Direct expansion type evaporator device of complete fresh air unit

A direct-expansion, evaporator technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as shortening the service life of compressors, and achieve the effect of prolonging the service life and improving the operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

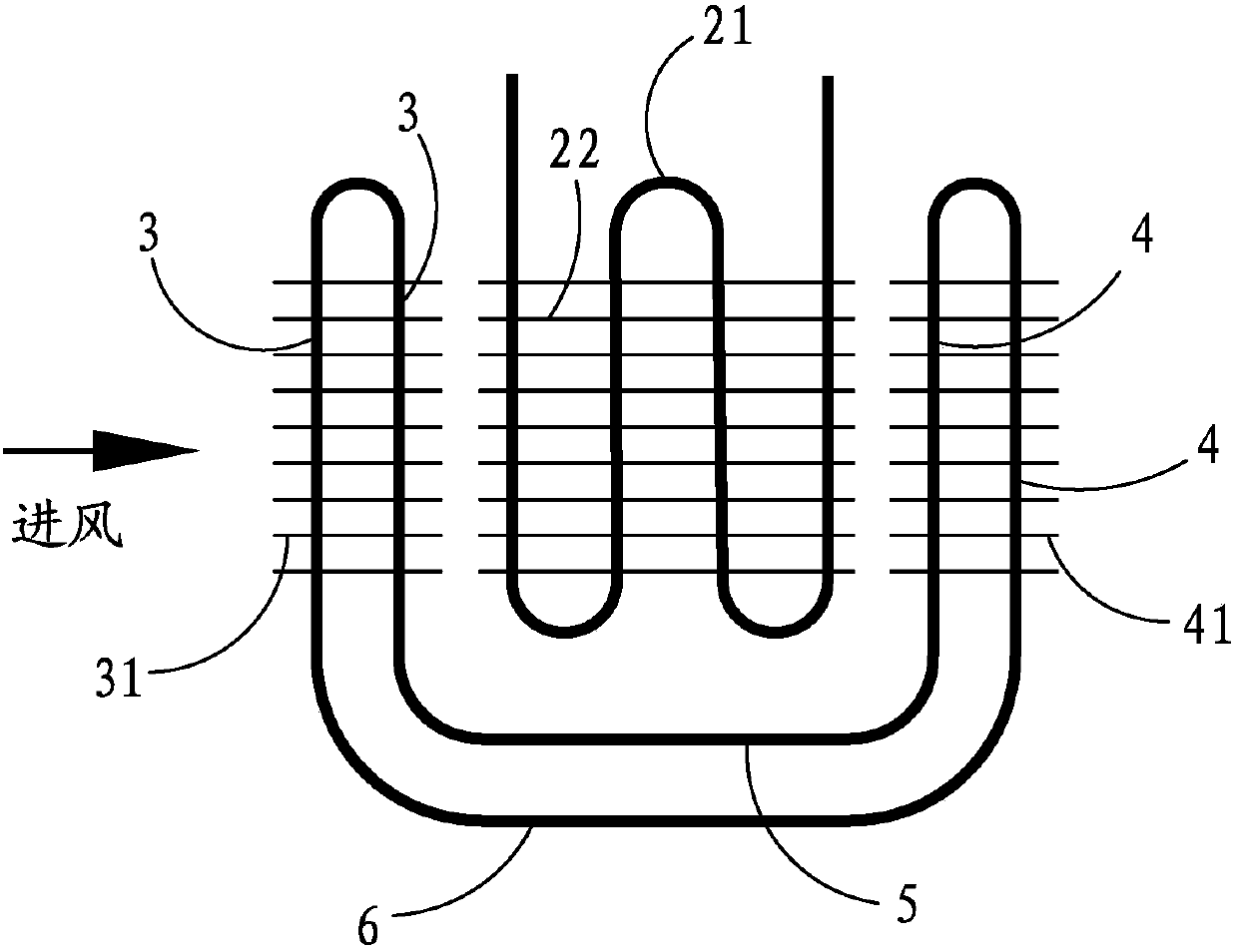

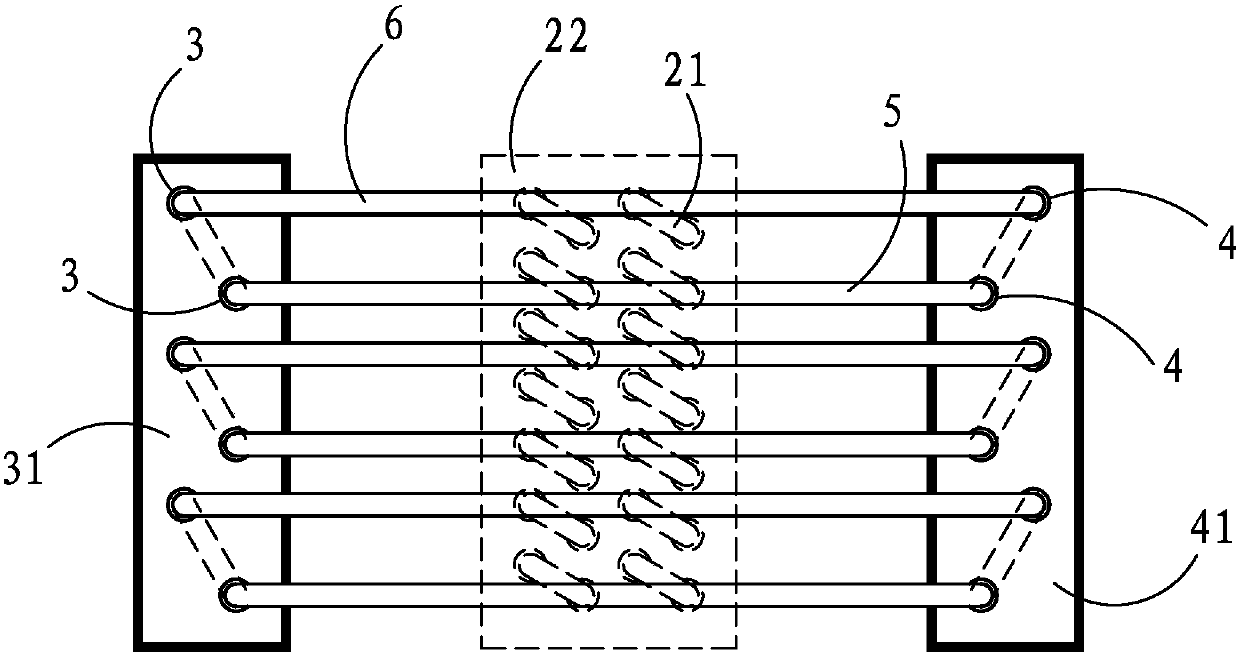

[0023] Embodiment one: see attached figure 1 , 2 , 4, a direct-expansion evaporator device for a fresh air unit, which includes an air duct 1 and a direct-expansion evaporator arranged in the air duct 1, and also includes three heat pipe assemblies, (in other embodiments , any number of heat pipe assemblies can be used) The heat pipe assembly includes an evaporation coil composed of at least two heat pipe evaporator pipes 3, a condensation coil composed of at least two heat pipe condenser pipes 4, and heat pipe steam pipes respectively connected to the evaporation coil and the condensation coil. Pipe 6, and the heat pipe return pipe 5 respectively connected to the evaporating coil and the condensing coil. On the air outlet side of the type evaporator, the evaporating coil, the condensing coil, the heat pipe steam pipe 6 and the heat pipe liquid return pipe 5 form a heat pipe loop and the internal pipes form a closed cavity.

[0024] A working fluid is arranged in the airtigh...

Embodiment 2

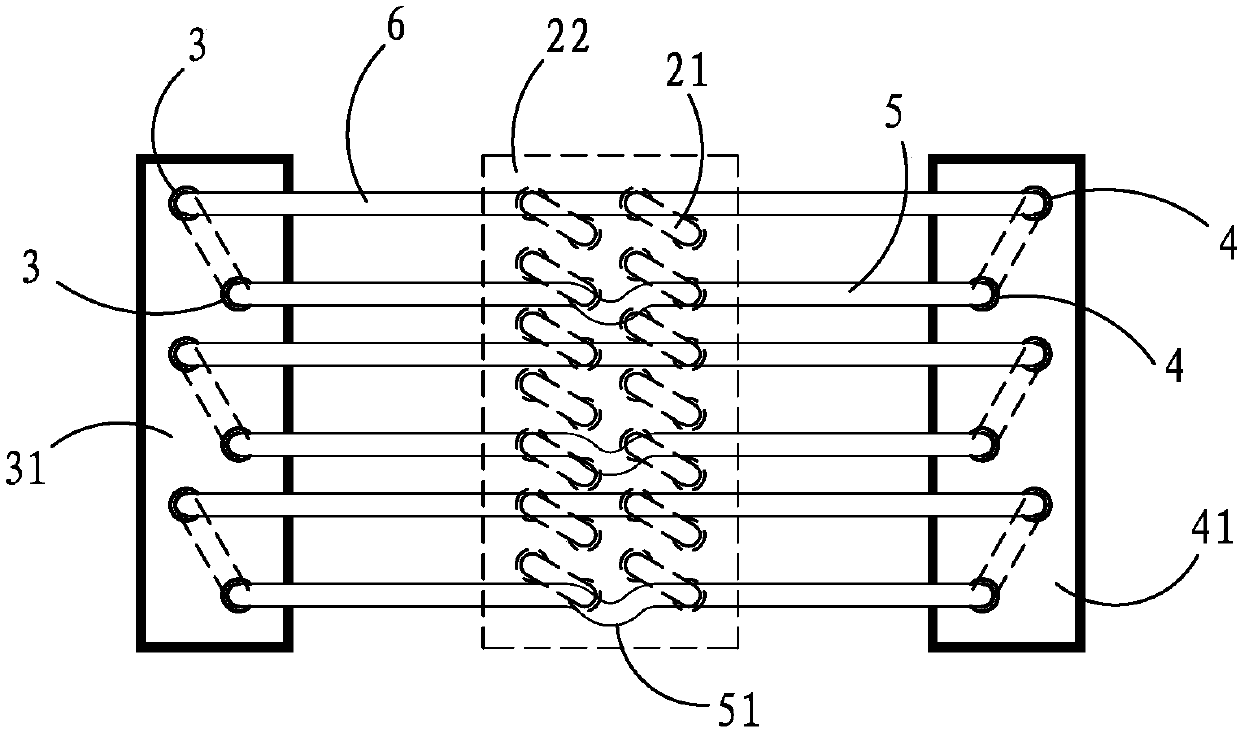

[0032] Embodiment two: see attached figure 1 , 3 , 4, this embodiment is basically the same as Embodiment 1, the difference is that: the heat pipe steam pipe 6 and the heat pipe liquid return pipe 5 are all arranged horizontally, the heat pipe liquid return pipe 5 has a concave curved portion, and the curved portion The height of the upper pipe wall is lower than the height of the lower pipe wall of other parts of the heat pipe liquid return pipe 5 . The bending part is always filled with liquid working medium, which can ensure that all the vaporized working medium in the evaporation coil passes through the steam pipe 6 of the heat pipe and enters the condensation coil.

[0033] Compared with the prior art, the foregoing embodiment has the following advantages:

[0034] 1. In the fresh air air conditioning unit of the above embodiment, the temperature of the airflow entering the direct expansion evaporator is reduced through the heat pipe assembly, which improves the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com