Grey mask and method for making same

A gray-tone mask and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, photoengraving process of pattern surface, optics, etc., can solve the problem of large aspect ratio, shape of light-shielding part, poor pattern accuracy, etching time and so on. long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

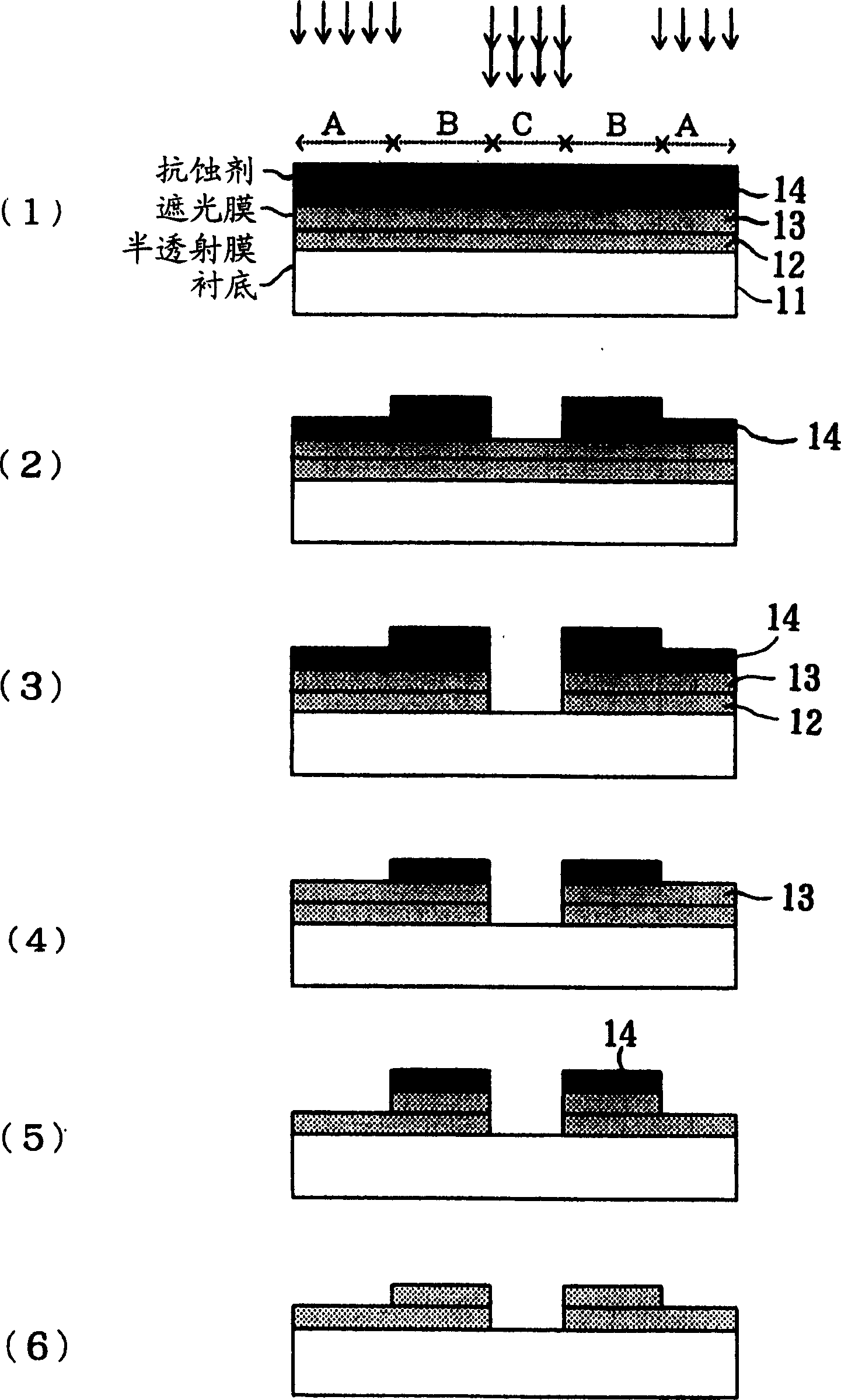

[0082] Next, a first embodiment of the present invention will be described.

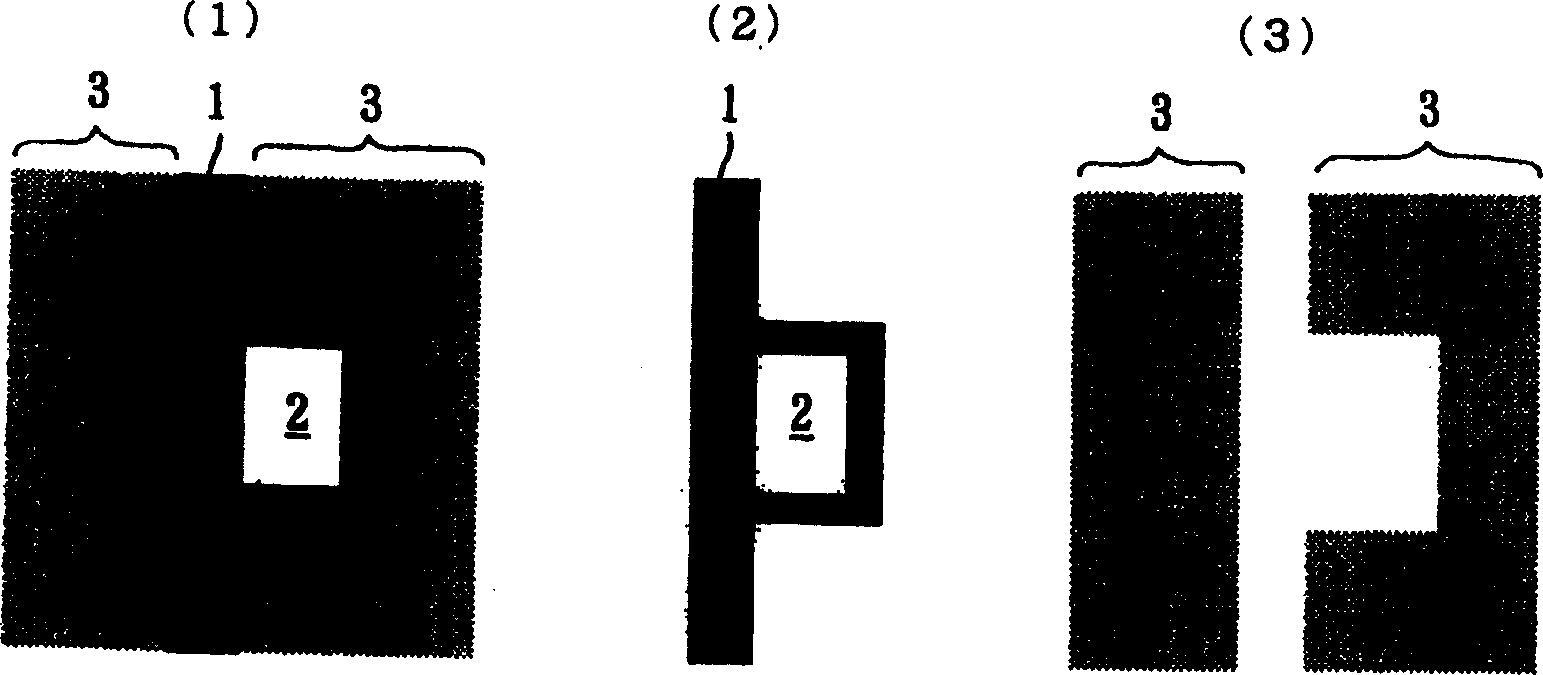

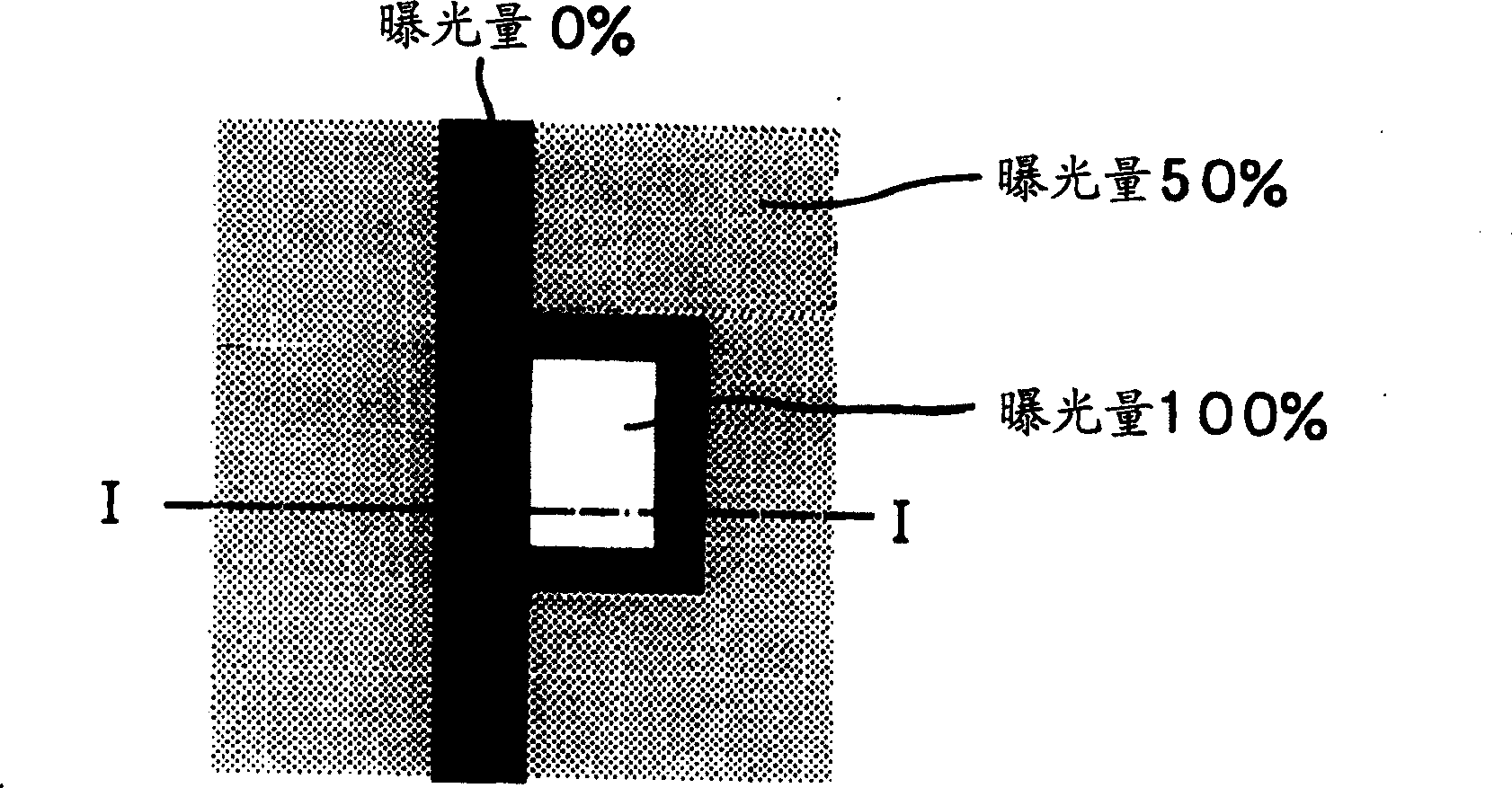

[0083]Synthetic data when all graphic data including the shading part, light-transmitting part and gray tone part are included, such as figure 1 As shown in (1), the case where the light-shielding part 1 and the light-transmitting part 2 (such as an amorphous silicon pattern of TFT) and the gray tone part 3 (semi-transmitting part and semi-transmitting part) formed around them is taken as an example. In this situation, figure 1 The data of the light shielding part 1 and the light transmitting part 2 shown in (2) and figure 1 Data separation of the gray tone section 3 shown in (3). Then, after drawing the light-transmitting portion with the exposure amount (100%) that can completely remove the resist, the gray tone portion 3 (semi-transmission portion or semi-transmission portion Translucent part), can be figure 1 (1) A depiction of the graph shown. if figure 1 The drawing pattern shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com