Integrated structure of evaporation tubes, evaporation tube type combustion chamber and miniature turbojet engine

A technology of evaporating tube and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, machine/engine, etc., can solve the problems of temperature field difference at the outlet of combustion chamber, insufficient fuel atomization, large deviation of coaxiality, etc. Improve the coaxiality, enhance the effect of atomization and evaporation, and improve the effect of manufacturing compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

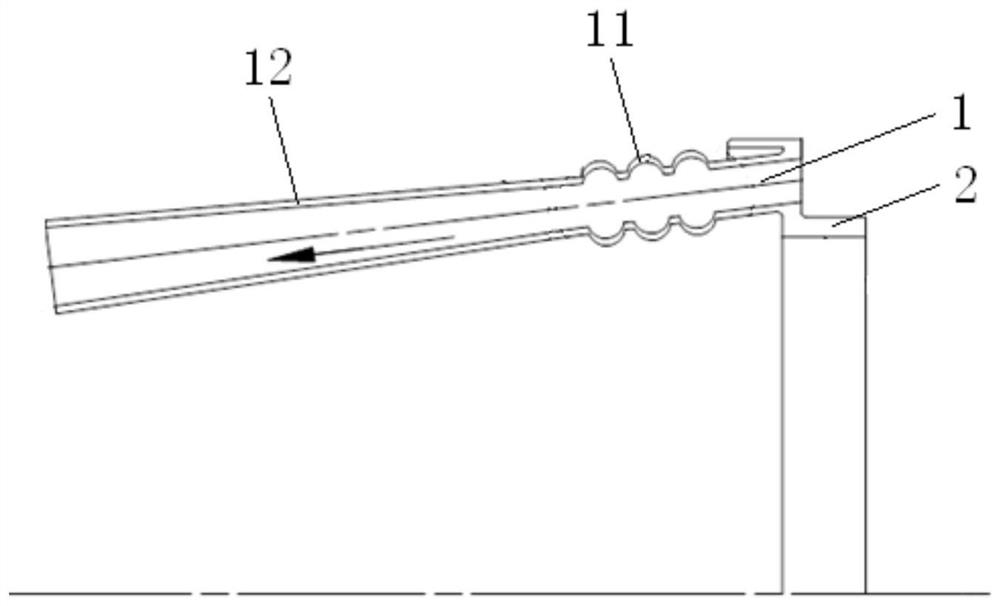

[0024] figure 1 It is a structural schematic diagram of the integrated structure of the evaporation tube in the preferred embodiment of the present invention.

[0025] Such as figure 1 As shown, the integrated structure of the evaporator tube in this embodiment is used to impact and mix the fuel sprayed by the fuel nozzle through the high-speed airflow to form a fuel-air mixture and spray it to the head area of the combustion chamber. The evaporator tube is integrated The structure includes an evaporation tube 1 integrated with the support ring 2 of the combustion chamber. A plurality of evaporation tubes 1 are evenly arranged on the support ring 2 of the combustion chamber along the circumferential direction. The first end of the evaporation tube 1 is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com