Aluminum alloy evaporating pipe for freezing device

A freezing device, aluminum alloy technology, applied in household refrigeration devices, evaporators/condensers, applications, etc., can solve the problem that the bottom of the cold plate and the tube plate are difficult to be in close contact, the unfavorable temperature field is evenly distributed, and the freezing process is reduced and reliable. It can reduce the contact thermal resistance, improve the freezing speed, and prevent aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

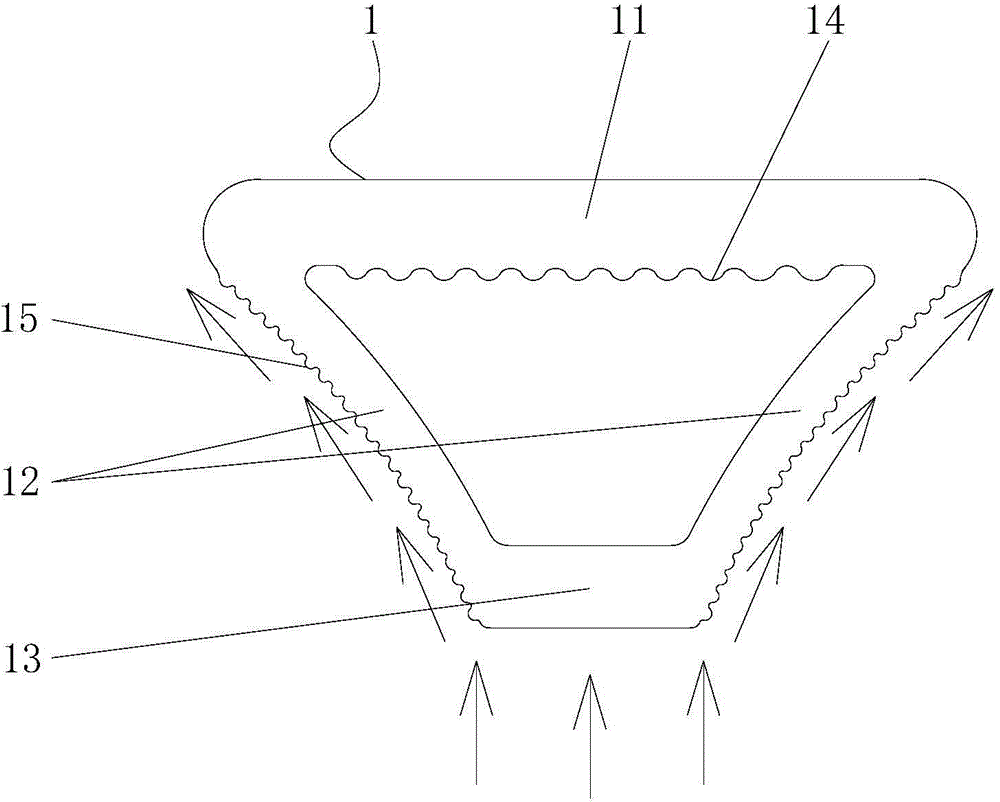

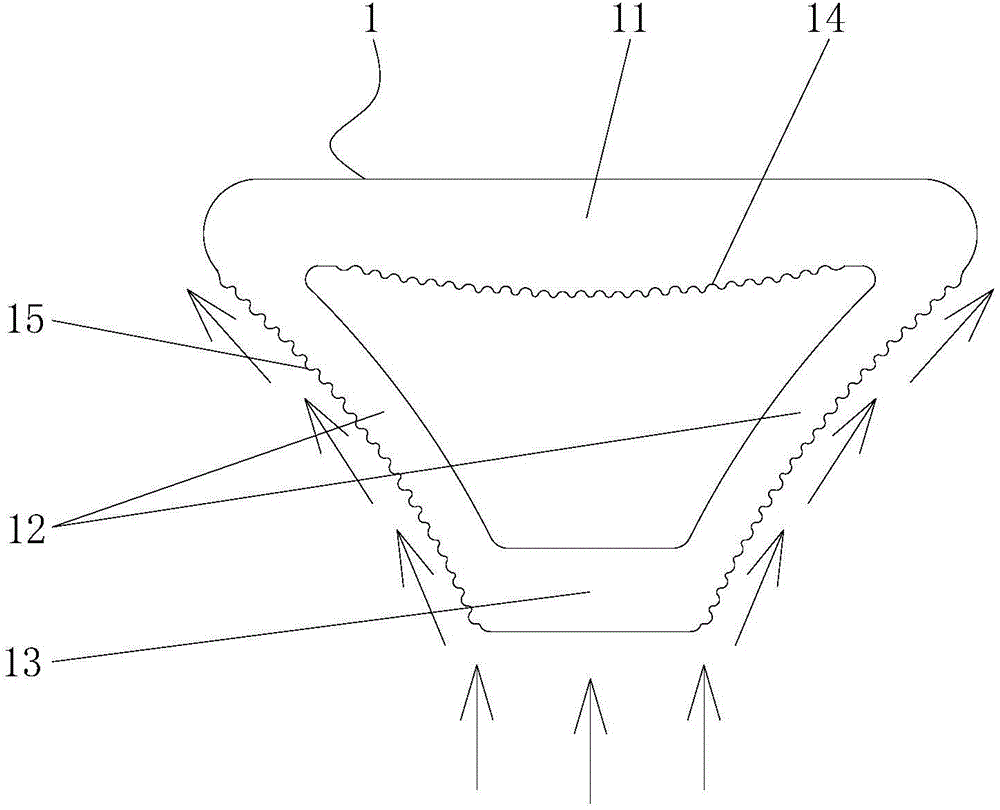

[0020] like figure 1 or figure 2 As shown, the present invention includes a tube body 1 formed by an aluminum alloy material, the inner cavity of the tube body 1 is used for the evaporation of liquid refrigerant, and the tube wall of the tube body 1 is composed of a top wall 11, a bottom wall 12 and two side walls 13, The width of the bottom wall 12 is 1 / 2 of the width of the top wall 11, the outer surface of the top wall 11 is smooth and flat, the outer surface of the bottom wall 12 is also flat, and the cold plate is directly placed on the outer surface of the top wall 11 , the inner surface of the top wall 11 is provided with a first fin structure 14, the outer surfaces of the two side walls 13 are arc-shaped protruding toward the inside of the tube body 1, and the inner surfaces of the two side walls 13 are also curved toward the tube body. 1. The inner arc-shaped convex structure, and the second fin structure 15 is provided on the outer surface of the two side walls 13....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com