Two-stage compression and air supplementing device, air conditioning system and air supplementing control method

A two-stage compression and air-conditioning system technology, applied in heating and ventilation control systems, heating and ventilation safety systems, refrigerators, etc., can solve the problem that the amount of supplementary air cannot be adjusted according to working conditions, and achieve the purpose of improving flexibility and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

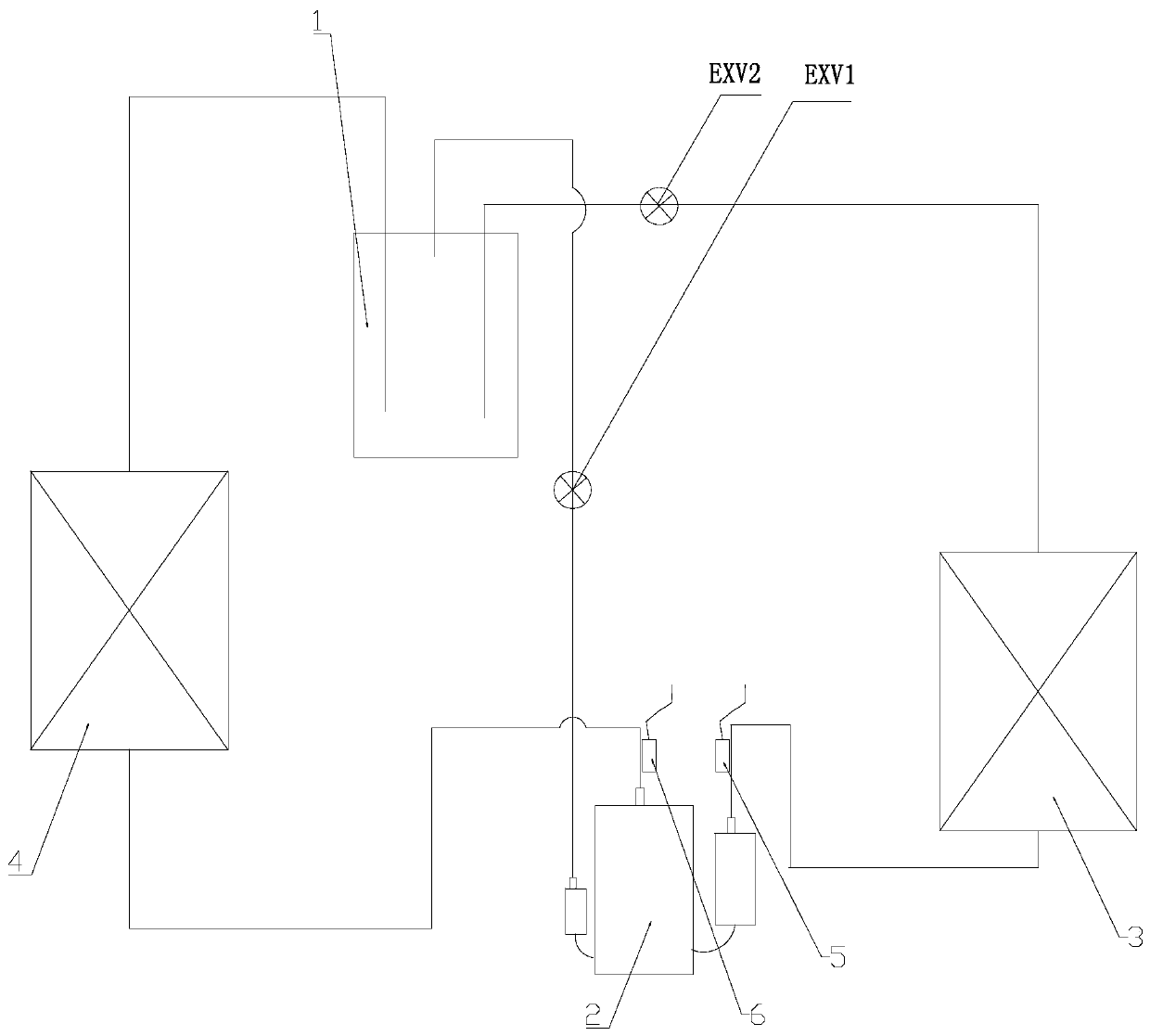

[0050] Such as figure 1 As shown, the present invention provides a high-temperature enthalpy-injection refrigeration system (single cooler), comprising an evaporator 3, a condenser 4, an enthalpy-injection compressor 2, a three-hole flash tank 1, and an electronic expansion valve EXV1 And the electronic expansion valve EXV2, as well as the exhaust temperature sensing package 6 and the suction temperature sensing package 5. Among them, the flash tank 1 is between the evaporator 3 and the condenser 4, and the electronic expansion valve EXV1 mainly controls the air supply volume, one end of which is connected to the outlet of the flash tank 1, and the other end is connected to the air supply port of the compressor 2; EXV2 mainly controls Exhaust temperature, one end of which is connected to the outlet of flash tank 1, and the other end is connected to the inlet pipe of evaporator 3.

[0051] When supplementary air control is required, the supplementary air electronic expansion v...

Embodiment 2

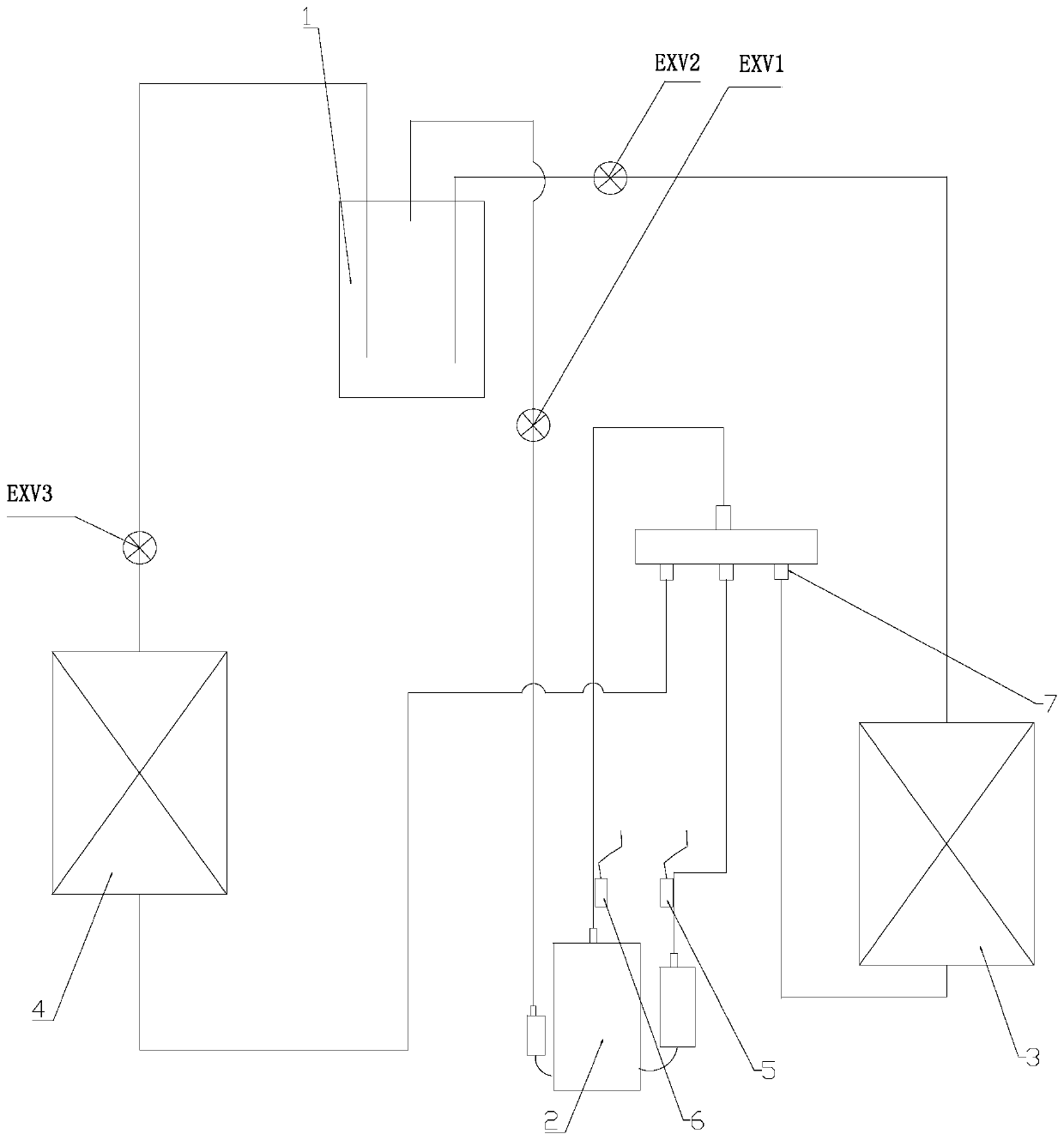

[0055] The difference between Embodiment 2 and Embodiment 1 lies in the addition of the four-way valve 7 and the third valve body (electronic expansion valve EXV3).

[0056] Such as figure 2 As shown, the present invention provides a high-temperature enthalpy-injecting refrigeration system (heat pump), comprising an evaporator 3, a condenser 4, an enthalpy-injecting compressor 2, a flash tank 1, a four-way valve 7, three Electronic expansion valves EXV1, EXV2 and EXV3, and exhaust temperature sensing package 6 and suction temperature sensing package 5.

[0057] During refrigeration operation: the cooled refrigerant from the outlet of condenser 4 flows into flash tank 1 after passing through EXV3, and the steam from flash tank 1 flows into compressor 2 after passing through electronic expansion valve EXV1 to control the amount of supplementary air Air supply port; another subcooled refrigerant from the flash tank 1 flows into EXV2 for throttling, and after throttling, the sat...

Embodiment 3

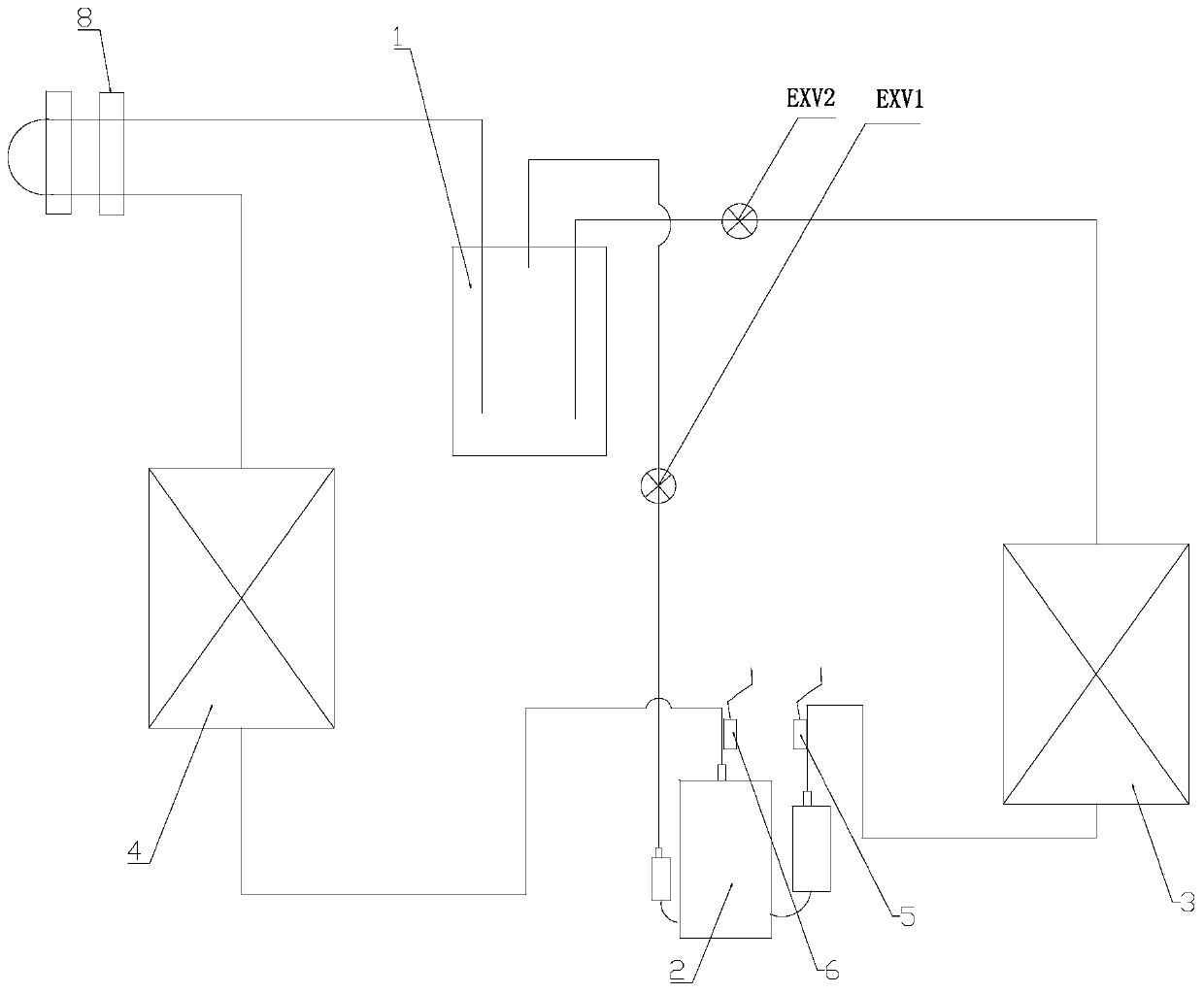

[0061] Such as image 3 As shown, the present invention provides a high-temperature enthalpy-spray refrigeration system (single cooler) with refrigerant pipe cooling. Compared with Embodiment 1, a refrigerant pipe cooling device 8 is added.

[0062] The high-temperature enthalpy injection refrigeration system includes an evaporator 3, a condenser 4, an enthalpy injection compressor 2, a three-hole flash tank 1, a refrigerant pipe cooling device 8, electronic expansion valves EXV1 and EXV2, and exhaust temperature sensing Package 6 and suction temperature sensing package 5. Among them, the refrigerant pipe cooling device 8 is on the outlet pipe of the condenser 4, and the electronic expansion valve EXV1 mainly controls the amount of air supply, one end of which is connected to the outlet of the flash tank 1, and the other end is connected to the air supply port of the compressor 2; EXV2 mainly controls the exhaust temperature, one end is connected to the outlet of flash tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com