Composite cathode material lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as lithium-ion batteries that have not yet been seen, reducing the first coulombic efficiency, battery short-circuit, etc., achieving reduced probability, low cost, The effect of improving the resistance to overcharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

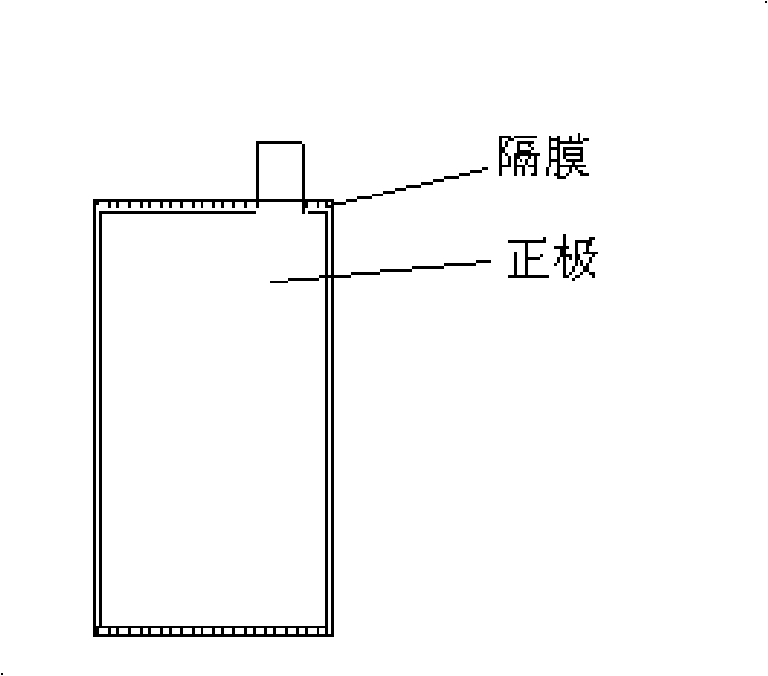

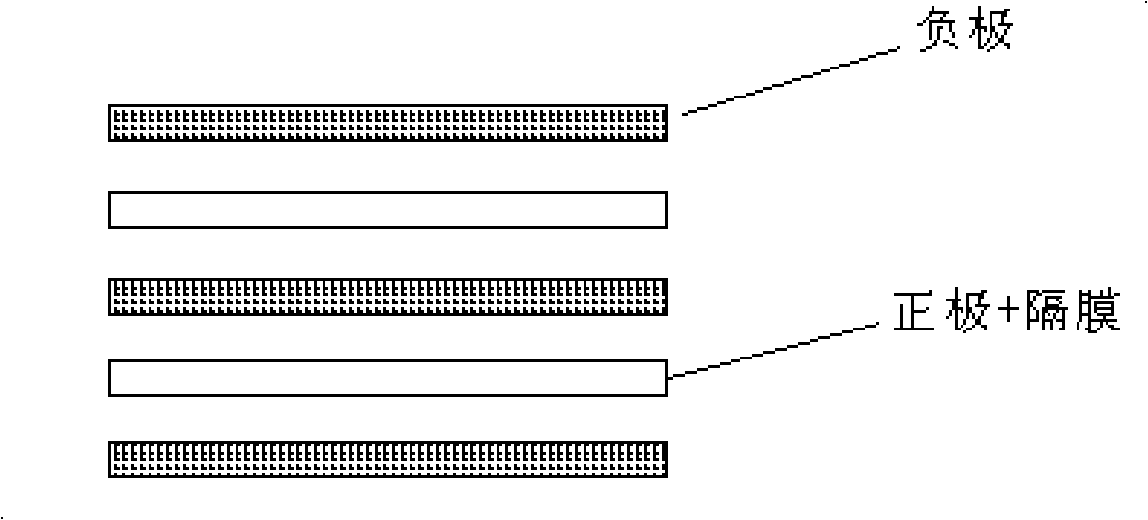

[0009] Embodiment of the present invention: the manufacturing method of the negative electrode is as follows: the negative electrode composite material is composed of 80-87 parts of lithium titanate and graphite composite material by weight, 4-7 parts of binder, 6-7 parts of conductive agent, liquid absorbing agent 3-6 parts are mixed, coated and dried to obtain a negative electrode. Lithium titanate / graphite composite material is prepared by mechanical alloying method, and the production method is as follows: take 85-90 parts of lithium titanate and 10-15 parts of graphite by weight, mix, ball mill, and sieve to prepare lithium titanate and graphite composite material . Place the positive electrode directly into the separator pocket and the negative electrode the same width as the separator pocket. A single-layer or double-layer separator bag with a positive electrode and a negative electrode are directly stacked to form a plate group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com