Efficient and rapid film evaporator

A thin-film evaporator, fast technology, applied in evaporator accessories, horizontal tube evaporators, forced circulation evaporators, etc., can solve the problems of affecting the heat exchange efficiency of liquids, blocking the contact between liquids and heat exchange tubes, and improving cooling efficiency , Avoid gas blocking, improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

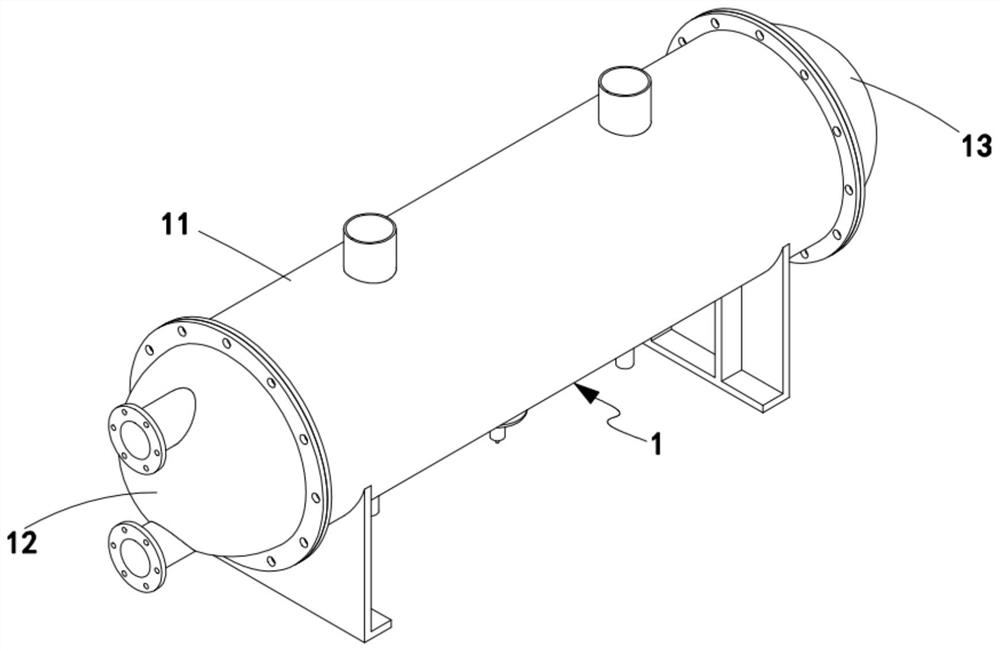

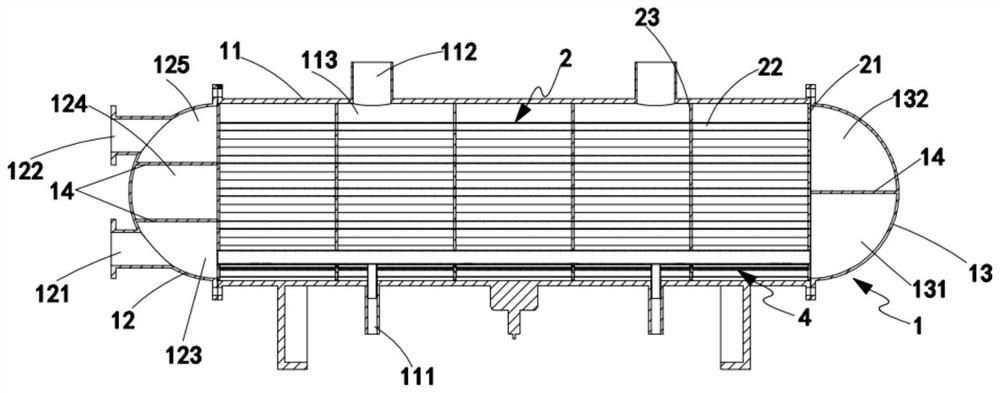

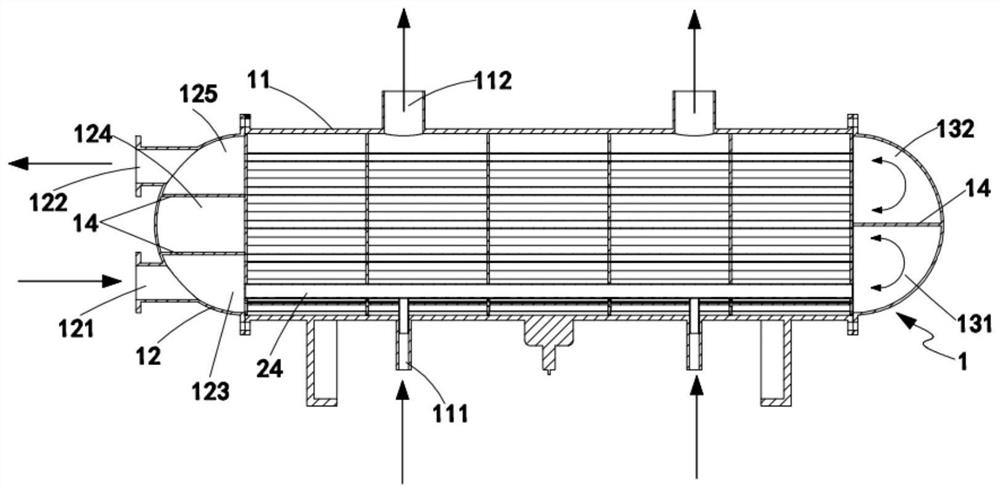

[0042] Such as Figure 1 to Figure 7 As shown, a high-efficiency and fast thin-film evaporator includes a cylindrical shell 1, and an evaporation tube group 2 is arranged inside the shell 1. It is characterized in that the shell 1 includes a cylindrical body 11 with openings at both ends and a sealing The water cover A12 and the water cover B13 are arranged at the openings at both ends of the cylindrical body 11. The bottom of the cylindrical main body 11 is provided with an input port 111 for inputting refrigerant, and the top of the cylindrical main body 11 is provided with an output port. The outlet 112 of the refrigerant, the lower part and the upper part of the water cover A12 are provided with a liquid inlet 121 and a liquid outlet 122 respectively, and two sets of partitions 14 are horizontally arranged in the water cover A12, and the partitions 14 The water cover A12 is divided into a liquid inlet area 123, a transfer area 124 and a liquid outlet area 125 from bottom t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com