Steel for drilling tools and method for smelting steel for drilling tools

A technology for drilling tools and molten steel is applied in the fields of steel for drilling tools and steel for smelting drilling tools. and the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

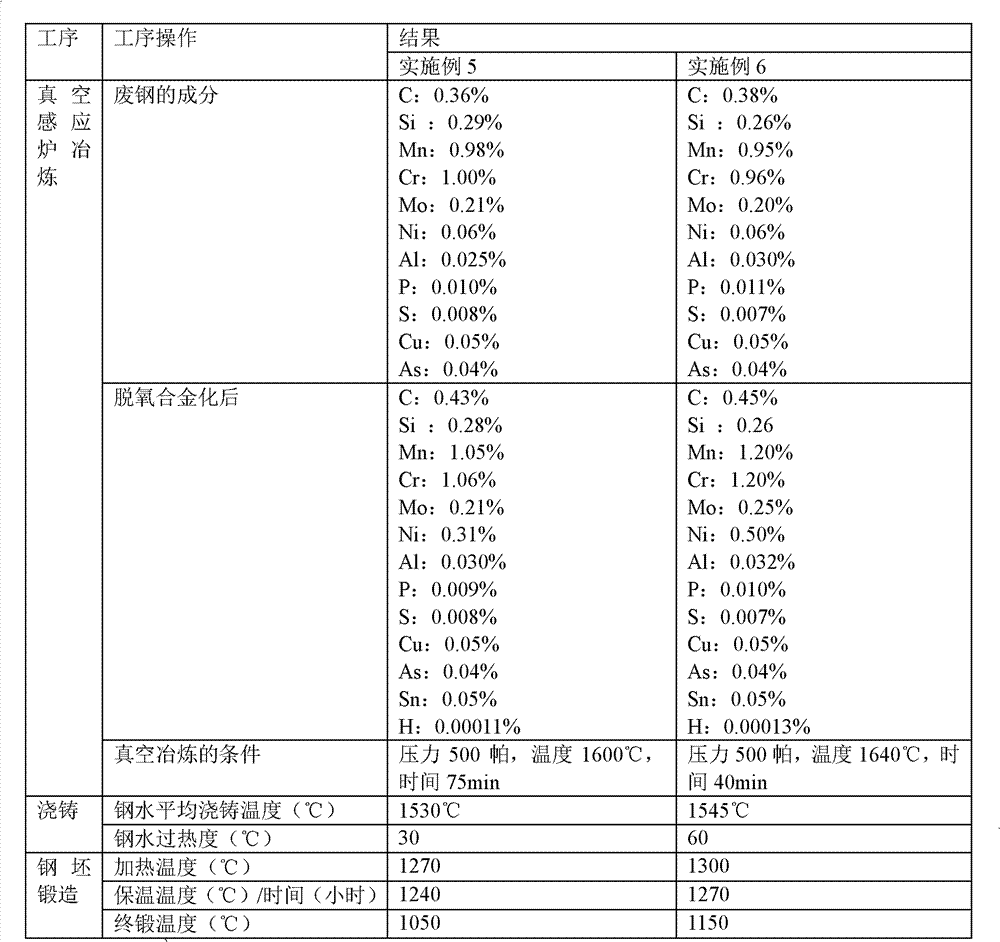

Examples

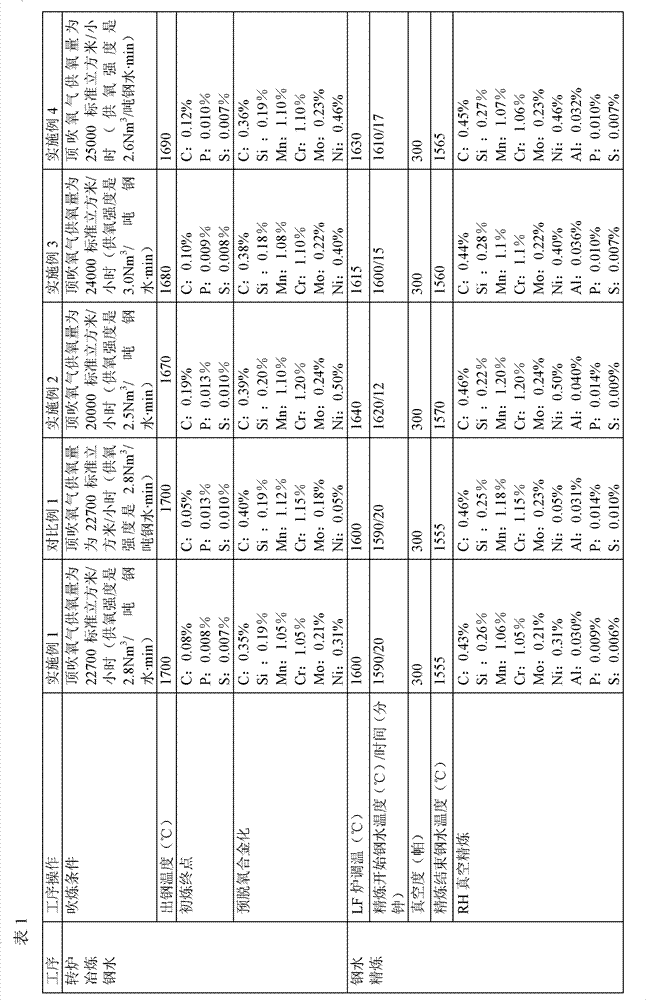

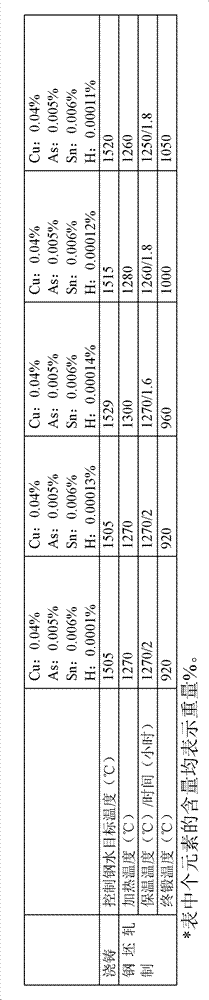

Embodiment 1

[0059] This example is used to illustrate the properties of the steel for drilling tools smelted by method 1).

[0060] (1) blowing and tapping

[0061] The desulfurized molten iron is poured into the oxygen top-blown converter for blowing, and the oxygen supply of the top-blown oxygen is 22,700 standard cubic meters per hour (the oxygen supply intensity is 2.8Nm 3 / ton of molten steel min), blowing for 28 minutes, based on the total weight of molten steel, the end point of blowing is controlled to be 0.08% by weight of C content, 0.008% by weight of P content, and 0.007% by weight of S content, and the molten steel obtained by blowing is discharged The steel is put into the ladle, and the tapping temperature is 1700°C.

[0062] When tapping, with respect to every ton of molten steel, 3.0 kilograms of deoxidizer aluminum-iron (Al content ≥ 40% by weight, Anyang Hengwang Metallurgical Refractories Co., Ltd.) is first added, and the amount of the deoxidizer makes the activity ...

Embodiment 2

[0071] This example is used to illustrate the properties of the steel for drilling tools smelted by method 1).

[0072] The method identical with embodiment 1 prepares drill steel, difference is:

[0073] (1) blowing and tapping

[0074] The desulfurized molten iron is poured into the oxygen top-blown converter for blowing, and the oxygen supply of the top-blown oxygen is 20,000 standard cubic meters per hour (the oxygen supply intensity is 2.5Nm3 / ton of molten steel min), blowing for 20 minutes, based on the total weight of molten steel, the end point of blowing is controlled to be 0.19% by weight of C content, 0.013% by weight of P content, and 0.010% by weight of S content, and the molten steel obtained by blowing is discharged The steel is put into the ladle, and the tapping temperature is 1670°C.

[0075] When tapping, with respect to every ton of molten steel, 2.6 kilograms of deoxidizer aluminum iron (Al content ≥ 40% by weight, Anyang Hengwang Metallurgical Refracto...

Embodiment 3

[0083] This example is used to illustrate the properties of the steel for drilling tools smelted by method 1).

[0084] The method identical with embodiment 1 prepares drill steel, difference is:

[0085] (1) blowing and tapping

[0086] The desulfurized molten iron is poured into the oxygen top-blown converter for blowing, and the oxygen supply of the top-blown oxygen is 24,000 standard cubic meters per hour (the oxygen supply intensity is 3.0Nm 3 / ton of molten steel min), blowing for 25 minutes, taking the total weight of molten steel as a basis, the end point of blowing is controlled to be 0.10% by weight of C content, 0.009% by weight of P content, and 0.008% by weight of S content, and the molten steel obtained by blowing is discharged The steel is put into the ladle, and the tapping temperature is 1680°C.

[0087] When tapping, it is equivalent to every ton of molten steel, first add 2.0 kilograms of deoxidizer aluminum-iron (Al content ≥ 40% by weight, Anyang Hengwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com