Battery positive pole piece and preparation method

A battery positive electrode and pole piece technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of not being able to solve the problem of battery overcharging well, achieve the effect of improving the anti-overcharging ability and prolonging the battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

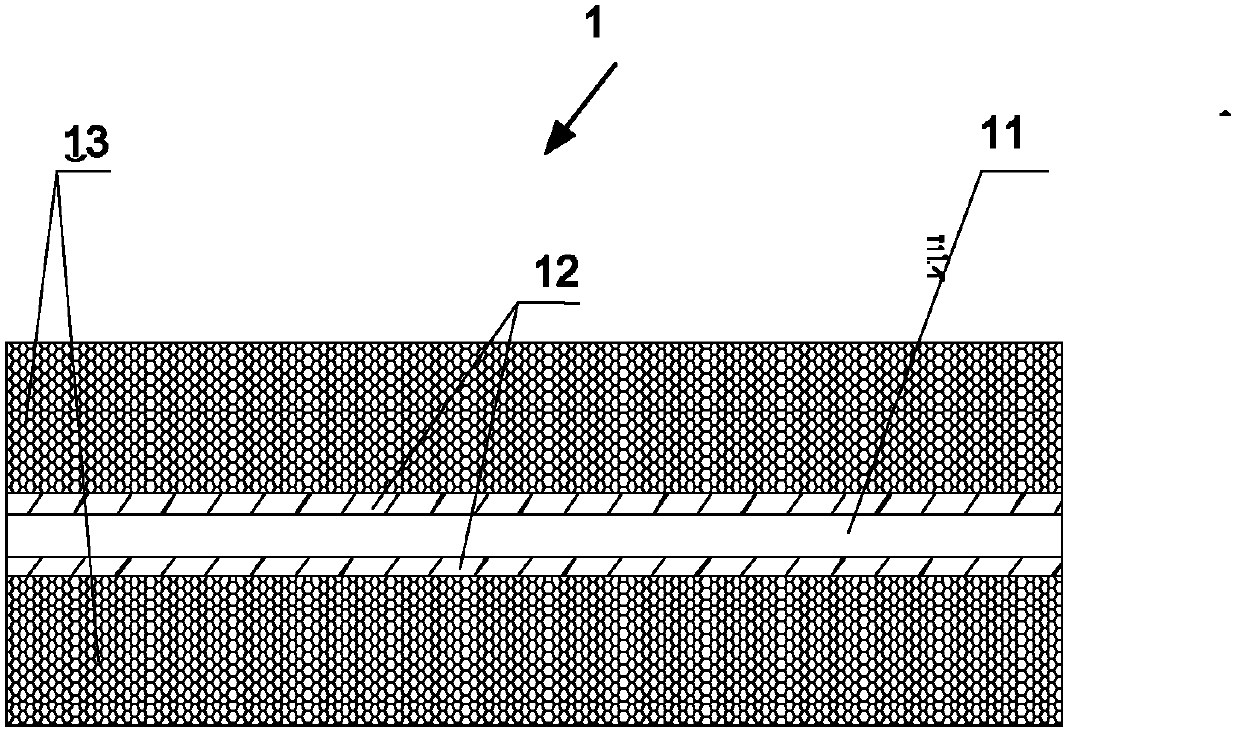

[0020] Such as figure 1 As shown, the present invention provides a method for preparing a positive electrode sheet of a battery. According to the method of the present invention, after forming a lithium-containing coating 12 on at least one surface of the substrate layer 11 used as a current collector, a lithium iron phosphate active material coating 13 is formed on the surface of the lithium-containing coating 12 to prepare the positive electrode of the battery. sheet; wherein, the material of the lithium-containing coating includes at least one of nickel-cobalt lithium manganese oxide, lithium manganese oxide, and lithium cobalt oxide.

[0021] Specifically, one surface or both surfaces of the substrate layer 11 used as a current collector is first coated with at least one of nickel cobalt lithium manganese oxide, lithium manganate, and lithium cobalt oxide, and a conductive agent is assisted. The formed mixed slurry is dried to form a lithium-containing coating 12; then a ...

Embodiment 1

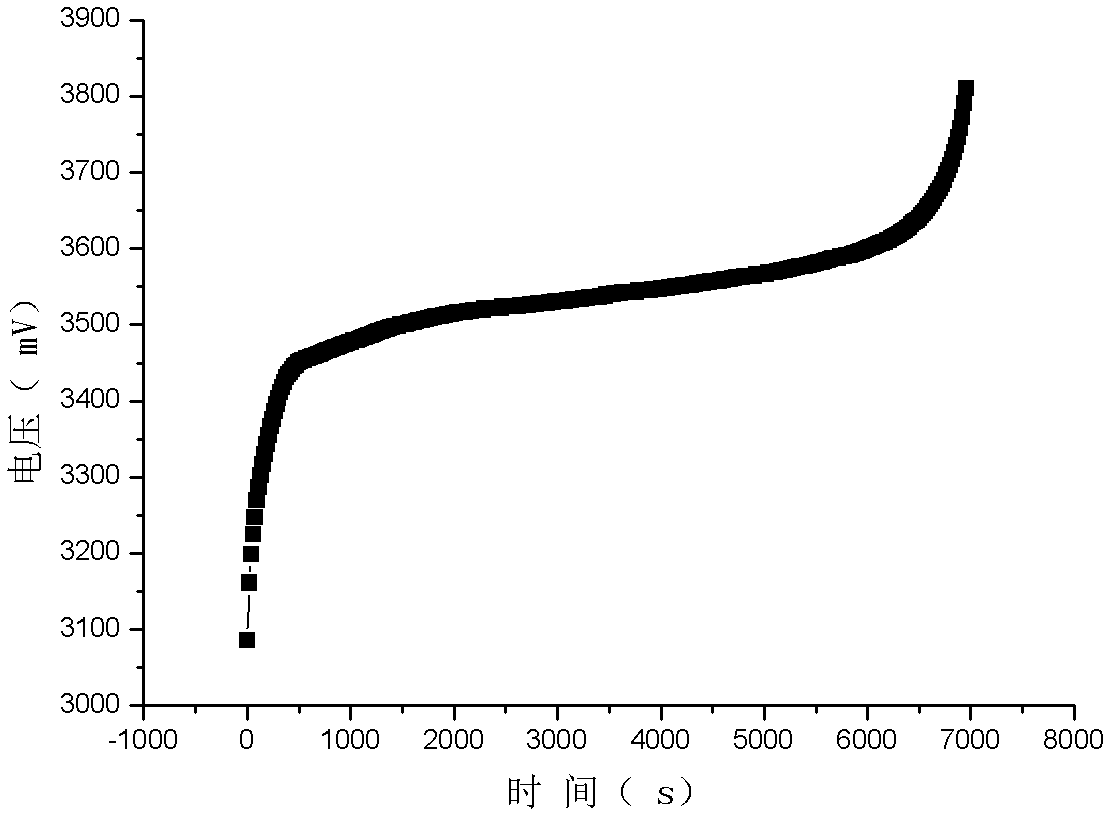

[0030] Firstly, lithium manganate, SP and polyvinylidene fluoride (PVDF) were mixed in a ratio of 93:3:4, and NMP was used as a solvent to form a slurry, which was evenly coated on an aluminum foil substrate, and after drying, a double-layer 5um thick slurry was formed. Lithium manganese oxide coating; then dry-mix 9.1kg lithium iron phosphate and 0.4kg SP in advance, then add 0.5kg PVDF NMP solution to mix at room temperature to form a slurry, evenly coat on the lithium manganate coating, dry, after Rolling, cutting into positive pole pieces; then based on the positive pole piece to make a lithium battery, the experiment measured that the lithium ion battery with the positive pole piece was charged to 3.8V 14.9 minutes later than the existing lithium iron phosphate battery.

Embodiment 2

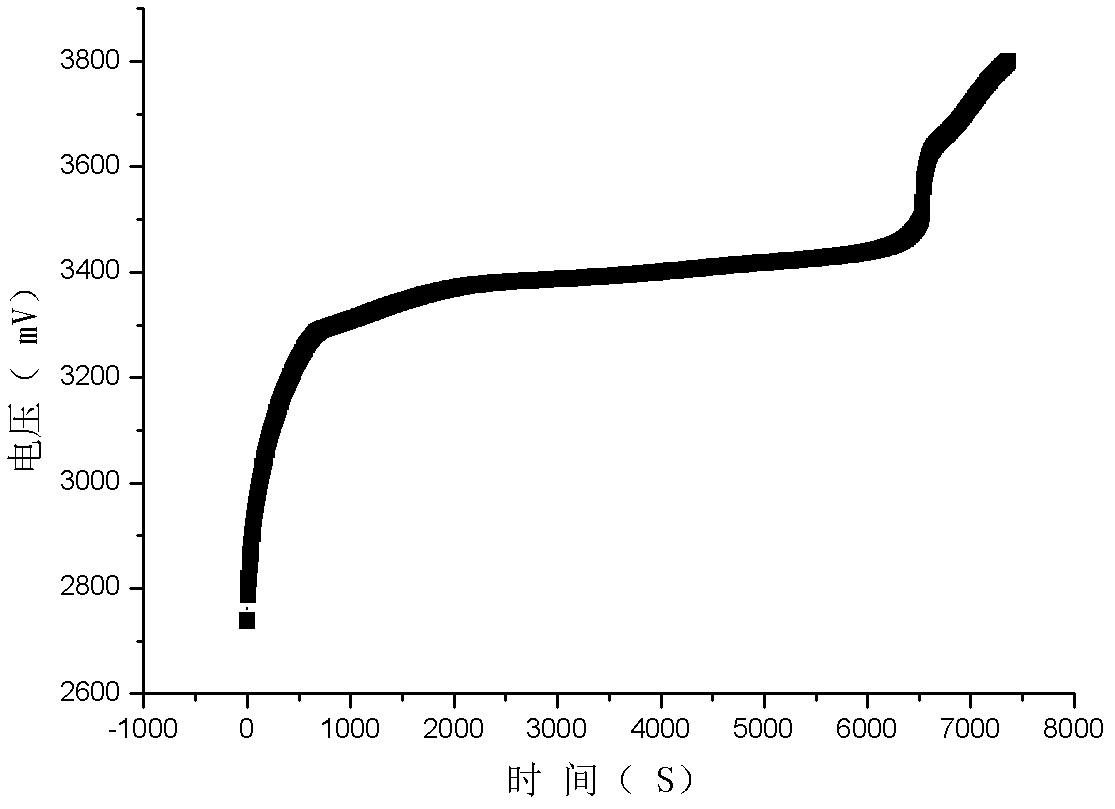

[0032] First mix lithium nickel cobalt manganese oxide, SP and PVDF at a ratio of 93:3:4, and use NMP as a solvent to form a slurry, evenly coat it on an aluminum foil substrate, and dry it to form a double layer of nickel cobalt manganese acid with a thickness of 5um. Lithium coating; then dry-mix 9.1kg lithium iron phosphate and 0.4kg SP in advance, then add 0.5kg PVDF NMP solution and mix at room temperature to form a slurry, which is evenly coated on the nickel-cobalt lithium manganese oxide coating, dried, and after Rolling, cutting into positive pole pieces; then based on the positive pole piece to make a lithium battery, experiments have measured that the lithium ion battery with the positive pole piece is charged to 3.8V 15.5 minutes later than the existing lithium iron phosphate battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com