Evaporator and heat absorber of separated gravity hot pipe

A gravitational heat pipe and evaporator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large liquid inflow, unfavorable heat transfer, and large liquid working mass, etc. good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

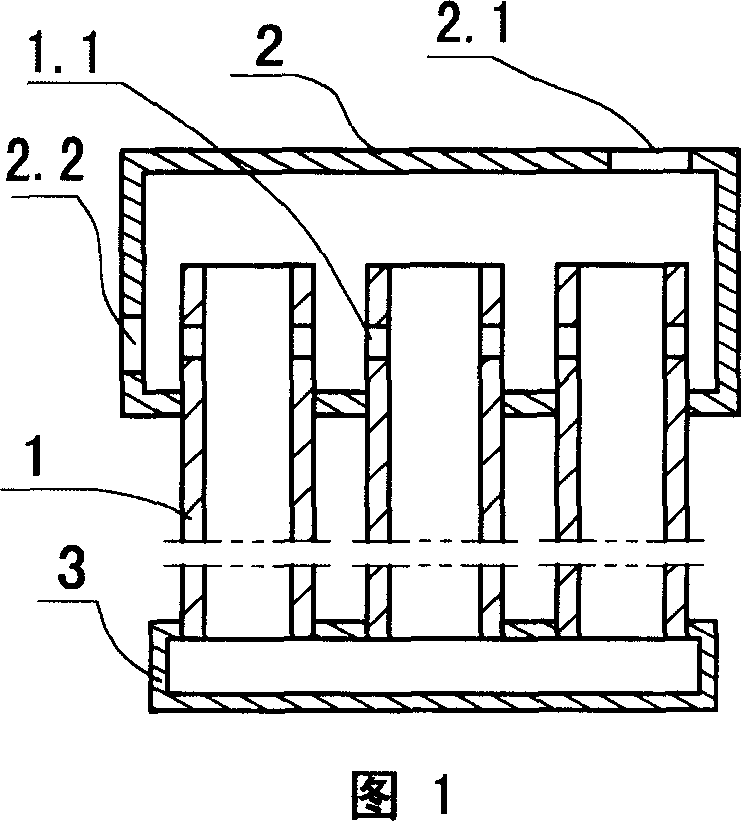

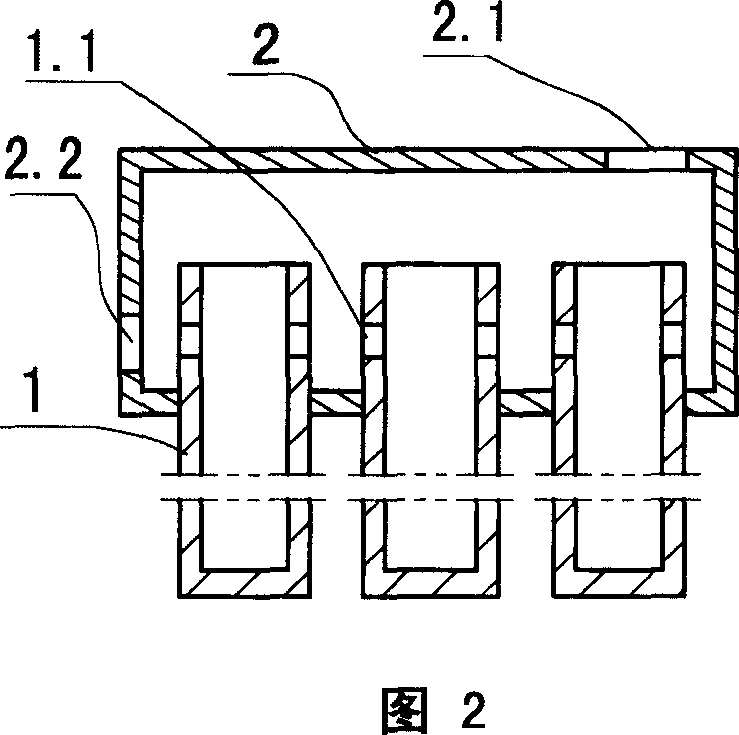

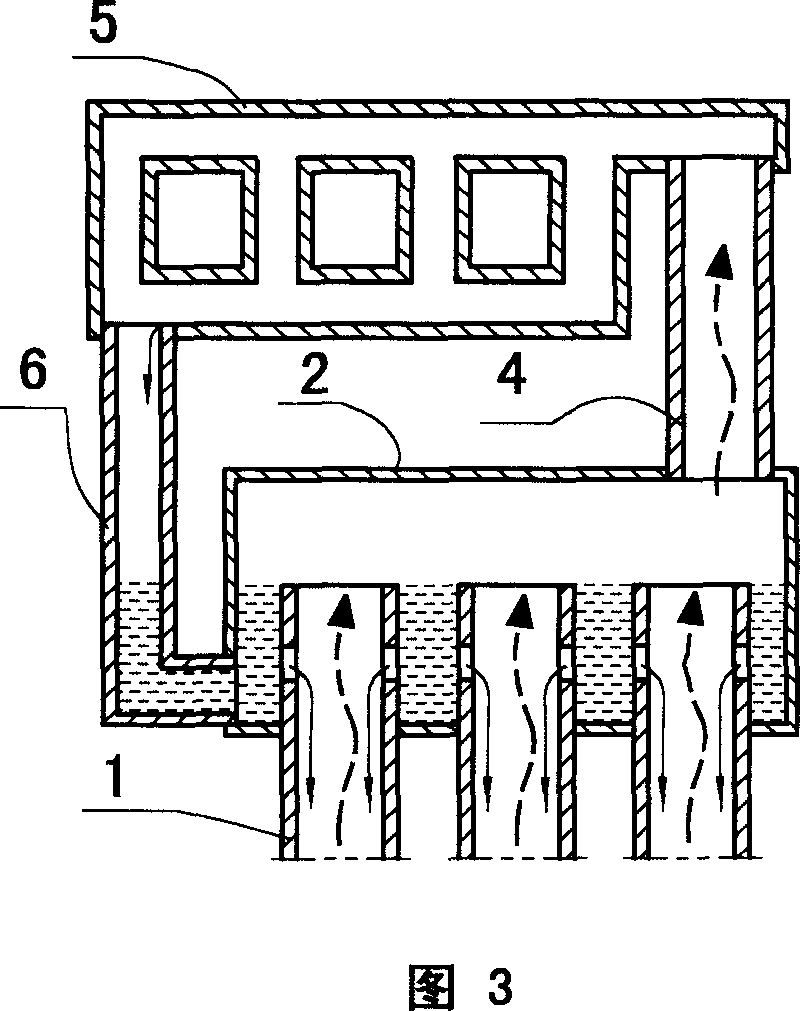

[0039] The evaporator adopting technical scheme A or technical scheme B is used for the separated heat pipe system, the steam outlet (2.1) of the evaporator is connected with the steam rising pipe (4) of the heat pipe system, and the liquid inlet (2.2) of the evaporator is connected to the heat pipe The liquid return pipe (6) of the system is communicated, as accompanying drawing 3. Evaporator can adopt any form shown in accompanying drawing 1, accompanying drawing 2.

[0040] If there is no error during implementation, it can be ensured that the upper ports of all the evaporation tubes (1) are at the same height, and it can be used in occasions where the heat load is fixed or where the heat load varies.

[0041] If there is an error during implementation, it can be used in situations where the thermal load changes within a certain range, and is described with technical solution A. In contrast to what is stated in the "Content of the Invention" of this manual, the position of...

Embodiment 2

[0048] Adopt technical scheme C or technical scheme D heat pipe type heat absorber. For the occasion of fixed heat load, the heat pipe heat absorber of technical scheme C or technical scheme D is feasible.

[0049] If there is no error during implementation, it can be ensured that the upper ports of all the evaporation tubes (1) are at the same height, and it can be used in occasions where the heat load is fixed or where the heat load varies.

[0050]If errors occur during implementation, it can be used in situations where the heat load varies within a certain range. The analysis of the technical solution C is the same as that of the technical solution A of the first embodiment.

[0051] In the case of small full load, when the implementation is prone to errors, technical scheme D should be adopted, and a capillary fabric block (12) can be arranged at the bottom of the upper header (2), and the capillary fabric strip (8) and the capillary fabric block (12 ) braided together. ...

Embodiment 3

[0055] As shown in accompanying drawing 10, the technical scheme is: multiple evaporators of the separated gravity heat pipe of the present invention are matched with a condenser to form a separated heat pipe system, with a liquid distribution box (10) and several liquid distribution pipes ( 9) Evenly distribute the reflux liquid of the condenser to each evaporator. The specific pipeline is that the steam outlet (2.1) of each evaporator is connected to a steam rising pipe (4), and the steam rising pipes (4) of all evaporators are connected to the steam main pipe (11), and the steam main pipe (11) is connected to the condensing pipe. The steam inlet of the condenser; the liquid outlet of the condenser is connected to the liquid return pipe (6), and the other end of the liquid return pipe (6) is connected to the liquid distribution tank (10); the upper ends of several liquid distribution pipes (9) extend into the liquid distribution tank (10) In the inner cavity, the liquid dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com