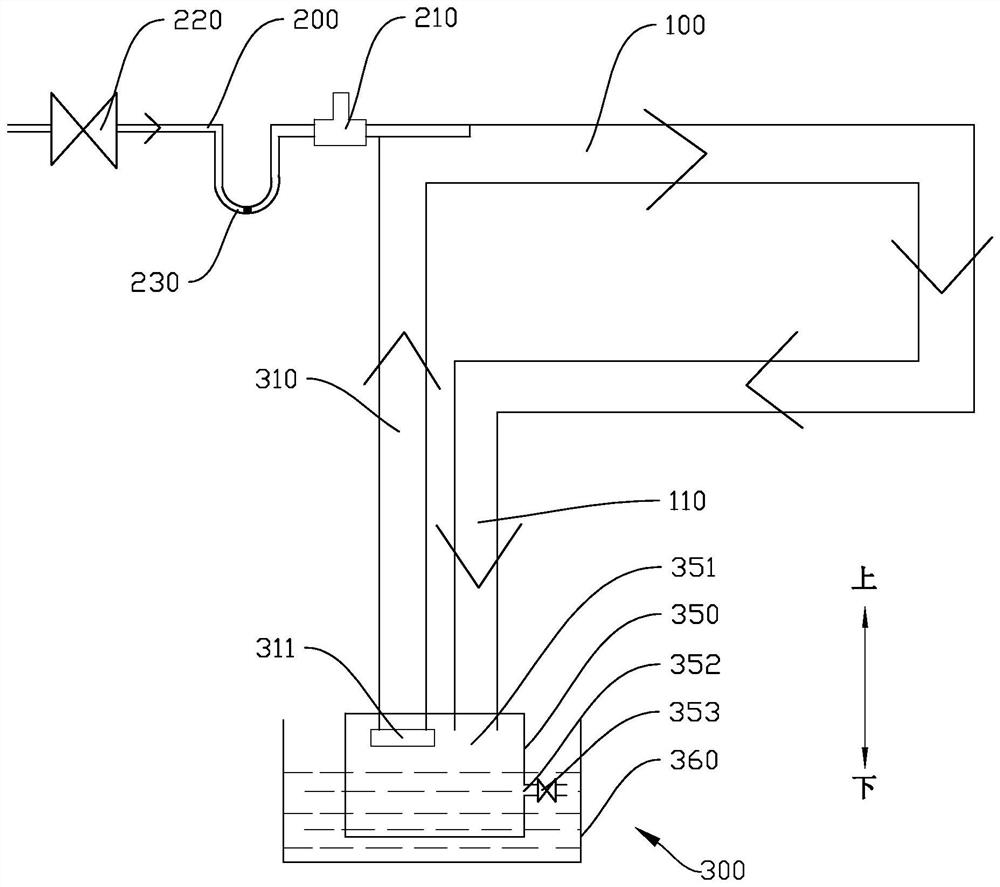

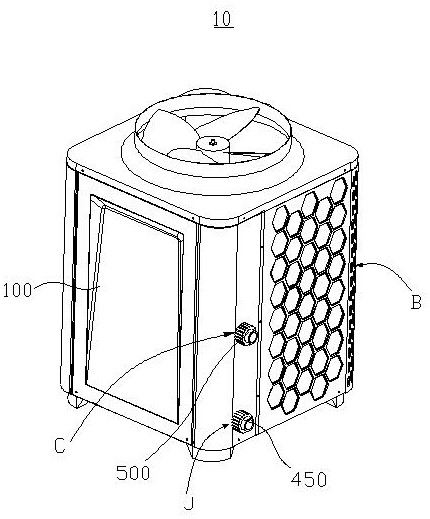

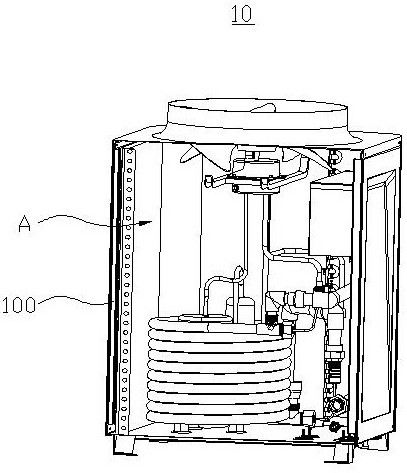

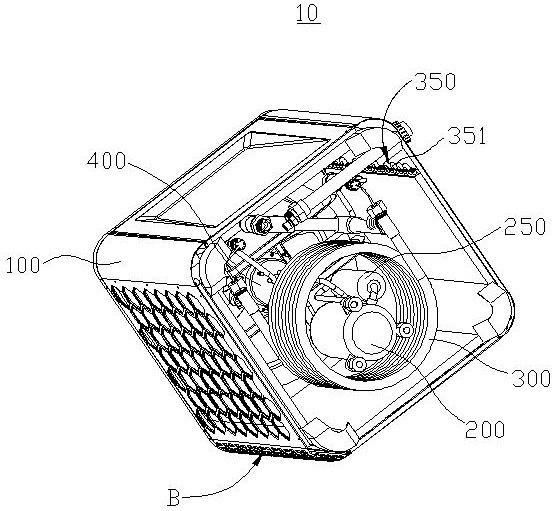

Two-stage compression and air supplementing device, air conditioning system and air supplementing control method

ActiveCN110925940AAvoid situations that damage the compressorIncrease flexibilityMechanical apparatusSpace heating and ventilation safety systemsEngineeringEvaporation duct

The invention provides a two-stage compression and air supplementing device, an air conditioning system and an air supplementing control method, relates to the technical field of air conditioners, andsolves the technical problem that the air supplementing amount of an existing flash tank air supplementing mode cannot be adjusted according to working conditions. The air supplementing device comprises a three-hole flash tank, an air supplementing pipeline and a temperature detection device, the flash tank communicates with an air supplementing port of a compressor through the air supplementingpipeline, and a first valve body is arranged in the air supplementing pipeline; the temperature detection device at least can detect the outdoor environment temperature, the suction temperature of thecompressor, the outer pipe temperature of the outdoor unit and the evaporation pipe temperature of the indoor unit and calculate the suction superheat degree according to the temperature value so asto control the opening degree of the first valve body. The opening and closing of the first valve body are determined according to the outdoor environment temperature, and the opening degree of the first valve body is controlled according to the air suction superheat degree in the opening state, so that the purpose of adjusting the air supplementing amount according to the working condition is achieved, the situation that the compressor is damaged due to excessive air supplementing is avoided, and the flexibility and reliability of the compressor are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

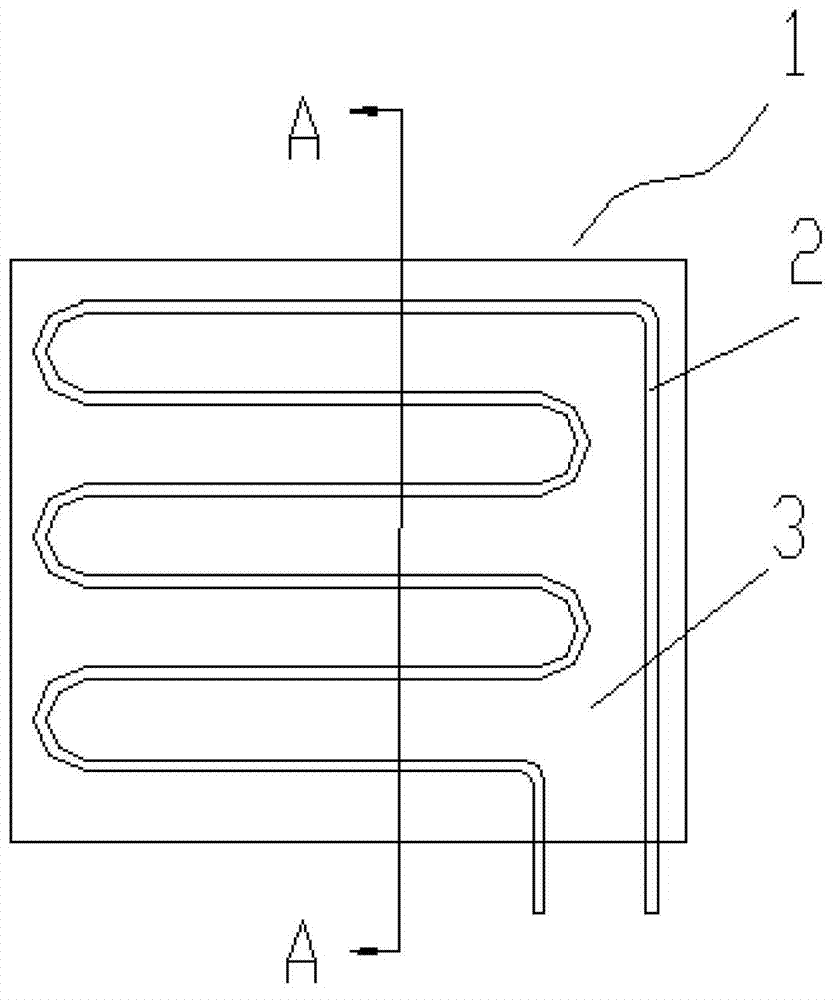

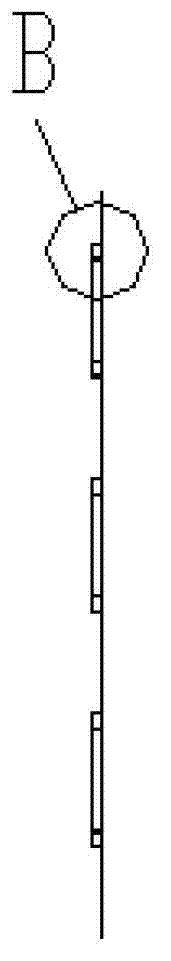

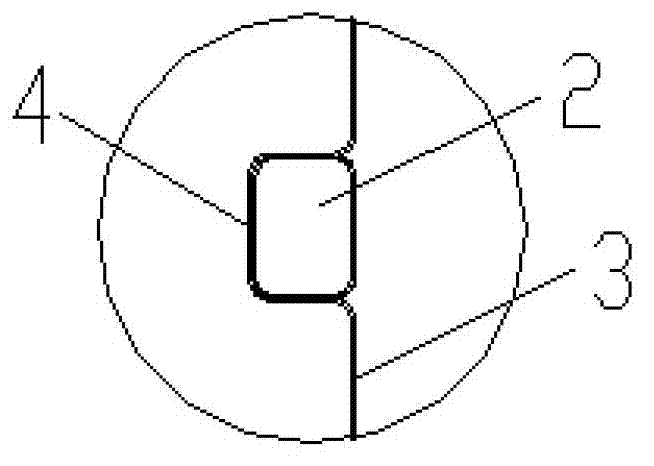

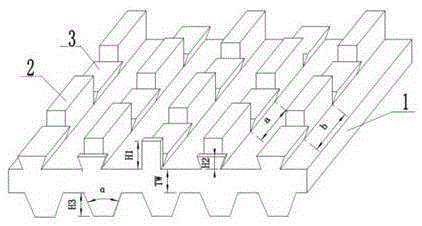

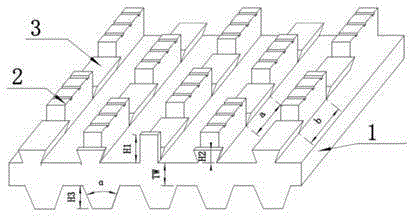

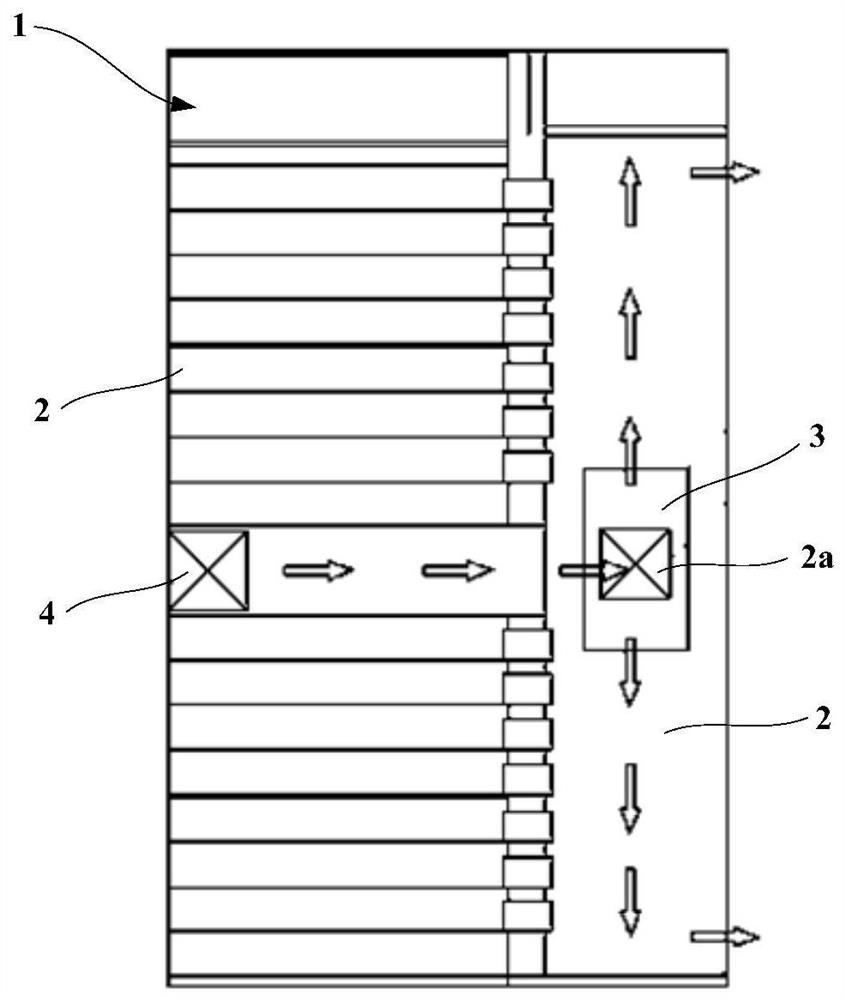

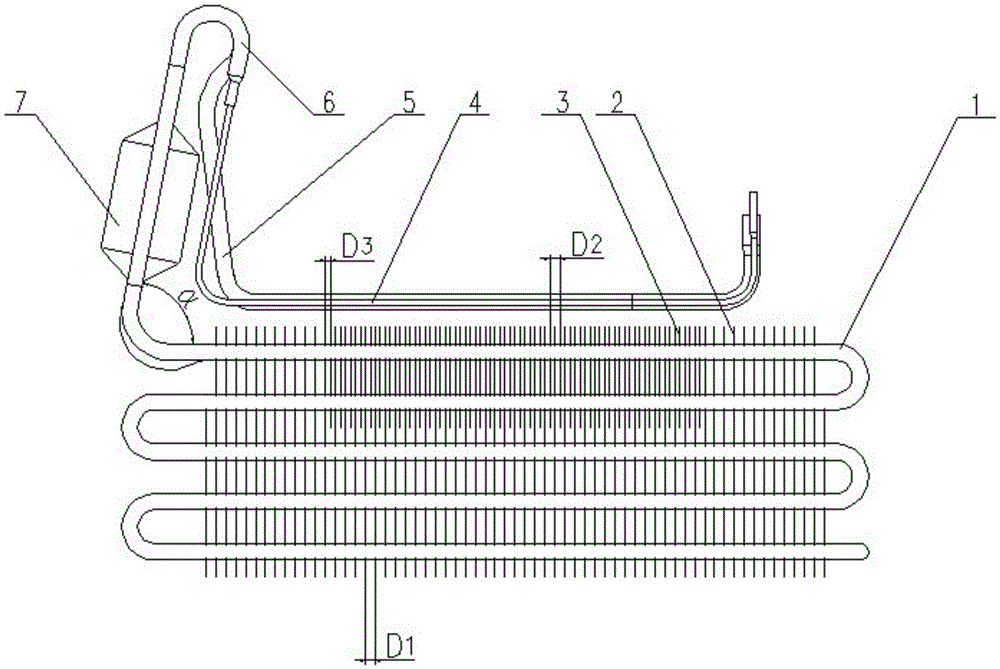

Evaporating pipe

InactiveCN105300155AIncrease contact areaReduce heat transfer resistanceTubular elementsEvaporation heat transferEvaporation duct

The invention relates to an evaporating pipe. The evaporating pipe comprises a main body pipe and a fin integrally molded with the main body pipe, wherein the fin is arranged on the outer surface of the main body pipe in a manner of being coiled around the axis of the main body pipe into helical angles, the fin comprises a plurality of main fins and auxiliary fins, which are continuously distributed in the length direction in a crossed manner, and the main fins are higher than the auxiliary fins. The main fins and the circumferential adjacent auxiliary fins are distributed in a circumferential butt joint and high-low staggered manner, the main fins are in a shape of a rectangular longitudinal cross section parallel to the axis of the pipe, and the auxiliary fins are in a shape of an inverted trapezoidal cross section parallel to the axis of the pipe. The evaporating pipe is suitable for the sprinkling evaporation heat transferring mode of an absorption type unit. The pipe fin structure can promote water drops falling on the outer wall of the pipe to rapidly spread at helical angles with the axis and in the circumference, so that the thickness of a liquid film is reduced, heat transferring resistance is reduced, and evaporation heat exchange efficiency is improved.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Rapid cooling system for heat-resistant high-strength cable processing

InactiveCN111791448AImprove cooling effectStable temperatureDrying solid materials without heatThermodynamicsCooling effect

The invention discloses a rapid cooling system for heat-resistant high-strength cable processing. The rapid cooling system comprises a cooling water tank, two guide rollers are rotationally connectedto the inner part of the cooling water tank, the upper end of one side of the cooling water tank is rotationally connected with a guide roller through a guide roller fixing frame, the upper end of theother side of the cooling water tank is fixedly connected with a wiping assembly and a winding assembly, a circulating water tank is arranged below the cooling water tank and connected with the cooling water tank through a circulating pipeline, the circulating water tank is connected with a cooling assembly, the upper end of the cooling water tank is detachably and fixedly connected with a cooling tank cover, and a cable inlet and a cable outlet are formed in the surface of the cooling tank cover. According to the rapid cooling system for heat-resistant high-strength cable processing, coolingwater in the cooling water tank is used for cooling a cable after extrusion molding; and the cooling assembly is arranged, cooling is carried out on the cooling water in the circulating water tank through an evaporation pipe, and the cooling water is guided into the cooling water tank through the circulating pipeline, so that the temperature stability of the cooling water in the cooling water tank is ensured, and then a good cooling effect on the cable can still be ensured after the cooling water works for a long time.

Owner:安徽天虹电缆有限公司

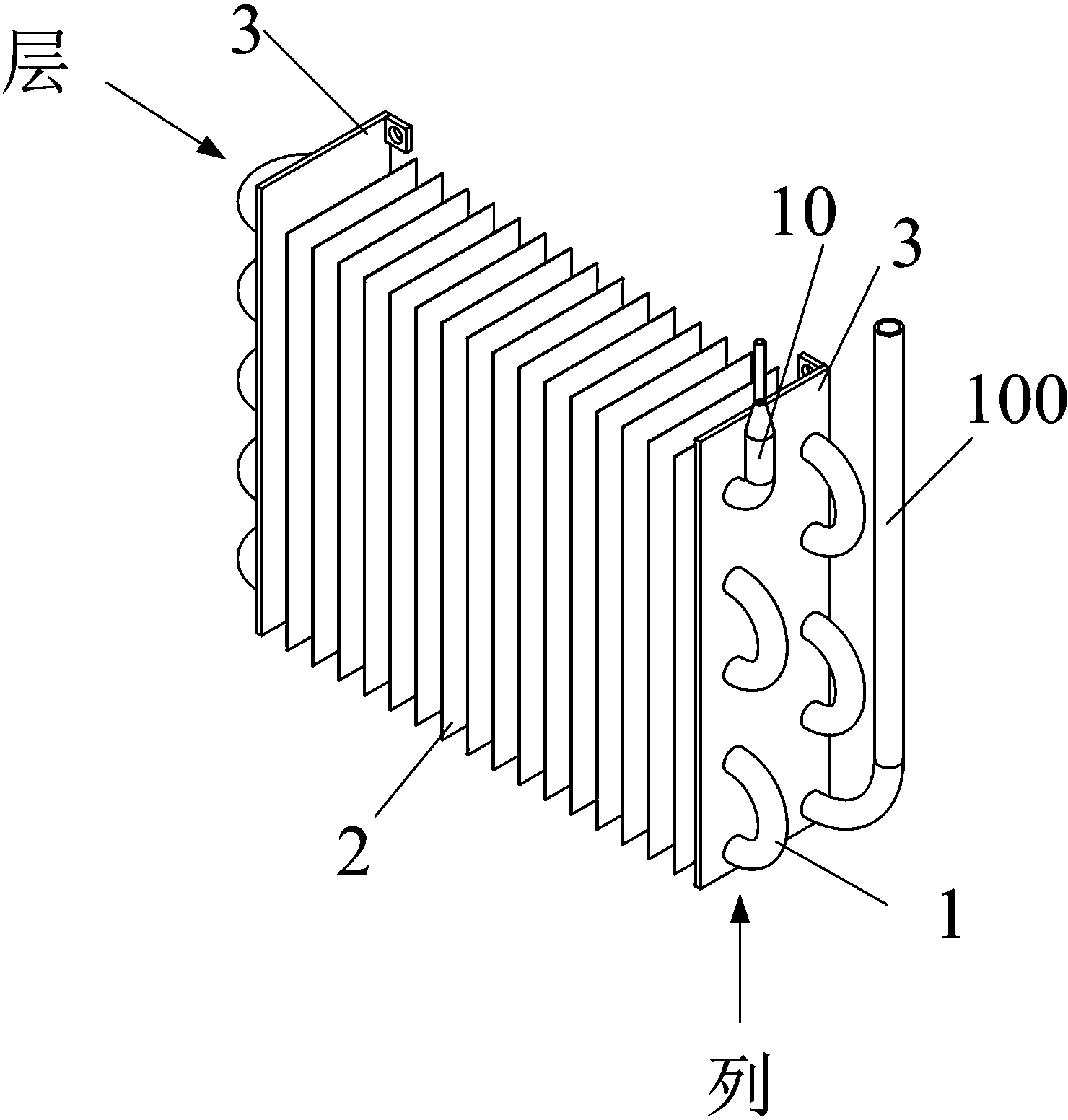

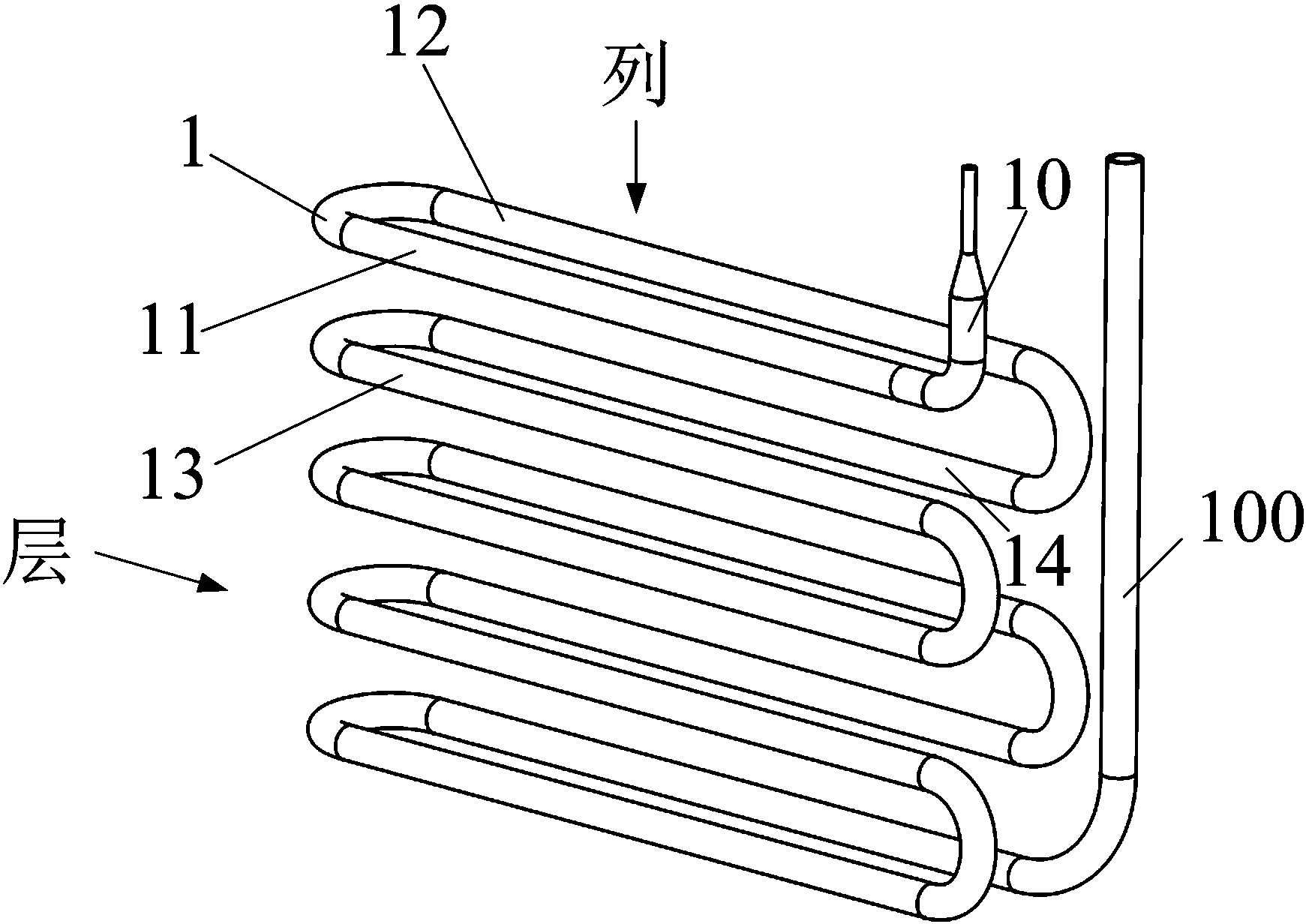

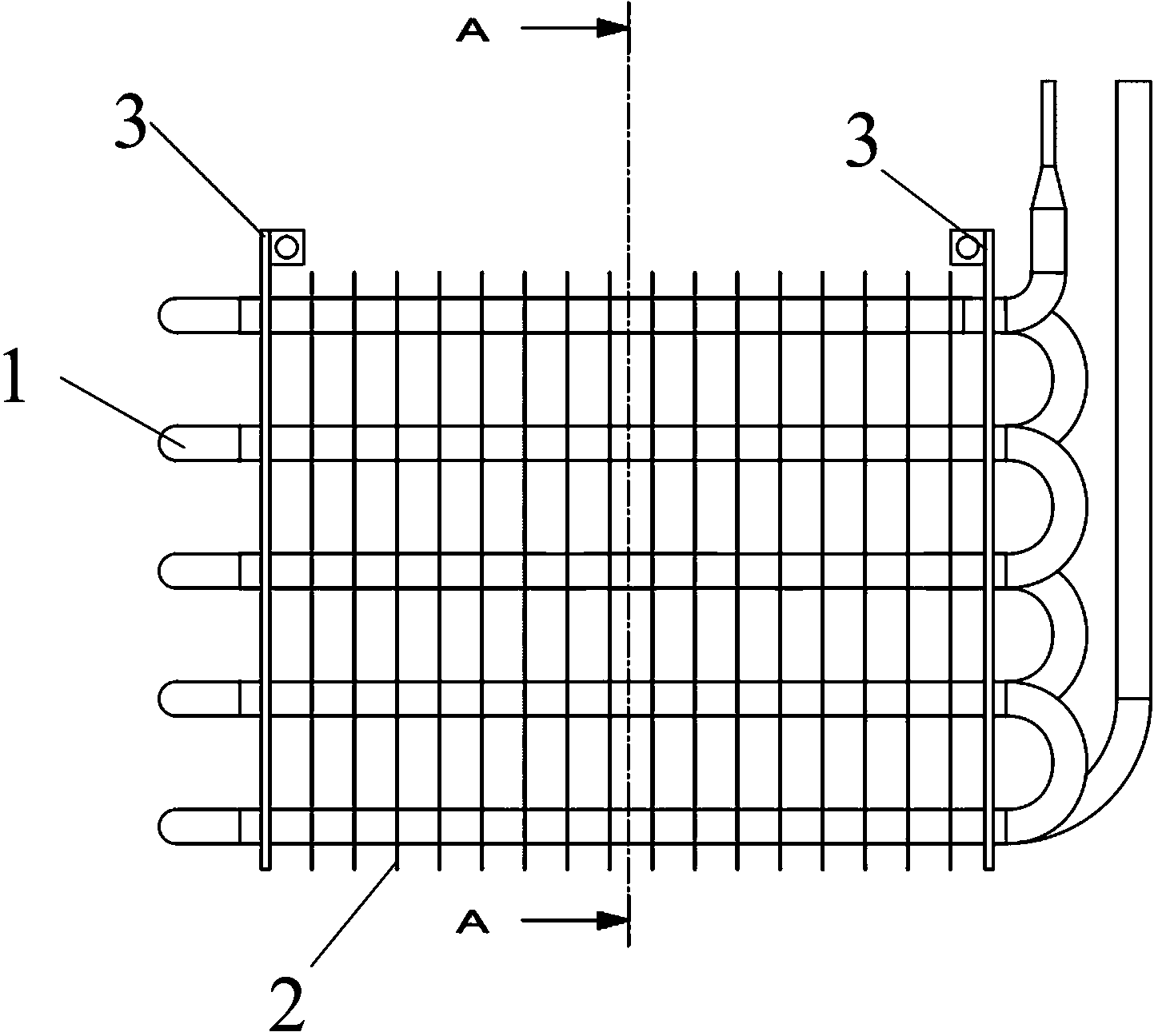

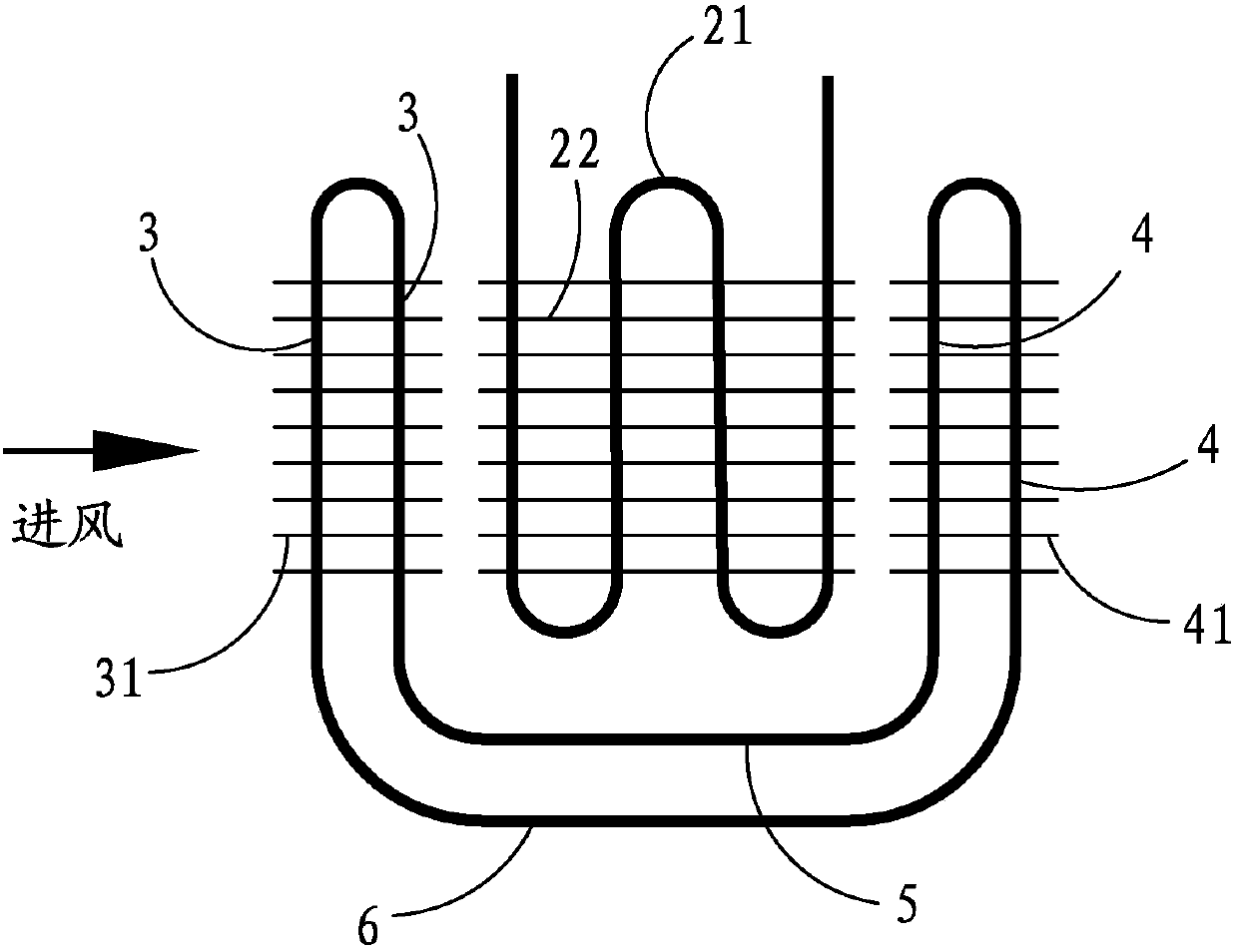

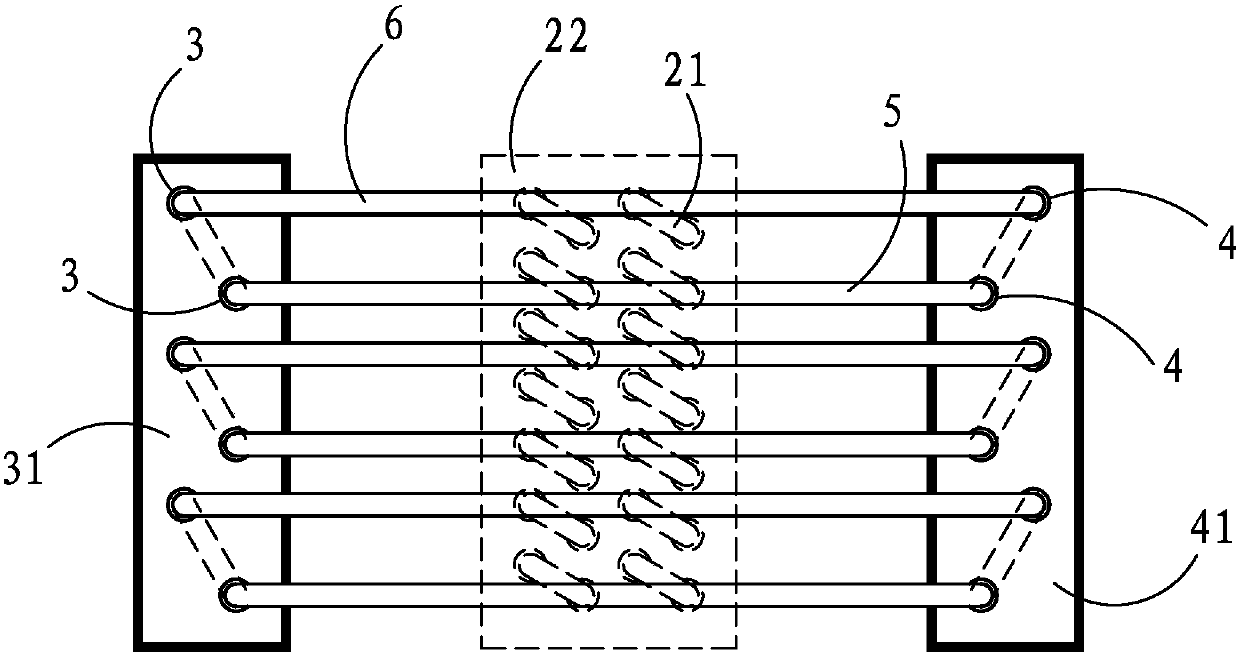

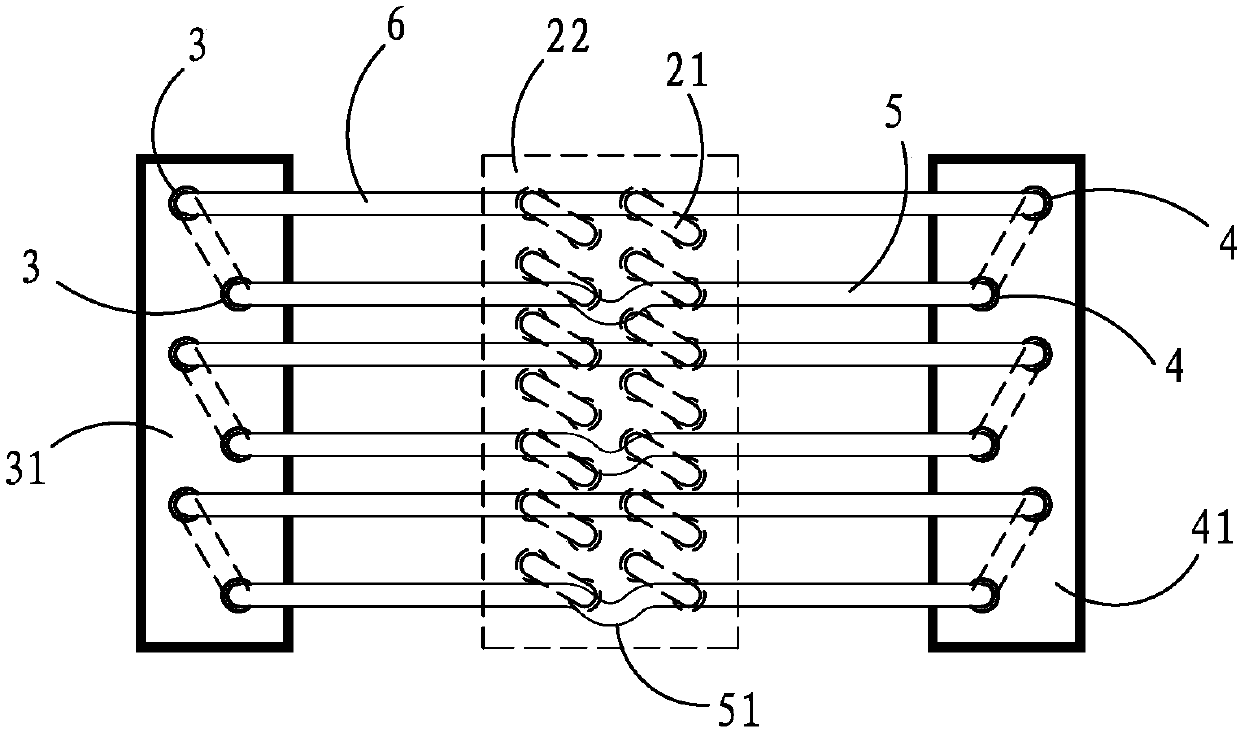

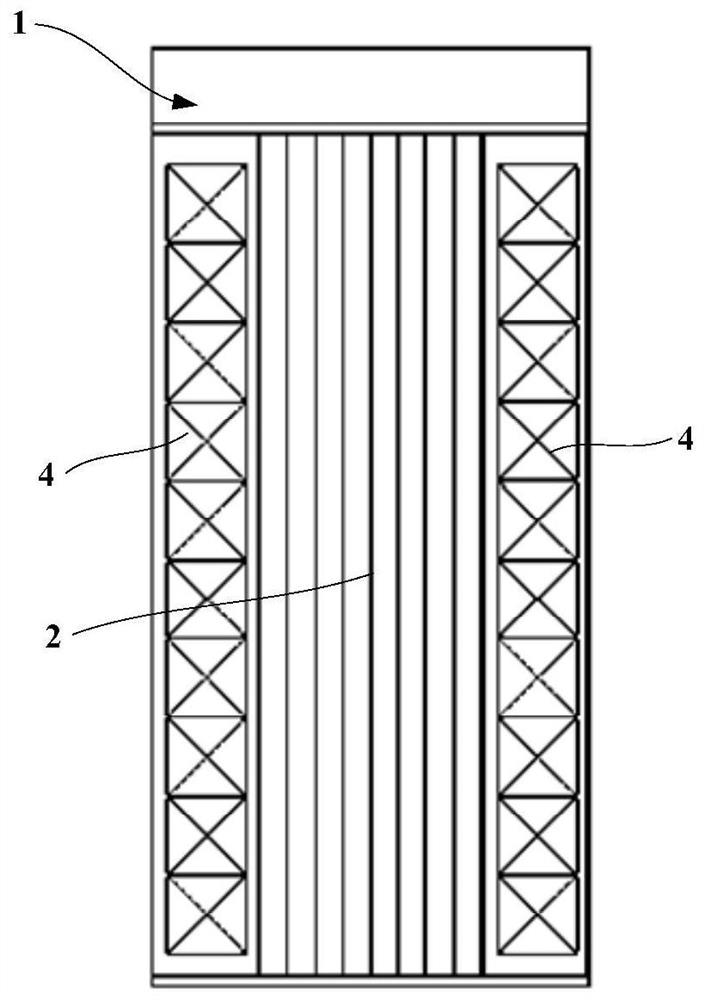

Fin evaporator and electric refrigerator adopting fin evaporator

InactiveCN104101136AAvoid direct connectionAvoid cooling grade reductionEvaporators/condensersEngineeringEvaporation duct

The invention relates to the technical field of an electric refrigerator in household appliances, in particular to a fin evaporator, which comprises a fixing plate, two lines or a plurality of lines of evaporation pipes and a plurality of fins, wherein the evaporation pipes are arranged on the fixing plate, the fins are sheathed on the evaporation pipes, and the evaporation pipes enter the evaporator from the top layer, spirally go downwards in a snake shape at each layer, and are sent out of the evaporator at the bottom layer. The air supply direction is upward from the bottom, the flowing direction of refrigerants in a pipeline is generally opposite to the air supply direction, through adopting the convection mode, the heat exchange is enhanced, and the cooling capacity transfer efficiency is improved. The refrigerant pipeline direction is integrally downward from the top, and the distance between an inlet section and an outlet section of each evaporation pipe reaches the maximum value. The temperature differences of the inlet section and the outlet section of each evaporation pipe are great, the heat exchange of the traditional evaporator through the fins since the inlet section and the outlet section of the evaporation pipe are adjacent is avoided, i.e., the cooling capacity grade reduction is avoided, and the cooling capacity utilization rate is improved. The frosting non-uniformity of the fins on the air supply cross section of the traditional evaporator, and the air supply non-uniformity and the heat exchange efficiency reduction due to the frosting non-uniformity are avoided.

Owner:孙卫华

Cooling tube system

PendingCN111795595ALow costLow cooling temperatureEvaporators/condensersIndirect heat exchangersMolecular sieveWater vapor

The invention discloses a cooling tube system which comprises an evaporation tube, a water inlet tube and a water removal assembly. The evaporation tube is arranged obliquely, and the input end of theevaporation tube is higher than the output end of the evaporation tube; the output end of the water inlet tube is connected to the input end of the evaporation tube, the water inlet tube is connectedto a three-way valve, and the three-way valve is used for inputting small molecular weight gas to the evaporation tube; the water removal assembly is located below the evaporation tube and is provided with a water sealing cavity, the output end of the evaporation tube is connected to the water sealing cavity through a recovery tube, the water sealing cavity is connected to a first pipeline, the first pipeline extends upward and communicates to the input end of the evaporation tube, the lower end of the first pipeline is connected to a molecular sieve, the molecular sieve is used for limitingpassing of water vapor, and the water removal assembly is used for absorbing the water vapor. The cooling tube system provided by the invention achieves refrigeration as water absorbs heat to evaporate, so that the cost is low. The refrigerating temperature of the cooling tube system is lower than air temperature and water temperature, and the refrigerating effect is good.

Owner:WUYI UNIV

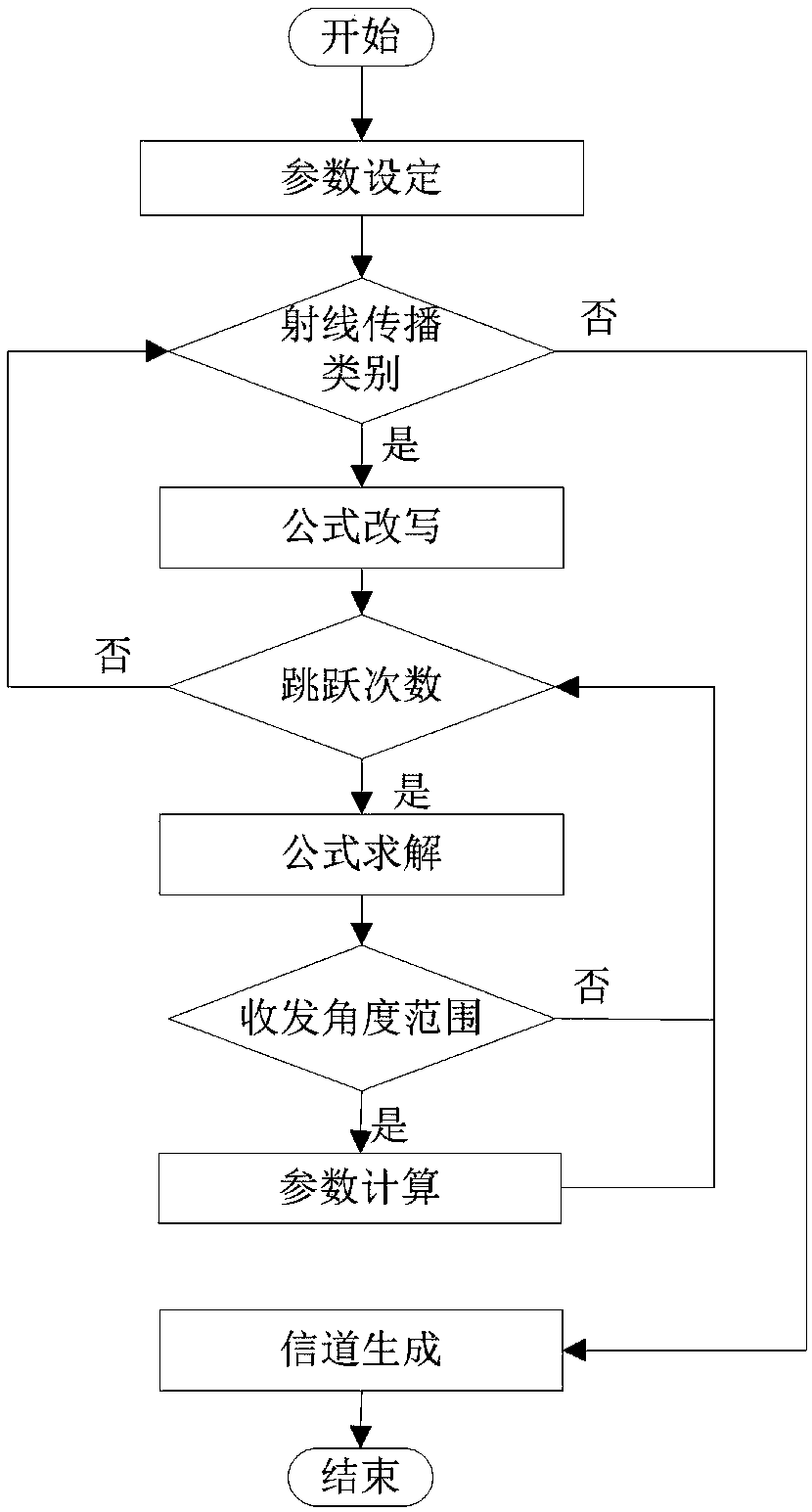

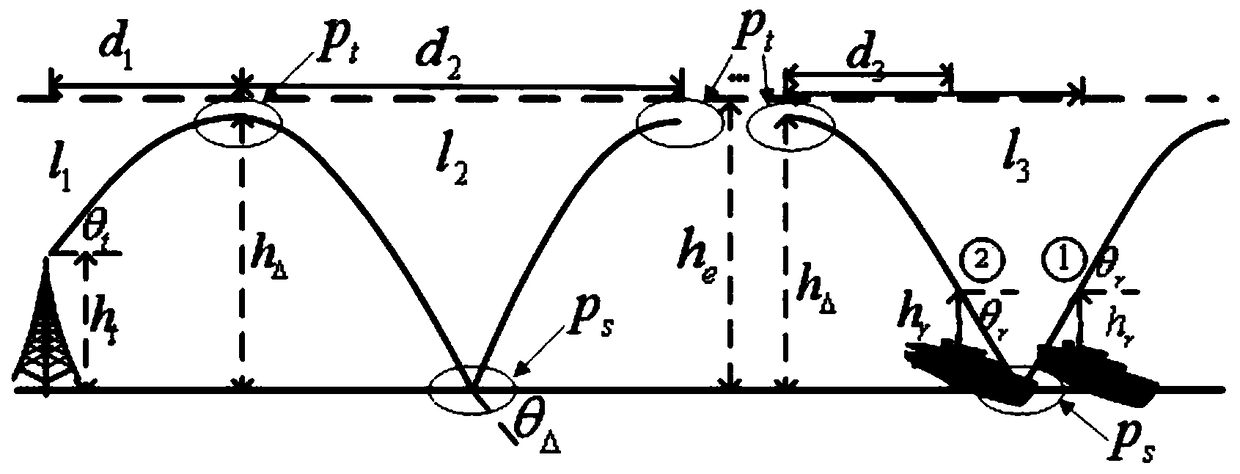

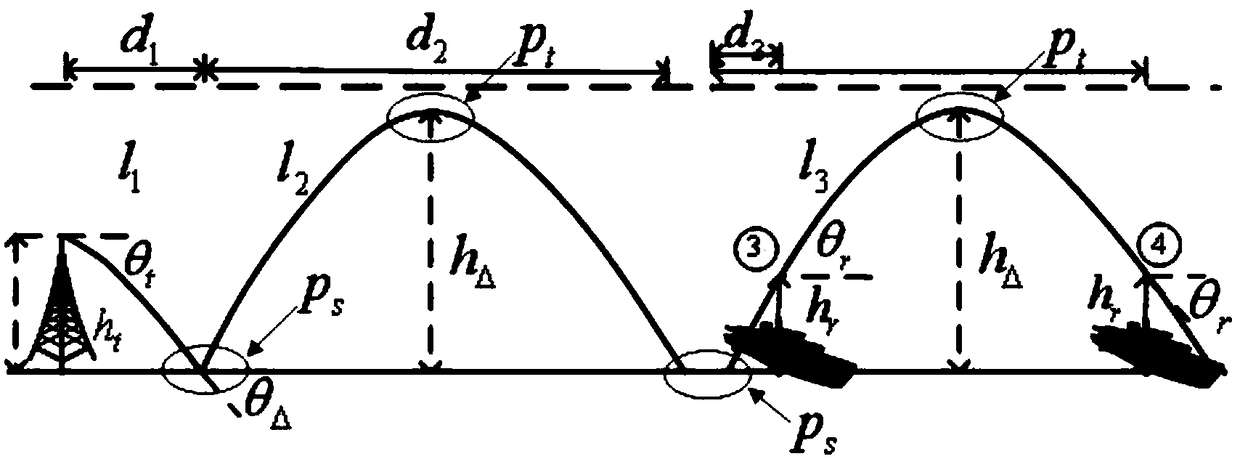

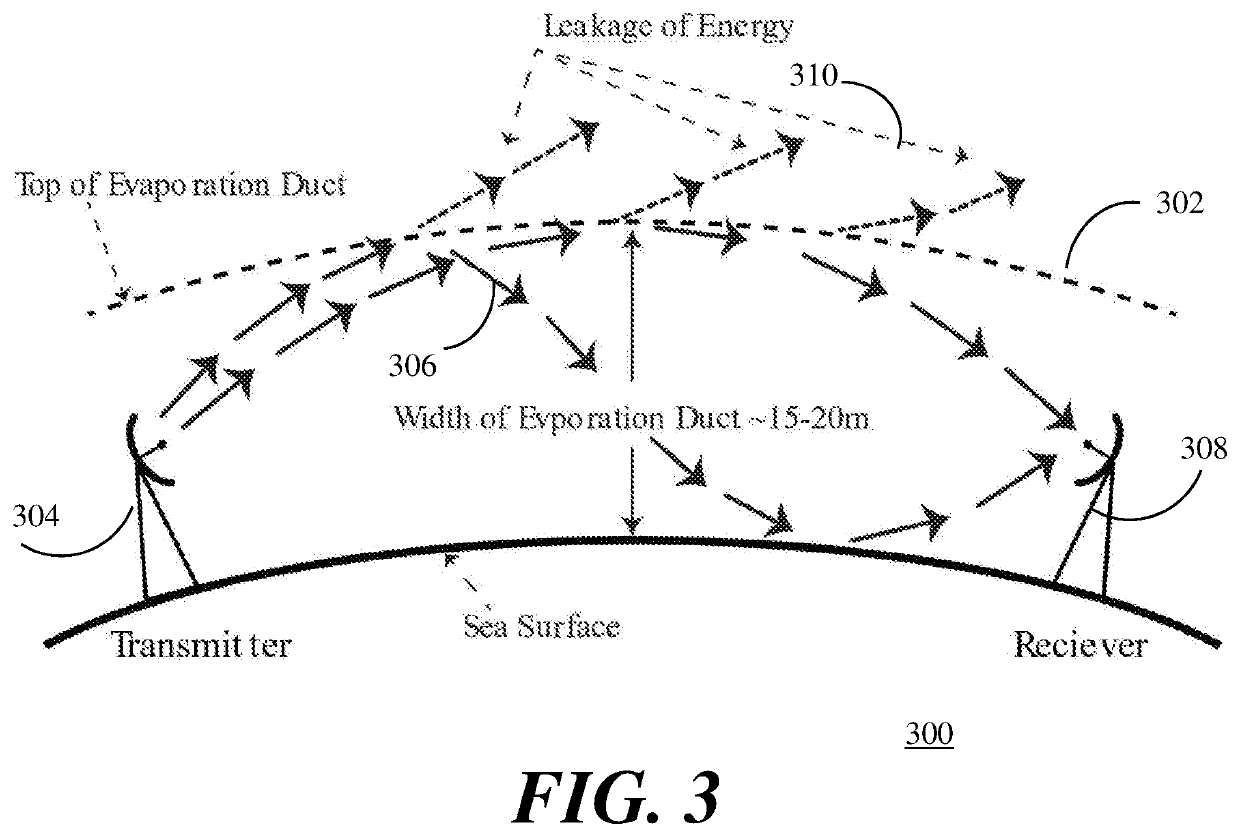

A method for generating channel of sea area evaporation duct

ActiveCN109408919AShorten the timeReduce complexityDesign optimisation/simulationSpecial data processing applicationsChannel parameterEvaporation duct

The invention discloses a method for generating channel of sea area evaporation duct. The waveguide channel generation is realized through the steps of parameter setting, ray propagation type discrimination, formula rewriting, hop number discrimination, formula solution, angle discrimination, parameter calculation and channel generation. The advantage of the method is that the channel parameters of the statistical arrival paths are brought into the channel generation module to form the evaporation waveguide channel. By using the actual parameters of each arrival path of the waveguide layer receiver, which are usually only simple real numbers, a fast and effective numerical method is used instead of the complex parabolic equation calculation to reduce the time required to generate the channel and the complexity of generating the channel. The applicability of the optical ray method is enhanced so as to generate evaporation duct channels which are more suitable for the actual situation.

Owner:NANTONG RES INST FOR ADVANCED COMM TECH CO LTD +1

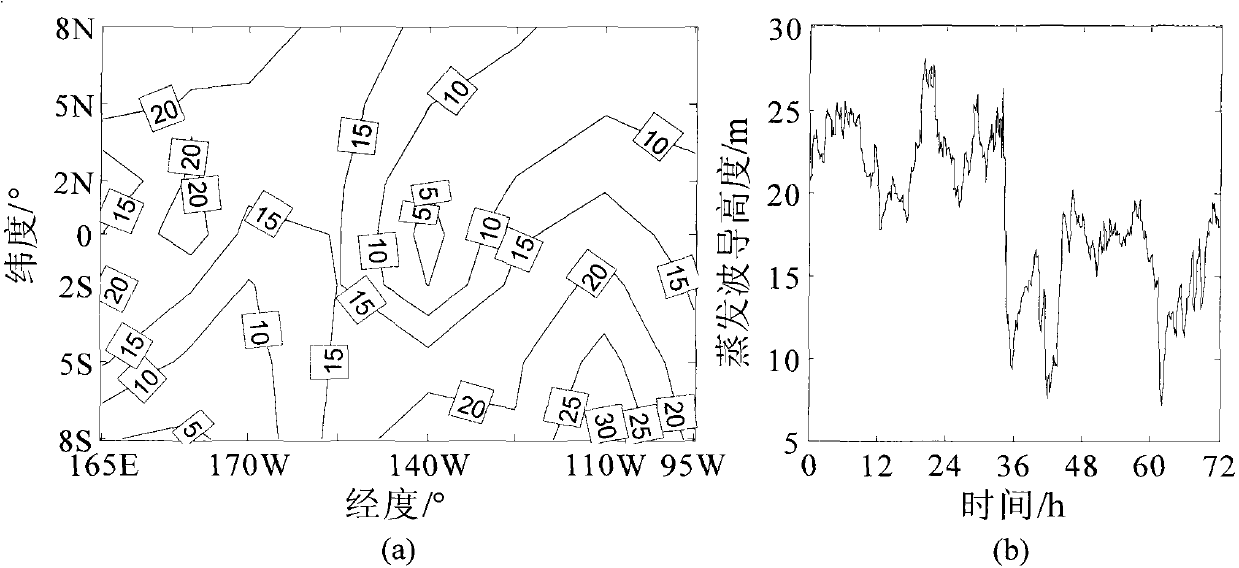

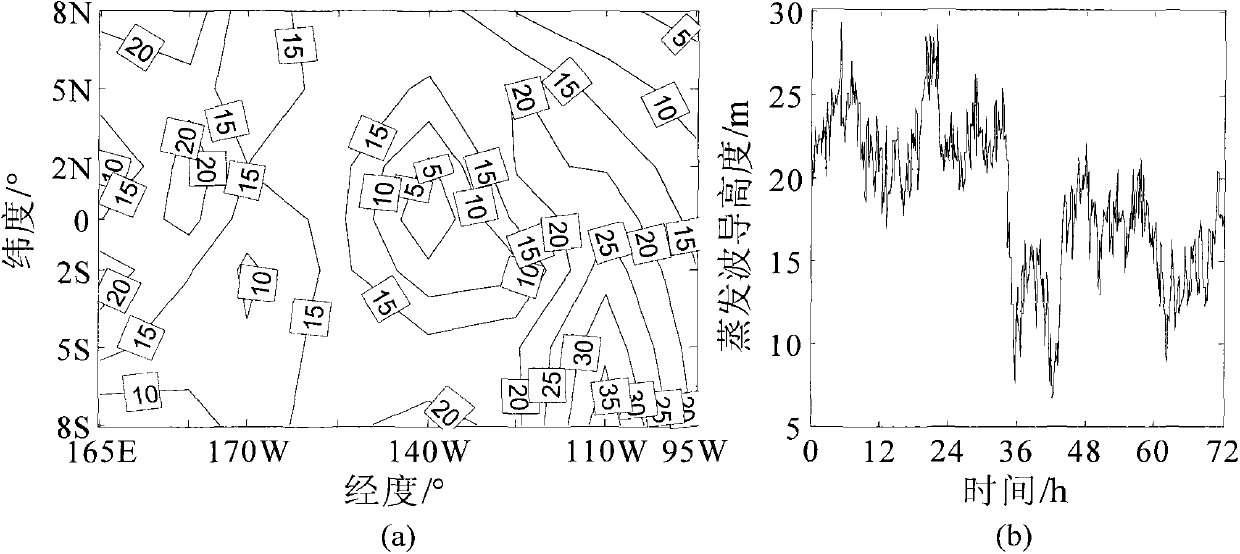

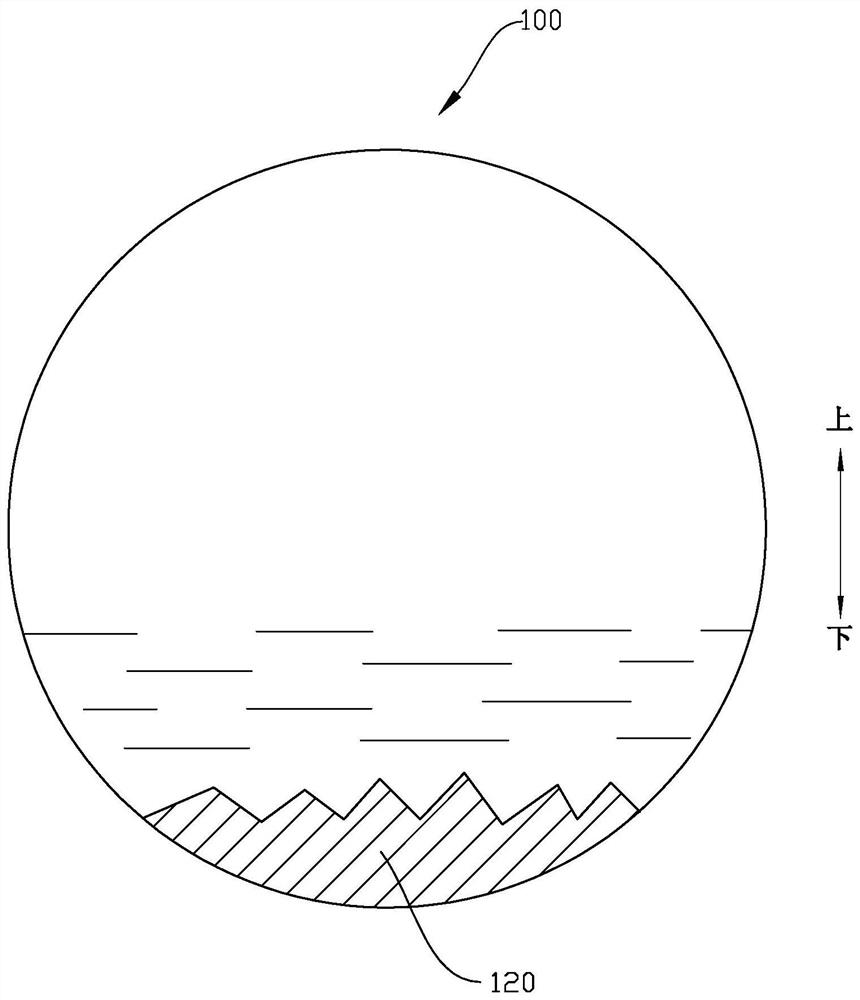

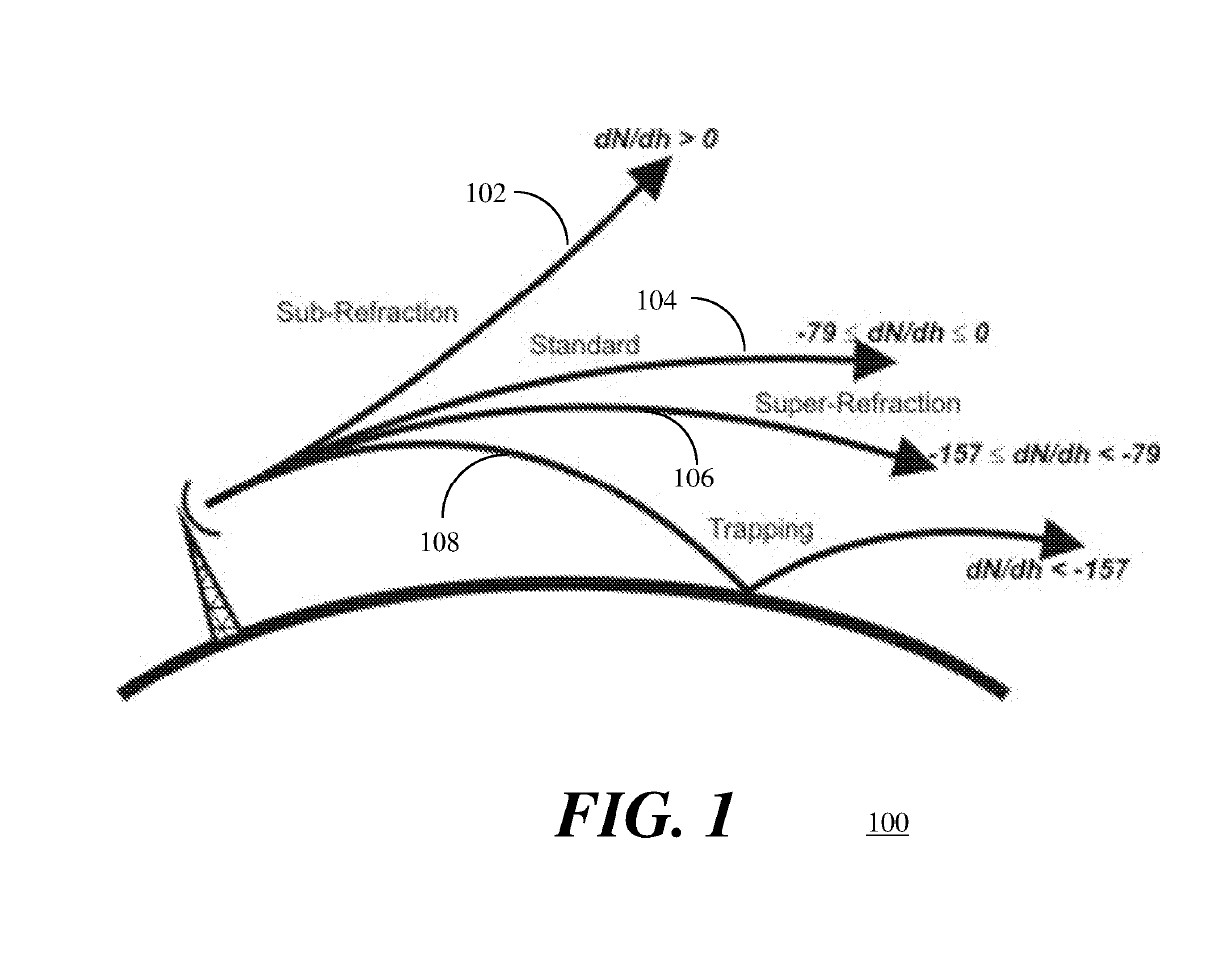

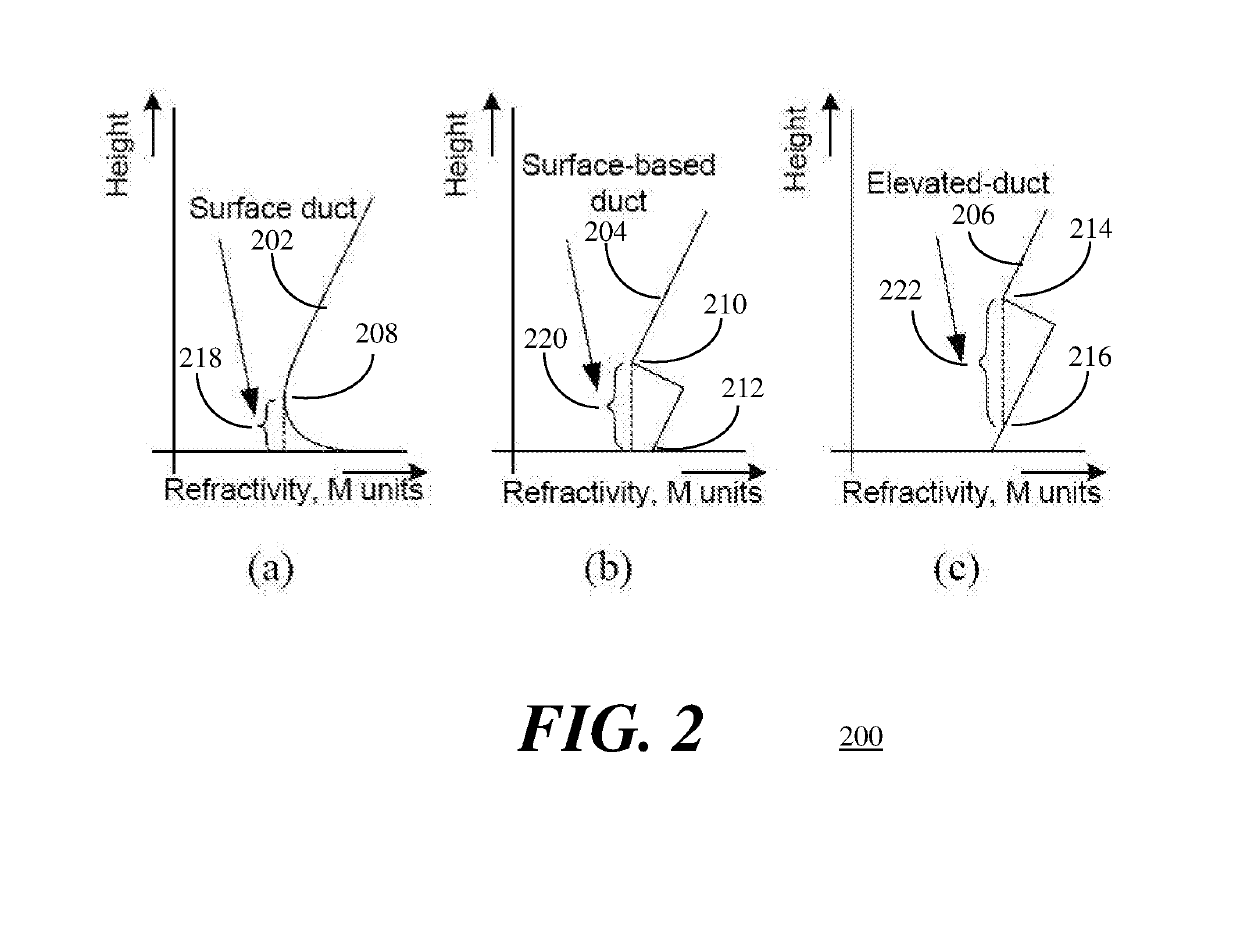

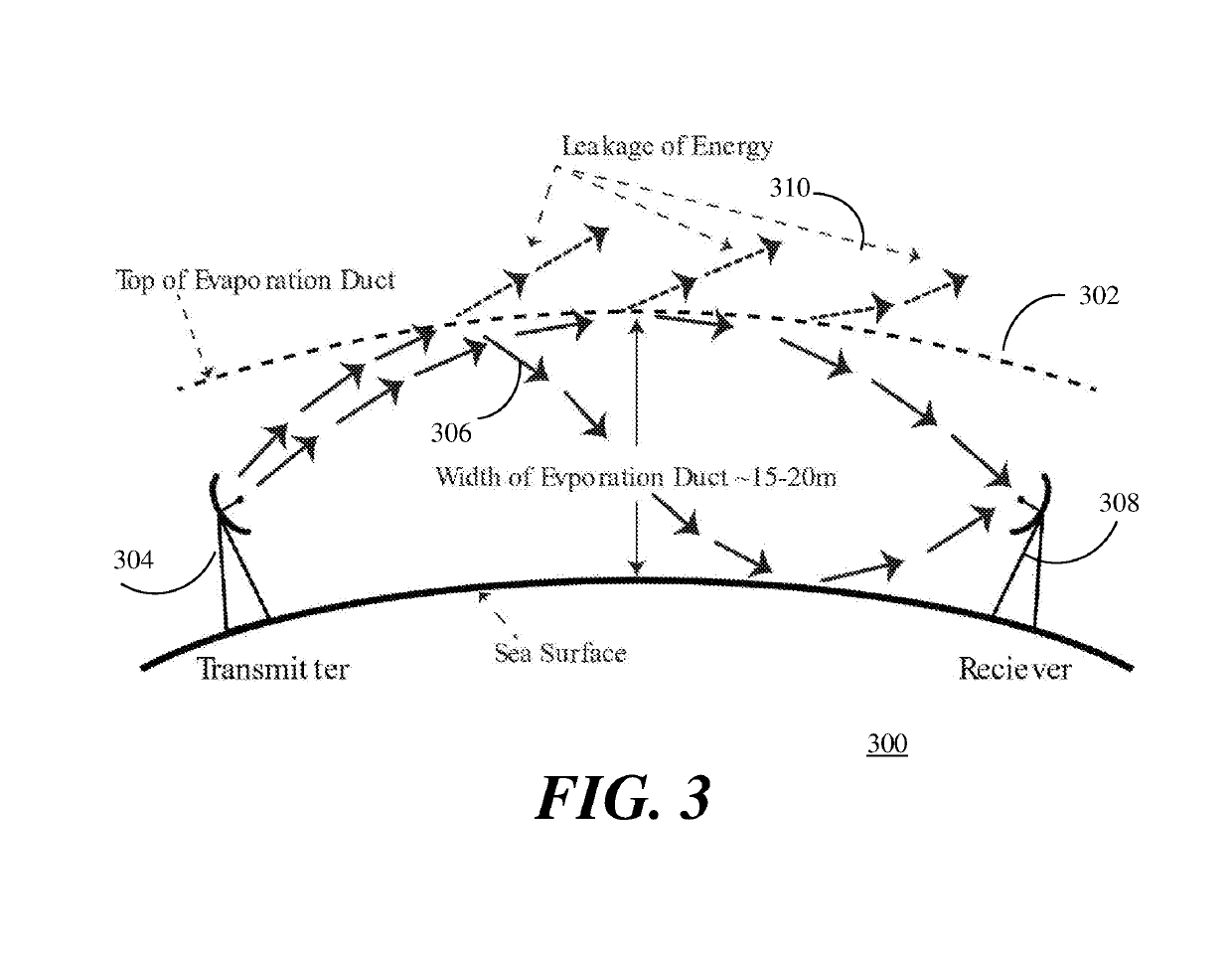

Trans-horizon wireless communication system using the tropospheric evaporation duct

ActiveUS20190296801A1Improve availabilityIncrease capacitySite diversitySpatial transmit diversityHorizonEngineering

A system for trans-horizon tropospheric-based wireless communication is provided. The system provides high availability and capacity as compared to a line-of-sight (LOS) standard microwave radio link while using very low height antenna towers. The system includes n×n MIMO transceiver circuitry and two or more antennas and adaptive modulation and demodulation in response to slow varying pathloss. Each of the two or more antennas is located at a vertical height above an average sea mean level within the evaporation duct. Availability percentage for different pathloss ranges along with adaptive modulation contributes to the overall availability according to the varying evaporation duct height.

Owner:GASOLINEIAM NASIONAL BERHAD

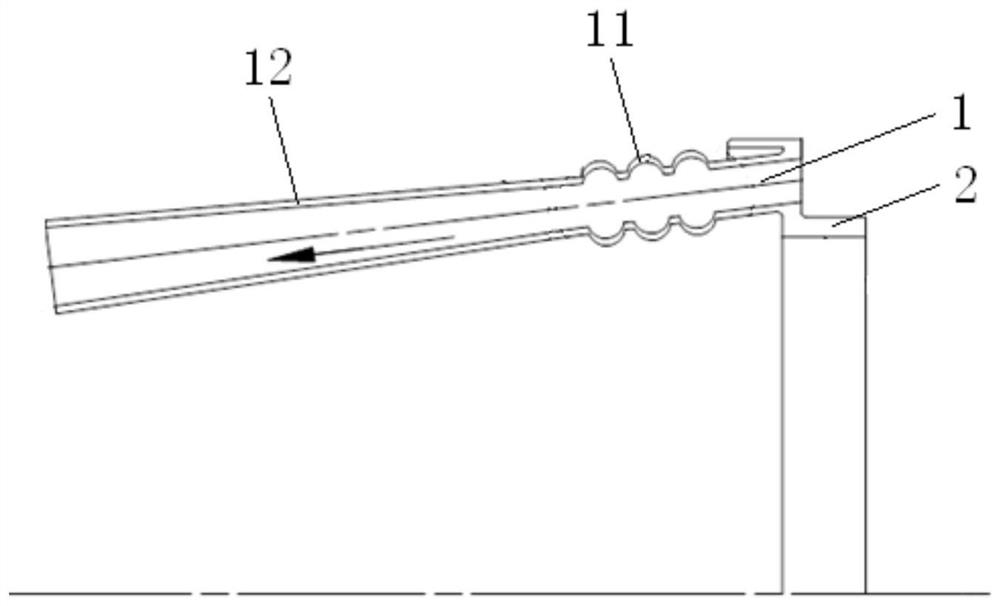

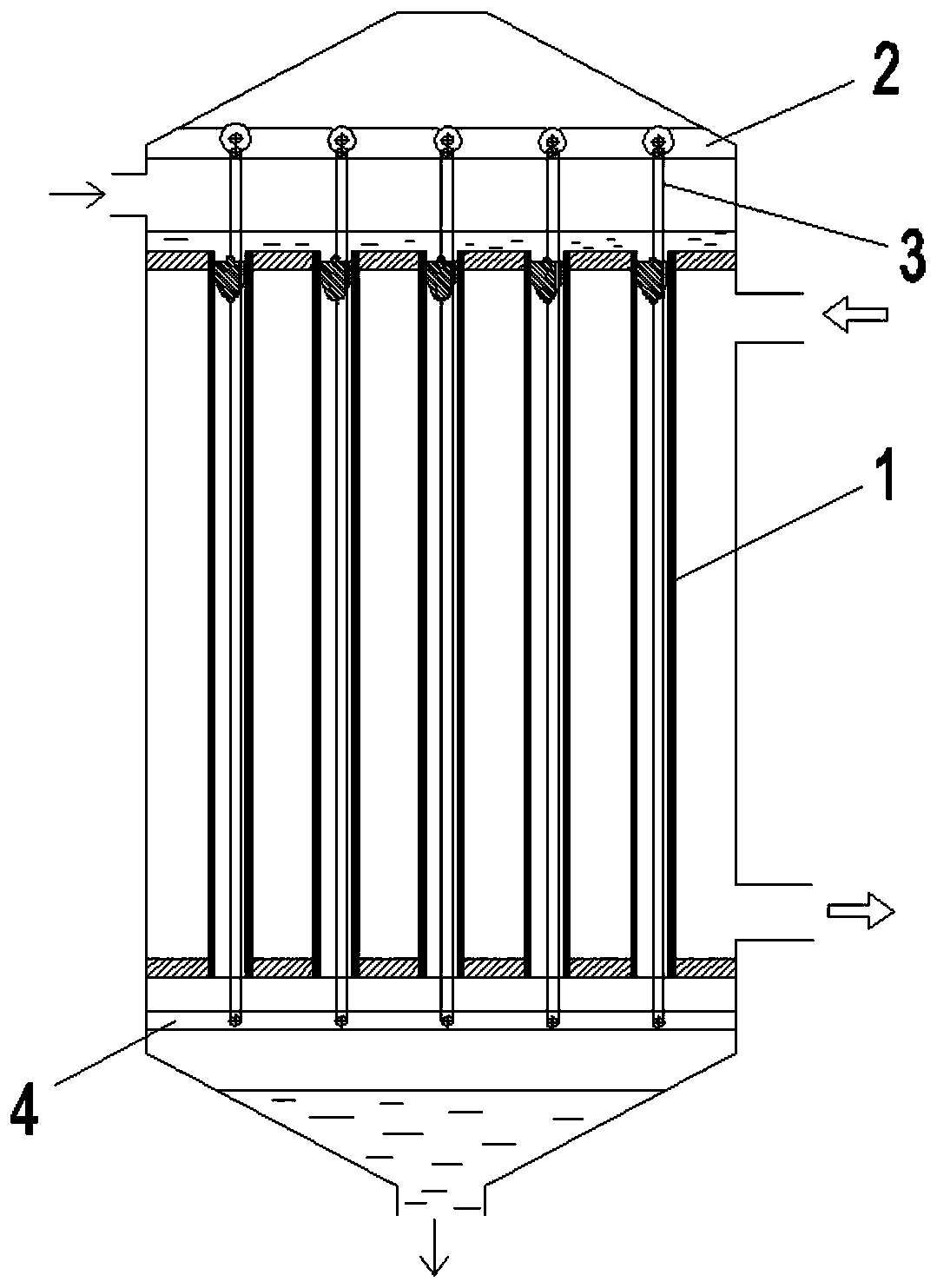

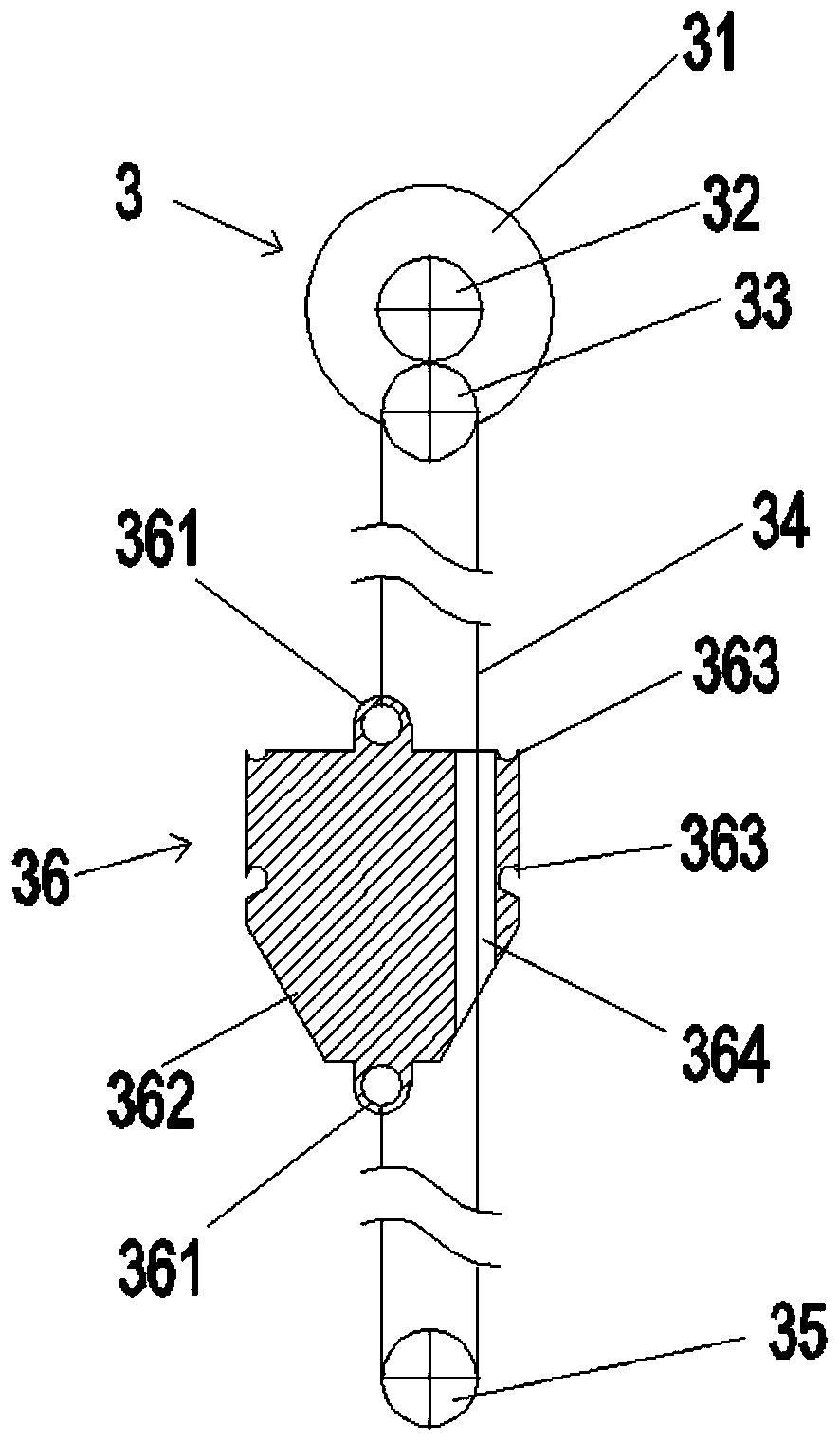

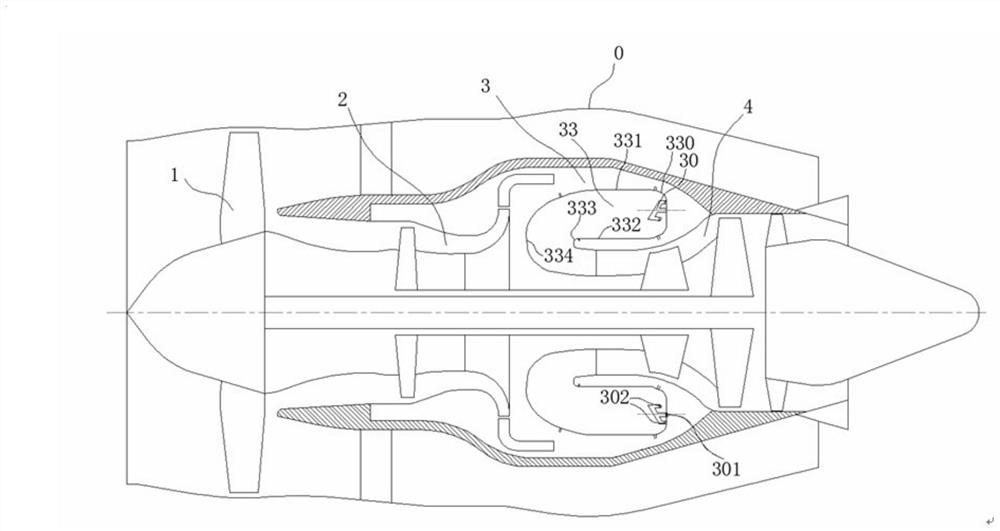

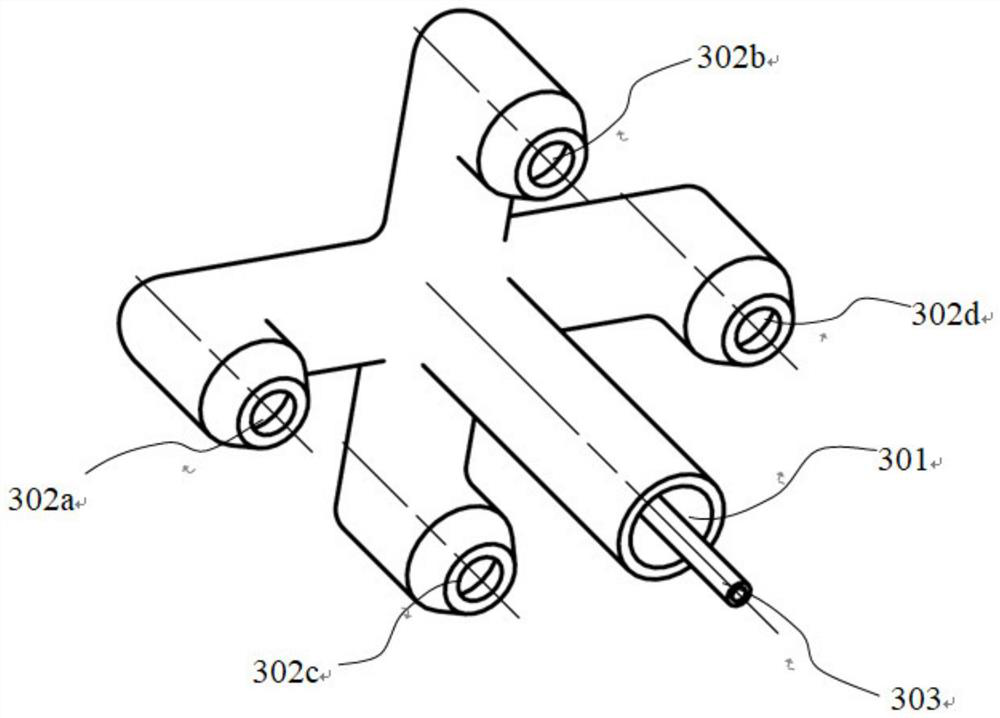

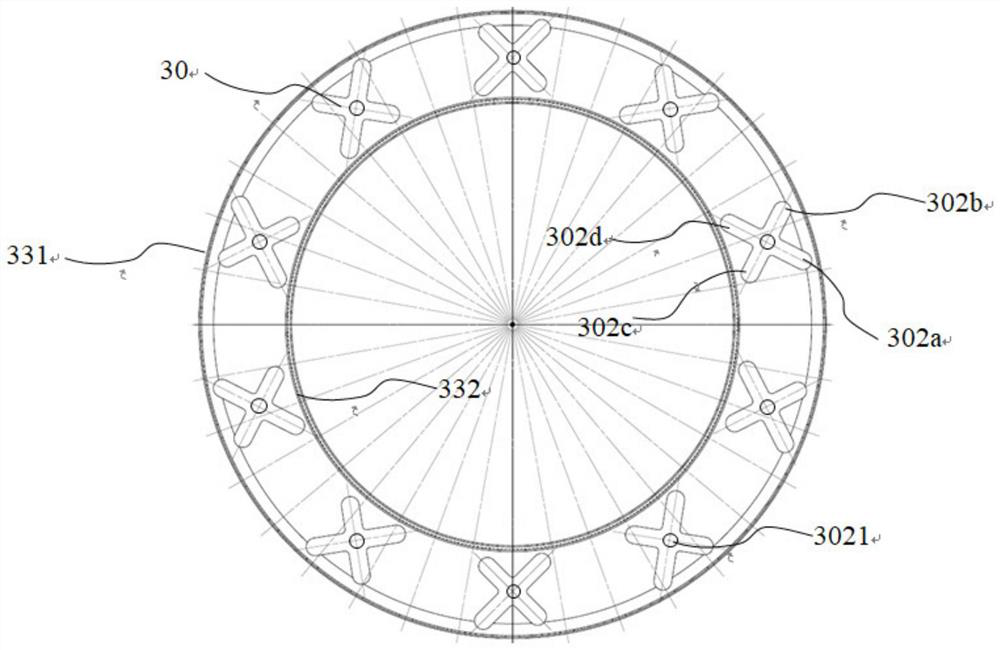

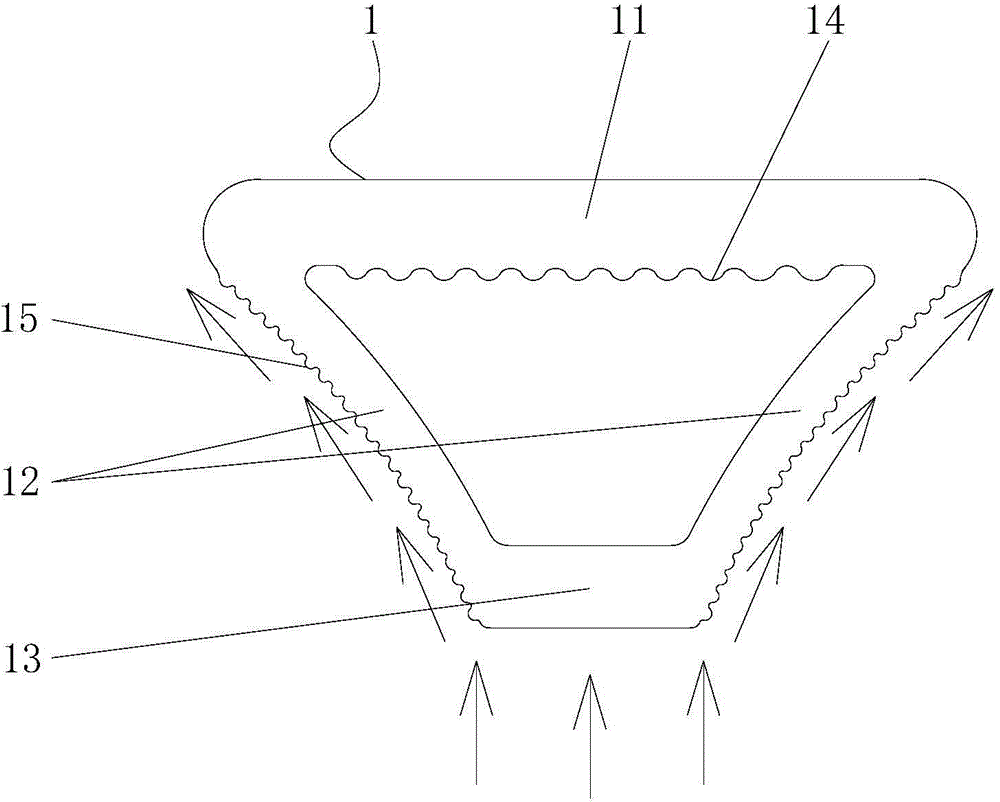

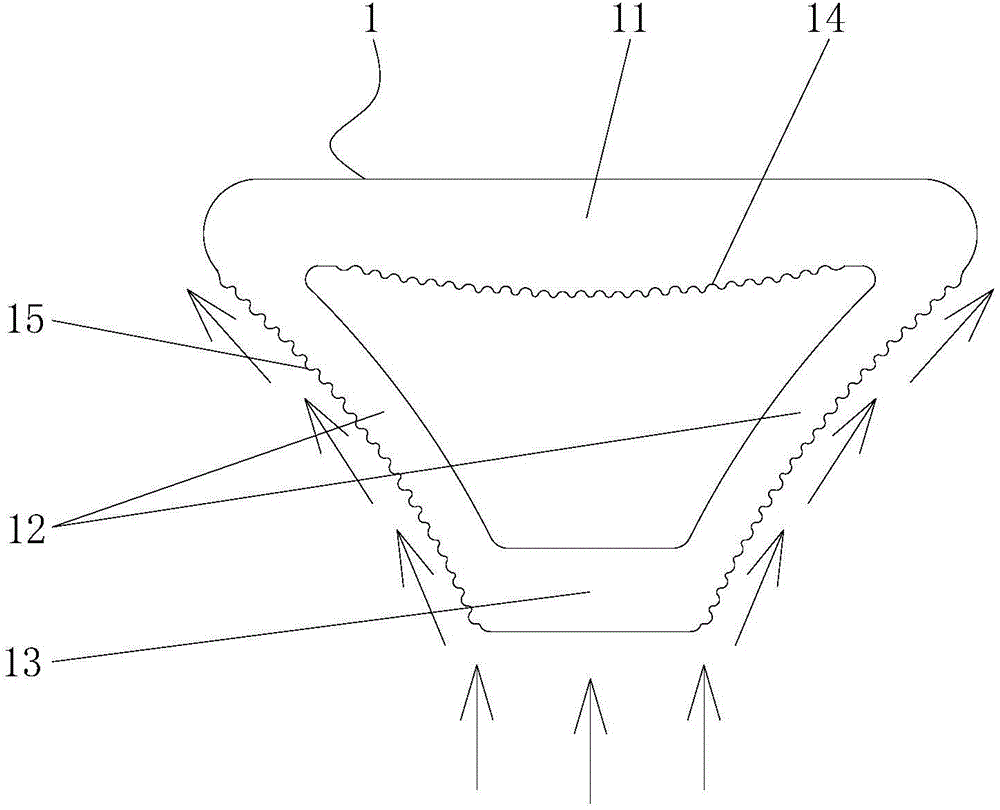

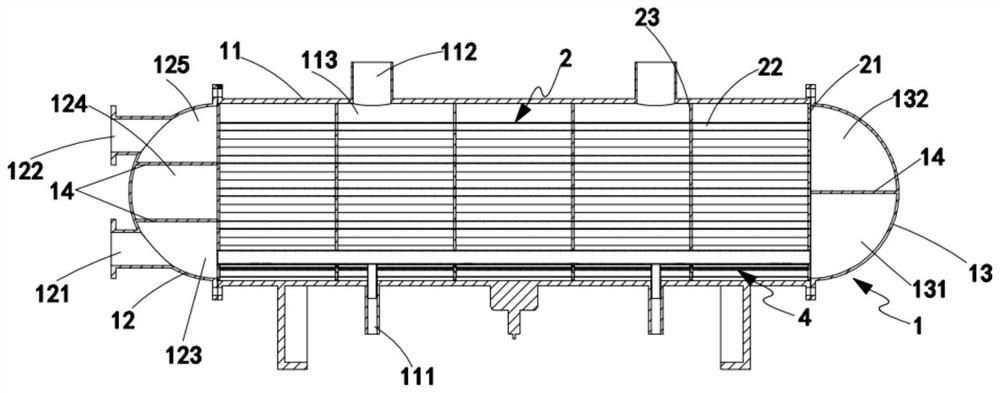

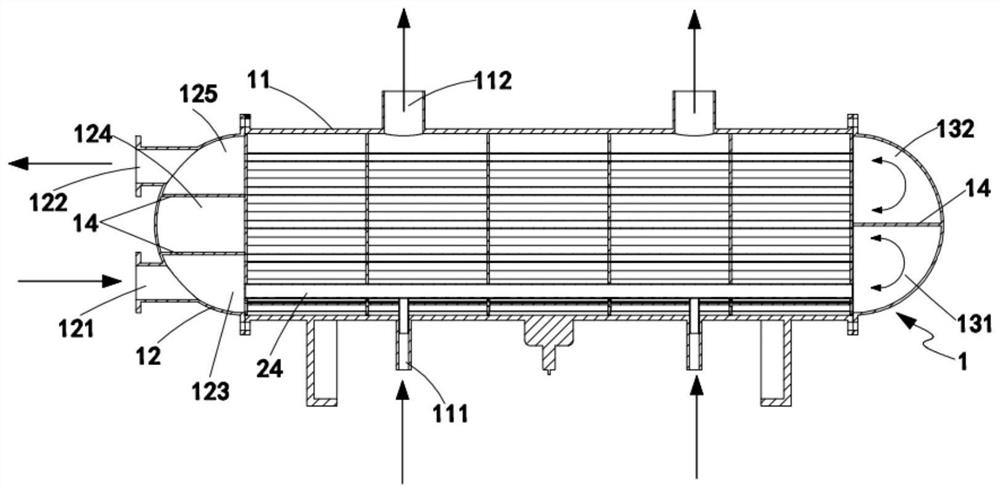

Integrated structure of evaporation tubes, evaporation tube type combustion chamber and miniature turbojet engine

ActiveCN111853854AImprove evaporation effectEnhance the effect of atomization and evaporationContinuous combustion chamberJet propulsion plantsEngineeringEvaporation duct

The invention discloses an integrated structure of evaporation tubes, an evaporation tube type combustion chamber and a miniature turbojet engine. The integrated structure of the evaporation tubes isused to impact and mix fuel sprayed from fuel nozzles through high-speed airflow to form a fuel-air mixture and spray the fuel to the head area of the combustion chamber. The integrated structure of the evaporation tubes comprises a plurality of evaporation tubes integrated with a support ring of the combustion chamber, wherein the evaporation tubes are evenly arranged on the support ring of the combustion chamber in the circumferential direction, first ends of the evaporation tubes are inlet ends for inputting the high-speed airflow, second ends of the evaporation tubes are outlet ends for spraying the fuel-air mixture, the evaporation tubes comprise corrugated sections close to the inlet ends, the corrugated sections are provided with corrugated cavities protruding outwards in the radialdirections of the evaporation tubes, and the fuel nozzles are inserted from the outlet ends of the evaporation tubes into the corrugated sections of the evaporation tubes, so that the fuel sprayed from the fuel nozzles is impacted and mixed by the high-speed airflow in the corrugated sections to form the fuel-air mixture, and then the fuel is sprayed from the outlet ends of the evaporation tubesto the head area of the combustion chamber.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Direct expansion type evaporator device of complete fresh air unit

InactiveCN107702383AImprove the operating environmentExtended service lifeEvaporators/condensersIndirect heat exchangersFresh airEngineering

The invention discloses a direct expansion type evaporator device of a complete fresh air unit. The direct expansion type evaporator device comprises an air flue and a direct expansion type evaporatorand further comprises at least one heat pipe assembly. Each heat pipe assembly comprises an evaporation coil pipe composed of at least two heat pipe evaporation pipes, a condensation coil pipe composed of at least two heat pipe condensation pipes, a heat pipe steam pipe and a heat pipe liquid return pipe, wherein the evaporation coil pipe is arranged in the part, on the air inlet side of the direct expansion type evaporator, in the air flue, the condensation coil pipe is arranged in the part, on the air outlet side of the direct expansion type evaporator, in the air flue, a heat pipe loop isformed by the evaporation coil pipe, the condensation coil pipe, the heat pipe steam pipe and the heat pipe liquid return pipe, and a closed cavity is formed by an inner pipeline. Due to the fact thatin a complete fresh-air air conditioner unit, the temperature of airflow entering the direct expansion type evaporators is reduced through the heat pipe loops of the heat pipe assemblies, the runningenvironment of a steam compression type refrigeration system is improved, and the service life of equipment compressors is prolonged.

Owner:SUZHOU SUJING AIM FAR AIR CONDITIONING

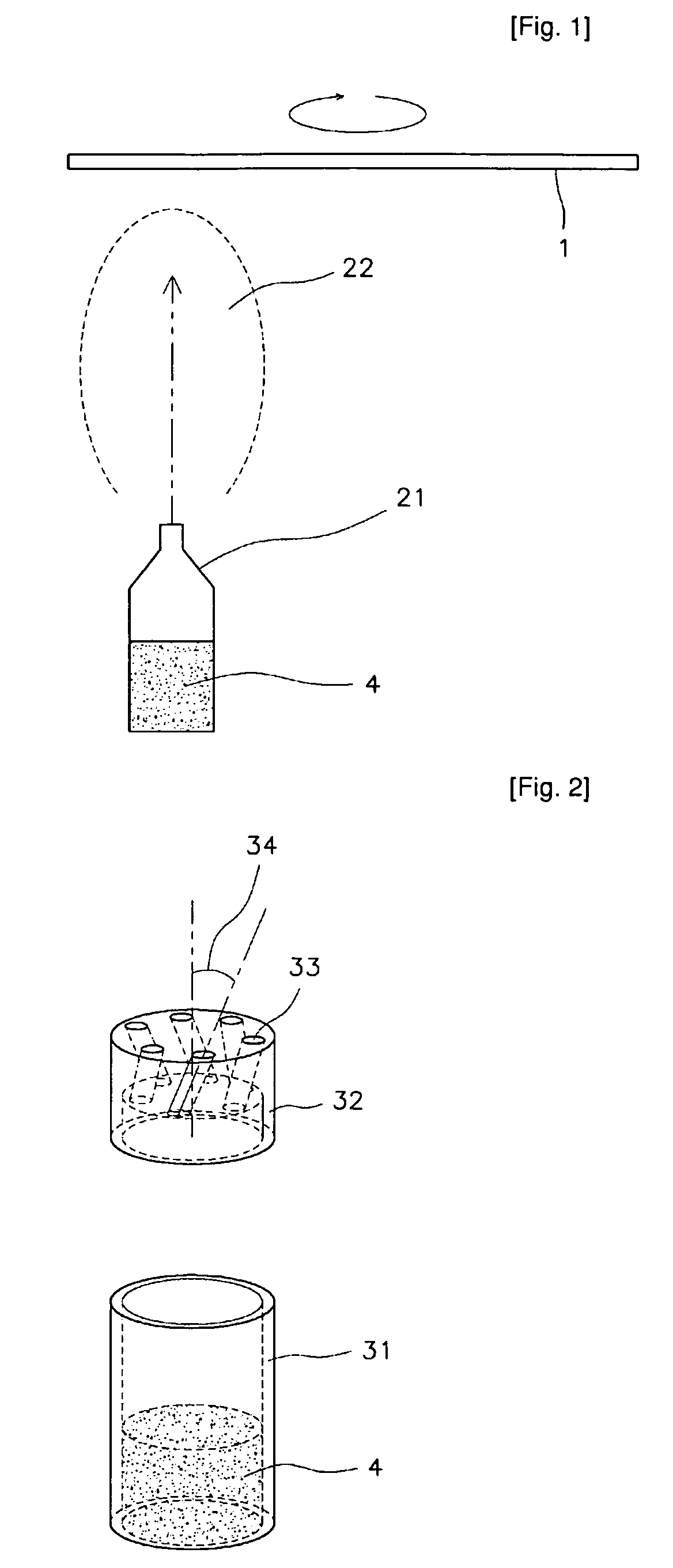

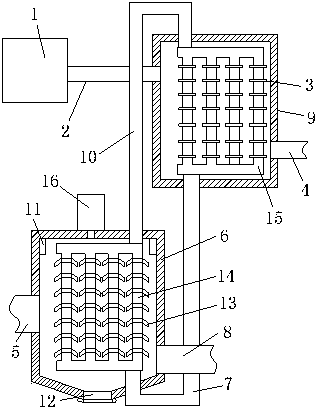

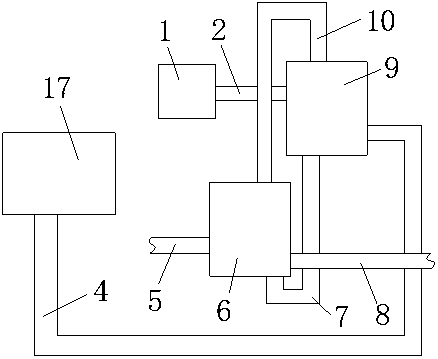

Method and device for producing a fragranced air stream

InactiveCN102686248AControl durationAvoid droplet segregationGaseous substancesEvaporation ductWaste management

The invention relates to a method for producing a fragranced air stream for fragrancing rooms, objects or the like, wherein fragrance is applied to a strip-like fragrance carrier (4) which is moved in an evaporation duct (1) through which fresh air flows. The fragrance is applied onto the moving fragrance carrier (4) by means of specific spraying before the latter enters the evaporation duct (1), and the fragrance carrier (4) is discarded as waste after exiting the evaporation duct (1).

Owner:RSH香味通道有限责任公司

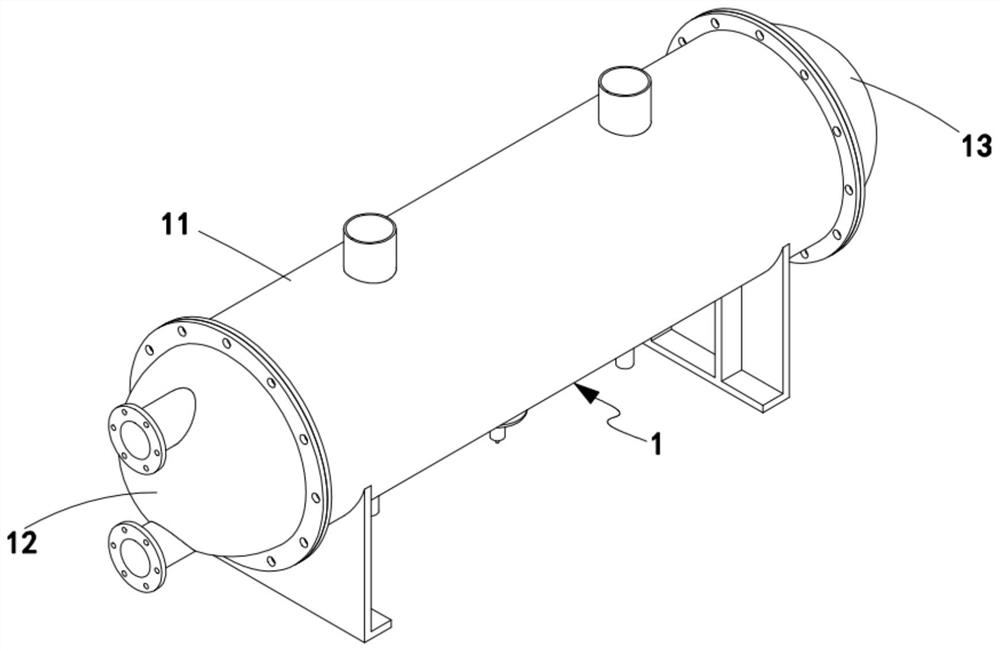

Heat pipe heat exchange device for waste heat recovery, and working method thereof

PendingCN110793364ARealize heat absorption utilizationIncrease profitIndirect heat exchangersCombustion technology mitigationAir compressionProcess engineering

The invention discloses a heat pipe heat exchange device for waste heat recovery, and a working method thereof. The heat exchange device comprises a hot air duct, and the hot air duct is fixedly installed on and communicates with a heat exchanger evaporation shell; the heat exchanger evaporation shell is fixedly provided with and communicates with an air outlet pipe, and an evaporation pipe is fixedly installed in the heat exchanger evaporation shell; the inner top end of the heat exchanger evaporation shell is fixedly provided with a plurality of acoustic soot blowers, and the middle part ofthe top end of the heat exchanger evaporation shell is fixedly connected with an air compression soot blower; the upper end of the evaporation pipe is fixedly provided with and communicates with a steam riser, and the other end of the steam riser is fixedly installed on and communicates with the top end of a heat exchanger condensation shell; a condensation pipe is fixedly installed in the heat exchanger condensation shell, and the other end of the steam riser penetrates through the heat exchanger condensation shell, and communicates with the top end of the condensation pipe; and the bottom end of the condensation pipe is fixedly provided with and communicates with a return pipe. The heat exchange device is scientific and reasonable and environmentally friendly, has the good effects of waste heat absorption and utilization, and is, and is suitable for promotion and application.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

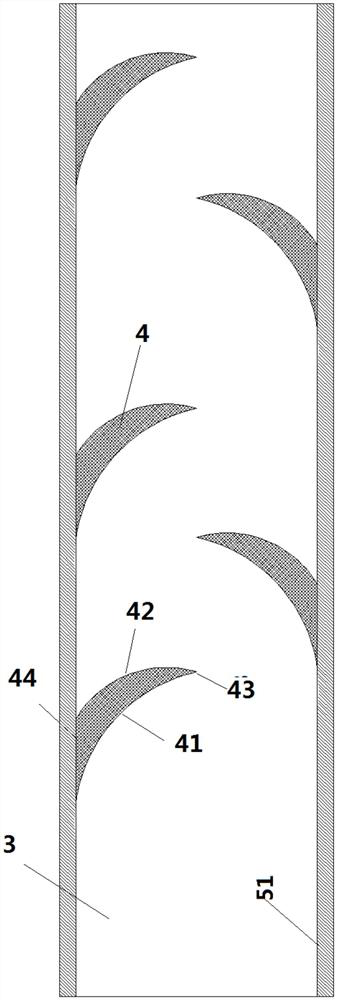

Arc uniform-temperature loop heat tube with variable upstream angle

The invention provides a loop heat tube which comprises an evaporation part, a condensation part, an evaporation tube and a condensation tube, wherein liquid absorbs heat and evaporates at the evaporation part, enters the condensation part through the evaporation tube to release heat, and then returns to the evaporation part through the condensation tube; a plurality of uniform-temperature components are arranged on the inner wall of the evaporation tube in the flowing direction of the steam, and the downstream angle becomes smaller and smaller in the flowing direction of the steam. According to the novel loop heat tube provided by the invention, the downstream included angle is set to be smaller and smaller, so that the flow resistance is reduced, and the temperature equalizing effect achieves the basically same effect on the aspects of resistance reduction and material cost saving.

Owner:青岛乾福圣耀商贸有限公司 +1

Evaporator and heat absorber of separated gravity hot pipe

InactiveCN101029803BImprove heat transfer coefficientImprove heat transfer effectIndirect heat exchangersRefluxEvaporation duct

It's a kind of evaporator of separating gravity heat pipe, which can make reflux condensed fluid in the hot pipe distribute uniformly on the evaporating pipe, and form falling film evaporation. The essentials of technological scheme are that the evaporator includes at least two evaporation tubes (1) and a upper header, and the part of the evaporation tube (1) in which there are liquid inlet holes(1.1) trends into the upper header (2), the upper ends of evaporators are the same height, so are the liquid inlet holes (1.1); outlet steam (2.1) and liquid inlet opening (2.2) are installed on the upper header; the openings of the evaporator (1) can be in its lower end, and all connect with sub-header; the evaporator (1) can be sealed in its lower end.

Owner:庞立升

Heat dissipation cabinet and communication equipment

PendingCN114007372AIncrease the number of slotsMuch layoutModifications using liquid coolingAir volumeThermodynamics

The embodiment of the invention relates to the technical field of heat dissipation, and relates to a heat dissipation cabinet and communication equipment. The heat dissipation cabinet is characterized in that: a first accommodating area of a cabinet body can accommodate a plugboard in a stacked manner, and a heat source device of the plugboard dissipates heat through a heat dissipation device; an evaporator, a condenser, an evaporation pipeline and a liquid return pipeline of the heat dissipation device are connected to form a heat exchange loop, the evaporator is in thermal contact with the outer surface of the heat source device, and the condenser is arranged in the second containing area and located above the evaporator; circulating flow of a refrigerant in the heat exchange loop is achieved, heat of a heat source device is pulled to the condenser, the heat of the condenser is taken away through blowing of a draught fan, and concentrated heat dissipation is achieved; a second accommodating area serves as an independent air duct, the air duct path is short, the air volume can be increased, and system resistance is reduced; the size of the condenser is increased, the heat dissipation area of convective heat exchange is increased, and the heat dissipation capacity is improved; and the condenser is moved out of the plugboard and serves as a heat dissipation resource pool, and the situation that the heat dissipation area of a radiator is limited by slot space and heat dissipation is poor due to uneven slot air volume is overcome.

Owner:HUAWEI TECH CO LTD

Automatic descaling device

InactiveCN110793381AImprove descaling efficiencyHigh removal rateNon-rotary device cleaningTool bitDrive wheel

The invention relates to an automatic descaling device. When liquid prone to scale formation is disposed through a falling film evaporation device, an evaporation pipe is often blocked by too much scale. According to an existing disposal method, the falling film evaporation device of an MVR evaporator is started to perform manual descaling on the evaporation pipe, workload is high and shutdown isneeded, so production efficiency is reduced and production cost is improved. A motor, a driving wheel, an upper guide wheel and a lower guide wheel are arranged, a tool bit is connected between the upper guide wheel and the lower guide wheel through a steel wire, tool edges are formed at the upper end and the lower end of the tool bit, and a guide hole is formed in the tool bit, so the steel wirecan penetrate through the guide hole; a guide conical head is arranged at the lower portion of the tool bit; and in this way, descaling can be performed on the evaporation pipe any time without shutdown for manual cleaning, the evaporation pipe can hardly be blocked by the liquid prone to scale formation, and production efficiency is effectively improved. The automatic descaling device is mainly used for descaling of the MVR evaporator.

Owner:常州市华恩服装机械厂

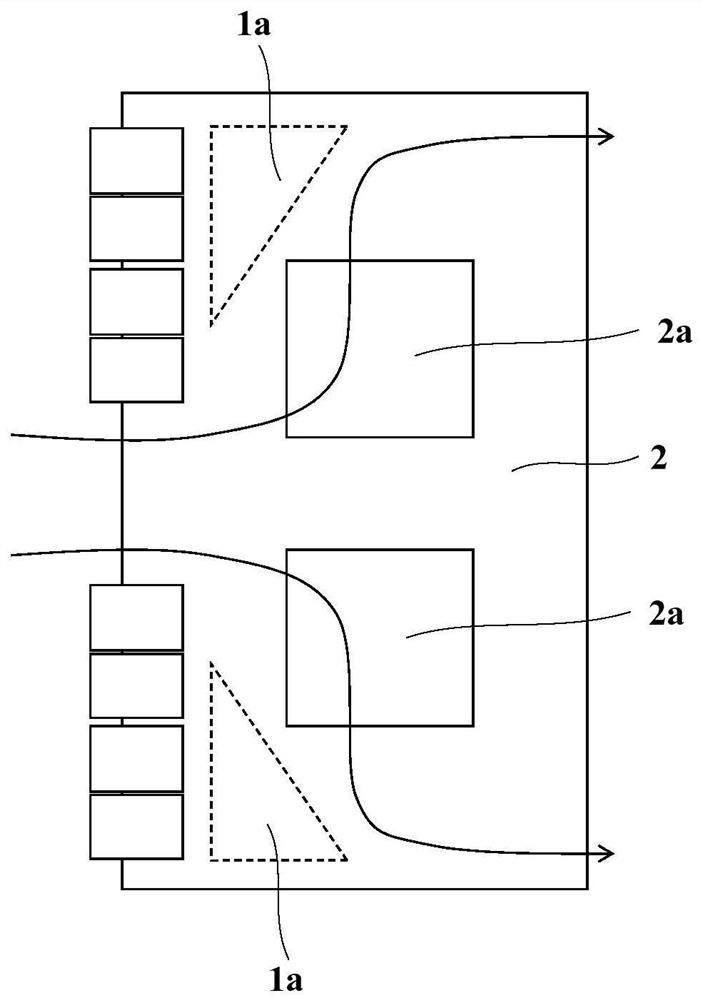

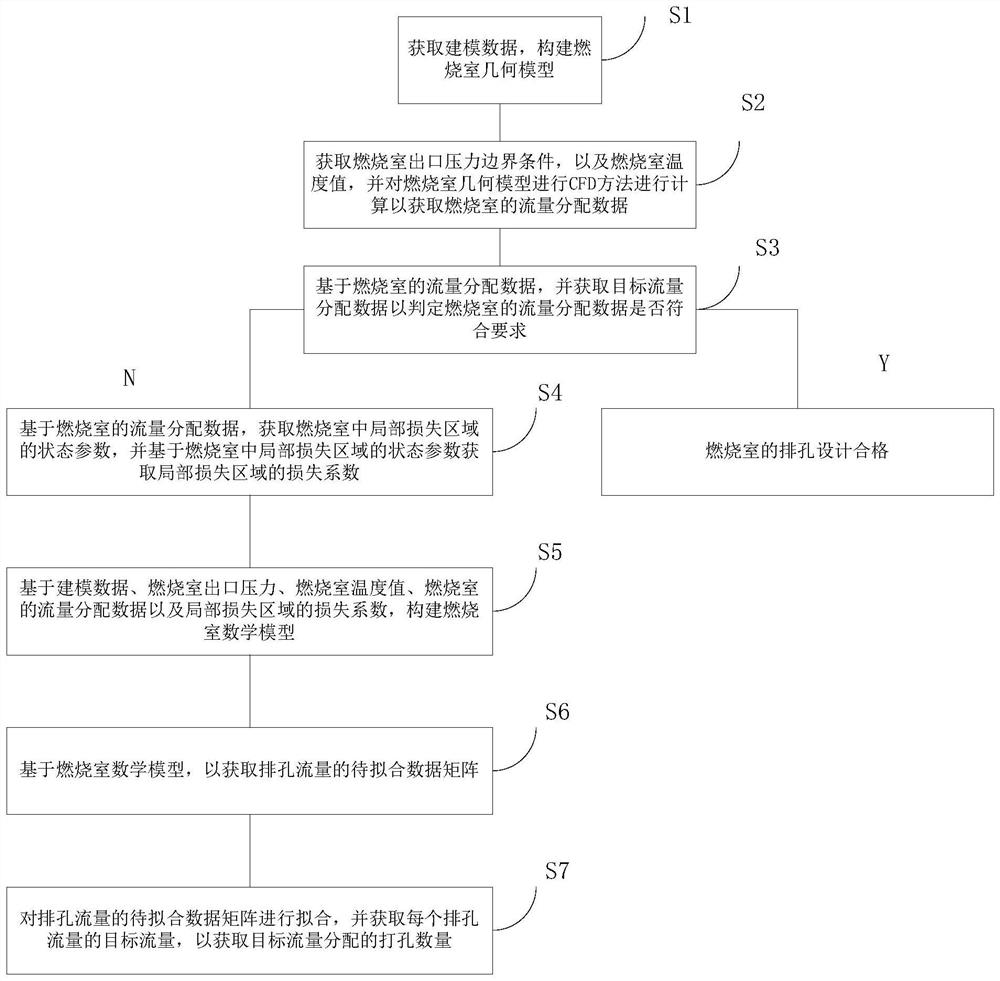

Flow distribution design method and device for micro evaporation tube type combustion chamber

ActiveCN111859505AAlleviate the technical problems of long calculation time and high simulation costGeometric CADSpecial data processing applicationsThermodynamicsCombustion chamber

The embodiment of the invention provides a flow distribution design method and device for a micro evaporation tube type combustion chamber, and relates to the technical field of combustion chamber designs. The method comprises: obtaining modeling data, and constructing a combustion chamber geometric model; calculating the combustion chamber geometric model through a CFD method to obtain flow distribution data of the combustion chamber, and obtaining target flow distribution data based on the flow distribution data of the combustion chamber to judge whether the flow distribution data of the combustion chamber meets requirements or not; if not, executing flow distribution data based on the combustion chamber, obtaining state parameters of a local loss area in the combustion chamber, and obtaining a loss coefficient of the local loss area based on the state parameters of the local loss area in the combustion chamber; and constructing a combustion chamber mathematical model, obtaining andfitting a to-be-fitted data matrix of the discharge hole flow, and obtaining the punching number distributed by the target flow. The technical problems of long calculation time and high simulation cost of a perforation flow rule method in the prior art can be solved.

Owner:CIVIL AVIATION UNIV OF CHINA

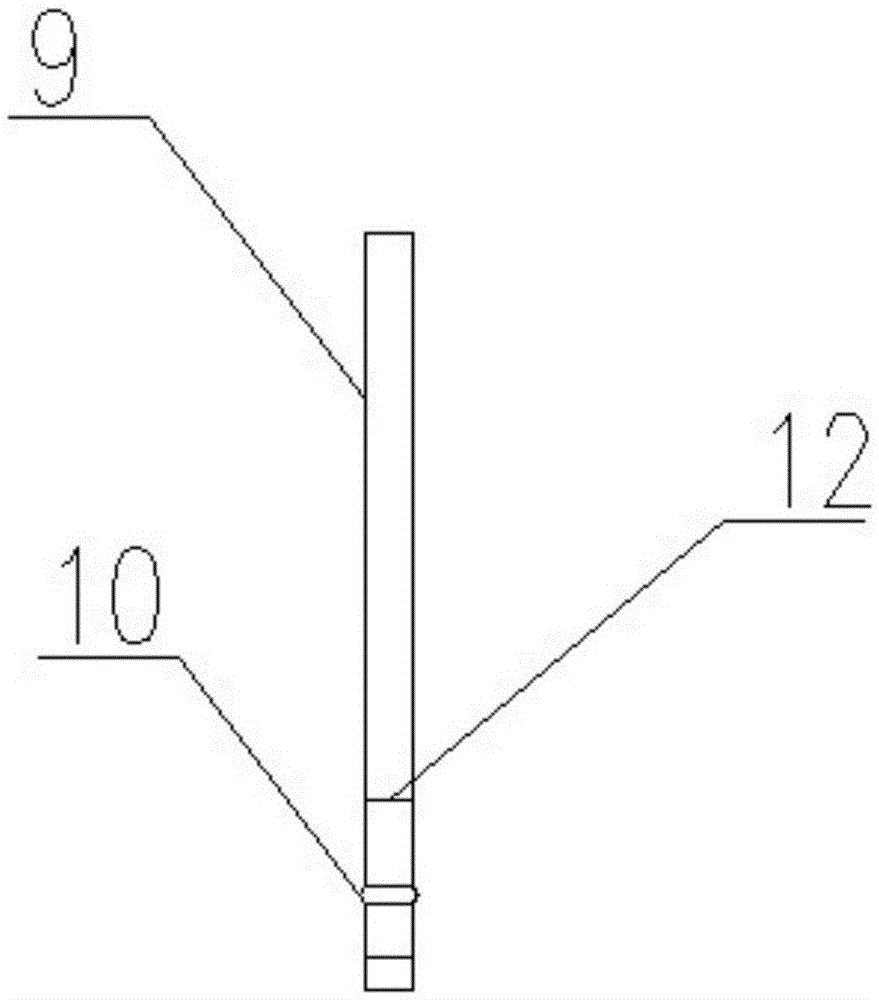

Evaporator

ActiveCN103673409BNot easy to damageLow costEvaporators/condensersBiochemical engineeringEvaporation duct

The invention relates to an evaporator which comprises evaporating pipes, a first fin group, a second fin group, a liquid storage barrel, a first copper aluminum pipe and a second copper aluminum pipe. The evaporator is characterized in that the evaporating pipes are in a bending spiral shape, one end of each evaporating pipe is directly connected with one end of the first copper aluminum pipe, the other end of the first copper aluminum pipe is connected with a transition pipe, the other end of each evaporating pipe is connected with one end of the liquid storage barrel, the other end of the liquid storage barrel is connected with the second copper aluminum pipe, a deforming pipe is arranged in the liquid storage barrel, one end of the deforming pipe is fixedly connected with one end, connected with each evaporating pipe, of the liquid storage barrel, each evaporating pipe is connected with the first fin group in a clamping mode, the second fin group is arranged on one side where the liquid storage barrel is placed and is connected with at least four evaporating pipes in a clamping mode, fins of the second fin group and the first fin group are arrayed in a gap-staggering mode, hanging plates are arranged on the two sides of each evaporating pipe, and the hanging plates are parallel to the fins of the first fin group. The evaporator has the advantages of being good in radiating effect, even in cooling and the like.

Owner:CHANGZHOU CHANGZHENG EVAPORATOR

Heat pump pre-cooling waste heat recovery system before throttling of integrated heat pump water heater

InactiveCN102287973AReduce the temperatureReduce descent speedFluid heatersHeat recovery systemsEvaporation ductRefrigerant

The invention relates to a heat pump pre-cooling waste heat recovery system before throttling of an integrated heat pump water heater, which includes a condenser, a throttle valve and an evaporator. The output port of the device is connected with the input port of the condensing pipe added in the evaporator through the pipeline, the output port of the condensing pipe added in the evaporator is connected with the input port of the throttle valve through the pipeline, and the output port of the throttle valve is connected through the pipeline It is connected with the input port of the evaporation tube of the evaporator. The invention can effectively reduce the temperature of the refrigerant before throttling, improve the evaporation efficiency of the refrigerant after throttling, and recover the waste heat of the condensed refrigerant through the evaporator, thereby reducing the heat loss of the system. These two advantages ensure that the heat pump water heater always maintains an ideal energy efficiency ratio during the entire process of water temperature rise, and the drop rate of the COP value is significantly reduced.

Owner:德华科电器科技(安徽)有限公司

Evaporating pipe atomization device and combustion chamber

ActiveCN114110659AImprove evaporation efficiencyImprove evaporation effectContinuous combustion chamberCombustion chamberFuel oil

According to the technical scheme, the evaporation pipe atomization device is characterized by comprising an evaporation pipe, the evaporation pipe comprises a single inlet and two or more outlets, the bottom of the evaporation pipe is provided with a rolling-ball-shaped cavity, and the diameter of the rolling-ball-shaped cavity is the same as the inner diameter of the inlet of the evaporation pipe. The problems that in a small and medium-sized aero-engine evaporation pipe combustion chamber, fuel oil in an evaporation pipe is insufficiently heated, the atomization effect is poor, the fuel oil liquid drop evaporation rate is low, the combustion efficiency is low, fuel oil steam and air are insufficiently mixed, partitioned combustion is difficult to achieve, and the outlet temperature field adjusting difficulty is high are solved.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Air conditioner unit and air conditioning system

InactiveCN111928391AReduce lossImprove evaporation efficiencyHeating and ventilation casings/coversEvaporators/condensersVapor–liquid separatorWater vapor

Owner:深圳市中鼎空调净化有限公司

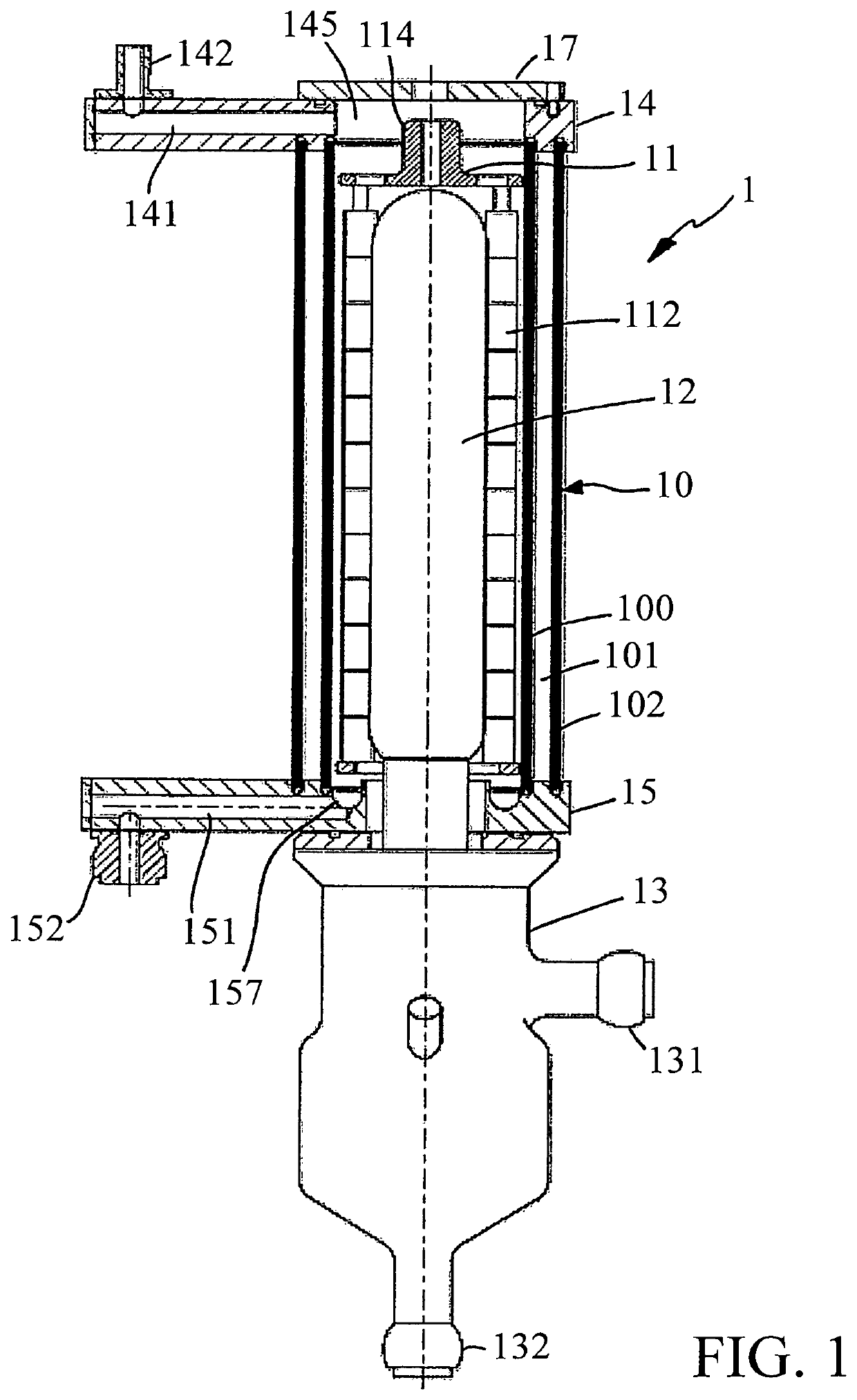

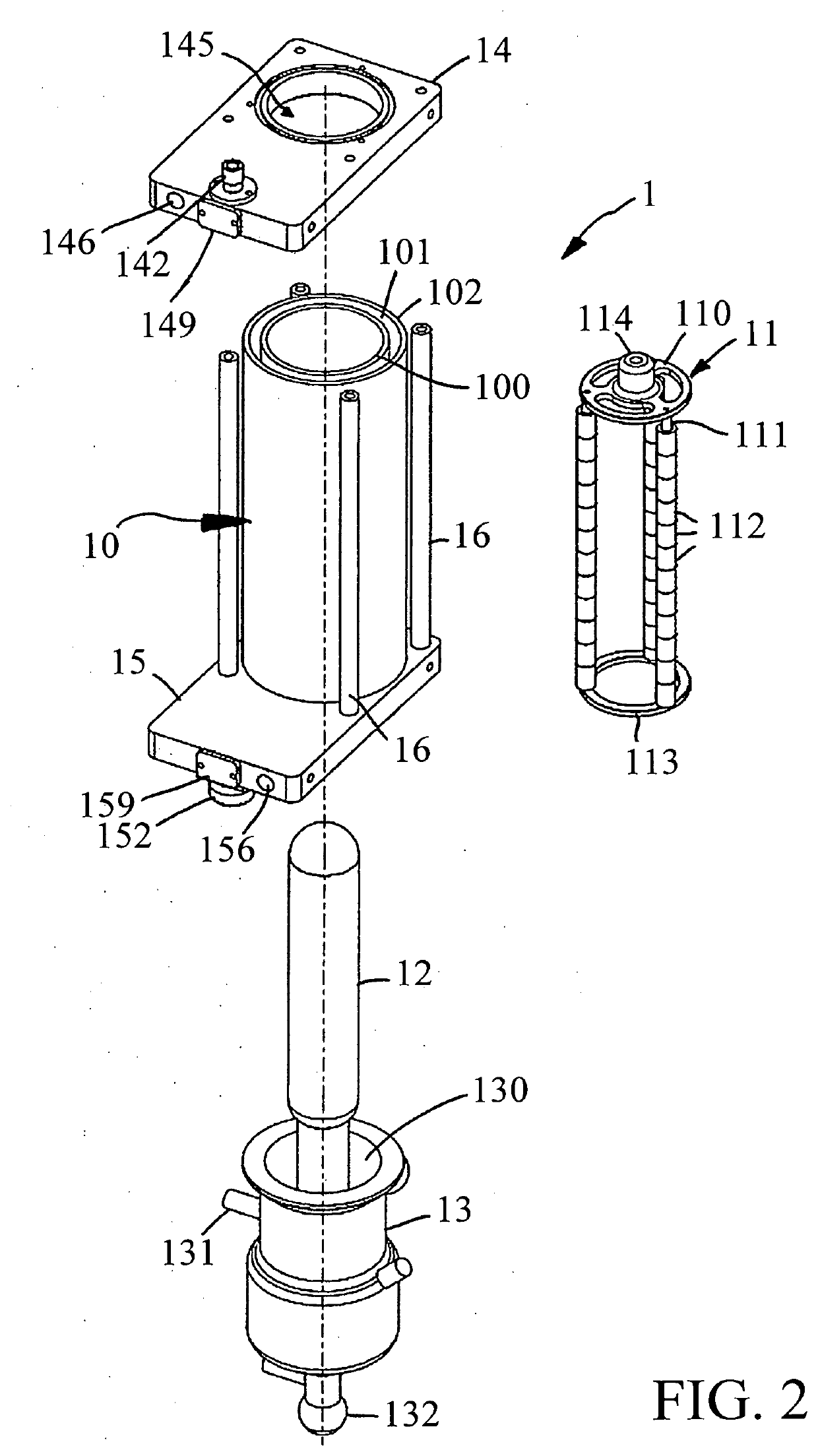

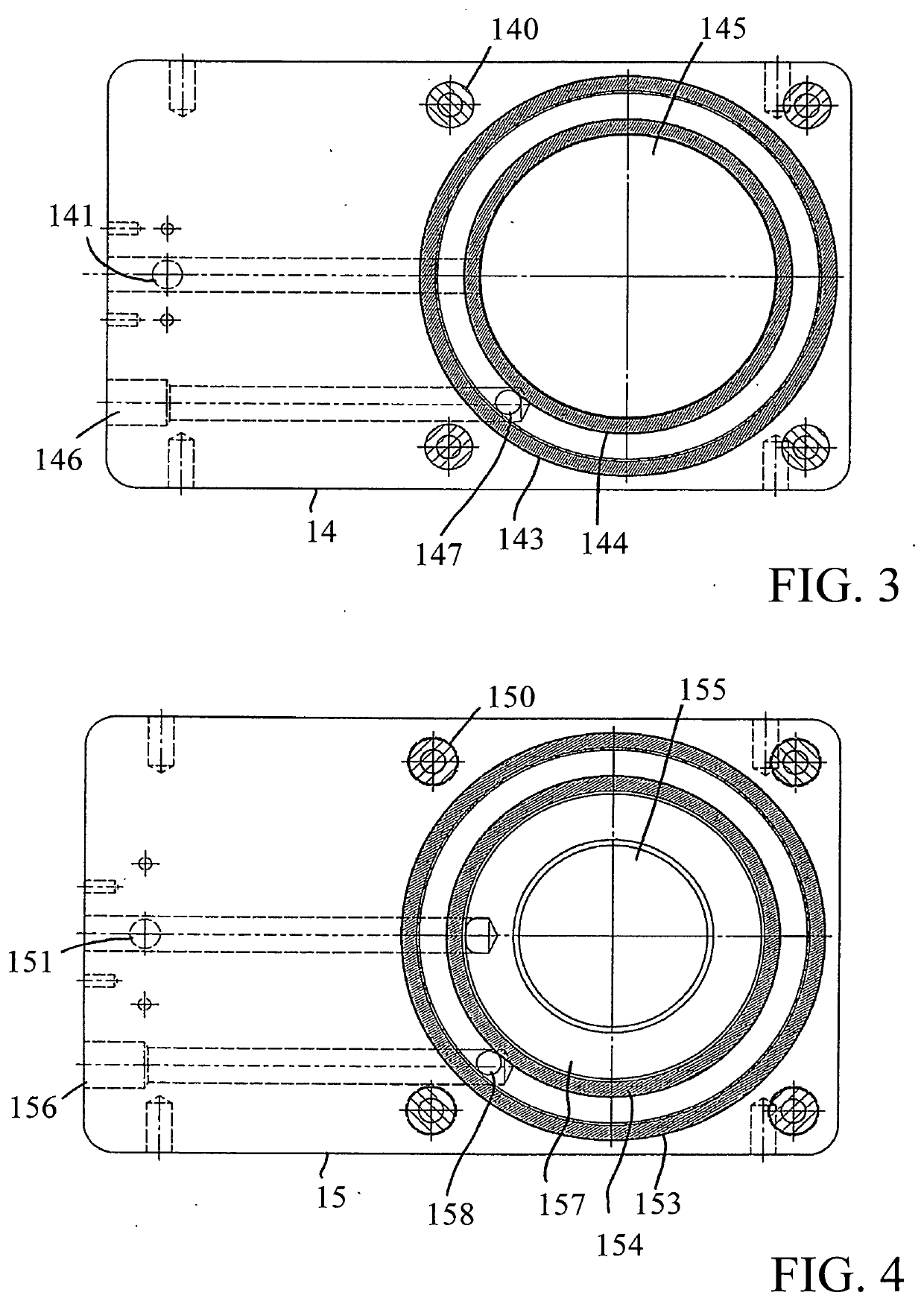

Short-path evaporator

ActiveUS20200306659A1Simple structureEasy to manufactureVapor condensationEvaporators with vertical tubesInterior spaceEvaporation duct

A short path evaporator including a heatable double-walled evaporator pipe having an inner interspace, with a rotatable rotor system disposed within the evaporator pipe and with a condenser disposed centrally in the evaporator pipe, and with an inlet for a product leading into the evaporator pipe, an outlet for a concentrate of the product leading out of the evaporator pipe, and an outlet for distillate accumulating at the condenser, and an inlet and an outlet for supplying and discharging heating medium to or from the interspace of the evaporator pipe, wherein the evaporator pipe is formed by an outer pipe and an inner pipe which, leaving the interspace, is disposed within the outer pipe, which are fixed at their ends in a sealing manner between two flange plates clamped together, wherein an inlet channel for the inlet of the product and an outlet channel for the outlet of the concentrate, which communicate with the interior of the inner pipe, are formed in the flange plates, as well as inlet and outlet channels for supplying and discharging the heating medium, which communicate with the interspace.

Owner:BUBLIES JULIAN ALEXANDER

Trans-horizon wireless communication system using the tropospheric evaporation duct

ActiveUS10756783B2Improve availabilityIncrease capacitySite diversitySpatial transmit diversityTransceiverControl theory

Owner:GASOLINEIAM NASIONAL BERHAD

In-tube evaporator

InactiveCN102661668AImprove heat transfer effectLow flow resistanceEvaporators/condensersStationary conduit assembliesInstabilityEngineering

The invention discloses an in-tube evaporator, which comprises a liquid distribution tube, evaporation tubes and an air outlet tube, wherein the liquid distribution tube is filled with a porous structural matter; one end of each evaporation tube is in close contact with the porous structural matter of the liquid distribution tube; the diameter of the air outlet tube is greater than the diameter of each evaporation tube or the sum of the diameters of a plurality of evaporation tubes, but does not exceed three times the sum of the diameters of the evaporation tubes; the porous structural matter is a metal particle sintered layer or a multi-layer metal mesh; the metal particle sintered layer is made of metal particles of 30-70 mum; the multi-layer metal mesh is a metal mesh of 200-400 meshes; and each evaporation tube is a metal sintered tube or a metal fluted tube. According to the in-tube evaporator, liquid is uniformly arranged in the evaporation tubes by using capillary force of a porous structure in the liquid distribution tube, and a thin film evaporation flow pattern is formed. Since only one thin film evaporation flow pattern exists in the evaporation tube, the in-tube evaporator has an excellent heat exchange effect, and the flow resistance and the instability in operation are greatly reduced.

Owner:DALIAN MARITIME UNIVERSITY

Aluminum alloy evaporating pipe for freezing device

InactiveCN104913581AEasy to shareGood frozen qualityEvaporators/condensersRefrigeration devicesMetallurgyEvaporation duct

The invention discloses an aluminum alloy evaporating pipe for a freezing device. The aluminum alloy evaporating pipe comprises a pipe body molded from an aluminum alloy material, wherein the pipe wall of the pipe body consists of a top wall, a bottom wall and two side walls; the width of the bottom wall is smaller than that of the top wall; the outer surface of the top wall is a smooth plane; a to-be-frozen object is directly placed on the outer surface of the top wall; a first fin structure is arranged on the inner side surface of the top wall; the outer surfaces of the two side walls are both of structures which are protruded towards the interior of the pipe body in the shape of arc. The aluminum alloy evaporating pipe for the freezing device, provided by the invention, has the characteristics of large heat exchange area, high heat exchange efficiency and the like.

Owner:福州开发区引射低温制冷技术有限公司

Efficient and rapid film evaporator

ActiveCN112619191AImprove heat transfer efficiencyEvenly distributedEvaporator accessoriesEvaporators with forced circulationThin membraneEngineering

The invention provides an efficient and rapid film evaporator which comprises a shell, an evaporation pipe set, an exhauster and a flow divider, the evaporation pipe set is arranged in the shell, the exhauster is rotationally arranged on evaporation pipes of the evaporation pipe set, and the flow divider divides liquid ammonia entering an evaporation chamber. The exhauster mounted on the evaporation pipes is driven to rotate by force generated by flowing of liquid ammonia from bottom to top, so that gas formed by evaporation of a liquid ammonia film on the evaporation pipes can be quickly dissipated, gas blocking is avoided, subsequent liquid ammonia quickly forms a new liquid ammonia film on the evaporation pipes, the heat exchange efficiency of the evaporation pipes is improved, and the energy consumption of the evaporation pipes is reduced. In cooperation with the flow dividing effect of the flow divider on the liquid ammonia, the liquid ammonia is distributed more uniformly, and the technical problem that gas hinders the liquid in the gas-liquid transferring process is solved.

Owner:SHANGHAI WANXIANG REFRIGERATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com