Grey mask and method for making it

A technology of gray-tone mask and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, photolithographic process exposure device, patterned surface photographic process, etc., which can solve the problem of difficult precise control of film thickness, large aspect ratio, and practical Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

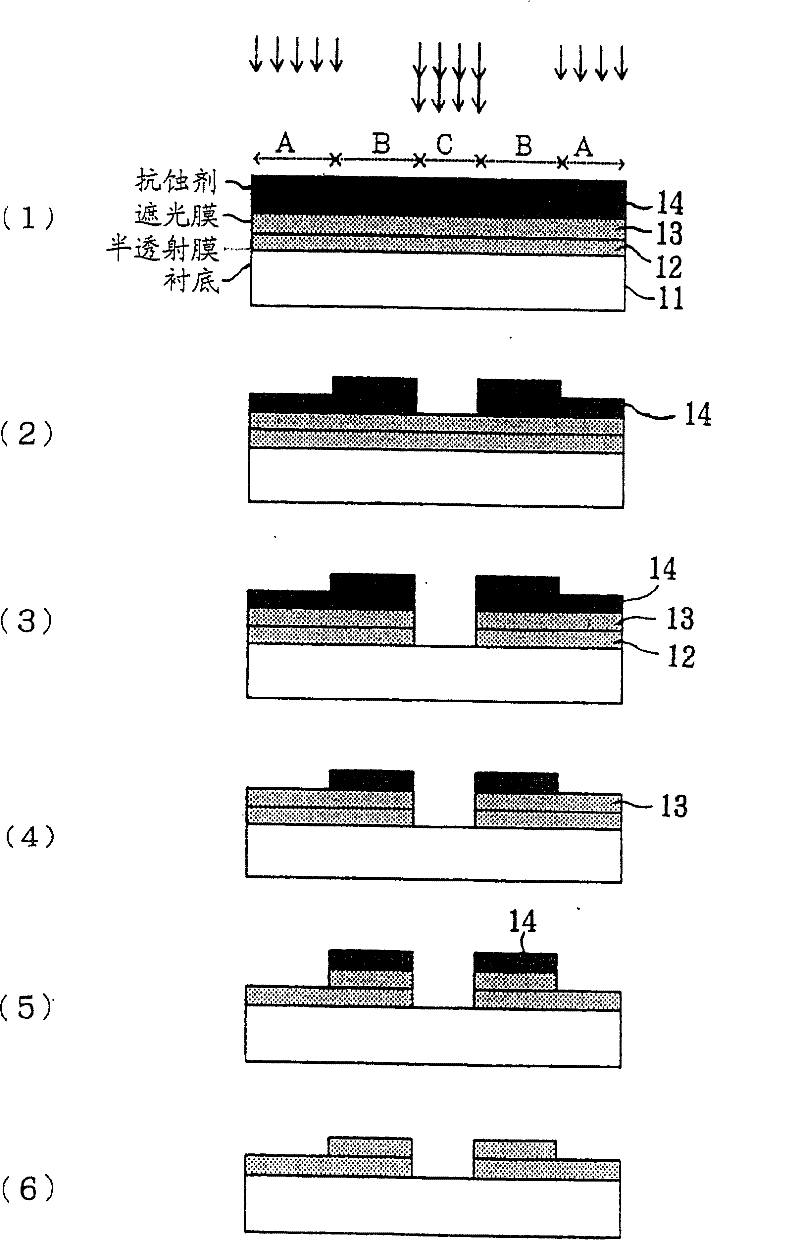

[0083] Next, a first embodiment of the present invention will be described.

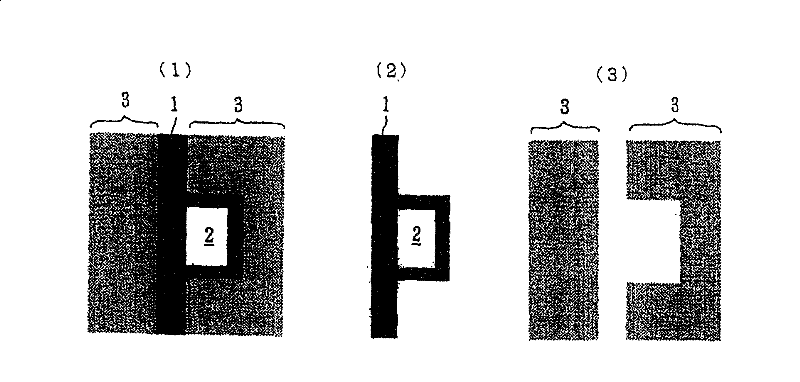

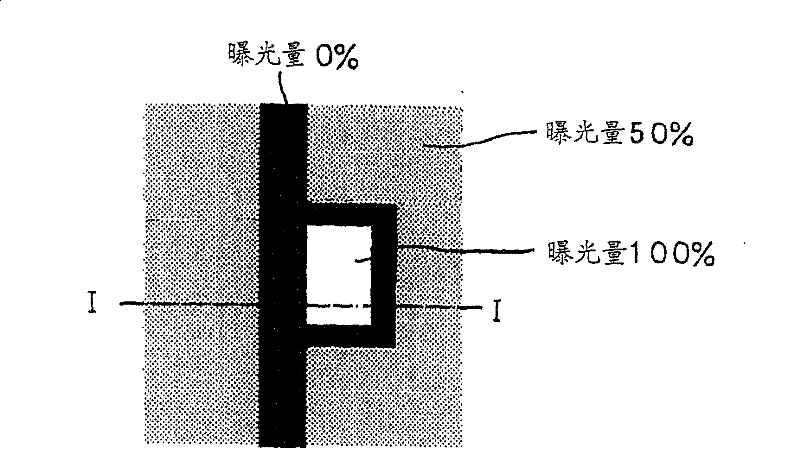

[0084] Synthetic data when all graphic data including the shading part, light-transmitting part and gray tone part are included, such as figure 1 As shown in (1), the case where the light-shielding part 1 and the light-transmitting part 2 (such as an amorphous silicon pattern of TFT) and the gray tone part 3 (semi-transmitting part and semi-transmitting part) formed around them is taken as an example. In this situation, figure 1 The data of the light shielding part 1 and the light transmitting part 2 shown in (2) and figure 1 Data separation of the gray tone section 3 shown in (3). Then, after drawing the light-transmitting portion with the exposure amount (100%) that can completely remove the resist, the gray tone portion 3 (semi-transmission portion or semi-transmission portion Translucent part), can be figure 1 (1) A depiction of the graph shown. in the case of figure 1 The drawing patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com