In-tube evaporator

A technology of evaporator and evaporating tube, applied in the direction of evaporator/condenser, heat exchanger type, indirect heat exchanger, etc., can solve the problems of small proportion, limited heat exchange effect, unfavorable system operation control, etc. Simple processing, good heat exchange effect, and the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

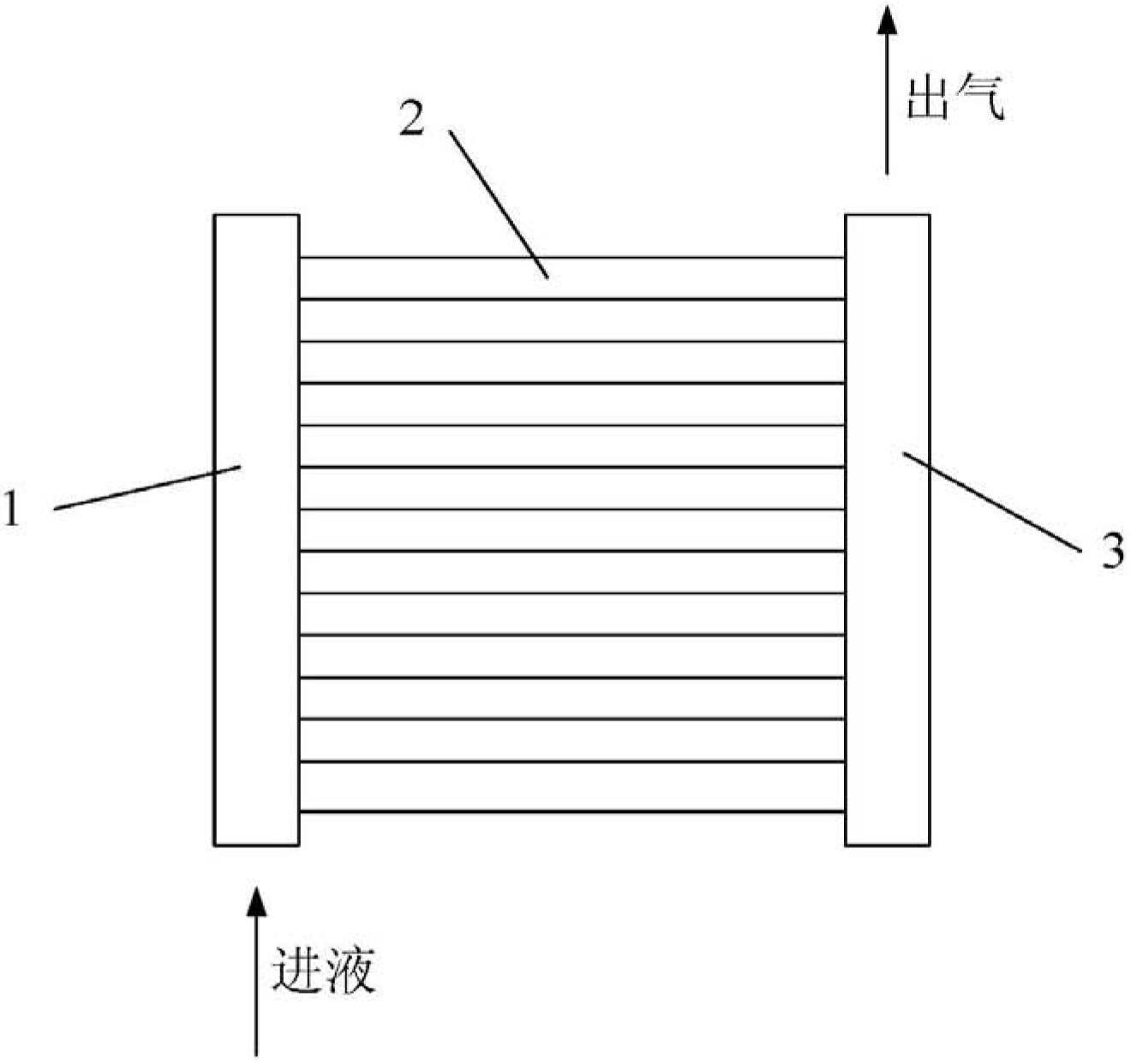

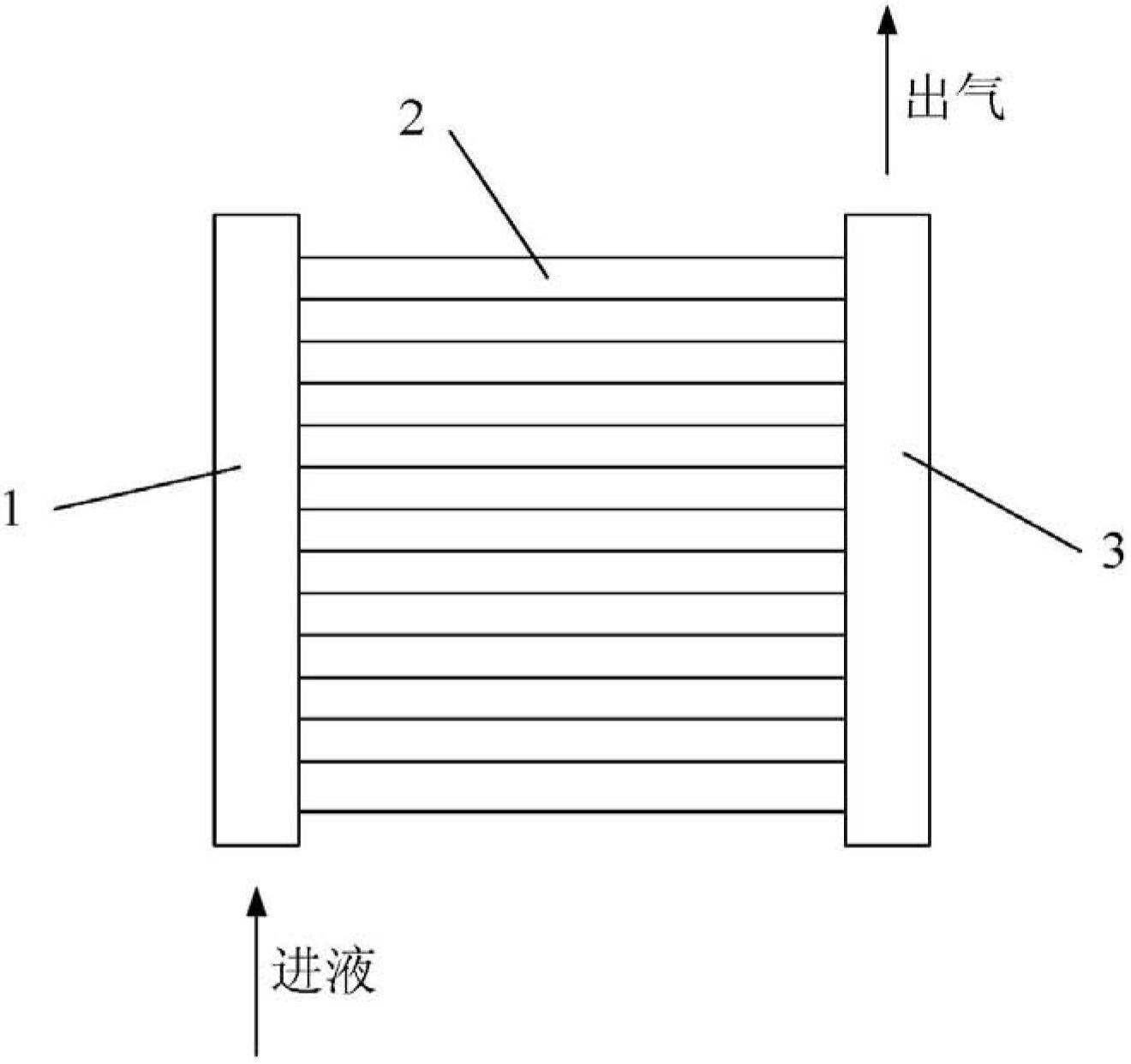

[0012] The present invention is described in further detail by the following examples. Such as figure 1 As shown, a tube evaporator includes a liquid distribution pipe 1, an evaporation pipe 2 and an air outlet pipe 3, one end of the evaporation pipe 2 is connected to the liquid distribution pipe 1, and the other end is connected to the air outlet pipe 3; the liquid distribution pipe 1 The inside is filled with a porous structure; one end of the evaporation tube 2 is in close contact with the porous structure of the liquid distribution tube 1; the diameter of the outlet tube 3 is larger than the diameter of the evaporation tube 2 or the sum of the diameters of multiple evaporation tubes 2, but not more than 3 times the sum of the diameters of the root evaporation tubes 2;

[0013] The porous structure is a metal particle sintered layer or a multi-layer wire mesh, the metal particle sintered layer adopts 30-70 μm metal particles, and the multi-layer wire mesh adopts a 200-400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com