Method and system for detecting defect of patterned substrate

A patterning and substrate technology, applied in the monitoring, measuring devices, instruments and other directions of photovoltaic systems, can solve the problems of reduced accuracy, limited width of laser beam expansion, light intensity, etc., and achieve the effect of accurate classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the drawings and description of the present invention have been simplified to illustrate elements useful in a clear understanding of the present invention, while other elements of a typical defect detection system have been removed for the purpose of clarity. Those skilled in the art will recognize that other elements may be desirable and / or necessary in order to practice the invention. However, since these elements are well known in the art, and since they do not contribute to a better understanding of the present invention, no description is given herein regarding these elements. It should also be understood that the drawings included herein merely give diagrammatic representations of current embodiments of the invention and that structures falling within the scope of the invention may include structures other than those shown in these drawings. In the drawings, similar structures are given similar reference numerals.

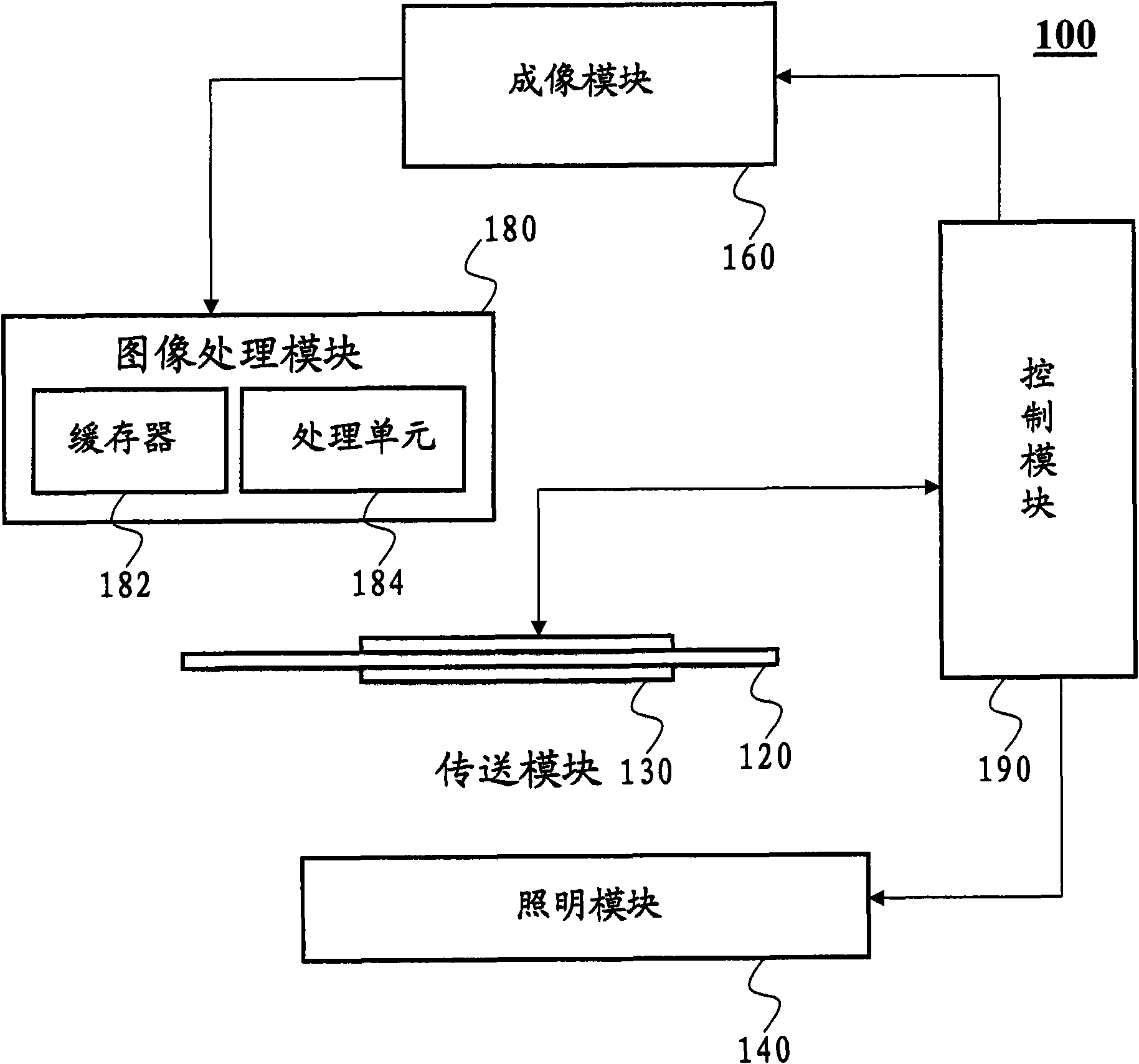

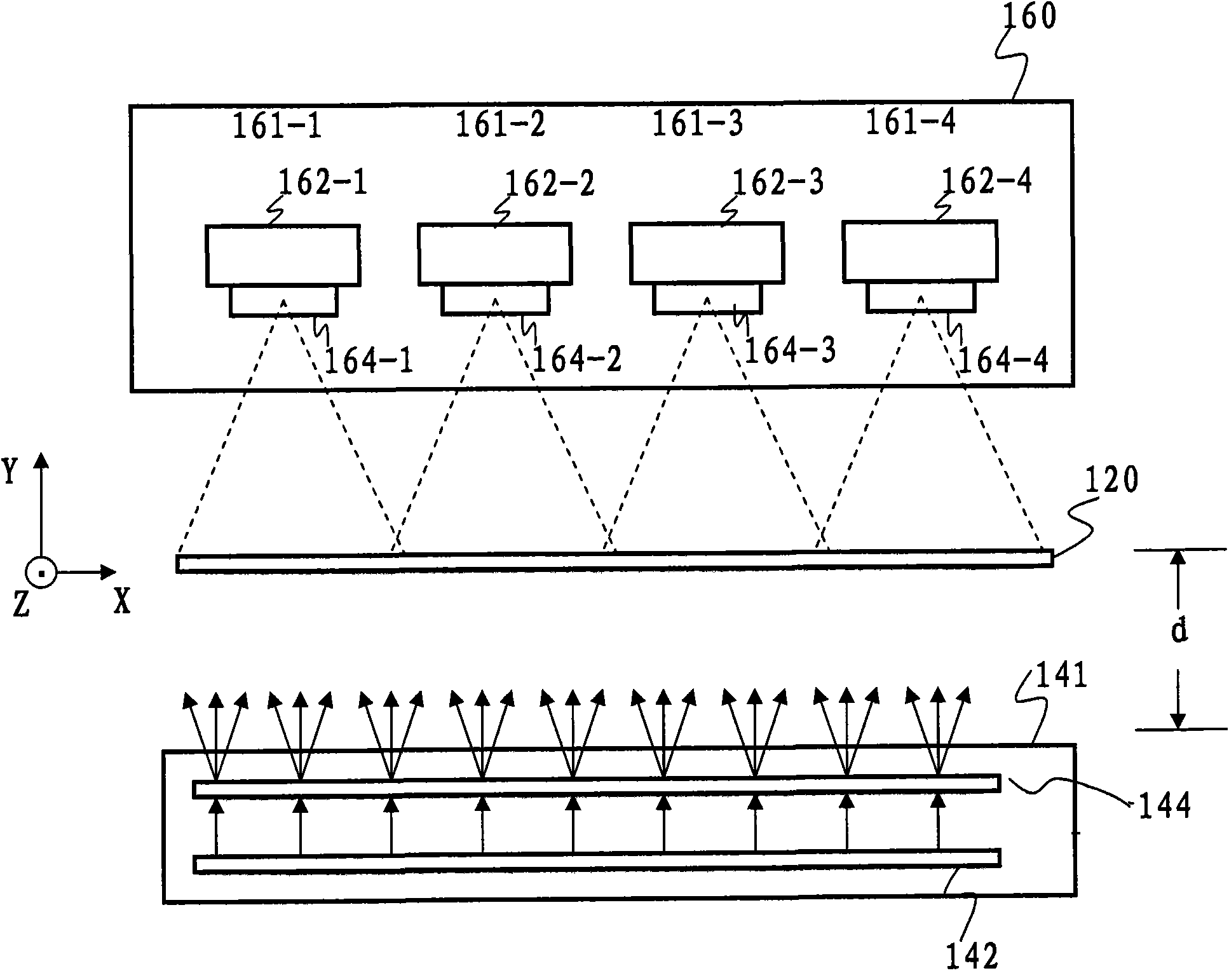

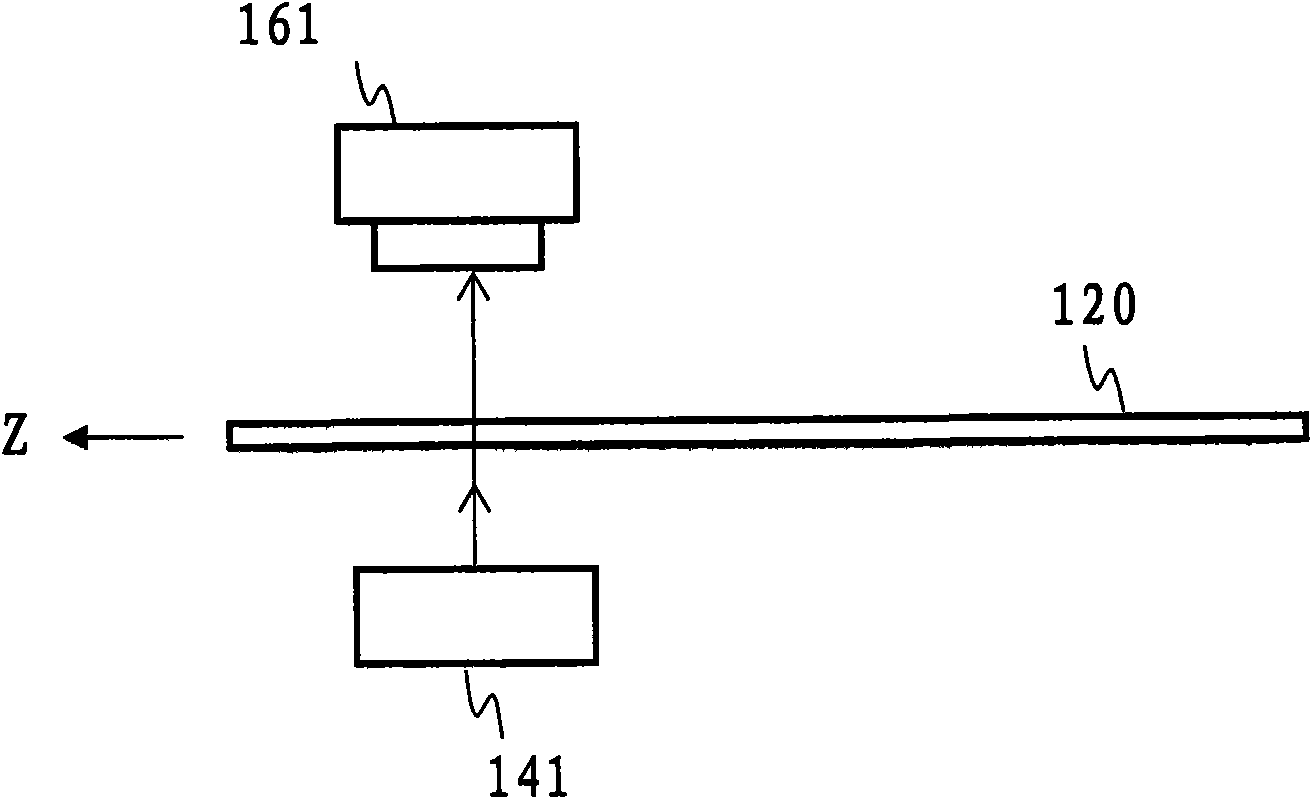

[0031] As mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com